Page 1

www.regency-fi re.com

Owners & Installation Manual

WOOD

Fireplace

Inserts &

Hearth Heater

Tested by:

908-332b

MODELS: H2100 I1100S I3100L

Installer: Please complete the details on the back cover

and leave this manual with the homeowner.

Homeowner: Please keep these instructions for future reference.

FPI FIREPLACE PRODUCTS INTERNATIONAL LTD. 6988 Venture St., Delta, BC Canada, V4G 1H4

11/15/07

Page 2

Thank-you for purchasing a

REGENCY FIREPLACE PRODUCT.

The pride of workmanship that goes into each of our products will give you years of trouble-free

enjoyment. Should you have any questions about your product that are not covered in this manual,

please contact the REGENCY DEALER in your area.

Keep those REGENCY FIRES burning.

SAFETY NOTE: If this Insert is not properly installed, a house fi re may result. For your safety,

follow the installation instructions, contact local building or fi re offi cials about restrictions and installation inspection requirements in your area.

Regency Wood Insert & Hearth Heater2

Page 3

TABLE OF CONTENTS

REGENCY FIREPLACE INSERTS

& HEARTH HEATER

SAFETY LABEL

Safety Label For I1100S & I3100L ................................. 4

Safety Label For H2100M .............................................5

INSTALLATION

Before Installing Your Insert ..........................................6

Chimney Specifi cations .................................................6

Fireplace Specifi cations ................................................6

Installing Your Insert ......................................................6

Optional Flue Connector Kit ..........................................7

Masonry and Factory Built Fireplace Clearances .........7

Leg Option on H2100 Hearth Heater .............................8

Flue Connector Bracket .................................................8

Installation Into a Factory Built Fireplace ......................8

Installation Into a Masonry Fireplace .............................8

Faceplate and Trim .......................................................9

Fan / Blower ................................................................10

Floor Protection ........................................................... 11

Firebrick Assembly ...................................................... 11

Door Handle ................................................................11

Brick Flue Baffl e & Secondary Air Tube Installation ....11

Draft Control ................................................................12

Screen Door ................................................................12

OPERATING INSTRUCTIONS

First Fire ......................................................................13

Fan Operation (All Units) .............................................13

Ash Disposal ...............................................................13

Some Safety Guidelines ..............................................13

Creosote ......................................................................14

MAINTENANCE

Maintenance of Gold-Plated Doors .............................14

Door Gasket ................................................................14

Door Latch Adjustment ................................................14

Glass Cleaning ............................................................14

Glass Replacement .....................................................14

Glass Removal ............................................................14

PARTS LIST

I1100 & I3100 Main Assembly .....................................15

I1100 & I3100 Faceplates ............................................16

H2100 Main Assembly .................................................17

I1100, I3100 & H2100 Firebrick ...................................18

WARRANTY

Warranty ......................................................................19

Regency Wood Insert & Hearth Heater 3

Page 4

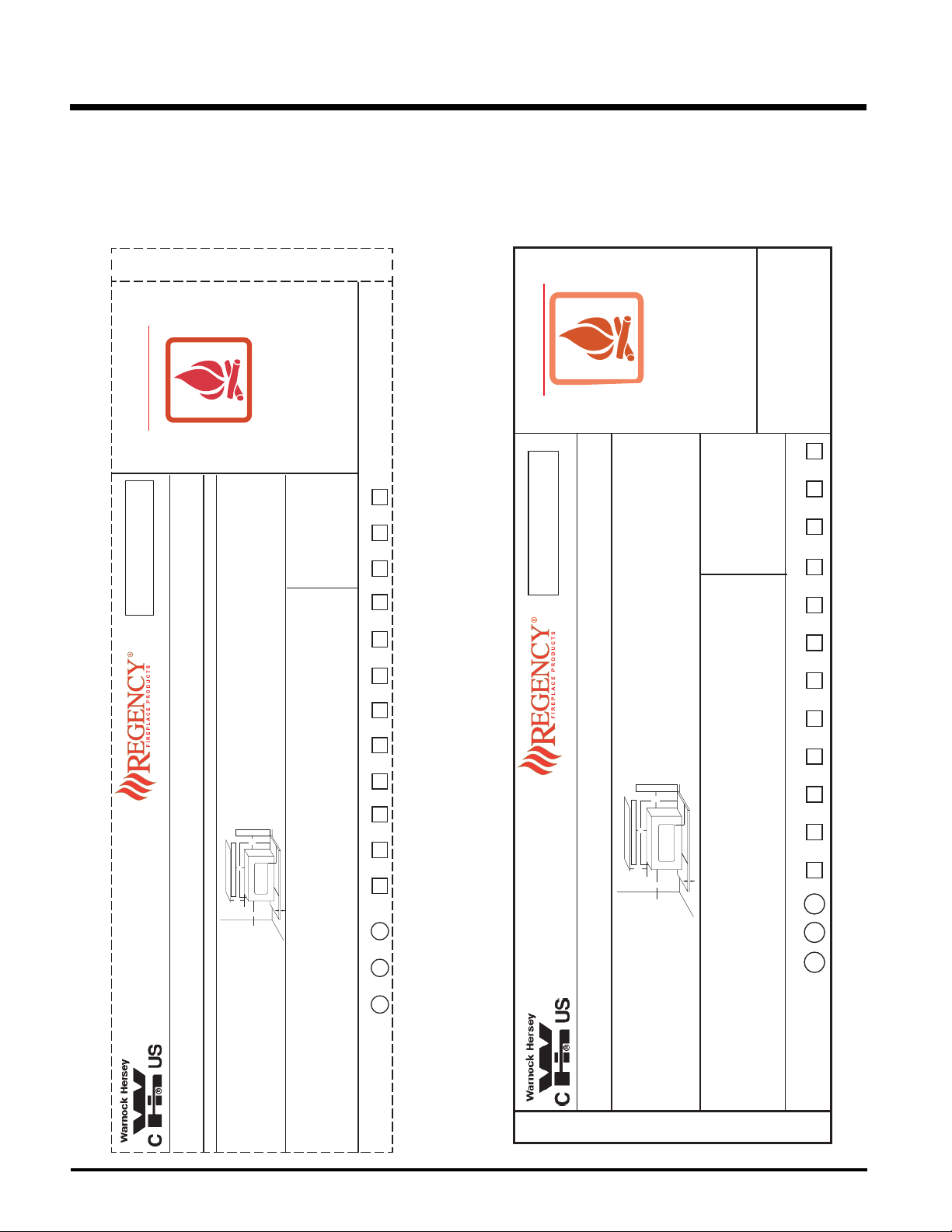

SAFETY LABEL

HOT

WHILE

IN

OPERATION

DO

NOT

TOUCH.

KEEP

CHILDREN,

CLOTHING

AND

FURNITURE

AWAY.

CONTACT

MAY

CAUSE

SKIN

BURNS.

READ

ABOVE

NSTRUCTIONS.

This is a copy of the label that accompanies each

Regency Small Flush Insert and Large Flush

Insert. We have printed a copy of the contents

here for your review.

SAFETY LABEL FOR I1100S AND I3100L

(Duplicate Serial #)

AWAY.

CHILDREN,

OPERATION

KEEP

IN

FURNITURE

CAUTION

DO NOT REMOVE THIS LABEL

104

AND

WHILE

TOUCH.

HOT

NOT

DO

CLOTHING

MANUFACTURED BY:

FPI FIREPLACE PRODUCTS

NOTE: Regency units are constantly being

improved. Check the label on the unit and if

there is a difference, the label on the unit is

the correct one.

104

BURNS.

SKIN

INSTRUCTIONS.

CAUSE

MAY

ABOVE

READ

CONTACT

UNITED STATES ENVIRONMENTAL PROTECTION

AGENCY CERTIFIED TO COMPLY WITH JULY 1990,

PARTICULATE EMISSION STANDARDS.

908-306b 10/03

6988 VENTURE ST.

INTERNATIONAL LTD.

DELTA, BC V4G 1H4

DO NOT REMOVE THIS LABEL

CAUTION

106

UNITED STATES

INSTRUCTIONS.

CHILDREN, CLOTHING

CONTACT MAY CAUSE

DO NOT TOUCH. KEEP

AND FURNITURE AWAY.

HOT WHILE IN OPERATION

SKIN BURNS. READ ABOVE

Manufactured by:

6988 Venture Street

Delta, BC V4G 1H4

INTERNATIONAL LTD.

