Page 1

Regency Horizon

™

HZ54E

Owners &

Installation Manual

Gas Fireplace

MODELS: HZ54E-NG1 Natural Gas

HZ54E-LP1 Propane

www.regency-fi re.com

WARNING:

If the information in these instructions are not followed exactly,

a fi re or explosion may result causing property damage,

personal injury or loss of life.

FOR YOUR SAFETY

Do not store or use gasoline or other fl ammable vapors and

liquids in the vicinity of this or any other appliance.

Installation and service must be performed by a qualifi ed

installer, service agency or the gas supplier.

919-269

Tested by:

FPI FIREPLACE PRODUCTS INTERNATIONAL LTD. 6988 Venture St., Delta, BC Canada, V4G 1H4

Installer: Please complete the details on the back cover

and leave this manual with the homeowner.

Homeowner: Please keep these instructions for future reference.

Horizon HZ54E Product Video

FOR YOUR SAFETY

What to do if you smell gas:

Do not try to light any appliance

Do not touch any electrical switch:

do not use any phone in your

building.

Immediately call your gas supplier

from a neighbour's phone. Follow

the gas supplier's instructions.

If you cannot reach your gas

supplier, call the fi re department.

09/30/13

Page 2

To the New Owner:

Congratulations!

You are the owner of a state-of-the-art Gas Fireplace by REGENCY®. The HZ54E has been

designed to provide you with all the warmth and charm of a wood fi replace at the fl ick of a switch.

The model HZ54E has been approved by Warnock Hersey/Intertek for both safety and effi ciency .

As it also bears our own mark, it promises to provide you with economy, comfort and security for

many trouble free years to follow. Please take a moment now to acquaint yourself with these

instructions and the many features of your Regency

®

Fireplace.

Regency Horizon

Gas Inserts Benefi ts Video

2

2

Horizon HZ54 Product Video

Regency Horizon HZ54E-1 Gas Fireplace

Page 3

MANUFACTURED MOBILE HOME REQUIREMENTS

INFORMATION FOR MOBILE/MANUFACTURED HOMES AFTER FIRST SALE

®

This Regency

standards: VENTED GAS FIREPLACE HEATERS ANSI Z21.88-2009 / CSA 2.33-2009 and GAS-FIRED APPLIANCES FOR

USE AT HIGH ALTITUDES CAN / CGA 2.17-M91.

This appliance may only be installed in an aftermarket permanently located, manufactured (U.S.A only) or mobile home,

where not prohibited by local codes.

This Direct Vent System Appliance must be installed in accordance with the manufacturer's installation instructions and the

Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280, or the current Standard of Fire Safety Criteria

for Manufactured Home Installations, Sites, and Communities ANSI/NFPA 501A, and with CAN/CSA Z240-MH Mobile Home

Standard in Canada.

This appliance installation must comply with the manufacturer's installation instructions and local codes, if any. In the absence

of local codes follow the current National Fuel Gas Code, ANSI Z223.1 and the current National Electrical Code ANSI/NFPA

70 in the U.S.A., and the current CAN/CGA B149 Gas Installation Code and the current Canadian Electrical Code CSA C22.1

in Canada.

This appliance comes equipped with a dedicated #8 Ground Lug for attachment of the ground wire to the steel chassis as

applicable to local codes.

The appliance, when installed, must be electrically grounded in accordance with local codes or, in the absence of local codes,

with the National Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.1.

product has been tested and listed by Warnock Hersey/Intertek as a Direct Vent Wall Furnace to the following

This appliance can only be used with the type of gas indicated on the rating plate.

This appliance is not convertible for use with other gases.

Ensure that structural members are not cut or weakened during installation.

This appliance may be installed as an OEM installation in a manufactured home (USA only) or mobile home and must be

installed in accordance with the manufacturer's instruction and the Manufactured Home Construction and Safety Standard,

Title 24 CFR, Part 3280, in the Untied States, or the Standard for Installation in Mobile Homes, CAN/CSA Z240 MH, in

Canada.

Regency Horizon HZ54E-1 Gas Fireplace

3

Page 4

TABLE OF CONTENTS

SAFETY LABEL

Copy of Safety Decal .....................................................5

REQUIREMENTS

MA Code - CO Detector.................................................6

DIMENSIONS

Unit Dimensions ............................................................7

INSTALLATION

Faceplate & Door frame overlay Dimensions ................7

Important Message ......................................................8

Before You Start ............................................................8

General Safety Information............................................8

Installation Checklist ......................................................9

Locating Your Gas Fireplace .........................................9

Heatwave Duct System .................................................9

Heat Release kit ............................................................9

Clearances ..................................................................10

Non-Combustible Requirements .................................10

Non combustible facing board .....................................11

Non combustible facing installation .............................11

Mantel Clearances.......................................................12

Mantel Leg Clearances................................................12

Framing & Finishing.....................................................13

Unit Assembly Prior To Installation ..............................15

Standoff Assembly ...............................................15

Nailing Strips ........................................................15

Venting Introduction .....................................................15

Vent Restrictor Position ...............................................16

Exterior Vent Termination Requirements .....................17

Venting Arrangements ................................................18

Horizontal Termination (Flex) ...............................18

Rigid Pipe Venting Systems ........................................19

Basic Horizontal & Vertical Terminations .............19

5” x 8” Rigid Pipe Cross Reference Chart ...................20

Venting Arrangements ................................................22

Allowable Horizontal Terminations for HZ54E-ng 22

Venting Arrangements ................................................22

Allowable Horizontal Terminations for HZ54E-lp .22

Venting Arrangements ................................................25

Allowable Vertical Terminations for HZ54E-ng .....25

Venting Arrangements ................................................26

Allowable Vertical Terminations for HZ54E-lp ......26

Unit Installation with Horizontal Termination ..........27

Unit Installation with Vertical Termination ....................28

Unit Installation ............................................................29

Horizontal Termination .........................................29

with Flex Vent System .........................................29

High Elevation .............................................................30

Gas Line Installation ....................................................30

Pilot Adjustment ...........................................................30

Gas Pipe Pressure Testing ..........................................30

886 S.I.T. Valve Description .........................................30

Valve cover removal ....................................................31

Aeration Adjustment ....................................................32

Wiring Diagram ............................................................32

AC power adaptor installation (for surefi re systems) ...33

Profl ame system GTMF with optional fan....................34

Optional fan Wiring Diagram ......................................35

Without ProFlame GTMF system ................................35

Optional Wall Thermostat ...........................................36

Optional Remote Control .............................................36

Wall Switch ..................................................................36

Battery & on | off switch installation ............................38

GT remote installation .................................................39

GTM remote installation ..............................................40

GTMF remote installation ............................................42

Optional Refl ective Panel Installation ..........................44

Glass Crystals or optional stones Installation ..............45

Optional Driftwood Log set Installation ........................47

Optional Log set Installation ........................................49

Faceplate & Door frame overlay Installation................52

Optional fan installation ...............................................54

OPERATING INSTRUCTIONS

Operating Instructions .................................................57

First Fire ......................................................................57

Lighting Procedure ......................................................57

Shutdown Procedure ...................................................57

Normal Operating Sounds of Gas Appliances .............57

Copy of Lighting Plate Instructions ..............................58

MAINTENANCE

Maintenance Instructions.............................................59

General Vent Maintenance ..........................................59

Glass Gasket ...............................................................59

Glass Door...................................................................59

Glass Replacement .............................................59

Glass Door Removal ...................................................60

V alve Tray Replacement ..............................................61

HZ54E-NG unit ............................................................62

HZ54E-LP unit .............................................................63

PARTS LIST

Main Assembly ............................................................64

Accessories .................................................................65

WARRANTY

The Warranty: Limited Lifetime ...................................67

4

Regency Horizon HZ54E-1 Gas Fireplace

Page 5

This is a copy of the label that accompanies

each HZ54E-NG and HZ54E-LP Direct Vent

Gas Fireplace. We have printed a copy of the

contents here for your review.

®

NOTE: Regency

units are constantly being

improved. Check the label on the unit and if

there is a difference, the label on the unit is the

correct one.

SAFETY LABEL

COPY OF SAFETY DECAL

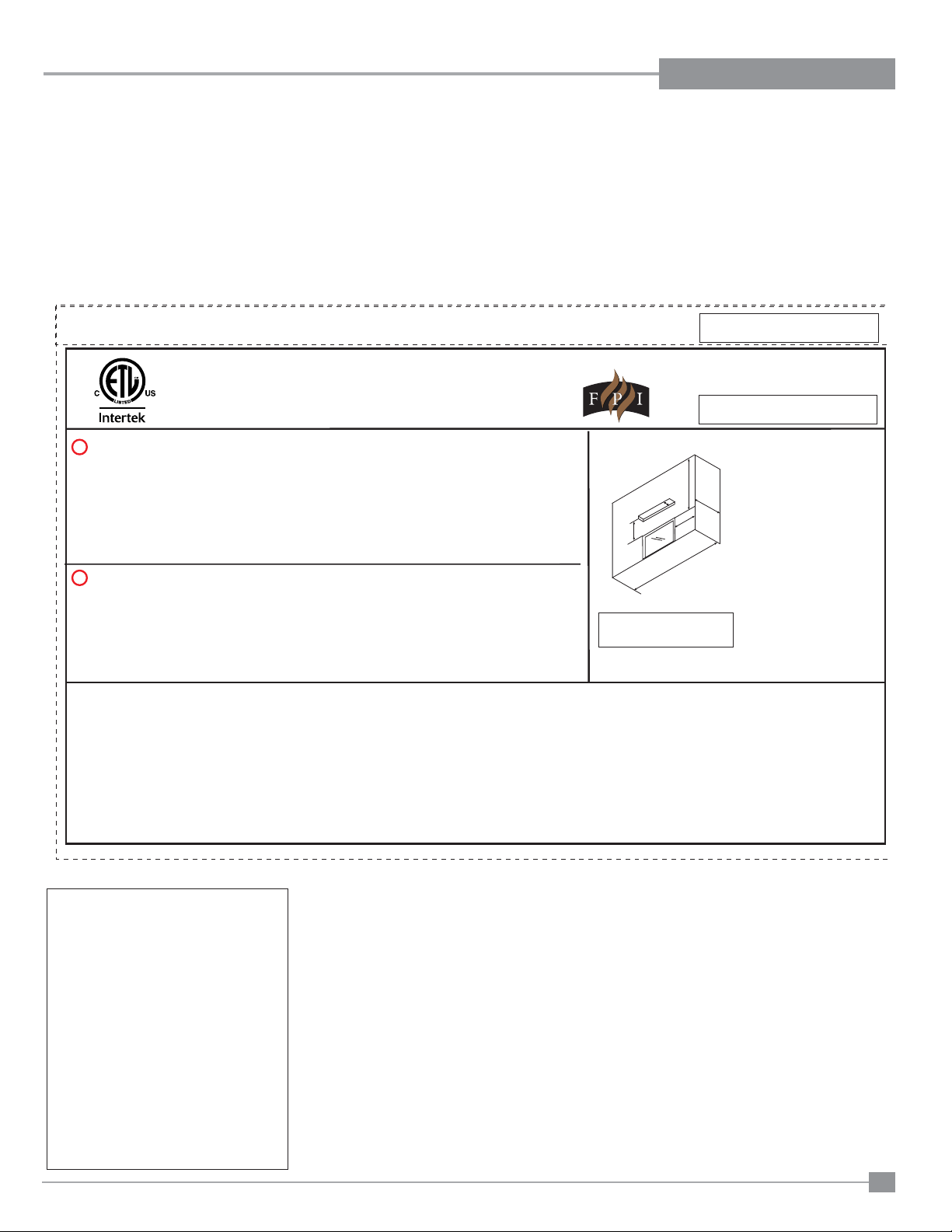

Duplicate S/N

Listed:

VENTED GAS FIREPLACE HEATER /

Certified for/Certifi e pour:

Tested to:

4001172

MAY BE INSTALLED IN MANUFACTURED (MOBILE) HOMES AFTER FIRST SALE.

NATURAL GAS: Model HZ54E-NG1

Min. Supply Pressure 5“ WC (1.25 kpa)

Low Setting Man. Pressure 1.6"WC (0.40 kpa)

Max. Manifold Pressure 3.5"WC (0.87 kpa)

Orifice Size #30DMS

Minimum Input 29,000Btu/h

Maximum Input 41,500 Btu/h (12.16 kW)

Altitude

PROPANE GAS: Model HZ54E-LP1

Min. Supply Pressure 12“WC (2.98 kpa)

Low Setting Man. Pressure 6.4"WC (1.59 kpa)

Max. Manifold Pressure 10"WC (2.49 kpa)

Orifice Size #49 DMS

Minimum Input 30,000Btu/

Maximum Input 37,000Btu/h (10.84 kW)

Altitude

This appliance must be installed in accordance with local codes, if any; if none, follow the National Fuel Gas Code, ANSI Z223.1, or Natural Gas and Propane Installation Code, CSA B149.1.

This appliancemust be installed inaccordance with theStandard CAN/CSAZ240 MH, MobileHousing, in Canada, orwith the Manufactured HomeConstruction and SafetyStandard, Title24 CFR, Part3280, in

the UnitedStates, orwhen such astandard isnot applicable,ANSI/NCSBCS A225.1/NFPA 501A, ManufacturedHome InstallationsStandard orANSI A119.2 ouNFPA501C Standard forRecreational Vehicles

This applianceis only foruse with the typeof gas indicatedon the rating plateand may beinstalled in an aftermarket,permanently located, manufactured(mobile) home where notprohibited by localcodes. See

owner's manualfor details.

Installer l'appareilselon lescodes ou règlementslocaux, ou,en l'absence detels règlements,selon les codesd'installation ANSIZ223.1, NationalFuel Gas Codeou CSA-B149.1en vigueur.

Installer l'appareil selon la norme CAN/CSA-Z240, Série MM, Maison mobiles ou CAN/CSA-Z240 VC, Véhicules de camping, ou la norme 24 CFR Part 3280, Manufactured Home Construction and Safety

Standard. Si cesnormes ne sont pas pertinentes,utilisez la norme ANSI/NCSBCSA225.1/NFPA 501A,Manufactured Home Installations Standard, ouANSI A119.2 ou NFPA 501CStandard for Recreational

Vehicles.

Cet appareildoit êtreutilize uniquementavec letype degaz indiqué sur laplaque signalétique. Cet appareilpeut être installé dans une maison préfabriquée ou mobile (É.-U. seulement)installée àdemeure si

les règlementslocaux lepermettent. Voirla notice del'utilisateur pourplus de renseignements.

This ventedgas fireplaceheater is notfor usewith air filters. Ne pasutiliser defiltre à airavec cefoyer au gazà évacuation.

FOR USEWITH GLASSDOORS CERTIFIED WITHTHE APPLIANCEONLY

.

NOT FOR USE WITH SOLID FUEL. / NE PAS UTILISER AVEC DU COMBUSTIBLE SOLIDE.

CAN/CGA-2.17-M91,ANSI Z21.88a-2007/CSA 2.33a-2007

(8.50 kW)

0-4500 ft/pi (0-1372 m)

0-4500 ft/pi (0-1372 m)

é

(8.79 kW)

CANADA and U.S.A.

