Page 1

Woodburning Range

SAFETY NOTICE

PLEASE READ THIS ENTIRE MANUAL BEFORE YOU INSTALL AND USE YOUR NEW COOK STOVE.

FAILURE TO FOLLOW INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE,

BODILY INJURY OR EVEN DEATH. SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

IF THIS APPLIANCE IS NOT PROPERLY INSTALLED, A HOUSE FIRE MAY RESULT. FOR YOUR SAFETY, FOLLOW THE INSTALLATION DIRECTIONS. CONTACT LOCAL BUILDING OR FIRE OFFICIALS

ABOUT RESTRICTIONS AND INSTALLATION INSPECTION REQUIREMENTS IN YOUR AREA.

THIS APPLIANCE MUST BE CONNECTED TO A LISTED, HIGH-TEMPERATURE RESIDENTIAL TYPE

AND BUILDING HEATING APPLIANCE CHIMNEY OR AN APPROVED MASONRY

CHIMNEY WITH FLUE LINER.

THE COMPLETE INSTALLATION MUST BE DONE IN ACCORDANCE WITH CURRENT STANDARDS AND

LOCAL CODES. IT SHOULD BE NOTED THAT THE REQUIREMENTS AND THESE PUBLICATIONS MAY

BE SUPERSEDED DURING THE LIFE OF THIS MANUAL.

THIS APPLIANCE IS HOT WHILE IN OPERATION AND RETAINS ITS HEAT FOR A LONG PERIOD OF

TIME AFTER USE. CHILDREN, AGED OR INFIRM PERSONS SHOULD BE SUPERVISED ATALL TIMES

AND SHOULD NOT BE ALLOWED TO TOUCH THE HOT WORKING SURFACES WHILE IN USE OR UNTIL

THE APPLIANCE HAS THOROUGHLY COOLED.

MANUFACTURED BY: WATERFORD STANLEY (MARKETING) LTD., BILBERRY, WATERFORD,

IRELAND.

ASSEMBLY INSTALLATION AND OPERATING INSTRUCTIONS

Page 2

Page 3

TABLE OF CONTENTS

PAGE

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation Clearances to Combustibles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Reduced Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Rear Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Floor Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chimney Types USA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chimney Type Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chimney Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chimney Connector USA Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Connecting to Masonry Chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Thimbles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chimney Connector Systems, Thimbles & Clearances From Combustible Walls . . . . . 6

Exploded View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 & 8

Masonry Fireplace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ventilation & Combustion Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Efficient Economical Use Of Wood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Creosote - Formation & Need For Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Disposal Of Ashes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Hints On Fire Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Fuels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Lighting The Fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Controlling The Fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

The Hotplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

The Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Overnight Burning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Riddling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Flue Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chimney Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Use Of Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Vitreous Enamel Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Warming Shelf - Left or Right Hand Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Assembly Instructions - Warming Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1

