Page 1

FPI FIREPLACE PRODUCTS INTERNATIONAL LTD.

6988 Venture St., Delta, BC Canada, V4G 1H4

918-515

G36D Zero Clearance Direct Vent Gas Fireplace

WARNING: If the information in these instructions are not followed exactly,

vapors and liquids in the vicinity of this or any other appliance. Installation

What to do if you smell gas:

Do not touch any electrical switch:

Do not touch any electrical switch:

Do not touch any electrical switch:

Do not touch any electrical switch:

do not use any phone in your building

Immediately call your gas supplier

Immediately call your gas supplier

Immediately call your gas supplier

Immediately call your gas supplier

from a neighbour's phone. Follow the

gas supplier's instructions.

If you cannot reach your gas supplier,

If you cannot reach your gas supplier,

If you cannot reach your gas supplier,

If you cannot reach your gas supplier,

call the fi re department.

www.regency-fi re.com

Installer: Please complete the details on the back cover

and leave this manual with the homeowner.

Homeowner: Please keep these instructions for future reference.

Page 2

®

G36D Zero Clearance Direct Vent Gas Fireplace

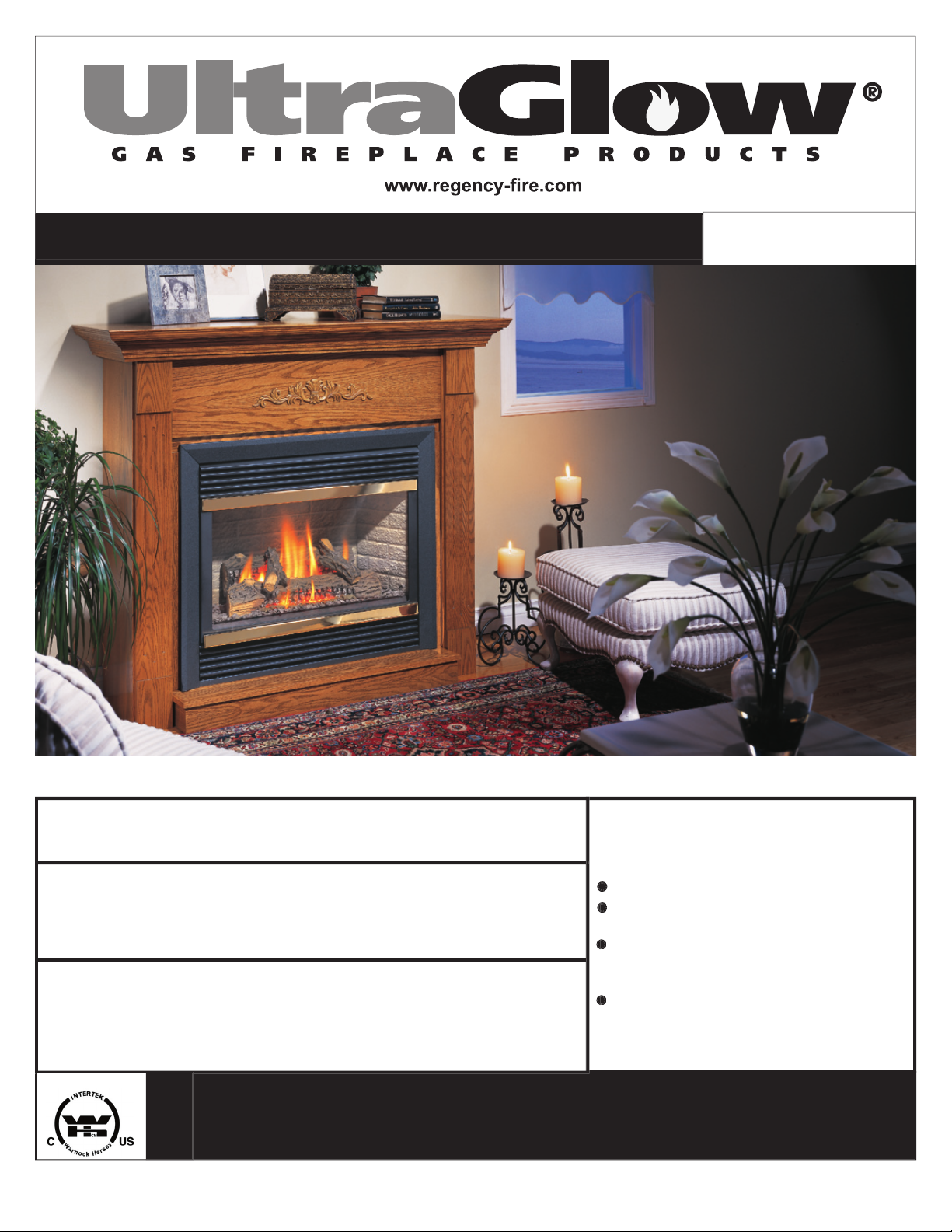

You are the owner of a state-of-the-art Gas Fireplace by

FIREPLACE PRODUCTS

®

®

product has been tested and listed by Warnock Hersey as a Direct Vent Wall Furnace to the following standards: VENTED GAS

®

®

Mobile/Manufactured Home Listed appliance

®

Mobile/Manufactured Home listed appliance

Page 3

®

G36D Zero Clearance Direct Vent Gas Fireplace

....................................................................

...................................................

Aeration

Adjustment

............

...........................................

...............................................................

.............................................................

.......................................

WARRANT

Y

............................................................

..................................................

Additional

...............................................

...................................................

Venting

.......................................................

Venting

...........................

...............................................

Vertical Termination

Venting Arrangements - Vertical Terminations

................

.............................................................

..........................................

1:

............................................

3:

...........................................................

Page 4

®

G36D Zero Clearance Direct Vent Gas Fireplace

UltraGlow

®

units are constantly being

APPAREIL FONCTIONNANT AU GAZ PROPANE

CONCU POUR ETRE POELE:

Pression d'allimentation

minimum

Pression à la tubulure d' chappement lev

e

Pression à la tubulure d' chappement basse

Grandeur de l'injecteur

D bit minimum selon

D bit maximum selon

l'altitude

Modéle

G36D-LP1

é é

é

é

é

é

Calorifique

Calorifique

DO NOT REMOVE THIS LABEL / NE PAS ENLEVER CETTE ÉTIQUETTE

300

NATURAL GAS:

Minimum supply pressure

Manifold pressure high

Manifold pressure

low

Orifice s

ize

Minimum input

Maximum input

Altitude

Model G36D-NG1

L

PROPANE:

Minimum supply pressure

Manifold pressure high

Manifold pressure

low

Orifice s

ize

Minimum input

Maximum input

Altitude

Model G36D-LP1

L

DOO R SEAL: Please

che ck that the do or is

pro perly seale d

FPI Fireplace Products International Ltd.