APPAREIL FONCTIONNANT AU NATURAL GAS

CONCU POUR CET POELE: Mod le

Pression d'allimentation minimum

Pression à la tubulure d' chappement lev e

Pression à la tubulure d' chappement basse

Grandeur de l'injecteur

é

D bit minimum selon

é

D bit maximum selon

l'altitude

ÉÉ

QUIP A L'USINE POUR GAZ PROPANE

CONCU POUR CET POELE: Mod le HZ54E-LP1

Pression d'allimentation minimum

Pression à la tubulure d' chappement lev e

Pression à la tubulure d' chappement basse

Grandeur de l'injecteur

é

D bit minimum selon

é

D bit maximum selon

l'altitude

FOYER AU GAZ À ÉVACUATION

ééé

é

Calorifique

Calorifique

ééé

é

Calorifique

Calorifique

POUR UTILISATION UNIQUEMENTAVECLES PORTESEN VERRE CERTIFIÉESAVECL'APPAREIL

DO NOT REMOVE THIS LABEL / NE PAS ENLEVER CETTE ÉTIQUETTE

Minimum Clearances to Combustibles /

HZ54E-NG1

é

é

Degagement Minimum De Materiaux Combustibles

D

C

DOOR SEAL: Please

check that the door is

properly sealed

(See Instruction Manual for

detailed instructions)

FPI Fireplace Products International Ltd. Delta, BC, Canada

363

Serial No./ No de serie

363

Side Walls

B

A

E

Made in Canada/ Fabrique au Canada

A 4” (102mm)

Ceiling

F

B 40-7/8” (1038mm)

Min. Mantel Height

C 20" (508mm)

Max. Mantel Depth

D 13” (330mm)

Alcove Width

E 83" (2108mm)

Alcove Depth

F 36" (914mm)

919-268

For the State of Massachusetts, installation

and repair must be done by a plumber or

gasfi tter licensed in the Commonwealth of

Massachusetts.

For the State of Massachusetts, fl exible con-

nectors shall not exceed 36 inches in length.

For the State of Massachusetts, the appliances individual manual shut-off must be a

t-handle type valve.

The State of Massachusetts requires the

installation of a carbon monoxide alarm in

accordance with NFPA 720 and a CO alarm

with battery back up in the same room where

the gas appliance is installed.

Regency Horizon HZ54E-1 Gas Fireplace

5

Page 6

REQUIREMENTS

5.08: Modifications to NFPA-54, Chapter 10

(2) Revise 10.8.3 by adding the following additional requirements:

(a) For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for

residential purposes, including those owned or operated by the Commonwealth and where the side wall exhaust vent termination is less than

seven (7) feet above finished grade in the area of the venting, including but not limited to decks and porches, the following requirements shall

be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of the side wall horizontal vented gas fueled

equipment, the installing plumber or gasfitter shall observe that a hard wired carbon monoxide detector with an alarm and battery back-up is

installed on the floor level where the gas equipment is to be installed. In addition, the installing plumber or gasfitter shall observe that a battery

operated or hard wired carbon monoxide detector with an alarm is installed on each additional level of the dwelling, building or structure

served by the side wall horizontal vented gas fueled equipment. It shall be the responsibility of the property owner to secure the services of

qualified licensed professionals for the installation of hard wired carbon monoxide detectors

a. In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space or an attic, the hard wired carbon

monoxide detector with alarm and battery back-up may be installed on the next adjacent floor level.

b. In the event that the requirements of this subdivision can not be met at the time of completion of installation, the owner shall have a period of

thirty (30) days to comply with the above requirements; provided, however, that during said thirty (30) day period, a battery operated carbon

monoxide detector with an alarm shall be installed.

MA Code - CO Detector

(for the State of Massachusetts only)

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as required in accordance with the above provisions

shall comply with NFPA 720 and be ANSI/UL 2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be permanently mounted to the exterior of the building at a minimum height of eight

(8) feet above grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled heating appliance or equipment. The

sign shall read, in print size no less than one-half (1/2) inch in size, "GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL

OBSTRUCTIONS".

4. INSPECTION. The state or local gas inspector of the side wall horizontally vented gas fueled equipment shall not approve the installation

unless, upon inspection, the inspector observes carbon monoxide detectors and signage installed in accordance with the provisions of 248 CMR

5.08(2)(a)1 through 4.

(b) EXEMPTIONS: The following equipment is exempt from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled "Equipment Not Required To Be Vented" in the most current edition of NFPA 54 as adopted by

the Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or structure separate from the dwelling, building or

structure used in whole or in part for residential purposes.

(c) MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM PROVIDED. When the manufacturer of Product

Approved side wall horizontally vented gas equipment provides a venting system design or venting system components with the equipment, the

instructions provided by the manufacturer for installation of the equipment and the venting system shall include:

1. Detailed instructions for the installation of the venting system design or the venting system components; and

2. A complete parts list for the venting system design or venting system.

(d) MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED. When the manufacturer of a

Product Approved side wall horizontally vented gas fueled equipment does not provide the parts for venting the flue gases, but identifies

"special venting systems", the following requirements shall be satisfied by the manufacturer:

1. The referenced "special venting system" instructions shall be included with the appliance or equipment installation instructions; and

2. The "special venting systems" shall be Product Approved by the Board, and the instructions for that system shall include a parts list and

detailed installation instructions.

(e) A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled equipment, all venting instructions,

all parts lists for venting instructions, and/or all venting design instructions shall remain with the appliance or equipment at the completion of

the installation.

6

Regency Horizon HZ54E-1 Gas Fireplace

Page 7

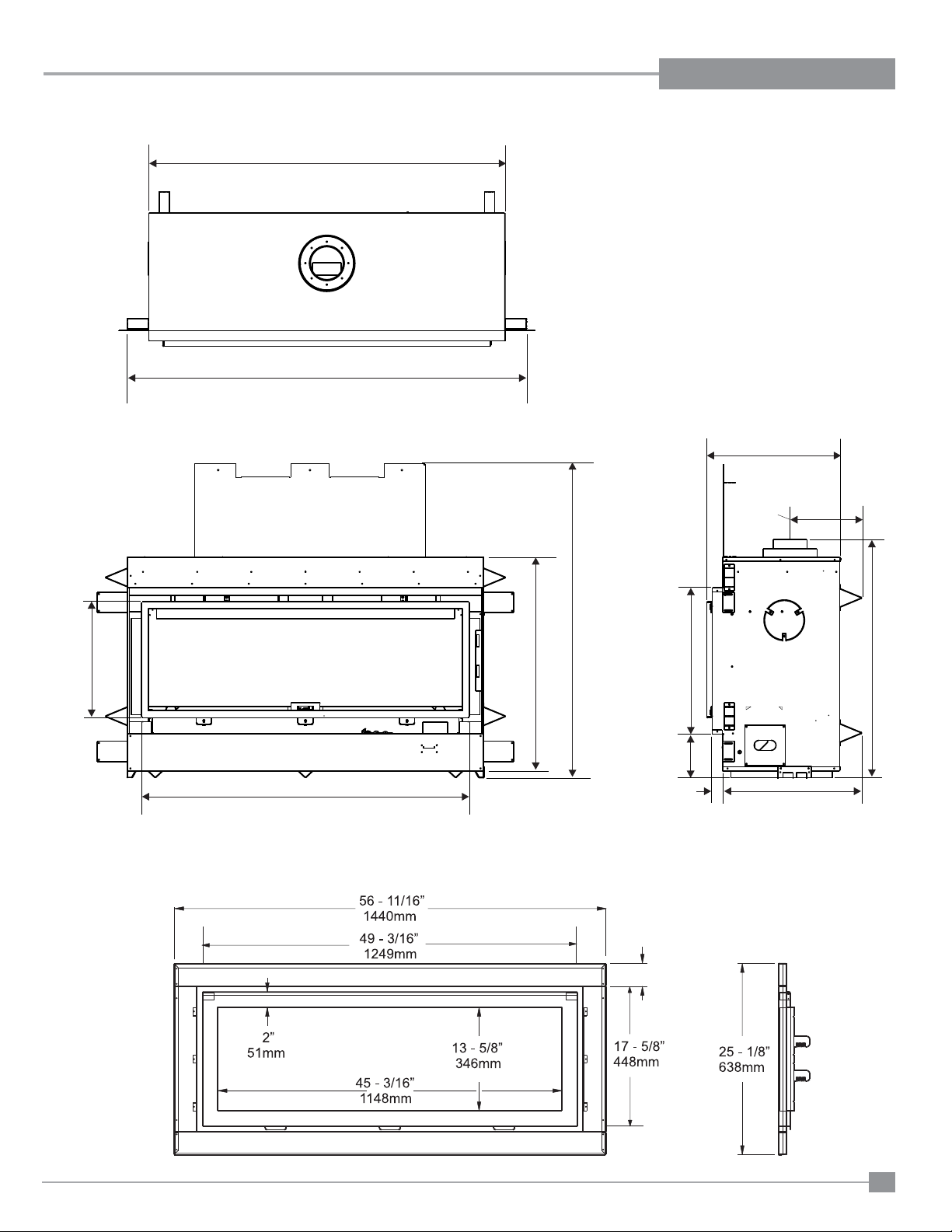

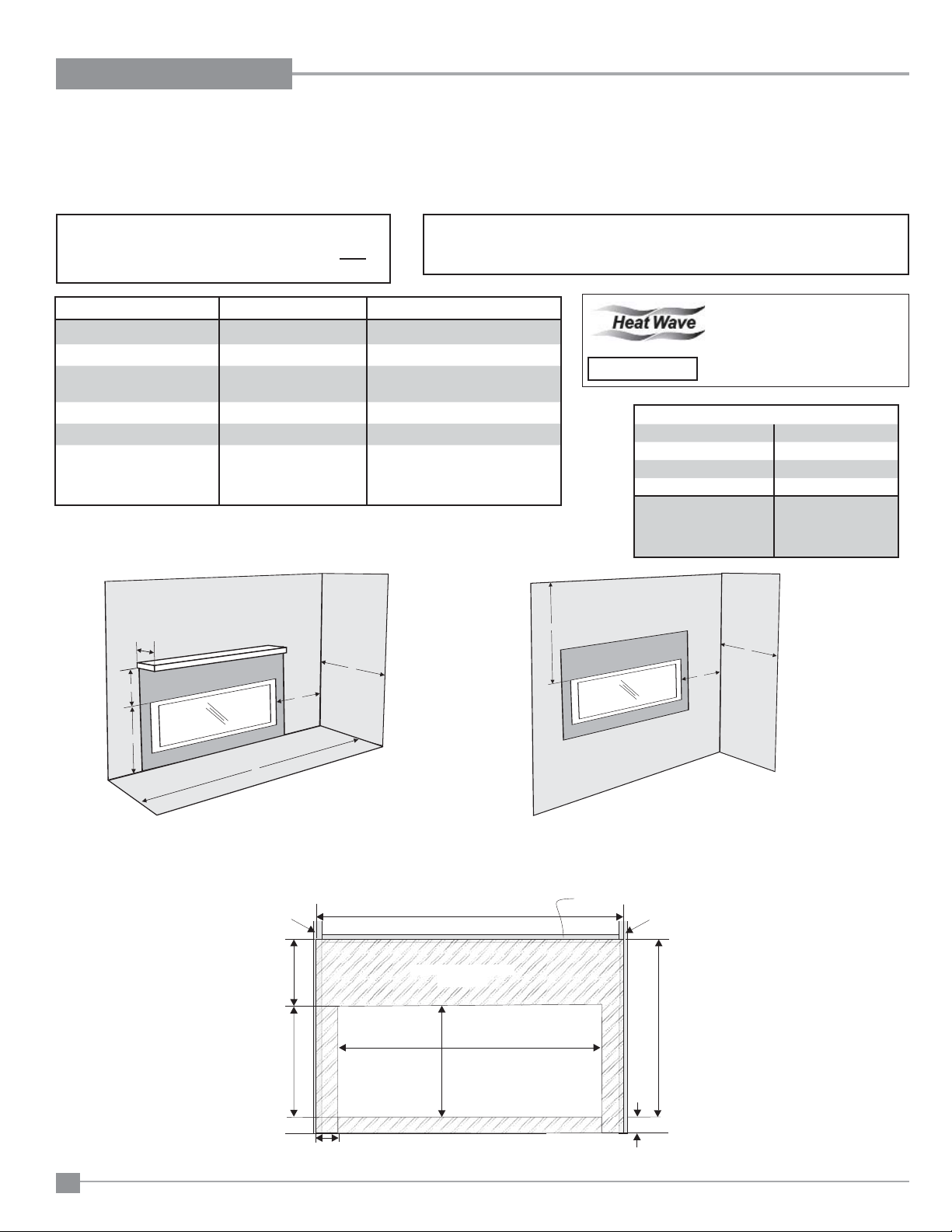

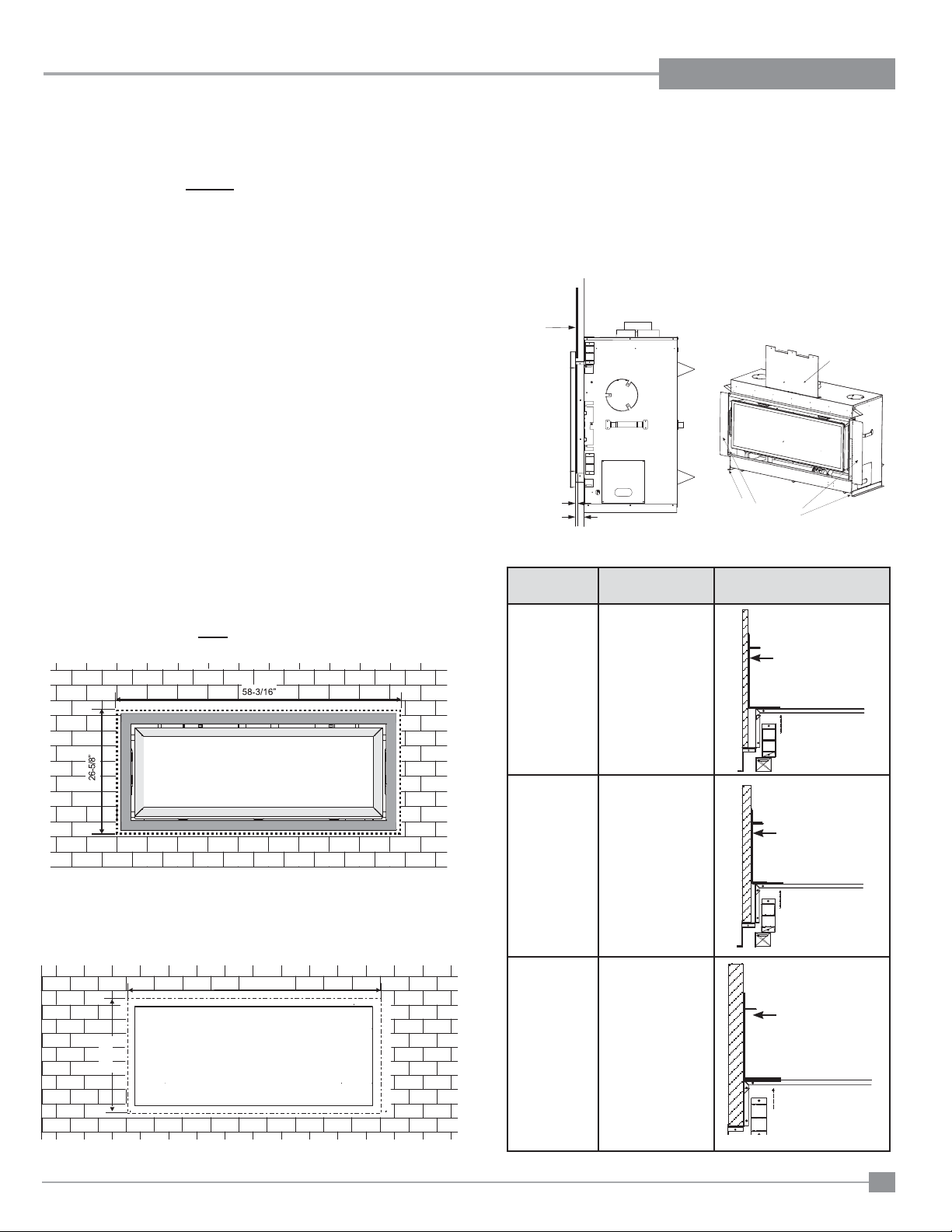

52-5/8” (1337mm)

59” (1499mm)

UNIT DIMENSIONS

DIMENSIONS

19-3/4” (502mm)

10-5/8”

(270mm)

17-1/8” (435mm)

46-3/8” (1178mm)

31-5/8” (803mm)

48-1/2” (1232mm)

22-3/8” (568mm)

5-11/16”

(144mm)

1-1/2”

(38mm)

FACEPLATE & DOOR FRAME OVERLAY DIMENSIONS

35-1/4” (895mm)

20-1/2” (521mm)

Regency Horizon HZ54E-1 Gas Fireplace

7

Page 8

INSTALLATION

IMPORTANT MESSAGE

SAVE THESE

INSTRUCTIONS

The HZ54E Direct Vent Fireplace must be installed

in accordance with these instructions. Carefully

read all the instructions in this manual fi rst. Consult

the "authority having jurisdiction" to determine the

need for a permit prior to starting the installation.

