Page 1

FITTING INSTRUCTIONS:

Rail Bar Universal (RBU)

PART No’s:

59897 / 59898

/ 59899 / 59711

Maximum Carrying Capacity: 75 kgs/ 165 lbs

(refer to owner’s manual for roof load specifications)

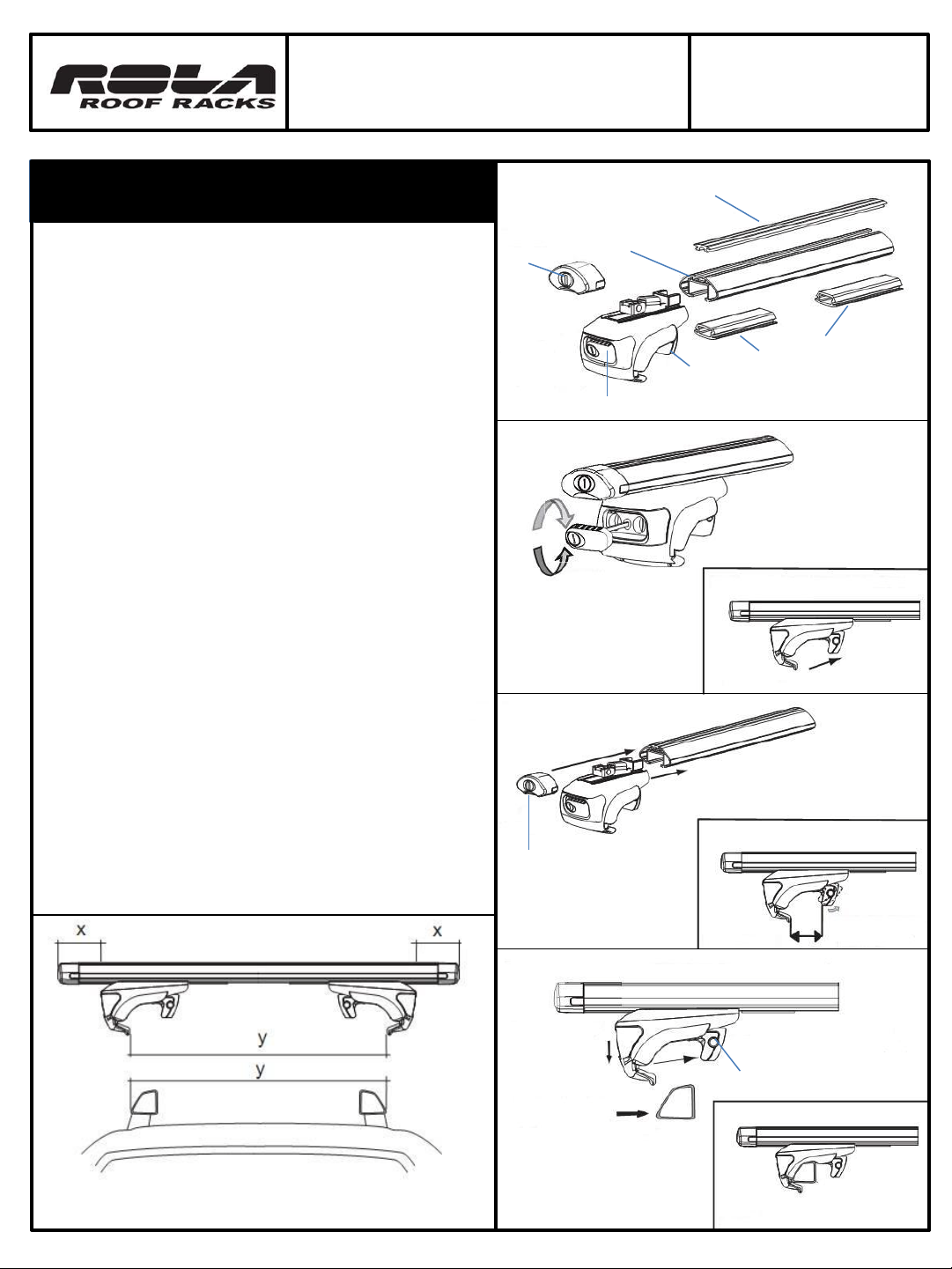

STEP 1: Fitting End Support to Cross Bar

A. Fully release locking jaws on each End Support prior to

assembly (fig 1b). Locking mechanism will resist turning

when locking jaws are fully released. DO NOT

OVERTURN.

