Page 1

Owners &

Installation

Freestanding Gas Stove

Models: F38-NG2

F38-LPG2

Manual

LISTINGS AND CODE APPROVALS

These gas appliances have been tested in

accordance with AS4553, NZS 5262 and

have been certifi ed by the Australian Gas

Association for installation and operation as

described in these Installation and Operating

Instructions.

Your unit should be serviced annually by

an authorised service person.

PLEASE KEEP THESE INSTRUCTIONS

FOR FUTURE REFERENCE

WARNING:

Improper installation, adjustment, alteration, service or maintenance can cause

injury or property damage. Refer to this

manual. For assistance or additional information consult an authorized installer,

service agency or the gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other fl am-

mable vapours and liquids in the vicinity of

this or any other appliance.

Installation and service must be performed

by an authorized installer, service agency or

the gas supplier.

918-534b

FOR YOUR SAFETY

What to do if you smell gas:

Do not try to light any appli-

ance

Do not touch any electri-

cal switch: do not use any

phone in your building.

Immediately call your gas

supplier from a neighbour's

phone. Follow the gas supplier's instructions.

If you cannot reach your

gas supplier, call the fi re

department.

10/14/09

Page 2

To the New Owner:

Congratulations! You are the owner of a state-of-the-art Gas Stove by FIREPLACE PRODUCTS

INTERNATIONAL LTD. The Regency Gas Series of hand crafted appliances has been designed

to provide you with all the warmth and charm of a woodstove, at the fl ick of a switch.

The models F38-NG2, and F38-LPG2 of this series has been approved by AGA for both safety

and effi ciency. As it also bears our own mark, it promises to provide you with economy, comfort

and security for many trouble free years to follow. Please take a moment now to acquaint yourself

with these instructions and the many features of your Regency Gas Stove.

F38-NG2 & F38-LPG2

2 Regency F38-2 Freestanding Gas Stove

Page 3

TABLE OF CONTENTS

SAFETY LABEL

Safety Label...................................................................5

INSTALLATION

General Information .......................................................5

Important .......................................................................5

Before You Start ............................................................5

General Safety Information............................................5

Clearances to Combustibles..........................................6

Draft Diverter .................................................................6

Flueing ...........................................................................6

Installation Checklist ......................................................6

Gas Connection .............................................................7

Gas Pipe Pressure Testing ............................................7

Conversion Kit# 731-968 from NG to LPG ....................8

Aeration Adjustment ......................................................9

Log Set Installation ........................................................9

Front Door Installation .................................................11

Test for Flue Spillage ...................................................11

Optional Wall Thermostat ...........................................12

Optional Remote Control ............................................12

Final Check..................................................................12

Wiring ..........................................................................13

MAINTENANCE

Maintenance Instructions.............................................17

Log Replacement ........................................................17

Door and Glass Gasket ...............................................17

Glass Replacement .....................................................17

Fan Maintenance .........................................................18

Removing Valve ...........................................................19

PARTS LIST

Main Assembly ............................................................20

Burner & Log Assembly ...............................................21

Door Assembly ............................................................22

WARRANTY

Warranty ......................................................................23

OPERATING INSTRUCTIONS

Operating Instructions ................................................14

Lighting Instructions.....................................................14

Shutdown Instructions .................................................14

First Fire ......................................................................14

Automatic Convection Fan Operation..........................14

Adjusting Flame Height ...............................................14

Copy of the Lighting Plate Instructions .......................15

Pilot Adjustment ...........................................................16

Normal Operating Sounds of Gas Appliances .............16

Regency F38-2 Freestanding Gas Heater

3

Page 4

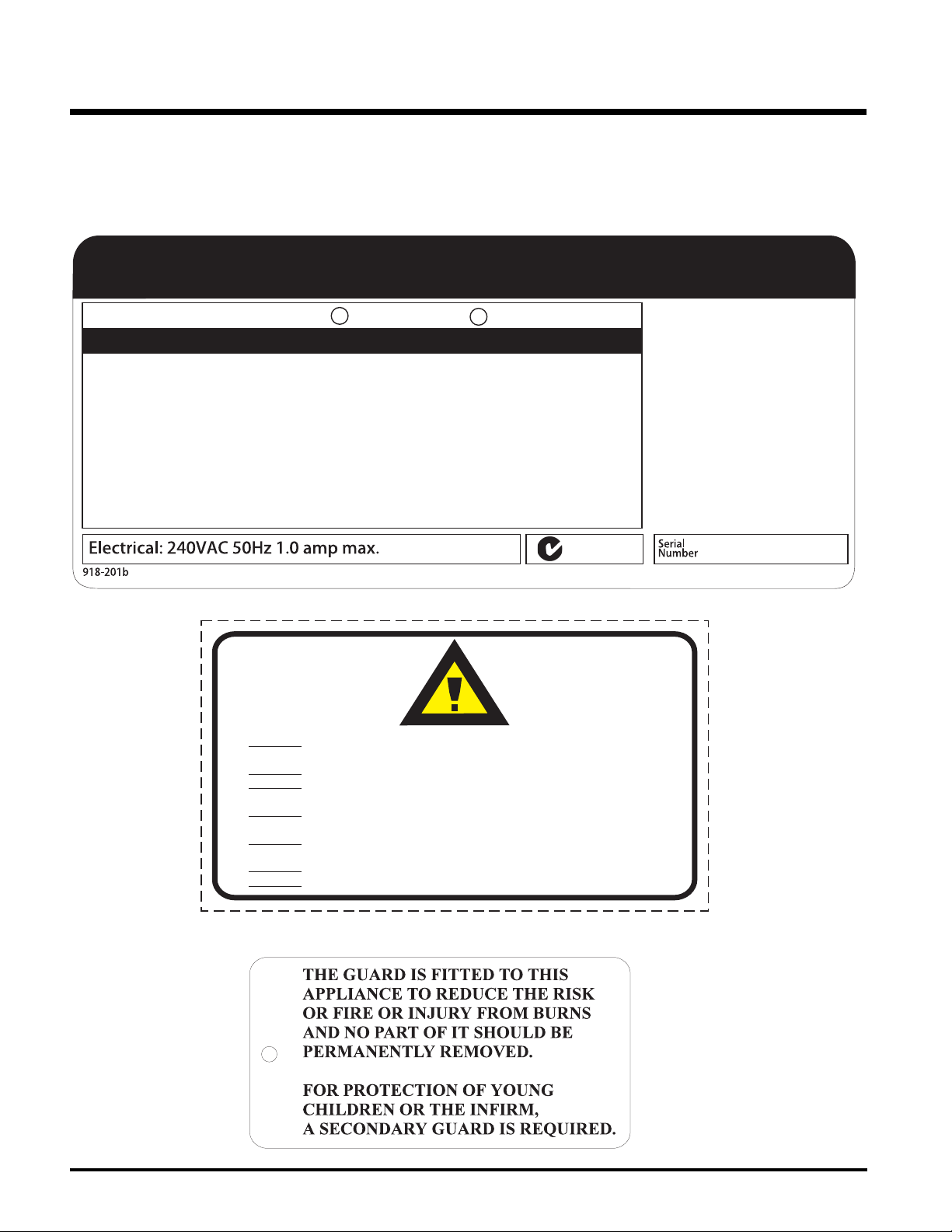

SAFETY LABEL

This is a copy of the label that accompanies

each Freestanding Gas Stove. We have printed

a copy of the contents here for your review. The

safety label is located on the inside of the drop

down pedestal door.

NOTE: Regency units are constantly being

improved. Check the label on the unit and if

there is a difference, the label on the unit is the

correct one.

Regency Gas Fireplace

Model

Gas Type NG LPG

Model

Gas Consumption 38 . 31 .

Manifold Pressure .87 2.65

Injector Size 1x 1x 52

AGA Approval number to

Code AS4553 6231 6231

F38-2 NG F38-2 LPG

mj mj

kPa kPa

33

##

2.87mm 1.61mm

N2134

Distributed by:

Western Australia:

Australian Heating

Distributors Pty. Ltd.

31 Clune St.

Bayswater, WA, 6053

Eastern Australia:

Fireplace Products

Australia Pty. Ltd.

21-23 South Link Blvd.

Dandenong, VIC 3175

To be installed by an authorised person in

accordance with installation instructions

provided with the appliance.

