Page 1

The RB2000 tonearm is packed with new features pushing the

boundaries of tonearm design. As with all Rega tonearms, each one is

meticulously hand built by a team of highly skilled technicians. The

RB2000 uses improved bearings with each one being hand selected to

be an interference fit with the paired spindle matching both the inside

and outside diameters. This is a Rega developed method of increasing

the amount of detail retrieved from the record surface, designed

specifically to maximise performance of the tonearm and cartridge.

The entire tonearm structure is designed to have the minimum of

mechanical joints whilst using the stiffest materials in all critical

areas. The tolerance of the RB2000 tonearm is so tight that no

adhesive is used at any point throughout the construction. A brand

new low mass, precision engineered, vertical bearing assembly has

been manufactured to further compliment the inherent design

philosophy of the RP10 turntable. The RB2000 uses the latest award

winning Rega arm tube. Each one which is meticulously hand polished

(keeping mass to an absolute minimum) and has been completely

redesigned to redistribute mass and further reduce stresses and

resonances. This advanced design tube increases the stiffness and

rigidity of the overall assembly whilst reducing stress on the bearings

even further.

Arm balancing and setup

With the cartridge correctly mounted and with the stylus guard

removed, ensure that the tracking force dial and Bias adjustment are

set to zero. Adjust the balance weight until the arm is “floating” with

the stylus approximately 1mm clear of the record. Note: It is normal

for the arm to swing back towards the arm clip position even with the

bias set at zero. Therefore it is advisable to gently hold the arm

bearing carrier (just below the tracking dial) thus preventing

horizontal movement during the balancing procedure.

Applying tracking pressure

Once the arm is balanced rotate the tracking force adjustment dial to

the required tracking force. Numbers ‘0’ to ‘3’ are marked on the dial.

If in doubt it is advisable to use a tracking force that corresponds

with the upper limits of the cartridge manufacturer’s range.

Applying Anti - Skating (bias) adjustment

Set the bias adjustment slider to the same figure as the cartridge

tracking force pressure quoted by your cartridge manufacturer.

Note: This is not critical and a figure between 1.0 & 1.5 will normally be

suitable for moving magnet cartridges and 1.5 & 2.0 for most moving

coil cartridges.

0

Fully extended 0.0 First position 1.0 Second Position 2.0

Simply push the slider in to the required anti skating setting .Your arm

is now balanced, setup and ready to use. If you have any doubts

regarding installation or setup please contact your official Rega

dealer who will be able to carry out the work for you. Thank you for

purchasing this Rega product and we wish you many hours of musical

enjoyment.