FPI FIREPLACE PRODUCTS

EMISSION STANDARDS.

WITH JULY 1990, PARTICULATE

AGENCY CERTIFIED TO COMPLY

ENVIRONMENTAL PROTECTION

MADE IN CANADA

INSTALL ONLY ON A NON-COMBUSTIBLE HEARTH RAISED (F) 1.5IN / 38MM

ABOVE AN ADJACENT COMBUSTIBLE FLOOR. COMBUSTIBLE FLOOR MUST

BE PROTECTED BY NON-COMBUSTIBLE MATERIAL EXTENDING

(E) 16 IN / 405MM TO FRONT AND (G) 8IN / 205MM TO SIDES FROM FUEL

DOOR.

D

G

C

E

B

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS (MEASURED FROM INSERT BODY)

LISTED FACTORY BUILT FIREPLACE INSERT

CERTIFIED FOR USE IN CANADA AND U.S.A.

MODEL: I1100S

TESTED TO:

ULC S628-M93 / UL 1482-1998 / ULC S627-00 / UL 737-2000 REPORT NO. 632-3198 (SEPT.1993)

INSTALL AND USE ONLY IN ACCORDANCE WITH THE MANUFACTURER'S INSTALLATION AND OPERATING INSTRUCTIONS. INSTALL AND USE ONLY IN MASONRY

ADJACENT SIDEWALL A) 15in / 380mm

FIREPLACE OR FACTORY BUILT FIREPLACE.

CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND INSTALLATION INSPECTION IN YOUR AREA.

F

A

ADJACEN

TSIDEWALL

MANTLE B) 20in / 510mm

TOP FACING C 14in / 355 mm

SIDE FACING D) 7.375in / 185mm

INSTALL ONLY ON A NON-COMBUSTIBLE HEARTH RAISED (F) 1.5" (38mm)

ABOVE AN ADJACENT COMBUSTIBLE FLOOR. COMBUSTIBLE FLOOR

MUST BE PROTECTED BY NON-COMBUSTIBLE MATERIAL EXTENDING (E)

16" (405mm) TO FRONT AND (G) 8" (205mm) TO SIDES FROM FUEL

DOOR.

D

G

C

E

B

JAN FEB MAR APR MAY JUN JUL AUG SEPT OCT NOV DEC

F

A

ADJ ACEN

TSIDEWALL

JAN FEB MAR APR MAY JUN JUL AUG SEPT OCT NOV DEC

2007

20062005

LISTED FACTORY BUILT FIREPLACE INSERT

CERTIFIED FOR USE IN CANADA AND U.S.A.

MODEL: I3100L

TESTED TO:

ULC S628-M93 / UL 1482-1998 / ULC S627-00 / UL 737-2000 REPORT NO. 632-323500 (MAR.1994)

2005 2006 2007

fireplace or factory built fireplace. Contact local building or fire officials about restrictions and installation inspection in your area.

Install and use only in accordance with the manufactuerer's installation and operating instructions. Install and use only in masonry

Minimum Clearances to Combustibles

(Measured from insert body)

ADJACENT SIDEWALL A) 13"(330mm)

MANTLE B) 19"(480 mm)

COMPONENTS REQUIRED FOR INSTALLATION: 6" (150mm) STAINLESS STEEL LINER.

OPTIONAL COMPONENT: FAN, ELECTRICAL RATING: VOLTS 115, 60 HZ, 0.6 AMPS, SCREEN DOOR

DO NOT REMOVE BRICKS OR MORTAR IN MASONRY FIREPLACE. FOR USE WITH SOLID WOOD FUEL ONLY. DO NOT

USE GRATE OR ELEVATE FIRE. BUILD WOOD FIRE DIRECTLY ON HEARTH. OPERATE WITH FEED DOOR CLOSED,

OPEN TO FEED FIRE ONLY. REPLACE GLASS ONLY WITH CERAMIC GLASS (5mm). INSPECT AND CLEAN CHIMNEY

FREQUENTLY. UNDER CERTAIN CONDITIONS OF USE CREOSOTE BUILDUP MAY OCCUR RAPIDLY. DO NOT

TOP FACING C) 18"(455 mm)

SIDE FACING D) 6.5"(165mm)

OVERFIRE, IF INSERT GLOWS YOU ARE OVER-FIRING.

DATE OF MANUFACTURE

(Duplicate Serial #)

DATE OF MANUFACTURE

COMPONENTS REQUIRED FOR INSTALLATION: 6IN / 150MM STAINLESS STEEL LINER.

OPTIONAL COMPONENT: FAN, ELECTRICAL RATING: VOLTS 115, 60 HZ, 0.6 AMPS, SCREEN DOOR

DO NOT REMOVE BRICKS OR MORTAR IN MASONRY FIREPLACE. FOR USE WITH SOLID WOOD FUEL ONLY. DO NOT USE GRATE

OR ELEVATE FIRE. BUILD WOOD FIRE DIRECTLY ON HEARTH. OPERATE WITH FEED DOOR CLOSED, OPEN TO FEED FIRE ONLY.

MADE IN CANADA

REPLACE GLASS ONLY WITH CERAMIC GLASS (5MM). INSPECT AND CLEAN CHIMNEY FREQUENTLY. UNDER CERTAIN

CONDITIONS OF USE CREOSOTE BUILDUP MAY OCCUR RAPIDLY. DO NOT OVERFIRE, IF INSERT GLOWS YOU ARE OVER-FIRING.

Regency Wood Insert & Hearth Heater4

908-343b rev. 11/05

Page 5

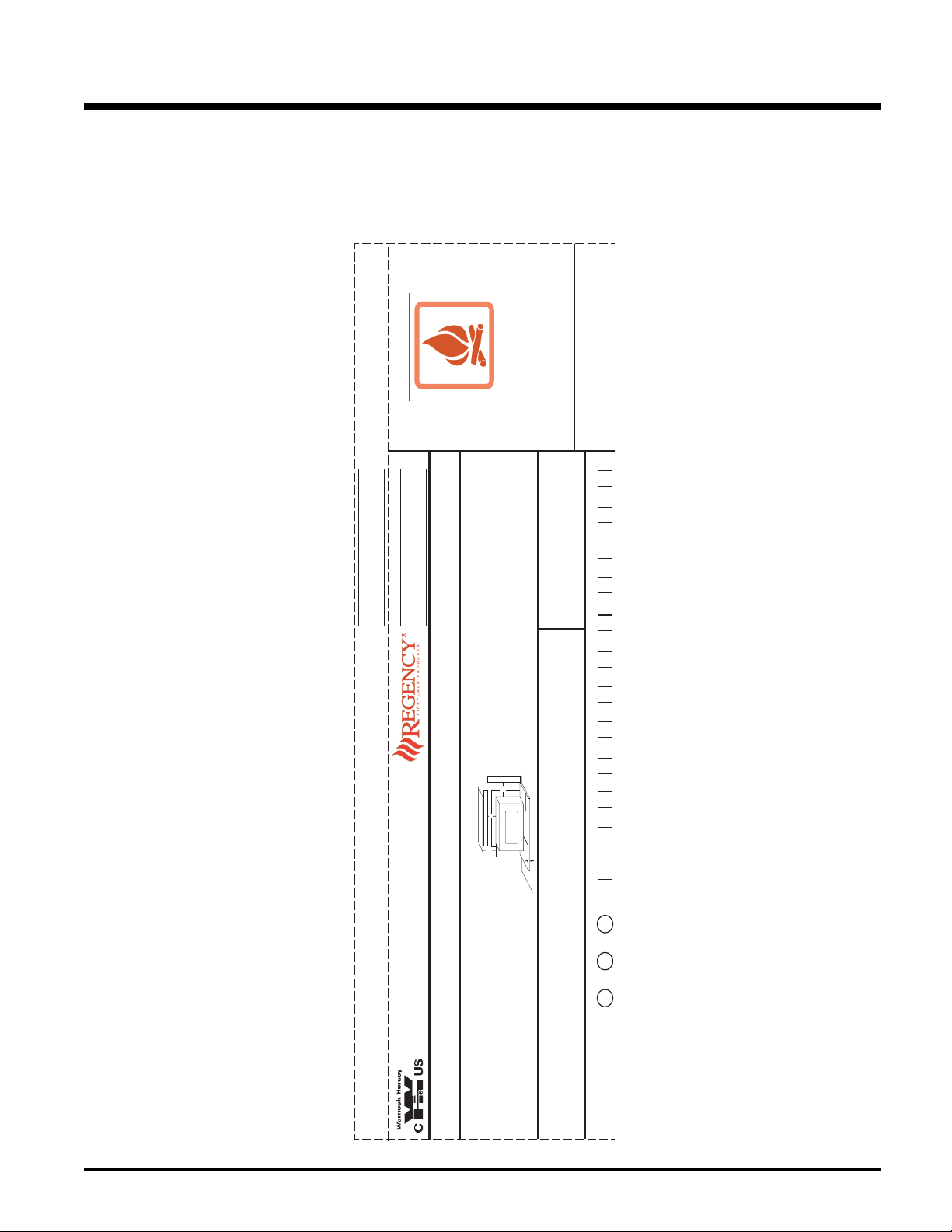

SAFETY LABEL

This is a copy of the label that accompanies each

Regency Hearth Heater. We have printed a

copy of the contents here for your review.