B. Insert end supports into cross bar (Fig 1c). Note: In

order to allow movement of the end support while in

the cross bar the locking jaw should be pushed inward

(Fig 1b. Inset).

C. Fit cross bar locking cap into cross bar and turn the

locking device in the front face of the end cap to fasten

(Fig 1c). Compress the buffer strip inwards along the

cross bar while replacing the end cap.

D. To fit the cross bars to the vehicle side rails rotate the

locking jaw of each support inwards so as to allow the

cross bar assembly to fit over the vehicle side rails (Fig

1c. Inset).

STEP 2: Placement of the Cross Bars to

Vehicle Side Rails

A. Adjust the end supports to the approximate width of the

vehicles side rails. Now the cross bars may be lowered

onto the vehicle’s side rails.

B. Push the end supports up against the vehicle side rails

(Fig 2b & 2b inset) making sure the cross bar has equal

overhang past the end supports (measure the distance

of the end of the cross bar to the end support on either

side of the vehicle and adjust until equal (Fig 2c.)

Fig 1a.

End Cap

End Support

Locking Handle

Fig 1b.

Tighten

Release

Fig 1c.

Locking devices

Buffer Strip

Cross Bar

Under Covers

Locking Jaw

Locking Jaw at fully released position

Fig 1b Inset

Rotate to allow Max. opening

59897-8-9N Pg1 of 6

Continued on Page 2

Fig 1c Inset

Side View of Cross Bar assembly and vehicle side rail

1.Lower Cross

Bar over vehicle

rails

2. Push End

Support against

vehicle rail.

Vehicle Rail

Fig 2b. Fig 2a.

Push Locking Jaw inward to

seat assembly on vehicle

rails

Fig 2b Inset

Vehicle Rail

Page 2

FITTING INSTRUCTIONS:

Rail Bar Universal (RBU)

PART No:

