Page 1

Owners &

Installation

IG34 GAS INBUILT

Manual

LISTINGS AND CODE APPROVALS

These gas appliances have been tested in

accordance with AS4553, NZS 5262 and

have been certifi ed by the Australian Gas

Association for installation and operation as

described in these Installation and Operating

Instructions.

Your unit should be serviced annually by

an authorised service person.

Models: IG34-NG

IG34-LPG

IG34-ULPG

PLEASE KEEP THESE INSTRUCTIONS FOR FUTURE

REFERENCE

WARNING:

Improper installation, adjustment, alteration, service or maintenance can cause

injury or property damage. Refer to this

manual. For assistance or additional information consult an authorised installer,

service agency or the gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other fl am-

mable vapours and liquids in the vicinity of

this or any other appliance.

Installation and service must be performed

by an authorised installer, service agency or

the gas supplier.

FOR YOUR SAFETY

What to do if you smell gas:

Do not try to light any appli-

ance

Do not touch any electri-

cal switch: do not use any

phone in your building.

Immediately call your gas

supplier from a neighbour's

phone. Follow the gas supplier's instructions.

If you cannot reach your

gas supplier, call the fi re

department.

918-793a

04/28/09

Page 2

REGENCY

GAS INBUILT FIREPLACE

TO THE NEW OWNER

Congratulations! Y ou are the owner of a state-of-the-art Gas Inbuilt Fireplace by FPI. The Regency

Gas Fireplace Series of appliances has been designed to provide you with all the warmth and

charm of a fi replace, at the fl ick of a switch. The model IG34 of this series has been approved

by Australian Gas Association for both safety and effi ciency. As it also bears our own mark, it

promises to provide you with economy, comfort and security for many trouble free years to follow.

Please take a moment now to acquaint yourself with these instructions and the many features of

your Regency Fireplace.

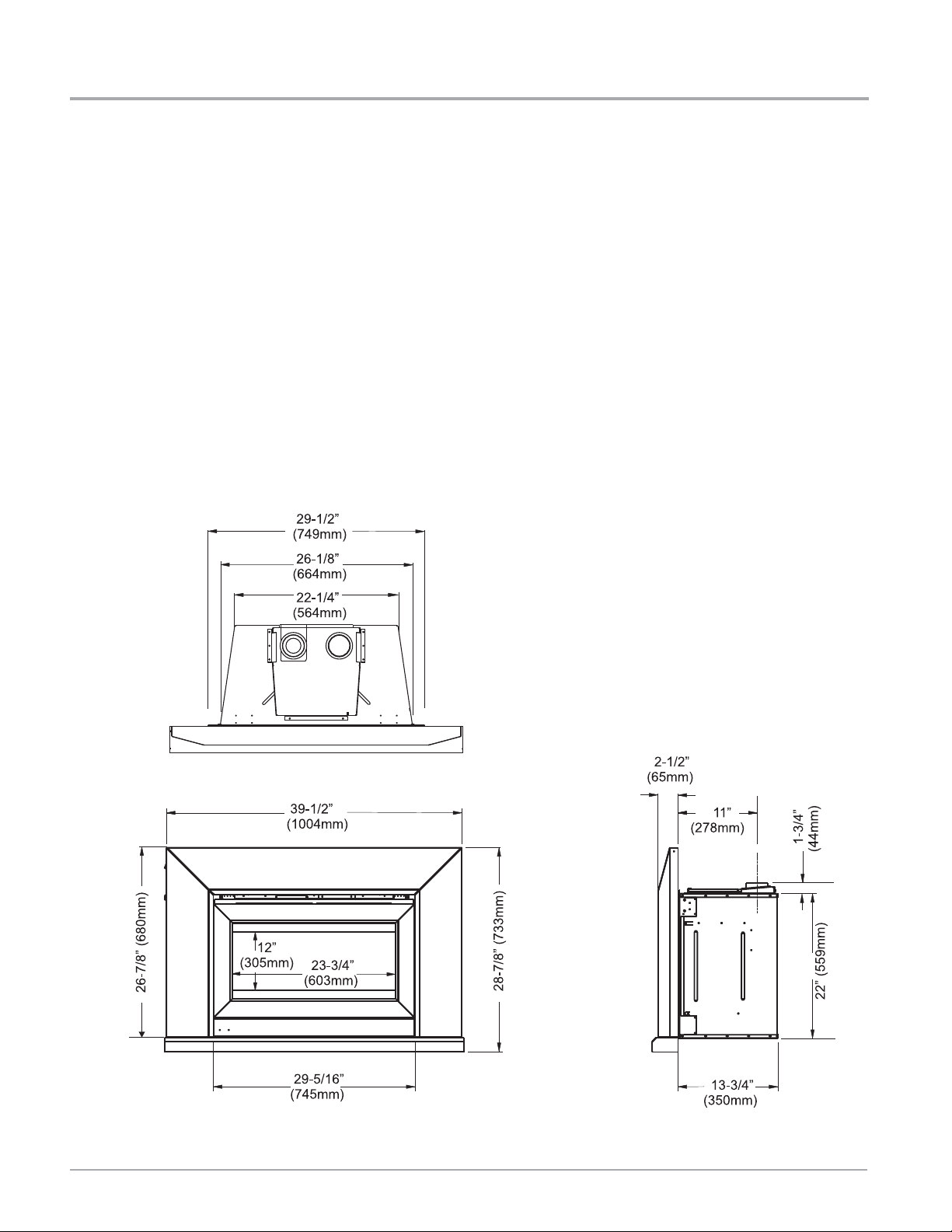

UNIT DIMENSIONS

2

Regency IG34 Gas Inbuilt Fireplace

Page 3

TABLE OF CONTENTS

DATA BADGE

Copy of Data Badge .....................................................4

INSTALLATION

Important Message ........................................................5

For Your Safety ..............................................................5

Before You Start ............................................................5

Installation Checklist ......................................................5

Materials Required ........................................................5

Minimum Fireplace Dimensions ....................................6

Clearances To Combustibles .........................................6

Gas Connection ............................................................6

Flueing ...........................................................................6

Flue Liner Installation ....................................................7

Gas Pipe Pressure Testing ............................................7

Installation in masonry or zero clearance chimney........8

Aeration Settings ...........................................................9

Conversion Kit #486-968 for NG to LPG Model ..........10

Conversion Kit #486-967 for NG to ULPG...................12

Optional Stainless steel inner panel install ..................14

Log set installation .......................................................15

Glass Door installation.................................................18

Standard Flush Door ...................................................18

Optional Flush Trim .........................................................

Faceplate & Optional plinth trim Assembly ..................19

Faceplate and door frame Installation .........................20

Thermodisc installation ................................................21

Final Check..................................................................22

Wiring standard ...........................................................22

Operating Instructions ................................................23

Lighting Instructions.....................................................23

Shutdown Instructions .................................................23

First Fire ......................................................................23

Remote Control ..........................................................23

Summary of Controls ..................................................23

Fan Operation..............................................................23

Copy Of Lighting Instruction Plate ...............................24

Normal Operating Sounds Of Gas Appliances ............24

Resetting the unit.........................................................24

MAINTENANCE

Door Glass ..................................................................25

Replacement ...............................................................25

Glass Gasket ...............................................................25

Fan Maintenance .........................................................26

Valve assembly replacement .......................................27

PARTS LIST

Electronic Components Parts List ...............................28

Main Assembly ............................................................29

Faceplate Assembly ....................................................30

WARRANTY

Warranty ......................................................................31

Regency IG34 Gas Inbuilt Fireplace

3

Page 4

DATA BADGE

This is a copy of the label that accompanies each Regency IG34 Gas

Inbuilt fi replace. We have printed a copy of the contents here for your

review.

DATA BADGE NOTE: Regency units are constantly being improved.

Check the label on the unit and if there is a difference, the label on the

unit is the correct one.

Regency Gas Fireplace

Model

Gas Type NG LPG ULPG

Model

Gas Consumption 31.7 . 30.6 26.4

Manifold Pressure 0.87

Injector Size 1x 1x#52 1x#53

AGA Approval 7469

Code AS4553 NZS 5262

Electrical: 240VAC 50Hz 1.0 amp

918-794

IG34-NG IG34-LPG IG34-ULPG

mj mj. mj.

kPa kPa kPa

37

#

2.51 2.51

2.64mm 1.61mm 1.51mm

N2134

Distributed by:

Western Australia:

Eastern Australia:

accordance with installation instructions provided

Serial

Number

Air Group Australia

28 Division St

Welshpool WA 6106

Fireplace Products

Australia Pty. Ltd.

21-23 South Link Blvd.

Dandenong, VIC 3175

To be installed by an authorised person in

with the appliance.

347

(Australia Only)

4

Regency IG34 Gas Inbuilt Fireplace

Page 5

INSTALLATION

IMPORTANT MESSAGE

The Regency Gas Inbuilt must be installed in

accordance with these instructions. Carefully

read all the instructions in this manual fi rst.

Note: Failure to follow these instructions

could cause a malfunction of the

heater which could result in death,

serious bodily injury, and/or property damage. Failure to follow these

instructions may also void your fi re

insurance and/or warranty.

FOR YOUR SAFETY

This appliance requires air for proper combustion. Always provide adequate combustion

and ventilation air. Follow instructions and

information in the current AS5601, NZS 5262

or local codes. Consult the "authority having

jurisdiction" to determine the need for a permit

prior to starting the installation.