It is the responsibility of the installer to ensure

this fi replace is installed in compliance with

manufacturers instructions and all applicable codes.

BEFORE YOU ST ART

Safe installation and operation of this appliance

requires common sense, however, we are required

by the Canadian Safety Standards and ANSI

Standards to make you aware of the following:

INSTALLATION AND REPAIR SHOULD

BE DONE BY AN AUTHORIZED

SERVICE PERSON. THE APPLIANCE

SHOULD BE INSPECTED BEFORE

USE AND AT LEAST ANNUALLY BY A

PROFESSIONAL SERVICE PERSON.

MORE FREQUENT CLEANING MAY

BE REQUIRED DUE TO EXCESSIVE

LINT FROM CARPETING, BEDDING

MATERIAL, ETC. IT IS IMPERATIVE THAT

CONTROL COMPARTMENTS, BURNERS

AND CIRCULATING AIR PASSAGEWAYS

OF THE APPLIANCE BE KEPT CLEAN.

YOUNG CHILDREN SHOULD BE CAREFULLY SUPERVISED WHEN THEY ARE

IN THE SAME AREA AS THE APPLIANCE. TODDLERS, YOUNG CHILDREN

AND OTHERS MAY BE SUSCEPTIBLE

TO ACCIDENTAL CONTACT BURNS. A

PHYSICAL BARRIERS IS RECOMMENDED IF THERE ARE AT RISK INDIVIDUAL

IN THE HOUSE. TO RESTRICT ACCESS

TO A FIREPLACE OR STOVE, INSTALL

AN ADJUSTABLE SAFETY GATE TO

KEEP TODDLERS, YOUNG CHILDREN

AND OTHER AT RISK INDIVIDUALS OUT

OF THE ROOM AND AWAY FROM HOT

SURFACES.

CLOTHING OR OTHER FLAMMABLE

MATERIAL SHOULD NOT BE PLACED

ON OR NEAR THE APPLIANCE.

GENERAL SAFETY

INFORMATION

1) The appliance installation must conform with lo-

cal codes or, in the absence of local codes, with

the current Canadian or National Gas Codes,

CAN1-B149 or ANSI Z223.1 Installation Codes.

2) The appliance when installed, must be electrically grounded in accordance with local codes,

or in the absence of local codes with the current

National Electrical Code, ANSI/NFP A 70 or CSA

C22.1 Canadian Electrical Code.

10) Be aware of electrical wiring locations in walls

and ceilings when cutting holes for termination.

11) Under no circumstances should this appliance

be modifi ed. Parts that have to be removed for

servicing should be replaced prior to operating

this appliance.

12) Installation and any repairs to this appliance

should be done by an authorized service person. A professional service person should be

called to inspect this appliance annually. Make

it a practice to have all of your gas appliances

checked annually.

13) Do not slam shut or strike the glass door.

14) Under no circumstances should any solid fuels

(wood, paper, cardboard, coal, etc.) be used in

this appliance.

15) The appliance area must be kept clear and

free of combustible materials, (gases and other

fl ammable vapours and liquids).

Emissions from burning wood or gas could

contain chemicals known to the State of

California to cause cancer, birth defects or

other reproductive harm.

DUE TO HIGH TEMPERATURES, THE

APPLIANCE SHOULD BE LOCATED

OUT OF TRAFFIC AND AWAY FROM

FURNITURE AND DRAPERIES.

WARNING: FAILURE TO INSTALL THIS

APPLIANCE CORRECTLY WILL VOID

YOUR WARRANTY AND MAY CAUSE A

SERIOUS HOUSE FIRE.

CHILDREN AND ADULTS SHOULD BE

ALERTED TO THE HAZARDS OF HIGH

SURFACE TEMPERATURES, ESPECIALLY THE FIREPLACE GLASS, AND

SHOULD STAY AWAY TO AVOID BURNS

OR CLOTHING IGNITION.

3) See general construction and assembly instructions. The appliance and vent should be

enclosed.

4) This appliance must be connected to the specifi ed vent and termination cap to the outside of

the building envelope. Never vent to another

room or inside a building. Make sure that the

vent is fi tted as per Venting instructions.

5) Inspect the venting system annually for blockage

and any signs of deterioration.

6) Venting terminals shall not be recessed into a

wall or siding.

7) Any safety glass removed for servicing must

be replaced prior to operating the appliance.

8) To prevent injury, do not allow anyone who is

unfamiliar with the operation to use the fi replace.

9) Wear gloves and safety glasses for protection

while doing required maintenance.

8

Regency Horizon HZ54E-1 Gas Fireplace

Page 9

INSTALLATION

INSTALLATION

CHECKLIST

1) Locate appliance

a) Room location (Refer to "Locating Y our Gas

fi replace" section)

b) Clearances to Combustibles (Refer to

"Clearances" section)

c) Mantle Clearances (Refer to "Mantel

Clearances" section)

d) Framing & Finishing Requirements (Refer

to "Framing & Finishing" section)

e) Venting Requirements (Refer to "Venting"

section)

2) Assemble Top and Side Standoffs (Refer to

"Unit Assembly Prior to Installation).

3) Slide unit into place.

4) Install vent (Refer to "Venting Arrangement"

sections).

5) Make gas connections (Refer to "Gas Line

Installation section).

6) Install 4 AA batteries into battery pack or optional

AC power adaptor.

7) Test the pilot (Refer to "Pilot Adjustment"

section).

8) T est Gas Pressure (Refer to "Gas Pipe Pressure

Testing" section).

9) Install standard and optional features. Refer to

the following sections:

a) Optional Log Set Installation

b) Glass Crystals/ Optional Ceramic

Stones

c) Optional Firebox Base Pebbles

d) Optional Refl ective Panels

e) Faceplate / Door Frame Overlay

f) Remote Control

g) Wall Thermostat

h) Wall Switch

10) Final check.

Before leaving this unit with the customer, the

installer must ensure that the appliance is fi ring

correctly and operation fully explained to

customer.

This includes:

1) Clocking the appliance to ensure the correct

fi ring rate (rate noted on label 41,500 Btu/h

(NG), after burning appliance for 15 minutes.

2) If required, adjusting the primary air to ensure

that the fl ame does not carbon. First allow the

unit to burn for 15-20 min. to stabilize.

CAUTION: Any alteration to the product that

causes sooting or carboning that results in damage is not the responsibility of the manufacturer.

LOCATING YOUR

GAS FIREPLACE

1) When selecting a location for your fi replace,

ensure that the clearances are met.

2) The appliance must be installed on a fl at, solid,

continuous surface For example a wood, metal

or concrete fl oor or in a raised (on the wall) ap-

plication. The appliance must be installed on

a metal or wood panel extending the full width

and depth of the appliance.

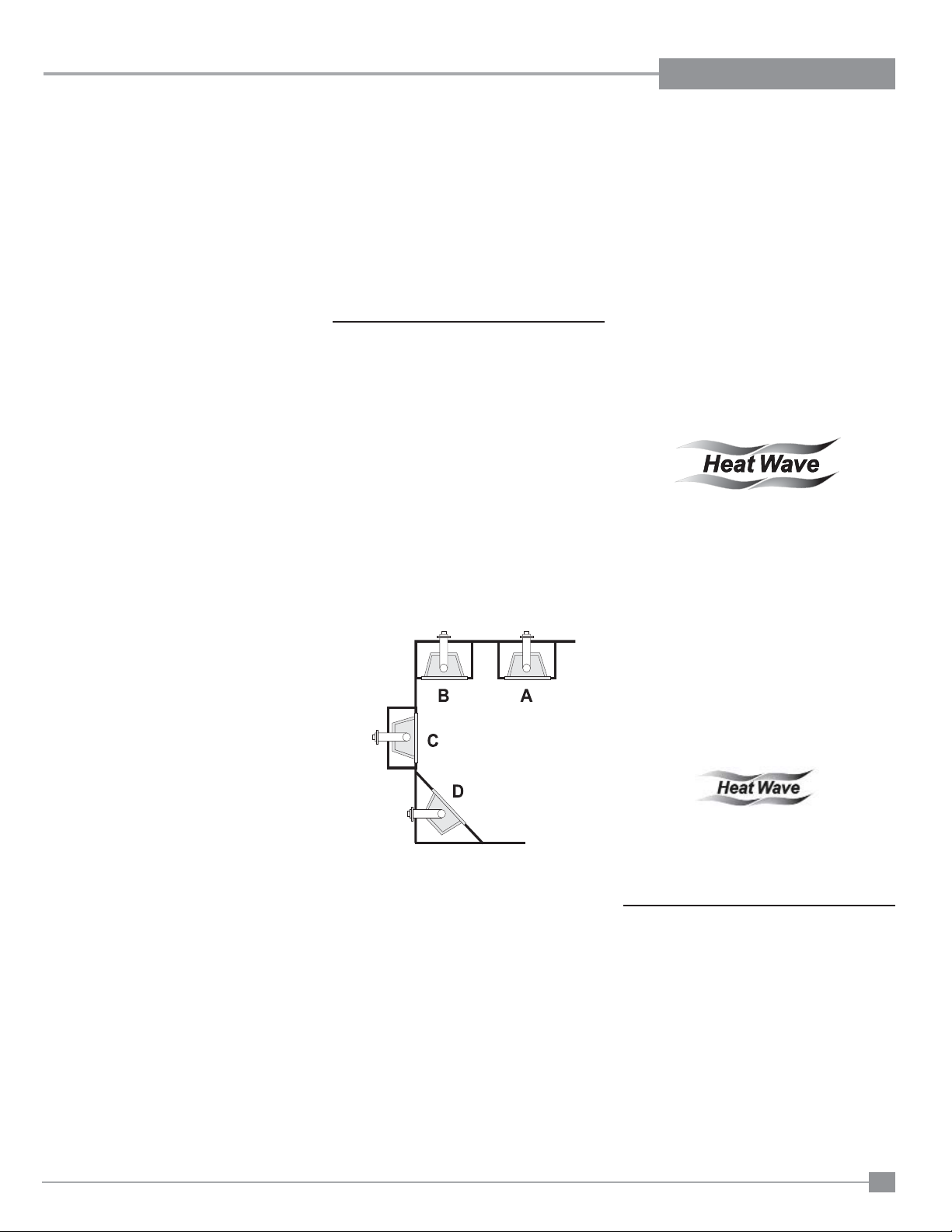

3) The HZ54E Direct Vent Gas Fireplace can be

installed in a recessed position or framed out

into the room as in A, B, C and D.

See Diagram 1.

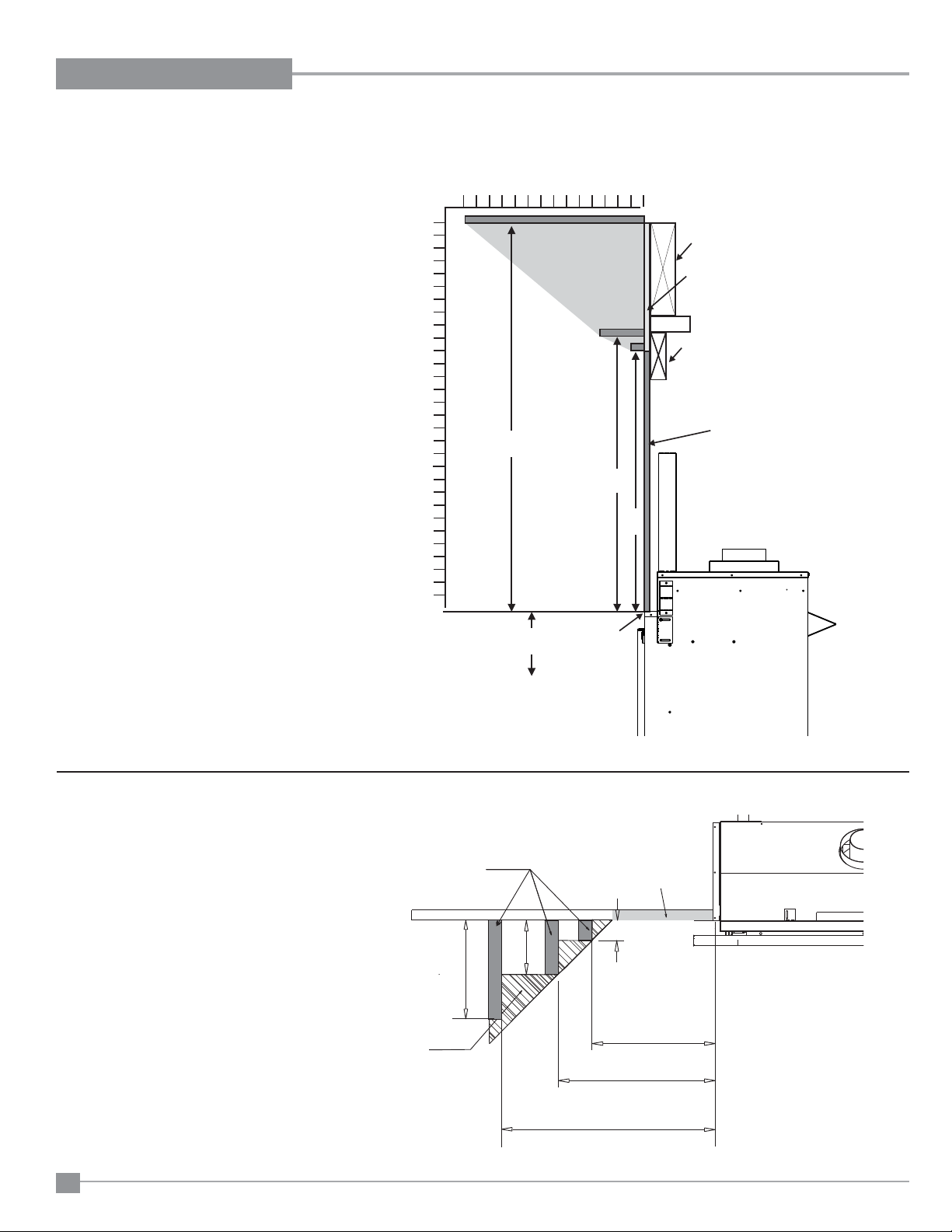

Diagram 1

A) Flat on Wall

B) Flat on Wall Corner

C) Recessed into Wall/Alcove

D) Corner

4) This appliance is Listed for bedroom

installations using the standard Remote

(millivolt thermostat system). Some areas may

have further requirements, check local codes

before installation.