Page 4

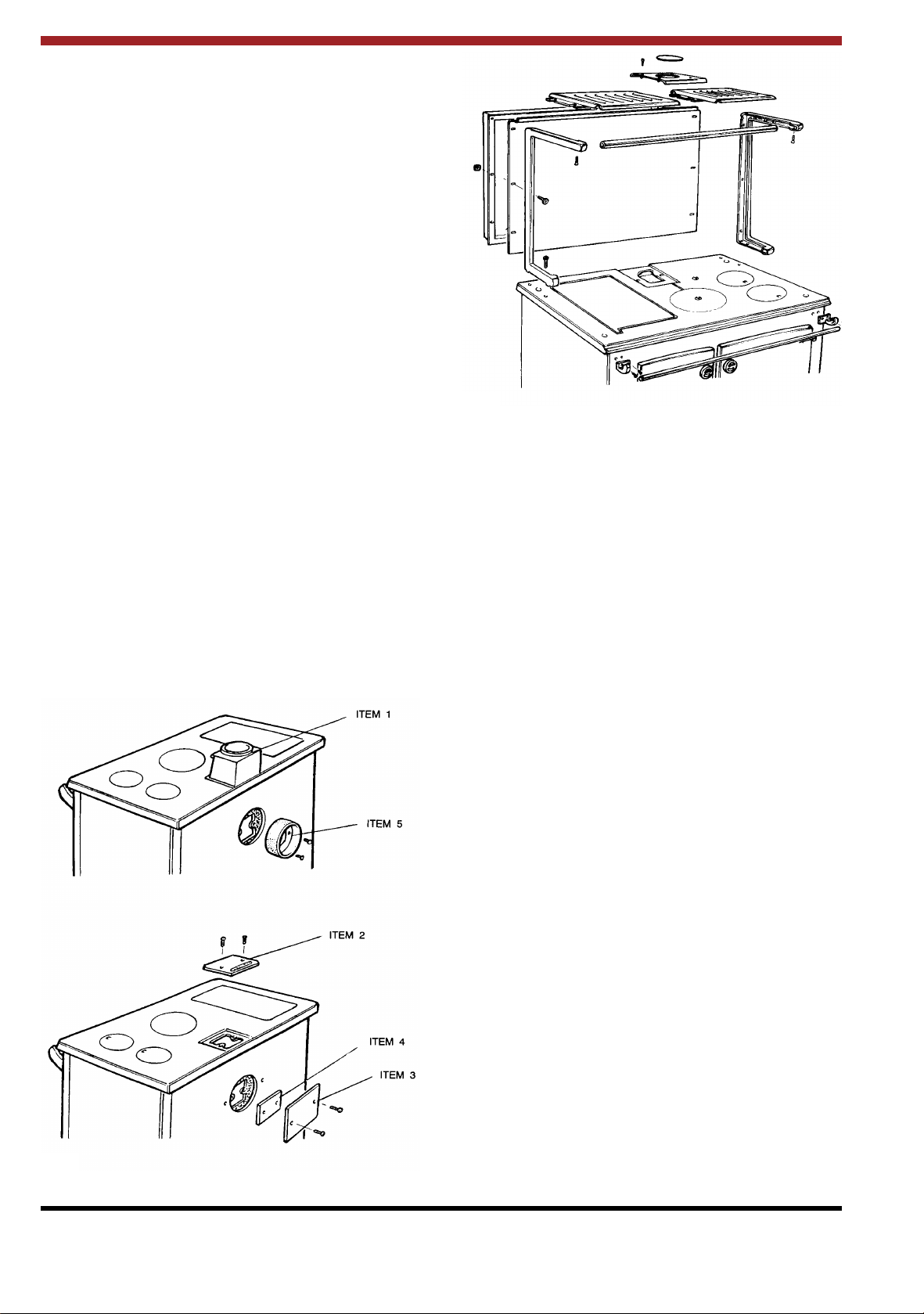

Fig.1

ASSEMBLY

1. Remove packing strip from the top of

the range. Place the sheet steel back

plate to one side. Remove all loose

components from the top of the range

and firebox and the oven. Remove the

oven door. Spread the components on

the floor so you can identify them easily.

Fig.2

2. Place cement blocks or other strong

supports about 458mm (13”) high

behind the range. Space the supports

behind it and lay the cooker on its back.

6. Fit the complete skirting under the front

of the range inside the front legs using a

screw and nut to secure it to each leg.

7. Move the range into position for

installation. CAREFUL: Do not break a

leg!

Fig.3

8. Ensure that the cast iron fire liners (part

nos.44,46,47,48 & 49) are secure in the

firebox at the front, sides and back.

3. Fit the four legs (Part no. 36) to the four

base corners (Part no. 13) using the

hexagon-head bolts and washers. Note

that each of the front legs (No. 36) has

a screw hole in the front.

4. Lift the range off the supports. Stand it

upright without putting any strain on the

legs.

5. Join the two sections of the front skirting

together (Part Nos. 37 and 38) by

screwing the name plate (Part No. 51)

with its back fixing strip (Part No. 54)

into position between the two sections

and secure the two sections tightly to

the name plate.

9. Place the oven damper in position (Part No.

63) on top of the oven and place the round

hotplate (Part No. 20) in position above it.

Place the oblong hotplate (Part No. 19) and

the two round cleaning cups (Part No. 15) in

position to complete the cooker top.

10. Place the top flue outlet (Part No. 55) in

position and fit its front cleaning door (Part

no. 56) in position.

11. Screw the towel rail brackets (Part Nos. 25

and 26) to the top front of the range (Part

No. 1) and fix the towel-rail (Part No.78) in

position between the brackets. Tighten up

the screws.

2

Page 5

12. Hang the fire door (Part No. 57) and the

ashpit door (Part No. 3) on their hinges.

13. Place the oven shelves in position (Part

No.12) the cast iron shelf below the sheet

steel shelf.

14. Place the cleaning door (Part No. 59) in

position beneath the oven door (Part No. 2).

15. Screw the splashback (Part No. 67) to its

two supports (Part Nos. 61 & 62) keeping

the folded end to the bottom. Screw the

plate rack (Part No. 88) to the splashback.

Screw the complete assembly on to the

cooker top (Part No. 18).

The Waterford Stanley Woodburning Range is

equipped for top flue connection. Should you wish

to vent the range to the rear the following modifications must be undertaken:

1. Remove the top flue collar (item 1) and seal

the opening with the blanking plate (item 2)

provided.

2. Remove the small panel (item 3) from the

back of the range and the blanking plate

(item 4) which will now be visible.

3. Screw the rear flue collar (item 5) provided

to the back of the range.

Fig.5

Note: Platerack and Splashback is an optional

extra, not supplied as standard.

Fig.4

3

Page 6

INSTALLATION

When installing, operating and maintaining a solid

fuel heater, respect basic standards of fire safety.