NOTE: Regency units are constantly being

improved. Check the label on the unit and if

there is a difference, the label on the unit is the

correct one.

SAFETY LABEL FOR H2100M

CAUTION

HOT WHILE IN OPERATION

DO NOT TOUCH. KEEP CHILDREN,

INSTRUCTIONS.

SKIN BURNS. READ ABOVE

CLOTHING AND FURNITURE

AWAY. CONTACT MAY CAUSE

UNITED STATES ENVIRONMENTAL PROTEC-

TION AGENCY CERTIFIED TO COMPLY WITH

JULY 1990, PARTICULATE EMISSION STAND-

ARDS.

908-389b 11/05

MANUFACTURED BY:

DO NOT REMOVE THIS LABEL

103

103

(Duplicate Serial #)

INSTALL ONLY ON A NON-COMBUSTIBLE HEARTH RAISED (F) 1.5 IN / 38 MM ABOVE

AN ADJACENT COMBUSTIBLE FLOOR. COMBUSTIBLE FLOOR MUST BE PRO-

TECTED BY NON-COMBUSTIBLE MATERIAL EXTENDING (E) 18 IN / 455 MM TO

FRONT AND (G) 6 IN / 150 MM TO SIDES.

COMPONENTS REQUIRED FOR INSTALLATION MUST HAVE A 6IN/150MM

D

C

B

A

TSIDEWALL

LISTED FACTORY BUILT FIREPLACE ACCESSORY HEARTH STOVE

CERTIFIED FOR USE IN CANADA AND U.S.A.

MODEL: H2100M

TESTED TO: ULC S628-M93 / UL 1482-1998 REPORT NO. 6255 (JULY 1991)

6988 VENTURE ST. DELTA, BC V4G 1H4

FIREPLACE PRODUCTS INTERNATIONAL LTD.

STAINLESS STEEL LINER.

G

E

F

ADJACEN

JAN FEB MA R APR MA Y JUN JUL AUG SEPT OCT NOV DEC

2005 2006 2007

DO NOT REMOVE BRICKS OR MORTAR IN MASONRY FIREPLACE. FOR USE WITH SOLID WOOD FUEL ONLY. DO NOT USE GRATE OR

ELEVATE FIRE. BUILD WOOD FIRE DIRECTLY ON HEARTH. OPERATE WITH FEED DOOR CLOSED, OPEN TO FEED FIRE ONLY.

REPLACE GLASS ONLY WITH CERAMIC GLASS (5 MM).

INSPECT AND CLEAN CHIMNEY FREQUENTLY. UNDER CERTAIN CONDITIONS OF USE CREOSOTE BUILDUP MAY OCCUR RAPIDLY. DO

ADJACENT SIDEWALL A) 10 in / 255 mm

MANTEL B) 2 5 in / 635 mm

TOP FACING C) 14 in / 355 mm

SIDE FACING D) 8.5 in/ 216mm

HEARTH EXTENSION (DEPTH) E) 18 in / 455 mm

HEARTH EXTENSION (ELEVATION) F) 1.5 in/ 38 mm

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS (MEASURED FROM INSERT BODY)

INSTALL AND USE ONLY IN ACCORDANCE WITH THE MANUFACTURER'S INSTALLATION AND OPERATING INSTRUCTIONS. INSTALL AND USE ONLY IN MASONRY FIREPLACE OR

FACTORY BUILT FIREPLACE.

CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND INSTALLATION INSPECTION IN YOUR AREA.

HEARTH EXTENSION (WIDTH) G) 6 in / 150 mm

NOT OVERFIRE, IF INSERT GLOWS YOU ARE OVER-FIRING.

DATE OF MANUFACTURE

MADE IN CANADA

Regency Wood Insert & Hearth Heater 5

Page 6

INSTALLATION

Regency Inserts are constructed with the highest quality materials and assembled under strict

quality control procedures that insure years of

trouble free and reliable performance.

It is important that you read this manual thoroughly and fully understand the safe installation and operating procedures. The more

you understand the way your Regency Insert

operates, the more enjoyment you will experience from knowing that your unit is operating

at peak performance.

BEFORE INSTALLING

YOUR INSERT

1) Read all instructions before installing and

using your fi replace insert. Install and use

only in accordance with manufacturer’s

installation and operating instructions.

2) Check your local building codes - Building

Inspection Department. You may require

a permit before installing your insert. Be

aware that local codes and regulations may

override some items in the manual.

WARNING: Careless installation is the

major cause of safety hazard. Check all

local building and safety codes before

installation of unit.

3) Notify your home insurance company that

you plan to install a fi replace insert or hearth

heater.

4) Your fi replace insert is heavy and requires

two or more people to move it safely. The

insert can be badly damaged by mishandling.

5) If your existing fi replace damper control

will become inaccessible once you have

installed your Regency Insert, you should

either remove or secure it in the open position.

6) Inspect your fi replace and chimney prior

to installing your insert to determine that it

is free from cracks, loose mortar or other

signs of damage. If repairs are required,

they should be completed before installing

your insert. Do not remove bricks or mortar

from your masonry fi replace.

7) Do not connect the insert to a chimney

system servicing another appliance or an

air distribution duct.

Emissions from burning wood or gas could

contain chemicals known to the State of California to cause cancer, birth defects or other

reproductive harm.

CHIMNEY

SPECIFICATIONS

Before installing, check and clean your chimney

system thoroughly. If in doubt about its condition, seek professional advice. Your Regency

Insert is designed for installation into a masonry

fi replace that is constructed in accordance with

the requirements of "The Standard for Chimneys,

Fireplaces, Vents, and Solid Fuel Burning Appliance", N.F.P.A. 211, the National Building

Code of Canada, or the applicable local code

requirements.

The appliance, when installed, must be electrically grounded in accordance with local codes or,

in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70, or the Canadian

Electrical code, CSA C22.1.

Regency Inserts are designed with a 6" (152mm)

fl ue.

Requirements for Installing

Solid-fuel Inserts in Factory-built

Fireplaces.

1) The insert must be tested and meet the

requirements of UL 1482 (U.S.) and or ULC

S628 (Canada) when tested in a masonry

fi replace built per ULC S628.

2) The factory-built fi replace must be listed per

UL 127 or ULC S610.

3) Clearances obtained from the masonry fi re-

place tests are also relevant for installation

in factory-built fi replaces.

4) Installation must include a full height listed

chimney liner type HT requirements (2100

degree F.) per UL 1777 (U.S.) or ULC

S635 (Canada). The liner must be securely

attached to the insert fl ue collar and the

chimney top.

5) Means must be provided to prevent room

air passage to the chimney cavity of the

fi replace. This may be accomplished by

sealing the damper area around the chimney

liner, or sealing the fi replace front.

6) Alteration of the fi replace in any manner is not

permitted with the following exceptions;

a. external trim pieces which do not affect

the operation of the fi replace may be

removed providing they can be stored

on or within the fi replace for re-assembly

if the insert is removed.

b. the chimney damper may be removed

to install the chimney liner.

7) Circulating air chambers (i.e. in a steel

fi replace liner or metal heat circulator) shall

not be blocked.

8) Means must be provided for removal of the

insert to clean the chimney fl ue.

9) Inserts that project in front of the fi replace

must be supplied with appropriate supporting

means.

10) Installer must mechanically attach the sup-

plied label to the inside of the fi rebox of the

fi replace into which the insert is installed.