MATERIALS REQUIRED

A 240 Volt AC power cord is hooked up to the

unit. Plug 3 wire cord into a suitable receptacle.

Do not cut the ground terminal off under any

circumstances.

When connected with 240 volts, the appliance

must be electrically grounded in accordance

with local codes.

This unit is polarity sensitive and will not

operate if polarity is incorrect.

BEFORE YOU ST ART

Installation is to be carried out ONLY by an

authorised person.

1) The appliance shall be installed in accord-

ance with the manufacturer's installation

instructions, local gas fi tting regulations,

municipal building codes, water supply

regulations, electrical wiring regulations,

with AS5601. (AGA gas installation code)

NZS 5262(New Zealand)

2) Installation and repair should be done

ONLY by an authorised person.

3) The appliance should be inspected before

use and at least annually by an authorised

service person. More frequent cleaning may

be required due to excessive lint from carpeting, bedding material, etc. It is imperative

that control compartments, burners and

circulating air passageways of the appliance

be kept clean and free from excessive lint

from carpeting.

4) See general construction and assembly

instructions. This appliance may only be installed in a fl ued, non-combustible fi replace.

The appliance and fl ue should be enclosed

when installed or passing through a living

area, where children may come in contact

with it.

5) Always connect this space heater to a chimney and fl ue to the outside of the building

envelope. Never fl ue to another room. Make

sure that the fl ue is properly sized and is

of adequate height to provide the proper

draft.

6) Inspect the fl ueing system annually for

blockage and any signs of deterioration.

7) Any safety glass removed for servicing

must be replaced prior to operating the appliance.

INSTALLATION

CHECKLIST

Before installing vent system ensure that the

damper plate is open and secure to prevent the

damper plate from falling down and crushing

the liner.

The FPI Gas Inbuilt is installed as listed.

1) Check all clearances to combustibles, (Refer

to sections "Minimum Fireplace Dimensions

and Clearances to Combustibles)

2) Make the gas connection. (Refer to section

"Gas Connection")

3) Install the 3" (76.2mm) fl ue liner to the sliding

connector plate. (Refer to section "Flue Liner

Installation.")

4) Slide the unit half way into the fi replace.

5) Pull the vent connector plate through the

tapered brackets and fasten to the front plate.

Refer to section "Flue Liner Installation.")

6) Slide the unit fully into the fi replace.

7) Test gas pressure (Refer to section "Gas

Pipe Pressure Testing"). Check aeration

system (Refer to section "Gas Insert Aeration

System").

8) Install standard and optional features. Refer

to the following sections:

a. Log Set

b. Faceplate & Door Trim

c. Inner Stainless Panels

9) Final check: Before leaving this unit with the

customer, the installer must ensure that the

appliance is fi ring correctly. This includes:

a) Clocking the appliance to ensure the

correct fi ring rate.

WARNING:

Suitable for installation into a masonry

fi replace only.

Regency IG34 Gas Inbuilt Fireplace

8) T o prevent injury , do not allow anyone who

is unfamiliar with the operation to use the

fi replace.

9) Installer must mechanically attach the supplied label to the inside of the fi rebox of the

fi replace into which the gas fi replace insert

is installed.

"WARNING: This fi replace has been converted

for use with a gas fi replace insert only and

cannot be used for burning wood or solid fuels

unless all original parts have been replaced,

and the fi replace re-approved by the authority

having jurisdiction."

b) Adjusting the primary air and restrictor

settings, if required, to ensure that the

fl ame does not carbon.

NOTE:

TO BE INSTALLED ON A

NON- COMBUSTIBLE FLOOR.

5

Page 6

INSTALLATION

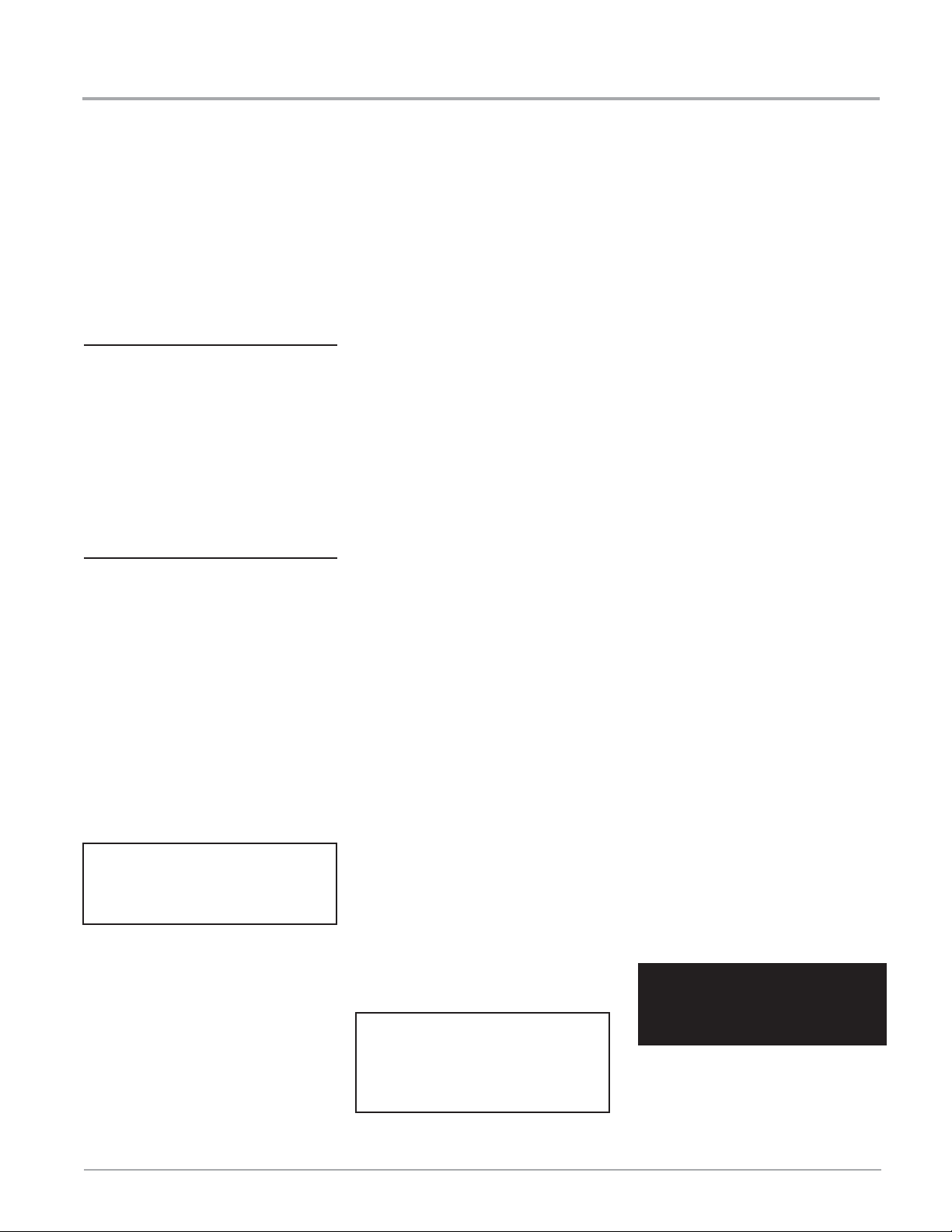

MINIMUM FIREPLACE

DIMENSIONS

The minimum fi replace dimensions for the

Regency gas space heater are shown in the

following diagrams:

CLEARANCES TO

COMBUSTIBLES

Minimum Clearances to Combustibles

From Unit

Sides A 10" / 255mm

Ceiling B 47.5" / 1205mm

Mantel C 13" / 330mm

Max. Mantle Depth E 12" / 305mm

(see Dia. 2)

Min. Alcove Width F 48" / 1220 mm

Max. Alcove Depth G 36" / 915 mm

*No hearth required.

Mantel Clearances

Note: A non-combustible mantel may be

installed at a lower height if the framing is made of metal studs covered

with a non-combustible board.

GAS CONNECTION

GAS CONNECTION WARNING:

Only persons licensed to work

with gas piping may make the

necessary gas connections

to this appliance.

1) If the appliance is to be installed into an

existing chimney system, thoroughly clean

the masonry fi replace.

2) The appliance is provided with an opening

on the right hand side of the control

compartment. The 9.5mm (3/8") fl exible

gas hose provided needs to be brought in

from behind this opening. Ensure all gas

connections are tight.

3) Locate the center point where the vent

will pass through the chimney above the

appliance. Move the appliance into the

exact location where it is to be installed.

Ensure that the Insert is level.

