Page 1

INSTALLATION INSTRUCTIONS

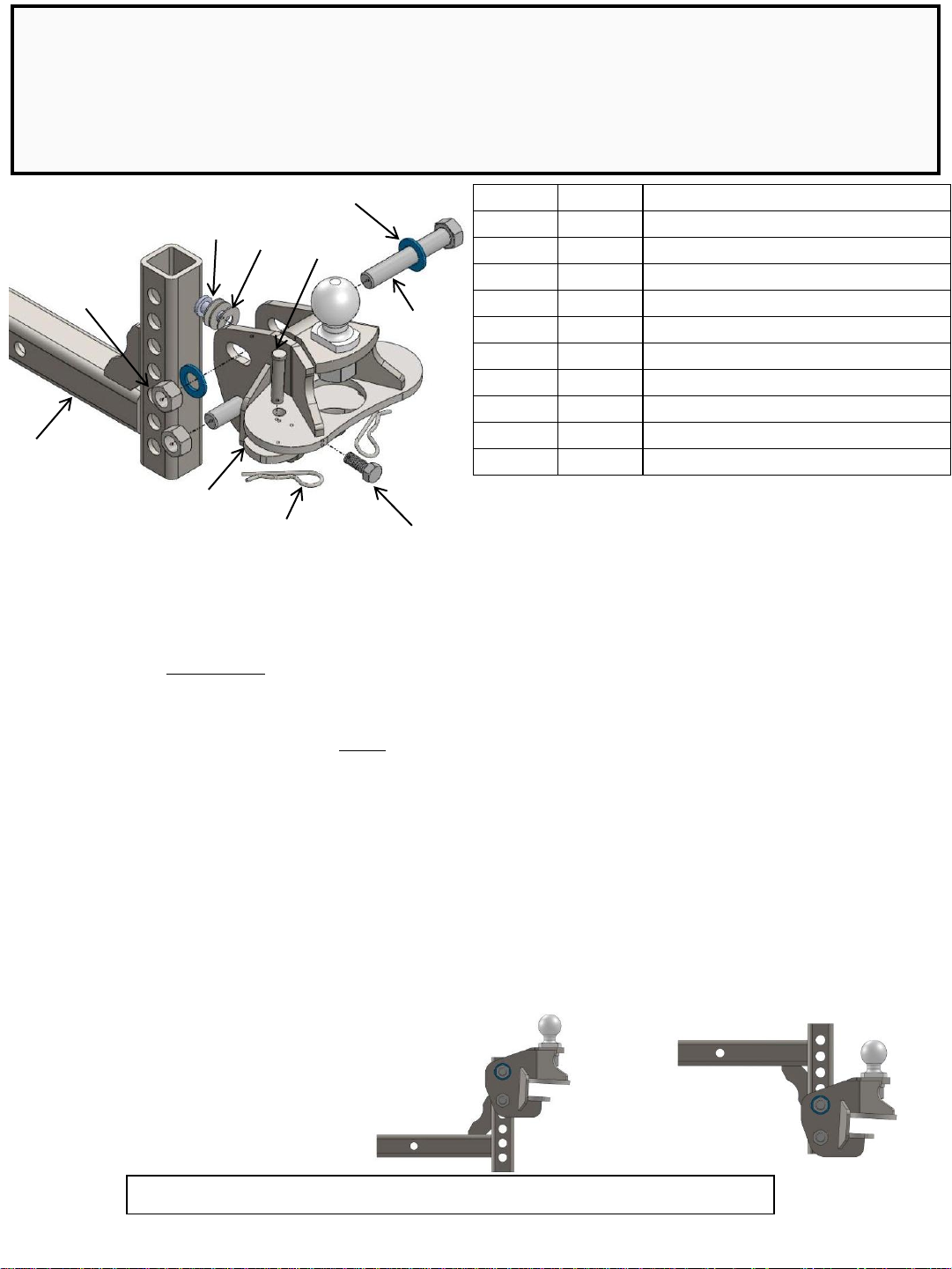

PART QTY DESCRIPTION

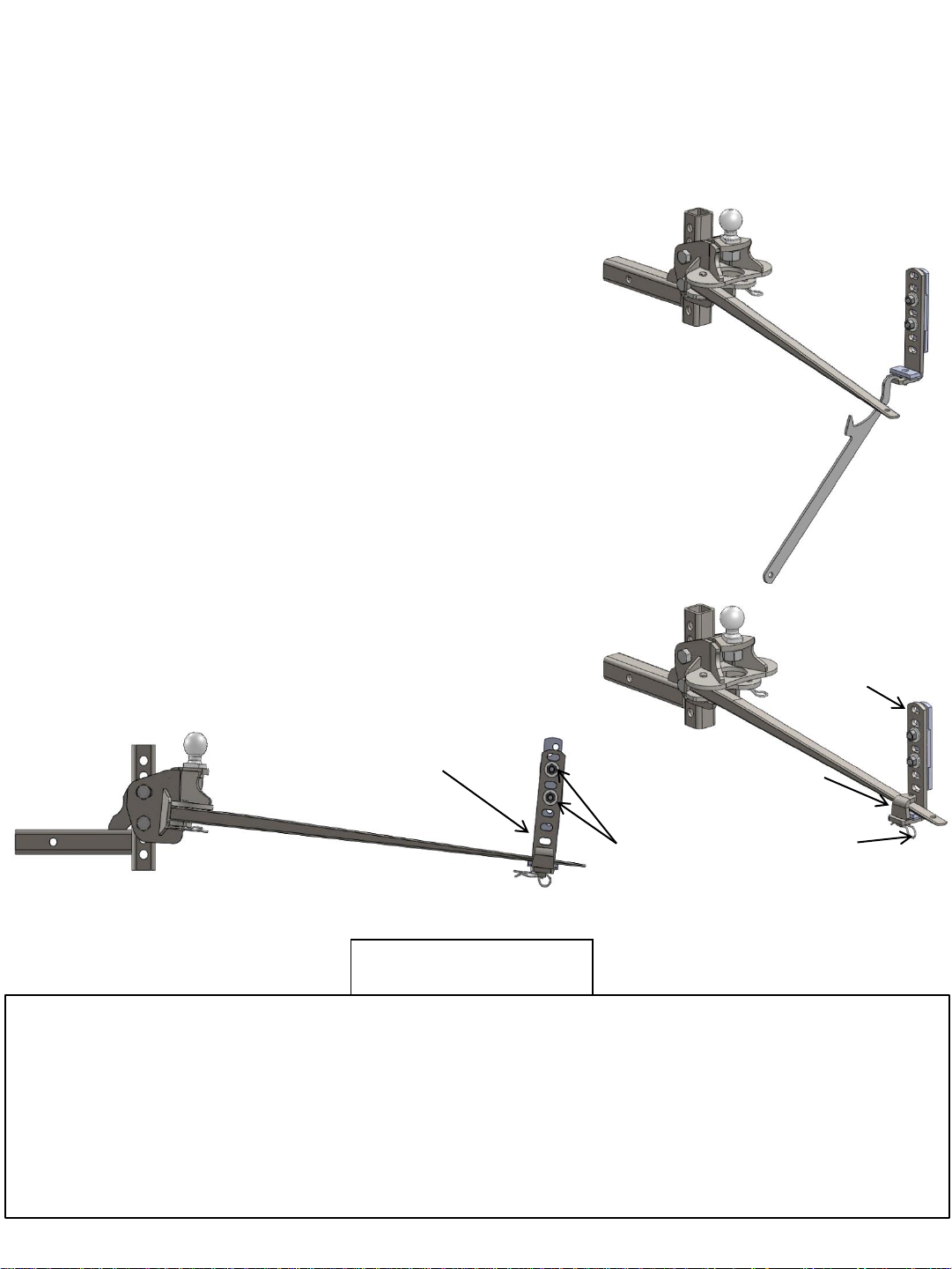

A 1 BALL MOUNT

B 1 DRAW BAR

C 2 3/4-10 x 4-1/2" GR.8 HEX HEAD BOLT

D 2 3/4" FLAT WASHER

E 2 3/4-10 NUT

F 1 1/2-13 x 1-1/4" GR.5 HEX HEAD BOLT

G 2 1/2" x 2-1/4" SPRING BAR PIN

H 2 CLIP

J 1 ADJUSTMENT PIN

K 6 ADJUSTMENT WASHERS

66557

250LB – 400LB

REESE Steadi-Flex

Weight Distributing Kits

PLYMOUTH, MI.

66558

400LB – 600LB

D

J

K

G

E

C

B

A

Fig. 1

H

F

TORQUE WRENCH TAPE MEASURE

3/4” SOCKET 1-1/8” SOCKET & WRENCH

TOOLS REQUIRED

SIZING WD AND TRAILER HITCH SYSTEMS

•Weigh loaded trailer tongue to determine proper system size.

•Choose a system with tongue rating at or above the actual trailer tongue weight.

•Tongue rating of trailer hitch must meet or exceed the measured tongue weight of the trailer. OEM hitches

may not be rigid enough for tongue weight and may need to be replaced (too much flex and won’t carry the

load).

•Total trailer gross weight rating must never exceed tow vehicle rated gross tow rating.

DRAW BAR AND BALL MOUNT ASSEMBLY

• Insert draw bar (B) into the tow vehicle receiver in the desired orientation and install the pull pin and clip.

• Install either a 2” or 2-5/16” ball, (check trailer for correct ball size), with a 1” shank, onto the ballmount

and torque the nut to the ball’s instruction sheet requirements.

• Measure the coupler height of your loaded trailer. Make sure trailer is setting level.

• To begin with, install 2 washers (K) on adjustment pin (J) and insert into top hole in ball mount(A), see

Fig. 1 above. Up to 6 washers(K) can be used.

• Set the ball mount so that the ball height is approx. 1” higher than the coupler height with the trailer

setting level. See Fig. 2 below for the range of height adjustments.

• Install bolt (C) in the bottom hole of the ball mount and bolt (C) with washers (D) in the upper hole.

Attach nut (E) to both bolts. Leave nuts loose at this time.