"WARNING: This fi replace has been converted

for use with a wood insert only and cannot be

used for burning wood or solid fuels unless

all original parts have been replaced, and the

fi replace re-approved by the authority having

jurisdiction."

In order for a solid-fuel insert to be certifi ed

for use in factory-built fi replaces, the above

information must be clearly stated in the installation manual and appropriate markings. Final

approval is contingent on the authority having

jurisdiction.

FIREPLACE

SPECIFICATIONS

Your fi replace opening requires the following

minimum sizes:

Height Width Depth

Small (I1100S) 20" 23" 13.25"

Large (I3100L) 25" 28" 17"

Hearth Heater (H2100M) 20.0" -- --

Two faceplates are available to seal the fi replace opening:

Standard Oversize

Small (I1100S)

36"W x 26"H 39.875"W x 30"H

Large (I3100L)

44"W x 32"H 50"W x 34.5"H

Hearth Heater (H2100M)

40 1/4"W x 30"H 48"W x 33"H

INSTALLING YOUR

INSERT

Your insert is very heavy and will require two

or three people to move it into position. The

insert can be made a little lighter by removing

the cast iron door by opening it and lifting it

off its hinges. Be sure to protect your hearth

extension with a heavy blanket or carpet scrap

during the installation.

Convection Grills for

I3100L

The convection grills are installed before the

unit is positioned inside the fi replace.

Regency Wood Insert & Hearth Heater6

Page 7

INSTALLATION

Position the grill on the inside bodyface side and

fasten using the bolts, washers and nuts provided

(2 per side) as shown in the diagrams.

Note: The grill has a front and rear, the holes

on the front side have rounded edges

and the rear holes have fl at edges.

View from Rear of Insert

OPTIONAL FLUE

CONNECTOR KIT

The optional Flue Connector Kit (Part # 846-527)

and the Straight Flue Adaptor (Part #846-504)

shown here, may be used to produce a secure

connection between your fl ue connector and the

insert collar. Detailed installation instructions are

included with the kit.

MASONRY AND FACTORY BUILT FIREPLACE CLEARANCES

The minimum required clearances to combustible materials when installed into a masonry or factory built fi replace are listed below.

Adjacent Mantle** Top Side Minimum Minimum Minimum

Unit Side Wall (to Top) Facing Facing Hearth Hearth Hearth Side

(to Side) (to Top) (to Side) Extension* Thickness* Extension

A B C D E F G

Small Flush

Insert (I1100S) 15"/380mm 20"/510mm 14"/355mm 7.375"/187mm 16"/406mm 1.5"/38mm 8"/205mm

Large Flush

Insert (I3100L) 13"/330mm 19"/480mm 18"/455mm 6.5"/165mm 16"/406mm 1.5"/38mm 8"/205mm

Hearth Heater

(H2100M) 10"/255mm 25"/635 mm 14"/355mm 8.5"/216mm 18"/455mm 1.5"/38mm 6"/152mm

Side and Top facing is a maximum of 1.5"

thick.

Floor protection must non-combustible, insulative material with an R value of 1.1 or greater.

* If the hearth extension is fl ush with the fl oor

(F) it must extend 19.5" in front of the body

face (E).

Note: Hearth Extension Width (G) is meas-

ured from edge of fuel door to side

of hearth.

** A non-combustible mantel may be in-

stalled at a lower height if the framing

is made of metal studs covered with a

non-combustible board.

Clearance diagram for installations

Regency Wood Insert & Hearth Heater 7

Page 8

INSTALLATION

LEG OPTION ON H2100

HEARTH HEATER

The addition of legs to the Hearth Heater does

not alter its certifi cation, it does not become a

freestanding woodstove. The H2100 can only

be installed as a Hearth Heater i.e. vented into

a masonry or factory built fi replace.

The instructions below apply to the steel leg,

painted cast leg and the gold plated cast leg.

It will be easier to attach the legs to the stove

if it is tipped on its back (preferably on a soft

surface to prevent scratching).

1) Thread the bolt and washer through the

leg, and then into the nutsert in the base

of the stove and tighten.

2) Level the stove by adjusting the levelling

bolts in the bottom of each leg.

INSTALLATION INTO A

MASONRY FIREPLACE

When referencing installation or connection to masonry fi replaces or chimneys, the

masonry construction must or shall be code

complying.

The insert must be installed as per the requirements of your local inspection authority. Three

methods of fl ue connection are acceptable in

most areas, these include:

1) Positive fl ue connection, where a large

blocking plate and a short connector pipe

is used.

2) Direct fl ue connection, where a smaller

blocking plate and a connector pipe to the

fi rst fl ue liner tile is used.

3) Full fl ue liner, where a stainless steel rigid

or fl exible liner pipe is routed from the insert

outlet collar to the top of the chimney.

Regency highly recommends the use of a full

liner as the safest installation and provides the

most optimum performance. Your retailer should

be able to help you decide which system would

be the best for your application.

In Canada this fi replace insert must be installed with a continuous chimney liner of 6"

diameter extending from the fi replace insert

to the top of the chimney. The chimney liner

must conform to the Class 3 requirements

of CAN/ULC-S640, Standard for Lining Systems for New Masonry Chimneys.

Note: A clean-out door is sometimes

required, by your inspector, to be

installed when either the Positive fl ue

connection or Direct fl ue connection

method is used.

The use of one of the connection methods listed

on this page not only increases the safety of your

insert by directing the hot gases up the fl ue, but

will also help increase the unit's effi ciency and

decrease creosote deposits in the chimney.

When a connected fl ue or liner is in use, the

insert is able to “breathe” better by allowing a

greater draft to be created. The greater draft can

decrease problems such as, diffi cult start-ups,

smoking out the door, and dirty glass.

INSTALLATION INTO A

FACTORY BUILT

FIREPLACE

NOTE: Adding the

legs changes the

height of the unit,

make sure you have

sufficient clearance

(min. 28") for your fl ue

connection.

FLUE CONNECTOR

BRACKET

Package contains: 3 brackets and 6 screws.

These brackets are to be used to hold the fl ue

liner (not supplied) to the Insert and keep the

connection. The brackets are screwed into the

top of the Insert in the pre-punched holes and

then screwed into the fl ue liner.

1) Positive Flue

Connection

with Cleanout

3a) Full Flue Liner

(No Cleanout

Required)

2) Direct Flue

Connection

with Cleanout

3b) Hearth Heater with

Full Flue Liner

(No Cleanout

Required)

1) When installed in a factory built fi replace, a

full stainless steel rigid or fl exible fl ue liner

is mandatory, for both safety and performance purposes. When a fl ue or liner is in

use, the insert is able to breathe better by

allowing a greater draft to be created. The

greater draft can decrease problems such

as, diffi cult start-ups, smoking out the door,

and dirty glass.

2) In order to position the fl ue liner, the exist-

ing rain cap must be removed from your

chimney system. In most cases the fl ue

damper should also be removed to allow

passage of the liner.

3) In most cases opening the existing spark

screens fully should give enough room for

the insert installation. If it does not, remove

and store.

Regency Wood Insert & Hearth Heater8

Page 9

INSTALLATION

4) If the fl oor of your fi replace is below the

level of the fi replace opening, adjust the

insert's levelling bolts to accommodate the

difference. When additional shimming is

required, use non-combustible masonry or

steel shims.

5) Measure approximately the alignment of

the fl ue liner with the position of the smoke

outlet hole on the insert to check for possible offset. If an offset is required, use a

proper stainless steel unit available with

the chimney liner.

Flush Inserts Hearth Heater

3) Attach the assembled faceplate to the

faceplate mounting brackets.

Diagram 2: I1100S

Rear View

B) H2100M and I3100L Insert

Diagram 4:

H2100M and I3100L

Faceplate Assembly

6) Once the above items have been checked,

slide your insert into position after fi rst positioning the fl ue liner and offset if required.

(Re-install raincap at completion of installation).

FACEPLATE AND TRIM

Prior to sliding your insert into its fi nal position

and attaching the connector or liner pipe, the

faceplate side panel plates must be installed

as follows:

A) I1100S Small Insert

1) Fasten the faceplate mounting bracket to the

side of the insert (one on each side) using

the screws provided (2 screws per bracket)

(refer to Diagram 1).

2) Assemble the faceplate sides and top with

4 screws (see Diagram 2).

