Page 1

Bulletin 733 Rev. F

Bulletin 733 Rev. F

Model DDX PrePaK, Type D

Preaction System

4”(100mm), 6” (150mm) &

8” (200mm)

Instructions for

Installation, Operation,

Care and Maintenance

10 PSI (0.7 bar) Pneumatic Supervising Pressure

Single Interlock - Electric Release

Double Interlock - Electric/Electric Release

Contents Page

General Description 2

Listings and Approvals 4

Technical Data 4

Installation Requirements 5

System Operation 5-6

System Reset Procedure 6

Inspection, Testing and Maintenance 6-7

Diagrams:

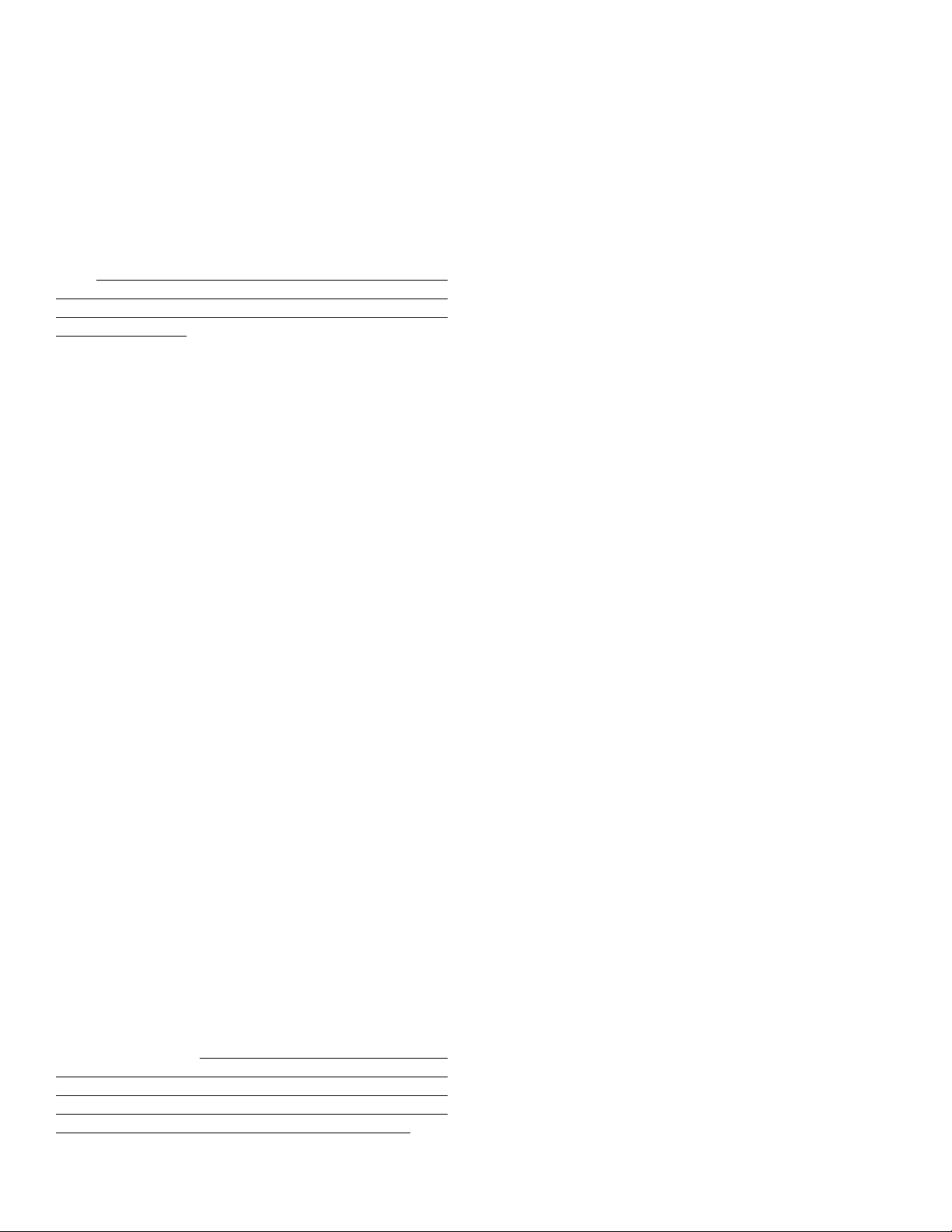

Assembly Dimensions 3

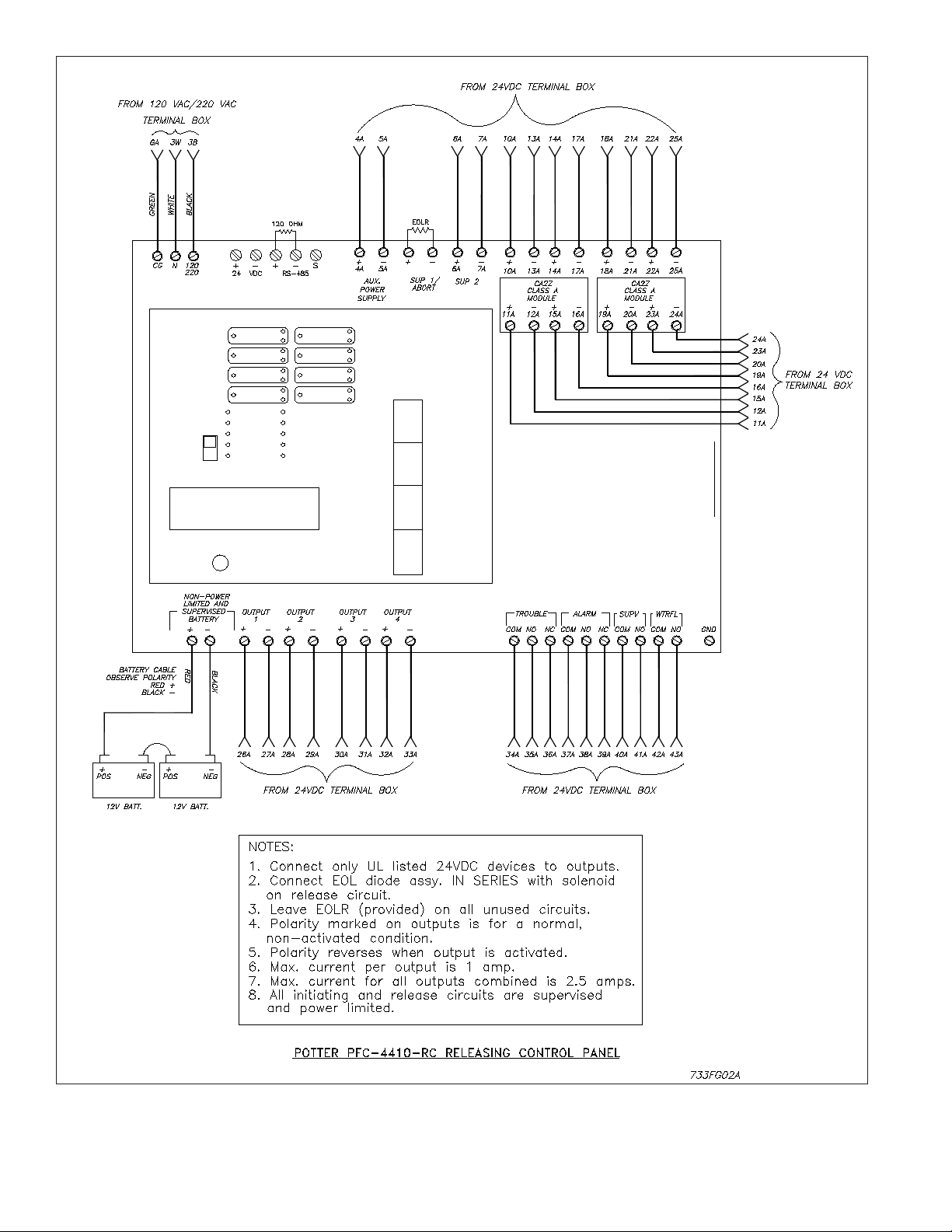

Potter PFC-4410-RC Releasing Control Panel 8

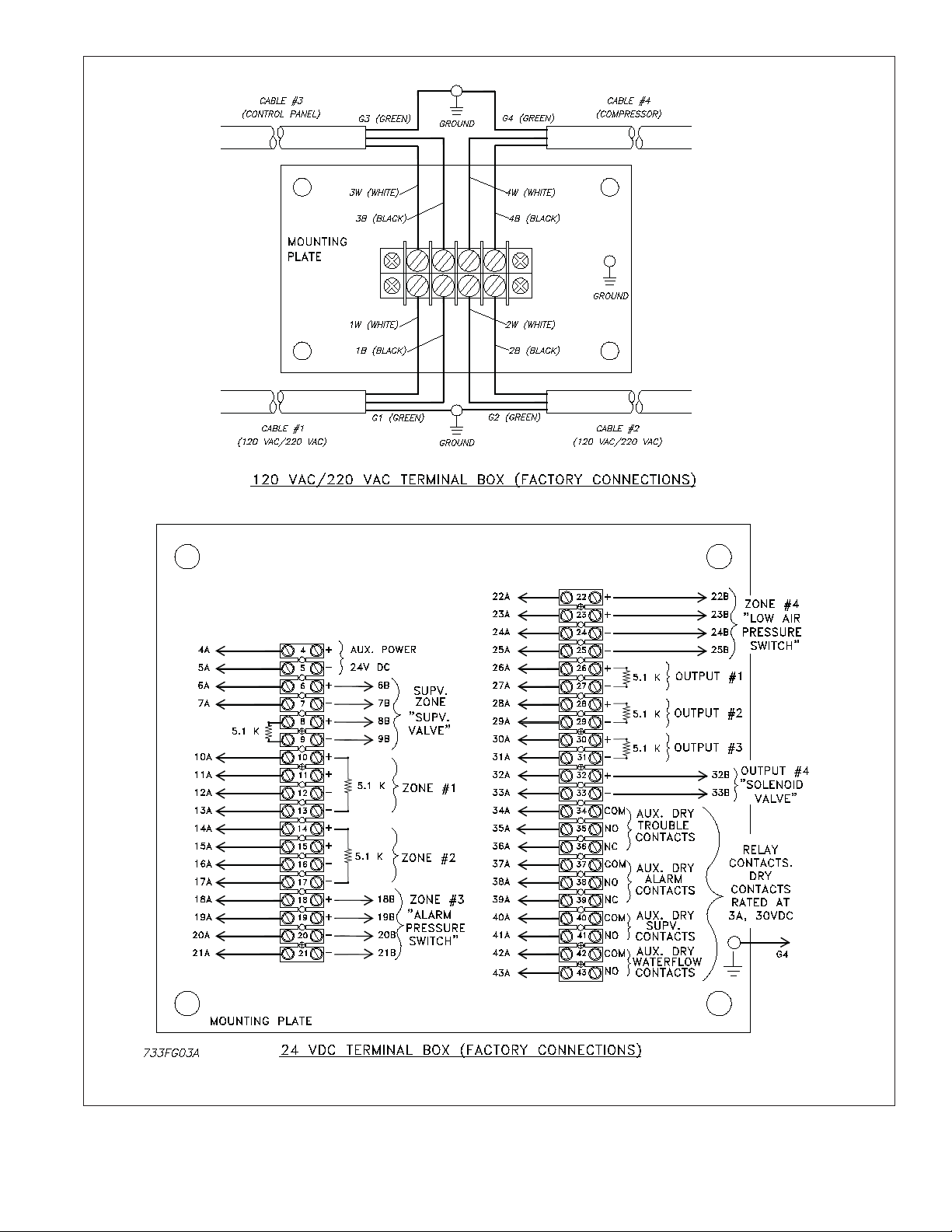

Terminal Box Wiring 9

Factory Installed Electrical Devices 10-11

Detector Circuit Wiring 12-13

Output Device Wiring 14

Component Identification/System Setup 15-16

Potter Panel Programming 17-26

Ordering Information 27-28

Reliable Automatic Sprinkler Co., Inc., 103 Fairview Park Drive, Elmsford, New York 10523

Page 2

General Description

The Reliable Model DDX 4” (100 mm), 6” (150mm) & 8”

(200mm) PrePaKs are completely self-contained, supervised

preaction systems that can be readily installed within a floor

space of 5.15ft

for the 8” (not including door swing). Installation of the PrePaK

(not including exterior devices, i.e., detectors and alarm bells),

requires just three piping connections. These connections are

