Page 1

Bulletin 748 July 2019

Model DDX-LP PrePak System

2” (50mm), 2

1

/

” (65mm),

2

3” (80mm), 4” (100mm),

6” (150mm) & 8” (200mm)

Bulletin 748 July 2019

Instructions for

Installation, Operation,

Care and Maintenance

Low Pressure Dry-Pipe System

10 psi - 26 psi (0.7 bar - 1.8 bar)

Recommended System Pressure

General Description

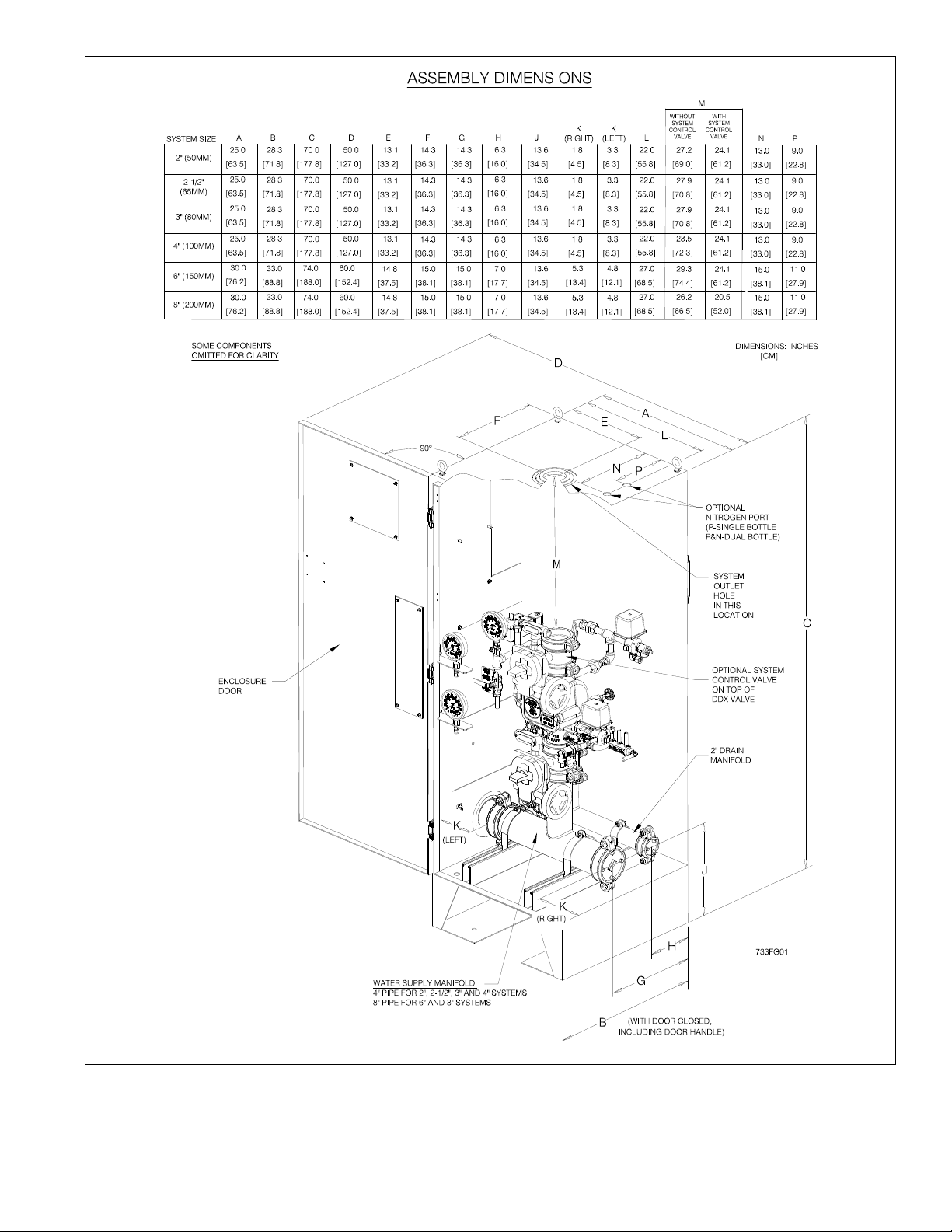

The Reliable Model DDX-LP PrePak (Sizes 2” (50mm),

2½” (65 mm), 3” (80 mm), 4” (100 mm), 6” (150mm) and

8” (200mm)) is a completely self-contained, supervised dry

pipe system that can be readily installed within a floor space

of less than 7 square feet (0.65 square meters). Refer to Fig.