Diagram 3: I1100S

1) Slide the spring nuts (supplied) over the

slots in the insert’s side convection panels

(the spring nuts may need to be squeezed

with a pair of pliers fi rst, to help them stay

in position).

2) Screw the side faceplate panels, (item A in

Diagram 4) one to each side.

3) Using the top panel (item B in the diagram)

as a gauge, check that the side panels are

within approximately 1/4" of the overall width.

If the difference is greater than this, use

the supplied washers to attain the required

width.

C) All units

The unit may now be slid into fi nal position and

attached to the connection system.

Once connection is made, the insulation strips

should be installed between the insert faceplates

and the fi replace face. The faceplate top may

now be installed (with insulation strip behind)

by aligning its brackets with the top fl ange on

the side shields and the angle iron bar on the

insert top. The faceplate trim may be installed

to the edge of the faceplate at this time.

I1100S: Drill two 5/32" diameter holes through

the trim and side panels and screw the trim to the

panels using the gold plated screws provided.

Note: It may be easier to install the insula-

tion, faceplate top and faceplate trim

with the unit pulled slightly away from

the fi replace face. If this is done, be

very careful not to disturb the connector when shifting the unit to its

fi nal position.

Now that your insert is installed, check once

more that all the clearances from the unit to

any combustible materials are correct as listed

earlier.

Diagram 1: I1100S

Regency Wood Insert & Hearth Heater 9

Page 10

INSTALLATION

FAN / BLOWER

Your fan should only be installed once the unit is

in place in order to prevent any damage to the

fan. To attach, follow the instructions provided

with the fan. Make sure to install the rubber

grommet to the fan housing before it is installed

on the insert.

1) Remove the protective covering from the

brass trim on the fan.

2) Align the fan support with the offset clip on

the bottom of the ashlip.

Thermo Switch Sensor

3) Slide the supports into the clips. The tension

holding the clips in place may be adjusted by

increasing or decreasing the offset spacing

of the clips.

4) Ensure that the power cord is not in contact

with any hot stove surfaces.

5) Push the Regency logo plate into the two

holes in the front bottom left corner of the

fan.

Thermo Switch Sensor

Do not turn fan ON until your insert has

reached operating temperature or at least

30 minutes after starting fi re.

CAUTION: Label all wires prior

to disconnection when servicing controls. Wiring errors can

cause improper and dangerous

operation.

WARNING:

Electrical Grounding Instructions

This appliance is equipped with a

three pronged (grounding) plug for

your protection against shock hazard

and should be plugged directly into

a properly grounded three-prong

receptacle. Do not cut or remove the

grounding prong from this plug.

Neutral

120V AC

60 Hz

Fan Thermodisc

(normally open)

Live

Ground

Green

Black Black

Black

Manual/

Auto

Switch

Blower/Fan Wiring Diagram

Fan

Switch

High (Black)

Fan Fan

White

Low (Red)

Regency Wood Insert & Hearth Heater10

Ground

Page 11

INSTALLATION

FLOOR PROTECTION

Please check to ensure that your fl oor protection

and hearth will meet the standards for clearance

to combustibles. Your hearth extension must be

made from a non-combustible material.

FIREBRICK ASSEMBLY

Firebrick is included to extend the life of your

insert and radiate heat more evenly. Check to

see that all fi rebricks are in their correct positions and have not become misaligned during

shipping.

Small Insert (I1100S)

BRICK FLUE BAFFLE &

SECONDARY AIR TUBE

INSTALLATION

The fl ue baffl e system located in the upper area

of the fi rebox is removable to make cleaning

your chimney system easier. The brick baffl es

must be installed prior to your fi rst fi re. Smoke

spillage and draft problems may occur if the

baffl es are improperly positioned. Check the

position of the brick baffl es on a regular basis as

they can be dislodged if too much fuel is forced

into the fi rebox.

The Large Insert I3100L is shipped with one of

the secondary air tubes loose inside the fi rebox.

It needs to be installed after the brick baffl e are

installed. Follow the directions below.

Large Insert I3100L

The unit arrives with the third air tube (from the

front) and the 2 baffl e bricks on the fl oor of the

fi rebox. The baffl e bricks are positioned fi rst and

then the air tubes are installed.

1) Slide the left baffl e brick over the two rear

air tubes and then push it all the way to the

left side of the fi rebox.

3) Important: push both baffl e bricks so

they are tight against the side walls.

Front View

4) Install the third air tube into the holes on the

side channels. The notch goes on the right

hand side with the air holes facing forward

toward the door opening. If the tube will not

slide in easily, simply use a pair of vise grips

or pliers and tap it into place with a hammer.

A tighter fi t will ensure the tube will not move

when the unit is burning.

Large Insert (I3100L)

Note: When cleaning the chimney reverse

the above procedures, removing

Hearth Heater (H2100M)

2) Tilt the fi rst Baffl e Brick down and then slide

the 2nd Baffl e Brick up and back. Reposition

both baffl e bricks fl at on the air tubes.

the air tube and baffl e bricks and

then replace them when cleaning is

completed.

DOOR HANDLE

Attach spring handle by rotating counter clockwise onto rod. Ensure that the rod fi ts into the

entire length of the spring handle.

Regency Wood Insert & Hearth Heater 11

Page 12

INSTALLATION

Small Insert I1100S

1) If the two air tubes are installed continue on

to Step 2), if not, follow the instructions below.

Install the air tube into the holes in the side

channels. The notch goes on the right hand

side with the air holes facing toward the door.

Slide the tube into the left hand side, as far

as possible and then bring it back into the

hole on the right hand side until it locks into

position. If the tube will not slide in easily

simply use a pair of vise grips or pliers and

tap it into place with a hammer. A tighter fi t

will ensure the tube will not move when the

unit is burning. There are only two air tubes

in the small units (refer to the diagram in the

Large Insert I3100L section).

2) Slide the left baffl e brick over the front air

tube and then slide it back over the rear air

tube.

Hearth Heater (H2100M)

Steel Baffl e

Place the insulation batt on top of the baffl e.

Make sure that this batt is laying fl at and does

not obstruct the smoke from getting up the fl ue

opening. This insulating batt may be wrapped

in paper for handling purposes and does not

require removal. Batt hold down weights are

supplied with the unit and are to be placed on

the insulation to either side of the fl ame spreader

as shown in the diagram and at the rear, directly

in front of the fl ue opening.

Lift the front end of the baffl e up and over

the rear of the

air tube. On

Hearth Heater

(H2100M) remove center

tube by sliding it sideways

fi rst and then

down.

Pull Open Push Closed

As well as a primary and glass wash air system,

the unit has a full secondary draft system that

allows air to the induction ports at the top of

the fi rebox, just below the fl ue baffl e.

WARNING: To build a fi re in ignorance or to

disregard the informa tion contained in this

section can cause serious permanent damage to the unit and void your warranty.

SCREEN DOOR

Hook screen to the inside on the right side

of the fi rebox door opening. Lock in place by

turning handle.

Side View

3) Tilt the left baffl e brick up on top of the side

channel and it will leave enough room to

position the right baffl e brick in the same

manner as Step 1) above. Then reposition

the left baffl e brick fl at on the air tube.

Front View

4) Important: push both baffl e bricks so

they are tight against the side walls.

Front View

Note: When getting the chimney cleaned,

remove the baffl e bricks for access

to the fl ue, then replace them when

cleaning is completed.

Lift the rear of the baffl e, pivoting it on the air

tube, until it clears the rear air channel.

Slide the rear of the baffl e on top of the rear

air channel in front of the locating tabs. Make

sure that the insulation is lying fl at and does

not obstruct the smoke from getting up the fl ue

opening. Place hold down weights on top of

the insulation - one on each side.

DRAFT CONTROL

Before establishing your fi rst fi re, it is important

that your fully understand the operation of you

draft control. The draft rod is on the left side of

the Inserts and it controls the intensity of the fi re

by increasing or decreasing the amount of air

allowed into the fi rebox. To increase your draft

- pull open, and to decrease - push closed.

Hooks

Back Side of Screen Shown

NOTE: The handle must be positioned at 10

o'clock when closed to avoid the handle from

getting hot and to ensure the screen stays in

place.

Handle at 10 o'clock position.

Handle Lock

WARNING

Fireplace Stoves equipped with doors

should be operated only with doors

fully closed. If doors are left partly

open, gas and fl ame may be drawn out

of the fi replace stove opening, creating risks from both fi re and smoke.