5) The HZ54E Direct Vent Gas Fireplace

is approved for alcove installations, see

"Clearances" section for details.

6) We recommend that you plan your installation

on paper using exact measurements for

clearances and fl oor protection before actually

installing this appliance. Have an authorized

inspector, dealer , or installer review your plans

before installation.

Note: For vent terminations refer to "Exterior

Vent Termination Locations" section.

HEATWAVE

DUCT SYSTEM

OPTIONAL KIT #946-556

The HeatWave Air Duct Kit increases the

effectiveness of your fi replace by dispersing warm

air from the fi replace to remote locations in the same

room or other rooms in your home.

Up to two kits may be installed on the fi replace.

Please Note: Only 1 HeatWave kit may be oper-

ated at one time. This includes the internal blower

option as well.

The HeatWave Duct Kit has different

clearance and framing requirements, check

the HeatWave manual for details.

OPTIONAL

HEAT RELEASE KIT

#946-570

Regency Horizon HZ54E-1 Gas Fireplace

The Heat Release Kit expels warm air from the

fi replace to the outside of the building, allowing

the fi replace to be operated with less heat entering

the room. The kit may be used on either the left

or right side.

9

Page 10

INSTALLATION

CLEARANCES

The clearances listed below are Minimum distances unless otherwise stated:

A major cause of chimney related fi res is failure to maintain required clearances (air space) to combustible materials. It is of the greatest importance

that this fi replace and vent system be installed only in accordance with these instructions.

The top, back and sides of the fi replace are defi ned by

Caution Requirements

standoffs. The metal ends of the standoff may NOT be

recessed into combustible construction.

Fire hazard is an extreme risk if these clearances (air space) to combustible materials

are not adhered to. It is of greatest importance that this fi replace and vent system be

installed only in accordance with these instructions.

WARNING

Clearance: Dimension Measured From:

A: Mantel Height (min.) 20" (508mm) Top of Fireplace Opening

B: Sidewall (on one side) 4" (102mm) Side of Fireplace Opening

C: Ceiling

(room and/or alcove)

D: Mantel Depth (max.) 13" (330mm) 30" Above Fireplace Opening

E: Alcove Width 83" (2108mm) Sidewall to Sidewall (Minimum)

F: Alcove Depth 36" (914mm) Front to Back Wall (Maximum)

G: To Floor 28 - 7/8" (733mm) Top of Fireplace Opening

Note 0" No hearth required

D

A

G

40-7/8" (1038mm) Top of Fireplace Opening

F

B

Heat Release Kit

C

The HeatWave Duct Kit and the Heat

Release Kit have different clearance

and framing requirements, check the

HeatWave and Heat Release manual

for details.

Flue Clearances to Combustibles

Horizontal - Top 3"

Horiztonal - Side 2"

Horiztonal - Bottom 2"

Vertical 2"

Passing through wall/

floor/ceiling - when

fi restop is used.

F

B

1-1/2"

10

E

Installed Close

to Floor

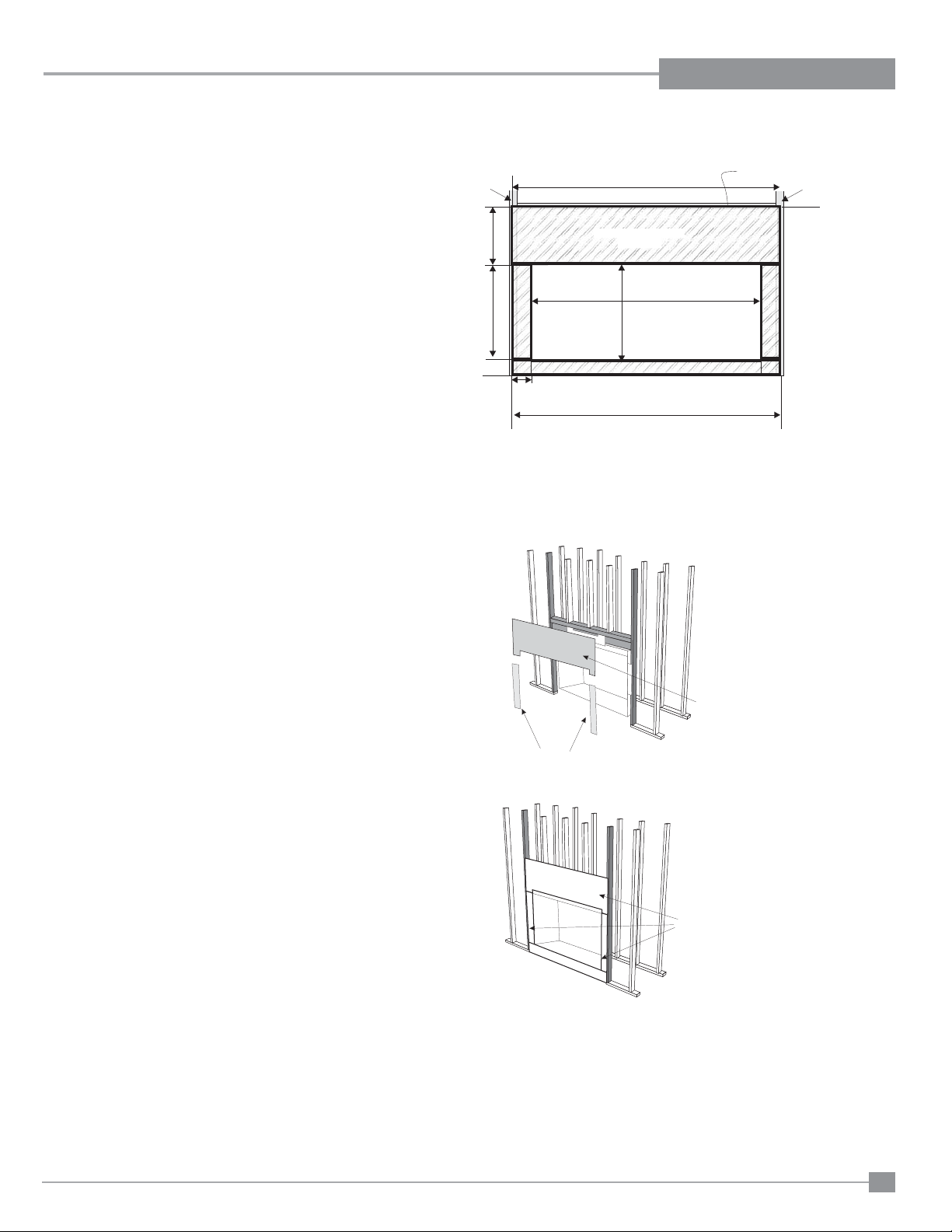

NON-COMBUSTIBLE REQUIREMENTS

Metal Stud (header)

Wood Stud

19-7/8"

(505mm)

mm)

22-1/2”

(572

3-7/8"

(

99mm)

Non-combustible Material

60-1/2" (1537mm)

Non-combustibl

Material

”

22-5/8

Non-combustible Material

e

52-7/8”

Non-combustible Material

5-1/2”

(140mm)

Installed Close

to Ceiling

Wood Stud

1079mm)

(

42-3/8”

Regency Horizon HZ54E-1 Gas Fireplace

Page 11

INSTALLATION

NON COMBUSTIBLE FACING BOARD

All four pieces (top, 2 sides, bottom) are now supplied to meet the non combustible requirements. Previously only the top was supplied.

If fi nishing the wall above the unit with paint the non-combustible board (shipped separately

from the unit) should be installed. Facing board

must be ordered when ordering the unit.

Calcium silicate board is a high - grade material

with cement, quartz, natural and selected

minerals as the main raw materials. It is widely

used for partitions and ceilings in buildings.

It is fi re proof and earthquake proof.

If fi nishing the wall above the unit with materials

such as tile, brick, marble, etc. non-combustible

board available from the building supply store

can be used.

Note: Calcium Silicate is 1/2" thick.

Caution: This non-combustible board can be damaged if

dropped or struck. Handle with care.

NON-COMBUSTIBLE FACING INSTALLATION

Caution: The non-combustible board supplied with this unit can

be damaged if dropped or struck. Handle with care.

1) Using drywall screws - secure non combustible material

around unit, framing and top nailing strip every 6 inches.

Wood Stud

5-5/8”

(143mm)

20"

(508mm)

22-3/8”

(568mm)

Non-combustible Facing Board

4"

(102mm)

61-1/2" (1537mm)

Non-combustible

Facing Board

52-5/8”

21-3/4”

Non-combustible Facing Board

61-1/2" (1537mm)

Metal Stud (header)

Wood Stud

Non-combustible Facing Board

Important Note: To avoid cracking the board - pre-drill holes prior to

securing to unit/ framing.

2) Wipe any debris/dust from the non combustible

material and drywall.

3) Prior to securing it is mandatory to prime the facing and edges

using a quality primer. This will ensure proper adhesion of both the

tape and mud. The supplied board is very porous.

Failure to follow this procedure will result in cracked seams.

4) Tape the seams using a mesh type tape.

5) Mud seams as normal. We recommend using a

product called Durabond high strength compound - for the fi rst coat.

This product can be found at any hardware store.

Mud must be cured as per manufacturer’s recommendations.

6) Prime wall for a second time for proper adhesion of paint

7) Paint walls using a high quality paint which will withstand

the high temperatures being emitted from this appliance.

Non-combustible board

shipped with unit.

Non-combustible board

shipped with unit.

Non-combustible board-faces and edges

MUST BE PRIMED.

Regency Horizon HZ54E-1 Gas Fireplace

11

Page 12

INSTALLATION

4"

7”

MANTEL CLEARANCES

Due to the extreme heat this fi replace emits, the mantel clearances are critical. Combustible mantel clearances from top of front facing are shown in

0

2

the diagram on the right.

14

12

6

810

4

Note: A non-combustible mantel may be

installed at a lower height if the framing

is made of metal studs covered with a

non-combustible board.

Note: Ensure the paint that is used on the mantel

and the facing is "High Quality" or the paint

may discolour.

30

20

10

0

30”

28-1/8”

To Unit

Base Legs

13" (330mm)

3 ½" (89mm)

1" (25mm)

Top of

Fireplace

Opening

Combustible Material

Drywall

Metal Stud

(On Edge)

Non-combustible

Facing

21”

Standoff

20”

Combustible mantel leg clearances as per diagram:

12

MANTEL LEG CLEARANCES

MANTEL LEG

Allowable mantel

leg projection

4”(102mm)

Non-Combustible

1.5" (38mm)

5-1/2” (140mm)

8” (203mm)

11” (279mm)

Regency Horizon HZ54E-1 Gas Fireplace

Page 13

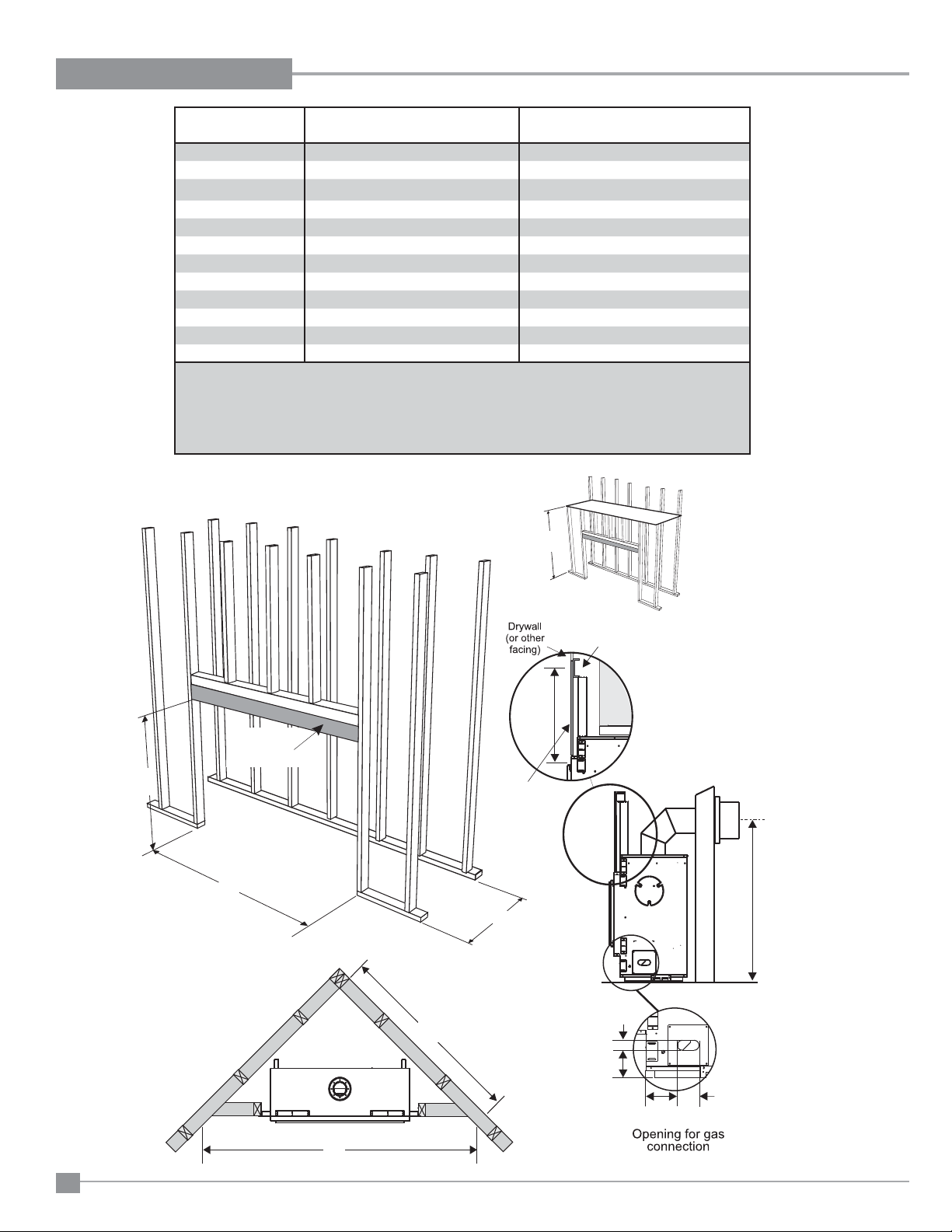

FRAMING & FINISHING

INSTALLATION

1) Frame in the enclosure for the unit with framing material.

IMPORTANT: Header must be metal stud. All other framing may be of

combustible type such as 2x4 / 2x6 framing materials.

ote: When constructing the framed opening, please ensure there is ac-

cess to install the gas lines when the unit is installed.

2) For exterior walls, insulate the enclosure to the same degree as the rest

of the house, apply vapour barrier and drywall, as per local installation

codes. (Do not insulate the fi replace itself.)

WARNING: Failure to insulate and add vapor barriers to the inside of

the exterior wall will result in operational and performance problems

including, but not limited to: excessive condensation on glass doors,

poor fl ame package, carbon, blue fl ames etc. These are not product

related issues.

3) The unit does not have to be completely enclosed in a chase. You must

maintain clearances from the vent to combustible materials: See "Clearances" section. Combustible materials can be laid against the side and

back standoffs and the stove base.

4) The combined total of non-combustible facing materials (ie. hardiboard

+ tile, slate, etc) may be brought up to and overlap the face of the unit

(top and bottom). The minimum thickness = 1/2"

to a maximum thickness = 1-1/2", as shown in the diagram below.

If material is thicker than 1-1/2" - it will not be possible to mount

the faceplace.

5) When fi nishing around the faceplate, if material such as brick, stone, etc.

extend past the faceplate depth - the minimum opening

dimensions noted below must be adhered to, this is to ensure removal

of the faceplate.