Read these instructions carefully before commencing the installation. Failure to do so may result in

damage to persons and property. Consult your local

municipal office, Fire Department and your insurance representative to determine what regulations

are in force.

INSTALLATION CLEARANCES TO

COMBUSTIBLES

Front 48” 1220mm

Back 16” 400mm

Oven Side 6” 150mm

Oven Side with Optional

Shelf Fitted 10” 250mm

Firebox Side 12” 300mm

Single Wall Flue Pipe 18” 460mm

(2130mm)

(300mm)

(225mm)

(200mm)

(150mm)

(460mm)

(2130mm)

(2130mm)

(300mm) (150mm)

(400mm)

Fig.6

REDUCED CLEARANCES

These clearances may be reduced by the application of protection to combustible walls and ceilings.

ULC/UL Labelled Heat Shields installed in accordance with the manufacturers instructions or shields

complying with the requirements of “Installation

Code for Solid Fuel Fired Appliances CAN31336” or

“Standard for Chimneys, Fireplaces and Ve n t s

NFPA No. 211.”

(2130mm)

(300mm)

(250mm)

(150mm) clearance or

less

(2130mm)

(150mm)

(100mm)

Fig.7

REAR EXIT

Back 6” 150mm

Oven side 6” 150mm

Firebox Side 12” 300mm

REAR EXIT

(300mm)

(150mm)

Fig.8

4

Page 7

FLOOR PROTECTION

CHIMNEY TYPE CANADA

When installing the Waterford Stanley Woodburning

Range on a combustible floor, a floor protector consisting of a layer of non-combustible material at least

3/8” (9mm) thick of 1/4” (6mm) thick covered with a

1/8” (3mm) sheet of metal is required to cover the

area under the heater and to extend to at least 18”

(460mm) at the front and 8” (200mm) to the sides

and back of stove. This will provide protection from

sparks and embers which may fall out from the door

when stoking or refuelling.

(200mm)

(200mm)

(460mm)

Fig.9

(200mm)

CHIMNEY

The Waterford Stanley Woodburning Range must

be connected to a Factory-Built Chimney, installed in

accordance with the manufacturer’s instructions or a

lined masonry chimney, acceptable to the authority

having jurisdiction. An existing masonry chimney

should be inspected and if necessary repaired by a

competent mason or be relined using an approved

relining system.

THE CHIMNEY S E RVING THE WAT E R F O R D

S TA N L E Y WOODBURNING RANGE SHOULD

NOT SERVE ANY OTHER APPLIANCES. If you

intend to use a fireplace chimney, the fireplace

opening must be sealed. The overall height of the

chimney, measured from the floor on which the

Range is installed must be at least 4.572 meters

(15ft). Do not use more than two elbows.

CHIMNEY TYPES USA

The Residential Type Chimney may be:

(a) FACTORY-BUILT U.L. Listed Residential

Type HT and Building Heating Appliance

chimney (ANSI/UL103) and acceptable to

the local building core or,

(b) MASONRY, Constructed in accordance

with NFPA211 code.

This Waterford Stanley Woodburning Range must

be connected to an Underwriters Laboratories of

Canada Labelled factory Built 650oC Chimney,

installed in accordance with the manufacturer’s

instructions or a lined masonry chimney acceptable

to the authority having jurisdiction.

CHIMNEY CONNECTOR

Single wall stove pipe, used to connect the appliance to the chimney must be installed with the

crimped end towards the stove. This will ensure that

condensing moisture from the burning wood will flow

back into the fire chamber. Each joint in the stove

pipe must be secured with a least 3 sheet metal

screws.

Connectors should be 6” 153mm in diameter and

crimped into the fire outlet collar. Corrosion-resistant steel, 24 gauge or heavier, is recommended.

(Cheap metal pipes are easily damaged by flue gas

acids).

A minimum clearance of 450mm (18”) is required for

a single wall connector.

CHIMNEY CONNECTOR USA ONLY

Connectors should maintain a pitch or rise of at least

1/4” (6mm) to the foot from this cook stove to the

chimney. It should be installed so as to avoid sharp

turns or other construction features that would create excessive resistance to the flow of flue gasses.

It should be securely supported with joints fastened

with sheet-metal screws, rivets or other approved

means. The entire length of a connector should be

readily accessible for inspection, cleaning and

replacement.

The connector may pass through walls or partitions

constructed of combustible materials provided the

connector is either listed for wall pass-through or is

routed through a device listed for a wall passthrough and is installed in accordance with the conditions of the listing. Any unexposed metal that is

used as part of a wall pass-through system is

exposed to flue gasses shall be constructed of stainless or other equivalent material that will resist corrosion, softening, or cracking from flue gas at temperatures up to 982oC.

Where passage through a wall, or partition of combustible construction is desired, the installation shall

conform to CAN/CSA - B 365, Installation Code for

Solid Fuel Burning Appliance & Equipment.