1 for cabinet dimensions. Installation of the DDX-LP PrePak

requires just three piping connections: the water supply, the

sprinkler system and the drain. Reference locations of these

piping connections are shown in Fig. 1. One electrical supply connection is required. Note: The Model DDX-LP PrePak

is available with an optional 115V VAC (60Hz) air compressor.

Full assembly drawings for the units are available on the

Reliable Automatic Sprinkler Company website (www.reliablesprinkler.com).

The heart of the Reliable Model DDX-LP PrePak is the

Model DDX-LP Dry Pipe Valve. The Reliable Model DDX-LP

Dry Pipe Valve is a hydraulically operated, differential-type

valve designed for use as a primary control valve in a low

pressure dry pipe valve system. The trim set used with the

Model DDX-LP Dry Pipe Valve contains the Reliable Model

LP Dry Pilot Actuator releasing device. This Actuator allows

the system air or nitrogen pressure to be considerably less

than the water supply pressure (see Table A). The following

benefits are a direct result of lower air pressure:

1. In refrigerated area systems, lower air pressure de-

creases the possibility of ice plugs that could impede

or prevent the flow of water to fire sprinkler heads in

the event of fire.

2. Lower air pressure allows for smaller capacity, lower

cost dehydration equipment, where required.

3. Lower air or nitrogen pressure can reduce water de-

livery time when the system actuates, and in some

cases, may eliminate the need for an accelerator.

4. For systems supplied with nitrogen, low supervisory

pressure reduces the quantity of nitrogen required to

maintain the system pressure.

Note: Photograph is for illustrative purposes only.

Reliable Automatic Sprinkler Co., Inc., 103 Fairview Park Drive, Elmsford, New York 10523

Page 2

When using the Reliable DDX-LP PrePak the sprinkler system is pressurized with air provided by the optional factoryinstalled air compressor or on-site Nitrogen supply and is

monitored by a system pressure switch. If bottled Nitrogen is

being used as the supervisory gas, an optional Nitrogen Kit

is available. This kit contains a regulator and an additional

pressure switch that is used to monitor any low pressure

conditions that may arise due to having a limited Nitrogen

supply. When using Nitrogen, the primary supervisory gas

should be the Nitrogen (not standard air) due to moisture

concerns (i.e. freezing conditions). The optional factoryinstalled air compressor should be utilized merely for initial

fill and make-up air when the Nitrogen supply is not active.

Note: Compressed air is not to be considered dry air and

may create ice plugs in the sprinkler system piping.

When a fire sprinkler operates, there will be a loss of air or

Nitrogen pressure in the sprinkler system piping which will

cause the Model LP-Dry Pilot Actuator to open. The opening

of this device allows the Model DDX-LP PrePak valve to flow

water into the system piping.

A Model B Hydraulic Manual Emergency Releasing station is standard equipment in the Reliable DDX-LP PrePak. It

consists of an aluminum nameplate mechanically attached

to a ball valve. The valve handle in its OFF position is guarded against accidental turning to the ON position (and system discharge) by a nylon cable tie provided with the DDXLP PrePak assembly. The cable tie is designed to allow, in

case of an emergency, forceful turning of the valve handle

to the ON position.

Listings and Approvals

1. Underwriters Laboratories, Inc. Listed and Certi-

fied for Canada (cULus) as an assembled unit in the

“Special System Water Control Valves Assembled

Units” category, (VKYL).

2. Factory Mutual Approved as a Dry Pipe Sprinkler

System.

Technical Data

1. The Reliable Model DDX-LP PrePak is rated for a mini-

mum water supply pressure of 20 psi (1.4 bar) and a

maximum water supply pressure of 250 psi (17.2 bar).