6) Determine the total thickness of facing material (eg. hardiboard + ceramic

tile) to ensure the fi nished surface is fl ush with the front edge of the

unit (see diagram below). If necessary, side and top nailing strips are

adjustable, loosen the 1/4" screws and adjust.

Total non-combustible facing allowable: Min. = 1/2"

Max. = 1- 1/2"

See diagram below.

Important:

Finished

facing

material to

be flush with

edge of unit.

½”

(13mm)

Min

1-1/2”

(38mm)

Max

Finished

Material

Nailing Strips

Nailing Strip

Position

Nailing strip/

Standoff bracket

1/2" 1"

Nailing Strip

1” Forward

For material such as brick, stone, etc that extends less than 1-1/2" , the

minimum opening dimensions noted below must be adhered to when

fi nishing around the unit. This is to ensure the removal of the faceplate

and for the safe operation of this appliance.

52-7/8 ”

22-5/8”

Unit shown without faceplate

Regency Horizon HZ54E-1 Gas Fireplace

Unit

1" 1/2"

Nailing Strip

½” Forward

Unit

1-1/2" 0" (fl ush)

Nailing Strip

Flush w/unit

Factory Set

Unit

13

Page 14

INSTALLATION

Framing

Dimensions

A Framing Height 46-5/8” (1184mm)

B Framing Width 60” (1524mm)

C

* Framing Depth*

D Minimum Height to Combustibles 51” (1295mm)

E Corner Wall Depth 72" (1829mm)

F Corner Facing Wall Width 101-7/8 (2586mm)

G Vent Centerline Height 44” (1118mm)

H Non-combustible facing height 20” (508mm)

I Gas Connection Opening Height 1-1/2” (38mm)

J Gas Connection Height 4” (102mm)

K Gas Connection Inset 7-1/4” (184mm)

L Gas Connection Opening Width 3-1/4” (83mm)

Description HZ54E

22” (559mm)

* Framing depth measurement is noted with the side nailing strips set as far forward on the fi rebox as possible.

The side nailing strips can be adjusted back up to 1” to allow for varying thicknesses in non-combustible material & wall fi nishes.

Important: The minimum framing dimensions given for height, width and depth must be maintained even if

using non combustible materials.

Dangerous operating conditions will occur if minimum framing dimensions are not adhered to.

D

A

Metal Stud

(Header)

on edge

B

Metal Stud (Header)

on edge

H

Non-Combustible

Facing

G

C

E

I

J

14

L

K

F

Regency Horizon HZ54E-1 Gas Fireplace

Page 15

INSTALLATION

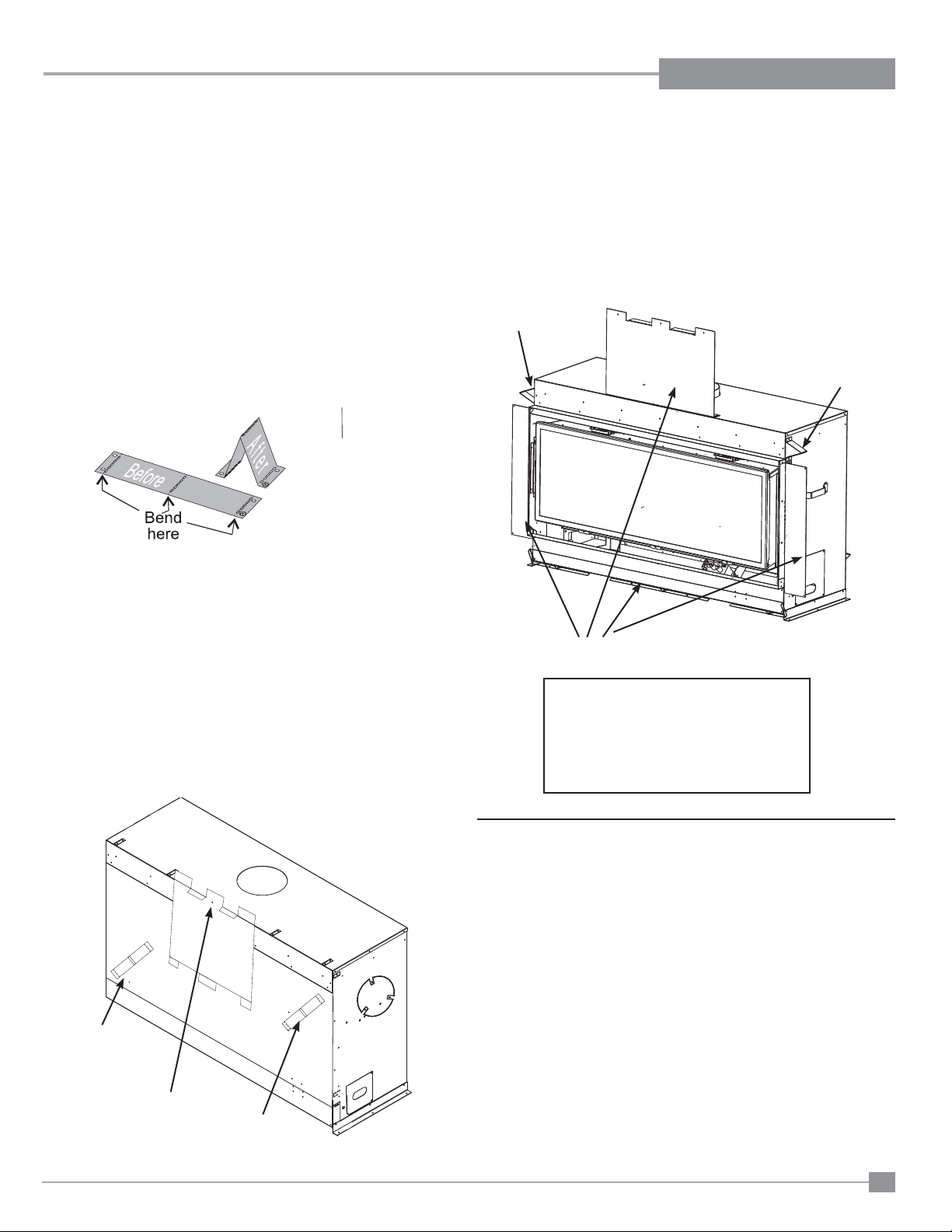

UNIT ASSEMBLY

PRIOR TO

INSTALLATION

The Top Standoff/ Nailing Strip, side nailing strips and standoffs must be

correctly positioned and attached to the unit before sliding the unit into position.

ST ANDOFF ASSEMBLY

The top, side, rear and bottom standoffs are shipped in a fl at position and

must be folded into shape and attached - see diagram 1.

1) Remove the standoffs from the unit.

2) T ake each standoff and bend into the correct shape. Bend up at the bend

lines until the screw holes in the standoff and the pre-punched screw holes

on the unit line up.

Diagram 1

NAILING STRIPS

The nailing strips come attached to the unit. There is 1 plate on each side,1

on the top, and one on the bottom that can be folded out as required. The

top and side nailing strips are secured to the framing. The bottom nailing

strip is secured to the unfi nished fl oor - if installing the unit directly on the

fl oor.

Note: The bottom nailing strip will need to be bent on site and

adjusted to accommodate the thickness of the facing material.

Standoff

Standoff

The top stand off / nailing strip is shipped attached to the back of the unit as

shown below.

1) Remove one screw in location shown below.

Replace the screw on the back the unit after removing the

standoff / nailing strip.

2) Bend the 3 tabs at the bottom of the stand off / nailing strip to 90°,

bend in the same direction as the top tabs.

3) Install on the top front of the unit as shown in diagram 3. Do not fully

tighten the screws when installing - until the facing thickness has been

determined.

Standoff

Nailing Strips

Diagram 3

IMPORTANT NOTE

Framing depth measurement is noted with

the side nailing strips set as far forward on

the fi rebox as possible. The nailing strips can

be adjusted back up to 1” to allow for varying

thicknesses in non-combustible material & wall

fi nishes.

VENTING INTRODUCTION

The HZ54E uses the "balanced fl ue" technology Co Axial system. The

inner liner vents products of combustion to the outside while the outer liner

draws outside combustion air into the combustion chamber thereby eliminating

the need to use heated room air for combustion and losing warm room air

up the chimney.

Note: These fl ue pipes must not be connected to any other appliance.

The gas appliance and vent system must be vented directly to the outside of

the building, and never be attached to a chimney serving a separate solid fuel

or gas burning appliance. Each direct vent gas appliance must use it's own

separate vent system. Common vent systems are prohibited.

Remove this screw to

release top standoff / nailing

strip

Regency Horizon HZ54E-1 Gas Fireplace

Standoff

Diagram 2

15

Page 16

INSTALLATION

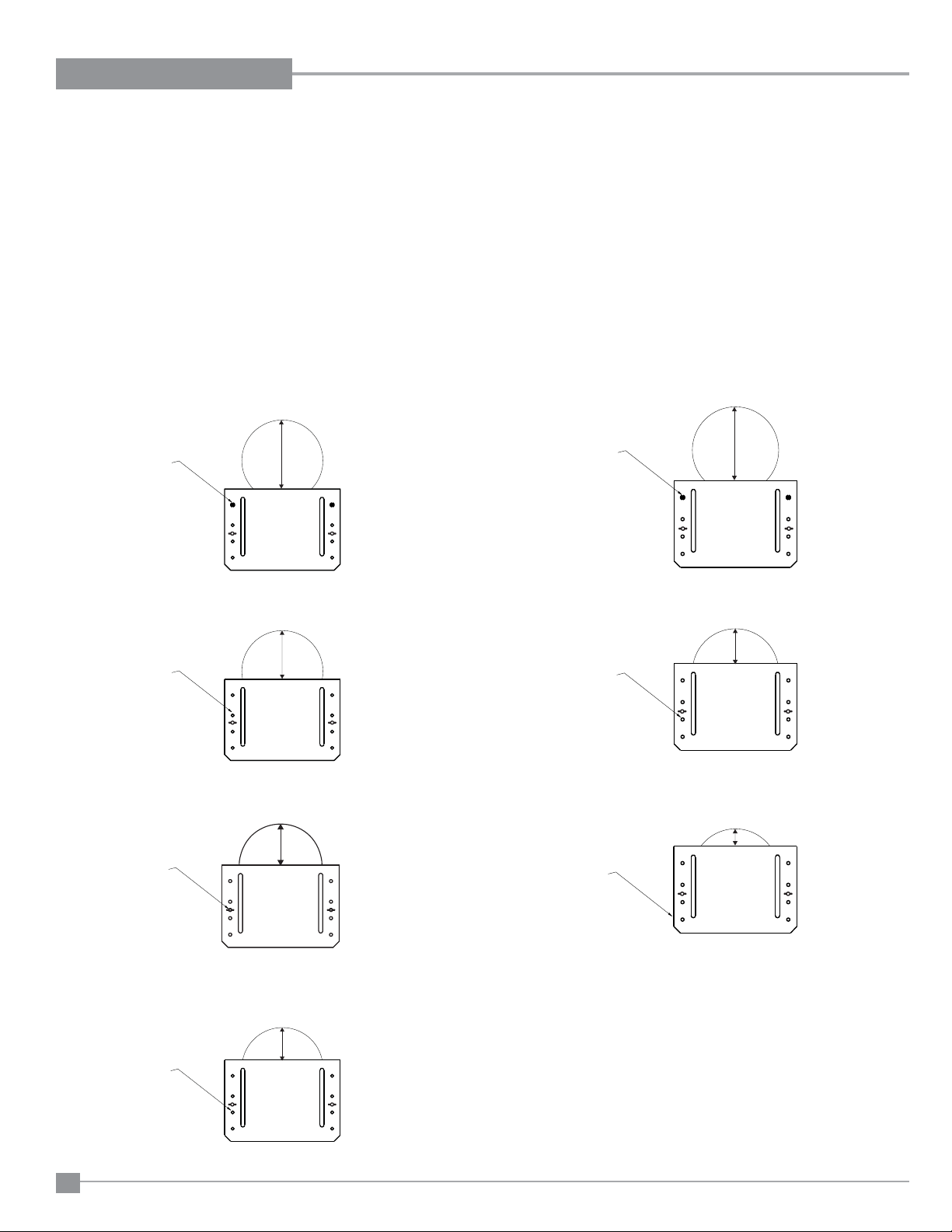

VENT RESTRICTOR POSITION

Vent restriction is required for certain venting installations, see the diagrams in the "Venting

Arrangements" section to determine if they are required for your installation.

The Vent Restrictor plate is located on the inside top of the fi rebox.

To set the vent restriction as indicated in the venting arrangements diagrams, refer to the following instructions;

1) Remove the glass door.

2) Remove the screws that hold the vent restrictor plate in place.

3) Adjust the vent restrictor plate to the required vent restrictor position as per the diagrams shown.

4) Once the vent restrictor plate is in the required position, secure with screws.

Vent Restrictor Settings for HZ54E-NG Vent Restrictor Settings for HZ54E-LP

SET 1

THIS HOLE SETS THE

VENTR ESTRICTOR

(factory setting)

AT 4.25”

SET 2

THIS HOLE SETS THE

VENTR ESTRICTOR

AT 3 ”

SET 3

THIS HOLE SETS THE

VENTR ESTRICTOR

AT 2-1/2”

4.25”

Vent Restrictor Set 1

Factory Set Vent Restrictor

(No adjustment required)

3”

Vent Restrictor Set 2

2.5”

SET 1

THIS HOLE SETS THE

VENT RESTRICTOR

(factory setting)

AT 4.25”

SET 4

THIS HOLE SETS THE

VENT RESTRICTOR

AT 2”

SET 5

THIS HOLE SETS THE

VENT RESTRICTOR

AT 1”

4.25”

V

ent Restrictor Set 1

Factory Set V

(No adjustment required)

ent Restrictor

2”

Vent Restrictor Set 4

1”

SET 4

THIS HOLE SETS THE

VENTR ESTRICTOR

AT 2 ”

16

Vent Restrictor Set 5

Vent Restrictor Set 3

2”