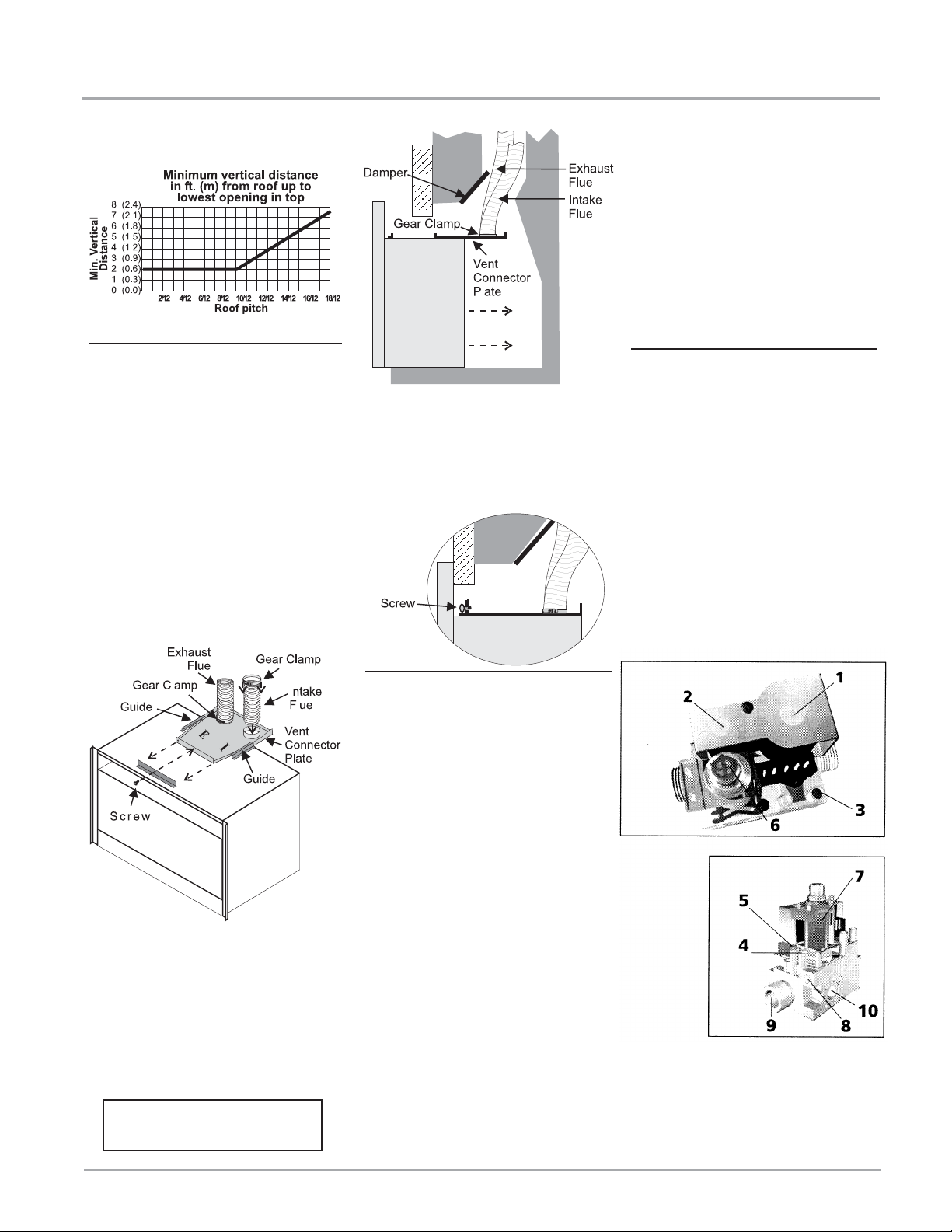

FLUEING

THE APPLIANCE MUST NOT

BE CONNECTED TO A

CHIMNEY FLUE SERVING A

SEPARATE SOLID FUEL

BURNING APPLIANCE AND

MUST BE TERMINATED TO

THE OUTDOORS.

This appliance is designed to be attached to

two 3" (76mm) co-linear aluminium fl ex running

the full length of the chimney. The fl ue length

must be a minimum length of 8 ' (2.44m) and

a maximum of 35' (10.7m). See chart below for

minimum distances from roof. Periodically check

that the vent is unrestricted.

Masonry chimneys may take various contours

which the fl exible liner will accommodate.

However, keep the fl exible liner as straight as

possible, avoid unnecessary bending.

The Air Intake pipe must be attached to the inlet

air collar of the termination cap.

Part # Description

948-305 76mm Flex - 10.6m

46dva-gk Simpson Duravent Adaptor

46dva-vch Simpson Vertical high wind cap

C

L

6

Note: When installing the fl ueing, identify

the fl ues.

Mark one exhaust and one intake as

indicated on the top of the unit.

Gas

Inlet

Regency IG34 Gas Inbuilt Fireplace

Page 7

INSTALLATION

The Air Intake pipe must be attached to the

inlet air collar of the termination cap.

FLUE LINER

INSTALLATION

1) Cut the fl ex liner as required.

2) Mark the end of one liner to indicate

Inlet.

3) Connect the other end of the above liner to

the inlet side of the termination adaptor, seal

connection with high temperature silicone.

Secure with gear clamp.

4) Connect the 2nd liner to the exhaust side

of the adaptor, seal connection with high

temperature silicone. Secure with gear

clamp.

Be careful not to damage thermal insula-

tion when sliding on vent connector plate.

This could cause blockage.

9) Connect the 2nd liner to the exhaust collar

marked with an "E", seal connection with

high temperature silicone. Secure with gear

clamp.

4) Seal and or check the pilot outlet (# 8)

5) The pressure check should be carried out

with the unit burning and the setting should

be within the limits specifi ed on the safety

label.

6) When fi nished reading manometer, turn

off the gas valve, disconnect the hose and

tighten the screw (clockwise) with a 1/8"

fl at screwdriver. Screw should be snug,

but do not over tighten.

S.I.T. Valve Description

1) On-Off Solenoid Valve EV1

2) On-Off Solenoid Valve EV2

3) Inlet Pressure Test Point

4) Outlet Pressure Test Point

5) Connection for Pressure Regulator/

Combustion Chamber Compensation

6) Pressure Regulator for Minimum and

Maximum Outlet Pressure

7) Gas Outlet Pressure Electric Modulator

8) Pilot Outlet

9) Main Gas Outlet

10) Side Outlet

5) Install fl ashing.

6) Insert both liners into chimney, passing

through the damper opening.

7) Install termination cap.

8) Connect the marked end of the liner to the inlet

collar of the vent connector plate marked with

an "I", seal connection with high temperature

silicone. Secure with gear clamp.

Install to AS5601 (Australia) /

NZS 5262 (New Zealand)

GAS PIPE PRESSURE

TESTING

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure

testing of the gas supply piping system at

test pressures equal to or less than 1/2 psig.

(3.45 kPa). Disconnect piping from valve at

pressures over 3.45 kPa (14" w.c.).

The manifold pressure is controlled by a

regulator built into the gas control, and should

be checked at the pressure test point.

Note: To properly check gas pressure,

both inlet and manifold pressures

should be checked using the valve

pressure ports on the valve.

1) Make sure the valve is in the "OFF"

position.

2) Loosen the "IN" (# 3) and/or "OUT" (# 4)

pressure tap(s), turning counterclockwise

with a 1/8" wide fl at screwdriver.

3) Attach manometer to "IN" and/or "OUT"

pressure tap(s) using a 5/16" (8mm) ID

hose.

Regency IG34 Gas Inbuilt Fireplace

7

Page 8

INSTALLATION

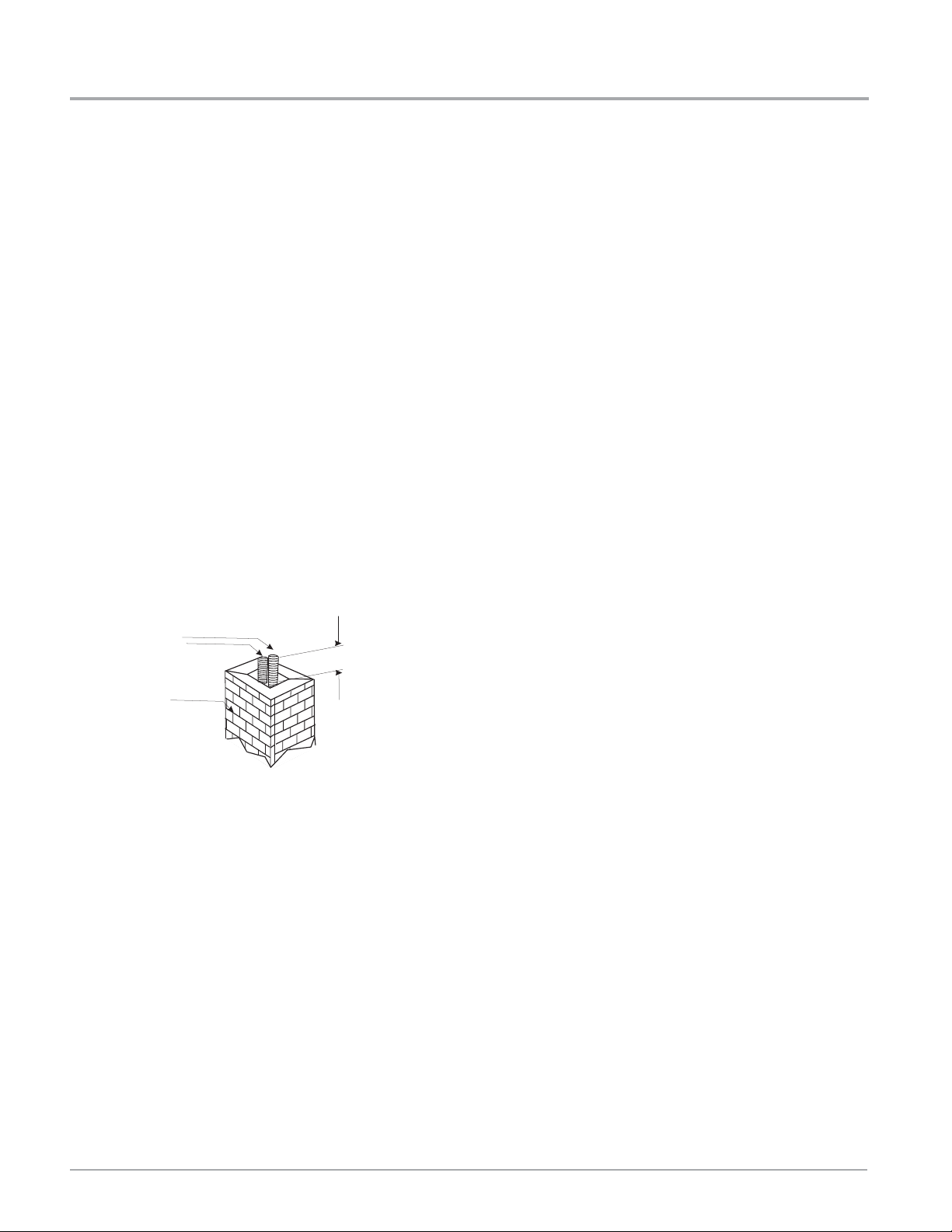

INSTALLATION IN MASONRY OR ZERO CLEARANCE CHIMNEY

1) Measure and record dimensions to determine total

Flex Liner length requirements (see instructions below

for details).