252

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

OPERATE THIS APPLIANCE BEFORE READING THE

INSTRUCTIONS BOOKLET.

PLACE ARTICLES ON OR AGAINST THIS APPLIANCE

STORE CHEMICALS OR FLAMMABLE MATERIALS

NEAR THIS APPLIANCE.

SPRAY AEROSOLS IN THE VICINITY OF THIS

APPLIANCE WHILE IN OPERATION.

OPERATE WITH PANELS, COVERS OR GUARDS

REMOVED FROM THIS APPLIANCE.

ENCLOSE THIS APPLIANCE.

DO NOT MODIFY THIS APPLIANCE.

908-602a

(Australia Only)

4 Regency F38-2 Freestanding Gas Stove

Page 5

INSTALLATION

GENERAL

INFORMATION

This installation must conform with local codes

or, in the absence of local codes, with AS56012004 (Australia) NZS 5261 (New Zealand).

THIS APPLIANCE SHOULD

BE INSTALLED, REP AIRED,

INSPECTED BEFORE USE

AND AT LEAST ANNUALLY

BY AN AUTHORISED SERV-

ICE PERSON. MORE FREQUENT CLEANING MAY BE REQUIRED,

DUE TO EXCESSIVE LINT FROM CARPETING, ETC. IT IS IMPERATIVE THAT

CONTROL COMPARTMENT, BURNERS

AND CIRCULATING AIR PASSAGEWAYS

OF THE APPLIANCE BE KEPT CLEAN.

DUE TO HIGH TEMPERATURES, THE APPLIANCE

SHOULD BE LOCATED OUT

OF TRAFFIC AND AWAY

FROM FURNITURE AND

DRAPERIES.

THIS APPLIANCE CAN ONL Y

BE FLUED IN ACCORDANCE

WITH AS5601-2004 OR LOCAL CODES.

FAILURE TO INSTALL THIS

APPLIANCE CORRECTLY

MAY CAUSE A SERIOUS

HOUSE FIRE.

Provide adequate clearances for servicing,

proper operation and around the air openings into

the combustion chamber. Adequate combustion

and ventilation air must also be provided.

The appliance must be installed on a fl at, solid,

continuous surface (i.e. wood, metal, concrete).

This may be the fl oor, or it can be raised up on

a platform to enhance its visual impact.

The Regency Freestanding Gas Heater can be

installed in a wide variety of ways and will fi t

nearly any room layout. It may be installed in a

recessed position, framed out into the room, or

across a corner.

We recommend that you plan your installation on

paper using exact measurements for clearances

and fl oor protection before actually installing this

appliance. If an existing chimney is not utilised,

position the appliance to allow free passage of

factory-built listed chimney through the ceiling

and roof.

IMPORTANT

The F38-2 Freestanding Gas Stove must be

installed in accordance with these instructions.

Carefully read all the instructions in this manual

fi rst. Consult the "authority having jurisdiction" to

determine the need for a permit prior to starting

the installation.

BEFORE YOU ST ART

INSTALLATION AND REPAIR

SHOULD BE DONE BY AN AUTHORISED SERVICE PERSON.

THE APPLIANCE SHOULD BE

INSPECTED BEFORE USE AND

AT LEAST ANNUALLY BY AN AUTHORISED SERVICE PERSON.

MORE FREQUENT CLEANING MA Y

BE REQUIRED DUE TO EXCESSIVE

LINT FROM CARPETING, BEDDING

MA TERIAL, ETC. IT IS IMPERATIVE

THA T CONTROL COMPARTMENTS,

BURNERS AND CIRCULATING AIR

PASSAGEWAYS OF THE APPLIANCE BE KEPT CLEAN.

DUE TO HIGH TEMPERA TURES, THE

APPLIANCE SHOULD BE LOCA TED

OUT OF TRAFFIC AND AW A Y FROM

FURNITURE AND DRAPERIES.

WARNING: FAILURE TO INSTALL

THIS APPLIANCE CORRECTLY

MAY CAUSE A SERIOUS HOUSE

FIRE AND WILL VOID YOUR WARRANTY.

CHILDREN AND ADULTS SHOULD

BE ALERTED TO THE HAZARDS OF

HIGH SURFACE TEMPERATURES,

ESPECIALLY THE FIREPLACE

GLASS, AND SHOULD ST AY AW AY

TO AVOID BURNS OR CLOTHING

IGNITION.

YOUNG CHILDREN SHOULD BE

CAREFULLY SUPERVISED WHEN

THEY ARE IN THE SAME ROOM AS

THE APPLIANCE.

CLOTHING OR OTHER FLAMMABLE MATERIAL SHOULD NOT BE

PLACED ON OR NEAR THE APPLIANCE.

GENERAL SAFETY

INFORMATION

1) The appliance shall be installed in accord-

ance with the manufacturer's installation

instructions, local gas fi tting regulations,

municipal building codes, water supply

regulations, electrical wiring regulations,

with AS5601-2004 (AGA gas installation

code) NZS 5261 (New Zealand)

2) Installation and repair should be done

ONLY by an authorised person.

3) See general construction and assembly

instructions. The appliance should be inspected before use and at least annually

by an authorised service person. More

frequent cleaning may be required due

to excessive lint from carpeting, bedding

material, etc. It is imperative that control

compartments, burners and circulating

air passageways of the appliance be kept

clean and free from excessive lint from

carpeting.

4) This appliance must be connected to a fl ue

and terminate to the outside of the building

envelope. Never fl ue to another room.

5) Inspect the fl ueing system annually for

blockage and any signs of deterioration.

6) Any safety glass removed for servicing

must be replaced prior to operating the appliance.

7) T o prevent injury, do not allow anyone who

is unfamiliar with the operation to use the

fi replace.

8) Wear gloves and safety glasses for protection while doing required maintenance.

9) Under no circumstances should this appliance be modifi ed. Parts that have to be

removed for servicing should be replaced

prior to operating this appliance.

10) Installation and any repairs to this appliance

should be done by an authorised service

person. An authorised service person should

be called to inspect this appliance annually.

Make it a practice to have all of your gas

appliances checked annually.

11) Do not strike the glass door.

12) Under no circumstances should any solid

fuels (wood, paper, cardboard, coal, etc.)

be used in this appliance.

13) The appliance area must be kept clear and

free of combustible materials, (gases and

other fl ammable vapours and liquids).

Regency F38-2 Freestanding Gas Heater

5

Page 6

INSTALLATION

14) This unit can be installed on a solid combus-

tible surface like a wood fl oor as well as on

carpeting.

INSTALLATION

CHECKLIST

1) Check Clearances to Combustibles. Refer to

the "Clearance to Combustibles" section.

2) Install flueing. Refer to the "Flueing"

section.

3) Make gas connections. Refer to the "Gas

Connection" section.

T est the pilot. Must be as per diagram in the

"Pilot Adjustment" section.

4) If necessary, convert NG to LPG. Refer to

the "Conversion from NG to LPG" section

5) Test Gas Pressure. Refer to the "Gas Pipe

Pressure Testing" section.

6) Install log set. Refer to the "Log Set

Installation" section.

7) Install Front Door. Refer to the "Front Door

Installation" section.

8) Test for fl ue spillage (draft test). Refer to the

"Test for Flue Spillage" section.

9) Install Optional Features. Refer to the

following sections where applicable:

a. Optional Wall Thermostat

b. Optional Remote Control

10) Final check. Refer to the "Final Check"

section.

Before leaving this unit with the customer, the

installer must ensure that the appliance is fi r-

ing correctly and operation fully explained to

customer.

This includes:

1) Clocking the appliance to ensure the correct

fi ring rate (rate noted on label) after burning

appliance for 15 minutes.

2) If required, adjusting the primary air to ensure

that the fl ame does not carbon. First allow

the unit to burn for 15-20 min. to stabilize.

CAUTION: Any alteration to the product that

causes sooting or carboning or that results in

damage is not the responsibility of the manufacturer.