the water supply, the sprinkler system, and the drain. Reference

locations of these piping connections are shown in Fig.1. Also,

two 120 / 220 VAC electrical supply connections are required.

Note: The Model DDX PrePak is available with an optional air

compressor and an optional Potter Model PFC-4410-RC Releasing/Control Panel wired for a 120 VAC / 60Hz or 220 VAC /

50 Hz power supply.

Figures 16, 17, and 18 in this Bulletin identify the standard and

optional equipment available in Reliable Model DDX PrePak,

Type D, Preaction Systems.

The Reliable Model DDX PrePaK utilizes an optional Potter

Model PFC-4410-RC Releasing Control Panel. This fully programmable, microprocessor-based releasing panel is Underwriters Laboratories, Inc. Listed and is in compliance with NFPA

13 and NFPA 72. Because the PFC-4410-RC is totally zone and

output programmable, the Reliable Model DDX PrePaK can be

utilized in many different preaction applications without having

to rewire any of the factory installed devices. Once the previously described connections are completed, the 24 VDC detectors, output devices, and relay contacts may be connected to

achieve the desired system implementation.

The Model DDX PrePaK can be used in both single and double interlock applications. Reliable Single and Double Interlock

Preaction Systems are designed for water sensitive areas that

require protection from inadvertent water flow into the sprinkler

system piping.