For Installation Assistance or Technical Help, Call 1-888-521-0510

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

HIGHEST POSITION

LOWEST POSITION

Fig. 2

Page 2

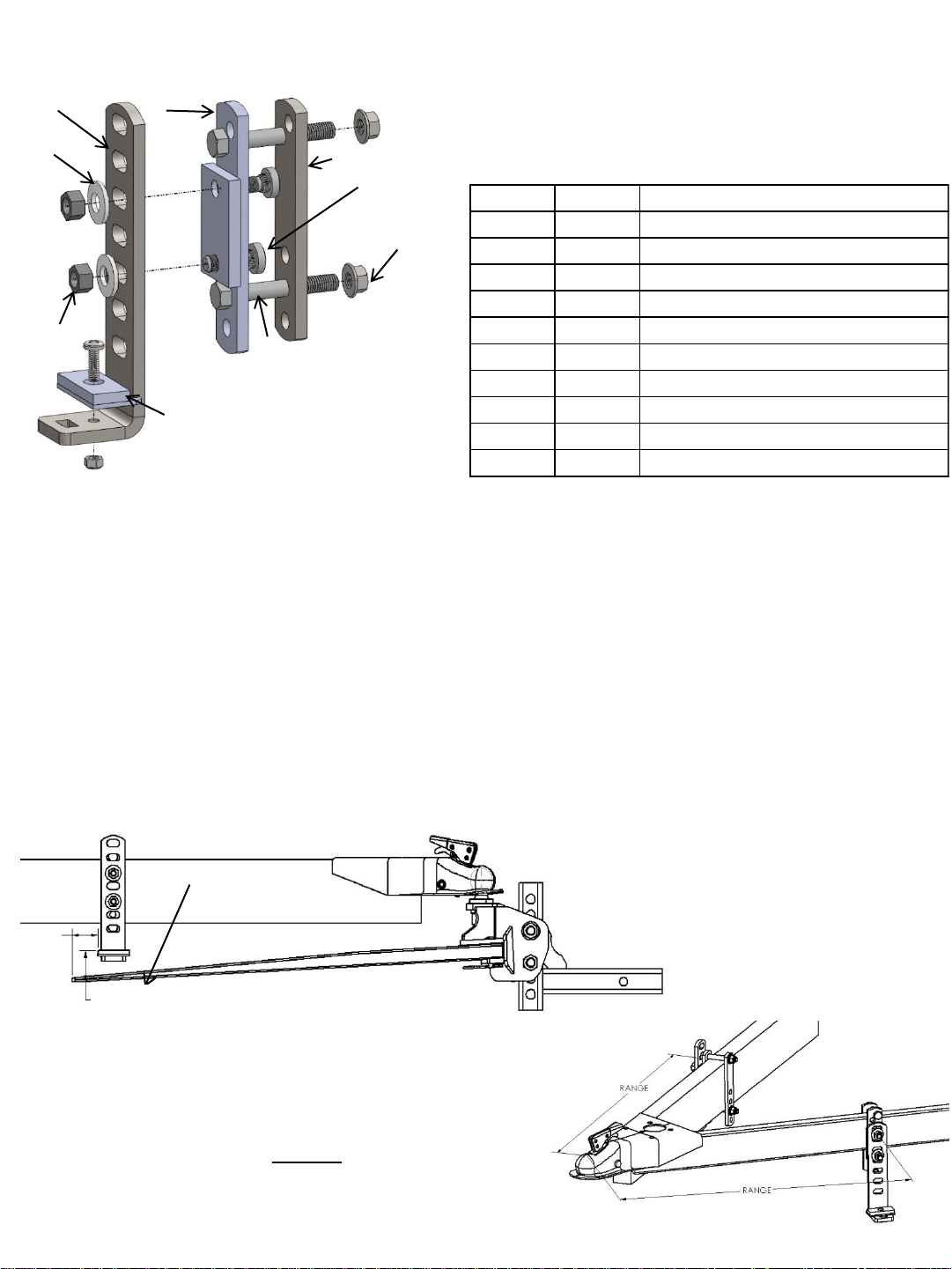

PART QTY DESCRIPTION

L 2 L - BRACKET

M 2 OUTER FRAME BRACKET ASSY.

N 2 INNER STRAP

O 2 FRICTION PAD

P 4 1/2-13 FLANGE LOCK NUT

Q 2 1/2-13 x 4" GR. 5 HEX HEAD BOLT

R 4 1/2-13 NUT

S 4 1/2" SERRATED WASHER

T 4 1/2-13 RIBBED BOLT

U 2 1/2-13 x 3.50" GR5 HEX HEAD BOLT

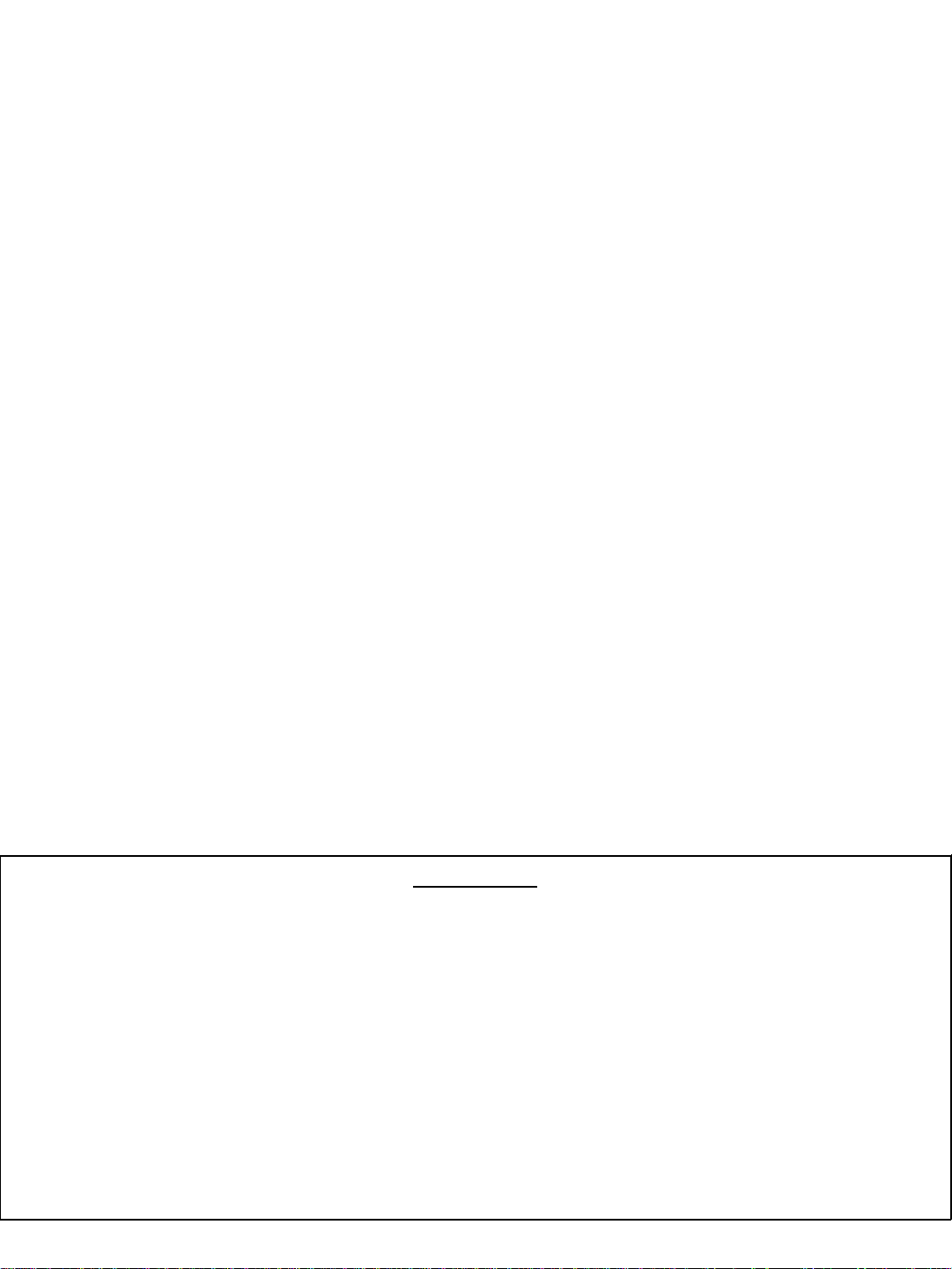

FRAME BRACKET ASSEMBLY FOR (66557) 250LB - 400LB SYSTEM (shown below.)

Use Fig. 3 for 4” – 6” tall frames. Otherwise use Fig. 4 on the next page.

L

S

M

N

T

R

R

O

Fig. 3

U

P

Fig. 3

O

•Place 1/2” ribbed bolts (T) thru the holes shown in bracket (M). Either tap the bolts (T) in with a hammer

or install a nut (R) and tighten until the head of the bolt is recessed below the surface of the bracket (M).

Remove nut (R).

•Place the upper bolt (U) thru outer frame bracket (M) and inner strap (N). Place this over the A-frame. See

chart 1 below for frame placement location..

•Always keep the bottom bolt (U) close to the bottom of the frame. If it is not, move the top bolt (U) slightly

up and over to the higher setting.

•Start out by placing L-bracket (L) into the middle of its height adjustment. Thread nuts (R) with washers

(S) onto bolt (T).

•Repeat for the other side.

•Keep at least 3” of spring bar extending beyond the L-bracket (L) as shown in Fig. 5 below.

•Leave nuts (R) finger tight at this time.

•Torque nuts (P) to 75 ft.*lbs.

DEPENDING ON

YOUR SYSTEM

3”

MIN.

NOTE: Propane bottles, batteries, etc. may obstruct installation of the

frame brackets to the trailer frame. The frame brackets can be located

within the following specified range from coupler ball center to the

center of friction pad:

Chart 1

Bracket Mounting Range = 25” to 32”

3” OR 4”

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

Fig. 5

2

Page 3

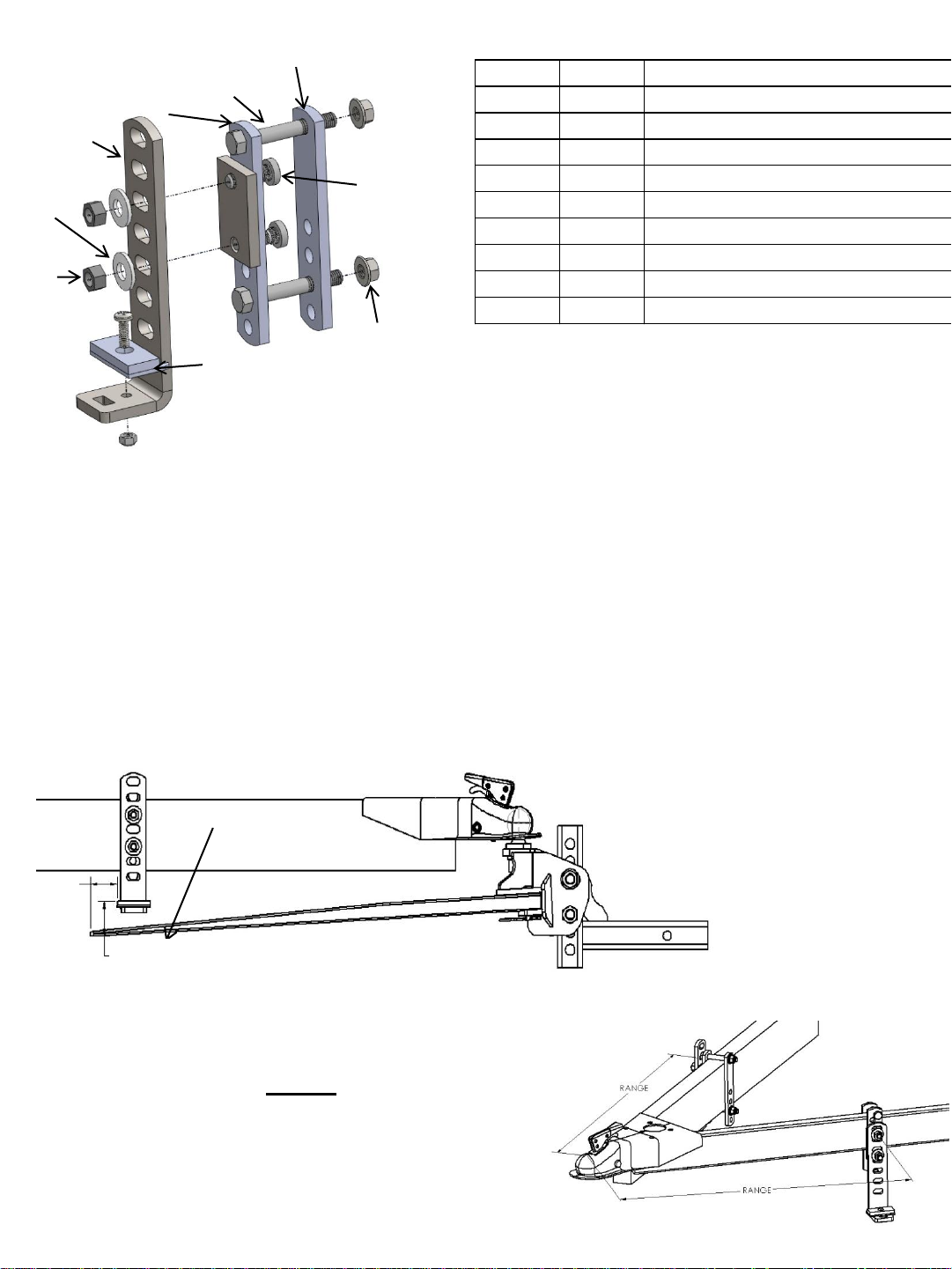

PART QTY DESCRIPTION

L 2 L - BRACKET

M 2 OUTER FRAME BRACKET ASSY.

N 2 INNER STRAP

O 2 FRICTION PAD

P 4 1/2-13 FLANGE LOCK NUT

Q 2 1/2-13 x 4" GR. 5 HEX HEAD BOLT

R 4 1/2-13 NUT

S 4 1/2" SERRATED WASHER

T 4 1/2-13 RIBBED BOLT

U 2 1/2-13 x 3.50" GR5 HEX HEAD BOLT

FRAME BRACKET ASSEMBLY FOR (66557) 250LB - 400LB SYSTEM (shown below.)