2) Carefully feed the liner down the chimney (masonry

or zero clearance) and out through the damper. One

person should feed the liner through the chimney, and

another person should pull the liner from the bottom.

3) After carefully feeding the Flex Liner down the chimney to the bottom, form and angle to line up the Flex

Liner with the vent opening on the appliance.

Important: Do not let the Flex Liner sag below the level

at which it will connect to the appliance or connector.

This could allow hot gas to become trapped and potentially become a fi re hazard. The Flex Liner path should

always be sloped up toward the Termination Cap.

4) Temporarily secure the Flex Liner at the top of the

chimney. Be sure to leave 2-3 inches of fl ex above the

existing chimney to allow for connection to the Termination Kit (Baseplate and Adaptor).

Flex

Liners

51-76mm

Existing

Chimney

Note: If you are planning to extend the height of the

chimney using Direct Vent GS Pipe, please refer to the

Direct Vent Installation Instructions for information concerning the proper procedure and restrictions of Direct

Vent Pipe.

Also, consult the appliance manufacturer for any height

restrictions of the chimney.

9) Connect the Co-Linear Flex to the two outlets on the

top of the appliance using four sheet metal screws each.

See the appliance manufacturer's instructions for details. Make sure the Flex Liners do not sag behind the

appliance. Finally, move the appliance into its appropriate place. Mount the Adaptor to the Baseplate using

sheet metal screws.

5) Repeat Steps 1-4 for second length of Flex Liner.

6) At the top of the chimney, slide the Baseplate over

the tow ends of the Flex Liner and secure it to the surrounding masonry using masonry anchor bolts. Before

installing the baseplate, run a bead of non-hardening

seal and between the Baseplate and the masonry to

prevent moisture from entering the chimney.

Note: Verify that there is suffi cient room to mount the

Baseplate on to the masonry. You must have a level

surface in order to install the Baseplate properly.

7) Attach the Flex Liner ends at the top of the chimney

to the Co-Linear to Co-Axial Adaptor. Use four sheet

metal screws to connect each Flex Liner run to the

Adaptor.

8) Twist lock the Vertical Termination Cap to the Adaptor.

8

Regency IG34 Gas Inbuilt Fireplace

Page 9

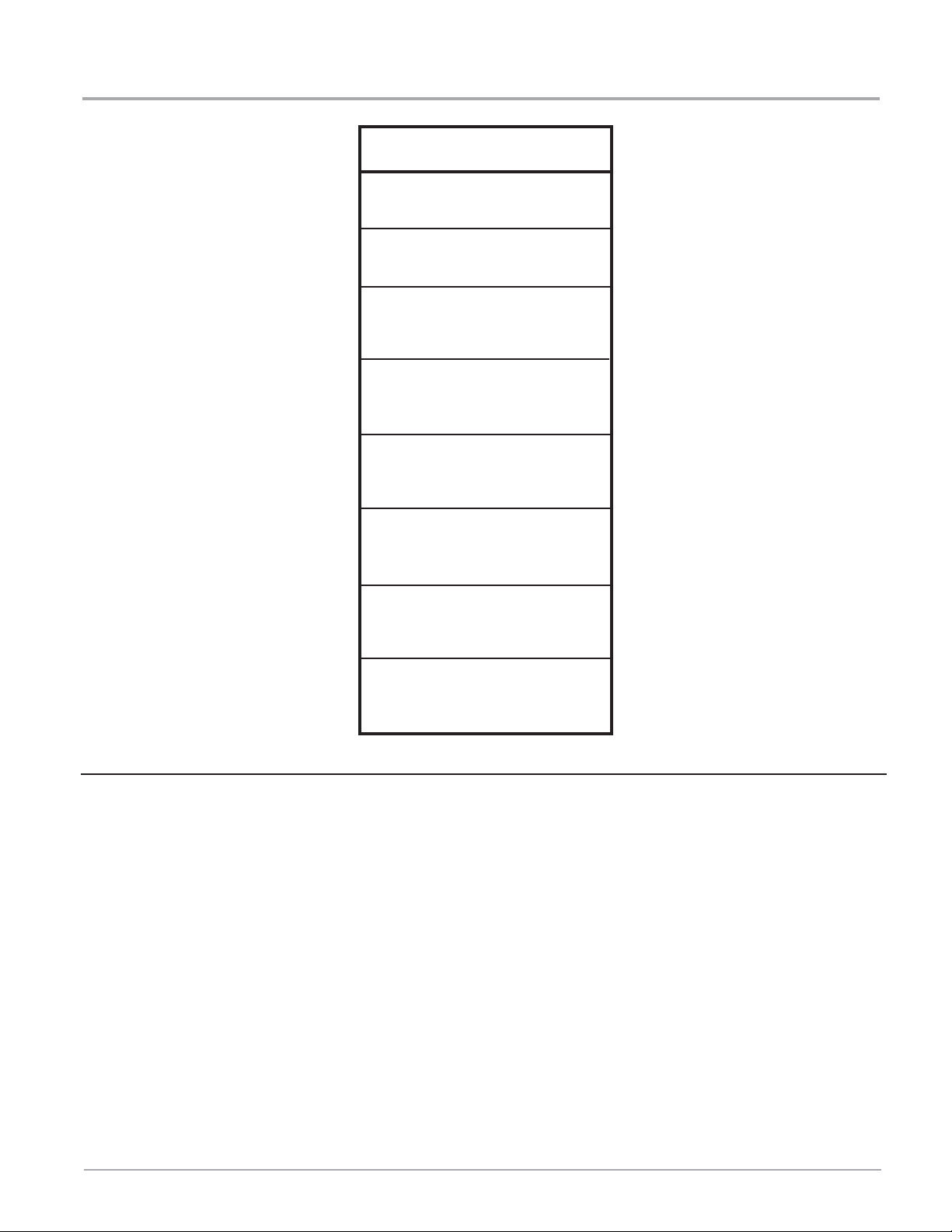

System Data

IG34

IG34-NG: For 0 to 610 meters altitude

IG34-LPG: For 0 to 610 meters altitude

IG34-ULPG: For 0 to 610 meters altitude

Burner Inlet Orifi ce Sizes:

NG LPG ULPG

Burner #37 #52 #53

Max. Input

NG 31.7 mj

LPG 30.6 mj

ULPG 26.4 mj

Min. Input

NG 21.1 mj

LPG 25.1 mj

ULPG 20.9 mj

Supply Pressure

NG 1.13 kPa

LPG 2.75 kPa

ULPG 2.75 kPa

INSTALLATION

Manifold Pressure HIGH LOW

NG 0.87 kPa 0.4kPa

LPG 2.51 kPa 1.6kPa

ULPG 2.51 kPa 1.6kPa

Electrical: 240 V. 50Hz.

Circulation: High/Off/LO speed fan,

150/89 CFM.

Log Set: Ceramic fi ber, 7 per set.

Aeration Setting

NG 13mm open

LPG 13mm open

ULPG 13mm open

AERATION SETTINGS

The burner aeration is factory set but may need adjusting due to either the local gas supply, air supply or altitude. This adjustment is performed by

the installer. (Close the aeration for a more yellow fl ame, or open it to make the fl ame bluer).

NG: 13mm open

LPG: 13mm open

ULPG: 13mm open

Note: Any damage due to carboning resulting from improperly setting the aeration and restrictor setting controls is NOT covered

under warranty.

Regency IG34 Gas Inbuilt Fireplace

9

Page 10

INSTALLATION

Conversion Kit #486-968 for NG to LPG Model

THIS CONVERSION MUST BE DONE BY A QUALIFIED GAS FITTER

IF IN DOUBT DO NOT DO THIS CONVERSION !!

onversion Kit 486-968 Contains:

9) Pull out the pilot hood by hand.

12) Replace the yellow "NG" label with

the red "ULPG" label.

ty. Part # Description

1 904-345 Burner Orifi ce #51

1 918-273 Red "LPG" label

1 918-272 Label "Converted to LPG"

1 910-037 LPG Pilot Injector

1 918-823 Instruction Sheet

) Shut off the gas supply and unplug

the power cord.

) Remove the glass door, logs and

lava rock.

) Remove the rear log tray by remov-

ing the 2 screws. (Log tray must be

rotated to clear the burner.)

) Remove the grate.

) Remove the burner and ensure the

aeration setting is 13 mm open.