When operated with doors open the

manufacturer supplied screen must

be used.

Regency Wood Insert & Hearth Heater12

Page 13

OPERATING INSTRUCTIONS

FIRST FIRE

When your installation is completed and inspected, you are ready for your fi rst fi re.

1) Open draft control fully.

2) Open fi rebox door and build a small fi re using

paper and dry kindling, wait a few minutes

for a good updraft in the fl ue to establish the

fi re. Leaving the door slightly open will help

your fi re start more rapidly.

CAUTION: Never leave unit unattended if door is left open. This

procedure is for fi re start-up only,

as unit may over-heat if door is left

open for too long.

3) With the draft still in the fully open position,

add two or three seasoned logs to your fi re.

Form a trench in the ash bed to allow air to

reach the rear of the fi rebox prior to closing

the door.

4) After about 15 to 20 minutes, when your

wood has begun to burn strongly, adjust

your draft control down to keep the fi re at a

moderate level.

WARNING: Never build a roaring

fi re in a cold stove. Always warm

your stove up slowly!

5) Once a bed of coals has been established,

you may adjust the draft control to a low

setting to operate the unit in its most effi cient

mode.

6) During the fi rst couple of hours, keep the

combustion rate at a moderate level and

avoid a large fi re until the paint is cured.

Only then can you operate the insert at its

maximum setting, and only after the metal

has been warmed.

7) For the fi rst few hours, the insert will give

off an odour from the paint. This is to be

expected as the high temperature paint

becomes seasoned. Windows and/or doors

should be left open to provide adequate

ventilation while this temporary condition

exists. Burning the insert at a very high

temperature the fi rst few times may damage

the paint. Burn fi res at a moderate level the

fi rst few days.

8) Do not place anything on the insert top

during the curing process. This may result

in damage to your paint fi nish.

9) During the fi rst few hours it may be more dif-

fi cult to start the fi re. As you dry out your fi re

brick and your masonry fl ue (if applicable),

your draft will increase.

10) For those units installed at higher elevations

or into sub-standard masonry fi replaces,

drafting problems may occur. Consult an

experienced dealer or mason on methods

of increasing your draft.

11) Some cracking and popping noises may be

experienced during the heating up process.

These noises will be minimal when your unit

reaches temperature.

12) Before opening your door to reload, open

draft fully for approximately 10 to 15 seconds

until fi re has been re-established. This will

minimize any smoking.

13) All fuel burning appliances consume oxygen

during operation. It is important that you

supply a source of fresh air to your unit

while burning. A slightly opened window is

suffi cient for this purpose.

CAUTION: If the body of your unit

(or in the H2100M fl ue baffl e) starts

to glow you are overfi ring. Stop

loading fuel immediately and close

the draft control until the glow has

completely subsided.

14) Green or wet wood is not recommended for

your unit. If you must add wet or green fuel,

open the draft control fully until all moisture

has been dispersed by the intense fi re.

Once all moisture has been removed, the

draft control may be adjusted to maintain

the fi re.

15) If you have been burning your insert on a low

draft, use caution when opening the door.

After opening the damper, open the door

a crack, and allow the fi re to adjust before

fully opening the door.

16) The controls of your unit should not be altered

to increase fi ring for any reason.

FAN OPERATION

(ALL UNITS)

The fan is to be operated only with the draft

control rod pulled out at least 1/2" from the

fully closed position. The fan is not to be

operated when the draft control rod is in the

closed position (pushed in). The fully closed

position is the low burn setting.

The fan unit must not be turned on until a fi re

has been burning for at least 30 minutes and

the unit is hot enough. As well, after each fuel

loading the fan must be shut off until 30 minutes

has elapsed.

To operate fan automatically, push switch on

side of fan housing to "Auto" and second switch

to either "High" or "Low" for fan speed. The

automatic temperature sensor will engage the

blower when the unit is at temperature and will

shut off the blower once the fi re has gone out

and the unit has cooled to below a useful heat

output range.

To manually operate the fan system, push the

fi rst switch to "Man" and second switch to either

"high" or "Low". This will bypass the sensing

device and allow full control of the fan. Switching from "Auto" to "Manual" or "High" to "Low"

may be done at any time.

ASH DISPOSAL

During constant use, ashes should be removed

every few days. Please take care to prevent the

build-up of ash around the start-up air housing

located inside the fi rebox, under the loading

door lip.

DO NOT ALLOW ASHES TO BUILD UP TO

THE LOADING DOORS.

Only remove ashes when the fi re has died down.

Even then, expect to fi nd a few hot embers.

Always leave 1 to 2 inches of ash in the bottom

of the fi rebox. This helps in easier starting and

a more uniform burn of your fi re.

Ashes should be placed in a metal container with

a tight fi tting lid. The closed container of ashes

should be placed on a noncombustible fl oor or

on the ground, well away from all combustible

materials, pending fi nal disposal. If the ashes

are disposed of by burial in soil or otherwise

locally dispersed, they should be retained in the

closed container until all cinders have thoroughly

cooled. Other waste should not be placed in

the ash container.

SOME SAFETY

GUIDELINES

1) Never use gasoline, gasoline type lantern

fuels, kerosene, charcoal lighter fuel, or

similar liquids to start or ‘freshen up’ a fi re

in your heater. Keep all such liquids well

away from the heater while it is in use.

2) Keep the door closed during operation and

maintain all seals in good condition.

3) Do not burn large quantities of paper in your

insert.

4) If you have smoke detectors, prevent smoke

spillage as this may set off a false alarm.

5) Do not overfi re your insert. If the insert or its

fl ue baffl e begin to glow, you are overfi ring.

Stop adding fuel and close the draft control.

Overfi ring can cause extensive damage to

your stove including warpage and premature

steel corrosion. Overfi ring will void your

warranty.

Regency Wood Insert & Hearth Heater 13

Page 14

MAINTENANCE

6) Do not permit creosote or soot buildup in the

chimney system. Check and clean chimney

at regular intervals.

7) Your Regency Insert can be very hot. You

may be seriously burned if you touch the

insert while it is operating. Warn children of

the burn hazard.

8) The insert consumes air while operating,

provide adequate ventilation with an air

duct or open a window while the insert is

in use.

9) Do not use grates, irons or other methods

for supporting fuel. Burn directly on the

bricks.

10) Open the draft control fully for 10 to 15

seconds prior to slowly opening the door

when refuelling the fi re.

11) Do not connect your unit to any air distribu-

tion duct.

12) Your insert should burn dry, standard fi re-

wood only. The use of “mill ends” is discouraged as this fuel can easily overheat your

insert. Evidence of excessive overheating

will void your warranty. As well, a large

portion of sawmill waste is chemically

treated lumber, which is illegal to burn in

many areas. Chemically treated fi re logs

also must not be burned in your insert.

13) Do not store any fuel closer than 2 feet from

your unit.

14) Do not burn salt drift wood as it will corrode

your unit and void the warranty.

15) Do not operate the unit if the glass is broken

or missing. Do not operate the unit if the

gasketing is worn out and not sealing the

door or the glass.

It is very important to carefully maintain your

insert, including burning seasoned wood and

maintaining a clean stove and chimney system.

Have the chimney cleaned before the burning

season and as necessary during the season, as

creosote deposits may build up rapidly. Moving

parts of your insert require no lubrication.

CREOSOTE

When wood is burned slowly, it produces tar and

other organic vapors, which form creosote when

combined with moisture. The creosote vapors

condense in the relatively cool chimney fl ue of a

slow-burning fi re. As a result, creosote residue

accumulates on the fl ue lining. When ignited, this

creosote can make an extremely hot fi re.

Removal for Cleaning etc.

Removal of your insert for cleaning purposes

is usually not required if a proper installation

has been done. In the event that removal is required, be sure not to damage any parts needed

for re-installation. In most cases removal and

replacement of the baffl e system should allow

full access for cleaning.

WARNING: Things to remember in case

of chimney fi re:

1) Close draft control

2) Call the Fire Department

Ways to Prevent and

Keep Unit Free of Creosote

1) Burn insert with draft control wide open for

about 15 minutes every morning during burning season. This helps to prevent creosote

deposits within the heating system.

2) Burn insert with draft control wide open for

about 10 - 15 minutes every time you add

fresh wood. This allows the wood to achieve

the charcoal stage faster and burns up any

wood vapors which might otherwise be

deposited within the system.