Use Fig. 4 for 3” to 3-1/2” tall frames.

S

P

U

T

R

N

M

Q

O

L

Fig. 4

L

•Place 1/2” ribbed bolt (T) thru the hole shown in outer frame bracket (M). In Fig. 4 the lower bolt (Q)

inserts into inner strap (N) from the inside of the trailer A-frame. Either tap the bolt (T) in with a hammer or

install a nut (R) and tighten until the head of the bolt is recessed below the surface of the bracket (M).

Remove nut (R).

•Place the upper bolt (U) thru outer frame bracket (M) and inner strap (N). Place this over the A-frame. See

chart 1 below for frame placement location. Always keep the bottom bolt (Q) close to the bottom of the

frame. If it is not, move the top bolt (U) slightly down and over to the lower setting.

•Start out by placing L-bracket (L) into the middle of its height adjustment. Place a nut (R) and washer (S)

on the long bolt (Q). Thread nut (R) with washer (S) onto bolt (T).

•Repeat for the other side.

•Keep at least 3” of spring bar extending beyond the L-bracket (L) as shown in Fig. 5 below.

•Leave nuts (R) finger tight at this time.

•Torque nuts (P) to 75 ft.*lbs.

DEPENDING ON YOUR

SYSTEM

3”

MIN.

NOTE: Propane bottles, batteries, etc. may obstruct installation of the

frame brackets to the trailer frame. The frame brackets can be located

within the following specified range from coupler ball center to the

center of friction pad:

Chart 1

Bracket Mounting Range = 25” to 32”

3” OR 4”

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

Fig. 5

3

Page 4

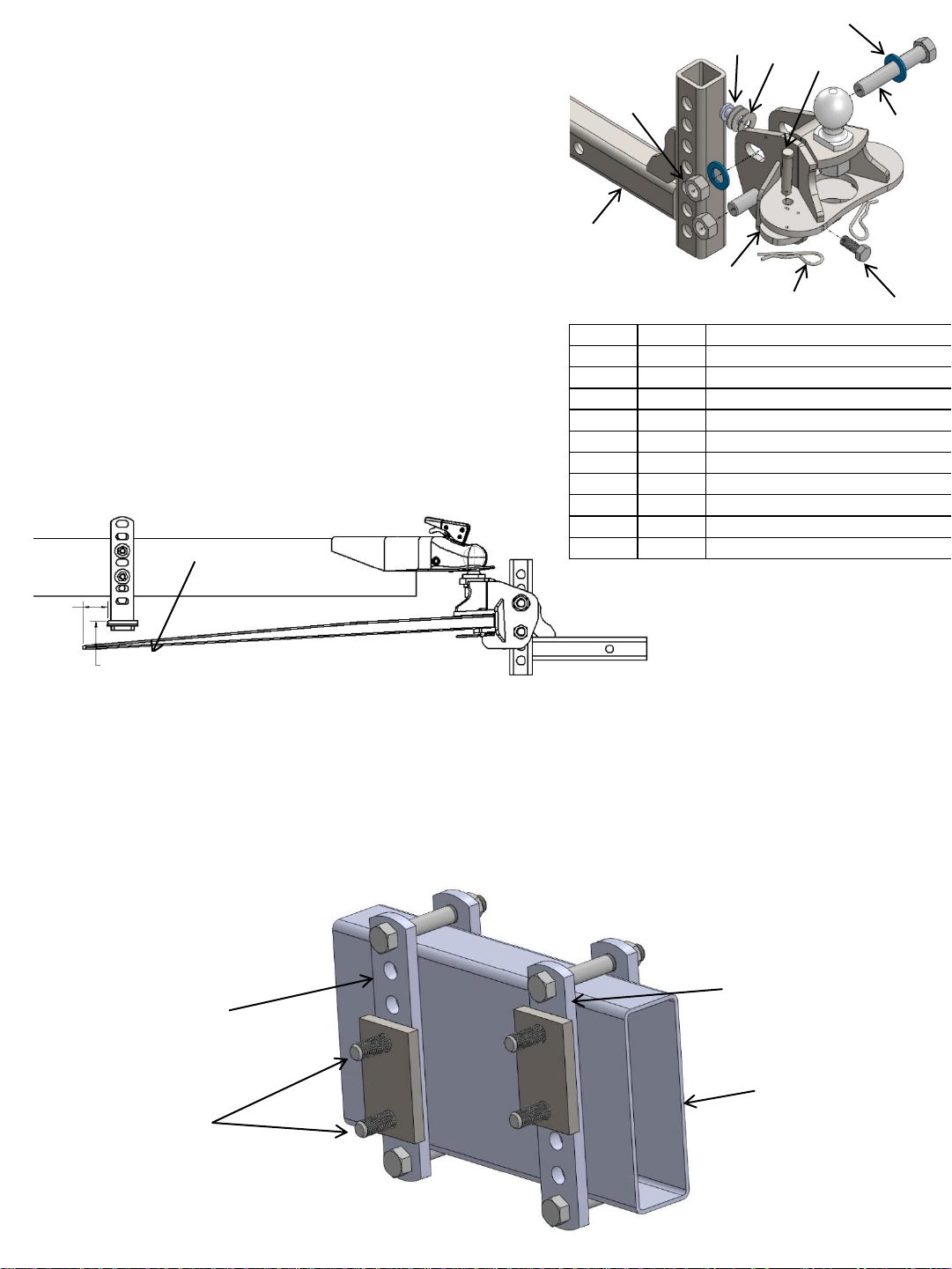

PART QTY DESCRIPTION

L 2 L - BRACKET

O 2 FRICTION PAD

P 4 1/2-13 FLANGE LOCK NUT

R 4 1/2-13 NUT

S 4 1/2" SERRATED WASHER

T 4 1/2-13 RIBBED BOLT

U 4 1/2-13 x 3.50" GR5 HEX HEAD BOLT

V 2 OUTER FRAME BRACKET ASSY.

W 2 INNER STRAP

FRAME BRACKET ASSEMBLY FOR (66558) 400LB - 600LB. SYSTEM, (shown in Fig.6 below).

W

U

L

V

T

S

R

P

O

Fig. 6

•Place ½” ribbed bolts (T) into holes the holes shown in bracket (V). Either tap them in with a hammer or

install a nut (R) and tighten until the head is recessed below the surface of the bracket (V). Remove nut (R).

•Place the upper bolt (U) thru outer frame bracket assy. (V) and inner strap (W). Place this over the A-frame.

See chart 1 below for the location.

•Place another bolt (U) into the bottom hole in the bracket. Keep this as high and close to the frame as

possible. Install nut (P) on the bolts.

•Place L-bracket (L) in about the middle of its height adjustment and secure by threading nuts (R) with

washers (S) into bolts (T). Leave nuts (R) finger tight at this time.

•Repeat for the other side.

•Keep at least 3” of spring bar extending beyond the L-bracket (L) as shown in Fig. 5 below.

•Leave nuts (R) finger tight at this time.

Torque nuts (P) to 75 ft.*lbs.

DEPENDING ON YOUR

SYSTEM

3”

MIN.

Fig. 5

3” OR 4”

NOTE: Propane bottles, batteries, etc. may obstruct installation of the

frame brackets to the trailer frame. The frame brackets can be located

within the following specified range from coupler ball center to the

center of friction pad:

Chart 1

Bracket Mounting Range = 25” to 32”

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

4

Page 5

BALLMOUNT ADJUSTMENT

PART QTY DESCRIPTION

A 1 BALL MOUNT

B 1 DRAW BAR

C 2 3/4-10 x 4-1/2" GR.8 HEX HEAD BOLT

D 2 3/4" FLAT WASHER

E 2 3/4-10 NUT

F 1 1/2-13 x 1-1/4" GR.5 HEX HEAD BOLT

G 2 1/2" x 2-1/4" SPRING BAR PIN

H 2 CLIP

J 1 ADJUSTMENT PIN

K 6 ADJUSTMENT WASHERS

•With your trailer NOT CONNECTED to the vehicle, pick

reference points on front and rear wheel wells of your vehicle.

Measure and record distance to pavement. Front wheel well to

pavement __________Rear wheel well to pavement _________.

•Insert the spring bars into the ball mount (A) and secure with

pin (G) and clip (H). Apply a lubricant on the spring bars as you

insert them into the ball mount.

•With the trailer coupled to the ball and the trailer setting level,

(use the tongue jack to level the trailer), the angle adjustment in

the ball mount should have the spring bar 3” below the friction

pad for the 400 lb. system and 4” below the friction pad for the

600 lb. system. See Fig. 5. If needed add or subtract washers (K)

shown in Fig. 1 to get the needed dimension. Each washer added

will move the spring bars down approx. 5/8” to ¾”.

•If you have the 66557 and a tongue wt. of only 250 lbs., you

may need only 1-2 washers.

•If you have the 66558 and a tongue wt. of 600 lbs., you may

need 3-4 washers.

•Install and tighten bolt (F) shown in Fig.1

B

E

Fig. 1

A

J

K

D

G

C

H

F

DEPENDING ON

YOUR SYSTEM

3”

MIN.

NOTE:

3” OR 4”

Fig. 5

• During ball mount adjustment, it may be necessary to raise or lower the L-bracket (L) to get the proper

spring bar load if there is not enough head angle adjustment. If their are not enough washers to get the

dimension shown in fig. 5, move the L-bracket (L) up 1 set of holes.

• If you have a 6” tall frame with a bottom mounted coupler (inverted coupler) it may be necessary to

install brackets (V) and (W) upside down in order to get the L-bracket (L) mounted low enough. This will

lower the L-bracket 1.75” Otherwise their may be too much spring bar pressure.

• Torque both 3/4” nuts(E) to 300 ft.*lbs. when the desired angle is achieved. If a large enough torque

wrench is not available, torque nuts to 150 ft.*lbs. then tighten the nuts an additional 1/4 turn. Do not

lubricate the threads.

Brackets in standard

Brackets flipped for

bottom mount coupler.

Studs 1.75” lower

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

position for standard

coupler.

Trailer

A-Frame

Fig. 7

5

Page 6

SPRING BAR HOOK-UP

• To place the spring bar on the L-bracket (L), keep the coupler attached to the ball. Raise the coupler using

the tongue jack until the spring bar will go onto the L-bracket (L).

• If the jack will not raise the coupler high enough, use the lifting handle shown in the Fig. 8 below. Place

the hooked end of the handle in the rectangular hole of the L-bracket (L). Place the end of the spring bar as

shown and lift the handle. Remove the handle.

• Place spring bar retention bracket (I) into the L-bracket (L) and secure with clip (H) as shown in Fig. 9.

WARNING: to avoid serious injury, always stand to the side of

the lift handle. Never stand at the end of the handle or allow any

part of your body under the handle.

• Lower tongue jack. Re-measure the front wheel well reference

point. Front wheel height must be equal to the original

measurement. If the front wheel height is higher than previously

measured, the head tilt angle must be increased (tilted

Fig. 8

downward). If the front wheel well height is substantially lower

than originally measured (1” or more), the head tilt angle must be

reduced (tilted upward). For coarse adjustment, the L-bracket (L)

can be lowered one hole to bring the front wheel well back up.

The spring bars must be unloaded and removed from the Lbracket (L) prior to adjusting the head tilt angle or removal of the

nuts (T). If the head angle or L-bracket adjustments are made,

repeat hook up steps until the front wheel well height is approx.

equal to the original measurement. It is preferred that the rear of

(L)

the vehicle settle about the same amount or more than the front.

L-BRACKET adjusted to

spring bar angle.

RETENSION

BRACKET (I)

Fig. 9

NUT (R)

CLIP (H)

Fig. 10

IMPORTANT

ADJUSTING & TIGHTENING THE L-BRACKETS

• Always keep nuts (R) finger tight until the spring bars are in place and loaded with pressure on the Lbrackets (L). This will allow the L-brackets (L) to adjust themselves to the spring bar angle giving the

maximum contact with the friction pad (O) and resulting in better sway control. See Fig. 10 above.