) Remove burner orifi ce with a 1/2"

wrench and discard. Use a wrench

to hold on to the elbow behind the

orifi ce.

Pilot

Hood

Pilot

Hood

removed

Pilot

Orifi ce

10) Remove the pilot orifi ce with the

allen key.

13) Carefully pull out the control box.

NOTE: The control box is held in

place with velcro.

14) Remove the heat shield from the

control box by removing the 2

screws.

15) Remove the control box cover by

undoing the 3 screws.

Manoeuvre through antenna.

Antenna

Control Box

Cover

16) Remove the jumper using a plier.

Burner

) Reinstall new burner orifi ce LPG

stamped #51 and tighten.

) Apply the conversion label "This

unit has been converted to ULPG"

over top of the serial number decal.

Note: Aeration settings do not need

to be adjusted.

10

11) Put in the new LPG orifi ce with the

allen key. Then put back the pilot

hood.

Jumper Location

Jumper

17) Reverse steps 13, 12, 11, 6, 5, 4, 3

& 2.

Regency IG34 Gas Inbuilt Fireplace

Page 11

INSTALLATION

18) Turn on gas supply and plug in power cord.

19) Adjusting the Outlet Pressure

All the adjustments must be

carried out in the following order:

Remove the modulator plastic cap (A) using needle nose

pliers.

Maximum pressure: Turn the unit ON to its highest input

rating. Screw in the nut (B) to increase the outlet pressure

and screw it out to decrease it. Use a 10 mm wrench.

NOTE: The outlet pressure must be set to maximum 2.51

kPa.

Minimum pressure: Remove one of the cables connect-

ed to the electric modulator. While holding the nut (B) with

a wrench, screw in the screw (C) to increase the pressure

and screw it out to decrease it. Use a screwdriver 6 x 1

blade.

NOTE: The outlet pressure must be set to minimum 1.6

kPa.

After carrying out all adjustments, block the setting screws

with paint, taking care not to obstruct the breather orifi ce

of the pressure.

Put back the modulator plastic cap.

WARNING: To ensure the correct operation of the modu-

lator it is necessary that the plastic cap (A) is returned to

its original location.

A

B

20) Turn on gas supply and plug in power cord.

C

Cable

Electric

Modulator

21) At the end of all setting and adjustment operations, check

electrical installation and gas leaks.

22) Check operation of fl ame control.

23) Check for proper fl ame appearance and glow on logs.

Installer Notice:

These instructions must be left

with the appliance.

Regency IG34 Gas Inbuilt Fireplace

11

Page 12

INSTALLATION

THIS CONVERSION MUST BE DONE BY A QUALIFIED GAS FITTER

Conversion Kit 486-967 Contains:

Conversion Kit #486-967 for NG to ULPG

IF IN DOUBT DO NOT DO THIS CONVERSION !!

12) Replace the yellow "NG" label with

9) Pull out the pilot hood by hand.

the red "ULPG" label.

Qty. Part # Description

1 904-345 Burner Orifi ce #53

1 918-273 Red "ULPG" label

1 918-272 Label "Converted to ULPG"

1 910-037 LPG Pilot Injector

1 918-824 Instruction Sheet

1) Shut off the gas supply and unplug

the power cord.

2) Remove the glass door, logs and

lava rock.

3) Remove the rear log tray by remov-

ing the 2 screws. (Log tray must be

rotated to clear the burner.)

4) Remove the grate.

5) Remove the burner and ensure the

aeration setting is 13 mm open.

6) Remove burner orifi ce with a 1/2"

wrench and discard. Use a wrench

to hold on to the elbow behind the

orifi ce.

Pilot

Hood

Pilot

Hood

removed

Pilot

Orifi ce

10) Remove the pilot orifi ce with the

allen key.

13) Carefully pull out the control box.

NOTE: The control box is held in

place with velcro.

14) Remove the heat shield from the

control box by removing the 2

screws.

15) Remove the control box cover by

undoing the 3 screws.

Maneuver through an

Antenna

Control Box

Cover

16) Remove the jumper using a plier.

tenna.

Burner

7) Reinstall new burner orifi ce ULPG

stamped #53 and tighten.

8) Apply the conversion label "This

unit has been converted to ULPG"

over top of the serial number decal.

Note: Aeration settings do not need

to be adjusted.

12

11) Put in the new LPG orifi ce with the

allen key. Then put back the pilot

hood.

Jumper Location

Jumper

17) Reverse steps 13, 12, 11, 6, 5, 4, 3

& 2.

Regency IG34 Gas Inbuilt Fireplace

Page 13

INSTALLATION

s

18) Turn on gas supply and plug in power cord.

19) Adjusting the Outlet Pressure

All the adjustments must be

carried out in the following order:

Remove the modulator plastic cap (A) using needle nose

pliers.

Maximum pressure: Turn the unit ON to its highest input

rating. Screw in the nut (B) to increase the outlet pressure

and screw it out to decrease it. Use a 10 mm wrench.

NOTE: The outlet pressure must be set to maximum 2.51

kPa.

Minimum pressure: Remove one of the cables connect-

ed to the electric modulator. While holding the nut (B) with

a wrench, screw in the screw (C) to increase the pressure

and screw it out to decrease it. Use a screwdriver 6 x 1

blade.

NOTE: The outlet pressure must be set to minimum 1.6

kPa.

Cable

After carrying out all adjustments, block the setting screw

with paint, taking care not to obstruct the breather orifi ce

of the pressure.

Put back the modulator plastic cap.

WARNING: To ensure the correct operation of the modu-

lator it is necessary that the plastic cap (A) is returned to

its original location.

A

B

20) Turn on gas supply and plug in power cord.

21) At the end of all setting and adjustment operations, check

electrical installation and gas leaks.

22) Check operation of fl ame control.

C

Regency IG34 Gas Inbuilt Fireplace

Electric

Modulator

23) Check for proper fl ame appearance and glow on logs.

Installer Notice:

These instructions must be left

with the appliance.

13

Page 14

INSTALLATION

OPTIONAL STAINLESS STEEL INNER PANEL INSTALL

Before you start:

Stainless panels must be inspected for scratches and dimples prior to installation. All claims to be recorded at this time. Claims for

damage after installation will not receive consideration.

To protect the fi nish during installation and handling - cotton gloves MUST be worn at all times while handling the panels (even

when removing protective coating).

Stainless panels will discolor a little during normal operation. This is normal and should not be considered a defect.

All hand and fi nger marks MUST be cleaned off with a soft cloth and a stainless steel cleaner. Most stainless steel cleaners leave a

fi lm/residue on the surface of the panels. Use an ammonia based cleaner (ie. glass cleaner) to remove this fi lm before applying heat to

the unit. Failure to do this will result in burn stains on panels which you will be unable to remove. This is not a warranty item.

1) Remove faceplate, inner door frame and screen if

already installed. Refer to page 18 in the instruction manual.

2) Remove the glass door by undoing 2 latches - lift up and out.

Refer to page 17 in the manual for detailed instructions.

3) Remove all the logs if installed and set aside carefully.

4) Loosen the 4 screws securing the brackets that hold the existing

back and side panels in place.

6) Remove the two side brackets and screws (set aside) - then

remove the side panels by tilting the top in and lifting them out.

7) Orient the stainless side panels with the larger fold in the

panel facing in towards the burner and facing the back of the

fi rebox.

Larger fold in the

metal.

5) Remove the two back brackets and screws (set aside) fi rst, then

remove the back panel by lifting it up slightly, tilt it forward,

then lift it out.

14

8) Secure the stainless panel with original bracket and screw - repeat

procedure on the opposite side.

9) Reinstall the (original black) back panel - secure with 2 brackets

and 2 screws (ones that were removed initially).

10) Reinstall the logs, glass door, inner door frame with screen

and fi nally the faceplate. See manual for detailed instructions.

Final installation of optional stainless panels.

Regency IG34 Gas Inbuilt Fireplace

Page 15

INSTALLATION

LOG SET INSTALLATION

Read the instructions below carefully and refer to the diagrams. If logs are broken do not use the unit until

they are replaced. Broken logs can interfere with the pilot operation.

The gas log kit contains the following:

a) 02-43 Rear Log

b) 02-45 Front Right Log

c) 02-56 Middle Left Log

d) 02-46 Left Top Log

e) 02-47 Center Log

f) 02-48 Middle Right Log

g) 02-44 Front Left Log

h) 902-154 Embers

i) 902-153 Rockwool

j) 902-179/P Vermiculite

k) 946-669 Platinum Embers

(supplied with packaged manual)

Vermiculite

and embers

Vermiculite

and embers

Vermiculite

and embers

3) Place Rear Log A)02-43 on the two pins on the rear

log support.

The "02" refer numbers (i.e. 02-43) are

molded into the rear of each log.

Note: Install Optional Brick Panels prior to installing logs.

1) Carefully remove the logs from the box and unwrap

them. The logs are fragile, handle with care - do not

force into position.

2) Sprinkle the vermiculite around the fi rebox base. Take

some of the embers (approx. 1/3 of the bag) and

sprinkle over the vermiculite.

A)02-43

Pins on Rear Log Support

4) Place Front Right Log B)02-45 on the two pins as

shown.

B)02-45

Regency IG34 Gas Inbuilt Fireplace

15

Page 16

INSTALLATION

5) Place the Middle Left Log C)02-56 on the two pins as

shown.

C)02-56

7) Place the notch in Center Log E)02-47 over Log B)02-

45 and across the cutout on Log A)02-43.