The major benefits of a single/double interlock preaction System, when compared with a wet pipe system, are as follows:

A. A fire alarm sounds prior to the flow of water from a sprin-

kler, which may enable extinguishing the fire by handheld

means before the operation of any sprinkler occurs.

B. An annunciator signals whenever the integrity of piping or

sprinklers is accidentally or intentionally disturbed; however, no water flow occurs at that time.

C. Detection and notification of a fire condition are provided

by fire detectors, without the delay associated with water

delivery time in the event of a fire. Note that with a wet pipe

system, the fire alarm is delayed until after water has begun

flowing from an operated sprinkler.

In single interlock applications, one fire detector senses the

presence of fire, thereby causing the electrical releasing control

panel to activate notification appliances and energize the solenoid releasing valve in the open position. The use of cross-zoned

detectors will require operation of two detectors before the solenoid valve can open (Note: Verify that the detection method,

including the use of cross-zoned detection, are permitted by all

applicable codes and standards, as well as the requirements

of all authorities having jurisdiction. Cross-zoned detection may

not be permitted in New York City or by Factory Mutual.) The

2

(0.44 m2) for the 4” and 6” and 7.5ft2 (0.70m2)

solenoid valve, when closed, preserves supply water pressure

in the Model DDX valve’s push-rod chamber. Actuating the solenoid valve releases that water pressure which allows the Model

DDX valve to open.

To discharge water from sprinklers on a single interlock system

with cross-zoned detection, two separate electrical detection

systems must activate and a sprinkler must open. During the

early stages of a fire, smoke or heat activates the first detector,

which causes the control panel to produce a local alarm and an

alarm at the fire alarm panel. Electrical relays inside the releasing

control panel can be used to shut down air moving equipment

or activate security doors and other electrical devices when the

panel goes into this first condition. Subsequent activation of a

second, nearby or adjacent detector, on a separate detection

system, will cause the panel to energize the solenoid valve open

and release water into the sprinkler piping. Water flowing into

the sprinkler piping will simultaneously produce water pressure

that cause the transfer of contacts in the alarm pressure switch

mounted in the riser assembly, thereby activating a water flow

alarm device. The flow of water into the sprinkler piping effectively converts the dry system into a wet-pipe sprinkler system.

In the event that the fire subsequently produces sufficient heat to

operate a sprinkler, water will flow from that sprinkler.

To flow water into a double interlock preaction system, two

events must take place: a fire detection device must operate,

and a pressure switch must be operated by the loss of system

pressure (sprinkler operation). These two signals, both an electric signal from the detection system and an electrical signal

from the pressure (pneumatic) sensor, must coexist at the releasing control panel, which only then will energize the solenoid

releasing valve, causing water flow into the sprinkler system and

out of the open sprinkler(s).

In the event that the system piping is ruptured or a sprinkler

is accidentally opened, the system pressure switch will operate and an alarm will sound. The Model DDX, Type D Valve assembly, however, will not release water since the solenoid valve

remains closed due to only one input into the releasing control

panel.

When using the Reliable Model DDX PrePaK, in either single

or double interlock applications, the sprinkler system is pressurized (supervised) with air provided by the air compressor and

is monitored by a system pressure switch. Alternatively, supervisory system pressure may be provided by a nitrogen source.

A Model B Hydraulic Manual Emergency Releasing station is

standard equipment in the Model DDX PrePaK. It consists of an

aluminum nameplate mechanically attached to a ball valve. The

valve handle in its OFF position is guarded against accidental

turning to the ON position (and system discharge) by a nylon

cable tie provided with the PrePaK assembly. The cable tie is

designed to allow, in case of an emergency, forceful turning of

the valve handle to the ON position.

2.

Page 3

Fig. 1

3.

Page 4

Approvals

1. Underwriters Laboratories, Inc. Listed and Certified for

Canada* (cULus) as an assembled unit in the “Special

System Water Control Valves Assembled Units” category,

(VKYL).

2. Factory Mutual (FM) Approved, as PrePak Single Interlock

and Double Interlock Preaction Systems.

* Electrical devices and control panel must be specified

to meet Canadian requirements. This option is available.

3. Approved for use in New York City based on UL Listing.

Note: Although PrePak units are UL Listed, custom built units

are sometimes supplied upon request. The components within

these special units maintain their individual Listings/Approvals,

whereas the assembled units do not.

PrePak units are also available without their door-mounted Potter PFC-4410-RC Releasing/ Control Panel and Air Compressor.

These units will still retain their Listings/Approvals, however the

installing contractor should make sure that any remote controlled

Releasing/Control Panels used with these units are Listed/Approved and programmed to handle the required sequence of

operation necessary to operate the automatic sprinkler system.

Any unauthorized modification or addition made on-site to a

factory-built Listed/Approved unit will void the Listing/Approval.

Such modifications or additions may void the unit’s warranty as

well. Consult Reliable’s Technical Services Department before

proceeding with any such modifications or additions.

Technical Data

1. The Reliable Model DDX 4” (100 mm), 6” (150 mm) and 8”

(200mm) PrePaKs are rated for a minimum supply pressure of 20 psi (1.4 bar) and a maximum supply pressure of

250 psi (17.2 bar). Note: 1 bar = 100 kPa.

2. Friction loss, expressed in equivalent length of Schedule 40

pipe and based on Hazen-Williams Formula with C=120

and a flowing velocity of 15 ft/s (4.6 m/s), is:

System Size Equivalent Length

4” (100 mm) 32.8 ft (17.7 m)

6” (150 mm) 54.7 ft (21.8 m)

8” (200mm) 79.3ft (24.2m)

These values account for the Model DDX valve, supply

manifold tee, butterfly control valve, and small pipe/manifold located directly above Model DDX valve.

3. Shipping Weight:

System Size Weight

4” (100 mm) 680 lbs (308 kg)

6” (150 mm) 770 lbs (349 kg)

8" (200mm) 1350lbs (531kg)

4. Dimensions:

System Size Cabinet Dimensions

4” (100 mm) & 6” (150 mm)

8” (200mm)

25.7” W x 28.9” D x 68” H

(0.65 m W x 0.73 m D x 1.73 m H)

30” W x 36 D x 74” H

(0.76m W x 0.91m D x 1.88m H)

5. Grooved-End Connections:

Pipe Size

4” (100mm)

6” (150mm)

8” (200 mm)

Pipe Size

2” (50mm)

Groove Dimensions (Inlet & Outlet)

Outlet

Diameter

4.500”

(114mm)

6.625’

(168mm)

8.625”

(219mm)

Groove

Diameter

4.334”

(110mm)

6.455”

(164mm)

8.441”

(214mm)

Groove

Width

3/8”

(10mm)

7/16” (11mm)

Groove Dimensions (Drain Manifold)

Outlet

Diameter

2.375”

(60mm)

Groove

Diameter

2.250”

(57mm)

Groove

Width

5/16”

(8mm)

Outlet

Face to

Groove

5/8”

(16mm)

3/4”

(19mm)

Outlet

Face to

Groove

5/8”

(16mm)

6. Flanged-End Connections:

Flange Dimensions (Inlet & Outlet)

System

size:

8”