Tighten nuts (R) to 75 ft.-lbs.

• If you tightened the nuts before you applied the spring bar tension, loosen the nuts (R) slightly. Do not

remove the nuts completely. They are under pressure from the spring bars. The L-bracket (L) will then

adjust to the spring bar angle by itself. Re-tighten the nuts (R) to 75 ft.-lbs.

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

6

Page 7

UNHITCHING

•Block trailer wheels front and rear.

•Raise tongue of trailer with tongue jack as high as possible, usually 8-12 inches.

•Remove spring clip (H), fig. 9, from spring bar retention bracket (I). Remove bracket.

•Push the spring bar off the L-bracket.

WARNING: To avoid serious injury, always stand to the side of the lift handle. Never stand at the end

of the handle or allow any part of your body under the handle or spring bar.

•Remove clip (H) and pin (G), fig. 1. Pull the spring bar out of head (A).

•Repeat for the other side.

•Lower the tongue of the trailer until the jack is slightly off the ground and unlatch the trailer coupler. Once

unlatched, the trailer may be raised again to clear the top of the ball and vehicle can be driven away.

LUBRICATION

•Lubricate the hitch ball to prevent unnecessary wear. Lubricate the contact area in the ball mount where the

spring bars insert. Excess oil and dirt should be wiped out whenever the trailer is uncoupled.

•Do not lubricate the friction pads (O).

Area to lubricate

Under coupler

Area to lubricate

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

7

Page 8

WARNINGS: LOADED BALL HEIGHT SHOULD NEVER BE GREATER THAN UNCOUPLED BALL HEIGHT. Front wheel overload and loss of rear wheel traction can

result, and can lead to unstable handling, reduced braking ability, and a tendency to "jackknife" when turning and braking at the same time. IF LOADED BALL HEIGHT IS

GREATER THAN UNCOUPLED HEIGHT, re-adjust head and re-measure until proper height is obtained.

DO NOT TOW MULTIPLE TRAILERS: Do not attempt to tow any type of trailer behind another trailer. Towing multiple trailers may cause severe instability, loss of

control and/or structural failure, and may result in vehicle accident, property damage and personal injury. Towing multiple trailers is illegal in many jurisdictions.

FRONT-WHEEL-DRIVE VEHICLES: DO NOT ATTEMPT TO HOOK-UP OR TOW WITH REAR WHEELS OF TOWING VEHICLE REMOVED. Severe structural damage

to towing vehicle, hitch, and trailer may result. A towing vehicle/trailer combination cannot be controlled adequately unless the towing vehicle's rear wheels are carrying

their share of the load.

MAINTENANCE: Keep the head assembly free of dirt and well lubricated. Excessive wear may indicate overload or inadequate lubrication.

Keep hitch painted to prevent rust and maintain a good appearance. (Do not paint over labels)

AT THE BEGINNING OF EVERY TOWING DAY:

Clean ball and coupler socket and coat ball lightly with grease.

TOWING TIPS

DRIVING: Good habits for normal driving need extra emphasis when towing. The additional weight affects acceleration and braking, and extra time should be allowed for

passing, stopping, and changing lanes. Signal well in advance of a maneuver to let other drivers know your intentions. Severe bumps and badly undulating roads can

damage your towing vehicle, hitch, and trailer, and should be negotiated at a slow steady speed. IF ANY PART OF YOUR TOWING SYSTEM "BOTTOMS" OUT, OR IF

YOU SUSPECT DAMAGE MAY HAVE OCCURED IN ANY OTHER WAY, PULL OVER AND MAKE A THOROUGH INSPECTION. CORRECT ANY PROBLEMS

BEFORE RESUMING TRAVEL.

CHECK YOUR EQUIPMENT: Periodically check the condition of all your towing equipment and keep it in top condition.

TRAILER LOADING: Proper trailer loading is important. Heavy items should be placed close to the floor near the trailer axle. The load should be balanced side-to-side

and firmly secured to prevent shifting. Tongue weight should be about 10-15 percent of the gross trailer weight for most trailers. Too low a percentage of tongue weight

will often produce a tendency to sway. Excess weight on the tongue can also lead to sway and damage hitch and / or tow vehicle.

SWAY CONTROLS: A sway control can help minimize the affects of sudden maneuvers, wind gusts, and buffeting caused by other vehicles. Use of a sway control is

recommended for trailers with large surface areas, such as travel trailers.

TIRE INFLATION: Unless specified otherwise by the towing vehicle or trailer manufacturer, tires should be inflated to their maximum recommended pressure.

TOWING VEHICLE AND TRAILER MANUFACTURERS' RECOMMENDATIONS: Review the owners' manuals for your towing vehicle and trailer for specific

recommendations, capacities, and requirements.

PASSENGERS IN TRAILERS: Trailers should NOT be occupied while being towed, under any circumstances.

TRAILER LIGHTS, TURN SIGNALS, AND ELECTRIC BRAKES: Always hook up and verify function of the trailer lights, turn signals, electric brakes and break-away

switch connection (if so equipped) even for short trips.

REMOVE HITCH WHEN NOT TOWING: Remove hitch from towing vehicle receiver when not towing, to prevent contamination of head sockets, reduce chance of

striking hitch on driveway ramps or other objects, and minimize damage in the event of a rear-end collision.

Check to see that all bolts are properly tightened and hitch pin and clip are securely in place.

Check to see that electrical hookups are in working order, and that safety chains are connected.

Hitches - Custom Receivers - Sway Controls

LIMITED WARRANTY

Cequent Performance Products, Inc. warrants its Hitches, Custom Hitch Receivers, and Sway Controls from date of purchase against defects in material and

workmanship under normal use and service, ordinary wear and tear excepted, for the ownership life of the original consumer purchaser.

Cequent Performance Products, Inc. will replace FREE OF CHARGE any part which proves defective in material or workmanship when presented to any Cequent

Performance Products, Inc. dealer, Cequent Performance Products, Inc. Warehouse or return to factory. TRANSPORTAION CHARGES PREPAID, at the address

below. THIS WARRANTY IS LIMITED TO DEFECTIVE PARTS REPLACEMENT ONLY. LABOR CHARGES AND/OR DAMAGE INCURRED IN INSTALLATION

OR REPLACEMENT AS WELL AS INCIDENTAL AN CONSEQUENTIAL DAMAGES CONNECTED THEREWITH ARE EXCLUDED.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

Any damage to the Hitch, Custom Hitch Receiver, and Sway Control as a result of misuse, abuse, neglect, accident, improper installation, or any use violative of

instructions furnished by us, WILL VOID THE WARRANTY.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state. In the event of a problem with warranty service or

performance, you may be able to go to a small claims court, or a federal district court.

Cequent Performance Products, Inc.

47912 Halyard Dr. Suite 100

Plymouth, Mi. 48170

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

8

Page 9

INSTRUCTIONS D'INSTALLATION

66557

250 LB – 400 LB

(113 - 181 kg)

Ensembles de répartition de charge

J

K

REESE Steadi-Flex

PLYMOUTH, MI

D

G

A 1 Montage de boule

B 1 Barre d’accouplement

66558

400 LB – 600 LB

(181 - 272 kg)

C 2 Boulon hex. ¾-10 x 4 ½ GR8

E

C

D 2 Rondelle plate ¾

E 2 Écrou ¾-10

F 1 Boulon hex. ½-13 x 1 ¼ GR5

G 2 Cheville de barre stab. ½ x 2 ¼

H 2 Agrafe

J 1 Tige d’ajustement

B

A

Fig. 1

H

DIMENSIONNEMENT DES SYSTÈMES D'ATTELAGE

•Mesurez le poids de la remorque chargée à son timon pour déterminer les dimensions appropriées du système.

•Choisissez un système dont la charge nominale maximum au timon est égale ou supérieure au poids mesuré au timon

de la remorque.

•La charge nominale maximum de l'attelage de remorque doit être égale ou supérieure au poids mesuré au timon de la

remorque. Il se peut que les attelages d'origine (du fabricant du véhicule) ne soient pas suffisamment robustes pour la

charge au timon et doivent être remplacés (flexion excessive et incapacité de transporter la charge).

•Le poids brut total de la remorque ne doit jamais excéder la capacité de charge brute nominale du véhicule.

F

K 6 Rondelles d’ajustement

Outils requis

Clé dynamométrique Ruban à mesurer

Douille 3/4 po Douille et clé 1-1/8 po

ENSEMBLE DE BARRE ET DE BOULE DE REMORQUAGE

•Insérer la barre de remorquage (B) dans le récepteur du véhicule dans l'orientation souhaitée, puis poser la cheville de

verrouillage et l'agrafe.

•Poser une boule de 2 po ou 2 5/16 po (vérifier que la taille de la boule convient à la remorque), ainsi qu'une barre d'accouplement

1 po, sur le montage de boule et serrer l'écrou selon les couples spécifiés sur la fiche d'instructions de la boule.

•Mesurer la hauteur du coupleur de la remorque chargée. S'assurer que la remorque repose sur une surface de niveau.

•Pour commencer, poser deux (2) rondelles (K) sur la tige d'ajustement (J) et insérer celle-ci dans le trou supérieur du montage de

boule (A), voir la Fig. 1 ci-dessus. Jusqu'à 6 rondelles (K) peuvent être utilisées.

•Placer le montage de boule de façon que la hauteur de boule soit environ 1 po plus élevée que la hauteur du coupleur (remorque

sur sol de niveau). Voir la Fig. 2 ci-dessous pour l'éventail d'ajustements de la hauteur.

•Poser un boulon (C) dans le trou inférieur du montage de boule et un boulon (C) avec rondelle (D) dans le trou supérieur. Fixer

un écrou (E) aux deux boulons. Ne pas serrer les écrous à fond pour le moment.

POSITION LA PLUS HAUTE

POSITION LA PLUS BASSE

Fig. 2

Pour obtenir de l'assistance pour l'installation ou un autre aspect technique, composer le 1-888-521-0510.

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

Page 10

MONTAGE DES SUPPORTS DE CADRE (66557) POUR SYSTÈME 250 À 400 LB

(illustré ci-dessous)

Utiliser la Fig. 3 pour les cadres de 4 – 6 po. Autrement, se fier à la Fig. 4 de la page suivante.

L

M

S

N

T

L 2 Support en L

M 2 Support de cadre extérieur

N 2 Bride intérieure

R

P

O 2 Plaque de friction

P 4 Contre-écrou embase ½-13

Q 2 Boulon hex. ½-13 x 4 GR5

R

O

Fig. 3

U

Fig. 3

R 4 Écrou ½-13

S 4 Rondelle striée ½

T 4 Boulon nervuré ½-13

U 2 Boulon hex. ½-13 x 3.50 GR5

O

•Placer les boulons striés 1/2 po (T) dans les trous indiqués dans le support (M). Tapoter les boulons (T) à

l'aide d'un marteau ou poser un écrou (R) et serrer jusqu'à ce que la tête du boulon se retrouve sous la

surface du support (M). Retirer l'écrou (R).

•Insérer le boulon supérieur (U) à travers le support de cadre extérieur (M) et la bride intérieure (N). Placer

cela au-dessus de la flèche en A. Voir le tableau 1 ci-dessous pour l'emplacement du cadre.

•Toujours garder le boulon inférieur (U) près du bas de la flèche. Si ce n'est pas le cas, déplacer le boulon

supérieur (U) légèrement vers le haut et au-dessus du montage supérieur.

•Commencer en plaçant le support en L (L) dans le milieu de son ajustement en hauteur. Serrer les écrous

(R) avec leurs rondelles (S) sur le boulon (T).

•Répéter de l’autre côté.

•Garder un prolongement de la barre stabilisatrice d'au moins 3 po au-delà du support en L (L) comme

illustré à la Fig. 5 ci-dessous.

•Laisser les écrous (R) serrés à la main à ce moment.

•Serrer les écrous (P) au couple de 75 lb-pi.

SELON VOTRE

SYSTÈME

3 po

min.