5

Page 8

CONNECTING TO MASONRY CHIMNEY

The connector to a masonry chimney must extend

through the wall to the inner face or liner but not

beyond, and must be firmly cemented to masonry.

The connector may pass through walls or partitions

constructed of combustible material to a masonry

chimney provided the connector system selected is

installed in accordance with the proper clearances

and conditions.

THIMBLES

CHIMNEY CONNECTOR SYSTEMS, THIMBLES

AND CLEARANCES FROM COMBUSTIBLE

WALLS

1. Minimum 3 1/2” (90mm) thick brick masonry

wall framed into combustible wall with a min.

of 12” (305mm) brick separation from clay

liner to combustibles. Fire clay liner (ASTM

C315 or equivalent) min. 5/8” (16mm) wall

thickness, should run from outer surface of

brick wall to, but not beyond, the inner surface of chimney flue liner and should be

firmly cemented in place.

Thimbles for chimneys or vent connectors should be

of fire clay (ASTM C 315, specifications for Clay

Flue Linings), galvanised steel of minimum

thickness of 24 gauge, or material of equivalent

durability. Thimbles should be installed without

damage to the liner. The thimble should extend

through the wall to, but not beyond, the inner face of

the liner and should be firmly cemented to masonry.

Thimbles should be located to provide adequate

pitch or rise of chimney or vent connectors and,

where the ceiling above the appliance is constructed

of combustible material, the location of the thimble

should provide minimum clearance required for the

connector as specified in section under Minimum

Clearances to Combustibles.

Insulation material used as part of wall pass-through

system should be of non-combustible material and

should have a thermal conductivity of 1.0 Btu. in./ft.F

(4.88kg.cal/hr.m.c) or less. All clearances and thicknesses are minimums; larger clearances and thicknesses are acceptable. Any material used to close

up the opening for the connector should be of noncombustible material. A connector to a masonry

c h i m n e y, except for System 2 (under heading

Chimney Connector System, Thimbles and

Clearances), shall extend to piece through the wall

pass-through system and the chimney wall to the

inner face of the flue liner, but not beyond.

Fig.10

(50mm)

of brick

(305mm)

(305mm) to

2. Solid insulated listed factory-built chimney

length of the same inside diameter as the

chimney connector and having 1” (25mm) or

more of insulation with a min. 9” (230mm) air

space between the outer wall of the chimney

length and combustibles. The inner end of

the chimney length shall be flush with the

inside of the masonry chimney flue and

shall be sealed to the flue and to the brick

masonry penetration with non water-soluble

refractory cement. Supports should be

securely fastened to wall surfaces on all

sides. Fasteners between supports and the

chimney length shall not penetrate the

chimney liner.

(50mm)

(230mm)

Fig.11

minimum

(230mm)