Note: 1 bar = 100 kPa.

2. Friction loss, expressed in equivalent length of Sched-

ule 40 pipe and based on Hazen-Williams Formula is:

System Size Equivalent Length

2” (50 mm) 19.4 ft (1.3 m)

2½” (65 mm) 24.5 ft (1.8 m)

3” (80 mm) 28.9 ft (3.8 m)

4” (100 mm) 32.8 ft (17.7 m)

6” (150 mm) 54.7 ft (21.8 m)

8” (200 mm) 79.3 ft (24.2 m)

The equivalent length in the table above includes the

Model DDX-LP PrePak valve, supply manifold tee, supply side control valve, and the section of pipe above the

Model DDX-LP PrePak valve.

3. Shipping Weight:

System Size Weight

2” (50 mm), 2½” (65 mm)

& 3” (80 mm)

4” (100 mm) 710 lbs (322 kg)

6” (150 mm) 800 lbs (363 kg)

8" (200mm) 1350 lbs (531kg)

554 lb. (252 kg)

4. Refer to Figure 1 for dimensions.

The following is a list of Technical Data Bulletins which de-

scribe the valves and devices which are used in the system:

Device

Model DDX-LP PrePak Deluge

Valve

Model DDX-LP Dry Pipe Valve Reliable Bulletin 338

Low Air Pressure Switch Potter, 5401564

Alarm Pressure switch Potter, 5400928

Nitrogen Pressure Switch Potter, 5400930

Mechanical Sprinkler Alarm Reliable Bulletins 612/613

Desiccant Dryer Wilkerson Catalog 9EM-TK-190-4

Reliable Bulletin #

(unless otherwise noted)

Reliable Bulletin 519

Installation Requirements

The automatic sprinklers utilized with the DDX-LP PrePak

must be UL and/or ULC Listed or FM Approved, as applicable.

The steel enclosure and all the interconnecting piping

must be located indoors in a readily visible and accessible

location and in an area that can be maintained at a minimum temperature of 40°F (4°C). Note: Heat tracing is not

permitted. The Model DDX-LP PrePak PrePak operation is

controlled by the Model LP Dry Pilot Actuator. The introduction of moisture into the system piping exposed to freezing

temperatures can create ice blockage, which could prevent

proper system operation. As a minimum, the air supply

should be taken from the area of lowest temperature within

the protected area. The air supply system must be carefully

designed to prevent plugging by frost deposits. Special requirements, such as those in FME&R “Installation Guidelines

for Refrigerated Storage” may need to be incorporated.

Hydrostatic Testing of DDX-LP PrePak Valves and

DDX-LP PrePak Systems

As required by NFPA 13, fire sprinkler systems with working pressures up to and including 150 psi are to be hydrostatically tested at a water pressure of 200 psi. Fire sprinkler

systems with working pressures above 150 psi are required

to be hydrostatically tested at 50 psi above the system working pressure. In addition to the hydrostatic tests described

above, dry pipe systems require an additional low pressure

air test.

In some cases, hydrostatic testing (in accordance with the

NFPA 13 requirements noted above) will result in pressures

2.

Page 3

Fig. 1

3.

Page 4

that exceed the working pressure of the valve and trim kit for

the two-hour test period.

The valve and applicable trim kit have been tested, approved and listed under these conditions and as such, hydrostatic testing in accordance with NFPA 13 is acceptable.

In addition, the clapper can remain in the closed position

and the trim kit need not be isolated, as each has been designed to withstand hydrostatic testing as required by NFPA

13.

Subjecting the valve and trim to pressures higher than

their rating is limited to the hydrostatic test as referenced

by NFPA13. It does not address the occurrence of a “water hammer” effect, which may damage the valve. A “water

hammer” in the water supply piping of the valve can create pressures in excess of the rated pressure and should

be avoided by all necessary means. This condition may be

created from improper fire pump settings, underground construction work, or an improper venting of trapped air in the

water supply piping.