Delta,

BC, Canada

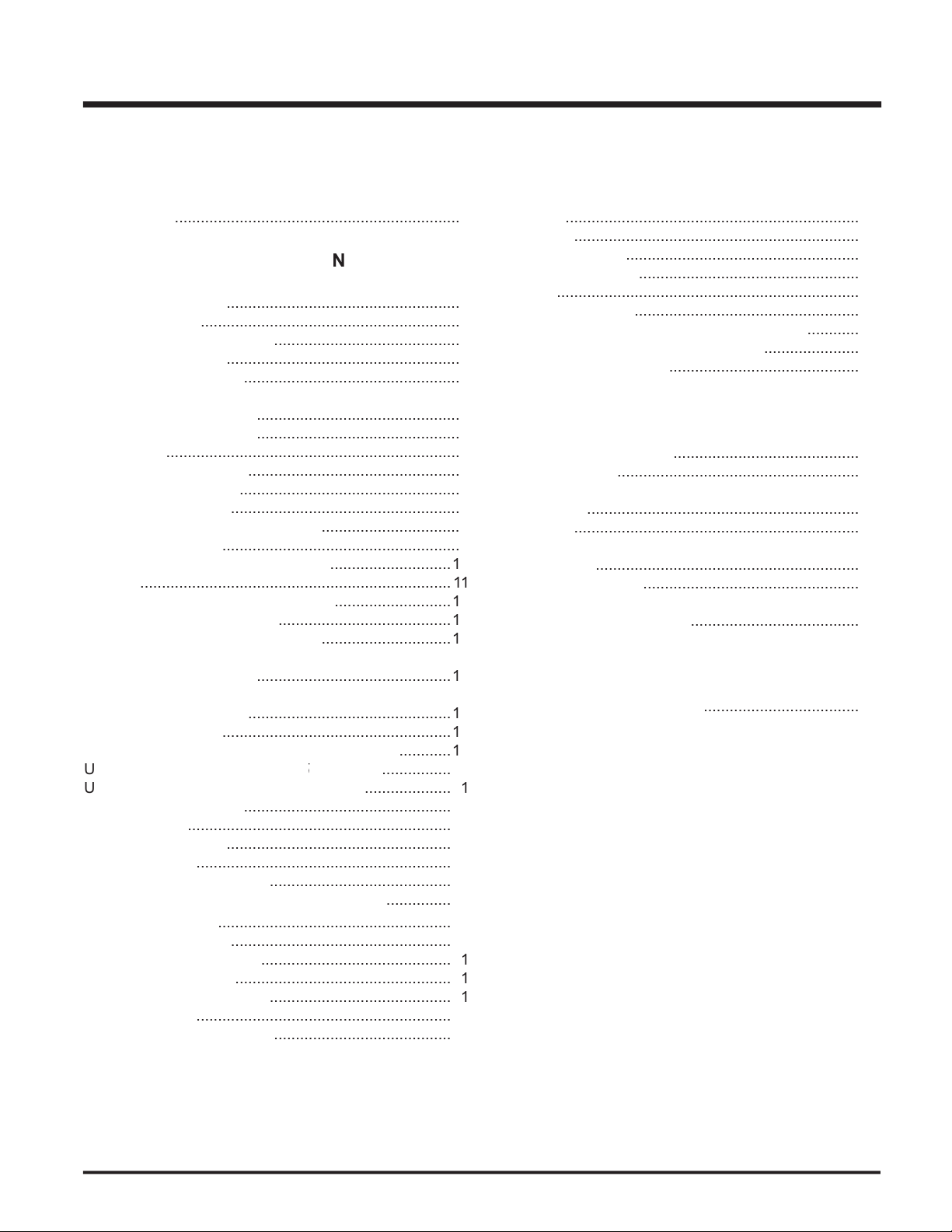

Minimum Clearances to Combustibles /

Degagement Minimum De Materiaux Combustibles

0" Clearance to

combustibles from

:

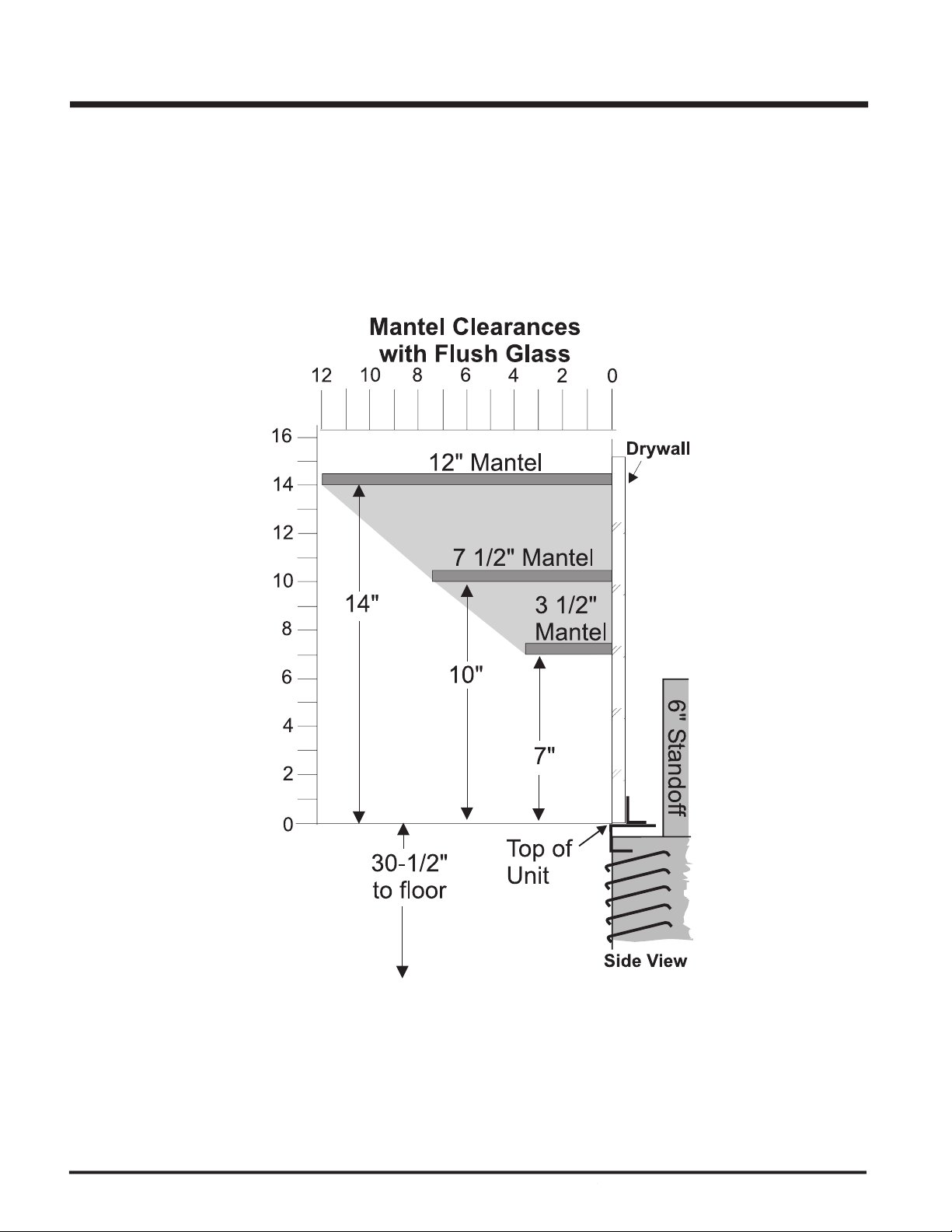

Mantel Clearances from

Top:

Side

Wall Clearance

from Side Facing

Alcove Clearances:

Minimum

Vent Clearances:

Top, sides, bottom and rear of unit

(A) Min. 7" (177mm

)

B) 6"

with Flush

Alcove approved for

Flush Louvers.

Max. Depth 36" (914mm)

Min. Widt

h 48" (1219mm),

Min. Height 72" (1229mm)

Horizontal To

p 2-1/2" (64mm)

Horizontal Side

Horizontal Bottom 1-1/2" (38mm

)

1-1/2" (38mm

)

Serial No./ No de serie

918-493

5" WC(1.25 kPa)

3.8" WC(0.95 kPa)

1.1" WC(0.27 kPa)

# 4

2 DMS

13,100 Btu/h (4.54 kW)

0-4500 ft/pi(0-1372 m)

26,000 B (8.79 )tu/h kW

12" WC(3.00 kPa)

11" W

C(2.74 kPa)

2.9" WC(0.72 kPa)

# 5

3 DMS

13,800 Btu/h (3.96 kW)

0-4500 ft/pi(0-1372 m)

26,000 B (7.91 )tu/h kW

APPAREIL FONCTIONNANT AU NATURAL GAZ

CONCU POUR ETRE POELE:

Pression d'allimentation

minimum

Pression à la tubulure d'

chappement lev e

Pression à la tubulure d'

chappement basse

Grandeur de l'injecteur

D bit minimum selon

D bit maximum selon

l'altitude

Modéle

G36D-NG1

é é é

é

é

é

Calorifique

Calorifique

VENTING: This appliance must be installed in accordance with the manufacturer's installation instructions and with local

codes, if any; if not, follow the current ANSI Z223.1 in the USA or the current CAN 1-B149 in Canada. For Manufactured

Home

Installation: This Direct Vent System Appliance must be installed in accordance with the manufacturer's

installation instructions

and Manufactured Home Construction and Safety Standard Title 24 CFR, Part 3280, or the

current Standard for Fire Safety Criteria for Manufactured Home Installations, Sites, and Communities ANSI/NFPA501A,

and with CAN/CSA Z240 MH Mobile Home Standard in Canada. This appliance is only for use with the type of gas

indicated

on the rating plate and may be installed in an aftermarket, permanently located, manufactured (mobile) home

where

not prohibited by local codes. See owner’s manual for details. This appliance is not convertible for use with other

gases, unless a certified kit is used.

Not for use

with solid fuel.

This vented gas fireplace is not for use with filters.

MAY BE INSTALLED IN MANUFACTURED (MOBILE)

HOMES AFTER FIRST SAL

E.

Listed:

Certified for/Certifi e pour:

Tested to:

Report No.

VENTED GAS FIREPLACE HEATER

CANADA and U.S.A.

Gas-Fired Appliances For Use At High Altitudes

476-3031-977

é

CAN/CGA-2.17-M91,

Vented Gas Fireplace Heaters ANSI Z21.88b-2003/CSA 2.33b-2003

Made in Canada/Fabrique au Canada

Duplicate S/N

B

B

32"

Ceilin

g

Wall

Wall

A

(See Instruction Manual for

Detailed Instructions)

Model/M

odele:

G36D-NG1

Model/Modele:

G36D-LP1

300

Page 5

®

G36D Zero Clearance Direct Vent Gas Fireplace

Check all clearances to combustibles. Refer

a) Locating Your Gas Stove

b) Clearances

c) Mantel Leg Clearances

d) Combustible Mantels

e) Framing and Finishing

f) Hearth Requirement

Assemble Top Standoffs and Top Facing

Install standard and optional features.

a. Log Set Installation

b. Standard Flush Door

c. Option 1: Remote Control

d. Option 2: Wall Switch

e. Option 3: Wall Thermostat

f. Installating the Optional Fan

Final check.

with these instructions. Carefully read all the

The appliance installation must conform

with local codes or, in the absence of local

The appliance when installed, must be

with the current National Electrical Code,

ANSI/NFPA 70 or CSA C22.1 Canadian

See general construction and assembly

This appliance must be connected to the

Inspect the venting system annually for

Venting terminals shall not be recessed into

Any safety glass removed for servicing

To prevent injury, do not allow anyone who

Wear gloves and safety glasses for protection

while doing required maintenance.