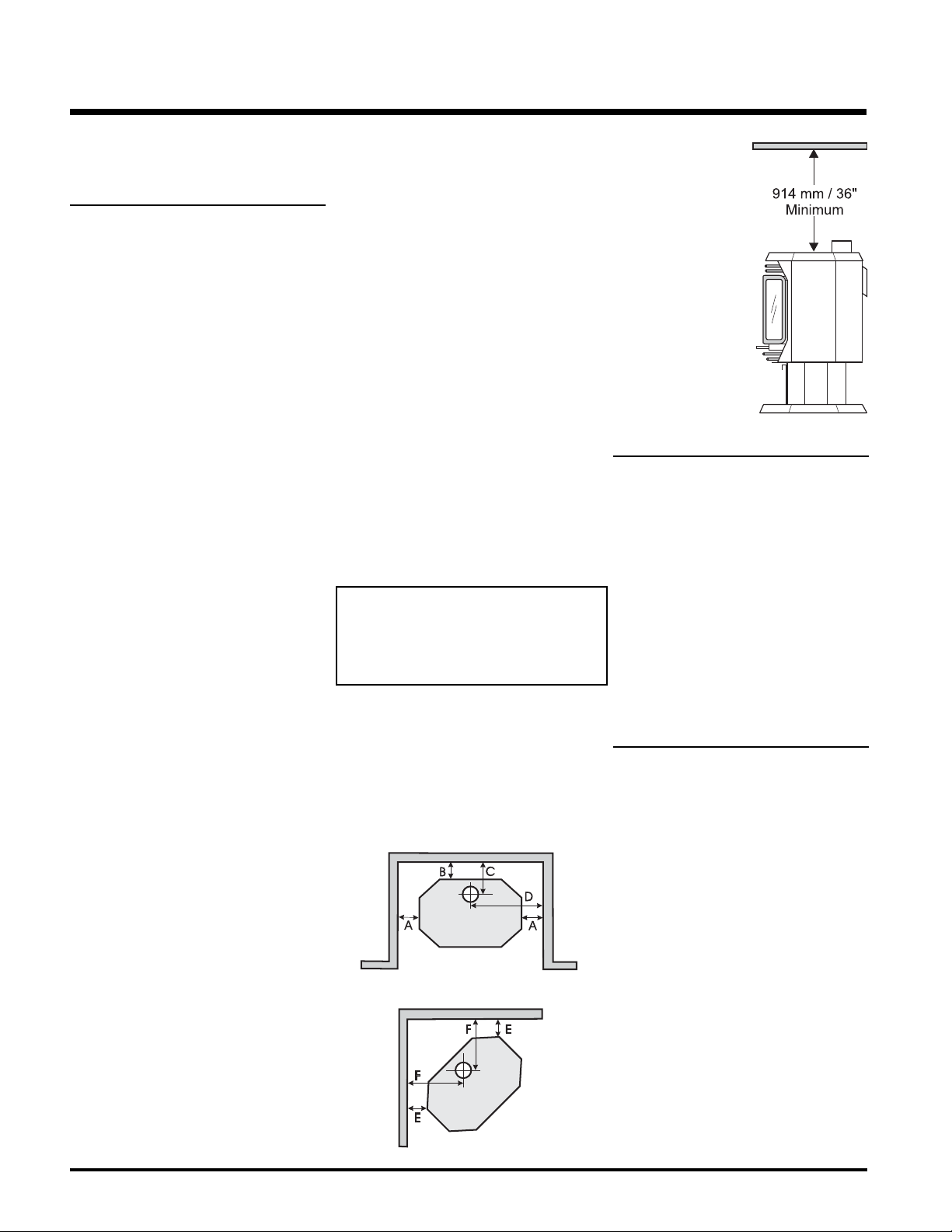

CLEARANCES TO

COMBUSTIBLES

The clearances listed below are MINIMUM

distances. Measure the clearance to both the

appliance and the chimney connector. (The

farthest distance is correct if the two clearances do not coincide.) For example, if the

appliance is set as indicated in one of the fi gures

but the connector is too close, move the stove

until the correct clearance to the connector is

obtained.

This unit can be installed on a solid combustible

surface like a wood fl oor. This unit can also be

installed directly on carpeting or vinyl when

the bottom pedestal cover plate (provided with

unit) is installed.

This appliance may be installed only with the

clearances as shown in the situations pictured.

Do not combine clearances from one type of

installation with another in order to achieve

closer clearances.

Use the minimum clearances shown in the

diagrams below for all installations.

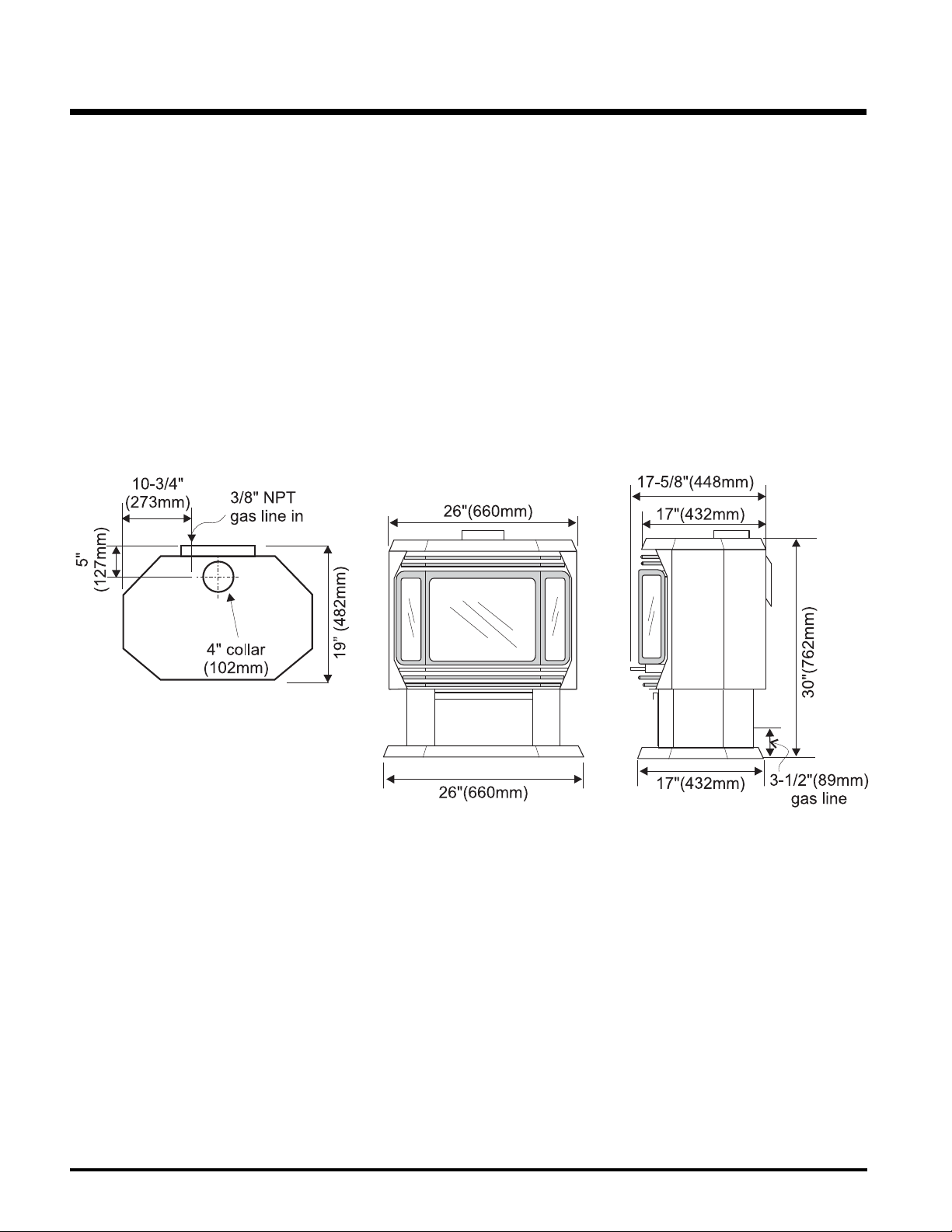

Clearances

A Side Wall to Unit 7-1/2" / 190 mm

B Back Wall to Unit 6" / 155 mm

E Side Wall to Unit 2" / 50 mm

Reference Dimensions

C Back Wall to Flue Centerline 10-3/4" / 273 mm

D Side Wall to Flue Centerline 20-1/2" / 520 mm

F Side Wall to Flue Centerline 11" / 280 mm

Minimum ceiling

height is 36" / 914 mm

from top of unit.

If further reduced clearances are needed, obtain requirements for

construction of a protected wall from your

local building authorities and their allowable

reductions of the listed

clearances.