6

Page 9

EXPLODED VIEW

Waterford Stanley

Woodburning Range

45. Oven Protecting Plate

46. Fire Lining L.H.

47. Fire Lining Back

48. Fire Lining Bottom Front

49. Fire Lining Top Front

50. Sham Cheek Top

51. Name Plate

52. Bonnet Ring

53. Hob Protecting Plate

54. Plinth Jointing Clip

55. Bonnet

56. Bonnet Door

57. Fire Door

58. Spin Valve

59. Base Cleaning Door

60. Optional Pipe Shield

61. Platerack Standard R.H.

62. Platerack Standard L.H.

63. Oven (Flue) Damper

64. Base Flue Cheek

65. Sheet Iron Side L.H.

66. Sheet Iron Side R.H.

67. Splashback

68. Platerack

69. Door Handles (3)

70. Ashpan

71. Base Protecting Plate S.I.

72. Oven Door Mineral Wool

73. Insulation

74. Thermometer

75. Spindle

76. Gasket

77. Back S.I.

78. Towel Rail

79. Sheet Iron Oven Door Panel

80. Stainless Steel Heatshield

81. Fire Door Mineral Wool

82. Top Back Panel S.I.

83. Inside R.H. Panel S.I.

84. Inside L.H. Panel S.I.

85. Rear Outlet Spigot

86. Hotplate Lifting Tool

87. Blanking Bracket

88. Plate Rack Front Bar

90. Door Operating Tool

91. Hob Blanking Plate

92. Oven Shelf S.I.

93. Wire Brush (Seno Only)

94. Poker

95. Scraper

1. Front

2. Oven Door

3. Ashpit Door

4. Oven Bottom

5. Oven Top

6. Oven Side R.H.

7. Oven Back

8. Front Flue Guide

9. Back Flue Guide

10. Flue Back Centre

11. Hob Protecting Plate

12. Oven Shelf

13. Base

14. Direct Damper

15. Hob Cleaning Cups (2)

16. Flue Back Blanking Plate

17. Steam Escape

18. Hob

19. Hot Plate

20. Hot Ring

21. Top Fire Back

22. Damper Guide L.H.

23. Flue Guide R.H.

24. Plate Rack Blanking Plate

25. Towel Rail Bracket R.H.

26. Towel Rail Bracket L.H.

27. Fire Door Protecting Plate

29. Door Catches (3)

30. Lifter

31. Base Cleaning Door Clip

32. Oven Side L.H.

33. Oven End Flue Top

34. Oven End Flue Bottom

35. Ashpit Bottom Back

36. Legs (4)

37. Plinth L.H.

38. Plinth R.H.

39. Ashpit Side R.H.

40. Ashpit Side L.H.

41. Bottom Grate

42. Bottom Grate Rest

43. Ashpit Bottom

44. Fire Lining R.H.

7 & 8

Page 10

3. Sheet steel chimney connector, min. 24

gauge in thickness, with a ventilated

thimble, min. 24 gauge in thickness, having

two 1” (25mm) air channels, separated from

combustibles by a min. of 6” (150mm) of

glass fibre insulation. Opening should be

covered and thimble supported with a sheet

steel support, min. 24 gauge in thickness.

Supports should be securely fastened to

wall surfaces on all sides and should be

sized to fit and hold chimney section.

Fasteners used to secure chimney sections

should not penetrate chimney flue liner.

Minimum clearances 2”(50mm)

1” (50mm)

air space to

chimney

length

Fig.13

(50mm)

Air space 2” (50mm)

(50mm)

(25mm)

glass fibre insulation

Fig.12

(150mm)

(25mm) constructed of

4. Solid insulated listed factory-built chimney

length with an inside diameter 2” (50mm)

larger than the chimney connector and having 1” (25mm) or more of insulation, serving

as a pass-through for a single wall sheet

steel chimney connector of min. 24 gauge

thickness, with a min. 2” (50mm) air space

between the outer wall of chimney section

and combustibles. Min. length of chimney

section shall be 12” (305mm). Chimney section concentric with and spaced 1” (25mm)

away from connector by means of sheet

steel support plates on both ends of chimney

section. Opening shall be covered and chimney section supported on both sides with

sheet steel supports of min. 24 gauge thickness.

MASONRY FIREPLACE

Before the installation the entire fireplace system

should be inspected for condition and code

compliance prior to connecting to the fireplace chimney. Older fireplaces and chimneys may not have

been constructed to current-day codes.

The fireplace and chimney should be in, or brought

up to, acceptable conditions and proper clearances

should be met before connecting to the fireplace

chimney.

The size of the flue must be considered. If the

fireplace chimney is too large, a relining system may

be installed using an approved relining system.

Supports should be securely fastened to wall surfaces on all sides and shall be sized to fit and hold

chimney section. Fasteners used to secure chimney

sections should not penetrate chimney flue liner.

Fig.14

9

Page 11

Fig.15

Connection to a masonry chimney may be done by

breaching into the chimney from the front of the fireplace, no less than 8” (200mm) above the bottom of

the first flue tile, by installing a stainless steel or

other listed chimney connector from the appliances

flue outlet up through the fireplace damper and

smoke chamber, terminating at the first flue tile, or

by installing a stainless steel or other listed relining

system from the flue outlet up the entire length of the

chimney, where necessary.

4. The house is equipped with a well-sealed

vapour barrier and tight fitting windows

and/or has any powered devices that

exhaust house air.

5. There is excessive condensation on windows in the winter.

6. A ventilation system is installed in the house.

If these or other indications suggest that infiltration

air is inadequate, additional combustion air should

be provided from the outdoors. Outside combustion

air can be provided to the appliance by the following

means:

1. Indirect method: for an appliance not

certified for direct connection of outside

combustion air, the outside air is ducted to a

point no closer than (12”) 300mm from the

appliance, to void affecting the performance

of the appliance.

2. A mechanical ventilation system: if the

house has a ventilation system (air change

or heat recovery):

a. The ventilation system may be able

to provide sufficient combustion make-up

air for the solid-fuel-fired appliance.

b. The householder should be informed that

the ventilation system might need to be

re-balanced by a ventilation technician

after installation of the appliance.

SPILLAGE TEST

VENTILATION & COMBUSTION AIR

REQUIREMENTS

Provision for outside combustion air may be necessary to ensure that fuel-burning appliances do not

discharge products of combustion into the house.

Guidelines to determine the need for additional combustion air may not be adequate for every situation.

If in doubt, it is advisable to provide additional air.

Outside combustion air may be required if:

1. The solid-fuel-fired appliance does not draw

steadily, smoke rollout occurs, fuels burns

poorly, or back drafts occur whether or not

there is combustion present.

2. Existing fuel-fired equipment in the house,

such as fireplaces or other heating appliances, smell, do not operate properly, suffer

smoke roll-out when opened, or back-draft

whether or not there is combustion present.

3. Opening a window slightly on a calm

(windless) day alleviates any of the above

symptoms.

