Rega RP1 User Manual

Rega Planar One

The RP1 has been designed and engineered to achieve outstanding performance way beyond the expectations of a product at this price point. Excellent build quality, reliability and ease of use combine to make a product which if used correctly will offer you a lifetime of musical enjoyment.

Omitting all the usual gimmicks allows us to concentrate the manufacturing costs on the high quality parts necessary to reproduce records accurately. Using a manual speed change rather than an automatic mechanism, eliminates speed inconsistencies and reduces wear of the drive belt. The money we save is spent across the design including a hand assembled RB101 tonearm, precision main bearing and a high quality low vibration motor which would normally be used on a turntable costing two or three times the amount. The minimalist design of the Rega RP1 and the use of extremely high quality components ensure that your turntable should last for many years. The tips on the reverse of these instructions will help increase the life of your turntable and ensure optimum performance.

Manual speed change 33 RPM 45 RPM

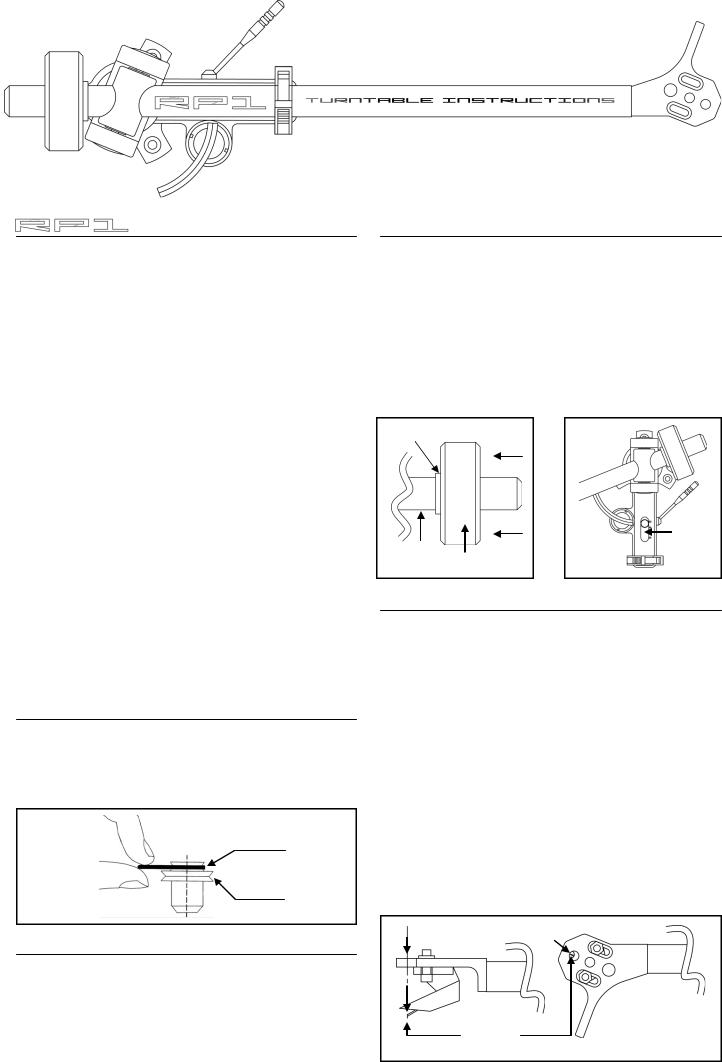

You can change playing speed by simply removing the platter and moving the belt to either the 33rpm or 45rpm wheel of the drive pulley see fig 1.

33 rpm

45 rpm

Fig 1.

Connection to the amplifier

The external phono leads must be connected to your amplifier. Connections : Red right channel / Black left channel. If your amplifier does not have an integrated phono stage you will require an external stage such as the Rega FONO mini.

Plug and play - Quick set up ( f actory fitted cartridge only )

Your turntable has been designed to be very simple to set-up and use. We have designed this turntable so that correct tracking weight can be achieved by simply pushing the balance weight as close to the stop point as possible. Fig 2. This will automatically set the arm to within the recommended tracking range for the factory fitted stylus. ( 1.5g - 2.0g ) The Bias slider should be set to the same figure as the tracking weight. Fig 3.

Stop point

|

|

Bias |

Tonearm |

|

Slider |

Fig 2. |

Weight |

Fig 3. |

|

Advanced Set-up ( when using a different model of cartridge)

If you choose to change the factory fitted cartridge a tracking pressure gauge is required to correctly apply the required down force. Any Hi-Fi dealer should be happy to help with this setup procedure when you purchase a new cartridge. Always use a down force which corresponds to the upper limit of the cartridge maker's recommended range. A new cartridge must be aligned correctly as shown in fig 4. Adjust the cartridge position in the head-shell so that the stylus tip is vertically aligned with the front of the hole marked A. Ensure the cartridge is sitting square in the head-shell before fully tightening. ( Take care not to over tighten ) . Set the bias adjustment slider fig 3. to the same number as the tracking force. For example 1.5g tracking force = 1.5 on the bias slider.

A

A

Stylus Tip

Fig 4.

Loading...

Loading...