DRAFT DIVERTER

This heater has a draft diverter built in. It must

not be altered, obstructed, or blocked in any way,

and the unit must be installed so that the draft

diverter is in the same atmospheric pressure

zone as the combustion air inlet to the burner.

This heater must be properly connected to a

fl ueing system. This heater is equipped with a

fl ue safety shutoff system.

WARNING: Operation of this heater when

not connected to a properly installed and

maintained fl ueing system or tampering with

the fl ue safety shutoff system can result in

carbon monoxide (CO) poisoning and possible death.

FLUEING

This heater is a fl ued appliance and must be

connected to a chimney/fl ue in accordance with

the installation codes.

Note: The rear pedestal cover plate must

always be fi tted for safety. Electrical

connections inside.

For your safety this heater is equipped with a

fl ue safety switch designed to sense incorrect

fl ueing and react by shutting down the gas sup-

ply. This thermally actuated switch is located

within the draft diverter and will detect either a

blocked chimney or backdraft condition where the

chimney fl ow has reversed. If this switch shuts

the unit down, it indicates a drafting problem that

must be identifi ed and rectifi ed without delay

- the thermally activated switch must never be

bypassed or disconnected as a hazardous or

deadly condition can result.

6 Regency F38-2 Freestanding Gas Stove

Page 7

INSTALLATION

Flueing Requirements

A100 mm diameter fl ue is required. For cosmetic

or aesthetic purposes 6" outer fl ue can be used

as long as an approved inner fl ue is installed.

Fasten but do not penetrate the inner sleeve of

the fl ue when tightening the screw.

The minimum fl ue required is 3.3m from fl oor

level.

Follow all fl ueing manufacturer’s requirements

and local building codes or AS5601-2004.

GAS CONNECTION

The gas line should be rigid pipe. Copper may

also be used if approved by AS5601-2004.

The gas connection at the valve is 1/2 male.

For minimum and maximum supply pressure

see the System Data Table.

GAS PIPE PRESSURE

TESTING

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig. (3.45

kPa). Disconnect piping from valve at pressures

over 3.45 kPa (14" w.c.).

The manifold pressure is controlled by a regulator

built into the gas control, and should be checked

at the pressure test point.

6) When fi nished reading manometer, turn

off the gas valve, disconnect the hose and

tighten the screw (clockwise) with a 1/8" fl at

screwdriver. Screw should be snug, but do

not over tighten.

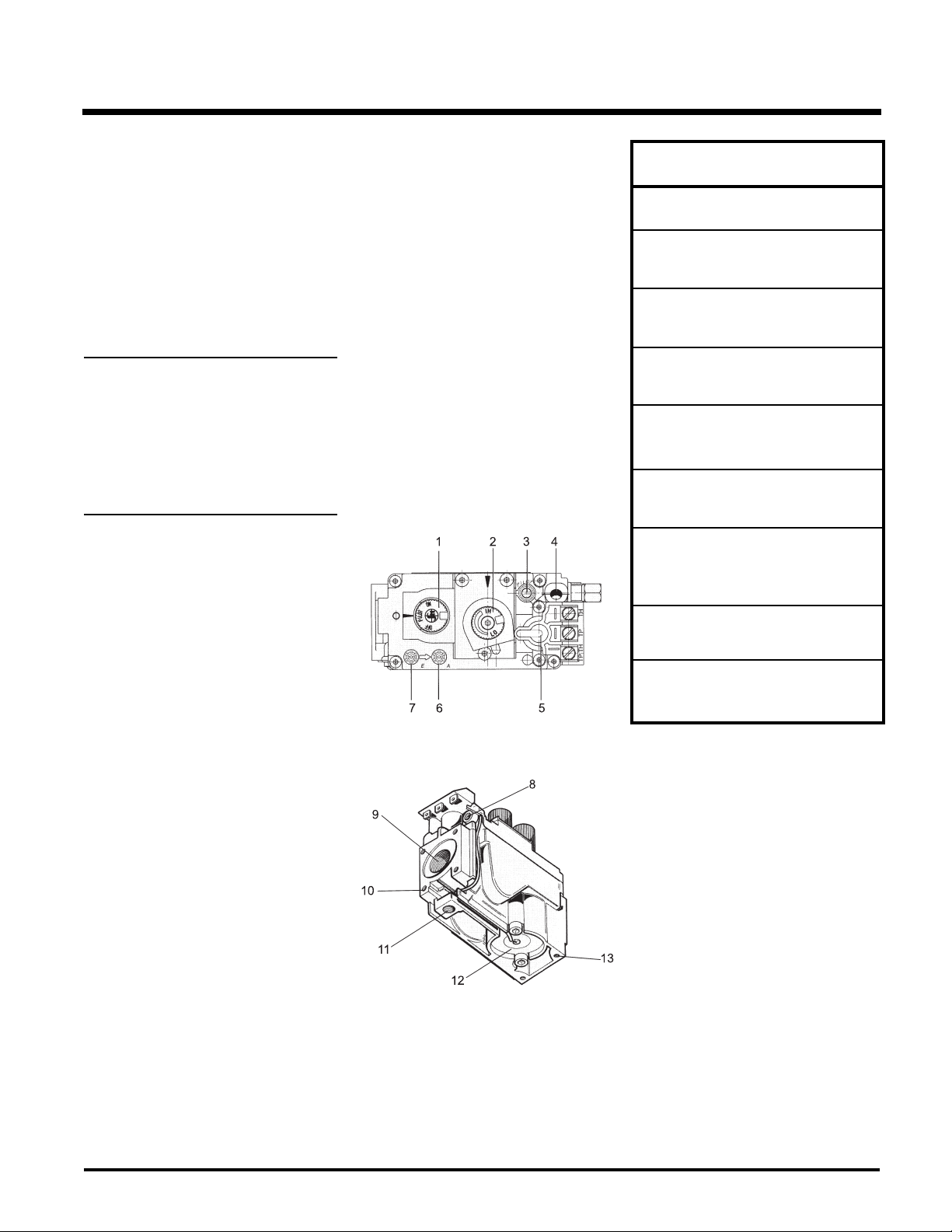

S.I.T. Valve Description

1) Gas on/off knob

2) Manual high/low adjustment

3) Pilot Adjustment

4) Thermocouple Connection

5) Main Operator

6) Outlet Pressure Tap

7) Inlet Pressure Tap

8) Pilot Outlet

9) Main Gas Outlet

10) Flange Securing Screw Holes

11) Alternative TC Connection Point

12) Thermoelectric Unit

13) Additional Valve Mounting Hole

System Data

F38-2

F38-NG2: For 0 to 610 meters altitude

F38-LPG2: For 0 to 610 meters altitude

Burner Inlet Orifi ce Sizes:

NG LPG

Burner #33 #52

Max. Input

NG 38 mj

LPG 31 mj

Min. Input

NG 24.1 mj

LPG 24.5 mj

Supply Pressure

NG 1.74 kPa

LPG 2.99 kPa

Manifold Pressure

NG 0.87 kPa

LPG 2.65 kPa

Electrical: 240 V. 50Hz.

Circulation: High/Off/LO speed fan, 150/89

CFM.

Log Set: Ceramic fi ber, 7 per set.

Aeration Setting

NG Full Open

LPG 6.4 mm

Flue Restrictor Setting

NG Full Open

LPG Full Open

Note: To properly check gas pressure,

both inlet and manifold pressures

should be checked using the valve

pressure ports on the valve.

1) Make sure the valve is in the "OFF" position.

2) Loosen the "IN" (# 7) and/or "OUT" (# 6)

pressure tap(s), turning counterclockwise

with a 1/8" wide fl at screwdriver.

3) Attach manometer to "IN" and/or "OUT"

pressure tap(s) using a 5/16" ID hose.

4) Light the pilot and turn the valve to "ON"

position.

5) The pressure check should be carried out

with the unit burning and the setting should

be within the limits specifi ed on the safety

label.

Regency F38-2 Freestanding Gas Heater

7

Page 8

INSTALLATION

CONVERSION KIT# 731-968 FROM NG TO LPG

THIS CONVERSION MUST BE DONE BY A QUALIFIED GAS FITTER IF IN DOUBT DO NOT DO THIS CONVERSION !!