3) Only burn seasoned wood! Avoid burning

wet or green wood. Seasoned wood has

been dried at least one year.

4) A small hot fi re is preferable to a large

smouldering one that can deposit creosote

within the system.

5) Check the chimney at least twice a month

during the burning season for creosote

build-up.

6) Have chimney system and unit cleaned by

competent chimney sweeps twice a year

during the fi rst year of use and at least once

a year thereafter or when needed.

MAINTENANCE OF

GOLD-PLATED DOORS

The gold electroplated fi nish on the doors

requires little maintenance, and need only be

cleaned with a damp cloth. DO NOT use abrasive

materials or chemical cleaners, as they may

harm the fi nish and void the warranty.

DOOR GASKET

If the door gasket requires replacement, 7/8"

diameter material must be used. A proper high

temperature gasket adhesive is required. A

gasket repair kit, Part # 846-570 is available

from your local Regency dealer.

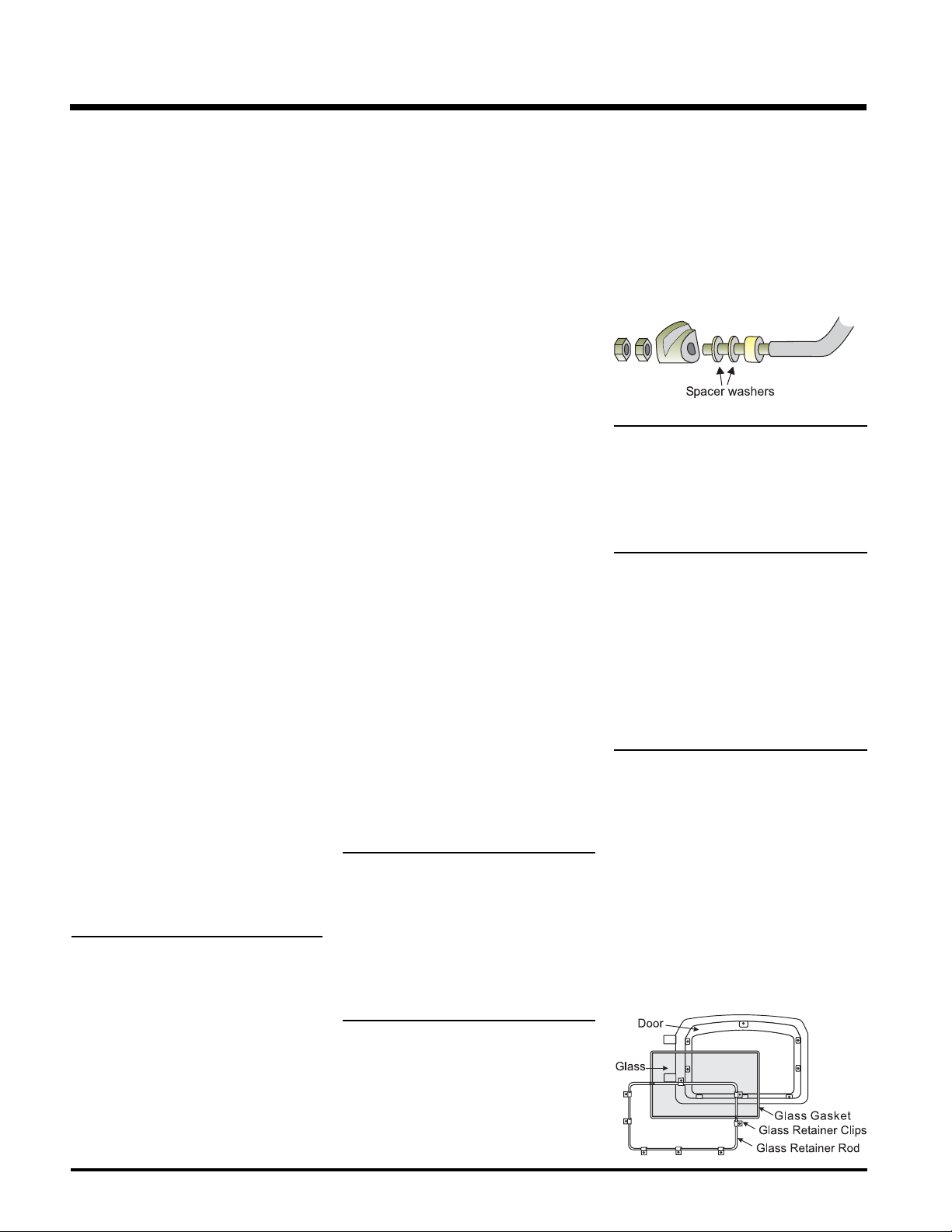

DOOR LATCH

ADJUSTMENT

The door latch may require adjustment as the

door gasket material compresses after a few

fi res. Removal of the spacer washer, shown

in the diagram below, will allow the latch to

be moved closer to the door frame, causing

a tighter seal. Remove and replace the nuts,

washer as shown.

GLASS CLEANING

Only clean your glass window when it is cool.

Your local retailer can supply you with special

glass cleaner if plain water and a soft cloth does

not remove all deposits.

GLASS

REPLACEMENT

Your Regency Insert is supplied with 5 mm.

Neoceram ceramic glass that will withstand

the highest heat that your unit will produce. In

the event that you break your glass by impact

- purchase your replacement from an authorized

Regency dealer only, and follow our step-by-step

instructions.

GLASS REMOVAL

Allow the stove to cool before removing or replacing glass. Remove the door from the insert and

remove the glass retainer. Use caution when

removing broken glass to prevent injury.

When placing the replacement glass in the

door, make sure that the glass gasketing will

properly seal your unit. Replace the retainer

and tighten securely, but do not wrench down

on the glass as this may cause breakage. Do

not substitute materials. If your glass door does

break, do not continue to use your unit until it

has been replaced.

Regency Wood Insert & Hearth Heater14

Page 15

I1100 & I3100 MAIN ASSEMBLY

Part # Description

846-913 Door Assembly-Small Gold (I1100)-no glass

846-915 Door Assembly-Small Black (I1100)-no glass

846-910 Door Assembly-Large Gold (I3100)-no glass

846-916 Door Assembly-Large Black (I3100)-no glass

2) 846-302 Glass - Replacement - (I1100)

3) 846-304 Glass - Replacement - (I3100)

4) 936-243 7/8" Adhesive Tape Gasket

5) 846-920 Glass Retainer Clips (set of 8)

6) * Screw 1/4-20 x 3/8"

7) 948-172/P Glass Retainer - Large (I3100)

8) 948-170/P Glass Retainer - Small (I1100)

9) 846-973 Door Handle Assembly

16) 846-570 Med. Density Door Gasket Kit

17) 846-918 Hinge Caps (2/set)

19) 948-101 Spring Handle - Large

20) 948-102 Spring Handle - Small

23) 820-235 Flue Brackets (Pkg)

163-915 I3100L Fan/Blower Assembly

170-915 I1100S Fan/Blower Assembly

24) 910-157/P Blower/Fan Motor

25) 910-678 Power Cord (120 Volts)

27) 910-142 Fan Thermodisc

28) 910-140 Fan Speed Switch

HI/OFF/LOW (3-way)

29) 910-138 Switch - Auto/Manual (2-way)

30) * Grommet Strain Relief

PARTS LIST

35) 063-954 Air Tube - 1" I3100 (Qty:1)

074-954 Air Tube - 1" I1100 (Qty: 1)

36) 033-953 Air Tube - 3/4" I1100 (Qty: 1)

063-953 Air Tube - 3/4" I3100 (Qty: 3)

37) 063-955 Baffl e (2/set) I3100

38) 073-955 Baffl e (2/set) I1100

42) 163-932 Convection Grill-Gold (I3100)

163-930 Convection Grill-Black (I3100)

43) * Hex Nut 10-24 Zinc coated

44) * Washer #10 Flat

45) * Bolt, 10-24 x 3/4" Black Carriage

47) 846-101 I1100 Wood Screen

846-103 I3100 Wood Screen

948-216 Regency Logo

908-332 Manual

*Not available as a replacement part.