System Supervisory Pressure Requirements

The DDX-LP PrePak includes gauges indicating the air/

nitrogen and water pressures on the Model DDX-LP system. Table A specifies the air or nitrogen pressure to be

maintained in the sprinkler system piping based on the water supply pressure. The factory installed Pressure Maintenance Device in the unit automatically regulates makeup air

or nitrogen flow to maintain pressure with normal leakage

from system piping, while restricting the flow of makeup air

or nitrogen to the system. Please note that when the optional

Model B1 Accelerator is to be utilized to expedite water-delivery time, the air or nitrogen pressure must be not less than

15 psi (1.0 bar).

Table A

Water Pressure

psi (bar)

Maximum Not Less Than Not More Than

20 (1.4) 10 (0.7) 14 (0.9)

50 (3.4) 12 (0.8) 16 (1.1)

75 (5.2) 13 (0.9) 17 (1.2)

100 (6.9) 15 (1.0) 19 (1.3)

125 (8.6) 16 (1.1) 20 (1.4)

150 (10.3) 17 (1.2) 21 (1.4)

175 (12.1) 18 (1.2) 22 (1.5)

200 (13.8) 19 (1.3) 23 (1.6)

225 (15,5) 21 (1.5) 25 (1.7)

250 (17.2) 22 (1.5) 26 (1.8)

Note: During system setup, a higher pneumatic pressure

may be required in order to properly set the Model LP Dry

Pilot Actuator.

The dew point of the air supply must be maintained below

the lowest ambient temperature to which the dry system will

be exposed. Introduction of moisture into the system piping

exposed to freezing temperatures can create ice blockage

which could prevent proper system operation. As a minimum, the air supply should be taken from the area of lowest

temperature within the protected area. The air supply system must be carefully designed to prevent plugging by frost

deposits. Special requirements, such as those in FME&R’s

Supervisory Air or Nitrogen Pressure in

Sprinkler System, psi (bar)

“Installation Guidelines for Refrigerated Storage” may need

to be incorporated.

Nitrogen used in refrigerated area systems minimizes the

possibility of ice build-up and blockage inside the system

piping that could inhibit proper system operation. The dewpoint of nitrogen compressed to 20 psig (1.4 bar) pressure

is -46°F (-43.3°C), and -52°F (-46.7°C) when compressed

to 10 psig (0.7 bar). High-pressure nitrogen cylinders can

typically be rented from a local source, with rental fees varying by supplier and cylinder sizes. The calculated nitrogen

supply in lbs (kg) to pressurize various system capacities to

10 psi (0.7 bar) at different freezer temperatures is shown in

Table B.

If the Reliable DDX-LP PrePak is to be used with Nitrogen,

a Nitrogen kit is available as an option. A pressure switch is

used to monitor the nitrogen supply; the electrical contacts

on the pressure switch close when the nitrogen supply falls

to 100 psi (6,9 bar). The nitrogen source should be replaced

promptly upon operation of the pressure switch. If the nitrogen supply is not replaced, make-up air will come solely

from the unit’s air compressor (if installed). Compressed air

is not considered dry air, and may create ice plugs in the

sprinkler system piping.

Table B

System

Capacity

Gal. (L)

250

(946)

500

(1891)

750

(2840)

1,000

(3785)

Note: To obtain required nitrogen supply (lbs.) for 15 psi (1.0

* When filled with the Rapid Air – Fill Shutoff Valve open.

20°F

(-6.7°C)

(1.65)

(2.50)

(3.30)

bar) or 22 psi (1.5 bar), multiply the tabulated values by

a factor of 1.5 or 2.2 respectively.

(1 bar = 100 kPa)

If the air compressor in the Model DDX-LP PrePak is to

be used to initially fill the sprinkler system with air, the steel

enclosure door should remain open in order to provide maximum intake air flow to the air compressor. The air compressor is connected to a storage tank. This tank functions as

a reservoir, providing make-up air to compensate for small,

intermittent leaks in the sprinkler system. It should be noted that significant leaks may overburden this storage tank,

thereby causing the air compressor to continuously cycle

on and off.

The factory-installed system low air pressure switch may

need on-site adjustment to correspond with the air pressure

values found in Table A. Adjustment, if required, should be

made according to Potter Bulletin 5401564 included with the

4.