LPG Conversion Kit Contains:

Qty. Part # Description

1 910-037 LPG Injector

(Pilot Orifi ce)

1 904-390 Burner Orifi ce #52

1 908-528 Red "LPG" label

1 908-255 Label "Converted to

LPG"

1 904-529 5/32" Allen Key

1) Shut off the gas supply.

2) Open the front door and carefully remove

the logs and lava rock.

3) Remove burner. See diagram below.

Note: Use a magnetic type screwdriver

if possible.

9) Insert a 5/32” or

4mm Allen wrench

into the hexagonal

key-way of the

screw (Fig. 2), rotate

it counter-clockwise

until it is free and

extract it.

Fig.3

10) Check that the screw is clean and if

necessary remove dirt.

11) Flip the screw (Fig. 3).

12) Using the Allen

wrench as shown

in Fig.4, rotate the

screw clockwise

until snug, do not

overtighten.

Fig.2

WARNING!

Also check that the pilot

and main burner injectors are

appropriate for the gas type.

15) Pull off the pilot cap to expose the pilot

orifi ce.

16) Unscrew the pilot orifi ce with the allen

key and replace with the LPG pilot orifi ce

in the kit.

Pilot assembly is now accessible

for steps 4) to 9).

4) Open pedestal door and remove the gold

chain from door which will allow door to

fall.

5) Remove lighting panel by removing the 6

Phillips head screws and put to the side.

6) Remove hi-low extension knob.

7) Turn control knob to

the “OFF” position.

8) Remove the black

protection cap by

hand from the highlow knob (Fig.1).

Fig. 1

Fig.4

WARNING!

Do not over tighten the screw.

Recommended to grip the

wrench by the short side.

13) Verify that if the conversion is from NG to

LPG, the screw must be re-assembled

with the red o-ring visible (Fig. 5).

Red o-ring visible

Fig.5

14) Re-assemble the

black protection

cap (Fig. 6).

LPG Configuration

Fig. 6

17) Remove burner orifi ce with a 1/2" wrench

while using a 9/16" wrench to hold onto

the elbow behind the orifi ce, then discard

the orifi ce.

Burner Orifi ce

18) Reinstall new burner orifi ce LPG stamped

#52 and tighten.

19) Reverse steps 3) to 2).

20) Attach the label "This unit has been con-

verted to LPG" near or on top of the Serial

# decal.

21) Replace yellow "NG" label with red "LPG"

label.

8 Regency F38-2 Freestanding Gas Stove

Page 9

INSTALLATION

AERATION

ADJUSTMENT

The burner aeration is factory set but may need

adjusting due to either the local gas supply or

altitude.

F38-2 with 38 mj

F38-NG2 NG: Full open

F38-LPG2 LPG: 6.4 mm open

Caution: Carbon will be produced if the air

shutter is closed too much.

Note: Any damage due to carboning re-

sulting from improperly setting the

aeration controls is NOT covered

under warranty.

LOG SET

INSTALLATION

Read the instructions below carefully and

refer to the diagrams. If logs are broken

do not use the unit until they are replaced.

Broken logs can interfere with the pilot

operation.

The gas log kit contains the following:

a) 02-65 Rear Log

b) 02-56 Middle Left Log

c) 02-44 Front Left Log

d) 02-46 Left Top Log

e) 02-45 Front Right Log

f) 02-47 Center Log

g) 02-48 Middle Right Log

h) Embers 902-151

i) Lava 902-154

Note: Install Optional Brick Panels prior to

installing logs.

3) Place Rear Log A)02-65 on the two pins on

the rear log support.

A)02-65

Pins on Rear Log Support

4) Place the Middle Left Log B)02-56 on the

two pins as shown.

B)02-56

The "02" refer numbers (i.e. 02-65) are

molded into the rear of each log.

1) Carefully remove the logs from the box and

unwrap them. The logs are fragile, handle

with care - do not force into position.

2) Sprinkle the embers on the left and right

sides of the fi rebox base.

Embers. Embers

5) Place Front Left Log C)02-44 onto the 2

front pins as shown.

C)02-44

Regency F38-2 Freestanding Gas Heater

9

Page 10

INSTALLATION

6) Place the Left Top Log D)02-46 on the pin

on Log B)02-56 and on top of the cutout

on Log A)02-65.

A)02-65

D)02-46

B)02-56

C)02-44

Pin

7) Place Front Right Log E)02-45 on the two

pins as shown.

Cutout

E)02-45

9) Place the notch in Center Log F)02-47 over

Log E)02-45 and across the cutout on Log

A)02-65.

F)02-47

CutoutNotch

10) Position notch in Front Right Log G)02-48

on Log F)02-47 and push the bottom right

edge against the bracket on the burner

tray.

G)02-48

A)02-65

A)02-65

E)02-45

G)02-48

E)02-45

Side View

Bracket

The bottom right edge of Log G)02-48 must

sit snugly against the bracket

11) Test fi re to ensure proper light off (make

sure fl ame fl ows smoothly from one end

of burner to the other. If there is any fl ame

hesitation, check that area for any blockage

of the burner port.

8) Place the lava rock in the area between

the left and right logs, leaving a space in

the middle for log (F) 02-47.

Ensure that the lava rocks are not placed

directly over the burner ports.

Notch

F)02-47

E)02-45

D)02-46

B)02-56

A)02-65

G)02-48

F)02-47

C)02-44

10 Regency F38-2 Freestanding Gas Stove

E)02-45

Page 11

INSTALLATION

FRONT DOOR

INSTALLATION

1) Open the two side panels.

2) Slide the door onto the two hinge pins making

sure the two pieces are fl ush together. See

diagram 1.

Diagram 1

3) Close the door. The latch plate must be

centered around the alignment pin. See

diagram 2. If the latch plate interferes with

the corner of the stove you may want to

angle the plate slightly so the door closes

easier.

6) Test the seal around the door by placing

a piece of paper between the unit and the

door, close the door and try to pull the paper

out. If it slips out easily, then the door is not

properly sealed. Tighten or loosen the latch.

See diagram 3.

Note: The door latch may require adjust-

ment as the door gasket material

compresses after a few fi res and

after glass replacement. Turn the

latch catch inward or outward to

loosen or tighten.

Diagram 3

TEST FOR

FLUE SPILLAGE

A "spillage" test must be made before the

installed unit is left with the customer. Follow

the procedure below:

The smoke should be drawn into the draft diverter. If the smoke is not drawn into the draft

diverter, turn the unit off and check for the cause

of lack of draft.

.

Note: If the fl ue is blocked or has a strong

reverse fl ow, the thermally actuated safety

switch mounted in the draft diverter will

automatically shut off the gas supply within

about 10 minutes. If the heater turns off because of this during the spillage test, check

for the cause of the lack of draft.

Diagram 2

4) The latches should already be at the proper

setting. If they are too hard or too easy

to close, you may want to adjust them by

loosening the latch catch. See diagram 3.

5) Remove the blue plastic protective coating

from the glass.

1) Start all exhaust fans in the home and any

other gas appliances. Then close all doors

and windows.

2) Light the unit and set controls to maximum.

3) After fi ve minutes, test that there is a "pull"

on the fl ue by placing a smoke match,

cigarette or similar device which gives off

smoke, on the edge of the draft diverter.

See diagrams.

The thermally activated safety switch must

be manually reset before fi rst startup.

Regency F38-2 Freestanding Gas Heater

11

Page 12

INSTALLATION

OPTIONAL WALL

THERMOSTAT

A wall thermostat may be installed if desired.

Connect the wires as per the wiring diagrams.

Note that the wires are connected to the "TH"

on the gas valve. Use table below to determine

the maximum wire length:

Note: Preferable if the thermostat is installed

on an interior wall.

Regency offers an optional programmable

thermostat but any 250-750 millivolt rated nonanticipator type thermostat that is CSA, ULC or

UL approved may be used.

CAUTION

Do not connect the millivolt

wall thermostat wires

to the 240 V wires.

Thermostat Wire Table

Recommended Maximum Lead Length

(Two-Wire) When Using Wall

Thermostat (CP-2 System)

Wire Size Max. Length

14 GA.

16 GA.

18 GA.

20 GA.

22 GA.

15.24 m

9.75 m

6.10 m

3.66 m

2.71 m

OPTIONAL REMOTE

CONTROL

Use the Regency Remote Control Kit approved

for this unit. Use of other systems may void

your warranty.