Regency Wood Insert & Hearth Heater 15

Page 16

PARTS LIST

I1100 & I3100 FACEPLATES

Part # Description

Faceplate: I3100L

163-910 Faceplate & Trim Set - Regular

385) 163-165 Trim Right Regular

386) 163-160 Trim Top Regular

387) 163-161 Trim Left Regular

388) * Faceplate Side Regular

389) * Faceplate Top Regular

163-912 Faceplate & Trim Set - Oversize

395) 163-164 Trim Right Oversize

396) 163-162 Trim Top Oversize

397) 163-163 Trim Left Oversize

398) * Faceplate Side Oversize

399) * Faceplate Top Oversize

Part # Description

Faceplate: I1100S

170-911 Faceplate & Trim Set - Regular

185) 170-160 Trim Right Regular

186) 170-159 Trim Top Regular

187) 170-162 Trim Left Regular

183) * Faceplate Right Side Regular

188) * Faceplate Left Side Regular

189) * Faceplate Top Regular

170-913 Faceplate & Trim Set - Oversize

195) 143-161 Trim Right Oversize

196) 170-168 Trim Top Oversize

197) 143-160 Trim Left Oversize

194)* Faceplate Right Side

Oversize

198)* Faceplate Top Oversize

199)* Faceplate Left Side Oversize

*Not available as a replacement part.

Regency Wood Insert & Hearth Heater16

Page 17

H2100 MAIN ASSEMBLY

Part # Description Part # Description

1) 846-910 Door Assembly-Large Gold - no glass

846-916 Door Assembly-Large Black - no glass

3) 846-304 Glass - Replacement

4) 936-243 7/8" Adhesive Tape Gasket

5) 846-920 Glass Retainer Clips (set of 8)

6) * Screw 1/4-20 x 3/8"

7) 948-172/P Glass Retainer - Large

9) 846-973 Door Handle Assembly

16) 846-570 Med. Density Door Gasket Kit

17) 846-918 Hinge Caps (2/set)

19) 948-101 Spring Handle - Large

20) 948-102 Spring Handle - Small

37) 836-212 Baffl e Insulation

38) * Insulation Weights

39) 120-950 Steel Baffl e

948-216 Regency Logo

Faceplate: H2100M

120-910 Faceplate & Trim Set - Regular

485) 120-161 Trim Right Regular

286) 143-158 Trim Top Regular

487) 120-162 Trim Left Regular

488)* Faceplate Side Regular

489) * Faceplate Top Regular

PARTS LIST

120-915 H2100M Fan/Blower Assembly

24) 910-157/P Blower/Fan Motor (120 Volts)

25) 910-678 Power Cord (120 Volts)

27) 910-142 Fan Thermodisc

28) 910-140 Fan Speed Switch HI/OFF/LOW (3-way)

29) 910-138 Switch - Auto/Manual (2-way)

30) * Grommet Strain Relief

35) 120-954 Air Tube Front

36) 120-953 Air Tube Rear

120-912 Faceplate & Trim Set - Oversize

585) 120-164 Trim Right Oversize

286) 120-163 Trim Top Oversize

587) 120-165 Trim Left Oversize

588)* Faceplate Side Oversize

589) * Faceplate Top Oversize

846-532 Trim Clips

836-300 Yellow Insulation 48" x 4"

846-531 Faceplate Hardware Pkg.

*Not available as a replacement part.

Regency Wood Insert & Hearth Heater 17

Page 18

PARTS LIST

I1100, I3100 & H2100 FIREBRICK

Part # Description

70) 902-111 Brick Regular Full Size: 1-1/4" x 4-1/2" x 9"

71) 802-104 Brick Partial: 1-1/4" x 4" x 9"

72) 802-146 Brick Partial: 1-1/4" x 1-3/4" x 9"

75) 802-139 Brick Partial: 1-1/4" x 4" x 8-3/4"

76) 802-152 Brick Partial: 1-1/4" x 2" x 9"

78) 802-143 Brick Partial: 1-1/4" x 2-1/4" x 2-1/4"

81) 802-135 Brick Partial: 1-1/4" x 1-1/4" x 9"

84) 802-107 Brick Partial: 1-1/4" x 4-1/2" x 8"

85) 802-156 Brick Partial: 1-1/4" x 4-1/4" x 8"

Regency Wood Insert & Hearth Heater18

Page 19

WARRANTY

Regency Fireplace Products are designed with reliability and simplicity in mind. In addition, our internal Quality Assurance Team carefully inspects

each unit thoroughly before it leaves our door. FPI Fireplace Products International Ltd. is pleased to extend this limited lifetime warranty to the

original purchaser of a Regency Product. This warranty is not transferable.

The Warranty: Lifetime

Covered under the agreement are the following components:

Firebox, ceramic baffl e, vermiculite baffl e, steel baffl es (H2100), convector airmate, castings, ashdrawer, glass (thermal breakage), gold plating (against

defective manufacture), airtubes (against warpage) and door handles.

The above will be covered for parts and subsidized labour for the fi rst fi ve years and parts only thereafter with the exception of the fi reboxes (see below).

FPI is not liable for freight or labor on any wood burning appliance replaced in fi eld.

Electrical components such as blowers, switches and thermodisc's are covered for two years parts and one year subsidized labour* from date of purchase.

Repair/replacement parts purchased by the consumer from FPI after the original coverage has expired on the unit will carry a 90 day warranty, valid with a

receipt only. Any item shown to be defective will be repaired or replaced at our discretion. No labor coverage is included with these parts.

Conditions:

Any part or parts of this unit which in our judgement show evidence of such defects will be repaired or replaced at FPI's option, through an accredited distributor or agent provided that the defective part be returned to the distributor or agent Transportation Prepaid, if requested.

It is the general practice of FPI to charge for larger, higher priced replacement parts and issue credit once the replaced component has been returned to FPI

and evaluated for manufacturer defect.

The authorized selling dealer is responsible for all in-fi eld service work carried out on your Regency product. FPI will not be liable for results or costs of

workmanship from unauthorized service persons or dealers.

At all times FPI reserves the right to inspect product in the fi eld which is claimed to be defective.

All claims must be submitted to FPI by authorized selling dealers. It is essential that all submitted claims provide all of the necessary information including

customer name, purchase date, serial #, type of unit, problem, and part or parts requested, without this information the warranty will be invalid.

Exclusions:

This limited Lifetime Warranty does not extend to or include paint, door or glass gasketing, fi rebrick or trim. It does not cover installation and operational related

problems such as over-fi ring, use of corrosive driftwood, downdrafts or spillage caused by environmental conditions, nearby trees, buildings, hilltops, mountains,

inadequate venting or ventilation, excessive offsets, negative air pressures caused by mechanical systems such as furnaces, fans, clothes dryers etc.

At no time will FPI be liable for any consequential damages which exceed the purchase price of the unit. FPI has no obligation to enhance or modify any unit

once manufactured. ie. as products evolve, fi eld modifi cations or upgrades will not be performed.

FPI will not be liable for travel costs for service work.

Installation and environmental problems are not the responsibility of the manufacturer and therefore are not covered under the terms of this warranty

policy.

Any unit which shows signs of neglect or misuse is not covered under the terms of this warranty policy.

The warranty will not extend to any part which has been tampered with or altered in any way, or in our judgment has been subject to misuse.

Freight damage to stoves and replacement parts is not covered by warranty and is subject to a claim against the freight carrier by the dealer.

FPI will not be liable for acts of God, or acts of terrorism, which cause malfunction of the appliance.

Performance problems due to operator error will not be covered by this warranty policy.

Products made or provided by other manufacturers and used in conjunction with the operation of this appliance without prior authorization from FPI, may

nullify your warranty on this product.

* Subsidy according to job scale as predetermined by FPI.

Regency Wood Insert & Hearth Heater 19

Page 20

Regency fi replace products are designed

with reliability and simplicity in mind. In

addition, our internal Quality Assurance

Team carefully inspects each unit thor-

oughly before it leaves our door.

Fireplace Products International

Ltd. is pleased to extend this

Limited Lifetime Warranty to the

original purchaser of a Regency

Product.

See the inside back cover for details.

Register your Regency online at

http://www.regency-fi re.com

Installer: Please complete the following information

Dealer Name & Address: ______________________________________________

___________________________________________________________________

Installer: ___________________________________________________________

Phone #: ___________________________________________________________

Date Installed: ______________________________________________________

Serial No.: __________________________________________________________

Regency and Classic are trademarks of FPI Fireplace Products International Ltd.

© Copyright 2007, FPI Fireplace Products International Ltd. All rights reserved.

Printed in Canada

Printed in Canada

Loading...

Loading...