Be aware of electrical wiring locations in

walls and ceilings when cutting holes for

Un der no ci rc um stances sh ou ld t his

Installation and any repairs to this appliance

A professional service person should be

Do not slam shut or strike the glass door.

Under no circumstances should any solid

fuels (wood, paper, cardboard, coal, etc.)

The appliance area must be kept clear and

free of combustible materials, (gases and

AND AT LEAST ANNUALLY BY A

APPLIANCE SHOULD BE LOCATED

WARNING: FAILURE TO INSTALL THIS

APPLIANCE CORRECTLY WILL VOID

YOUR WARRANTY AND MAY CAUSE

A SERIOUS HOUSE FIRE.

AND SHOULD STAY AWAY TO AVOID

YOUN G CHILD REN SHOULD B E

ANCE.

Page 6

®

G36D Zero Clearance Direct Vent Gas Fireplace

Clocking the appliance to ensure the correct

If required, adjusting the primary air to ensure

When selecting a location for your fi replace,

Provi d e a d e q u a t e clear a n c e s f o r

The appliance must be installed on a fl at,

width and depth of the appliance.

The G36D Direct Vent Gas Fireplace can be

This appliance is Liste d for bedroom

The G36D Direct Vent Gas Fireplace is

A)

Flat on Wall

Flat on Wall Corner

Recessed into

Wall/Alcove

Corner

ADDITIONAL

Ensure that structural members are not cut

Ensure proper grounding using the #8

Page 7

®

G36D Zero Clearance Direct Vent Gas Fireplace

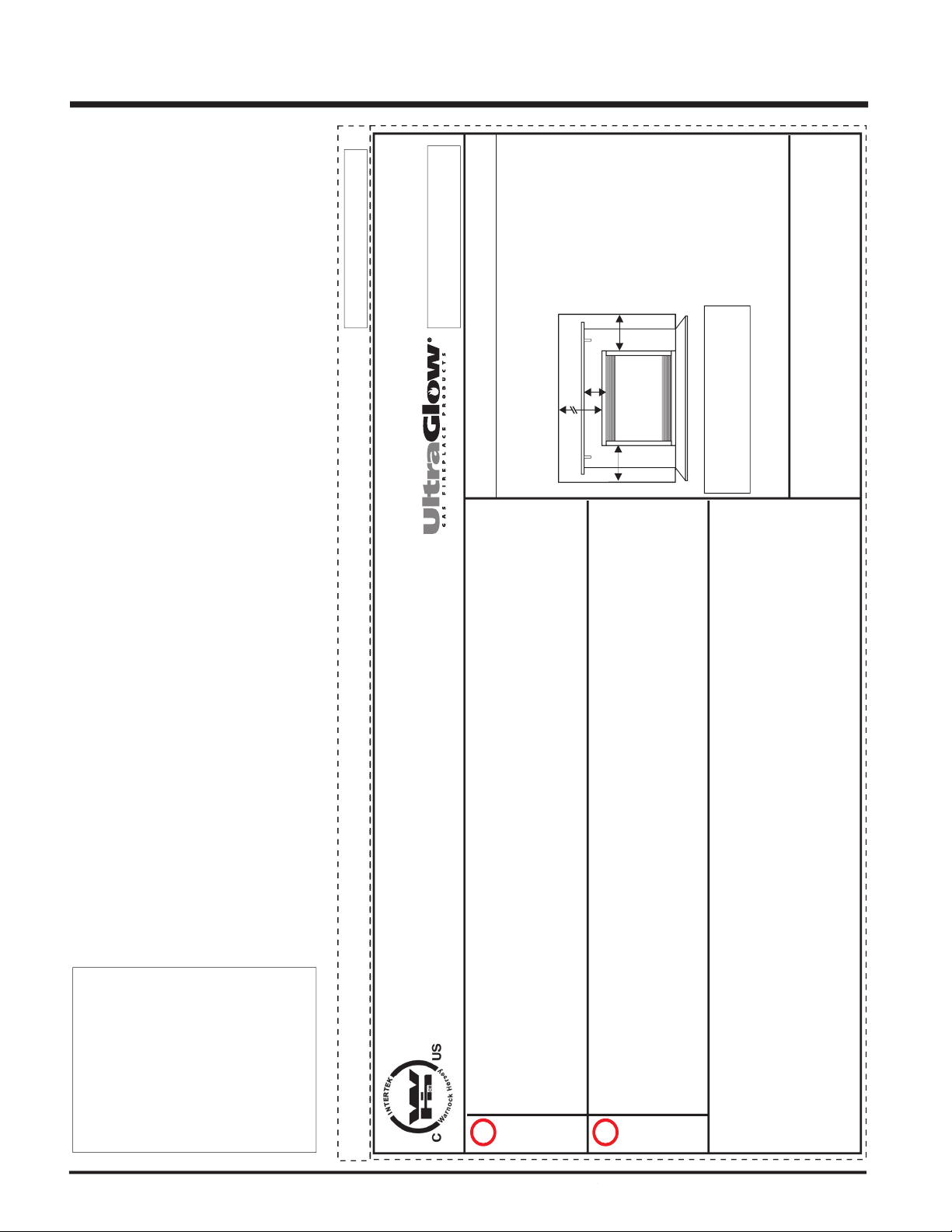

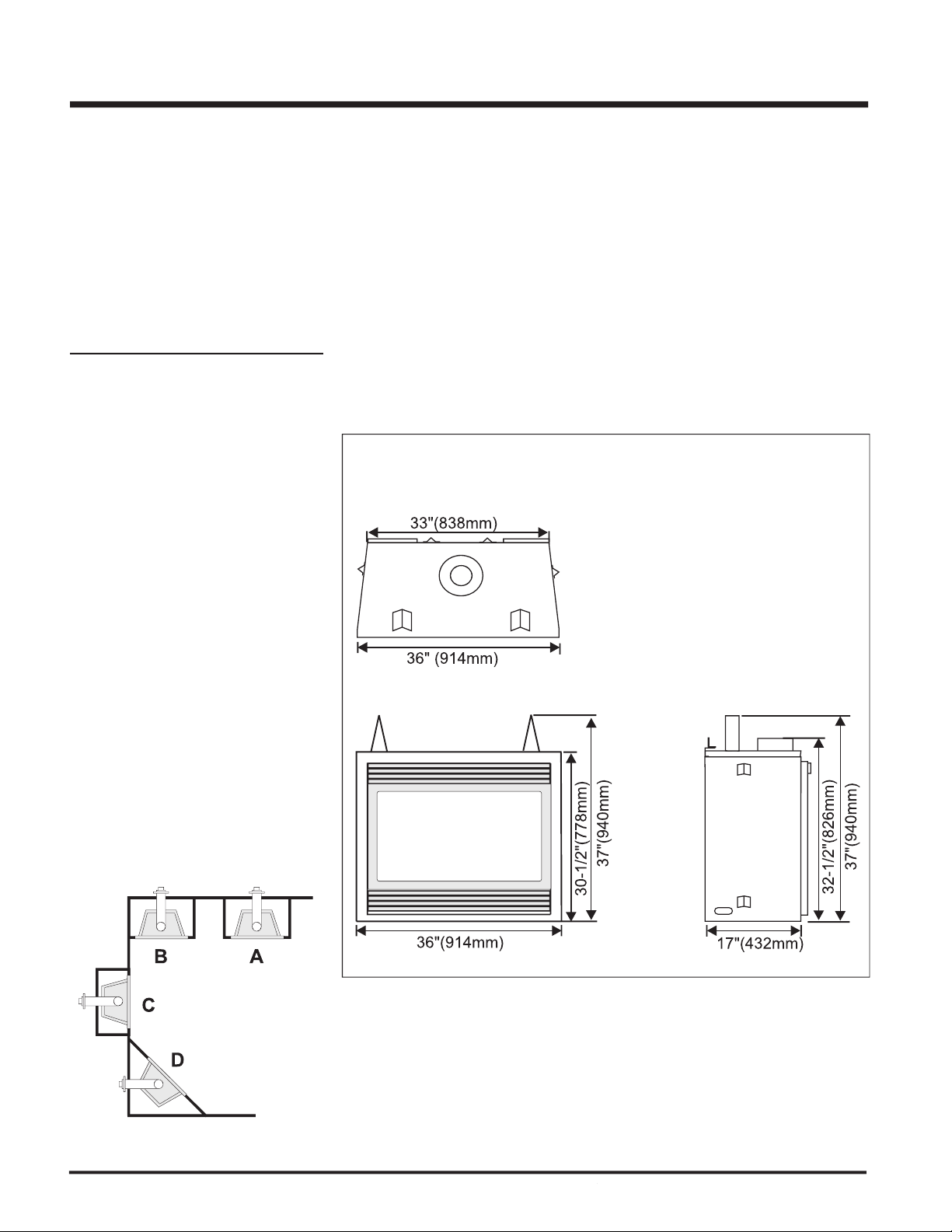

Determine the total thickness of facing

Frame in the enclosure for the unit with

framing material. The framed opening is

37-1/4" high x 36-1/4" wide x 17-3/8" deep

A major cause of chimney related fi res is

vent system be installed only in accordance

with these instructions.