Vent Restrictor Set 4

Regency Horizon HZ54E-1 Gas Fireplace

Page 17

INSTALLATION

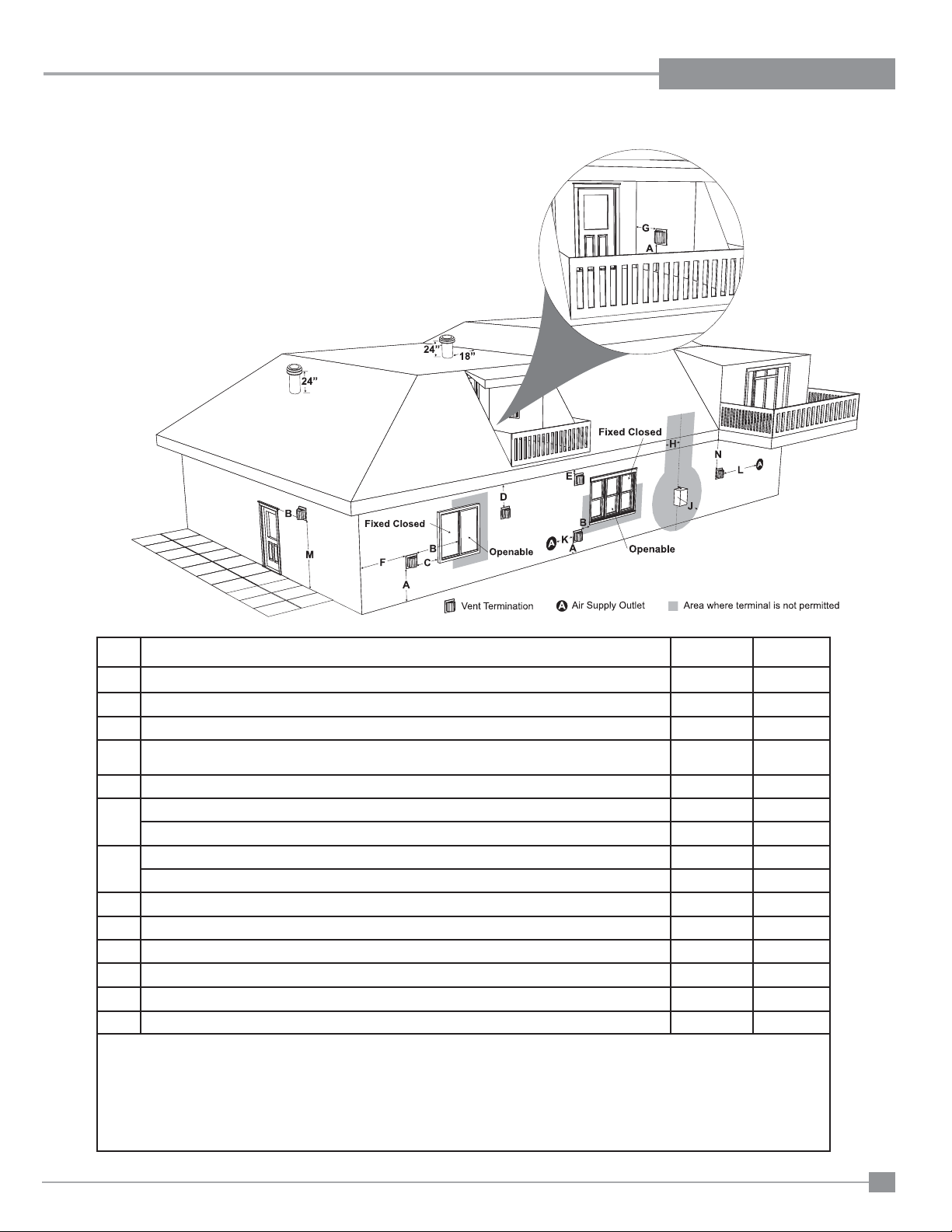

EXTERIOR VENT TERMINATION REQUIREMENTS

1

Minimum Clearance Requirements

A

Clearance above grade, veranda, porch, deck, or balcony 12"(30cm) 12"(30cm)

B

Clearance to window or door that may be opened 12"(30cm) 9" (23cm)

C

Clearance to permanently closed window **

D

Vertical clearance to ventilated soffi t located above the terminal within a horizontal distance of 2 feet (61cm)

from the center line of the terminal (check with the local code)

E

Clearance to unventilated soffi t 24"(60cm) 24"(60cm)

F

Clearance to outside corner: with AstroCap Termination Cap. 13"(33cm) 13"(33cm)

Clearance to outside corner: with all other approved Termination Caps. 13"(33cm) 13"(33cm)

G

Clearance to inside corner: with AstroCap Termination Cap 13"(33cm) 13"(33cm)

Clearance to inside corner: with all other approved Termination Caps. 13"(33cm) 13"(33cm)

H

Clearance to each side of center line extended above meter/regulator assembly 36"(90cm)

J

Clearance to service regulator vent outlet 36"(90cm) *

K

Clearance to non-mechanical air supply inlet to building or the combustion air inlet to any other appliance 12"(30cm) 9" (23cm)

L

Clearance to a mechanical air supply inlet 72"(1.8m) 36"(90cm)

M

Clearance above paved sidewalk or a paved driveway located on public property 84"(2.1m)

N

Clearance under veranda, porch, deck, or balcony 12"(30cm)

1

In accordance with current CSA B149.1, Natural Gas and Propane Installation Code

2

In accordance with the current ANSI Z223.1/NFPA 54, National Fuel Gas Code

┼

A vent shall not terminate directly above a sidewalk or paved driveway which is located between two single family dwellings and serves both dwellings

‡ Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the fl oor

Clearance in accordance with local installation codes and the requirements of the gas supplier

*

a

3 feet (91cm) within a height of 15 feet (4.5m) above the meter / regulator assembly

b

3 feet (91cm) above - if within 10 feet (3m) horizontally

Canada

24"(60cm) 24"(60cm)

USA

a

┼

‡

*

*

*

2

b

Regency Horizon HZ54E-1 Gas Fireplace

17

Page 18

INSTALLATION

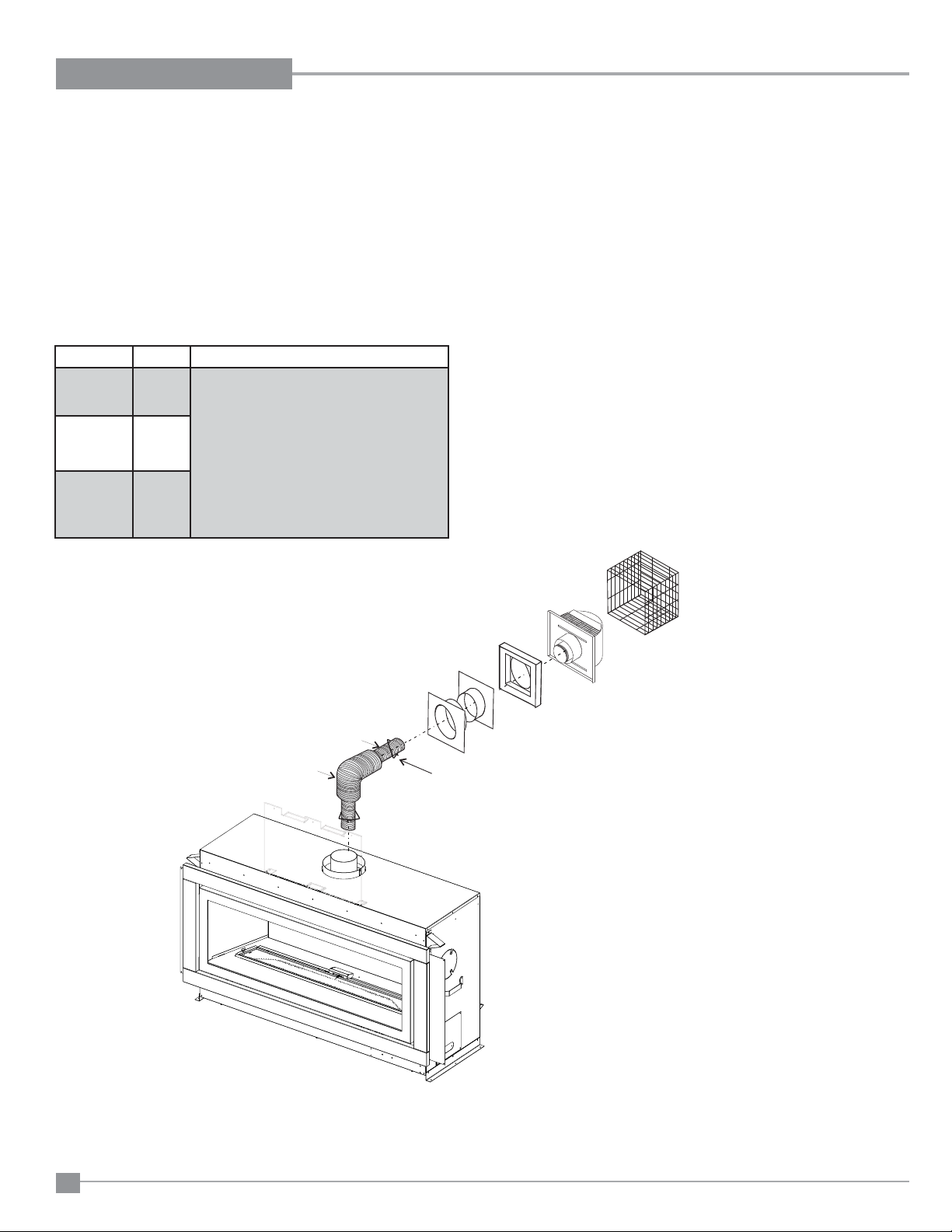

VENTING ARRANGEMENTS

HORIZONTAL TERMINATION (FLEX)

Regency® Direct Vent System

These venting systems, in combination with the HZ54E, have been tested and listed as a direct vent system by Warnock Hersey/Intertek. The location of the

termination cap must conform to the requirements in the Vent Terminal Locations diagram from the "Exterior Vent Termination Locations" section.

FPI Direct Vent (Flex) System Termination Kits include all the parts needed to install the HZ54E using a fl exible vent.

Notes:

1) Liner sections should be continuous without any joints or

seams.

FPI Kit # Length Contains:

#946-615 4 Feet 1) 8” fl exible liner (Kit length)

2) 5” fl exible liner (Kit length)

3) spring spacers

#946-618 6 Feet

#946-616 10 Feet

4) thimble

5) AstroCap termination cap

6) screws

7) tube of Mill Pac

8) plated screws

9) S.S. screws #8 x 1-1/2” drill point

10) vinyl siding standoff

5” dia. flue pipe

8” dia.

Flue pipe

Wall Thimble

(Mandatory in all

Horizontal Terminations)

spring spacer

Vinyl Siding

Standoff

Vent Guard - if required*

(Part #946-506/P)

AstroCap XL

Termination Cap

(Part #946-623/P)

2) Only Flex pipe purchased from FPI may be used for Flex

installations.

3) Horizontal vent must be supported every 3 feet.

4) A wall thimble is mandatory for all horizontal terminations

due to high temperatures.

TM

18

Regency Horizon HZ54E-1 Gas Fireplace

Page 19

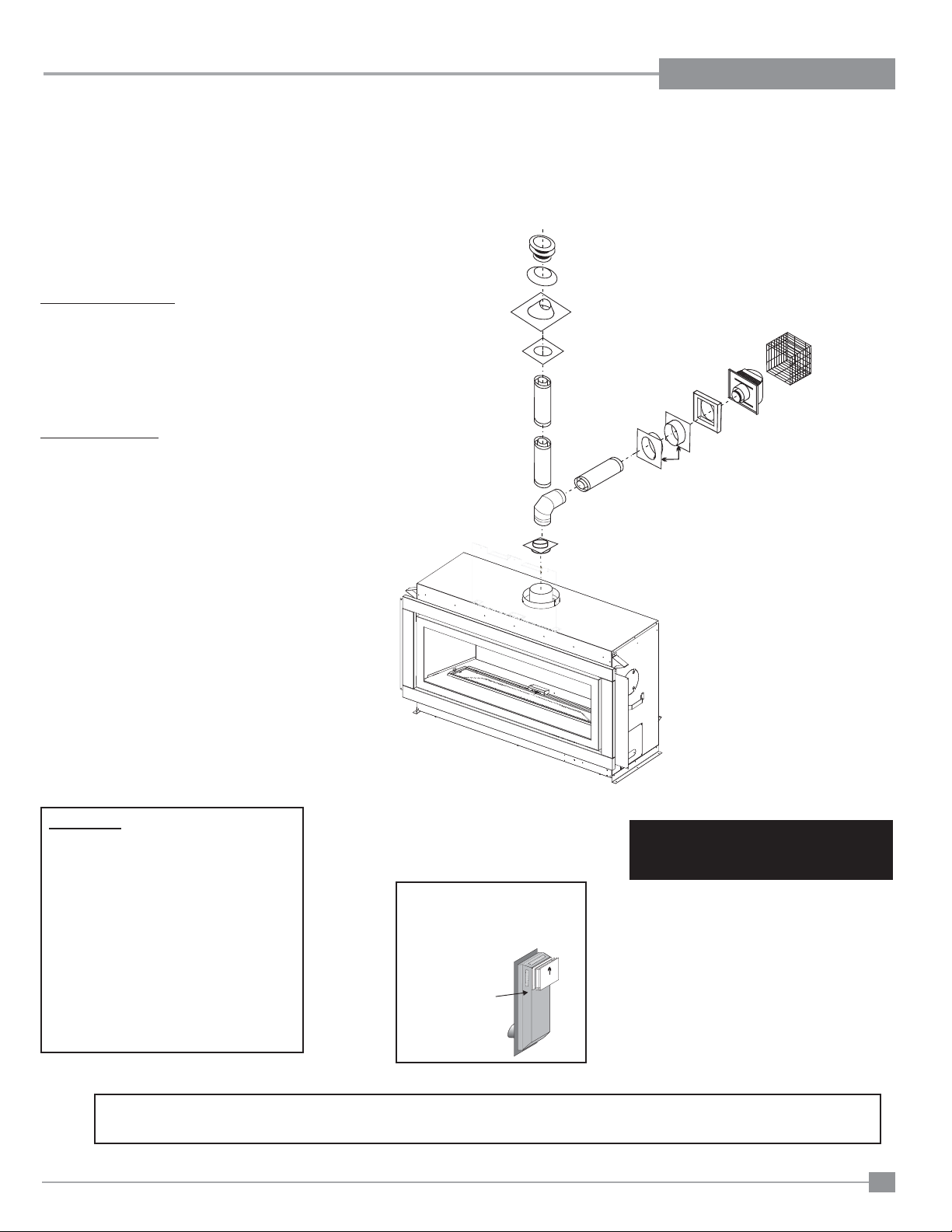

BASIC HORIZONTAL & VERTICAL TERMINATIONS

Rigid Pipe Vent Systems offer a complete line of

component parts for installation of both horizontal

and vertical installations. Many items are offered

in decorative black, as well as galvanized fi nish.

The minimum components required for a basic

Horizontal Termination are:

1 AstroCap XL Termination Cap

1 90o Elbow

1 Rigid Pipe Adaptor

1 Wall Thimble

1 Length of rigid pipe to suit wall thickness

The minimum components required for a basic

Vertical Termination are:

1 Vertical Termination Cap

1 Rigid Pipe Adaptor

1 Lengths of pipe to adequately

penetrate roof

1 Ceiling Firestop

1 Flashing

1 Storm Collar

RIGID PIPE VENTING SYSTEMS

Vertical Terminal

Storm Collar

Flashing

Ceiling Firestop

Pipe Length

Pipe

Length

Pipe Length

o

90 Elbow

Rigid Pipe

Adaptor (770-994)

Vinyl Siding

Standoff (Optional)

Wall Thimble

(Mandatory in all

Horizontal Terminations)

INSTALLATION

Vent Guard - if required*

(Part #946-506/P)

AstroCap XL

Termination Cap

(Part #946-623/P)

Wall thickness is measured from the back

standoffs to the inside mounting surface of

termination cap. For siding other than vinyl, furring

strips may be used, instead of a vinyl siding

standoff, to create a level surface to mount the

vent terminal. The T erminal must not be recessed

into siding. Measure the wall thickness including

furring strips.

If a Vinyl Siding Standoff is required (it must be

used with vinyl siding), measure to outside surface

of wall without siding and add 2 inches.

WARNING:

Do not combine venting components from

different venting systems.

Exception: However, use of the the AstroCap

XLTM is acceptable with all systems.

This product has been evaluated by Intertek for

using a Rigid Pipe Adaptor in conjunction with

Simpson DV Pro, Metal-Fab Sure-Seal, ICC

Excel and Selkirk Direct-Temp systems. Use

of these systems with the Rigid Pipe adaptor

is deemed acceptable and does not affect the

Warnock Hersey/Intertek listing of components.

Alternate

Horizontal Termination

Caps

Alternate Snorkel

Termination Cap

HOT

When using Rigid Vent other than

Simpson Dura-Vent, 3 screws must be

used to secure rigid pipe to adaptor.