3 ou 4 po

REMARQUE : Les bouteilles de propane, les batteries, etc. peuvent gêner

le montage des supports de cadre sur le cadre de remorque. Les supports

de cadre peuvent être placés dans les intervalles indiqués ci-dessous,

mesurés depuis le centre de la boule du coupleur jusqu'au centre de la

plaque de friction :

Tableau 1

Fig. 5

Marge de montage du support = 25 à 32 po

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

Marge

Marge

10

Page 11

MONTAGE DES SUPPORTS DE CADRE (66557) POUR SYSTÈME 250 À 400 LB

(illustré ci-dessous)

Utiliser la Fig. 4 pour les cadres de 3 po à 3 1/2 po.

S

P

L 2 Support en L

M

U

T

R

M 2 Support de cadre extérieur

N 2 Bride intérieure

O 2 Plaque de friction

P 4 Contre-écrou embase ½-13

N

Q 2 Boulon hex. ½-13 x 4 GR5

R 4 Écrou ½-13

S 4 Rondelle striée ½

Q

T 4 Boulon nervuré ½-13

U 2 Boulon hex. ½-13 x 3.50 GR5

O

L

Fig. 4

L

•Placer le boulon strié 1/2 po (T) dans le trou indiqué dans le support de cadre extérieur (M). Dans la Fig. 4, le boulon

inférieur (Q) s'insère dans la bride intérieure (N) depuis l'intérieur du cadre en A de la remorque. Tapoter le boulon (T)

à l'aide d'un marteau ou poser un écrou (R) et serrer jusqu'à ce que la tête du boulon se retrouve sous la surface du

support (M). Retirer l'écrou (R).

•Insérer le boulon supérieur (U) à travers le support de cadre extérieur (M) et la bride intérieure (N). Placer cela au-

dessus de la flèche en A. Voir le tableau 1 ci-dessous pour l'emplacement de la flèche. Toujours garder le boulon

inférieur (Q) près du bas du cadre. Si ce n'est pas le cas, déplacer le boulon supérieur (U) légèrement vers le bas et audessus du montage inférieur.

•Commencer en plaçant le support en L (L) dans le milieu de son ajustement en hauteur. Enfiler un écrou (R) et une

rondelle (S) sur le boulon long (Q). Serrer l'écrou (R) avec sa rondelle (S) sur le boulon (T).

•Répéter de l’autre côté.

•Garder un prolongement de la barre stabilisatrice d'au moins 3 po au-delà du support en L (L) comme illustré à la Fig.

5 ci-dessous.

•Laisser les écrous (R) serrés à la main à ce moment.

•Serrer les écrous (P) au couple de 75 lb-pi.

SELON VOTRE

SYSTÈME

3 po

min.

Fig. 5

3 ou 4 po

REMARQUE : Les bouteilles de propane, les batteries, etc. peuvent gêner

le montage des supports de cadre sur le cadre de remorque. Les supports

de cadre peuvent être placés dans les intervalles indiqués ci-dessous,

mesurés depuis le centre de la boule du coupleur jusqu'au centre de la

plaque de friction :

Tableau 1

Marge de montage du support = 25 à 32 po

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

Marge

Marge

11

Page 12

MONTAGE DES SUPPORTS DE CADRE (66558) POUR SYSTÈME 400 À 600 LB (illustré à la Fig.

6 ci-dessous).

W

U

L 2 Support en L

L

V

O 2 Plaque de friction

P 4 Contre-écrou embase ½-13

T

R 4 Écrou ½-13

S 4 Rondelle striée ½

S

T 4 Boulon nervuré ½-13

U 2 Boulon hex. ½-13 x 3.50 GR5

R

V 2 Support de cadre extérieur

W 2 Bride intérieur

P

O

Fig. 6

•Placer les boulons striés 1/2 po (T) dans les trous indiqués dans le support (V). Tapoter les boulons à l'aide d'un

marteau ou poser un écrou (R) et serrer jusqu'à ce que la tête des boulons se retrouve sous la surface du support (V).

Retirer l'écrou (R).

•Insérer le boulon supérieur (U) à travers le support de cadre extérieur (V) et la bride intérieure (W). Placer cela audessus de la flèche en A. Voir le tableau 1 ci-dessous pour l'emplacement.

•Placer un autre boulon (U) dans le trou inférieur du support. Le garder aussi haut et proche du cadre que possible.

Enfiler un écrou (P) sur les boulons.

•Placer le support en L (L) environ au milieu de son ajustement en hauteur et le fixer en vissant les boulons (R) avec

rondelles (S) sur les boulons (T). Laisser les écrous (R) serrés à la main à ce moment.

•Répéter de l’autre côté.

•Garder un prolongement de la barre stabilisatrice d'au moins 3 po au-delà du support en L (L) comme illustré à la

Fig. 5 ci-dessous.

•Laisser les écrous (R) serrés à la main à ce moment.

Serrer les écrous (P) au couple de 75 lb-pi.

SELON VOTRE

SYSTÈME

3 po

min.

3 ou 4 po

Fig. 5

REMARQUE : Les bouteilles de propane, les batteries, etc. peuvent gêner

le montage des supports de cadre sur le cadre de remorque. Les supports

de cadre peuvent être placés dans les intervalles indiqués ci-dessous,

mesurés depuis le centre de la boule du coupleur jusqu'au centre de la

plaque de friction :

Tableau 1

Marge de montage du support = 25 à 32 po

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

Marge

Marge

12

Page 13

AJUSTEMENT DU MONTAGE DE BOULE

PART QTY DESCRIPTION

A 1 BALL MOUNT

B 1 DRAW BAR

C 2 3/4-10 x 4-1/2" GR.8 HEX HEAD BOLT

D 2 3/4" FLAT WASHER

E 2 3/4-10 NUT

F 1 1/2-13 x 1-1/4" GR.5 HEX HEAD BOLT

G 2 1/2" x 2-1/4" SPRING BAR PIN

H 2 CLIP

J 1 ADJUSTMENT PIN

K 6 ADJUSTMENT WASHERS

•Remorque NON ATTELÉE au véhicule, prendre des points de

référence sur les passages de roue avant et arrière de votre véhicule.

Mesurer et noter la distance jusqu'à la chaussée. Passage de roue avant

à la chaussée __________ Passage de roue arrière à la chaussée

__________.

•Insérer les barres de stabilisation (A) et verrouiller avec la cheville (G)

et l'agrafe (H). Appliquer un lubrifiant sur les barres stabilisatrices en

les insérant dans le montage de boule.

•Avec la remorque attelée par la boule et de niveau (utiliser le vérin de

flèche pour mettre la remorque de niveau), l'ajustement d'angle du

montage de boule doit faire en sorte que la barre stabilisatrice se situe à

3 po sous la plaque de friction pour le système 400 lb, et à 4 po sous la

plaque de friction pour le système 600 lb. Voir la Fig. 5. Au besoin,

ajouter ou retirer les rondelles (K) illustrées à la Fig. 1 pour obtenir la

distance voulue. Chaque rondelle ajoutée déplacera les barres

stabilisatrices d'environ 5/8 à ¾ po vers le bas.

•S'il s'agit du produit 66557 avec un poids au timon de seulement 250

lb, 1 ou 2 rondelles peuvent s'avérer nécessaires.

•S'il s'agit du produit 66558 et d'un poids au timon de 600 lb, le

nombre de rondelles peut s'élever à 3ou 4.

•Poser et serrer le boulon (F) illustré à la Fig.1

SELON VOTRE

SYSTÈME

J

K

D

G

E

B

A

Fig. 1

H

A 1 Montage de boule

B 1 Barre d’accouplement

C 2 Boulon hex. ¾-10 x 4 ½ GR8

D 2 Rondelle plate ¾

E 2 Écrou ¾-10

F 1 Boulon hex. ½-13 x 1 ¼ GR5

G 2 Cheville de barre stab. ½ x 2 ¼

H 2 Agrafe

J 1 Tige d’ajustement

K 6 Rondelles d’ajustement

C

F

3 po

min.

REMARQUE :

3 ou 4 po

Fig. 5

• Lors de l'ajustement du montage de boule, il peut s'avérer nécessaire de soulever ou abaisser le support en L pour

obtenir la charge de barre stabilisatrice appropriée si l'ajustement de l'angle de tête n'est pas suffisant. Si le nombre de

rondelles n'est pas suffisant pour obtenir la dimension indiquée à la Fig. 5, déplacer le support en L (L) vers le haut par

1 jeu de trous.

•Si vous avez un cadre de 6 po de long avec un coupleur monté sur le bas (coupleur inversé), il peut être nécessaire de

poser les supports (V) et (W) à l'envers afin de monter le support en L (L) suffisamment bas. Cela abaissera le support

en L de 1,75 po. Autrement, la pression des barres stabilisatrices risque d'être trop importante.

•Serrer les deux écrous 3/4 po (E) à 300 lb-pi lorsque l'angle souhaité est obtenu. Si une clé dynamométrique de cette

capacité n'est pas disponible, serrer les écrous au couple de 150 lb-pi puis les serrer d'un 1/4 de tour additionnel. Ne

pas lubrifier le filetage.

Supports en position

Supports déplacés

pour coupleur

monté en bas.

Goujons plus bas

de 1,75 po

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

standard pour coupleur

standard.

Flèche en A de

la remorque

Fig. 7

13

Page 14

ACCROCHAGE DE LA BARRE STABILISATRICE

•Pour placer la barre stabilisatrice sur le support en L (L), garder le coupleur attelé à la boule. Soulever le

coupleur à l'aide du vérin de la flèche jusqu'à ce que la barre stabilisatrice se place sur le support en L (L).

•Si le vérin ne soulève pas le coupleur suffisamment haut, utiliser la poignée de soulèvement illustrée à la

Fig. 8 ci-dessous. Placer l'extrémité avec crochet de la poignée dans le trou rectangulaire du support en L

(L). Placer l'extrémité de la barre stabilisatrice comme illustré et soulever la poignée. Retirer la poignée.

•Placer le support de retenue de la barre stabilisatrice (I) dans le support en L (L) et verrouiller avec l'agrafe

(H) comme illustré à la Fig. 9.

AVERTISSEMENT : Afin de prévenir les blessures sévères, toujours

demeurer sur le côté de la poignée de soulèvement. Ne jamais

demeurer à l'extrémité de la poignée ni laisser une partie du corps

sous celle-ci.

•Abaisser le vérin de timon. Mesurer de nouveau à partir du point de

référence sur le passage de roue avant. La hauteur de la roue avant doit

être égale à la mesure initiale. Si la hauteur de la roue avant est plus élevée

que la mesure précédente, l'angle d'inclinaison de la tête doit être

augmenté (incliné vers le bas). Si la hauteur du passage de roue avant est

substantiellement plus basse que la mesure initiale (1 po ou plus), l'angle

d'inclinaison de la tête doit être réduit (incliné vers le haut). Pour un

ajustement grossier, le support en L (L) peut être baissé d'un trou pour

remettre le passage de roue avant plus haut. Les barres stabilisatrices

doivent être déchargées et retirées des supports en L (L) avant d'ajuster

l'angle d'inclinaison de tête ou d'enlever les écrous (T). Si des ajustements

à l'angle de tête ou au support en L sont effectués, répéter les étapes de

connexion jusqu'à ce que la hauteur du passage de roue avant soit approx.

égale ou inférieure à la mesure initiale. Il est préférable que l'arrière du

véhicule présente la même mesure ou davantage que l'avant.

Fig. 8

(L)

Support en L ajusté à

l'angle de barre

stabilisatrice.

SUPPORT DE

RETENUE (I)

Fig. 9

Écrou (R)

AGRAFE (H)

Fig. 10

IMPORTANT

AJUSTEMENT ET SERRAGE DES SUPPORTS EN L

•Toujours garder les écrous (R) serrés à la main jusqu'à ce que les barres stabilisatrices soient en place et chargées en

exerçant une pression sur les supports en L (L). Cela permettra aux supports en L (L) de s'ajuster à l'angle de la barre

stabilisatrice, procurant le contact maximal avec la plaque de friction (O) et ainsi une meilleur contrôle du roulis. Voir

la Fig. 10 ci-dessus. Serrer les écrous (R) au couple de 75 lb-pi.