In all installations a spillage test should be carried

out to ensure there is sufficient combustion air and

the flue system is

1. Light/burn appliance under normal conditions in accordance with this installation

manual.

2. Close all doors and windows.

3. Operate all appliances requiring air at full

rate (eg. extraction hoods, tumble dryers

etc).

4. Check for spillage.

10

Page 12

MAINTENANCE

WARNING: DO NOT CLEAN STOVE WHEN HOT.

To ensure that the Waterford Stanley Woodburning

Range will operate safely and with maximum efficiency, the entire installation must be properly maintained. During periods of use, the range, chimney

connectors, joints and the main flue itself must be

kept clean and in good working condition. You can

clean the connectors manually. Use an approved

chimney cleaner to clear creosote deposit and

repeat as often as necessary. If you use only seasoned hardwoods, then only occasional chimney

cleaning will be necessary.

During the off-season the range may be stored in a

dry, covered area, but before storing it, remove the

ashes and thoroughly clean out the fire chamber

and oven flues. Touch up the black Senotherm finish as required with similar heat-resistant finish. If

such are not readily available apply a suitable oil to

prevent rust spots, so your Stanley will stay in good

condition until you need it again.

EFFICIENT ECONOMICAL USE OF WOOD

Wood combustion occurs in three stages. First the

moisture is evaporated (converted to steam), then

the volatiles are distilled and finally the fixed carbon

(charcoal) is burned. All stages of combustion can

occur at the same time, such as when fresh fuel is

added to the glowing embers.

Moisture must be evaporated and dispersed before

wood will burn. Consequently, wood should be cut

and dried for a period of several months (preferably

a year) before it is used. The moisture content of

some trees may be as high as 100%, i.e. equal in

volume to the wood itself. After dry storage over six

to ten months the moisture content will usually range

from 15% to 25%. Splitting the wood prior to storage reduces drying time and this results in more

even burning. It minimises condensation of the

water vapour and volatile distillates, that in turn creates creosote deposits in chimney flues.

It is apparent that greater efficiency and safety will

ensure from burning moderate quantities of dry

wood in a hot fire than using green or wet wood that

only smoulders.

The Waterford Stanley Woodburning Range

ensures that air enters the fire chamber over and

around the sides of the fire. This assures complete

combustion which in turn minimises heat losses up

the flue and reduces the amount of unburned

gasses and distillates to the flue. If you have no

alternative but to use soft wood, like elder, spruce or

pine, or when green wood has to be used, then the

result will be low heat and the formation of much creosote. In these conditions the fire must receive

plenty of draught which will help to prevent creosote

forming. The Waterford Stanley Woodburning

Range is sealed to prevent air leaks at the joints,

consequently, wood will burn evenly by day and

overnight, because of the control you can exercise

over the rate of burning.

Cut your wood to size: 406mm (16”) logs, which will

fit the Waterford Stanley Woodburning Range fire

chamber. The longer the logs the better and more

enduring the fire will be.

Hardwoods are best for heat. These include: Beech,

Cherry, Ash, Oak, Hickory, Hard (Sugar) Maple,

Birch, Larch (Tamarack) and Elm. Elm is hard to

split but is fine for a slow burning fire, and like all

other woods, it is all the better for seasoning. Your

hardwood ashes will benefit the garden; they contain

valuable minerals including carbon, potash, phosphorus, copper, manganese etc. reference to the

characteristics of wood are quoted from NFPA No.

H8- I, 1974 (U.S.A).

CREOSOTE- Formation and Need for Removal

When wood is burned slowly, it produces tar and

other organic vapours, which combine with expelled

moisture to form creosote. The creosote vapours

condense in the relatively cool chimney flue of a

slow-burning fire. As a result, creosote residue

accumulates on the flue lining. When ignited this

creosote makes an extremely hot fire. We suggest

the chimney connector and chimney should be

inspected at least twice monthly during the heating

season to determine if a creosote build-up has

occurred. If creosote has accumulated it should be

removed to reduce the risk of a chimney fire.

Inspect the chimney connector frequently. Tap the

connector with your finger when the pipe is cool. If

you hear a dull echo, the pipe may need cleaning.

Disassemble the chimney connector and clean the

sections. Replace corroded pipe sections. The

fitting of a slip-joint in the stove pipe makes the

dismantling easy for cleaning and inspection of

chimney and stove.

When inspecting a masonry chimney, start at the

clean-out door, normally found in the basement, at

the base of the chimney, or on the outside. If your

chimney does not have a clean-out door it must be

inspected and cleaned by removing stove from

chimney.

11

Page 13

DISPOSAL OF ASHES

Ashes should be placed in a metal container with a

tight-fitting lid. The closed container of ashes should

be placed on a non-combustible floor or on the

ground well away from all combustible materials

pending final disposal. If the ashes are disposed of

by burial in soil or otherwise locally dispersed they

should be retained in the closed container until all

cinders have thoroughly cooled.