Freezer Temperature

0°F

(-18°C)

1.90

(.86)

3.64

5.50

7.30

1.90

(.86)

3.80

(1.72)

5.70

(2.60)

7.60

(3.44)

-20°F

(-29°C)

2.00

(.90)

4.00

(1.81)

6.00

(2.72)

8.00

(3.62)

-40°F

(-40°C)

2.10

(.95)

4.20

(1.91)

6.30

(2.86)

8.33

(3.78)

-60°F

(-51°C)

2.20

(1.00)

4.40

(2.00)

6.60

(3.00)

8.80

(4.00)

Approx.

Fill Time

(min.)*

1

2

3

4

Page 5

switch.

LP PrePak Deluge Valve.

System Electrical Requirements

All 24 VDC electrical connections in the Reliable Model

DDX-LP PrePak are translated to a water tight terminal box

mounted on the inside of the enclosure. All field wiring connections are made at this terminal box.

A separate power connection is provided for the optional

air compressor.

Note: The air compressor must be connected to a

grounded metallic, permanent wiring system, or an equipment grounding terminal or lead on the product. Power supply wiring must conform to all required safety codes and be

installed by a qualified person. Check that the supply voltage agrees with that listed on compressor nameplate. Also

the wires running from the main electrical supply to the compressor must agree with the values specified in Table C. An

undersized wire is a potential fire hazard and will cause a

drop in line voltage resulting in loss of power causing the

compressor to overheat.

Table C

Amps Volts Length of cord in feet

120v 20 50 100 150 200 250 300 400 500

240v 60 100 200 300 400 500 600 800 1000

0-2

2-3

3-4

4-5

5-6

6-8

8-10

10-12

12-14

14-16

16-18

18-20

18 18 18 16 16 14 14 12 12

18 18 16 14 14 12 12 10 10

18 18 16 14 12 12 10 10 8

18 18 14 12 12 10 10 8 8

18 16 14 12 10 10 8 8 8

18 16 12 10 10 8 6 6 6

18 14 12 10 8 8 6 6 4

16 14 10 8 8 6 6 4 4

16 12 10 8 6 6 6 4 2

16 12 10 8 6 6 4 4 2

14 12 8 8 6 4 4 2 2

14 12 8 6 6 4 4 2 2

The Reliable Model DDX-LP PrePak is available with the

following factory installed electrical devices:

1. A system low air pressure switch, which is used to

monitor sprinkler piping.

2. An alarm pressure switch, which indicates actuation

of the system.

3. An optional low nitrogen pressure switch, which indicates a depleted nitrogen supply.

4. An optional air compressor.

5. A supervised supply side butterfly water control valve.

6. A optional supervised system side butterfly water control valve.

The factory electrical connections of these devices are

illustrated in Fig. 3.

Maintenance

The Reliable DDX-LP PrePak and associated equipment

shall periodically be given a thorough inspection and test.

NFPA 25, Standard for Inspection, Testing and Maintenance

of Water Based Fire Protection Systems, provides minimum

maintenance requirements. Systems should be tested, operated, cleaned and inspected at least annually, and parts

replaced as required. Periodically open the condensate

drain valve beneath the air tank to drain any condensate accumulation. Reliable Technical Bulletins 338 and 519 provide additional information for maintaining the Model DDX-

System Setup (Refer to Figure 2)

1. Close the main valve controlling water supply to the

Model DDX-LP PrePak deluge valve. Also, close the

two ¼” valves supplying air or nitrogen to the system.

2. Close the pushrod chamber supply valve.

3. Open the main drain valve and drain the system.

4. Open all drain valves and vents at low points throughout the system, closing them when flow of water has

stopped.

5. Open the Manual Emergency Release valve. Note: The

above steps accomplish the relieving of pressure in the

pushrod chamber of the deluge valve.

6. Push in the plunger of ball drip valve to force the ball

from its seat, and drain any water in the alarm line.