•Si vous avez serré les écrous avant d'appliquer la tension de la barre stabilisatrice, desserrer les écrous (R)

légèrement. N'enlevez pas les écrous complètement. Ils sont sous la pression des barres stabilisatrices. Le support en L

(L) s'ajustera alors à l'angle de barre stabilisatrice par lui-même. Resserrer les écrous (R) au couple de 75 lb-pi.

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

14

Page 15

PROCÉDURE DE DÉTELAGE

•Bloquer les roues avant et arrière de la remorque.

•Soulever le timon de la remorque à l'aide du vérin aussi haut que possible, habituellement 8 à 12 po.

•Retirer l'agrafe à ressort (H), Fig. 9, du support de retenue de la barre stabilisatrice (I). Enlever le support.

•Pousser la barre stabilisatrice pour la dégager du support en L.

AVERTISSEMENT : Afin de prévenir les blessures sévères, toujours demeurer sur le côté de la poignée de

soulèvement. Ne jamais se tenir à l'extrémité de la poignée ni laisser une partie du corps sous celle-ci ou sous la

barre stabilisatrice.

•Retirer l'agrafe (H) et la cheville (G), Fig. 1. Tirer sur la barre stabilisatrice pour la dégager de la tête (A).

• Répéter de l’autre côté.

•Abaisser le timon de la remorque jusqu'à ce que le vérin se dégage légèrement du sol, puis déverrouiller le coupleur.

Une fois déverrouillée, la remorque peut être soulevée de nouveau pour dégager le dessus de la boule et le véhicule

peut s'éloigner.

LUBRIFICATION

•Lubrifier la boule d'attelage pour prévenir l'usure excessive. Lubrifier la surface de contact dans le montage de boule

où s'insèrent les barres stabilisatrices. L'huile et la saleté en excès doivent être nettoyées à chaque fois que la remorque

est dételée.

•Ne pas lubrifier les plaques de friction (O).

Surface à

lubrifier sous le

coupleur

Surface à lubrifier

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

15

Page 16

AVERTISSEMENTS : LA HAUTEUR DE LA BOULE CHARGÉE NE DOIT JAMAIS ÊTRE SUPÉRIEURE À LA HAUTEUR DE LA BOULE AVEC REMORQUE

DÉTACHÉE. Une surcharge sur les roues avant et une perte de traction aux roues arrière peut en résulter, menant à un contrôle instable, à un freinage moins efficace et

une tendance à la mise en portefeuille lors d'un virage et d'un freinage simultanés. SI LA HAUTEUR DE LA BOULE CHARGÉE EST SUPÉRIEURE À SA HAUTEUR NON

CHARGÉE, ajuster encore la tête puis mesurer de nouveau jusqu'à obtenir la hauteur voulue.

NE PAS REMORQUER PLUS D'UNE REMORQUE À LA FOIS : Ne pas tenter de remorquer une remorque, quelle qu'elle soit, derrière une autre. Le remorquage

simultané de plusieurs remorques peut causer une instabilité importante, une perte de contrôle et/ou une défaillance structurale, et mener à un accident provoquant des

blessures sévères et des dommages à la propriété. Le remorquage de plusieurs remorques est prohibé par la loi en plusieurs endroits.

VÉHICULES À TRACTION AVANT : NE PAS TENTER D'ACCOUPLER OU REMORQUER UNE REMORQUE SI LES ROUES ARRIÈRE DU VÉHICULE SONT

ENLEVÉES. Des dommages sévères au véhicule, à l'attelage et à la remorque peuvent en résulter. Une combinaison véhicule-remorque ne peut être contrôlée

adéquatement que si les roues arrière du véhicule supportent la charge qui leur revient.

ENTRETIEN : Garder l'assemblage de la tête libre de saleté et bien lubrifié. Une usure excessive à cet endroit peut signaler une surcharge ou une lubrification

insuffisante.

Maintenir la peinture de l'attelage en bon état afin de prévenir la rouille et conserver une apparence agréable. (Ne pas peindre les étiquettes)

EN DÉBUT DE JOURNÉE AVANT CHAQUE DÉPLACEMENT :

Nettoyer le boule et le réceptacle du coupleur, et enduire légèrement la boule avec de la graisse.

Vérifier que tous les boulons sont adéquatement serrés et que la cheville d'attelage et son agrafe sont bien verrouillées en place.

S'assurer que toutes les connexions électriques sont en état de fonctionner, et que les chaînes de sécurité sont accrochées.

CONSEILS DE REMORQUAGE

CONDUITE : Il faut insister davantage sur les bonnes pratiques de conduite lors du remorquage. Le poids supplémentaire affecte l'accélération et le freinage, et il faut

plus de temps pour dépasser, s'arrêter et changer de voie. Signaler bien à l'avance une manoeuvre pour faire connaître vos intentions aux autres conducteurs. Les

bosses accentuées et les routes en mauvais état peuvent endommager le véhicule, l'attelage et la remorque, il vaut mieux y circuler à basse vitesse constante. SI UNE

PARTIE DU SYSTÈME DE REMORQUAGE HEURTE LA CHAUSSÉE OU SI L'ON SOUPÇONNE UN DOMMAGE D'UNE AUTRE FAÇON, IL FAUT SE TASSER ET

PROCÉDER À UNE INSPECTION. CORRIGEZ TOUT PROBLÈME AVANT DE POURSUIVRE LE TRAJET.

VÉRIFIER L'ÉQUIPEMENT : Inspecter régulièrement la condition de l'ensemble de l'équipement de remorquage et garder celui-ci en parfaite condition.

CHARGEMENT DE LA REMORQUE : Il est important de bien charger la remorque. Placer les objets lourds près du plancher et de l’essieu de la remorque. La charge

doit être équilibrée d'un côté à l'autre et solidement arrimée pour prévenir les déplacements. Le poids au timon doit représenter 10 à 15 pour cent du poids brut de la

plupart des remorques. Un pourcentage de poids trop faible au timon peut déstabiliser la remorque. Un poids excessif au timon peut aussi causer une instabilité et

endommager l'attelage et/ou le véhicule.

DISPOSITIFS ANTI-ROULIS : Les dispositifs anti-roulis peuvent réduire les effets des manœuvres brusques, des coups de vent et des secousses causées par d'autres

véhicules. Nous les recommandons pour les remorques qui présentent de grandes surfaces comme dans le cas des caravanes, par exemple.

GONFLAGE DES PNEUS : Sauf indication contraire par le fabricant du véhicule ou de la remorque, les pneus doivent être gonglés à la pression maximale recommandée.

RECOMMANDATIONS DES FABRICANTS DE LA REMORQUE ET DU VÉHICULE DE REMORQUAGE : Consulter les manuels du propriétaire du véhicule et de la

remorque pour connaître les recommandations, les capacités de charge et les spécifications.

PASSAGER(S) DANS LA REMORQUE : AUCUN passager ne doit être toléré dans une remorque en déplacement.

FEUX DE REMORQUE, SIGNAUX DE DIRECTION ET FREINS ÉLECTRIQUES : Veiller à toujours brancher et vérifier le fonctionnement des feux de signalisation et de

direction, des freins électriques et de l'interrupteur de rupture d'attelage (le cas échéant), même dans le cas de courts trajets.

ENLEVER L'ATTELAGE S'IL NE SERT PAS : Retirer l'attelage du récepteur du véhicule lorsqu'il ne sert pas afin de prévenir la contamination des réceptacles de tête,

réduire le risque de heurter l'attelage contre des rampes ou d'autres objets, et minimiser les dommages dans l'éventualité d'une collision par l'arrière.

Attelages - Récepteurs sur mesure - Dispositifs de stabilisation

Cequent Performance Products, Inc. garantit ses attelages, ses récepteurs d'attelage sur mesure et ses dispositifs de stabilisation contre les vices de matériaux et

de fabrication manifestés dans le cadre d’un usage et d’un entretien normaux (à l’exception de l’usure normale), et ce pendant toute la période de propriété de

l’acheteur initial à compter de la date d’achat.

Cequent Performance Products, Inc. remplacera SANS FRAIS toute pièce qui s’avère défectueuse suite à un vice de matériau ou de fabrication et qui est retournée

au concessionnaire Cequent Performance Products, Inc., ou à l’entrepôt ou l’usine Cequent Performance Products, Inc. FRAIS DE TRANSPORT PRÉPAYÉS, à

l’adresse ci-dessous. CETTE GARANTIE SE LIMITE AU REMPLACEMENT DES PIÈCES DÉFECTUEUSES SEULEMENT. ELLE NE COUVRE NI LES FRAIS DE

MAIN-D’ŒUVRE, NI LES DOMMAGES SUBIS LORS DE L’INSTALLATION OU DU REMPLACEMENT, Y COMPRIS LES DOMMAGES ACCESSOIRES OU

INDIRECTS.

Certaines provinces ne permettant pas d’exclure ou de restreindre les dommages accessoires ou indirects, il se peut que la restriction ou l’exclusion ci-dessus ne

vous concerne pas.

Tout dommage à l’attelage, au récepteur d'attelage sur mesure ou au dispositif de stabilisation attribuable à une mauvaise utilisation, un usage abusif, la négligence,

un accident, une installation inadéquate, ou à toute utilisation contraire aux instructions fournies par nous, ANNULERA LA GARANTIE.

Certains droits particuliers vous sont dévolus en vertu de la présente garantie et peuvent s'accompagner d'autres droits qui varient selon votre lieu de résidence.

Dans l'éventualité d'un problème avec le service de la garantie ou le rendement du produit, il se peut que vous puissiez recourir à la cour des petites créances ou

une cour d'une autre juridiction.

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

GARANTIE LIMITÉE

Cequent Performance Products, Inc.

47912 Halyard Dr. Suite 100

Plymouth, MI. 48170

16

Page 17

INSTRUCCIONES DE INSTALACIÓN

66557

250LB – 400LB

E

B

Fig. 1

A

J

K

REESE Steadi-Flex

Reese

Plymouth, MI.

D

G

C

H

F

66558

400LB – 600LB

PAR

TE

A 1 MONTAJE ESFÉRICO

B 1 BARRA DE TRACCIÓN

C 2 PERNO CABEZA HEX. GR.8 ¾-10 x 4-

D 2 ARANDELA PLANA ¾”

E 2 TUERCA ¾-10

F 1 PERNO CABEZA HEX. GR. 5 ½-13 x 1-

G 2 PASADOR BARRA DE RESORTE ½” X

H 2 CLIP

J 1 PASADOR DE AJUSTE

K 6 ARANDELAS DE AJUSTE

LLAVE DE TORSIÓN CINTA DE MEDIR

TUBO DE 3/4", TUBO Y LLAVE DE 1-1/8”

CAN

T.

DESCRIPCIÓN

1/2”

1/4”

2-1/4”

HERRAMIENTAS NECESARIAS

DETERMINACIÓN DEL ANCHO Y DE LOS SISTEMAS DE ENGANCHE DEL REMOLQUE

•Pese la horquilla del remolque cargada para determinar el tamaño correcto del sistema.

•Elija un sistema con una calificación de horquilla al nivel o por encima del peso real de la horquilla del remolque.

•La calificación de peso de la horquilla del enganche del remolque debe cumplir o superar el peso de la horquilla del

remolque. Los enganches OEM no pueden ser lo suficientemente rígidos para el peso de la horquilla y podría ser

necesario reemplazarlos (demasiado flexibles y no soportan la carga).

•La calificación de peso bruto total del remolque nunca debe superar la calificación bruta de remolque calificada del

vehículo de remolque.

ENSAMBLE DE LA BARRA DE ENGANCHE Y MONTAJE ESFÉRICO

•Inserte la barra de enganche (B) en el receptor del vehículo de remolque en la orientación deseada e instale el pasador

de halar y clip.

•Instale ya sea una esfera de 2” o de 2-5/16”, (revise el remolque para el tamaño de esfera correcto), con un vástago de

1”, sobre el montaje esférico y apriete a torsión la tuerca según los requisitos de la hoja de instrucciones de la esfera.

•Mida la altura de acoplador de su remolque cargado. Asegúrese de que el remolque esté a nivel.