E)02-47

Notch

A)02-43

B)02-45

Cutout

Logs A)02-43, C)02-56, and B)02-45 in position

6) Place the Left Top Log D)02-46 on the pin on Log

C)02-56 and on top of the cutout on Log A)02-43.

D)02-46

A)02-43

C)02-56

Pin

Cutout

Logs D)02-46 and E)02-47 in position.

8) Position notch in Front Right Log F)02-48 on Log

E)02-47 and push the bottom right edge against the

bracket on the burner tray and the front edge of the

rear burner.

Notch

F)02-48

Bracket

E)02-47

B)02-45

16

Regency IG34 Gas Inbuilt Fireplace

Page 17

INSTALLATION

Front edge of

rear burner

A)02-43

F)02-48

B)02-45

Side View

Bracket

The bottom right edge of Log F)02-48 must sit snugly against

the bracket and the front edge of the rear burner.

9) Place Front Left Log G)02-44 onto the 2 front pins as

shown.

10) Place the embers and Rockwool on the exposed front

burner tray.

11) Separate platinum embers and place on and around

the embers and rockwool on the burner tray. Avoid

stacking platinum embers.

12) Test fi re to ensure proper light off (make sure fl ame

fl ows smoothly from one end of burner to the other. If

there is any fl ame hesitation, check that area for any

blockage of the burner port.

G)02-44

A) 02-43 D) 02-46

C) 02-44

B) 02-56

The "02" refer numbers (i.e. 02-43) are

molded into the rear of each log.

G) 02-48

F) 02-47 E) 02-45

Regency IG34 Gas Inbuilt Fireplace

17

Page 18

INSTALLATION

GLASS DOOR INSTALLATION

STANDARD FLUSH DOOR

The standard fl ush door comes with a black frame. To install the frame

and glass door, simply hook the top door fl ange onto the top of the unit

and swing the door towards the unit, diagram 1. Be careful that the glass

gasket does not roll up; there must be a gap between the gasket and the

door lip to ensure that the door sits securely on the unit. See Diagram 2.

Diagram 1

Diagram 2

Use the hook to pull the spring out until you can put the hook

into the slot on the bottom door bracket. Repeat for 2nd spring.

See diagram 3.

To remove the fl ush door, reverse the above steps.

Diagram 3

To remove the fl ush door, reverse the above steps.

18

Regency IG34 Gas Inbuilt Fireplace

Page 19

e

FACEPLATE & OPTIONAL PLINTH TRIM ASSEMBLY

1) Lay the faceplate panels fl at, face down on something soft so they don't scratch.

2) Take the top faceplate and align the holes in it with the holes in the side panels.

Secure with provided nuts and bolts.

IG34 Faceplate Assembly / Plinth

1 336-914 Faceplate / Trim Kit

1 366-942 Plinth Kit (optional)

1 336-016 Mesh Screen Door

1 336-072F Mesh Bottom Screen

6 904-576 #8 Phillips pan head screws

1 336-012 Bottom Door

INSTALLATION

Plinth Trim Option:

Plinth Trim Kits are an option that can be used to fi nish off the installation when the bottom of the fi replace is higher than the

hearth or to raise the fi replace.

1) Lay the faceplate side panels fl at, face down on something soft so they don't scratch.

2) Attach the Plinth Trim to the bottom of the faceplate side panels with the screws provided.

3) Install faceplate on unit - see next page.

SCREEN INSTALLATION

1) Hook the screen over the top of the door frame - lower until

screen is fl ush with the door frame.

2) Flip door frame and screen over - locate the bracket tab at

the bottom of the door frame - fold the tab over 90º to secur

the screen in place.

3) Install screen and door frame on to unit - follow directions

on next page.

Regency IG34 Gas Inbuilt Fireplace

19

Page 20

INSTALLATION

1) Positi

4) Push both bott

til

FACEPLATE AND DOOR FRAME INSTALLATION

on faceplate on unit lining up screw holes on

faceplate with screw holes on unit - secure with 4 screws.

they are fully seated.

om frame hinges down on the metal lip un

2) Install lower screw below glass door - secure with 4 screws.

Note: Ensure that the fl anges on the sides of the fi rebox

are on the outside, when installing the faceplate

(see below).

Faceplate

Flange on fi rebox

5) Flip bottom louver up to close.

6) Install the door frame by hooking the top fl ange over the

top of the glass door.

3) Fold down the 2 hinges on the bottom frame to a fl at

position.

The bottom frame is installed with a friction fi t - the

opening in the corner of each hinge slides over the

metal lip located on the fl oor of the unit.

Note: Ensure the bottom frame is positioned properly

before installing, by making sure there is equal spacing on

either side.

Openings on hinge

Metal Lip

Glass Door

7) Lower the door frame gently into place.

8) To uninstall - reverse procedure.

Completed Faceplate & Door Frame Installation

with Safety Screen

Door Frame

20

Regency IG34 Gas Inbuilt Fireplace

Page 21

THERMODISC INSTALLATION

INSTALLATION

1) Install faceplate and door frame as per previous page.

2) After faceplate has been installed - place the touch pad (facing

out) in the knockout located on the left side of the faceplate.

3) Secure with 2 screws as shown below.

5) Secure wiring along the vertical right side of the faceplate

(facing the back of the faceplate) with supplied grey adhesive clips.

Back of Faceplate

6) Slide unit into fi nal position.

4) Take the limit switch harness and slide the thermodisc into the

bracket located on the top backside of the faceplate. Secure with

2 screws as shown below.

Thermodisc

Bracket

Back of Faceplate

Regency IG34 Gas Inbuilt Fireplace

21

Page 22

INSTALLATION

FINAL CHECK

Before leaving this unit with the customer, the installer must ensure that the appliance is fi ring correctly. This includes:

1) Clocking the appliance to ensure the correct fi ring rate (rate noted on label) at 15 minutes.

2) If required, adjusting the primary air to ensure that the fl ame does not carbon. First allow the unit to burn for 15 min. to stabilize.

3) Check for proper draft.

CAUTION

Any alteration to the product that causes sooting or carboning that results in damage to the exterior facia is not the

responsibility of the manufacturer.

WIRING

Caution: Ensure that the wires do not

touch any hot surfaces and are away

from sharp edges.

This unit is polarity sensitive and will

not operate if polarity is incorrect.

STANDARD WIRING

CAUTION: Label all wires pr ior to disconnection

when servicing controls. Wiring errors can

cause improper and dangerous operation.

22

Regency IG34 Gas Inbuilt Fireplace

Page 23

OPERATING INSTRUCTIONS

OPERATING

INSTRUCTIONS

Before operating this appliance, proceed through

the following check list.

1) Read and understand these Instructions

before operating this appliance.

2) Check to see that all wiring is correct and

enclosed to prevent possible shock.

3) Check to ensure there are no gas leaks.

4) Make sure the glass door is in place. Never

operate the appliance with the door glass

removed.

5) Verify that all fl ueing and the cap is unob-

structed.

6) Verify log placement.

7) The unit should never be turned off and on

again without a minimum of a 60 second

wait.

8) When lighting the appliance, the inside of

the glass may fog up. This will burn off after

a few minutes of operation.

FIRST FIRE

The FIRST FIRE in your heater is part of the

paint curing process. To ensure that the paint

is properly cured, it is recommended that you

burn your fi replace for at least four (4) hours the

fi rst time you use it with the fan on.

When fi rst operated, the unit will release an

odour caused by the curing of the paint and the

burning off of any oils remaining from manufacturing. Smoke detectors in the house may go off

at this time. Open a few windows to ventilate

the room for a couple of hours. The glass may

require cleaning.

NOTE: The main burner will always start on

"HIGH" and resume it's last setting after

20 seconds of operation.

NOTE: When the glass is cold and the appliance

is lit, it may cause condensation and fog

the glass. This condensation is normal

and will disappear in a few minutes as

the glass heats up.

DO NOT ATTEMPT TO CLEAN THE

GLASS WHILE IT IS STILL HOT!

DO NOT BURN THE APPLIANCE WITHOUT THE GLASS FRONT IN PLACE.

SUMMARY OF

CONTROLS

On/Off Button

If the unit is switched off, pressing and releasing

this button once will switch the unit on. The unit

will resume its last settings.

If the unit is switched on, pressing and releasing

this button once will switch the unit off.

Flame:

Increase - If the unit is switched on, pressing

and releasing the fl ame plus (+) button once will

increase the fl ame height to the next available

high setting.

Decrease - If the unit is switched on, pressing

and releasing the fl ame minus (-) button once

will decrease the fl ame height to the next avail-

able low setting.

Fan:

Increase - If the unit is switched on, pressing

and releasing the fan plus (+) button once will

increase the fan speed to the next available

high setting.

Decrease - If the unit is switched on, pressing

and releasing the fan minus (-) button once will

decrease the fan speed to the next available

low setting.

LIGHTING

INSTRUCTIONS

1) Plug the power cord into a power outlet.

2) Press and release the ON/OFF switch once

to start the unit. The LED will be lit.

3) After approximately 8 seconds the spark

ignition system will spark for 8 seconds to

light the main burner.

4) If the main burner does not light, repeat step

2 to restart the unit.

SHUTDOWN

INSTRUCTIONS

1) Press the ON/OFF switch once.

2) The LED will fl ash.

3) Turn off all electric power to the appliance

if service is to be performed.