The FPI AstroCap XL

Direct-Temp. AstroCap XLTM is a proprietary trademark of FPI Fireplace Products International Ltd. Dura-Vent® and Direct Vent are registered and/or

proprietary trademarks of Simpson Dura-Vent Co. Inc.

TM

is certifi ed for installations using FPI venting systems as well as Simpson Dura-Vent® Direct Vent Pro, ICC Excel and Selkirk

Regency Horizon HZ54E-1 Gas Fireplace

19

Page 20

INSTALLATION

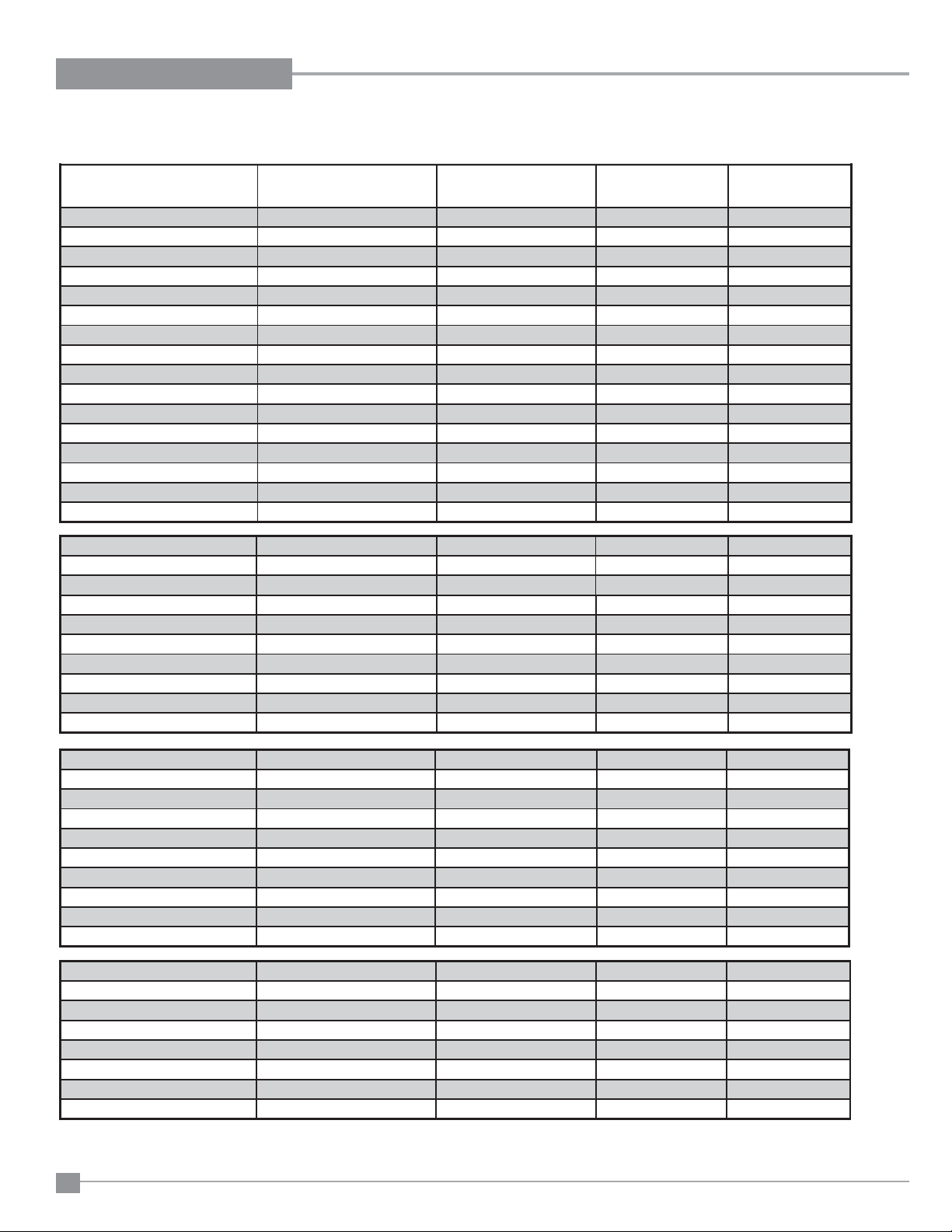

5” X 8” RIGID PIPE CROSS REFERENCE CHART

Components from different Manufacturers may not be mixed. Not All Rigid Pipe components are available directly from FPI.

Description

6” Pipe Length-Galvanized 58DVA-06 5DT-6 5D6 TC-5DL6

6” Pipe Length-Black 58DVA-06B 5DT-6B 5D6B TC-5DL6B

9” Pipe Length-Galvanized 58DVA-09 5DT-9 N/A N/A

9” Pipe Length-Black 58DVA-09B 5DT-9B N/A N/A

12” Pipe Length-Galvanized 58DVA-12 5DT-12 5D12 TC-5DL1

12” Pipe Length-Black 58DVA-12B 5DT-12B 5D12B TC-5DL1B

18” Pipe Length-Galvanized 58DVA-18 5DT-18 5D18 TC-5DL18

18” Pipe Length-Black 58DVA-18B - N/A from FPI 5DT-18B 5D18B TC-5DL18B

24” Pipe Length-Galvanized 58DVA-24 5DT-24 5D24 TC-5DL2

24” Pipe Length-Black 58DVA-24B 5DT-24B 5D24B TC-4DL2B

36” Pipe Length-Galvanized 58DVA-36 5DT-36 5D36 TC-5DL3

36” Pipe Length-Black 58DVA-36B 5DT-36B 5D36B TC-5DL3B

48” Pipe Length-Galvanized 58DVA-48 5DT-48 5D48 TC-5DL4

48” Pipe Length-Black 58DVA-48B 5DT-48B 5D48B TC-5DL4B

60” Pipe Length-Galvanized 58DVA-60 N/A N/A N/A

60” Pipe Length-Black 58DVA-60B - N/A from FPI N/A N/A N/A

Adjustable Length 3”-10”-Galvanized N/A N/A 5DAL TC-5DLT

Adjustable Length 3”-10”-Black N/A N/A 5DALB TC-5DLTB

Adjustable Length 11”-14” -Galvanized Disc. - See 58DV-08A 5DT-AJ N/A N/A

Adjustable Length 11”-14” -Black Disc. - See 58DV-08B 5DT-AJB N/A N/A

Extension Pipe 17”-24” -Galvanized Disc. - See 58DV-16A N/A N/A N/A

Extension Pipe 17”-24” -Black Disc. - See 58DV-16AB N/A N/A N/A

Adjustable Length 8-1/2”-Galvanized 58DVA-08A - N/A from FPI N/A N/A N/A

Adjustable Length 8-1/2”-Black 58DVA-08AB N/A N/A N/A

Extension Pipe 16”-Galvanized 58DVA-16A - N/A from FPI N/A N/A N/A

Extension Pipe 16”-Black 46DVA-16AB N/A N/A N/A

Simpson

Direct Vent Pro

®

Selkirk

Direct Temp™

Metal-Fab™

Sure Seal

ICC Excel

Direct

45º Elbow-Galvanized 58DVA-E45 5DT-EL45 5DT-EL45 TE-5DE45

45º Elbow-Black 58DVA-E45B 5DT-EL45B 5DT-EL45B TE-5DE45B

45º Elbow Swivel-Galvanized

45º Elbow Swivel-Black

90º Elbow-Galvanized 58DVA-E90 5DT-EL90S 5DT-EL90S TE-5DE90

90º Elbow-Black 58DVA-E90B 5DT-EL90SB 5DT-EL90SB TE-5DE90B

90º Elbow, Swivel-Galvanized

90º Elbow, Swivel-Black

90º Starter Elbow, Swivel-Galvanized N/A N/A N/A N/A

Adaptor* N/A N/A N/A N/A

Ceiling Support 58DVA-DC 5DT-CS 5DSP TE-5DE45

Cathedral Support Box 58DVA-CS 5DT-CSS 5DRS TE-5DE45B

Wall Support/Band 58DVA-WS 5DT-WS/B 5DWS N/A

Offset Support

Wall Thimble-Black 58DVA-WT 5DT-WT 5DWT TE-5DE90

Wall Thimble Support/Ceiling Support 58DVA-DC

Firestop Spacer 58DVA-FS 5DT-FS 5DFS N/A

Trim Plate-Black 58DAV-WFS 5DT-TP 5DCP N/A

Disc. - See 58DVA-E45

Disc.-See 58DVA-E45B

Disc. - See 46DVA-E45

Disc. - See 46DVA-E45

58DVA-ES - N/A from FPI

- N/A from FPI N/A N/A TE-5DE90B

20

N/A N/A N/A

N/A N/A N/A

N/A N/A N/A

N/A N/A N/A

5DT-OS N/A N/A

Regency Horizon HZ54E-1 Gas Fireplace

Page 21

INSTALLATION

Description

Attic Insulation Shield 12” 58DVA-IS N/A from FPI N/A N/A N/A

Basic Horizontal Termination Kit (A) N/A 5DT-HKA N/A N/A

Horizontal Termination Kit (B) 58DVA-KHA 5DT-HKB N/A N/A

Vertical Termination Kit 58DVA-VHA 5DT-VKC N/A N/A

High Wind Vertical Cap 58DVA-VCH N/A N/A TM-5VT

High Wind Horizontal Cap N/A N/A N/A TM-5DHT

Horizontal Square Termination Cap N/A 5DT-HHC 5DHT TM-5HT

Vertical Termination Cap N/A 5DT-HVC 5DVT TM-5VT

Storm Collar 58DVA-SC 5DT-SC 5DSC TM-SC

Adjustable Flashing 0/12-6/12 58DVA-F6 5DT-AF6 5DF TF-5FA

Adjustable Flashing 6/12-12/12 58DVA-F12 5DT-AF12 5DF1-2 TF-5FB

Vinyl Siding Standoff 58DVA-VSS 5DT-VS 5DVS TM-VSS

Vinyl Siding Shield Plate N/A 5DT-VSP N/A N/A

Snorkel Termination 14” 58DVA-SNK14 N/A N/A TM-5ST14

Snorkel Termination 36” 58DVA-SNK36 (N/A - FPI) N/A N/A TM-5ST36

Restrictor Disk 58DVA-RD N/A N/A TM-5DS

Colinear Flex Connectors N/A N/A N/A N/A

Simpson

Direct Vent Pro

®

Selkirk

Direct Temp™

Metal-Fab™

Sure Seal

ICC Excel

Direct

FPI

946-604/P Simpson Direct Vent -Vent Guard (Optional) 946-623/P AstroCap XL Horizontal Cap

770-994 Rigid Pipe Adaptor (Must use with all rigid piping) 946-506/P Vent Guard (Optional)

946-606 Starter collar reducer 5” x 8” to 4” x 6-5/8” 946-625 Vinyl Siding Standoff - AstroCap XL

Note: When using Metal-Fab Sure Seal Rigid Piping - please note that the Adaptor (4DDA) must be used in conjunction with FPI Rigid Pipe Adaptor (510-994).

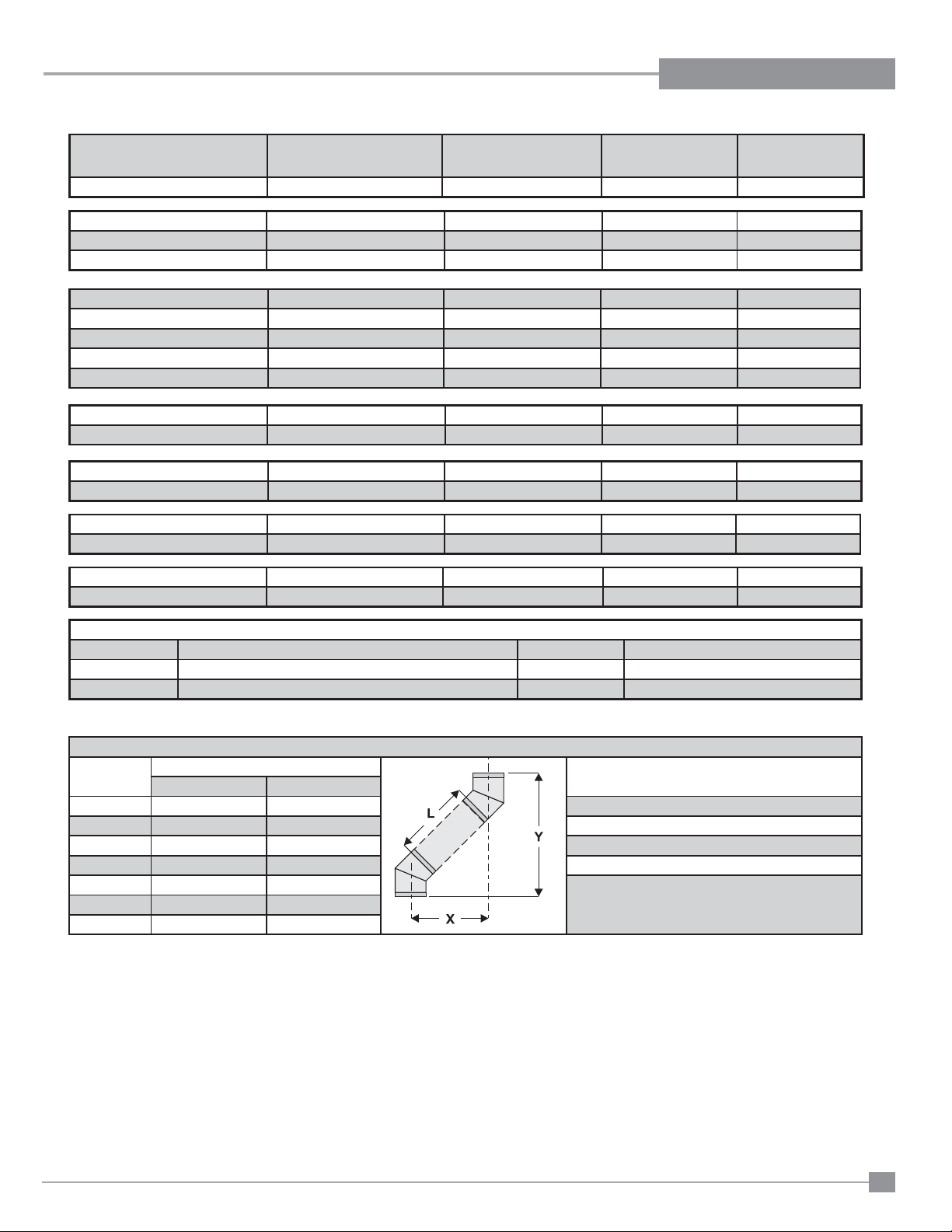

Offset Pipe Selection: Use this table to determine offset pipe lengths.

Pipe Length

(L)

0” (0mm) 5-11/16” (144mm) 15-5/16” (389mm) Simpson Direct Vent Pro: www.duravent.com

6” (152mm) 8-13/16” (224mm) 18-7/16” (468mm) Selkirk Direct-Temp: www.selkirkcorp.com

9” (229mm) 10-15/16” (278mm) 20-9/16” (522mm) Metal-Fab Sure Seal: www.mtlfab.com

12” (305mm) 13” (330mm) 22-11/16” (576mm) Industrial Chimney Company: www.icc-rsf.com

24” (610mm) 21-7/16” (697mm) 31-1/16” (789mm) Note: Horizontal runs of vent must be level, or have a 1/4”

36” (914mm) 29-13/16” (757mm) 39-7/16” (1002mm)

48” (1219mm) 38-1/4” (972mm) 47-7/8” (1216mm)

5” x 8” Venting For specifi c instructions on venting components - visit the

Run (X) Rise (Y)

manufacturers website listed below.

rise for every 1 foot of run towards the termination.