•Para empezar, instale 2 arandelas (K) en el pasador de ajuste (J) e inserte dentro del orificio de arriba en el montaje

esférico (A), ver Fig. 1 arriba. Se pueden usar hasta 6 arandelas (K).

•Coloque el montaje esférico de manera que la altura de la esfera sea aproximadamente 1” más alta que la altura del

acoplador con el remolque en el nivel de configurar. Vea Fig. 2 abajo para la gama de ajustes de altura.

•Instale el perno (C) en el orificio inferior del montaje esférico y el perno (C) con arandelas (D) en el orificio superior.

Coloque la tuerca (E) en ambos pernos. Deje las tuercas flojas por ahora.

POSICIÓN MÁS

ALTA

POSICIÓN MÁS

BAJA

Fig. 2

Para asistencia con la instalación o ayuda técnica, llame al 1-888-521-0510

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

Page 18

ENSAMBLE DEL SOPORTE DEL BASTIDOR PARA (66557) SISTEMA DE 250 LB - 400 LB

(mostrado abajo).

Use Fig. 3 para bastidores de 4” – 6” de alto. De lo contrario, use la Fig. 4 en la siguiente

página.

L

S

R

M

N

T

P

PARTE CANT. DESCRIPCIÓN

L 2 SOPORTE EN L

M 2 ENSAMBLE DEL SOPORTE DEL BASTIDOR EXT.

N 2 CORREA INTERIOR

O 2 ALMOHADILLA DE FRICCIÓN

P 4 TUERCA DE BLOQUEO CON REBORDE ½-13

R

O

Fig. 3

U

Q 2 PERNO DE CABEZA HEX. GR. 5 ½’-13 x 4”

R 4 TUERCA ½’-13

S 4 ARANDELA DENTADA ½”

Fig. 3

O

T 4 PERNO ESTRIADO ½-13

U 2 PERNO DE CABEZA HEX. GR. 5 ½-13 x 3.50”

•Coloque los pernos estriados de 1/2” (T) a través de los orificios que aparecen en el soporte (M). Golpee

los pernos (T) ya sea con un martillo o instale una tuerca (R) y apriete hasta que la cabeza del perno quede

por debajo de la superficie del soporte (M). Retire la tuerca (R).

•Coloque el perno superior (U) a través del soporte del bastidor exterior (M) y correa interior (N). Coloque

este sobre el bastidor en A. Consulte la tabla 1 abajo para la ubicación del bastidor.

•Siempre mantenga el perno inferior (U) cerca del fondo del bastidor. Si no es así, mueva el perno superior

(U) ligeramente hacia arriba y hacia el nivel más alto.

•Empiece colocando el soporte en L (L) en el centro de su ajuste de altura. Inserte las tuercas (R) con

arandelas (S) sobre el perno (T).

•Repita para el otro lado.

•Mantenga al menos 3” de la barra de resorte extendida más allá del soporte en L (L) como aparece en la

Fig. 5 abajo.

•Deje los pernos (R) apretados a mano en este momento.

•Apriete a torsión las tuercas a 75 pies-libras.

DEPENDIENDO DE

SU SISTEMA

3"

MIN.

3" Ó 4"

NOTA: Los envases de propano, las baterías, etc. pueden obstruir la

instalación de los soportes del bastidor en el bastidor del remolque. Los

soportes del bastidor se pueden localizar dentro del siguiente espacio

especificado desde el centro de la esfera del acoplador al

centro de la almohadilla de fricción:

Tabla 1

Fig. 5

Rango de montaje del soporte = 25” a 32”

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

18

Page 19

ENSAMBLE DEL SOPORTE DEL BASTIDOR PARA (66557) SISTEMA DE 250 LB - 400 LB

(mostrado abajo). Use Fig. 4 para bastidores de 3” a 3-1/2” de alto.

M

R

S

O

L

U

N

Q

Fig. 4

T

P

PARTE CANT. DESCRIPCIÓN

L 2 SOPORTE EN L

M 2 ENSAMBLE DEL SOPORTE DEL BASTIDOR EXT.

N 2 CORREA INTERIOR

O 2 ALMOHADILLA DE FRICCIÓN

P 4 TUERCA DE BLOQUEO CON REBORDE ½-13

Q 2 PERNO DE CABEZA HEX. GR. 5 ½’-13 x 4”

R 2 TUERCA ½’-13

S 4 ARANDELA DENTADA ½”

T 4 PERNO ESTRIADO ½-13

U 2 PERNO DE CABEZA HEX. GR. 5 ½-13 x 3.50”

L

•Coloque los pernos estriados de 1/2” (T) a través del orificio que aparece en el soporte exterior del bastidor

(M). En la Fig. 4 el perno más bajo (Q) se inserta dentro de la correa más interior (N) desde el interior del

bastidor tipo A del remolque. Golpee el perno (T) ya sea con un martillo o instale una tuerca (R) y apriete

hasta que la cabeza del perno quede por debajo de la superficie del soporte (M). Retire la tuerca (R).

•Coloque el perno superior (U) a través del soporte del bastidor exterior (M) y correa interior (N). Coloque

este sobre el bastidor en A. Consulte la tabla 1 abajo para la ubicación del bastidor. Siempre mantenga el

perno inferior (Q) cerca del fondo del bastidor. Si no es así, mueva el perno superior (U) ligeramente hacia

abajo y hacia el nivel más bajo.

•Empiece colocando el soporte en L (L) en el centro de su ajuste de altura. Coloque una tuerca (R) y

arandela (S) en el perno largo (Q). Inserte la tuerca (R) con arandela (S) sobre el perno (T).

•Repita para el otro lado.

•Mantenga al menos 3” de la barra de resorte extendida más allá del soporte en L (L) como aparece en la

Fig. 5 abajo.

•Deje los pernos (R) apretados a mano en este momento.

•Apriete a torsión las tuercas a 75 pies-libras.

DEPENDIENDO DE SU

SISTEMA

3"

MIN.

Fig. 5

3" Ó 4"

NOTA: Los envases de propano, las baterías, etc. pueden obstruir la

instalación de los soportes del bastidor en el bastidor del remolque. Los

soportes del bastidor se pueden localizar dentro del siguiente espacio

especificado desde el centro de la esfera del acoplador al

centro de la almohadilla de fricción:

Tabla 1

Rango de montaje del soporte = 25” a 32”

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

19

Page 20

ENSAMBLE DEL SOPORTE DEL BASTIDOR PARA EL SISTEMA (66558) 400 LB - 600 LB.

(exhibido en la Fig. 6 abajo).

U

L

V

S

R

W

T

P

PARTE CANT. DESCRIPCIÓN

L 2 SOPORTE EN L

O 2 ALMOHADILLA DE FRICCIÓN

P 4 TUERCA DE BLOQUEO CON REBORDE ½-13

R 4 TUERCA ½’-13

S 4 ARANDELA DENTADA ½”

T 4 PERNO ESTRIADO ½-13

U 4 PERNO DE CABEZA HEX. GR. 5 ½-13 x 3.50”

V 2 ENSAMBLE DEL SOPORTE DEL BASTIDOR EXT.

W 2 CORREA INTERIOR

O

Fig. 6

•Coloque los pernos estriados de 1/2” (T) dentro de los orificios que se muestran en el soporte (V).

Golpéelos ya sea con un martillo o instale una tuerca (R) y apriete hasta que la cabeza del perno quede por

debajo de la superficie del soporte (V). Retire la tuerca (R).

•Coloque el perno superior (U) a través del ensamble del soporte del bastidor exterior (U). (V) y correa

interior (W). Coloque este sobre el bastidor en A. Consulte la tabla 1 abajo para la ubicación.

•Coloque otro cerrojo (U) en el orificio inferior en el soporte. Mantenga esto tan alto y cercano al bastidor

como sea posible. Instale la tuerca (P) en los pernos.

•Coloque el soporte en L (L) cerca de la mitad del ajuste de altura y asegure enroscando las tuercas (R) con

arandelas (S) dentro de los pernos (T). Deje los pernos (R) apretados a mano en este momento.

•Repita para el otro lado.

•Mantenga al menos 3” de la barra de resorte extendida más allá del soporte en L (L) como aparece en la

Fig. 5 abajo.

•Deje los pernos (R) apretados a mano en este momento.

Apriete a torsión las tuercas a 75 pies-libras.

DEPENDIENDO DE SU

SISTEMA

3"

MIN.

3" Ó 4"

Fig. 5

NOTA: Los envases de propano, las baterías, etc. pueden obstruir la

instalación de los soportes del bastidor en el bastidor del remolque. Los

soportes del bastidor se pueden localizar dentro del siguiente espacio

especificado desde el centro de la esfera del acoplador al centro de la

almohadilla de fricción:

Tabla 1

Rango de montaje del soporte = 25” a 32”

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

20

Page 21

AJUSTE DE MONTAJE ESFÉRICO

•Con el remolque SIN CONECTAR al vehículo, seleccione puntos de

referencia en los receptáculos de las ruedas delanteras y traseras.

Mida y registre la distancia hasta el pavimento. Receptáculo de la

rueda frontal hasta el pavimento ___________ Receptáculo de la

rueda trasera hasta el pavimento ___________.

•Inserte las barras de resorte dentro del montaje esférico (A) y asegure

con pasador (G) y clip (H). Aplique un lubricante en las barras de

resorte a medida que las inserta en el montaje esférico.

•Con el remolque acoplado a la esfera y el remolque en nivel de

configuración (use el gato de remolque para nivelar) el ajuste del

ángulo en el montaje esférico debe tener la barra de resorte 3” por

debajo de la almohadilla de fricción para el sistema de 400 lb. y 4” por

debajo de la almohadilla de fricción para el sistema de 600 lb. Ver Fig.

5. Si es necesario agregue o quite arandelas (K) como aparece en la

Fig. 1 para obtener la dimensión necesaria. Cada arandela agregada

bajará las barras de resorte aprox. 5/8” a ¾".

•Si usted tiene el 66557 y un peso de horquilla de solo 250 lbs., podría

necesitar solo 1-2 arandelas.

•Si usted tiene el 66558 y un peso de horquilla de 600 lbs., podría

necesitar 3-4 arandelas.

•Instale y apriete el perno (F) que aparece en la Fig. 1

DEPENDIENDO DE

SU SISTEMA

3"

MIN.

3" Ó 4"

Fig. 5

E

B

Fig. 1

PARTE CAN

A 1

B 1

C 2

D 2

E 2

F 1

G 2

H 2

J 1

K 6

T.

J

K

D

G

C

A

H

DESCRIPCIÓN

MONTAJE ESFÉRICO

BARRA DE TRACCIÓN

PERNO CABEZA HEX. GR.8 ¾-

10 x 4-1/2”

ARANDELA PLANA ¾”

TUERCA ¾-10

PERNO CABEZA HEX. GR. 5 ½-

13 x 1-1/4”

PASADOR BARRA DE RESORTE

½” X 2-1/4”

CLIP

PASADOR DE AJUSTE

ARANDELAS DE AJUSTE

F

NOTA:

•Durante el ajuste del montaje esférico, puede ser necesario levantar o bajar el soporte en L (L) para obtener la carga

apropiada de la barra de resorte si no hay suficiente ajuste para el ángulo de la cabeza. Si no hay suficientes arandelas

para obtener la dimensión que se muestra en la Fig. 5, mueva el soporte en L (L) 1 set de orificios hacia arriba.

•Si usted tiene un bastidor de 6” de alto con un acoplador instalado en la base (acoplador invertido) podría ser

necesario instalar soportes (V) y (W) de manera invertida para que el soporte en L (L) quede tan bajo como sea

necesario. Esto bajará el soporte en L 1.75”. De lo contrario podría haber demasiada presión en la barra de resorte.

•Apriete a torsión ambas tuercas de 3/4" a 300 pies-*libras. cuando se logre el ángulo deseado. Si no hay una llave

de torsión del tamaño necesario disponible, apriete las tuercas a 150 pies*lbs., luego apriete las tuercas un giro

adicional de 1/4. No lubrique las roscas.

Soportes en la

Soportes invertidos

para acoplador de

posición estándar para

el acoplador estándar.

montaje inferior.