REMOTE CONTROL

Use the Regency Remote Control Kit approved

for this unit. Use of other systems may void

your warranty.

The remote control kit comes with a hand held

transmitter and a wall mounting plate.

1) Choose a convenient location to mount

the hand held transmitter, protection from

extreme heat is very important.

By using the wall mounting plate to house the

transmitter, the remote can also be used as a

wall thermostat.

FAN OPERATION

Set the fan speed on the control panel at the top

rear of the unit to adjust to the desired speed.

Pressing and releasing the plus (+) FAN button

will change the fan speed as follows:

OFF -> LOW -> MEDIUM -> HIGH -> OFF,

etc.

Pressing and releasing the minus (-) FAN button

will be the reverse of the above.

Fan must be running at all times

when the unit is in operation.

ADJUSTING FLAME

HEIGHT

There are six fl ame settings that can be adjusted

by pressing and releasing the plus (+) and minus

(-) FLAME button.

Regency IG34 Gas Inbuilt Fireplace

23

Page 24

OPERATING INSTRUCTIONS

COPY OF LIGHTING INSTRUCTION PLATE

FOR YOUR SAFETY READ BEFORE LIGHTING

This appliance must be installed in accordance with local codes, if any; if not,

follow the current CAN1-B149/ANSI Z 223.1 (Australia: AS5601-2004, New Zealand: NZS 5261)

WARNING: If you do not follow these instructions exactly, a fi re or explosion may result

causing property damage, personal injury or loss of life. Improper installation, adjustment,

alteration, service or maintenance can cause injury or property damage. Refer to the

owner’s information manual provided with this appliance. For assistance or additional

information consult a qualifi ed installer, service agency or gas supplier.

A) BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the fl oor because some

gas is heavier than air and will settle on the fl oor.

WHAT TO DO IF YOU SMELL GAS

- Do not try to light any appliance

- Do not touch any electric switch, do not use any

phone in your building

- Immediately call your gas supplier from a neighbors

phone. Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call the

fi re department.

CAUTION: Hot while in operation. Do not touch. Severe Burns may result. Due to high

surface temperatures keep children, clothing and furniture, gasoline and other liquids

having fammable vapors away. Keep burner and control compartment clean. See installation

and operating instructions accompanying appliance.

LIGHTING INSTRUCTIONS

STOP! Read the safety information above on this label.

1) Plug the power cord into a power outlet.

2) Press and release the ON/OFF switch once to start

the unit. The LED will be lit.

TO TURN OFF GAS APPLIANCE

1) Press the ON/OFF switch once.

2) The LED will fl ash.

You may shut off the pilot during prolonged non use periods to conserve fuel.

DO NOT REMOVE THIS INSTRUCTION PLATE

B) Do not use this appliance if any part has been under water.

Immediately call a qualifi ed service technician to inspect

the appliance and to replace any part of the control system

and any gas control which has been under water.

This appliance needs fresh air for safe operation and

must be installed so there are provisions for adequate

combustion and ventilation air.

3) After approximately 8 seconds the spark ignition

system will spark for 8 seconds to light the main

burner.

4) If the main burner does not light, repeat step 2 to

restart.

3) Turn off all electric power to the unit if service is

to be performed.

918-247b

NORMAL OPERATING

SOUNDS OF

GAS APPLIANCES

It is possible that you will hear some sounds

from your gas appliance. This is perfectly normal

due to the fact that there are various gauges

and types of steel used within your appliance.

Listed below are some examples. All are normal

operating sounds and should not be considered

as defects in your appliance.

Blower:

Regency gas appliances use high tech blowers

to push heated air farther into the room. It is not

unusual for the fan to make a "whirring" sound

when ON. This sound will increase or decrease

in volume depending on the speed setting of

your fan speed control.

Burner Tray:

The burner tray is positioned directly under the

burner tube(s) and logs and is made of a different gauge material from the rest of the fi rebox

and body. Therefore, the varying thicknesses of

steel will expand and contract at slightly different

rates which can cause "ticking" and "cracking"

sounds. Y ou should also be aware that as there

are temperature changes within the unit these

sounds will likely re-occur. Again, this is normal

for steel fi reboxes.

Gas Control Valve:

As the gas control valve turns ON and OFF, a

dull clicking sound may be audible, this is normal

operation of a gas regulator or valve.

Unit Body/Firebox:

Different types and thicknesses of steel will

expand and contract at different rates resulting

in some "cracking" and "ticking" sounds will be

heard throughout the cycling process.

24

WARNING:

DO NOT SPRAY AEROSOLS IN THE VICINITY OF

THIS APPLIANCE WHILE IN OPERATION.

"Appliances incorporating a live fuel effect, and designed to

operate with luminous fl ames, may exhibit slight carbon

deposition."

RESETTING THE UNIT

If the appliance goes to 'lockout', the system

will have to be reset by depressing the reset

button - located behind bottom louver.

*Important: Wait at least 5 min for any un-

burned gas to clear before resetting the

appliance.

1) Open the bottom louver on the unit.

2) Press and release the reset button - once.

The button is located near the gas valve.

3) Wait for approximately 3 seconds - the

pilot sparks can be heard and seen. It will

take approximately 2 to 3 seconds for the

fl ame to be lit.

NOTE: Wait 30 seconds between reset

attempts.

Regency IG34 Gas Inbuilt Fireplace

Page 25

MAINTENANCE

MAINTENANCE

INSTRUCTIONS

Any maintenance required accessing the

glass door of the unit must be performed

by an authorized service person.

1) Always unplug the power cord before

cleaning. For relighting, refer to lighting

instructions. Keep the burner and control

compartment clean by brushing and vacuuming at least once a year. When cleaning

the logs, use a soft clean brush as the logs

are fragile and easily damaged.

2) Clean glass (never when unit is hot), appliance, louvres, and door with a damp cloth.

Never use an abrasive cleaner. The gold

louvres (and optional gold door) may be

scratched if abrasives are used to clean

them.

The heater is fi nished in a heat resistant

paint and should only be refi nished with

heat resistant paint (not with wall paint).

Regency uses StoveBright Paint - Metallic

Black #6309.

3) Make a periodic check of burner for proper

position and condition. Visually check the

fl ame of the burner periodically, making sure

the fl ames are steady; not lifting or fl oating.

If there is a problem, call an authorized

service person.

4) The appliance and fl ueing system must be

inspected before use, and at least annually, by an authorized fi eld service person,

to ensure that the fl ow of combustion and

ventilation air is not obstructed.

During the annual service call, the burners

should be removed from the burner tray

and cleaned. Replace the embers - do not

block the burner ports.

5) Keep the area near the appliance clear and

free from combustible materials, gasoline

and other fl ammable vapours and liquids.

6) Verify proper operation after servicing.

WARNING: CHILDREN AND

ADULTS SHOULD BE ALERTED

TO THE HAZARDS OF HIGH

SURFACE TEMPERATURE AND

SHOULD STAY AWAY TO AVOID

BURNS OR CLOTHING IGNITION.

YOUNG CHILDREN SHOULD BE

CAREFULL Y SUPERVISED WHEN

THEY ARE IN THE SAME ROOM

AS THE APPLIANCE.

CAUTION: ANY SAFETY SCREEN

OR GUARD REMOVED FOR SERVICING AN APPLIANCE MUST BE

REPLACED PRIOR TO OPERATING THE APPLIANCE.

CLOTHING OR OTHER FLAMMABLE MA TERIAL SHOULD NOT

BE PLACED ON OR NEAR THE

APPLIANCE.

DO NOT USE THIS APPLIANCE

IF ANY PART HAS BEEN UNDER

WATER. IMMEDIATELY CALL AN

AUTHORIZED SERVICE TECHNI

CIAN TO INSPECT THE APPLIANCE AND TO REPLACE ANY

PART OF CONTROL SYSTEM AND

ANY GAS CONTROL WHICH HAS

BEEN UNDER WATER.

LOG REPLACEMENT

The unit should never be used with broken logs.

Unplug the power cord and allow the unit to cool

before opening door to carefully remove the logs.

If for any reason a log should need replacement,

you must use the proper replacement log. The

position of these logs must be as shown in the

diagram under Log Installation.

Note: Improper positioning of logs may

create carbon build-up and will alter

the unit’s performance which is not

covered under warranty.

DOOR GLASS

REPLACEMENT

Y our Regency stove is supplied with high temperature, 5 mm Neoceram ceramic glass that

will withstand the highest heat that your unit will

produce. In the event that you break your glass

by impact, purchase your replacement from an

authorised Regency dealer only, and follow our

step-by-step instructions for replacement.

WARNING: do not operate appliance with the glass front removed,

cracked or broken. Replacement

of the glass should be done by

a licensed or authorised service

person.

Flush Glass Replacement

Slide old glass out of the side frames and

replace with new glass.

GLASS GASKET

If the glass gasket requires replacement use

glass gasket (Part # 936-155).

Regency IG34 Gas Inbuilt Fireplace

25

Page 26

MAINTENANCE

FAN MAINTENANCE

To Remove Fan:

1) Turn the unit off and allow it to cool to room temperature,

2) Unplug or disconnect power source to stove.

3) Open the bottom louvre.

4) Remove screws that secure protective screen.

5) Remove door frame and screen

6) Remove the ECS harness from the back clip.

7) Pull out the ECS box.

NOTE: The ECS box is held in place with velcro.

8) Remove the 2 screws that secure the fan in place.

9) Carefully slide the fan to the front, rotate it 45 degrees and slide it out simultaneously with the ECS box.