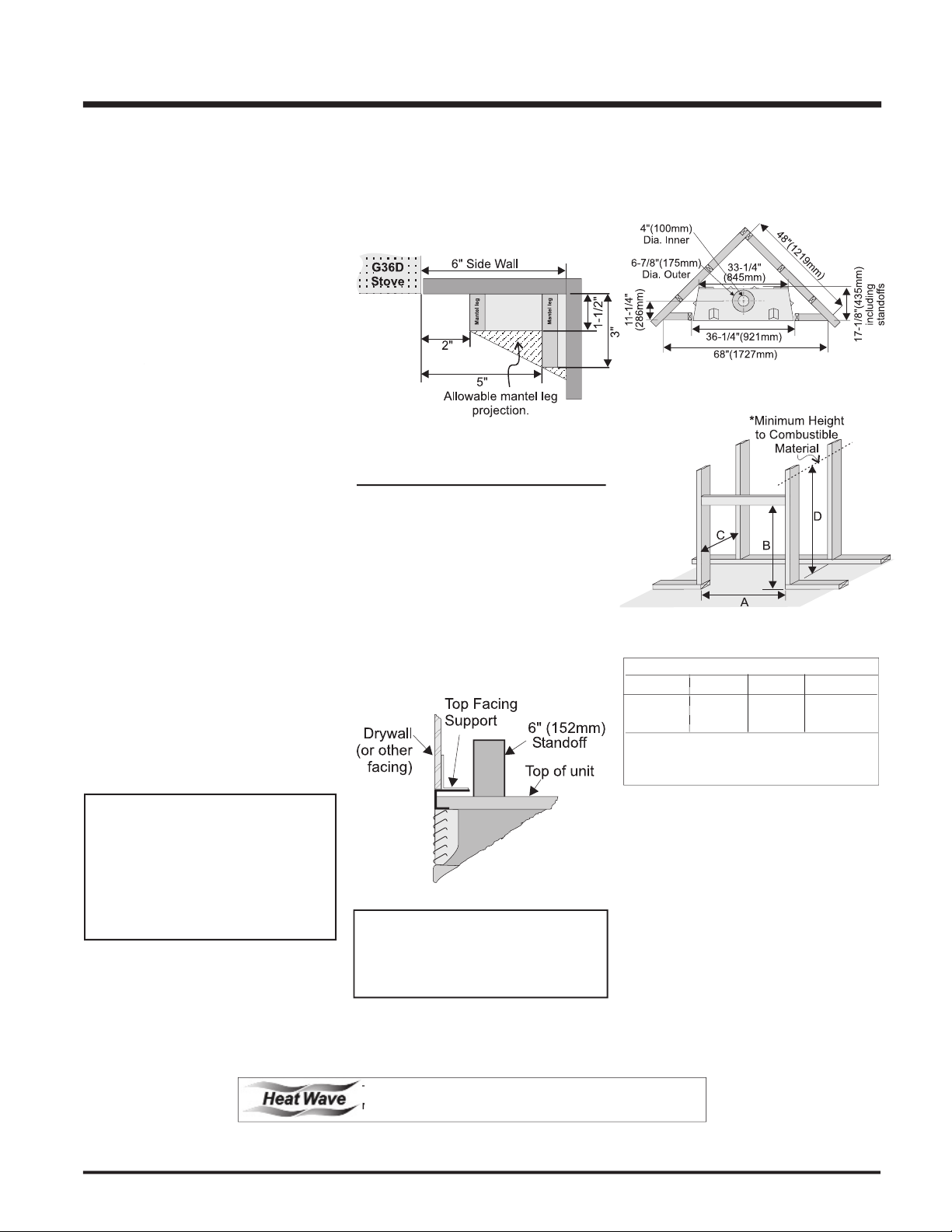

Back

0" (0mm)

Side

0" (0mm)

Floor

0" (0mm)

Mantel*

Ceiling

from top of unit. 32" (1016mm)

Flush Front

6" (152mm)

Top 2-1/2" (64mm)

Side 1-1/2" (38mm)

Bottom 1-1/2" (38mm)

Vertical Vent Clearances

1-1/4" (32mm)

Alcove Clearances**:

Max. Depth

36" (914mm)

Min. Width

48" 1219mm)

Min. Height

72" 1829mm)

For exterior walls, insulate the enclosure to

The top of the unit must not be closer than

WARNING:

Aseembly Prior to Installation" section for

Duct Kit has different clearance and framing

manual for details.

A B C D

36-1/4" 37-1/4" 17-3/8" 46-1/2"*

921mm 946mm 441mm 1181mm*

Page 8

®

G36D Zero Clearance Direct Vent Gas Fireplace

with a non-combustible board.

Page 9

®

G36D Zero Clearance Direct Vent Gas Fireplace

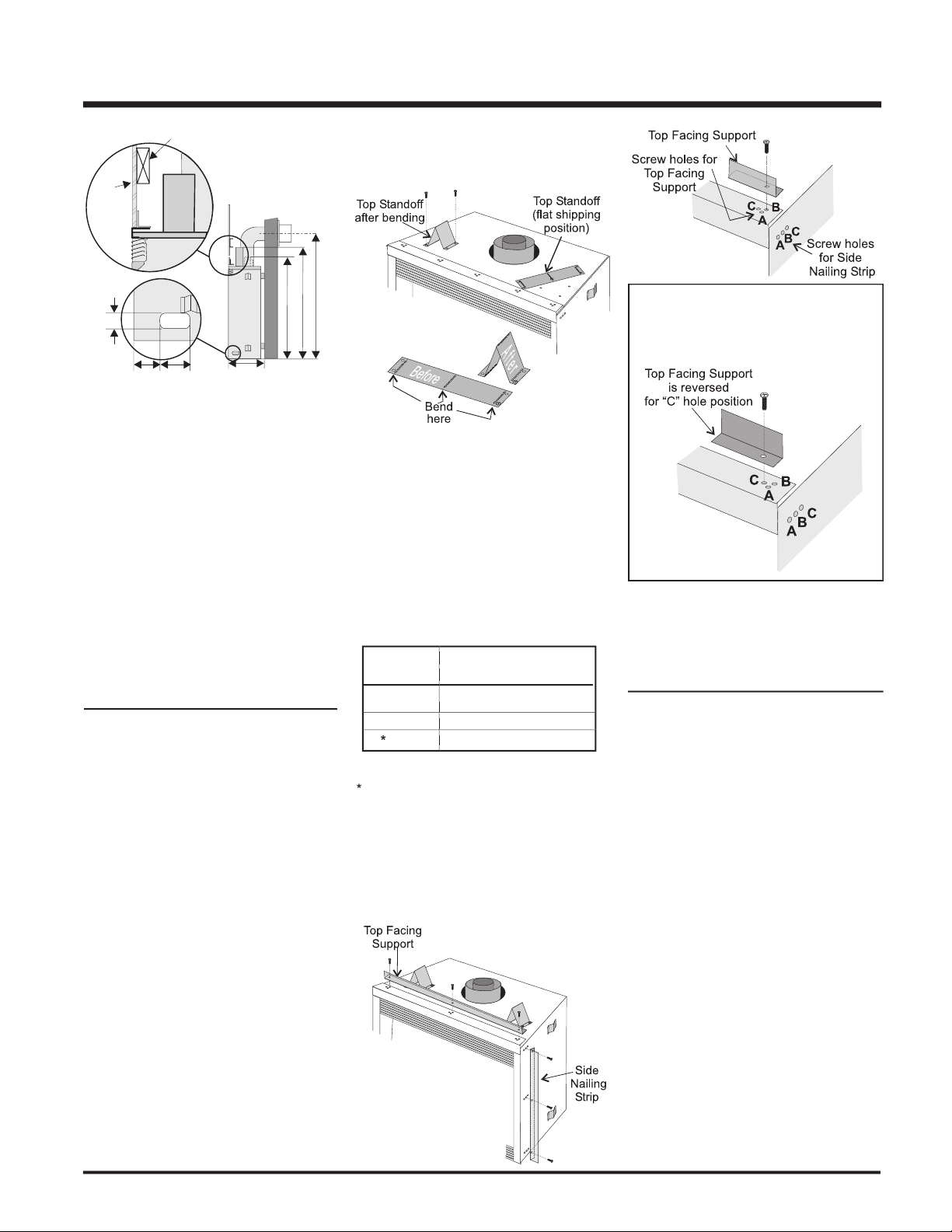

For "C" screw position the top facing support

Mount Top Facing Support using the 3

facing depth.

Use the same screw hole position for the

VENTING

17-1/8"

3-1/2"

4"

2"

40-1/2"

37

”

32-1/2"

10" dia. hole

through wall

for Flex

or for DuraVent

1/2"

Drywall

To

p Header

Opening for gas

connection

Use steel studs for framing where the

1-1/2" (38mm) clearance from the vent to

with 2 screws per standoff (on opposite

A 1/2" / 13mm

1-1/4" / 32mm

Page 10

®

G36D Zero Clearance Direct Vent Gas Fireplace

.