(200mm)

Flange

Type

ASME

B16.5

Class

150

Bolt

Circle

Diameter

11¾”

(298mm)

Bolt

Hole

Diameter

7/8”

(22mm)

Flange

Outside

Diameter

13½”

(343mm)

Flange

thickness

1”

(25.4mm)

Number

of Bolts

8

Flange Dimensions ( Drain)

System

(200mm)

size:

8”

Flange

Type

ASME

B16.5

Class

150

Bolt

Circle

Diameter

4¾”

(120mm)

Bolt Hole

Diameter

Flange

Outside

Diameter

3/4”

(19mm)6” (150mm)

Flange

thickness

3/4”

” (19mm)

Number

of Holes

4

The following is a list of Technical Data Bulletins which de-

scribe the valves and devices which are used in the system:

Device

Model DDX Deluge Valve Reliable Bulletin 519

Type D Double Interlock Preaction

Trim

Low Air Pressure Switch Potter 5400928

Alarm Pressure switch Potter 5400928

Nitrogen Pressure Switch Potter 5400930

Mechanical Sprinkler Alarm Reliable Bulletins 612/613

Solenoid Valve Reliable Bulletin 718

Releasing Control Panel Potter Manual #5403550

Fire Alarm Devices Reliable Bulletin 700

Desiccant Dryer

Reliable Bulletin #

(unless otherwise noted)

Reliable Bulletin 750

Wilkerson Catalog 9EM-

TK-190-4

The following table provides a quick reference to various programs (found in this bulletin and the Potter Manual #5403550)

that may be utilized with a Model DDX PrePaK:

Desired

Applications

Single Interlock

Single Interlock,

Cross-Zoned

(1)

Refer to Potter Manual # 5403550 included with the PrePak, for other

programming options available.

(2)

Factory Program setting.

(1)

Single Hazard, Cross-Zoned, 2

Zone and 2 Supervisory Zones

Description

Single Hazard, 2 Alarm Zones

with 1 Waterflow Zone and 2

Supervisory Zones

Alarm Zones with 1 waterflow

Program

No.

Potter

Program #6

Custom

Program #1

(NYC)

Potter

Program #7

(2)

4.

Page 5

Installation Requirements

The automatic sprinklers, releasing devices, fire detection

devices, manual pull stations, and signaling devices which are

utilized with the Reliable Model DDX 4” (100 mm), 6” (150 mm)

and 8” (200 mm) PrePaKs must be UL and/or ULC Listed or FM

Approved, as applicable.

The steel enclosure and all the interconnecting piping must

be located indoors in a readily visible and accessible location

and in an area that can be maintained at a minimum temperature of 40°F (4°C). Note: Heat tracing is not permitted. The solenoid valve is operated and supervised by the Potter Model

PFC-4410-RC Releasing Control Panel. Details on the electrical

connections of this system to the Potter Panel can be found in

the Potter Manual #5403550, Installation, Operation and Instruction of PFC-4410-RC Releasing Control Panel (this manual is

included with other pertinent manuals and shipped inside the

enclosure). This panel is fully zone and output programmable

and may be adapted to several applications.

System Supervising Pressure Requirements

In accordance with NFPA 13, when using the Reliable Model DDX 4” (100 mm), 6” (150 mm) or 8” (200 mm) PrePaK in

double interlock applications, a minimum of 7 psi (0.5 bar)

pneumatic pressure is required to supervise the sprinkler system. When initially filling the system with air, the enclosure’s door

should remain open in order to provide maximum intake air flow

to the air compressor. The air compressor is connected to an 8

gallon (30.3 liter) ASME rated storage tank. This tank functions

as a reservoir, providing make-up air to compensate for small,

intermittent leaks in the sprinkler system. It should be noted

that significant leaks may overburden this storage tank, thereby

causing the air compressor to continuously cycle on and off.

The Pressure Maintenance Device supplied with the system

(refer to Fig. 9 or 10), is factory set to maintain system pneumatic pressure at approximately 10 psi (0.7 bar). Readjusting

system pressure to approximately 10 psi (0.7 bar), if necessary,

is accomplished by first loosening the locknut on the air pressure regulator and turning the adjustment screw (refer to Fig. 9

or 10). The system air pressure gauge that is attached to the

vertical pipe/manifold (mounted directly above the Model DDX

Deluge Valve) may be used to verify the correct level of pneumatic pressure.

The system air pressure switch (refer to Fig. 9 or 10) is factory

set to operate between 8 psi and 4 psi (0.6 bar and 0.3 bar)

with decreasing pressure. Adjustment, if required, should be

made according to System Sensor Bulletin A05-0176 included

with the switch.

System Electrical Requirements

All releasing, alarm, and detection devices in the Reliable

Model DDX 4” (100 mm), 6” (150 mm) and 8” (200 mm) PrePaKs are supervised by a Potter Model PFC-4410-RC Releasing

Control Panel. To utilize one of the doors of the steel enclosure

as a mount for the releasing control panel, all of the terminals

are translated to two, water-tight terminal boxes mounted on the

interior of the enclosure. Note: The EOL (End of Line) resistors

have also been relocated. It is from these terminal boxes that all

field wiring is connected. There is one terminal box that contains

the 24 VDC connections and one that contains the 120 / 220

VAC connections. The Reliable Model DDX PrePaK is delivered

with five factory-installed electrical devices. They consist of the

following:

1. A system air pressure switch, which is used to monitor

sprinkler piping.

2. An alarm pressure switch, which indicates an actuation of

the deluge valve.

3. A normally-closed, releasing solenoid valve, which is used

to actuate the deluge valve.

4. A ¾ HP or 1½ HP air compressor with 8 gallon (30.3 liter)

tank (1½ HP compressor is optional with 6” (150 mm) system only).

5. A supervised butterfly water control valve (A System Side

butterfly valve is optional).

The factory electrical connections of these devices are illustrated in Fig. 4. For information on how to install fire detection

devices to initiating Zones 1 and 2 of the Potter Model PFC4410-RC Releasing Control Panel, refer to Fig. 6 or Fig. 7. For

information on how to install output devices, i.e., alarm bells or

trouble annunciators, to the Potter Model PFC-4410-RC Releasing Control Panel, refer to Fig. 8. The power supply, standby

emergency power supply, battery charger and rectifier circuitry

are all contained within the PFC-4410-RC panel. Batteries that

provide 90 hours of standby power are provided with the panel.

For additional information and detailed wiring diagrams, refer to

Potter Manual #5403550, Installation, Operation and Instruction

of PFC-4410-RC Releasing Control Panel.

Note:

In order for the solenoid valve to maintain Reliable’s warranty it must remain sealed as it came from the factory. If

there are concerns about the valve’s internal components,

immediate replacement is recommended.

System Operation (Single Interlock)

To fully activate (water flow) the Reliable Model DDX 4” (100

mm), 6” (150 mm) or 8” (200 mm) PrePaK in a single interlock

application, a fire detection device (smoke, heat, etc.) (two detectors with cross-zoned detection) must activate. Subsequently, a sprinkler head must open to discharge water on the fire.