I M P O R TA N T: UNDER NO CIRCUMSTA N C E S

SHOULD ANY FLAMMABLE LIQUID, GASOLINE

KEROSENE, LIGHTER FLUID OR CHARCOALSTARTERS BE USED TO LIGHT OR “FRESHEN

UP” THE FIRE. NEVER USE MANUFACTURED

LOGS. OPERATE APPLIANCE ONLY W I T H

FUELLING DOOR AND ASHPIT DOOR CLOSED.

“KEEP ALL SUCH LIQUIDS WELL AWAY FROM

STOVE WHILE IN USE”

HINTS ON FIRE SAFETY

To provide reasonable fire safety the following

should be given serious consideration:

1. The installation of smoke detectors.

2. A conveniently located Class A fire

extinguisher.

3. A practical evacuation plan.

4. A plan to deal with chimney fire as follows:

(a) Notify the fire department

(b) Prepare occupants for immediate

evacuation.

(c) Close all openings into the stove

(d) While awaiting fire department,

watch for ignition of adjacent com

bustibles from overheated stove pipe

or hot embers or sparks from the

chimney.

NOTE: Inspect the chimney flue weekly until a safe

frequency is established.

FUELS

Wood logs up to 406 mm (16”).

LIGHTING THE FIRE

Open the fire door (Part no. 57), lay a few crumpled

sheets of paper on the bottom grate (Part no. 41)

then a few small dry pieces of sticks or kindling.

Open the spin wheel (Part no. 58) fully by rotating it

in an anti-clockwise direction. Turn the direct

damper (Part no. 63) to open by using the operating

tool. Now light the paper, close the fire door (Part

no. 57) when the kindling has caught fire (allow 15

minutes for this to happen) add larger pieces of dry

wood, until the fire box is half filled. When the larger pieces of wood have caught fire, add full sized

logs.

OPERATE APPLIANCE ONLY WITH FUELLING

DOOR AND ASHPIT DOOR CLOSED.

Fig. 16

CONTROLLING THE FIRE

The chimney damper must be kept closed except

when lighting the fire. Combustion is governed by

using the spin-wheel (Part No. 58) which controls

both primary and secondary air supply to the firebox.

The oven damper (Part No. 63) under the round hotplate (Part No. 20) reduces the chimney draught.

You will get to know how to use the spin-wheel (Part

No. 58) and the oven damper (Part No. 63) in conjunction for the best results. Remember NOT to try

to get a quick temperature increase by opening the

chimney damper. Keep the ashpit door (Part No. 3)

closed securely except when de-ashing the fire.

Keep the firedoor (Part No. 57) closed securely

except when fuelling from the front. Loading frequency of the fuel depends on burn rate. Once they

are well alight, logs need little draught to maintain

combustion.

K E E P A L L COMBUSTIBLE MATERIALS AT

LEAST 1220mm (4 feet) AWAY FROM THE

RANGE.

They include rugs, fabrics, furnishings, papers, firewood, etc. NEVERdry clothing on or within 1220mm

(4 feet) of the range.

12

Page 14

THE HOTPLATE

Use the hotplate and the cooking-top of the range

for boiling simmering, frying, grilling, braising, etc.

Best results can be obtained by using flat bottomed

utensils. The lacquer which was applied to protect

the surface-ground hotplates will burn off. Keep the

hotplates clean with a wire brush. Over a short period you will quickly adapt to the best ways and

means of using the cooker-top in order to obtain

utmost satisfaction and efficiency.

THE OVEN

When the oven is required for baking, roasting, or

casseroling, open the oven dampers (Part No. 63)

and the spin-wheel (Part No. 58) until the oven

thermometer (Part No. 74) shows a temperature of

about 25 C below that required. Then adjust the

oven damper (Part No. 63) to reach the required

temperature without exceeding it. A little practice

will soon show how much adjustment is necessary.

OVERNIGHT BURNING

The correct setting for the spin-wheel (Part No. 58)

and the oven damper (Part No. 63) for overnight

burning can be found by experimenting. The

following routine should give the requirement. (If it

does not, the spin-wheel or the damper can be

closed more for another attempt). Open the spinwheel (Part No. 58) a quarter of a turn and close the

oven damper (Part No. 63) to one quarter of its maximum opening. Lightly riddle the fire bottom bar and

re-fuel with logs until the firebox is full. In the morning open the spin-wheel (Part No. 58) and oven

damper (Part No. 63). Lightly riddle the fire. When

the fire is burning well, top up with logs.

CHIMNEY CLEANING

Inspect the chimney connector frequently. Tap the

connector with your finger when the pipe is cool. If

you hear a dull echo, the pipe may need cleaning.

Disassemble the chimney connector and clean the

sections. Replace corroded pipe sections, the

fitting of a slip-joint in the stove pipe makes the

dismantling easy for cleaning and inspection of

chimney and stove.