B

B

B

B

A

C

V

V

V

V

V

V

V

A

A

V

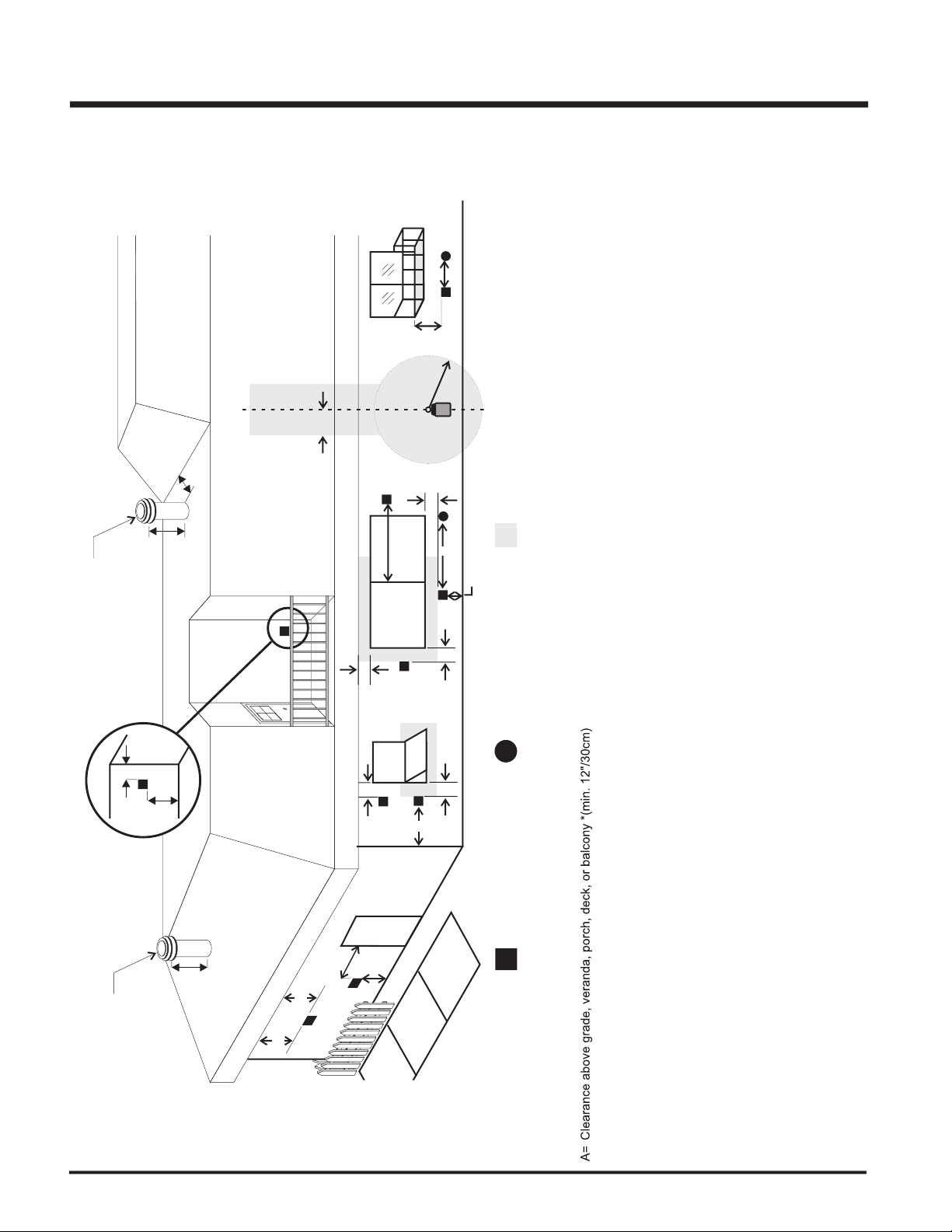

Fixed

Fixed

Openable

Closed

Closed

Openabl

e

N

L

B

E

B

M

D

F

K

H

j

Vertical

Termination

V

Vent

terminal

Area

where

terminal

is

not

permited

A

Air

supply

outlet

24"

V

A

G

Inside

corner

det

ail

V

24"

18"

Vertical

Termination

A= Clearance above grade, veranda, porch, deck, or balcony *(min. 12"/30cm)

AstroCap

AstroCap

Page 11

®

G36D Zero Clearance Direct Vent Gas Fireplace

VENTING

®

®

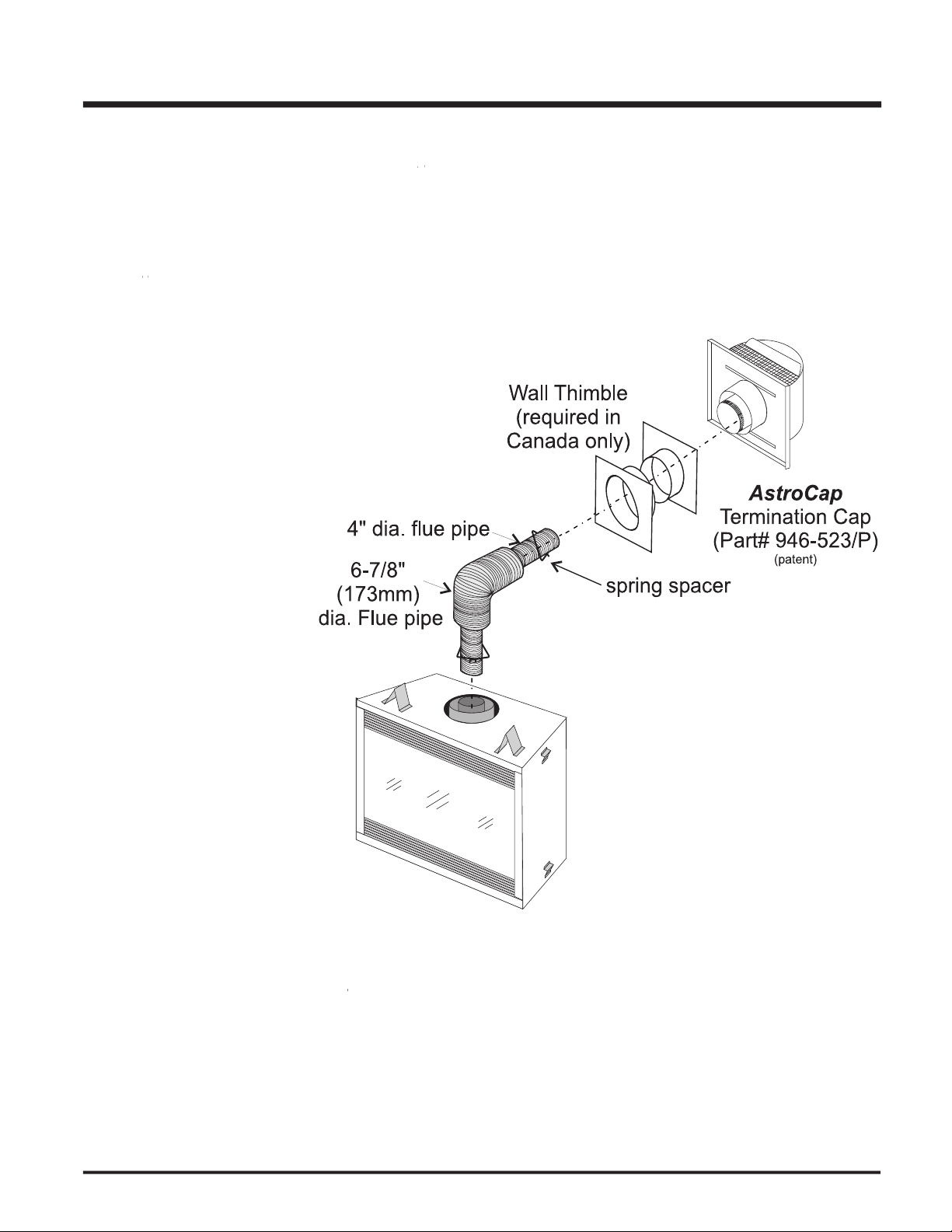

Direct Vent System (Flex)

®

®

Direct Vent Flex Termination Kit (Part # 946-515) includes all the parts

®

may be used for Flex installations.