When the single interlock preaction system is set for service,

the supply pressure acts both on the underside of the deluge

valve’s clapper and on the valve’s push rod by means of the

pressurized push rod chamber. The pressure force acting on

the push rod, when utilized with the mechanical advantage of

the deluge valve’s lever, is more than sufficient to hold the clapper in the closed position against the water supply pressure.

Energizing the releasing solenoid valve allows the deluge

valve’s push-rod chamber to be vented to drain through its

outlet. Since the pressure cannot be replenished through the

inlet restriction as rapidly as it is vented though the outlet, the

push-rod chamber pressure falls rapidly. When the push-rod

chamber pressure drops below one-third of the supply pressure, the opening force acting beneath the clapper becomes

greater than the push-rod force acting on the lever. This causes

the clapper to open. Refer to Reliable Bulletins 518 and 519 for

further details.

Once the clapper has opened, the lever acts as a latch, preventing the clapper from returning to the closed position. Water

from the supply flows through the deluge valve into the system

piping. Water also flows through the deluge valve alarm outlet

to activate any water flow alarm devices. Note that the solenoid

valve will be maintained open by the Potter Model PFC-4410RC Releasing Control Panel’s latching feature until it is reset for

operation.

5.

Page 6

After system shutdown and draining, the Model DDX Deluge

Valve is easily reset without special tools (see Fig. 9 or 10). Restore detection devices by resetting or replacing any operated

device. Once detection devices are restored, (the Potter Model

PFC-4410-RC Releasing Control Panel reset), and supply pressure is re-supplied to the push-rod chamber, the deluge valve

is reset.

System Operation (Double Interlock)

To fully activate (water flow) the Reliable Model DDX 4” (100

mm), 6” (150 mm) or 8” (200 mm) PrePaK in a double interlock

application, two independent events must coexist. An electrical

fire detection device (smoke, heat, etc.) and the system air pressure switch must be activated. This pressure switch is activated

by a reduction of the system’s pneumatic pressure (as a result of

sprinkler operation). Both of these events will cause the control

panel to energize the solenoid valve, thereby releasing water

through the deluge valve and into the sprinkler system. The initiation of either one of these events will only cause an alarm to

annunciate, and will not fill the sprinkler system.

When the double interlock preaction system is set for service,

the supply pressure acts both on the underside of the deluge

valve’s clapper and on the valve’s push rod by means of the

pressurized push rod chamber. The pressure force acting on

the push rod, when utilized with the mechanical advantage of

the deluge valve’s lever, is more than sufficient to hold the clapper in the closed position against the water supply pressure.

Energizing the releasing solenoid valve allows the deluge

valve’s push-rod chamber to be vented to drain through its

outlet. Since the pressure cannot be replenished through the

inlet restriction as rapidly as it is vented though the outlet, the

push-rod chamber pressure falls rapidly. When the push-rod

chamber pressure drops below one-third of the supply pressure, the opening force acting beneath the clapper becomes

greater than the push-rod force acting on the lever. This causes

the clapper to open. Refer to Reliable Bulletins 518 and 519 for

further details.

Once the clapper has opened, the lever acts as a latch, preventing the clapper from returning to the closed position. Water

from the supply flows through the deluge valve into the system

piping. Water also flows through the deluge valve alarm outlet

to activate any water flow alarm devices. Note that the solenoid

valve will be maintained open by the Potter Model PFC-4410RC Releasing Control Panel’s latching feature until it is reset for

operation.

After system shutdown and draining, the Model DDX Deluge

Valve is easily reset without special tools (see Fig. 9 or 10). Restore detection devices by resetting or replacing any operated

device. Once detection devices are restored, (the Potter Model

PFC-4410-RC Releasing Control Panel reset), and supply pressure is re-supplied to the push-rod chamber, the deluge valve

is reset.

Resetting Single And Double Interlock Systems

Refer to Fig. 9 or 10.

1. Close the main valve controlling water supply to the deluge

valve and close the ¼” air shutoff valve, valve J.

2. Close the pushrod chamber supply valve, valve A.

3. Open the main drain valve, valve B, and drain system.

4. Open all drain valves and vents at low points throughout

the system, closing them when flow of water has stopped.

Open valve D. Note: The above steps accomplish the

relieving of pressure in the pushrod chamber of the deluge

valve.

5. Push in the plunger of ball drip valve, valve F, to force the

ball from its seat, and drain any water in the alarm line.

6. With the Model B Manual Emergency Station, valve D,

open, push in and rotate the deluge valve’s external reset

knob clockwise until you hear a distinct clicking noise, indicating that the clapper has closed. Note: The reset knob

can be rotated only after pressure in the pushrod chamber

is reduced to atmospheric conditions (0 psig).

7. Inspect and replace any portion of the sprinkler system

subjected to fire conditions.

8. Verify that the following valves are in their respective positions:

valve C – open, valve E – closed, valve H – closed,

valve K – open, valve M – closed.

9. Open valve A and allow water to fill the deluge valve’s pushrod chamber. Close valve D.

10. Bleed any air from the actuation piping by energizing the

solenoid valve. This is done by operating a detector or an

electric manual emergency station. While water is flowing

through the solenoid valve, cause it to close by pressing the

system reset button on the Potter PFC-4410-RC Releasing

Control Panel. Note: All detection devices must be reset

before the releasing/control panel can be reset.

11. Open the ¼” air shutoff valve, valve J, to restore air pressure in the sprinkler system. The rapid air-fill shutoff valve,

valve M, may be opened here to expedite the filling of the

sprinkler system.

12. Open slightly the main valve controlling water supply to the

Model DDX Deluge Valve, closing drain valve B when water flows. Observe if water leaks through the ball drip valve,

valve F, into the drip cup or drain manifold, G. If no leak

occurs, the deluge valve’s clapper is sealed. Open slowly,

and verify that the main valve controlling water supply is

fully opened and properly monitored.

13. Verify that valve A is open.

14. Secure the handle of the Model B Manual Emergency Station, valve D, in the OFF position with a nylon tie (supplied

with the assembly).

15. Press the system reset button on the Potter PFC-4410-RC

Panel to place the system in the ready condition. Note: All

detection devices must be reset before the panel can be

reset.

Maintenance

The Reliable Model DDX PrePaK and associated equipment

shall periodically be given a thorough inspection and test. NFPA

25, Standard for the Inspection, Testing and Maintenance of

Water Based Fire Protection Systems, provides minimum maintenance requirements. Systems should be tested, operated,

cleaned and inspected at least annually, and parts replaced as

required. Periodically open the air/condensate drain valve (refer

to Fig. 9 or 10) beneath the air tank to drain any condensate accumulation. Bulletin 518 provides information for maintaining the

Model DDX Deluge Valve. Potter Manual #5403550 provides

information for maintaining the PFC-4410-RC Releasing Control

Panel.

6.

Page 7

Inspection And Testing Of Single And Double

Interlock Systems

Refer to Fig. 9 or 10.

1. Water supply — Verify that the valve controlling water supply to the deluge valve is opened fully and

properly monitored.