When inspecting a masonry chimney, start at the

clean-out door, normally found in the basement, at

the base of the chimney, or on the outside. If the

chimney does not have a clean-out door it must be

inspected and cleaned by removing the stove from

the chimney.

USE OF TOOLS

Cup Lifter

Fig. 17

VITREOUS ENAMEL CLEANING

RIDDLING

Open the ashpit door (Part No. 3). Use the

operating tool (Part No. 30) to lightly move the

bottom grate (Part No. 41) to and fro. Empty the ash

pan (Part No. 70) as required. Always close the ashpit door tightly.

FLUE CLEANING

Open the oblong hot plate (Part No. 19). Remove

the simmering/oven hob cleaning cups (Part No.

15), open the direct damper (Part No. 14). Brush

deposits on the oven top into the fire box, brush

downwards the deposits in the space both behind

and at the side of the oven. Remove the cleaning

door (Part No. 59) from below the oven door (Part

No. 2). Rake the deposits through from underneath

the oven towards the front and out through the

cleaning aperture in the cooker front (Part No. 1) into

a container.

General cleaning must be carried out when the

stove is cool.

If this stove is finished in a high gloss vitreous enamel, to keep the enamel in the best condition observe

the following tips:

1. Wipe over daily with a soapy damp cloth,

followed by a polish with a clean dry duster.

2. For stubborn deposits a soap impregnated

pad can be carefully used on the vitreous

enamel.

3. DO NOT USE ABRASIVE PADS OR OVEN

CLEANSERS CONTAINING CITRIC ACID

ON ENAMELLED SURFACES. ENSURE

THAT THE CLEANSER MANUFACTUR

ERS INSTRUCTIONS ARE ADHERED TO.

13

Page 15

WARMING SHELF - LEFT OR RIGHT HAND LOCATION

ASSEMBLY INSTRUCTIONS

1. Remove the

head screws (2 off) from the hob and

(6mm) x

1

/4” (6mm) x 1/4” (6mm) round

1

/4” (6mm) round head screw (1 off)

1

/4”

from the front and dispose of (used for

packing purposes only).

2. Bolt the bracket (2) to the Warming Shelf (1)

using the 1

screw (6) and the 1” (25mm) x

hex head bolt (9) and

1

/2” (38mm) x 1/4” (6mm) csk

3

/8” washers (10 pro-

1

/4” (6mm)

vided.

3. Place the Warming Shelf beside the hob (3)

keeping the top face flush with the hob top

and in line with the front of the hob.

4. Attach Warming Shelf to hob with

(12mm) x

vided and fit 1” (25mm) x

1

/4” (6mm) hex head bolts (8) pro-

1

/4” (6mm)

1

/2”

round head screw (7) to front.

5. Tighten all screws.

Fig. 18

CONTENTS

1. Warming Shelf (1 off).

2. Bracket to Shelf (1 off).

3. Hob of Stove.

4. Front of Stove.

5. Side of Stove.

6. 1

1

/2” (38mm) x 1/4” (6mm) csk chrome

plated (1 off).

7. 1” (25mm) x

1

/4” (6mm) R.H. chrome plated

(1 off).

8.

1

/2” (12mm) x 1/4” (6mm) hex head bolts (2

off).

9. 1” (25mm) x

1

/4” (6mm) hex head bolts (1

off).

10.

3

/8” (9mm) Washers (2 off).

14

Page 16

ASSEMBLY INSTRUCTIONS - WARMING OVEN

1. Your warming oven is supplied in a part

assembled condition.

2. The oven is complete and the splashback,

top rail, top rail brackets and side brackets

are separate components complete with 4

No. short (M5 x 12) set screws and 4 No.

long (M5 x 20) set screws all with washers.

3. To assemble on a WOODSTANLEY already

installed with a top flue outlet proceed as

follows:

(a) Remove the inside top bolts of the warming

oven and fit the top rail between the

brackets. Place the brackets on top of the

warming oven and replace the bolts.

(b) Dismantle, clean and remove flue pipe.

Fig. 19

(c) Remove the four screws from the hob and

place the side brackets, with the flat sur

faces outwards, on the hob. Replace the

screws but do not tighten them.

(d) Slide flue through warming oven and

loosely fit warming oven to brackets using

long set screws (M5 x 20). Reassemble

flue.

(e) Remove the two small set screws (M5 x 12)

from both sides of back of warming oven

and fit splash back using the extra set

screws (M5 x 12) to bolt splash back to side

brackets.

(f) TIGHTEN ALL BOLTS. Your warming oven

is now ready for use.

Fig. 20

Waterford Stanley (Marketing) Ltd.,

Bilberry, Waterford, Ireland.

Telephone: (051) 302300

Facsimile: (051) 302375

15

DP 030826 Rev:009

Loading...

Loading...