Never allow the vent to run downward - this could cause high

temperatures and may present a possible fi re hazard.

Regency Horizon HZ54E-1 Gas Fireplace

21

Page 22

INSTALLATION

2

2

0

0

12

12 20

6

6 14

4

4

14

8

8 16

10

10

18

16

18

2

2

0

0

12

12 20

6

6 14

4

4

14

8

8 16

10

10

18

16

18

VENTING ARRANGEMENTS

ALLOWABLE HORIZONTAL TERMINA-

TIONS FOR HZ54E-NG

The diagram shows all allowable combinations of vertical runs with horizontal

terminations, using one 90o (two 45o elbows equal one 90o elbow).

Note: Must use optional rigid pipe adapter (Part# 770-994) when using

Rigid Pipe Venting Systems.

18

Vertical Height (Feet)

Vent Restrictor

on Set 3

Vent Restrictor

on Set 2

Horizontal (Feet)

Vent Restrictor

on Set 1

(factory setting)

18

VENTING ARRANGEMENTS

ALLOWABLE HORIZONTAL TERMINA-

TIONS FOR HZ54E-LP

The diagram shows all allowable combinations of vertical runs with horizontal

terminations, using one 90o (two 45o elbows equal one 90o elbow).

Note: Must use optional rigid pipe adapter (Part# 770-994) when using

Rigid Pipe Venting Systems.

18

Vertical Height (Feet)

Vent Restrictor

on Set 4

Horizontal (Feet)

Vent Restrictor

on Set 1

(factory setting)

18

44” (1118mm)

Minimum Height

Requirement

VENT RESTRICTOR SETTING:

Vent restrictor factory set, no adjustment required unless otherwise

indicated.

Refer to the "Vent Restrictor Position" section for details on how to

change the vent restrictor from the factory setting of Set 1 to Set 2 or

Set 3 if required.

®

Note: Regency

Direct Vent System (Flex) is only approved for

horizontal terminations.

• Maintain clearances to combustibles as listed in "Clearances"

section

• Horizontal vent must be supported every 3 feet.

• Firestops are required at each fl oor level and whenever passing

through a wall.

• A wall thimble is mandatory for all horizontal terminations due

to high temperatures.

44” (1118mm)

Minimum Height

Requirement

VENT RESTRICTOR SETTING:

Vent restrictor factory set, no adjustment required unless otherwise

indicated.

Refer to the "Vent Restrictor Position" section for details on how to change the

vent restrictor from the factory setting of Set 1 to Set 4 if required.

Note: Regency

®

Direct Vent System (Flex) is only approved for horizontal

terminations.

• Maintain clearances to combustibles as listed in "Clearances" section

• Horizontal vent must be supported every 3 feet.

• Firestops are required at each fl oor level and whenever passing

through a wall.

• A wall thimble is mandatory for all horizontal terminations due to

high temperatures.

22

Regency Horizon HZ54E-1 Gas Fireplace

Page 23

Horizontal Venting with Two (2) 90o Elbows

One 90o elbow = Two 45o elbows.

Option V H + H1

A) 2' Min. 4' Max.

B) 3' Min. 6' Max.

C) 4' Min. 8' Max.

D) 5' Min. 9' Max.

E) 6' Min. 10' Max.

Please note minimum 1 foot between 90o elbows is

required.

With these options,

maximum total pipe

length is 30 feet with

minimum of 6 feet total

vertical and maximum

10 feet total horizontal.

NG and LP

H1

INSTALLATION

H

V

VENT RESTRICTOR SETTING:

Vent restrictor factory set at Set 1, no adjustment

required.

Horizontal Venting with Three (3) 90o Elbows

One 90o elbow = Two 45o elbows.

Option V H V + V1 H + H1

A) 2' Min. 1' Max. 3' Min. 2' Max.

B) 2' Min. 2' Max. 5' Min. 4' Max.

C) 3' Min. 2' Max. 7' Min. 5' Max.

D) 4' Min. 3 Max. 9' Min. 6' Max.

E) 5' Min. 4' Max. 10' Min. 7' Max.

F) 6' Min. 6' Max. 11' Min. 9' Max.

VENT RESTRICTOR SETTING:

Vent restrictor factory set at Set 1, no adjustment required.

With these options, max.

total pipe length is 30 feet

with min. of 11 feet total

vertical and max. 9 feet total

horizontal.

Please note min. 1 foot

between 90o elbows is

required.

NG and LP

H1

H

V1

V

Regency Horizon HZ54E-1 Gas Fireplace

23

Page 24

INSTALLATION

One 90o elbow = Two 45o elbows.

Option V H + H1 V + V1

A) 2' Min. 2' Max. 4' Min.

B) 3' Min. 4' Max. 6' Min.

C) 4' Min. 5' Max. 7' Min.

D) 5' Min. 6' Max. 8' Min.

E) 6' Min. 8' Max. 9' Min.

VENT RESTRICTOR SETTING:

Vent restrictor factory set at Set 1, no adjustment required.

V1

Vertical Venting with Three (3) 90o Elbows

NG and LP

With these options, max. total

pipe length is 30 feet with min.

of 9 feet total vertical and max.

8 feet total horizontal.

Please note min. 1 foot

between 90o elbows is

required.

H1

H

V

24

Regency Horizon HZ54E-1 Gas Fireplace

Page 25

INSTALLATION

0

2

4

6

40

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

6

8

2

0

4

10

12 16

18

14

20

VENTING ARRANGEMENTS

ALLOWABLE VERTICAL TERMINATIONS FOR HZ54E-NG

The shaded area in the diagram shows all allowable

combinations of straight vertical and offset to vertical

terminations, using two 90o elbows, with Rigid Pipe Venting

Systems for Natural Gas. Two 45

o

elbows equal to one 90o

elbow. Maximum of four 45o elbows allowed.

Horizontal (Feet)

12

Maximum: 40 ft. (12.2m)

Vent Restrictor on Set 4

Vent Restrictor on Set 2

Vertical Height (Feet)

Please note min. 1 foot between 90

o

Maximum: 27 ft. (8.2m)

elbows is required.

Vent Restrictor on Set 1

• Vent must be supported at offsets.

• Firestops are required at each fl oor level and

(factory setting)

whenever passing through a wall.

• Maintain clearances to combustibles as listed in

the "Clearances" section.

• Refer to the "Vent Restrictor Position" section

for details on how to change the vent restrictor

from the factory setting of Set 1 to Set 2 or Set 4

if required.

Note: Must use optional fl ue adaptor when using

Rigid Pipe (Part # 770-994).

Minimum length of pipe

between elbows 12” (305mm)

Min. 44”

(1118mm)

Max. 10’ (3m)(centerline to centerline)

Minimum

8’6” (2.6m)

Regency Horizon HZ54E-1 Gas Fireplace

25

Page 26

INSTALLATION

0

2

4

6

40

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

6

8

2

0

4

10

12 16

18

14

20

ALLOWABLE VERTICAL TERMINATIONS FOR HZ54E-LP

VENTING ARRANGEMENTS

The shaded area in the diagram shows all allowable

combinations of straight vertical and offset to vertical

terminations, using two 90o elbows, with Rigid Pipe Venting

Systems for Propane. Two 45

o

elbows equal to one 90o

elbow. Maximum of four 45o elbows allowed.

Horizontal (Feet)

12

Maximum: 40 ft. (12.2m)

Vent Restrictor on Set 5

Vent Restrictor on Set 4

Vertical Height (Feet)

Please note min. 1 foot between 90

o

Maximum: 27 ft. (8.2m)

elbows is required.

• Vent must be supported at offsets.

Vent Restrictor on Set 1

(factory setting)

• Firestops are required at each fl oor level and

whenever passing through a wall.

• Maintain clearances to combustibles as listed in

the "Clearances" section.

• Refer to the "Vent Restrictor Position" section for

details on how to change the vent restrictor from

the factory setting of Set 1 to Set 4 or Set 5

if required.

Note: Must use optional fl ue adaptor when using

Rigid Pipe (Part # 770-994).

Minimum length of pipe

between elbows 12” (305mm)

Min. 44”

(1118mm)

Max. 10’ (3m)(centerline to centerline)

Minimum

8’6” (2.6m)

26

Regency Horizon HZ54E-1 Gas Fireplace

Page 27

INSTALLATION

UNIT INSTALLATION

WITH HORIZONTAL

TERMINATION

(Rigid Vent Systems)

A top clearance of 3"(76mm) and side & bottom

clearance of 2"(51mm) must be maintained;

except when passing through a wall, ceiling, or

at the termination where the use of a fi restop

or wall thimble reduces the required clearance

to 1-1/2" (38mm). We recommend framing a

11"(279mm) x 1 1"(279mm) (inside dimensions)

hole to give structural rigidity for mounting the

termination.

Install the vent system according to the manufacturer's

instructions included with the components.

1) Set the unit in its desired location. Check to

determine if wall studs or roof rafters are in

the way when the venting system is attached.

If this is the case, you may want to adjust the

location of the unit. Rough in the gas preferably

on the right side of the unit.

2) Direct Vent pipe and fi ttings are designed with

special twist-lock connections to connect the

venting system to the appliance fl ue outlet. A

twist-lock appliance adaptor is required.

3) In conjunction with the Simpson Direct Vent

Pro system, install the adaptor after the unit is

set in its desired location. Put a bead of high

temperature silicone inside the outer section

of the adapter and a bead of Mill Pack on the

inner collar. Slip the adapter over the existing

inner and outer fl ue collar. Fasten to the outer

collar only with the 3 supplied screws (drilling

pilot holes will make this easier).

4) Level the fi replace and fasten it to the framing

using nails or screws through the top and side

nailing strips.

5) Assemble the desired combination of pipe and

elbows to the appliance adaptor and twist-lock

for a solid connection.

Note: For best results and optimum performance

with each approved venting system, it is

highly recommended to apply “Mill-Pac”

sealant (supplied) to every inner pipe

connection. Failure to do so may result

in drafting or performance issues not

covered under warranty. Silicone (red

RTV) is optional.

Diagram 1

Horizontal runs of vent must be supported every

3 feet (0.9meter). Wall straps are available for

this purpose.

6) Mark the wall for a 11" x 1 1" (279mm x 279mm)

square hole. The center of the square hole

should line up with the center-line of the

horizontal pipe. Cut and frame the 11 inch

(279mm) square hole in the exterior wall where

the vent will be terminated. See diagram 2 for

center line requirements.

If the wall being penetrated is constructed of

non-combustible material, i.e. masonry block

or concrete, an 8" (203mm) diameter hole is

acceptable.

Diagram 2

Note:

a) The horizontal run of vent must be level, or

have a 1/4 inch rise for every 1 foot of run

towards the termination. Never allow the

vent to run downward. This could cause

high temperatures and may present the

possibility of a fi re.

b) The location of the horizontal vent

termination on an exterior wall must meet

all local and national building codes, and

must not be blocked or obstructed. See

"Exterior Vent Termination Locations"

section for more details.

7) Ensure that the pipe clearances to combustible

materials are maintained (Diagram 5). Install

the termination cap.

Note: If installing termination on a vinyl siding

covered wall, a vinyl siding standoff or

furring strips must be used to ensure

that the termination is not recessed into

the siding.

Diagram 5

The four wood screws provided should be

replaced with appropriate fasteners for stucco,

brick, concrete, or other types of sidings.

8) Before connecting the horizontal run of vent pipe

to the vent termination, slide the Wall Thimble

over the vent pipe. The wall thimble is required

for all horizontal terminations.

9) Slide the appliance and vent assembly towards

the wall carefully inserting the vent pipe into the

vent cap assembly. It is important that the vent

pipe extends into the vent cap suffi cient distance

so as to result in a minimum pipe overlap of

1-1/4 inches (32mm). Secure the connection

between the vent pipe and the vent cap.

10) Install wall thimble in the center of the 11"

(279mm) square and attach with wood screws

(Diagram 7).

Diagram 7

Regency Horizon HZ54E-1 Gas Fireplace

27

Page 28

INSTALLATION

UNIT INSTALLATION

WITH VERTICAL

TERMINATION

(Rigid Vent Systems)

Note: A clearance of 2"(51mm) must be

maintained; except when passing

through a wall, ceiling, or at the

termination where the use of a fi restop

or wall thimble reduces the required

clearance to 1-1/2" (38mm). We

recommend framing a 11"(279mm) x

11"(279mm) (inside dimensions) hole

to give structural rigidity for mounting

the termination.

1) Maintain the 1-1/2" (38mm)

clearances (air spaces)

to combustibles when

passing through ceilings,

walls, roofs, enclosures,

attic rafter, or other nearby

combustible surfaces,

ensuring that the use of

a firestop or wall thimble

is used as noted above.

Do not pack air spaces

with insulation. Check

"Venting Arrangement

- Vertical Termination"

section for the maximum

vertical rise of the venting

system and the maximum

horizontal offset

limitations.

2) Set the gas appliance

in its desired location.

Drop a plumb bob

down from the ceiling

to the position of the

appliance fl ue exit,

and mark the location

where the vent will

penetrate the ceiling.

Drill a small hole at

his point. Next, drop

a plumb bob from

the roof to the hole

previously drilled in the ceiling, and mark the spot

where the vent will penetrate the roof. Determine

if ceiling joists, roof rafters or other framing will

obstruct the venting system. You may wish to

relocate the appliance or to offset, as shown in

Diagram 2 to avoid cutting load bearing members.

3) A Firestop spacer must be installed in the fl oor

or ceiling of every level.

Diagram 1

Diagram 2

4) Assemble the desired lengths of pipe and elbows.

Ensure that all pipes and elbow connections are

in the fully twist-locked position and sealed.

Note:

For best results and optimum performance

with each approved venting system, it is highly

recommended to apply “Mill-Pac” sealant to

every inner pipe connection. Failure to do so

may result in drafting or performance issues

not covered under warranty. Silicone (red RTV)

is optional.

5) Cut a hole in the roof centered on the small

drilled hole placed in the roof in Step 2. The hole

should be of suffi cient size to meet the minimum

requirements for clearance to combustibles of

1-1/2"(38mm). Slip the fl ashing under the shingles

(shingles should overlap half the fl ashing) as per

Diagram 4.

Diagram 4: The upper half of the fl ashing is

installed under the roofi ng material and not

nailed down until the chimney is installed.

This allows for small adjustments.

6) Continue to assemble pipe lengths.

Note: If an offset is necessary in the attic to

avoid obstructions, it is important to

support the vent pipe every 3 feet (0.9

meter), to avoid excessive stress on the

elbows, and possible separation. Wall

straps are available for this purpose

(Diagram 2).

Galvanized pipe is desirable above the roofl ine

due to its higher corrosion resistance. Continue

to add pipe sections through the fl ashing until

the height of the vent cap meets the minimum

height requirements specifi ed in Diagram 5 or

local codes. Note that for steep roof pitches, the

vertical height must be increased.

Diagram 5

Minimum Vent

Roof Pitch

fl at to 7/12 2 0.61

over 7/12 to 8/12 2 0.61

over 8/12 to 9/12 2 0.61

over 9/12 to 10/12 2.5 0.76

over 10/12 to 11/12 3.25 0.99

over 11/12 to 12/12 4 1.22

over 12/12 to 14/12 5 1.52

over 14/12 to 16/12 6 1.83

over 16/12 to 18/12 7 2.13

over 18/12 to 20/12 7.5 2.29

over 20/12 to 21/12 8 2.44

A poor draft, or down drafting can result from high

wind conditions near big trees or adjoining roof

lines, in these cases, increasing the vent height