2. Alarm line — Verify that valve C is opened and remains in this position.

3. Other trimming valves — Verify that valve A is

open as well as all of the pressure gauge’s ¼” 3-way

valves. Valves D, E, and H should be closed.

4. Ball drip valve F — Push in on the plunger to be sure

the ball check is off its seat. If no water appears, the

deluge valve’s water seat is tight. Inspect the bleed

hole in the front of the Model DDX Deluge Valve for

leakage.

5. System pneumatic pressure — Verify that system

air pressure is between 7 and 10 psi (0.5 bar 0.7

bar). Check the Pressure Maintenance Device for

leakage and proper pressure.

6. Releasing device — Check the outlet of the releasing device (i.e., solenoid valve or the Model B Manual

Emergency Station, valve D) for leakage. Also verify

that tubing drain lines from releasing devices are not

pinched or crushed which could prevent proper releasing of the deluge valve.

7. Testing alarms — Open valve E permitting water

from the supply to flow to the alarm pressure switch

and to the mechanical sprinkler alarm (if present).

After testing, close this valve completely. Push in on

the plunger of ball drip valve F until all of the water

has drained from the alarm line.

8. Operational test — Open the Model B Manual Emergency Station, valve D only, OR, operate the solenoid

valve by electrical actuation. This is done by operating a detector or an electric manual emergency

station. Double interlock systems also require that

the sprinkler system’s air pressure be discharged,

through the inspectors test station or other venting

means, below 4 psi (0.3 bar) before total system

operation will occur. Note: An operational test will

cause the Deluge Valve to open and flow water into

the sprinkler system.

9. Secure the Model B Manual Emergency Station,

valve D, in the OFF position with a nylon tie (included

with the assembly) after the deluge valve is reset.

Testing The Model DDX PrePaK Without

Causing Water Flow

Refer to Fig. 9 or 10.

1. Close the main valve controlling water supply to the deluge

valve and open drain valve B.

2. Verify that valve A is open, allowing water to enter the pushrod chamber.

3. Operate the detection system - Operate a cross-zoned releasing control panel by operating two detectors. For double interlock applications, close valve J and open valve H.

Doing so will discharge the sprinkler system’s air pressure.

4. Step #3 should result in a sudden drop of water pressure

in the deluge valve’s push-rod chamber via an energized

solenoid valve.

5. Reset the detection system - Reverse the detection system

operations performed in Step #3 above. Note: All detection devices must be reset before the Potter PFC-4410-RC

Releasing Control Panel can be reset.

6. Proceed according to the directions listed in the “Resetting

Single And Double Interlock Systems” section of this bulletin.

Draining Excess/Condensate Water From

The System

Refer to Fig. 9 or 10.

1. Close the main valve controlling water supply to the deluge

valve. Also, close valve A and open the main drain valve,

valve B.

2. Open the condensate drain valve, valve H, until all of the

water (if any) drains completely. Note: Be sure not to keep

valve H open for an extended period of time because that

will cause enough system air to bleed off, thereby activating the system pressure switch and causing an potentially

undesirable alarm condition.

3. Close the main drain valve B. Allow the system’s air pressure to return to its previous level. Open valve A first, and

then open the main valve controlling the water supply to the

deluge valve.

SOLENOID VALVE INSPECTIONS, TESTS

AND MAINTENANCE

WARNING: THE OWNER IS RESPONSIBLE FOR MAINTAINING THE FIRE PROTECTION SYSTEM IN PROPER OPERATING CONDITION. ANY SYSTEM MAINTENANCE OR TESTING THAT INVOLVES PLACING A

CONTROL VALVE OR DETECTION SYSTEM OUT OF

SERVICE MAY ELIMINATE THE FIRE PROTECTION

OF THAT SYSTEM. PRIOR TO PROCEEDING, NOTIFY

ALL AUTHORITIES HAVING JURISDICTION. CONSIDERATION SHOULD BE GIVEN TO EMPLOYMENT OF

A FIRE PATROL IN THE AFFECTED AREA.

WARNING: PRIOR TO OPERATING THE SOLENOID

VALVE, BE SURE TO CLOSE THE SYSTEM CONTROL

VALVE TO AVOID UNINTENTIONAL OPERATION OF

THE DELUGE VALVE

1. Inspections: It is imperative that the system be inspected

and tested in accordance with NFPA 25 on a regular basis.

The frequency of the inspections may vary due to contaminated water supplies, corrosive water supplies, or corrosive

atmospheres. In addition, the alarm devices, detection systems, or other connected trim may require a more frequent

schedule. Refer to the system description and applicable

codes for minimum requirements.

2. The valve must be inspected at least monthly for cracks,

corrosion, leakage, etc., cleaned and replaced as necessary.

3. If leakage is suspected through the solenoid valve, it should

be replaced.

7.

Page 8

RUN

PROGRAM

RED OUTPUT LED STEADY: ABORT

ZONE 1

ZONE 2

ZONE 3

ZONE 4

AC POWER

POWER TBL

SYSTEM TBL

SUP TBL

GROUND

FAULT

OUTPUT 1

OUTPUT 2

OUTPUT 3

OUTPUT 4

SUP 1/ABORT

SUPERVISORY 2

COMMON ALARM

ALARM SILENCE

STEADY:

DISCHARGED

FLASHING:

PRE-DISCHARGE

PROGRAM

MODE

SET

SELECT

RUN

MODE

SCROLL-UP

BUZZER SILENCE

LAMP

}

TEST

SCROLL-DOWN

BUZZER SILENCE

SIGNAL SILENCE

VIEWING ANGLE

FUNCTION

SYSTEM RESET

Fig. 2

8.

Page 9

Fig. 3

9.

Page 10

Fig. 4

10.

Page 11

Fig. 5

11.

Page 12

12.

Fig. 6

Page 13

13.

Fig. 7

Page 14

14.

Fig. 8 — Wiring Diagram

Page 15

15.

Fig. 9

Page 16

16.

Fig. 10

Page 17

Potter Program #6

Single Interlock Programming Instructions (Single

Hazard; 2 Alarm Zones, 1 Waterfl ow Zone, and 2

Supervisory Zones)

1. Apply power to panel.

2. Slide the program switch down.

3. Press the FUNCTION button until the display reads “PASSWORD=000.”

4. To enter a password, press the SELECT button until the

proper number is displayed above the “^” symbol; then

press the SET button to move to the next digit. After entering the third number the display will change. (All panels are

shipped with a “000” password.)

5. Press the FUNCTION button until the display reads “PROGRAM ##.” (the second “#” character refers to the current

program number between “0” and “24”).

6. Press the SELECT button until the display reads “PROGRAM #6.”

7. Press the SET button

8. The panel is completely programmed except for the custom banner and zone messages. Slide the program switch

back up.

POTTER PROGRAM #6

ZONES

#1

OUTPUTS

#1 ALARM X X

#2 WATERFLOW X

#3 SUPERVISORY X X

#4 RELEASE X X

*Supervisory 2

Conventional

#2

Manual Release

#3

Waterfl ow

#4

Low Air Supervisory

INPUTS: 1 conventional zone, 1 manual release zone, 1 waterflow zone, 1 low air zone, 1 supervisory zone.