7. Push in and rotate the deluge valve’s external reset knob

counter-clockwise (when facing valve) until you hear a

distinct clicking noise, indicating that the clapper has

reset. Note: The reset knob can be rotated only after

pressure in the pushrod chamber is reduced to atmospheric conditions (0 psig).

8. Inspect and replace any portion of the sprinkler system

subjected to fire conditions.

9. Verify that the following valves are in their respective positions prior to continuing:

Manual Emergency Release - open

Main Drain Valve - open

Alarm Line Valve - open

Alarm Test Valve - closed

Condensate Drain valve - closed

Air/Nitrogen Supply Valves - closed

10. Open pushrod chamber supply valve and allow water

to fill the pushrod chamber. Close the Manual Emergency Release valve after any trapped air has had a

chance to escape from the deluge valve’s pushrod

chamber.

11. Upon seeing this solid flow of water coming out of the

Model LP Dry Pilot Actuator, open the Rapid-Air Fill

Valve thereby rapidly applying compressed air or nitrogen into the Model LP Dry Pilot Actuator and the

sprinkler system until the pressure conforms to Table

A levels, as indicated by the system air pressure

gauge. The Model LP Dry Pilot Actuator will eventually

close during this pressurizing process and water will

stop flowing through the drain tube. At this point, the

pressure gauge on the pushrod chamber pressure will

equalize to the available water supply pressure. Once

the actuator is set up correctly, close the Rapid-Air Fill

Valve and open the Regulated Air Shutoff Valve.

Note: For systems using nitrogen as the primary

source, the system may be set up using the nitrogen

source following the steps above. The air compressor, if present, may then be placed into operation as

the backup pneumatic source.

5.

Page 6

12. Open the alarm line valve.

13. If the Model B1 Accelerator Kit is installed, open valve

P. Prior to opening valve P, be sure that the Model B1

Accelerator has been successfully reset per Reliable

Technical Bulletin 323.

Note: The B1 Accelerator requires a minimum of 15

psi (1,0 bar) supervisory air or nitrogen pressure for

proper operation.

14. Slightly open the main valve controlling water supply

to the Model DDX-LP PrePak Deluge Valve. This will

begin to fill the deluge valve beneath the clapper with

water. Once any trapped air has been vented, close

the main drain valve. Observe if water leaks through

the ball drip valve into the 1” drain manifold through

the clear tubing. If no leakage occurs, the deluge

valve clapper is sealed. Fully open the main valve

controlling the water supply to the Model DDX-LP PrePak Deluge Valve and that it is properly monitored

15. Verify that the pushrod chamber supply valve is open.

16. Secure the handle of the Model B Manual Emergency

Station in the OFF position with a nylon tie (supplied

with the assembly).

Inspection And Testing Of The DDX-LP PrePak

Systems (Refer to Figure 2)

1. Water supply — Verify that the valve controlling water

supply to the deluge valve is opened fully and properly

monitored.

2. Pushrod Chamber supply — Verify that the valve supplying water to the pushrod chamber is open.

3. Other trimming valves — Verify that the alarm line valve

is open as well as all of the pressure gauge valves. The

main drain valve, alarm test valve, and condensate

drain valve should be closed.

4. Ball drip valve — Push in on the plunger to be sure the

ball check is off its seat. If no water appears, the deluge

valve’s water seat is tight. Inspect the small bleed hole

located on the underside of the Model DDX-LP PrePak

Deluge Valve pushrod chamber for leakage.

5. System air pressure — Verify that system air pressure

is in conformance with the values posted in Table A for

the supply water pressure.

6. Releasing device — Check the outlet of the (Model LP

Dry Pilot Actuator and Model B Manual Emergency Station) for leakage. Also verify that tubing drain lines from

releasing devices are not pinched or crushed which

could prevent proper releasing of the deluge valve.

7. Testing alarms — Open the alarm test valve permitting water from the supply to flow to the alarm pressure

switch and to the mechanical sprinkler alarm (if present). After testing, close this valve completely. Push

in on the plunger of ball drip until all of the water has

drained from the alarm line.

8. Operational test — Open the Model B Manual Emergency Station or, alternatively, reduce air/nitrogen pressure on the system. Note: An operational test will cause

the Deluge Valve to open and flow water into the sprin-

kler system.