Bastidor

en A del

Montante 1.75” más

bajo

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

bastidor

Fig. 7

21

Page 22

CONEXIÓN DE LA BARRA DE RESORTE

•Para colocar la barra de resorte en el soporte en L (L), mantenga el acoplador unido a la esfera. Levante el

acoplador usando el gato del remolque hasta que la barra de resorte entre en el soporte en L (L).

•Si el gato no levanta el acoplador lo suficiente, utilice la manija de elevación que aparece en la Fig. 8 abajo.

Coloque el extremo con gancho de la manija en el orificio rectangular del soporte en L (L). Coloque el

extremo de la barra de resorte como se muestra y levante la manija. Quite la manija.

•Coloque el soporte de retención de la barra de resorte (I) dentro del soporte en L (L) y asegure con un clip

(H) como se muestra en la Fig. 9.

ADVERTENCIA: Para evitar lesiones graves, siempre párese a

un lado de la manija de elevación. Nunca se pare al final de la

manija ni permita que ninguna parte de su cuerpo esté debajo de

la manija.

•Baje el gato para remolques. Vuelva a medir el punto de referencia

del receptáculo de la rueda frontal. La altura del receptáculo de la

rueda frontal debe ser igual o menor que la medida original. Si la

altura del receptáculo de la rueda frontal es más alta que la

previamente medida, el ángulo de inclinación de la cabeza se debe

incrementar (inclinado hacia abajo). Si la altura del receptáculo de la

Fig. 8

rueda frontal es sustancialmente más baja que la medida

originalmente (1" o más), el ángulo de inclinación de la cabeza se

debe reducir (inclinado hacia arriba). Para un ajuste tosco, el soporte

en L (L) se puede bajar un orificio para traer el receptáculo de la

rueda delantera de nuevo hacia arriba. Las barras de resorte se deben

descargar y retirar del soporte en L (L) antes de ajustar el ángulo de

inclinación de la cabeza o retirar las tuercas (T). Si se hacen ajustes

en el ángulo de cabeza o del soporte en L, repita los pasos de

conexión hasta que la altura del receptáculo de la rueda frontal sea

aproximadamente igual a la medida original. Es preferible que la

(L)

parte trasera del vehículo se asiente aproximadamente la misma

cantidad o más que la parte frontal.

SOPORTE EN L ajustado

al ángulo de la barra de

resorte.

Fig. 9

RETENCIÓN

SOPORTE (I)

TUERC

A (R)

CLIP (H)

Fig. 10

IMPORTANTE

AJUSTE Y SUJECIÓN DE LOS SOPORTES EN L

•Siempre mantenga las tuercas (R) apretadas a mano hasta que las barras de resorte estén en su lugar y

cargadas con presión en los soportes en L (L). Esto permitirá que los soportes en L (L) se ajusten a sí

mismos al ángulo de la barra de resorte dando el contacto máximo con la almohadilla de fricción (O) y que

tiene como resultado mejor control de oscilación. Ver Fig. 10 arriba. Apriete las tuercas (R) a 75 pies- lbs.

•Si apretó las tuercas antes de aplicar la tensión a la barra de resorte, afloje las tuercas (R) ligeramente. No

retire las tuercas completamente. Están bajo presión de las barras de resorte. El soporte en L (L) se ajustará

al ángulo de la barra de resorte por sí mismo. Vuelva a apretar las tuercas (R) a 75 pies- lbs.

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

22

Page 23

DESENGANCHE

•Bloquee las ruedas del remolque de adelante y de atrás.

•Levante la horquilla del remolque con un gato para remolque tan alto como sea posible, por lo general 8-12

pulgadas.

•Retire el clip de resorte (H) Fig. 9 del soporte de retención de la barra de resorte (I). Retire el soporte.

•Empuje la barra de resorte fuera del soporte en L.

ADVERTENCIA: Para evitar lesiones graves, siempre párese a un lado del cargador manual. Nunca

se pare al final de la manija ni permita que ninguna parte de su cuerpo esté debajo de la manija o

barra de resorte.

•Retire el clip (H) y el pasador (G), fig. 1. Saque la barra de resorte de la cabeza (A).

•Repita para el otro lado.

•Baje la horquilla del remolque hasta que el gato esté ligeramente despegado del piso y libere el acoplador

del remolque. Una vez liberado, se puede volver a levantar el remolque para despejar la parte superior de la

esfera y se pueda conducir el vehículo.

LUBRICACIÓN

•Lubrique la esfera del enganche para prevenir el desgaste innecesario. Lubrique el área de contacto en el

montaje esférico donde las barras de resorte se insertan. Se debe limpiar el exceso de aceite y suciedad en

donde no se acopla el remolque.

•No lubrique las almohadillas de fricción (O).

Área para lubricar

Debajo del acoplador

Área para lubricar

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

23

Page 24

ADVERTENCIAS: LA ALTURA DE LA ESFERA CARGADA NUNCA DEBE SER SUPERIOR A LA ALTURA DE LA ESFERA DESACOPLADA. Puede resultar una

sobrecarga de la rueda frontal y pérdida de la tracción de la rueda trasera, y resultar en una manipulación inestable, menor capacidad para frenar y una tendencia a

"colear" al girar y frenar al mismo tiempo. SI LA ALTURA DE LA ESFERA CARGADA ES MAYOR QUE LA ALTURA NO ACOPLADA reajuste la cabeza y vuelva a medir

hasta que se alcance la altura correcta.

NO HALE REMOLQUES MÚLTIPLES: No intente remolcar ningún tipo de remolque detrás de otro. Llevar varios remolques puede causar grave inestabilidad, pérdida

del control y/o falla estructural y puede resultar en accidente del vehículo, daños a la propiedad y lesiones personales. Llevar múltiples remolques es ilegal en muchas

jurisdicciones.

VEHÍCULOS CON TRACCIÓN DELANTERA: NO INTENTE ENGANCHAR O REMOLCAR SIN LAS RUEDAS TRASERAS DEL VEHÍCULO DE REMOLQUE. Pueden

resultar graves daños estructurales al vehículo de remolque, enganche y remolque. Una combinación de vehículo de remolque/remolque no se puede controlar

correctamente a menos que las ruedas posteriores del vehículo de remolque estén soportando su parte de la carga.

MANTENIMIENTO: Mantenga el ensamble de la cabeza libre de suciedad y bien lubricado. El desgaste excesivo puede indicar sobrecarga o lubricación inadecuada.

Mantenga pintado el enganche para evitar el óxido y mantener un buen aspecto. (No pinte sobre las etiquetas)

AL INICIO DE CADA DÍA DE REMOLQUE:

Limpie la esfera y el receptáculo del acoplador y cubra la esfera ligeramente con grasa.

Revise para ver que todos los pernos estén correctamente apretados y el clip y pasador del enganche estén seguros en su lugar.

Revise para ver que las conexiones eléctricas estén funcionando y que las cadenas de seguridad estén conectadas.

SUGERENCIAS PARA EL REMOLQUE

CONDUCCIÓN: Los buenos hábitos para manejar normalmente requieren un énfasis adicional al remolcar. El peso adicional afecta la aceleración y frenado, y se debe

permitir tiempo adicional para pasar, frenar y cambiar de carriles. Indique con anticipación una maniobra para informar a otros conductores de sus intenciones. Los

impactos severos y las carreteras con muchas ondulaciones pueden dañar su vehículo de remolque, enganche y remolque, y se debe conducir a una velocidad baja

constante. SI CUALQUIERA DE LAS PARTES DE SU SISTEMA DE REMOLQUE SE CAE O SI USTED SOSPECHA QUE HAN OCURRIDO DAÑOS DE CUALQUIER

CLASE, SÁLGASE DE LA CARRETERA Y HAGA UNA REVISIÓN A FONDO. CORRIJA CUALQUIER PROBLEMA ANTES DE SEGUIR DESPLAZÁNDOSE.

REVISE SU EQUIPO: Revise con frecuencia el estado de todo su equipo de remolque y manténgalo en condiciones óptimas.

CARGA DEL REMOLQUE: La carga correcta del remolque es importante. Los artículos pesados se deben colocar cerca al piso y al eje del remolque. La carga se debe

balancear de lado a lado y asegurarse firmemente para evitar los movimientos. El peso de la horquilla debe ser 10-15 por ciento del peso bruto del remolque para la

mayoría de los remolques. Un porcentaje muy bajo de peso de la horquilla producirá una tendencia a oscilar. El peso excesivo en la horquilla también puede resultar en

una oscilación y daño al enganche y/o al vehículo de remolque.

CONTROLES DE OSCILACIÓN: Un control de oscilación puede ayudar a minimizar los efectos de maniobras repentinas, ráfagas de viento y sacudidas causadas por

otros vehículos. Se recomienda un control de oscilación para remolques con áreas grandes de superficie, como remolques de viaje.

INFLADO DE LLANTAS: A menos que se especifique lo contrario por parte del fabricante del vehículo de remolque, las llantas se deben inflar a la presión máxima

recomendada.

RECOMENDACIONES DEL FABRICANTE DEL REMOLQUE Y VEHÍCULO DE REMOLQUE: Revise los manuales del propietario para su remolque y vehículo de

remolque para las recomendaciones específicas, capacidades y requisitos.

PASAJEROS EN LOS REMOLQUES: Los remolques NO se deben ocupar mientras se remolcan, bajo ninguna circunstancia.

LUCES, DIRECCIONALES Y FRENOS ELÉCTRICOS DEL REMOLQUE: Siempre instale y verifique el funcionamiento de las luces del remolque, las direccionales, los

frenos eléctricos y la conexión del interruptor de liberación (si viene equipado) incluso para viajes cortos.

RETIRE EL ENGANCHE CUANDO NO ESTÉ REMOLCANDO: Retire el enganche del receptor del vehículo de remolque cuando no esté remolcando, para evitar la

contaminación de los receptáculos de la cabeza, reducir la probabilidad de golpear el enganche en las rampas de los estacionamientos u otros objetos, y reducir daños

en el caso de una colisión por detrás.

Cequent Performance Products, Inc. garantizan sus enganches, receptores de enganche hechos a la medida y controles de oscilación desde el día de la compra

Enganches - Receptores a la medida - Controles de oscilación

contra defectos de materiales y mano de obra bajo condiciones normales de uso y servicio, excepto por el desgaste normal, de por vida de propiedad del

comprador consumidor original.

Cequent Performance Products, Inc. reemplazará SIN CARGO cualquier parte que resulte defectuosa en los materiales o mano de obra cuando se presente a

cualquier distribuidor de Cequent Performance Products, Inc. bodega de Cequent Performance Products, Inc. o se devuelva a la fábrica. CARGOS POR

TRANSPORTE PREPAGADOS, a la dirección a continuación. ESTA GARANTÍA ESTÁ LIMITADA A LA REPOSICIÓN DE PARTES DEFECTUOSAS

ÚNICAMENTE. SE EXCLUYEN LOS CARGOS DE MANO DE OBRA Y/O DAÑOS INCURRIDOS EN LA INSTALACIÓN O REEMPLAZO ASÍ COMO LOS DAÑOS

CONSECUENCIALES Y INCIDENTALES RELACIONADOS.

Algunos estados no permiten la exclusión o limitación de los daños incidentales o consecuenciales, por lo que la exclusión o limitación anterior podría no

corresponderle.

Cualquier daño al enganche, receptor de enganche hecho a la medida y control de oscilación como resultado del mal uso, abuso, negligencia, accidente,

instalación incorrecta, o cualquier uso en contra de las instrucciones entregadas por nosotros INVALIDARÁ LA GARANTÍA.

Esta garantía le otorga derechos legales. Usted también podría tener otros derechos que varían de estado a estado. En el evento de un problema con el servicio

de garantía o desempeño, usted puede acudir a una corte de demandas menores, una corte estatal, o una corte federal del distrito.

66557N-7/18/13 REV E PCN2169 ©2012 TOWING PRODUCTS, INC

GARANTÍA LIMITDA

Cequent Performance Products, Inc.

47912 Halyard Dr. Suite 100

Plymouth, MI. 48170

24

Loading...

Loading...