OUTPUTS: 1 general alarm bell, 1 waterflow bell, 1 supervisory bell, 1 solenoid release circuit.

OPERATION: Activation of either the conventional zone or the manual release will operate the solenoid release

circuitand the general alarm bell.Activation of the waterflow zone will operate the waterflow bell.Activation of either the low air zone or the supervisory zone will operate the supervisory bell.When either

Zone #1 or #2 is in alarm, Output #1 (general alarm) and Output #4 (solenoid release) willoperate.

When Zone #3 is in alarm, Output #2 (waterflow bell) will operate.When either Zone #4 or the supervisory zone is activated, Output #3 (supervisory bell) will operate.

* The Butterfl y valve in the PrePaK assembly is connected to Supervisory 2 input of the Potter PFC-4410RC

Releasing/Control panel

Refer to the “Installation, Operation and Instruction Manual” for the PFC-4410-RC Releasing

Control Panel for Additional Information.

17.

Page 18

Fig. 11 — Wiring Diagram

18.

Page 19

Potter Program #7

Single Interlock Programming Instructions (Single

Hazard - Cross-Zoned, 2 Alarm Zones, 1 Waterfl ow

Zone and 2 Supervisory Zones)

1. Apply power to panel.

2. Slide the program switch down.

3. Press the FUNCTION button until the display reads “PASSWORD = 000.”

4. To enter a password, press the SELECT button until the

proper number is displayed above the “^” symbol; then

press the SET button to move to the next digit. After entering the third number the display will change. (All panels are

shipped with a “000” password).

5. Press the FUNCTION button until the display reads “PROGRAM ##.” (the second “#” character refers to the current

program number between “0” and “24”).

6. Press the SELECT button until the display reads “PROGRAM #7.”

7. Press the SET button.

8. The panel is completely programmed except for the custom banner and zone messages. Slide the program switch

back up.

POTTER PROGRAM #7

ZONES

#1

OUTPUTS

#1 ALARM X X

#2 WATERFLOW X

#3 SUPERVISORY X X

#4 RELEASE X X

*Supervisory 2

Conventional

#2

Conventional

#3

Waterfl ow

Low Air Supervisory

#4

INPUTS: 2 conventional zones (cross-zoned), 1 waterflow zone, 1 low air zone, 1 supervisory zone.

OUTPUTS: 1 general alarm bell, 1 waterflow bell, 1 supervisory bell, 1 solenoid release circuit.

OPERATION: Activation of both conventional zones at the same time will operate the solenoid release circuit and

thegeneral alarm bell.Activation of either conventional zone will operate the general alarm bell.Activation of the waterflow zone will operate the waterflow bell.Activation of either the low air zone or the

supervisory zone will operate the supervisory bell.When either Zone #1 or #2 is in alarm, Output #1

(general alarm) will operate.When Zones #1 and #2 are in alarm at the same time, Output #4 (solenoid

release) and Output #1(general alarm) will operate.When Zone #3 is in alarm, Output #2 (waterflow

bell) will operate.When either Zone #4 or the supervisory zone is activated, Output #3 (supervisory

bell) will operate.

* The Butterfl y valve in the PrePaK assembly is connected to Supervisory 2 input of the Potter PFC-4410RC

Releasing/Control panel.

Refer to the “Installation, Operation and Instruction Manual” for the PFC-4410-RC Releasing

Control Panel for Additional Information.

19.

Page 20

Fig. 12

20.

Page 21

Potter Program #9

Double Interlock Programming Instructions

(Single Hazard, Cross Zoned, 2 Alarm Zones

(1 Detection & 1 Low Air), 1 Waterfl ow Zone,

and 1 Supervisory Zone)

1. Apply power to the panel.

2. Slide program switch down.

3. Press the FUNCTION button until display reads “PASSWORD=000.”

4. To enter a password, press the SELECT button until the

proper number is displayed above the “^” symbol; then

press the SET button to move to the next digit. After entering the third number, the display will change. (All panels are

shipped with a “000” password).

5. Press the FUNCTION button until the display reads “PROGRAM ##.” (the second “#” character refers to the current

program number between “0” and “24”).

6. Press the SELECT button until the display reads “PROGRAM #9.”

7. Press the SET button.

8. The panel is completely programmed except for the custom banner and zone messages. Slide the program switch

back up.

POTTER PROGRAM #9

ZONES

#2

Low Air

#1

OUTPUTS

#1 ALARM X

#2 WATERFLOW X

#3 SUPERVISORY X X X

#4 RELEASE X X

*Supervisory 2

Conventional

Supervisory

(Empty)

#3

Waterfl ow

Low Air Alarm

#4

INPUTS: 1 supervisory zone, 1 conventional detection zone, 1 low air supervisory zone, 1 waterflow zone, 1 low

air alarm zone.

OUTPUTS: 1 general alarm, 1 supervisory, 1 waterflow, 1 solenoid release circuit.

OPERATION: Activation of the conventional detection zone and the low air alarm zone at the same time will operate

the solenoid release circuit and the general alarm bell.

Activation of the conventional zone only will operate the general alarm output.

Activation of the low air supervisory zone will operate the supervisory bell output.

Activation of the waterflow zone will operate the waterflow bell output.

Activation of the low air alarm zone will operate the supervisory bell output. It will not operate the alarm

relay.

When Zone #1 is in alarm, Output #1 will operate.

When Zone #2 is activated, Output #3 will operate.

When Zone #3 is in alarm, Output #2 will operate.

When Zone #4 is activated, Output #3 will operate. This will create a supervisory condition not an

alarm condition. The alarm relay will not operate, the supervisory relay will.

When both Zones #1 and #4 are activated at the same time, the solenoid circuit will operate.

* The Butterfl y valve in the PrePaK assembly is connected to Supervisory 2 input of the Potter PFC-4410RC

Releasing/Control panel.

Refer to the “Installation, Operation and Instruction Manual” for the PFC-4410-RC Releasing

Control Panel for Additional Information.

21.

Page 22

Fig. 13

22.

Page 23

Potter Program #10

Double Interlock Programming Instructions

(Single Hazard, Cross Zoned, 3 Alarm Zones

(2 Detection & 1 Low Air),

1 Waterfl ow Zone, and 1 Supervisory Zone)

1. Apply power to the panel.

2. Slide program switch down.

3. Press the FUNCTION button until the display reads “PASS-

WORD=000.”

4. To enter a password, press the SELECT button until the

proper number is displayed above the “^” symbol, then

press the SET button to move to the next digit. After entering the third number the display will change. (All panels are

shipped with a “000” password).

5. Press the FUNCTION button until the display reads “PROGRAM ##.” (the second “#” character refers to the current

program number between “0” and “24”).

6. Press the SELECT button until the display reads “PROGRAM #10.”

7. Press the SET button.

8. The panel is completely programmed except for the custom banner and zone messages. Slide the program switch

back up.