The remote control kit comes with a hand held

transmitter, a receiver and a wall mounting

plate.

1) Choose a convenient location on the wall

to install the receiver and the receptacle

box (protection from extreme heat is very

important). Run wires from the fi replace to

that location, use Thermostat Wire Table.

2) Connect the wires as per the wiring diagram

above.

CAUTION

Do not connect the millivolt

remote control wires to

the 240V wires.

3) Install 3 AAA alkaline batteries in transmitter

and 4 AA alkaline batteries in the receiver.

Install the receiver and its cover in the wall.

Switch the remote receiver to "remote"

mode. The remote control is now ready for

operation.

FINAL CHECK

Before leaving this unit with the customer, the

installer must ensure that the appliance is fi ring

correctly. This includes:

1) Clocking the appliance to ensure the correct fi ring rate (rate noted on label) at 15

minutes.

2) If required, adjusting the primary air to

ensure that the fl ame does not carbon.

First allow the unit to burn for 15 min. to

stabilize.

3) Check for proper draft.

CAUTION

Any alteration to the product that

causes sooting or carboning that

results in damage to the exterior

facia is not the responsibility of the

manufacturer.

12 Regency F38-2 Freestanding Gas Stove

Page 13

WIRING

INSTALLATION

No electrical power supply is required for the

gas control to operate. However, a 240V A.C.

power supply is needed for the fan/blower

operation.

Caution: Ensure that the wires do not

touch any hot surfaces and are away

from sharp edges.

WARNING: Electrical Grounding

Instructions

This appliance is equipped with a three

pronged (grounding) plug for your

protection against shock hazard and

should be plugged directly into a properly grounded three-prong receptacle.

Do not cut or remove the grounding

prong from this plug.

CAUTION:

Label all wires prior to disconnection

when servicing controls.

Wiring errors can cause improper

and dangerous operation.

Regency F38-2 Freestanding Gas Heater

13

Page 14

OPERATING INSTRUCTIONS

OPERATING

INSTRUCTIONS

Before operating this appliance, proceed through

the following check list.

1) Read and understand these Instructions

before operating this appliance.

2) Check to see that all wiring is correct and

enclosed to prevent possible shock.

3) Check to ensure there are no gas leaks.

4) Make sure the three pieces of door glass

are properly positioned. Never operate the

appliance with any of the glass removed or

with the door open.

5) Verify that all fl ueing and the cap is unob-

structed.

6) Verify log placement. If the pilot cannot be

seen when lighting the unit - the logs or the

embers have been incorrectly positioned.

7) The unit should never to turned off and on

without a minimum of a 60 second wait.

LIGHTING

INSTRUCTIONS

IMPORTANT: The PILOT knob cannot be

turned from pilot to off unless it is partially

depressed.

Note: Open the pedestal door of the unit

before lighting the pilot. Once the

pilot is lit, close the door. Y ou should

never operate the unit with the door

open.

1) If the PILOT knob is in the off position

proceed to Step 4.

4) Turn the PILOT knob counterclockwise to

pilot and align it with the arrow as shown

in diagram 1.

5) Push in PILOT knob all the way in and hold.

Immediately push IGNITOR button until pilot

lights. Continue to hold the PILOT knob in

for approximately one minute, then release

the PILOT knob. The pilot fl ame should

continue to burn. If the pilot does not remain

lit, repeat operation allowing a longer period

before releasing PILOT knob.

6) Turn PILOT knob counter clockwise to

on.

7) Use the ON/OFF switch to turn on the

burner.

8) Rotate the HEAT control to adjust the fl ame

height higher or lower.

SHUTDOWN

INSTRUCTIONS

1) Use the ON/OFF switch, wall switch,

thermostat or remote control to turn off the

burner.

2) Push in the PILOT knob slightly and turn

clockwise to off. Do not force.

3) Turn off all electric power to the appliance

if service is to be performed.

FIRST FIRE

The FIRST FIRE in your heater is part of the

paint curing process. To ensure that the paint

is properly cured, it is recommended that you

burn your fi replace for at least four (4) hours the

fi rst time you use it with the fan on.

When fi rst operated, the unit will release an

odour caused by the curing of the paint and the

burning off of any oils remaining from manufacturing. Smoke detectors in the house may go

off at this time. Open a few windows to ventilate

the room for a couple of hours. The glass may

require cleaning.

DO NOT BURN THE APPLIANCE

WITHOUT THE GLASS FRONT IN

PLACE.

AUTOMATIC

CONVECTION

FAN OPERATION

Set the fan speed on

control panel at the

top rear of the unit to

adjust to the desired

speed. The fan will

turn on as the stove

comes up to operating

temperature. After the

unit has been turned

off and the unit cooled

to below a useful heat

output range the fan

will shut off automatically.

ADJUSTING FLAME

HEIGHT

Y our heater has an adjustable fl ame to tailor the

look and heat output to your specifi c needs. It

is adjusted by turning the fl ame adjustment dial

on the gas control valve.

Turn clockwise to adjust the fl ame higher, coun-

terclockwise for a lower fl ame.

Diagram 1

2) Push in PILOT knob slightly and turn clockwise to off. Knob cannot be turned from

pilot to off unless knob is pushed in slightly .

Do not force.

3) Wait fi ve minutes to allow gas, that may have

accumulated in the main burner compartment, to escape. If you smell gas, follow

the instructions on the front of this manual.

If you don't smell gas continue on to the next

step.

14 Regency F38-2 Freestanding Gas Stove

DO NOT ATTEMPT TO CLEAN THE GLASS

WHILE IT IS STILL HOT!

Note: When the glass is cold and the appli-

ance is lit, it may cause condensation

and fog the glass. This condensation

is normal and will disappear in a few

minutes as the glass heats up.

DO NOT BURN THE APPLIANCE

WITHOUT THE GLASS FRONT IN

PLACE.

WARNING

DO NOT SPRAY AEROSOLS IN

THE VICINITY OF THIS

APPLIANCE WHILE IN

OPERATION

Page 15

OPERATING INSTRUCTIONS

1) Push in the gas control knob slightly and turn

clockwise to OFF. Do not force.

FOR YOUR SAFETY READ BEFORE LIGHTING

A) This appliance has a pilot which must be lighted

by hand, following the instructions below

exactly.

B) BEFORE LIGHTING smell all around the appliance

area for gas. Be sure to smell next to the floor

because some gas is heavier than air and will

settle on the floor.

WHAT TO DO IF YOU SMELL GAS

- Do not try to light any appliance

- Do not touch any electric switch, do not use any

phone in your building

- Immediately call your gas supplier from a

neighbors phone. Follow the gas suppliers instructions.

- If you cannot reach your gas supplier, call the

fire department.

C) Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will not

push in or turn by hand, dont try to repair it, call

STOP! Read the safety information above on this

label.

1)

Push in gas control knob slightly and turn

clockwise

to OFF. Knob cannot be turned

from PILOT to OFF unless knob is pushed in

slightly. Do not force.

2) Wait five (5) minutes to clear out any gas. If you

then smell gas STOP! follow B in the safety

information above on this label. If you dont smell

gas, go to the next step.

3) Turn knob on gas control counterclockwise

to PILOT.

4) Push in control knob all the way and hold in.

Immediately push black button on spark igniter

until pilot lights. Continue to hold the control

knob in for about 1/2 minute after the pilot is lit.

Release knob and it will pop back up. Pilot should

remain lit. If it goes out, repeat steps 3) and 4).

If knob does not pop up when released, stop and

immediately call your service technician or gas

supplier.

If the pilot will not stay lit after several tries, turn the

gas control knob to OFF and call your service

technician or gas supplier.

5) Turn gas control knob counterclockwise to ON.

6) Use rocker switch to operate main burner.

908-649c

OFF

WARNING: If you do not follow these instructions exactly, a fire or explosion may result causing

property damage, personal injury or loss of life. Improper installation, adjustment, alteration, service

or maintenance can cause injury or property damage. Refer to the owners information manual

provided with this appliance. For assistance or additional information consult a qualified installer,

service agency or gas supplier.

a qualified service technician. Force or attempted

repair may result in a fire or explosion.

D) Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to inspect the appliance and to replace any part

of the control system and any gas control which has

been under water.

This appliance needs fresh air for safe operation and

must be installed so there are provisions for adequate

combustion and ventilation air.