6-7/8" dia. fl exible liner (4 ft. length)

4" dia. fl exible liner (4 ft. length)

spring spacers (4)

thimble (2)

AstroCap

termination cap (1)

screws (12)

tube of Mill Pac (1)

plated screws (8)

screws #8 x 1-1/2" Drill Point, Stainless Steel (4)

Page 12

®

G36D Zero Clearance Direct Vent Gas Fireplace

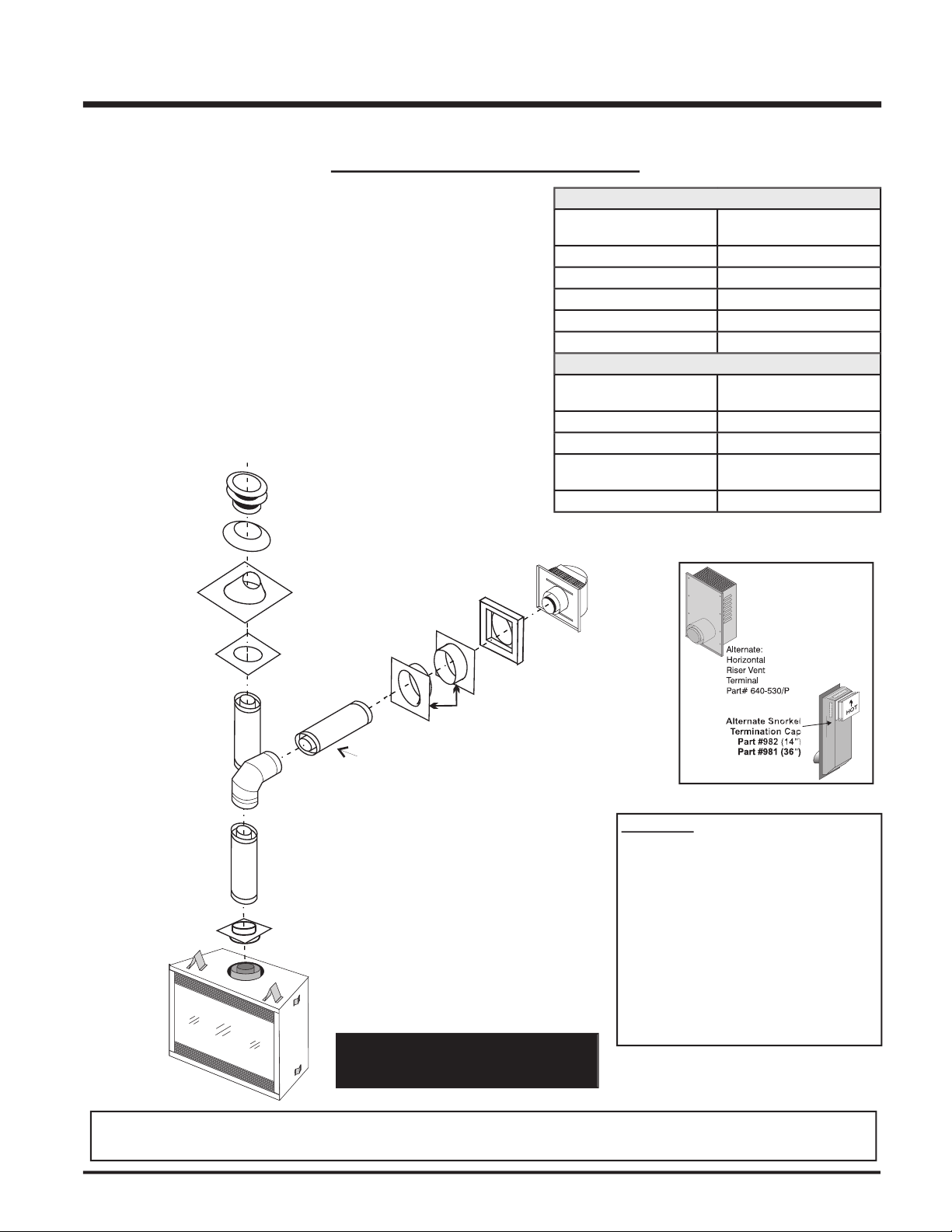

All Simpson Dura-Vent components are available directly from FPI.

®

Direct VentGS

®

Direct Vent

®

Adjustable Length, 11"-14", Galv. 911 4DT-AJ N/A

Adjustable Length, 11"-14", Black 911B 4DT-AJB N/A

Adjustable Length, 17"-24", Black 917B N/A N/A

Adjustable Length, 7" Galvinized N/A N/A 4D7A

Adjustable Length, 7" Black N/A N/A 4D7AB

Adjustable Length, 12" Galvinized N/A N/A 4D12A

Adjustable Length, 12" Black N/A N/A 4D12AB

Elbow, Galvinized 945 4DT-EL45 4D45L

Elbow, Black 945B 4DT-EL45B 4D45LB

Elbow, Swivel, Galvinized 945G N/A N/A

Elbow, Swivel, Black 945BG N/A N/A

Elbow, Galvinized 990 4DT-EL90S 4D90LS

Elbow, Black 990B 4DT-EL90SB 4D90LBS

Elbow, Swivel, Galvinized 990G N/A N/A

Elbow, Swivel, Black 990BG N/A N/A

Attic Insulation Shield 12" N/A N/A 4DAIS12

Attic Insulation Shield - Cold Climates 36" N/A N/A 4DAIS36

Vertical Termination Kit 978 4DT-VKC 4DVTK

Verical Termination Cap 980 4DT-HVC 4DVC

Adjustable Flashing, 0/12-6/12 943 4DT-AF6 4DF

Adjustable Flashing, 6/12-12/12 943S 4DT-AF12 4DF12

Vinyl Siding Standoff 950 4DT-VS N/A

Vinyl Siding Shield Plate N/A 4DT-VSP N/A

#N/A

#N/A

#N/A

#N/A

#N/A

#N/A

#N/A

#N/A

#N/A

#N/A

#N/A

#N/A

#N/A

#N/A

#N/A

Page 13

®

G36D Zero Clearance Direct Vent Gas Fireplace

Rigid Pipe Adaptor

(Part# 510-994)

Pipe Length

Vertical

Terminal

Storm Collar

(Part # 953)

Flashing

943 or 943S

Ceiling Firestop

(Part # 963)

24" Pipe

Length

Adj.Pipe

Length

11" - 14-5/8"

90 Elbow

o

Horizontal

Termination Cap

(Part# 946-523/P)

Wall Thimble

(Part # 942)

Vinyl Siding

St

andoff (Optional)

(Part

#950)

1 Horizontal Termination Cap

1 90

Elbow

1 Rigid Pipe Adaptor

1 Wall Thimble

1 Length of pipe to suit wall thickness (see chart)

Alternate

American Metal Products Ameri Vent Direct Vent and Selkirk Direct-Temp.

AstroCap

is the proprietary trademark of FPI Fireplace Products International

for using a Rigid Pipe Adaptor in conjunction

with Dura-Vent Direct Vent GS, Selkirk Direct-

WARNING:

and FPI

Wall Thickness

Vent Length

12"

Wall Thickness

Vent Length

When using Rigid Vent piping other than

Simpson Dura-Vent, 3 screws must be

used to secure rigid pipe to adaptor.

Page 14

®

G36D Zero Clearance Direct Vent Gas Fireplace

DIRECT VENT SYSTEM (FLEX)

elbow

(two 45

All Rigid Pipe Systems

All Rigid Pipe Systems

Flex Vent

A v ent g uar d s hou ld be u se d

whenever the termination is lower

®

Direct Vent System

Page 15

®

G36D Zero Clearance Direct Vent Gas Fireplace

DIRECT VENT SYSTEM (FLEX)

elbows (two 45

elbow).

elbows are permitted.

2) A minimum of 6 ft. (1.8m) vertical from base of unit is required if two 90

elbows are used.

3) Minimum distance between elbows is 2 ft. (0.6m).

4) Determine the permitted range of horizontal termination arrangements by using chart in the "Rigid Pepi Venting

Arrangements - Vertical Termination" section and deducting 3 ft. (0.9m) from the maximum horizontal distance for the

second 90

All Rigid Pipe Systems

All Rigid Pipe Systems

Flex Vent

and Finishing," & "Hearth Requirement" sections.

A vent guard should be used whenever the

Page 16

®

G36D Zero Clearance Direct Vent Gas Fireplace

elbows (two 45

elbow) with

vent systems for Propane and

elbow (two 45

elbow) with

vent systems for Propane

Vent must be supported at offsets

®

®

Direct Vent System (Flex) is only approved for horizontal terminations.

Page 17

®

G36D Zero Clearance Direct Vent Gas Fireplace

vent systems for Propane and Natural Gas, as per the diagram 3.

vent systems for

elbows allowed.