Resistor

Connectors

10) Disconnect all the connectors from the fan and resistor.

11) Remove the fan ground cable.

12) Reverse the above steps to install the new fan.

Fan

Connectors

Fan Ground

Cable

26

Regency IG34 Gas Inbuilt Fireplace

Page 27

V ALVE ASSEMBLY REPLACEMENT

1) Unplug or disconnect the power source to the stove and shut off gas supply.

2) open bottom louvre and remove protective screen.

3) Remove the door frame and safety screen.

4) Remove the glass door, logs, and black or stainless inner liner, if installed.

5) Remove the rear log tray, burner and grate.

MAINTENANCE

6) Disconnect gas line from the valve.

7) Remove the fi rebox base plate by removing the 10 screws which hold it in place.

8) Remove all the wire connectors from the valve and spark ignitor.

9) Remove the valve tray assembly.

10) To replace the valve tray assembly, simply reverse the above steps.

Regency IG34 Gas Inbuilt Fireplace

27

Page 28

PARTS LIST

ELECTRONIC COMPONENTS PARTS LIST

910-084

910-909 Fan Resistor

910-936

910-527

910-935

910-521, 910-522, 910-523, 910-525

910-080

FG37 FG38 FG39 PG33 PG36 HG35 PG121/PG131 IG35 IG34

PG36D

910-088

910-082

910-089

910-906

910-912

910-083

910-916

910-514

910-936 Intermittent Pilot

910-082 Direct Spark Ignitor

910-089 Flame Cable

910-088 Spark Cable

910-084 Control Box

910-527 Manual Control

910-080 Valve

910-521 Control Box Cable (1)

910-522 Control Box Cable (2)

910-523 Control Box Cable (3)

910-525 Control Box Cable (4)

910-912 Ignition Module to Valve Cable

910-906 Reset Switch

910-083 Ignition Module (1)

910-922 Ignition Module (2)

910-514 Jumper

N/A

N/A

N/A

N/A

(2) (2) (2)

N/A

(2) (2) (2)

N/A*

N/A

N/A

(1)

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

(1)

(2) (2)

N/A N/A

N/A N/A

N/A N/A

N/A

(3)

(4)

(2)

N/A

N/A

N/A*

N/A

(1)

N/A

N/A

N/A

N/A

(2)

(2)

910-935 Manual Control Switch

*Note: The Control Box Cable wires for the FG38 come separately: 910-502, 910-505, 910-506, 910-507, 910-509

The Control Box Cable wires for the IG35 come separately: 910-530, 910-504, 910-528

28

N/A

N/A

N/A

N/A

Regency IG34 Gas Inbuilt Fireplace

Page 29

MAIN ASSEMBLY

Part # Description Part # Description

1) 910-169/P Fan Motor (240 V)**

2) 910-995 Thermodisc**

10) 910-936 Pilot Assy (NG) - 3 fl ame convertible top

910-947 Pilot Assy (LPG) - 3 fl ame convertible top

PARTS LIST

3) 486-968 LPG Conversion Kit**

486-967 ULPG Conversion Kit**

4) 336-574/P Valve Assembly - NG

336-576/P Valve Assembly - LPG

5) 910-080 SIGMA Valve 845

6) 336-001 Valve Tray Gasket**

7) 402-526 Grate Assembly**

8) 336-535 Burner Assembly - NG/LPG

9) 402-935 Log Set**

11) 904-240 Orifi ce #37 (NG)

904-645 Orifi ce #51 (LP)

12) 336-013 Glass Door Frame

13) 936-155 Gasket Tadpole Tape

14) 940-307/P Neoceram Glass

948-223 Logo Plate

918-793 Manual

*Not available as a replacement part.

** Part not shown.

14

Regency IG34 Gas Inbuilt Fireplace

4

10

8

12

11

29

Page 30

PARTS LIST

F ACEPLATE ASSEMBL Y

Part # Description

14) 336-914 Faceplate & Trim Complete - Regular

15) 366-942 Plinth Kit

16) 336-532 Flush Screen Door**

*Not available as a replacement part.

14

15

30

Regency IG34 Gas Inbuilt Fireplace

Page 31

WARRANTY

Regency® Fireplace Products are designed with reliability and simplicity in mind. In addition, our internal Quality Assurance Team carefully inspects each

unit thoroughly before it leaves our door. Regency® is pleased to extend this limited lifetime warranty to the original purchaser of a Regency

The Warranty: Lifetime

Covered under the agreement are the following components: The combustion chamber, heat exchanger, burner tubes/pans, logs, glass crystals, ceramic spa stones,

pebbles, brick panels and gold plating (against defective manufacture only) are covered under the Limited Lifetime Warranty for fi ve (5) years for parts and labour and

parts only thereafter.

External casting, surrounds and grills are covered against cracks and warps resulting from manufacturer defects, parts and labour for one (1) year from the date of

purchase and parts only thereafter.

Special Finishes - One year on stainless steel panels, nickel overlays, nickel faceplates, brushed nickel and antique copper full screens and doors. Y ou can expect some

changes in color as the product "ages" with constant heating and cooling. FPI warranties the product for any manufacturing defects on the original product. However,

the manufacturers warranty does not cover changing colors and marks, ie. fi nger prints, etc applied after the purchase of the product. Damage from the use of abrasive

cleaners is not covered by warranty.

Electrical components such as fans, switches, ignition modules, wiring, thermodiscs, remote control, thermopiles, thermocouples and gas valves are covered for one

year for parts and labour from the date of purchase.

The warranty on brass parts is for one year, no labour. The brass is not warranted against tarnishing.

®

Repair/replacement parts purchased by the consumer from Regency

only. Any item shown to be defective will be repaired or replaced at our discretion. No labour coverage is included with these parts.

Conditions:

All installations must be performed by a qualifi ed gas fi tter and installed according to all applicable local and national codes. Also, all service work must be carried out

by a qualifi ed gas service person provided by the selling dealer. It is the responsibility of the installer to ensure that the appliance is fi ring as per rating plate. Any part

or parts of this unit which in our judgement show evidence of such defect will be repaired or replaced at Regency®'s option, through an accredited distributor or agent

provided that the defective part be returned to the distributor or agent Transportation Prepaid, if requested. In areas where there is not an approved service agent or

the closest approved service agent is situated more than thirty (30) kilometres from the installation, Regency is not obliged to arrange warranty repairs and travel and/

or additional labour charges will apply.

Porcelain/Enamel - Absolute perfection is neither guaranteed nor commercially possible. Any chips must be reported and inspected by an authorised dealer within three

days of installation. Reported damage after this time will be subject to rejection.

It is the general practice of Regency® to charge for larger, higher priced replacement parts and issue credit once the replaced component has been returned to Regency

and evaluated fro manufacturer defect.

At all time Regency reserves the right to inspect product in the fi eld which is claimed to be defective.

All claims must be submitted to Regency® by authorised selling dealers. It is essential that all submitted claims provide all of the necessary information including customer

name, purchase date, serial #, type of unit, problem, and part or parts requested, without this information the warranty will be invalid.

Exclusions:

This limited Lifetime Warranty does not extend to or include paint, door or glass gasketing or trim. It does not cover installation and operational related problems such as

over-fi ring, downdrafts or spillage caused by environmental conditions, nearby trees, buildings, hilltops, mountains, inadequate fl ueing or ventilation, excessive offsets,

negative air pressures caused by insuffi cient make up air, mechanical systems such as furnaces, fans, clothes dryers etc.

Embers, rockwool, gaskets, door handles and paint are not covered under the terms of this warranty policy.

Regency® will not be liable for acts of God, or acts of terrorism, which cause malfunction of the appliance.

Performance problems due to operator error will not be covered by this warranty policy.

The warranty does not extend to any part or parts which show evidence of misuse or abuse, neglect, accident, lack of maintenance, or improper installation.

Products made by other manufacturers and used in conjunction with the operation of this appliance without authorisation from Regency®, may nullify your warranty on

this product.

Regency shall in no event be liable for any special, indirect consequential damages of any nature whatsoever which are in excess of the original purchase price of the

product. Any alteration to the unit which causes sooting or carboning that results in damage to the exterior facia is not the responsibility of FPI.

SUBJECT TO CHANGE.

after the original coverage has expired on the unit will carry a 90 day warranty valid with a receipt

®

Product.

DISTRIBUTORS: Western Australia Eastern Australia

Air Group Australia

28 Division St

Welshpool WA 6106

FIREPLACE PRODUCTS AUSTRALIA PTY. Ltd.

21-23 South Link

Dandenong, VIC 3175

NOTE: PLEASE RETAIN YOUR INVOICE AS PROOF OF PURCHASE FOR WARRANTY VERIFICATION

INCORRECT INSTALLATION, ELECTRICAL SURGES WHICH MAY CAUSE DAMAGE TO ELECTRICAL COMPONENTS/ GAS VALVES OR

GAS PRESSURE SETTINGS ARE NOT COVERED BY WARRANTY

A SERVICE OR CALL OUT FEE WILL BE CHARGED IN THESE CIRCUMSTANCES.

Regency IG34 Gas Inbuilt Fireplace

31

Page 32

FIREPLACE PRODUCTS AUSTRALIA PTY. LTD.

21-23 SOUTH LINK, DANDENONG SOUTH

VICTORIA, 3175

AUSTRALIA

© Copyright 2009, FPI Fireplace Products International Ltd. All rights reserved.

Printed in Canada

Loading...

Loading...