1

2

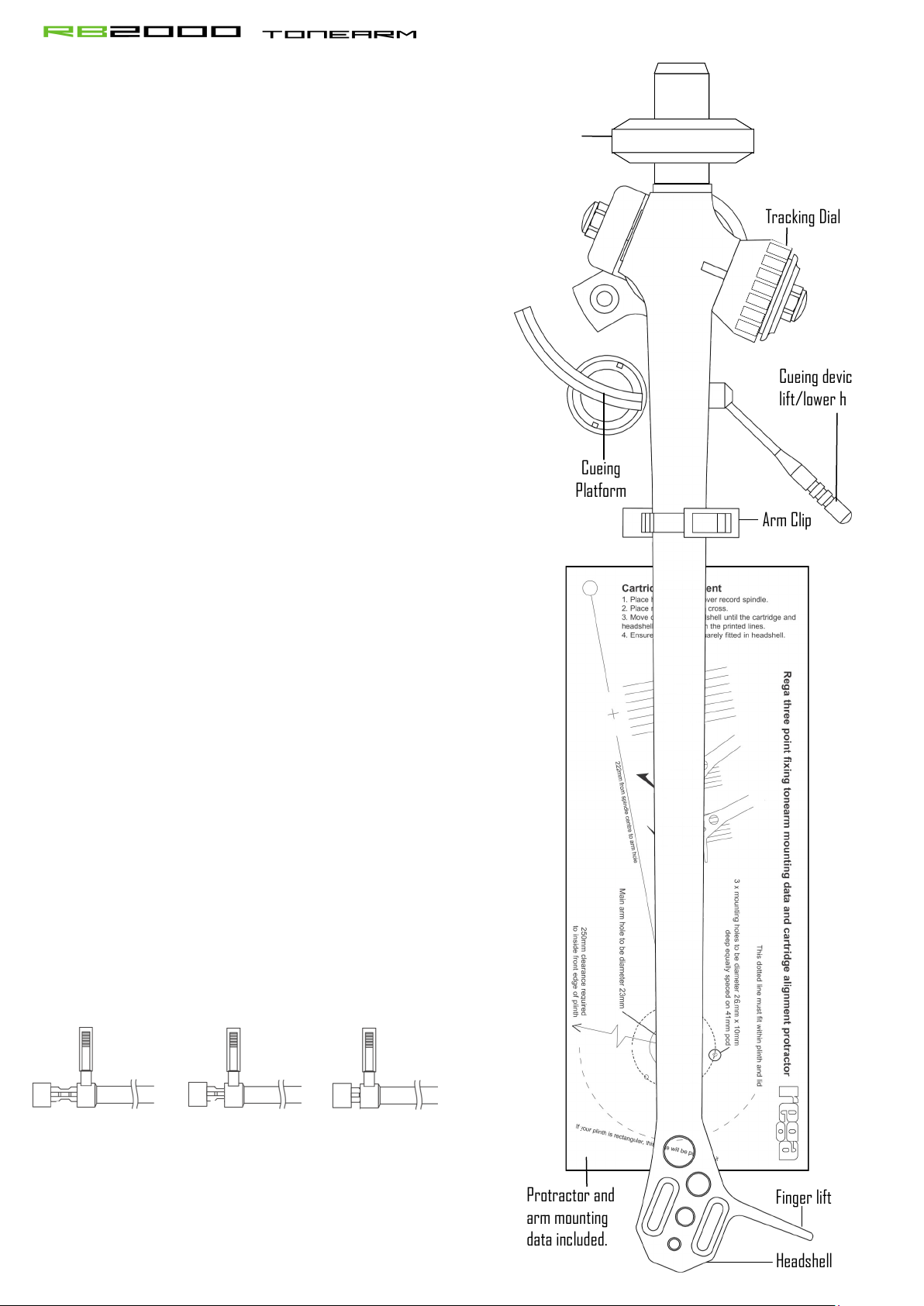

Balance Weight

Protractor and

arm mounting

data included.

Names of Tonearm parts

Tracking Dial

Cueing device

lift/lower handle

Cueing

Platform

Arm Clip

6

Finger lift

Headshell

Page 2

Fitting your Tonearm

The RB2000 will directly replace any other Rega tonearm that

currently uses the 3 point mounting without any modification. If fitting

to another manufacturers product or an older Rega turntable (with

the single point nut fixing) the supplied template should be used as a

guide to ensure correct position and alignment. With so many variants

in turntable models it is important to contact your turntable

manufacturer if in any doubt before making any holes in plinths or arm

boards. Before attempting to fit the RB2000 arm to the turntable it is

important to ensure that there is sufficient clearance beneath the

turntable and that the arm does not hit the lid, top or sides. Having

checked that there is sufficient clearance in all directions (including

the maximum potential arm movement horizontal and vertical). The

next step is to find the position of the centre of the arm mounting hole.

The easiest way to do this will probably be to use the arm mounting

template supplied.

Arm mounting template guide

The supplied template is for mounting Rega three point fixing arms to

other manufacturers turntables. N.B protractor for cartridge

alignment is also printed on the same template.

1. The template should be kept flat and not bent. The distance between

the centre of the spindle and the centre of the arm hole is critical and

must be 222mm. This template will help you check your positioning

before you attempt fitting and drilling.

3. Position the other end of the template so that the clearance arc is

within the rear and side edges of the turntable base (and the lid when

closed). Also check that there is at least 250mm clearance from the

centre of the hole to the inside front of the turntable.

4. Use a long pointed probe such as a needle and push it through the

‘arm hole centre’ on the template. Keep the needle perpendicular to

the template and mark the position of centre on the turntable.

5. Having marked the centre, check again that if the arm is placed in

this position it will clear the under side of the turntable and the lid.

Also, check that the arm is in a satisfactory position to ensure easy

operation and that the position is pleasing aesthetically. When you are

certain that the arm hole centre is in its correct position (exactly

222mm from the record centre) you can drill the required arm hole.

6. The arm mounting pillar requires a diameter of 25mm which will

provide adequate clearance for accurate fitting. You can then drill the

three screw mounting holes as illustrated on the template. Make sure

the arm is straight and the holes are correctly aligned before drilling.

7. With the holes drilled, you are now ready to fit the arm to the

turntable. Ensure that you also follow the turntable manufacturer’s

instructions regarding arm fitting. Each individual turntable

manufacturer may have different requirements regarding positioning

of the arm signal lead.

Loading...

Loading...