Page 18

®

G36D Zero Clearance Direct Vent Gas Fireplace

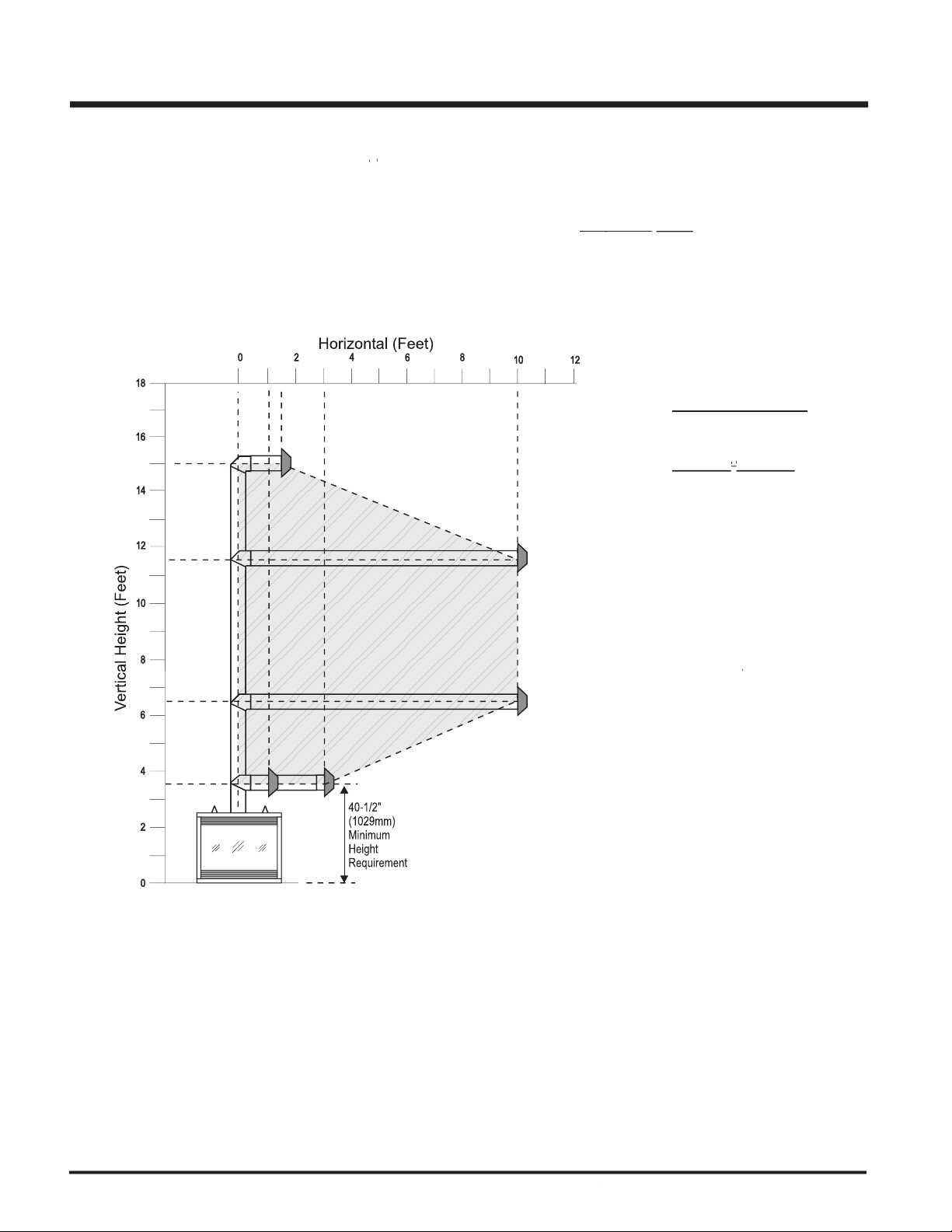

VERTICAL TERMINATION

WITH CO-LINEAR FLEX SYSTEM

Arrangements on next page for minimum and

Termination Cap

which contains the following:

Co-linear Flex Adapter

Outer Pipe

Inner Pipe Adapter

Alternate Approved Caps

3" Co-linear Adapter with fl ashing

Flex Liner

Exhaust

Flue

A maximum

of two certified

joiner kits

may be used

per length.

#948-305 (35 ft

)

Air Intake

Co-linear

DV

Vertical Termination

Cap # 946-529

Co-Linear

Flex

Adapter

with Kit#

946-563

Outer

Pipe

with Kit#

946-563

Inner Pipe

Adapter

with Kit#

946-563

Rigid Pipe

Adaptor

# 510-994

90 Degree

Elbow

Pipe

Length

Page 19

®

G36D Zero Clearance Direct Vent Gas Fireplace

VENTING ARRANGEMENTS - VERTICAL TERMINATIONS

with Co-linear Flex System for both

Page 20

®

G36D Zero Clearance Direct Vent Gas Fireplace

Insure that the 1-1/2"

from entering the Snorkel Termination. Refer

WITH HORIZONTAL

Set the unit in its desired location. Check

Direct Vent pipe and fi ttings are designed with

with the Simpson Dura-Vent Direct Vent GS

Put a bead of silicone inside the outer section

Assemble the desired combination of pipe

a) Twist-lock procedure: Four indentations,

will not be visible from the outside, on

female ends.

b)

Horizontal ru ns o f vent must be

Mark the wall for a 10" x 10" square hole.

elbo w

The horizontal run of vent must be

The location of the horizontal vent

For installations requiring a vertical

Vent. Follow

Page 21

®

G36D Zero Clearance Direct Vent Gas Fireplace

joint.

WITH VERTICAL

Maintain the 1-1/2" clearances

when passing through ceilings,

wal l s, r o ofs, e nclo s ures ,

The four wood screws provided should

Before connecting the horizontal run of vent

Slide the appliance and vent assembly

Install wall thimble in

wit h wood screws

Set the gas appliance in its

where the vent will penetrate the ceiling. Drill

wi ll o bs tru ct

A Firestop spacer must be installed in the

Assemble the desired lengths of pipe and

Cut a hole in the roof centered on the small

Continue to assemble pipe lengths.

Wall straps are available for this

Galvanized pipe is desirable above the

Feet Meters

Page 22

®

G36D Zero Clearance Direct Vent Gas Fireplace

Separate the 2 halves of the wall thimble and

for 2 x 4 or 2 x 6 walls.

Slip the assembled liner and termination

with proper down slope for draining water.

Pull the centre 4"(100mm) liner and outer

6-7/8"(175mm) liner out enough to slip over

wish to cut the liner shorter to make it more

workable.) Do not bend liner more than

Apply Mill Pac over the fi replace inner collar

Do the same with the 6-7/8"(175mm) liner.

Apply a bead of silicone between the thimble

Do not locate termination

®

®

Direct Vent

Locate the unit in the framing, rough in the

x 10"(254mm) (inside dimensions)

to ensure that the termination

Level the fi replace and fasten it to the framing

Assemble the vent assembly by applying

with the 3 screws.

Ensure vent is vertical and secure the base

Install the vertical termination cap by twist-

Page 23

®

G36D Zero Clearance Direct Vent Gas Fireplace

®

dealer for

Make sure the valve is in the "OFF"

Loosen the "IN" and/or "OUT" pressure

1/8" wide fl at screwdriver.

Attach manometer to "IN" and/or "OUT"

Light the pilot and turn the valve to "ON"

The pressure check should be carried out

with the unit burning and the setting should

When fi nished reading manometer, turn

Gas on/off knob

Manual high/low adjustment

Pilot Adjustment

Thermocouple Connection -

Inlet Pressure Tap

Pilot Outlet

Main Gas Outlet

Alternative TC Connection

Alternative TC Connection

Point

#42

26,000 Btu/h

min.5.0" w.c.

(High)

3.8"+/- 0.2"w.c.

Vent System:

Vent System or UltraGlow

®

Direct

Vent System (Flex)

#53

min.12.0" w.c.

(High)

11"+/- 0.2" w.c.

Vent System:

Vent System or UltraGlow® Direct

Vent System (Flex)

Page 24

®

G36D Zero Clearance Direct Vent Gas Fireplace

THIS CONVERSION MUST BE DONE BY A QUALIFIED GAS FITTER

IF IN DOUBT DO NOT DO THIS CONVERSION !!

f the gas supply

R

Assembly to the

Assembly to the left and lift out

f the pilot cap to expose the pilot

pilot ori

Assembly to the left and lift out.

position

or 4mm

Allen wrench into

R

wrench and discard. Use another wrench

R

stamped

y.

P

Allen Ke

Injector (Pilot Ori

y.

Power Cord

Ve

Ve

THIS CONVERSION MUST BE DONE BY A QUALIFIED GAS FITTER IF IN DOUBT DO NOT DO THIS CONVERSION !!

Page 25

®

G36D Zero Clearance Direct Vent Gas Fireplace

WA

Re-assemble the black protection cap

Also check that the pilot

Attach the label "This unit has been

U

Allen wrench as shown in

D

C

wires

with

which

C

washer from the kit.

Page 26

®

G36D Zero Clearance Direct Vent Gas Fireplace

It should be kept away from the

Page 27

®

G36D Zero Clearance Direct Vent Gas Fireplace

Position Log

across the cutouts in Logs 02-75 and 02-51 with

Carefully remove the logs from the box and unwrap them. The logs

Place Log

on the rear log support pins with the fl at side to the

f) 02-54 Center Right Log

02-51

Place Log

on the front right side of the burner. Push the back

Sprinkle the vermiculite all over the top of the base brick panel.

02-75

02-51

02-75

02-53

02-75

02-51

02-51

Page 28

®

G36D Zero Clearance Direct Vent Gas Fireplace

positioning of Log 02-52.

Place the bottom left front edge of Log

against the rear bracket

Place Log

between Logs 02-51 and 02-75 and on the indentation

Sit Log

on the front left side of the burner. Push the back of

Position Log

02-54

across the cutouts in Logs 02-51 and 02-53. The

02-51

02-54

02-54

02-75

02-52

02-51

02-54

02-75

02-55

02-51

02-55

02-50

Page 29

®

G36D Zero Clearance Direct Vent Gas Fireplace

Place the embers on the front of the burner tray in the places shown

Test fi re to ensure proper light off (make sure fl ame fl ows smoothly

from one end of burner to the other). If there is any fl ame hesitation,

Install fl ush glass as per instructions in manual.