POTTER PROGRAM #10

ZONES

#1

OUTPUTS

#1 ALARM X X

#2 WATERFLOW X

#3 SUPERVISORY X X

#4 RELEASE X X X

*Supervisory 2

Conventional

#2

Conventional

#3

Waterfl ow

Low Air Alarm

#4

INPUTS: 1 supervisory zone, 2 conventional detection zones, 1 waterflow zone, and 1 low air alarm zone.

OUTPUTS: 1 general alarm, 1 supervisory,1 waterflow, and 1 solenoid release circuit.

OPERATION: Activation of both conventional zones and the low air alarm zone at the same time will operate

the solenoid release circuit and the general alarm bell.

Activation of either conventional zone only will operate the general alarm output.

Activation of the waterflow zone will operate the waterflow bell output.

Activation of the low air alarm zone will operate the supervisory bell output. It will not

operate the alarm relay.

When either Zone #1 or #2 is in alarm, Output #1 will operate.

When Zone #3 is in alarm, Output #2 will operate.

When Zone #4 is activated, Output #3 will operate. This will create a supervisory

condition not an alarm condition. The alarm relay will not operate, the supervisory relay will.

When Zones #1, #2 and #4 are activated at the same time, the solenoid release circuit will operate.

* The Butterfl y valve in the PrePaK assembly is connected to Supervisory 2 input of the Potter PFC-4410RC

Releasing/Control panel.

Refer to the “Installation, Operation and Instruction Manual” for the PFC-4410-RC Releasing

Control Panel for Additional Information.

23.

Page 24

Fig. 14

24.

Page 25

Custom Program #1

(For New York City Compliance)

Single Interlock Programming Instructions for

New York City Compliance (Single Hazard, 2 Alarm

Zones, 1 Waterfl ow Zone, and 2 Supervisory Zones)

1. Apply power to the panel.

2. Slide the program switch down.

3. Press the FUNCTION button until the display reads “PASSWORD=000.”

4. To enter a password, press the SELECT button until the

proper number is displayed above the “^” symbol; then

press the SET button to move to the next digit. After entering the third number, the display will change (All panels are

shipped with a “000” password).

5. Press the FUNCTION button until the display reads “PROGRAM ##” (the second “#” character refers to the current

program number between “0” and “24”).

6. Press the SELECT button until the display reads “PROGRAM #6.”

7. Press the SET button.

8. Slide the program switch up.

9. Slide the program switch down.

10. Apply steps 3 to 5.

POTTER PROGRAM #1

11. Press the SELECT button until the display reads “PROGRAM #0.”

12. Press the SET button.

13. Press the FUNCTION button until the display reads “OUTPUT 1: INDICATING.”

14. Press the SET button until the display reads “OUTPUT #2:

INDICATING.”

15. Press the SELECT button until the display reads “TROUBLE

BELL.” Press the SET button.

16. Press the FUNCTION button until the display reads “ZONE

1 OUTPUTS.” The “v” is pointing to the first available output for the zone indicated on the display. If the number is

displayed, it is turned on for that zone. If the number is not

displayed, the zone is turned off.

17. Press the FUNCTION button until the display reads “ZONE

3 OUTPUTS.”

18. Press the SELECT button. The “1” should appear under the

“v”.

19. Press the SET button twice. The panel is completely programed except for the custom banner and zone messages. If these messages are not desired, then slide the

program switch back up.

ZONES

#4

#1

OUTPUTS

#1 ALARM X X X

#2 TROUBLE

#3 SUPERVISORY X X

#4 RELEASE X X

*Supervisory 2

Conventional

#2

Manual release

#3

Waterfl ow

Low Air

Supervisory

INPUTS: 1 conventional zones, 1 manual release zone, 1 waterflow zone, 1 low air zone, 1 supervisory zone.

OUTPUTS: 1 general alarm bell, 1 trouble bell, 1 supervisory bell, and 1 solenoid release circuit.

OPERATION: Activation of either the conventional zone or the manual release will operate the solenoid release

circuit and the general alarm bell.

Activation of the waterflow zone will operate the general alarm bell.

Activation of either the low air zone or the supervisory zone will operate the supervisory bell.

A trouble condition (low battery, wiring problem, etc.) will operate the trouble bell.

When either Zone #1 or #2 is in alarm, Output #1 (general alarm) and Output #4 (solenoid release)

will operate.

When Zone #3 is in alarm, Output #1 (alarm bell) will operate.

When either Zone #4 or the supervisory zone is activated, Output #3 (supervisory bell) will operate.

When the panel is in a trouble condition, Output # 2 (trouble bell) will operate.

* The Butterfl y valve in the PrePaK assembly is connected to Supervisory 2 input of the Potter PFC-4410RC

Releasing/Control panel.

Refer to the “Installation, Operation and Instruction Manual” for the PFC-4410-RC Releasing

Control Panel for Additional Information.

25.

Page 26

Fig. 15

26.

Page 27

Ordering Information:

Model DDX 4” (100mm) & 6” (150mm) PrePAK Part Number Code Key

4

6

4 = PrePaK Assembly

with 4” (100 mm)

Grooved Ends

Model

DDX Deluge Valve

6 = PrePaK Assembly

with 6” (150 mm)

Grooved Ends

Model

DDX Deluge Valve

Unit Size

Example: 4 - 175 - 1 - 1

175

250

175 = 175 psi

(12.1 bar)

System Pressure

Rating

250 = 250 psi

(17.2 )

System Pressure

Rating

Pressure Rating

0

1

2

3

4

0 = No Air Compressor

1 = ¾ Hp

(120 VAC @ 60 Hz)

Air Compressor

2 = ¾ Hp

(220 VAC @ 50 Hz)

Air Compressor

3 = 1-1/2 Hp

(120 VAC @ 60 Hz)

Air Compressor

(Not Available in the

4” (100 mm) Assembly)

Air Compressor

Voltage

0

1

0 = No

Releasing/Control Panel

1 = Potter

PFC-4410-RC

Releasing/Control Panel

Releasing/Control

Panel

4” (100 mm) Model DDX PrePaK Assembly with 175 psi (12.1 bar) System Pressure Rating, ¾ Hp Air Compressor

Factory Wired to 120 VAC @ 60 Hz, and Potter PFC-4410-RC Releasing/Control Panel.

27.

Page 28

www.reliablesprinkler.com Internet Address

(800) 848-6051 Sales Fax

(914) 829-2042 Corporate Offices

Manufactured by

Reliable Automatic Sprinkler Co., Inc.

(800) 431-1588 Sales Offices

The equipment presented in this bulletin is to be installed in accordance with the latest published Standards of the National Fire Protection Association, Factory

Mutual Research Corporation, or other similar organizations and also with the provisions of governmental codes or ordinances whenever applicable.

Products manufactured and distributed by Reliable have been protecting life and property for almost 100 years.

EG. Printed in U.S.A. 10/16

Revision lines indicate updated or new data.

P/N 9999970306

Recycled

Paper

Fig. 16

Loading...

Loading...