9. Secure the Model B Manual Emergency Station in

the OFF position with a nylon tie (included with the assembly) after the deluge valve is reset.

Testing the Model DDX-LP PrePak Deluge

Valve Without Flowing Water (Refer to Figure 2)

1. Close the valve controlling water supply to deluge valve

and open the main drain.

2. Verify that the pushrod chamber supply valve is open,

allowing water to enter the pushrod chamber.

3. Close the air/nitrogen supply to the sprinkler system.

4. Decrease pneumatic pressure in the system by opening

the condensate drain valve, until the Model LP Dry Pilot

Actuator operates. Doing so will result in a sudden drop

of water pressure in the deluge valve pushrod chamber.

5. Reset the system per the directions listed in “System

Setup” section of this bulletin.

Draining Excess/Condensate Water From System

1. Close the main valve controlling water supply to the Model

DDX-LP system.

2. Close the pushrod chamber supply valve, and open the

main drain valve.

3. Slightly open the condensate drain valve until all water

has drained, then close.

Note: Leaving the condensate drain open for an extended

period of time may allow excess air/nitrogen to bleed off and

result in accidental release of the Model LP Dry Pilot Actuator and/or the Model DDX-LP valve.

4. Close the main drain valve. Allow the system air/nitrogen

pressure to return to its previous level. Open the pushrod

chamber supply valve first, and then open the main valve

controlling water supply to the system.

6.

Page 7

Fig. 2

7.

Model DDX-LP Low Pressure Dry Pipe System

Valve Legend

(Note: Some items omitted for clarity)

Page 8

Fig. 3

8.

Page 9

Fig. 4

9.

Page 10

Manufactured by

The equipment presented in this bulletin is to be installed in accordance with the latest published Standards of the National Fire Protection Association, Factory

Mutual Research Corporation, or other similar organizations and also with the provisions of governmental codes or ordinances whenever applicable.

Products manufactured and distributed by Reliable have been protecting life and property for almost 100 years.

Ordering Information: PrePak Part Number Configuration

655 U 3 0 0 Y Z 0

Reliable Automatic Sprinkler Co., Inc.

(800) 431-1588 Sales Offices

(800) 848-6051 Sales Fax

(914) 829-2042 Corporate Offices

www.reliablesprinkler.com Internet Address

EG. Printed in U.S.A. 07/19

Revision lines indicate updated or new data.

P/N 9999970425

Recycled

Paper

DDX-LP PrePak Valve

Size/System

Side Control Valve

Trim Type

3

Solenoid Valve

0

U

2 = 2” 0 = None 0 = None 0 = None 0 = None

0 = 2-1/2”

3 = 3” 3 = PrePak

4 = 4”

6 = 6”

8 = 8” 5= Model B Accelerator

A = 2” w/ System Side

Control Valve

B = 2-1/2” w/ System Side

Control Valve

C = 3” w/ System Side

Control Valve

D = 4” w/ System Side

Control Valve

E = 6” w/ System Side

Control Valve

F =8” w/ System Side

Control Valve

Note:

(1)

No Solenoid Valve or Control Panel are utilized with this trim. If selected, the 6th and 7th digits in the P/N are required to be “0” (None).

(2)

Not Used

(3)

Air Compressor sizing may differ if specified sprinkler system has an uncommon volume capacity.

(1)

Releasing/Control

Panel

0

Air Compressor

(3)

Y

1 = 1/2 HP 115 VAC

(systems up to 3” in size)

2 = 1 HP 115 VAC

(for 4” systems)

3 = 1-1/2 HP 115 VAC

(for 6” & 8” systems)

System Air Devices

1 = Nitrogen Supply Kit

2 = Nitrogen Supply Kit &

Model B Accelerator

3 = NS-ASAM (Nitrogen

Supply w/ Auto Switchover

and Monitoring)

4 = NS-ASAM (Nitrogen

Supply w/ Auto Switchover

and Monitoring) & Model

B Accelerator

6 = Desiccant Kit

7 = Desiccant Kit &

Model B Accelerator

Z

Loading...

Loading...