02-51

02-75

02-54

02-55

02-55

02-50

02-51

02-54

Page 30

®

G36D Zero Clearance Direct Vent Gas Fireplace

Install each top by clipping the louver lip

The bottom louver has a hinge that is

Open the bottom louver. Pull the Burner

frame. To install the frame, simply hook the top

Attach the round magnets to the back of the

Page 31

®

G36D Zero Clearance Direct Vent Gas Fireplace

3:

WALL THERMOSTAT

A wall thermostat may be installed if desired,

wire length.

®

offers an optional programmable

wall thermostat wires

®

®

Remote Control Kit approved

for this unit. Use of other systems may void

Choose a convenient location on the wall

Connect the two wires to the gas valve. See

WALL SWITCH

Run the wire through the right or left side inlet

Connect the wire to the wall switch and install

wall switch wire to a 120V wire.

Install 3 AAA alkaline batteries in transmitter

Page 32

®

G36D Zero Clearance Direct Vent Gas Fireplace

WIRING DIAGRAM

will continue to operate.

CAUTION: Label all wires prior

to disconnection when servicing

cont r o ls. Wiring errors can

cause improper and dangerous

Page 33

®

G36D Zero Clearance Direct Vent Gas Fireplace

Open the bottom louver door.

Slide the fan in towards the rear of the unit

If you require extra space to slide the fan to the back, the left spring can be unhooked

from the bracket.

If the left spring was unhooked in step 3),

wire holder clip (Part #910-199) onto the

Plug the fan to the receptacle as shown in

Shut the power off.

Reverse the above instructions.

you vacuum the fan area on a regular

Page 34

®

G36D Zero Clearance Direct Vent Gas Fireplace

Read and understand these instructions

Check to see that all wiring is correct and

Check to ensure there are no gas leaks.

Make sure the glass in the door frame is

Verif y t ha t the ven ti ng an d cap are

Ensure that the brick panels are installed.

Verify log placement. If the pilot cannot be

The unit should never be turned off, and on

wait.

Turn burner OFF using "ON/OFF" switch.

Turn gas control knob so indicator points

Turn gas control knob counterclockwise

When the pilot stays lit, turn the gas knob

furthe r counterclockwise to the "ON"

Use the wall switch, thermostat or remote

Rotate the fl ame height regulator to adjust

Use the wall switch, thermostat or remote

Turn the main gas control clockwise to the

Turn off all electric power to appliance if

will disappear in a few minutes as

or the fi lm will bake on and

AERATION

ADJUSTMENT

3/16" Natural Gas

1/2" Propane

Carbon will be produced if air shutter

®

Installer at the time of

Adjustment Wire: push to close or

pull to open aeration cap.

IMPORTANT

be operated with the tension springs

WITHOUT THE GLASS FRONT IN

To ignite or reignite the pilot,

you must fi rst release the ten-

sion springs below the door.

Page 35

®

G36D Zero Clearance Direct Vent Gas Fireplace

Always turn off the gas valve before cleaning.

Clean appliance and door with a damp

The heater is fi nished in a heat resistant

®

uses StoveBright

Gas Inlet

TURN OFF GAS

APPLIANCE

YOUR SAFETY

READ BEFORE LIGHTING

READ BEFORE LIGHTINGYOUR SAFETY

LIGHTING INSTRUCTIONS

f th e fl ame s wi tc h.

f al l el ect ri c po we r to th e ap pl ia nce i f se rv ic e is to b e pe rform ed .

Yo

f th e pi lot d ur in g pr olo ng ed n on u se pe ri od s to cons er ve f ue l.

Wa

way

when

A)

which

When

follow

for

fl

DO IF

YOU SMELL

GAS

from

fi

will

water

vapors

DO NOT REMOVE THIS INSTRUCTION PLATE

W

ARNING:

you

with

ANSI Z223.1/NFP

B149.1. (Australia:

B149.1. (Australia:

AG601, New Zealand: NZS 5261

AG601, New Zealand: NZS 5261

FOR UNITS NOT EQUIPPED WITH ELECTRIC SPARK BOXES:

FOR ALL PROPANE UNITS AND UNITS EQUIPPED WITH ELECTRIC SPARK BOXES:

Gas Inlet

position.

way

fl

BURNER

VEILLEUSE

APPLIANCES

from your gas appliance. This is perfectly normal

will expand and contract at slightly different

for steel fi reboxes.

As the gas control valve turns ON and OFF, a

Page 36

®

G36D Zero Clearance Direct Vent Gas Fireplace

Make a periodic check of burner for proper

The appliance and venting system must be

Do not use this appliance if any part has been

water.

Verify operation after servicing.

Check the Venting System for corrosion in

Remove the Cap, and shine a fl ashlight

Ch e ck for evi d enc e s o f e xce ssi v e

Ins pect jo ints, to verify that no pipe

Open the bottom louvers.

Loosen the thermocouple or thermopile with

Disconnect thermocouple by loosening

Drop the thermocouple or thermopile down

from the bracket and pull it out of the unit.

Reinstall the new ones in reverse order.

# 936-155).

Your UltraGlow

®

fi replace is supplied with high

withstand the highest heat that your unit will

when hot.

®

dealer only, and follow our step-by-

WARNING

with the glass panels removed, cracked

Page 37

®

G36D Zero Clearance Direct Vent Gas Fireplace

Undo the pilot tube from the valve with a

7/16" wrench.

Undo the quick drop out thermocouple nut

Remove the Piezo ignitor wire and push

Undo the "gas out" fl are nut with a 13/16"

wrench.

wrench.

Remove the 4 Phillips head screws from

Attach the valve to the valve bracket with

Reconnect the "gas out" fl are fi tting with an

Reconnect the "gas out" fl are nut with a

13/16" wrench.

Reconnect the quick drop out thermocouple

Reconnect the pilot tube nut with a 7/16"

wrench.

Scrape off the old gasket from the fl oor of the

Install a new gasket and reinstall the valve

performance.

Reinstall the 12 hold down screws.

Hook up the 2 TP and 2 TH wires to the

Reinstall the bottom brick panel and the

front log stand.

Hook up the gas line and check for gas

for leak testing.)

Fire up the unit temporarily

Check the manifold pressure.

Reinstall the logs and base panels as

Close the door and replace the louvers.

Fire up the unit again and check for proper

Remove louvers.

Open and remove the fl ush door.

Remove logs.

Remove the burner assembly by removing

Remove the rear log stand by removing the

Lift out the bottom base panel.

Disconnect the inlet gas line.

Disconnect the 2 TP wires and the 2 TH

wires from the valve.

Verify proper operation

Page 38

®

G36D Zero Clearance Direct Vent Gas Fireplace

Part # Description

910-882 Wire-Harness-Valve to Burner

331-917 Fan & Speed Control Assy

(120 Volts) Optional

918-515 Manual

290-969 Conversion Kit - NG to LP

Page 39

®

G36D Zero Clearance Direct Vent Gas Fireplace

Part # Description

786-574/P Valve Assy - Natural Gas

786-576/P Valve Assy - Propane

910-380 Valve - S.I.T. - Propane

910-039 Pilot Assy - S.I.T. - 3 Flame LP

904-430 Orifi ce #42 - Natural Gas

904-345 Orifi ce #53 - Propane

936-170 Orifi ce Gasket

Page 40

®

G36D Zero Clearance Direct Vent Gas Fireplace

510-947 Flush Glass Trim (Set) - Steel

510-932 Flush Glass Trim (Set) - Gold

Part # Description

Page 41

®

G36D Zero Clearance Direct Vent Gas Fireplace

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

Page 42

®

G36D Zero Clearance Direct Vent Gas Fireplace

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

Page 43

®

G36D Zero Clearance Direct Vent Gas Fireplace

®

®

products, are designed with reliability and simplicity in mind. In addition, our internal Quality Assurance Team carefully

®

®

is pleased to extend this one year warranty to the original purchaser

®

®

product. This warranty is not transferable.

Any part or parts of this unit which in our judgement show evidence of such defects will be repaired or replaced at FPI's option, through an accredited

if requested.

workmanship from unauthorized service persons or dealers.

At all times FPI reserves the right to inspect product in the fi eld which is claimed to be defective.

All claims must be submitted to FPI by authorized selling dealers. It is essential that all submitted claims provide all of the necessary information

At no time will FPI be liable for any consequential damages which exceed the purchase price of the unit. FPI has no obligation to enhance or modify

warranty policy.

Any unit which shows signs of neglect or misuse is not covered under the terms of this warranty policy.

Any alteration to the unit which causes sooting or carboning that results in damage to the interior / exterior facia is not the responsibility of FPI.

Page 44

G36D Zero Clearance Direct Vent Gas Fireplace

______________________________________________

___________________________________________________________________

___________________________________________________________

___________________________________________________________

______________________________________________________

__________________________________________________________

®

®

online at

© Copyright 2005, FPI Fireplace Products International Ltd. All rights reserved.

Loading...

Loading...