LIGHTING INSTRUCTIONS

TO TURN OFF GAS APPLIANCE

THERMOPILE

ELEMENT

THERMO-

ELECTRIQUE

PILOT BURNER

VEILLEUSE

This appliance must be installed in accordance with local codes, if any; if none, follow the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, or Natural Gas and Propane Installation Codes, CSA B149.1. (Australia: AS5601-2004, New Zealand: NZS 5261)

DO NOT REMOVE THIS INSTRUCTION PLATE

CAUTION: Hot while in operation. Do not touch.

Severe Burns may result. Due to high surface

temperatures keep children, clothing and

furniture, gasoline and other liquids having

fammable vapors away. Keep burner and control

compartment clean. See installation and

operating instructions accompanying appliance.

2) Turn off all electric power to the appliance if

service is to be performed.

You may shut off the pilot during prolonged non use periods to conserve fuel.

COPY OF THE LIGHTING PLATE INSTRUCTIONS

DO NOT SPRAY AEROSOLS IN THE VICINITY OF

THIS APPLIANCE WHILE IN OPERATION.

Regency F38-2 Freestanding Gas Heater

WARNING:

Gas Inlet

15

Page 16

OPERATING INSTRUCTIONS

PILOT ADJUSTMENT

Periodically check the pilot fl ames. Correct

fl ame pattern has three strong blue fl ames: 1

fl owing around the thermopile and 1 around the

thermocouple, and 1 fl owing across the rear of

the burner (it does not have to be touching the

burner).

Note: If you have an incorrect fl ame pat-

tern, contact your Regency dealer

for further instructions.

Top View of pilot fl ame

Incorrect fl ame pattern will have small, probably

yellow fl ames, not coming into proper contact

with the rear of the burner or thermopile.

NORMAL OPERATING

SOUNDS OF

GAS APPLIANCES

It is possible that you will hear some sounds

from your gas appliance. This is perfectly normal

due to the fact that there are various gauges

and types of steel used within your appliance.

Listed below are some examples. All are normal

operating sounds and should not be considered

as defects in your appliance.

Blower:

Regency gas appliances use high tech blowers

to push heated air farther into the room. It is not

unusual for the fan to make a "whirring" sound

when ON. This sound will increase or decrease

in volume depending on the speed setting of

your fan speed control.

Burner Tray:

The burner tray is positioned directly under the

burner tube(s) and logs and is made of a different gauge material from the rest of the fi rebox

and body. Therefore, the varying thicknesses of

steel will expand and contract at slightly different

rates which can cause "ticking" and "cracking"

sounds. Y ou should also be aware that as there

are temperature changes within the unit these

sounds will likely re-occur. Again, this is normal

for steel fi reboxes.

Top View of pilot fl ame

Blower Thermodisc:

When this thermally activated switch turns ON

it will create a small "clicking" sound. This is the

switch contacts closing and is normal.

Pilot Flame:

While the pilot fl ame is on it can make a very

slight "whisper" sound.

Gas Control Valve:

As the gas control valve turns ON and OFF, a

dull clicking sound may be audible, this is normal

operation of a gas regulator or valve.

Unit Body/Firebox:

Different types and thicknesses of steel will

expand and contract at different rates resulting

in some "cracking" and "ticking" sounds will be

heard throughout the cycling process.

16 Regency F38-2 Freestanding Gas Stove

Page 17

MAINTENANCE

MAINTENANCE

INSTRUCTIONS

1) Always shut the valve off before cleaning.

For relighting, refer to lighting instructions.

Keep the burner and control compartment

clean by brushing and vacuuming at least

once a year. When cleaning the logs, use

a soft clean brush as the logs are fragile

and easily damaged.

2) Clean glass (never when unit is hot), appliance, louvres, and door with a damp cloth.

Never use an abrasive cleaner. The gold

louvres (and optional gold door) may be

scratched if abrasives are used to clean

them.

The heater is fi nished in a heat resistant

paint and should only be refi nished with

heat resistant paint (not with wall paint).

Regency uses StoveBright Paint - Metallic

Black #6309.

3) Make a periodic check of burner for proper

position and condition. Visually check the

fl ame of the burner periodically, making sure

the fl ames are steady; not lifting or fl oating.

If there is a problem, call an authorized

service person.

4) The appliance and fl ueing system must be

inspected before use, and at least annually, by an authorized fi eld service person,

to ensure that the fl ow of combustion and

ventilation air is not obstructed.

During the annual service call, the burners

should be removed from the burner tray

and cleaned. Replace the embers - do not

block the pilot or burner ports.

5) Keep the area near the appliance clear and

free from combustible materials, gasoline

and other fl ammable

vapours and liquids.

WARNING: CHILDREN AND ADULTS

SHOULD BE ALERTED TO THE

HAZARDS OF HIGH SURFACE

TEMPERATURE AND SHOULD

STAY AWAY TO AVOID BURNS

OR CLOTHING IGNITION. YOUNG

CHILDREN SHOULD BE CAREFULLY SUPERVISED WHEN THEY

ARE IN THE SAME ROOM AS THE

APPLIANCE.

CLOTHING OR OTHER FLAMMABLE MATERIAL SHOULD NOT BE

PLACED ON OR NEAR THE APPLIANCE.

DO NOT USE THIS APPLIANCE

IF ANY PART HAS BEEN UNDER

WATER. IMMEDIATELY CALL AN

AUTHORIZED SERVICE TECHNICIAN TO INSPECT THE APPLIANCE

AND TO REPLACE ANY PART OF

CONTROL SYSTEM AND ANY GAS

CONTROL WHICH HAS BEEN UNDER WATER.

6) Verify proper operation after servicing.

LOG REPLACEMENT

The unit should never be used with broken logs.

Turn off the gas valve and allow the unit to cool

before opening door to carefully remove the

logs. The pilot light generates enough heat to

burn someone. If for any reason a log should

need replacement, you must use the proper

replacement log. The position of these logs

must be as shown in the diagram under Log

Installation.

Note: Improper positioning of logs may cre-

ate carbon build-up and will alter

the unit’s performance which is not

covered under warranty.

DOOR AND

GLASS GASKET

If the door gasket requires replacement use

7/8" diameter oval door gasket (Part # 650-920).

The glass requires 5/8" fl at glass gasket. See

your Regency dealer.

GLASS

REPLACEMENT

Your Regency heater is supplied with high

temperature, 5mm Neoceram silica coated

ceramic glass that will withstand the highest

heat that your unit will produce. In the event

that you break your glass, purchase your replacement from an authorized Regency dealer

only, and follow the step-by-step instructions

for replacement.

Removing Glass:

Note: Wearing gloves will protect your

hands while handling glass.

1) Remove the door from the unit and place

on a soft surface to prevent scratching.

2) Pull out the door gasket.

3) Remove the 24 nuts holding the glass

retainers in place. Do not remove the nuts

underneath the retainers.

4) Remove the door catch plate.

5) Remove glass retainers on sides fi rst (3 each

side) then remove two center retainers.

6) Remove glass from door assembly. When

removing glass, leave white insulation in

place.

7) Reverse steps 6 to 2.

CAUTION: ANY SAFETY SCREEN

OR GUARD REMOVED FOR SERV ICING AN APPLIANCE MUST BE

REPLACED PRIOR TO OPERA TING

THE APPLIANCE

Regency F38-2 Freestanding Gas Heater

.

Safety Screen: Only required in Australia

17

Page 18

MAINTENANCE

Installing Glass:

1) Install both center and side glass onto

aluminium extrusions as per diagram.

2) Place glass assembly into door frame.

3) Install retainers by placing 1 drop of glue

where previously glued and put in place.

4) Install side retainers.

5) Install door catch plate.

6) Install the 24 nuts loosely, do not tighten

yet.

7) Tighten side panels nuts using the following

procedure:

a. tighten top & bottom outside corner nuts

(2)

b. tighten inside nuts (3)

c. tighten top & bottom inside corners (2)

8) Tighten the 10 nuts on center glass re-

tainer.

IMPORTANT

Disconnect power supply

before servicing

IMPORT ANT : These fans collect a lot of

dust from within your home. Ensure you

maintain these fan motors on a regular

basis by vacuuming out the fan squirrel

cages, around the motor, and around the

grills on the back of the stove.

WARNING: Electrical Grounding Instructions This appliance is equipped

with a three pronged (grounding) plug

for your protection against shock hazard and should be plugged directly

into a properly grounded three-prong

receptacle. Do not cut or remove the

grounding prong from this plug.

To Remove F38-2 Fan:

1) Unplug or disconnect power source to

stove.

2) Remove all logs and the rear log support,

then remove the 10 screws holding the access panel in place, see Diagram 1. (Fan

is also accessible by opening the right side

door. See Diagram 2).

3) Unclip the black and white wires from the

fan motor.

4) Lift fan off of the 2 pins, tip back and pull

through fi rebox opening. Disconnect the

green ground wire from the left side of the

fan as soon as you can reach it.

Diagram 2

Replacing F38-2 Fan:

Reverse the above steps (1 - 4). If necessary

install a new gasket before replacing the fan

access panel. Make sure the fan wires and the

ground wire are reattached.

9) Repeat step 7 for other side panel.

10) Replace new gasket by gluing it in place.

FAN MAINTENANCE

If your fan requires maintenance or replacement,

access to the fan is through the access panel

on the rear wall of the fi rebox.

If the unit is damaged or needs repair, it shall

be repaired by the manufacturer or its service

agent or similiarly qualifed person in order to

avoid a hazard.

Note: The unit MUST NOT be operated

without the fan access panel securely

in place and correctly sealed.

18 Regency F38-2 Freestanding Gas Stove

Diagram 1

Page 19

REMOVING VALVE

MAINTENANCE

If your valve requires maintenance or replacement, follow these instructions:

NOTE: Always shut off the gas supply

before removing the valve.

1) Open front pedestal door and unhook chain.

Y ou may want to put a soft cloth on the base

of the unit so that when the pedestal door

is open it doesn't scratch the paint. See

diagram below.

4) Remove the two outside frame pieces by

removing two screws per side. See diagram

below.

5) Carefully remove the logs and lava rock.

6) At this point you should disconnect the gas

at the valve.

7) Remove the burner by removing the two

1/4" hex head screws. See diagram be-

low.

9) Carefully lift the burner tray assembly out.

10) To replace the burner tray assembly , simply

reverse these instructions.

2) Undo the six screws holding the control

panel in place.

3) Disconnect all wires from the back of the

panel and then remove panel. You should

lay the panel on a soft cloth so it doesn't get

marked up. See diagram below.

Regency F38-2 Freestanding Gas Heater

Note: Use a magnetic type screwdriver.

8) Remove eight 1/4" hex head screws holding

the burner tray assembly in place.

19

Page 20

PARTS LIST

MAIN ASSEMBLY

Part#: Aust. New Zealand Description Aust. New Zealand Description

1) 560-920 Top/Bottom Gold Louvre (Set)

560-922 Top/Bottom Black Louvre (Set)

2) 750-532 Safety Screen (Australia only)

9) 750-040 Fan Access Door

10) 730-034 Gasket for Fan Access Door

560-519 Fan Assembly

11) 910-169/P Fan Motor (240 Volt)

12) 910-714 Power Cord (240 Volt)

15) * Pedestal Assembly

16) 730-039 Pedestal Door

17) 904-257 551893 Pedestal Door Magnet

18) 560-025 Pedestal Back

19) 756-518 Side Panel Door Assy (Right Side)

20) 756-520 Side Panel Door Assy (Left Side)

21) 560-031 560242 Hinge for Side Panel

23) 904-258 551891 Side Panel Door Magnet

24) 948-255 556074 Door Latch c/w Hook

27) 910-233 560065 Thermodisc - Fan Auto On/Off

28) * Mounting Bracket - Fan Thermodisc

29) * Thermodisc Cover

30) 750-026 Rear Panel

32) 730-018 Firebox Baffl e

33) 560-535 False Top Assembly

34) 590-273 560245 Flue Attachment Bracket

35) 590-930 Ult. 6" Flue Collar (Optional)

38) 820-058 556077 Pedestal Base Cover

46) 750-067 Rear Control Panel

731-968 Conversion Kit - to LPG

948-216 Logo Plate

918-534 Manual

*Not available as a replacement part.

20 Regency F38-2 Freestanding Gas Stove

Page 21

BURNER & LOG ASSEMBLY

Part # Description

52) 910-190 Piezo Ignitor & Nut

54) 910-373 Knob - S.I.T. Valve Extension

55) 910-372 Flame Adjusting Knob

56) 918-088 Control Panel Decal

57) * Control Panel Plate

750-527/P Valve Assembly - NG

750-526/P Valve Assembly - LPG

60) 910-478 Valve S.I.T. - NG/LPG

904-689 #33 Orifi ce - NG at 38 mj.

904-390 #52 Orifi ce - LPG at 31 mj.

71) 752-528 Rear Log Bracket Assy

72) 910-126 Pilot Assy-S.I.T. - 3 fl ame - NG

910-035 Pilot Assy-S.I.T. - 3 fl ame - LPG

75) 730-935 Log Set

78) 752-525 Burner Assy - NG/LPG

90) 910-386 Thermocouple

91) 910-341 Thermopile

PARTS LIST

92) 902-267 Rear Log

93) 902-231 Left Top Log

94) 902-232 Center Log

95) 902-226 Middle Right Log

96) 902-230 Middle Left Log

97) 902-229 Front Right Log

98) 902-228 Front Left Log

*Not available as a replacement part.

Regency F38-2 Freestanding Gas Heater

21

Page 22

PARTS LIST

DOOR ASSEMBLY

Part # Description

730-933 Black Wrap Door - Complete

101) 846-570 Door Gasket Kit

105) * Ceramic Paper

107) 936-243 Glass Gasket

111) * Door Frame Fibre Paper

208) 940-325/P Wrap Glass

*Not available as a replacement part.

208

111

WRAP DOOR

107

101

105

111

22 Regency F38-2 Freestanding Gas Stove

Page 23

WARRANTY

Regency Fireplace Products are designed with reliability and

simplicity in mind. In addition, our internal Quality Assurance T eam carefully inspects each unit thoroughly before it

leaves our door. Regency Industries Ltd. is pleased to extend

this limited lifetime warranty to the original purchaser of a

Regency Product.

The Warranty: Lifetime

Covered under the agreement are the following components:

Combustion chamber, heat exchanger, burner tubes, logs,

embers, glass (thermal breakage) and all gold plating (against

defective manufacture).

The above will be covered for parts and labour for the fi rst fi ve

years and parts only thereafter.

Electrical components such as fans, switches, wiring, thermodiscs,

remote control, thermopiles, thermocouples and gas valves are

covered for one year from the date of purchase.

Conditions:

All installations must be performed by an authorised gas fi tter

and installed according to all applicable local and national codes.

Also, all service work must be carried out by an authorised gas

service person. It is the responsibility of the installer to ensure

that the appliance is fi ring as per rating plate. Any part or parts

of this unit which in our judgement show evidence of such defect

will be repaired or replaced at Regency's option, through an

accredited distributor or agent provided that the defective part

be returned to the distributor or agent Transportation Prepaid,

if requested. In areas where there is not an approved service

agent or the closest approved service agent is situated more

than twenty-fi ve (25) kilometres from the installation, Australian

Heating Distributors are not obliged to arrange warranty repairs

and travel and/or additional labour charges will apply.

Exclusions:

This limited Lifetime Warranty does not extend to or include paint,

door or glass gasketing or trim. It does not cover installation

and operational related problems such as over-fi ring, downdrafts

or spillage caused by environmental conditions, nearby trees,

buildings, hilltops, mountains, inadequate fl ueing or ventilation,

excessive offsets, negative air pressures caused by insuffi cient

make up air, mechanical systems such as furnaces, fans, clothes

dryers etc.

The warranty does not extend to any part or parts which show

evidence of misuse or abuse, neglect, accident or lack of maintenance.

Products made by other manufacturers and used in conjunction

with the operation of this appliance without authorization from

Regency, may nullify your warranty on this product.

Regency Industries Ltd., shall in no event be liable for any special,

indirect consequential damages of any nature whatsoever which

are in excess of the original purchase price of the product. Any

alteration to the unit which causes sooting or carbonning that

results in damage to the exterior facia is not the responsibility

of Regency Industries Ltd.

General:

It is essential that all submitted claims provide all of the necessary information including purchase date, serial #, type of unit

and part or parts requested.

Loading...

Loading...