59897 / 59898

/ 59899 / 59711

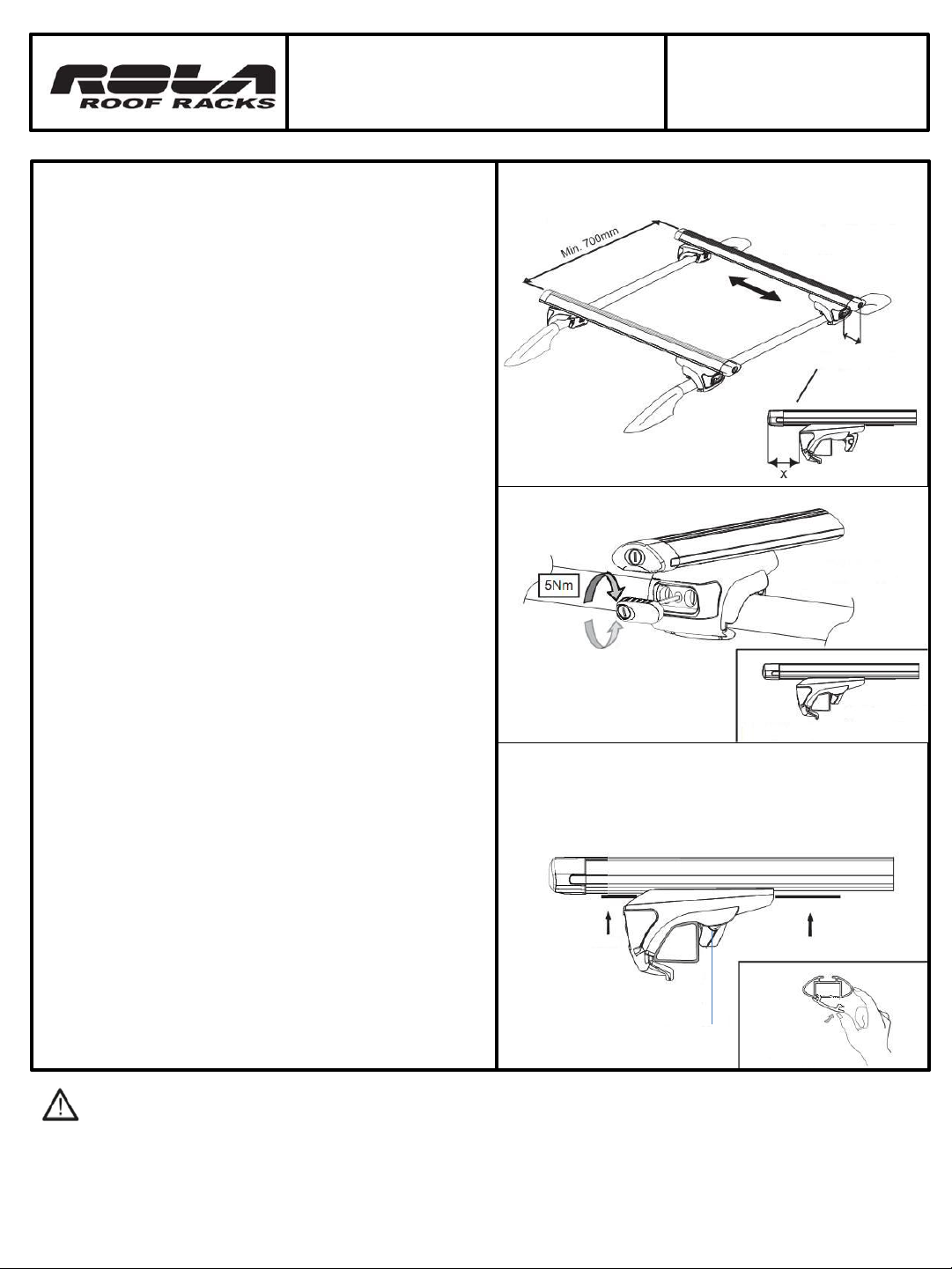

C. Be sure the distance between the cross bars front to

back is at least 700.0mm (27 ½”) Fig 2c.

D. Turn the locking handle in a clockwise direction to

tighten the end support to the vehicles side rails (Fig

2d). The handle must be firmly turned (Equivalent to

5Nm or 44 in/ lbs) to achieve a positive and tight fit.

Always turn the handle clockwise until horizontal to

align the lock with the internal locking position. At the

same time the locking jaw is tightened the end support

will clamp the cross bar into position. Repeat this

procedure on all end supports.

Note: To release the cross bar from the vehicle side rails

simply rotate the locking mechanism handle counterclockwise. Additional movement of the locking jaw with

your hand will assist the release of the end support.

STEP 3: Placement of Under Cover

A. Push Locking Mechanism Handle back into the End

Support and secure by turning the locking device.

Measure the space under the bars in front of and

behind the End Supports. Using scissors cut the Under

Cover strips to each measured length (Fig 3a) and push

the under cover into the channel by inserting one side

first and then push the other side into place making sure

that it sits flat when properly installed.

Note: Installing the Under Covers is optional but will reduce

potential wind noise.

Fig 2c.

Fig 2d.

Tighten

44 in/ lbs

Release

Slide Cross Bar

back or forth until

overhang is equal

Measure

overhang on

both sides

Vehicle Rail

Fig 2d Inset

Final

assembled

view

Check Fit is secure by grabbing the Cross Bar and

applying forces in upwards and sideways motions. If any

Fig 3a

movement occurs repeat steps 2b & 2c while also

further tightening the Handle. Visually check to see that

the Locking Jaw is firmly pressed against the vehicles

side rails on all four End Supports (Fig 3a).

Note: If a Security Lock Kit is to be added please refer to our

Lock Kit’s instructions for installation instructions. It is

Front Behind

advised to record the key combination so replacement

keys can be ordered in case of misplacement or loss.

Key Number: _ _ _

REGULARLY CHECK THE TIGHTNESS OF LOCKING JAWS.

Loads should be evenly distributed and secured

Any weight carried on the vehicle will adversely affect its handling particularly in cornering or in a cross wind and the vehicle should therefore be driven

with increased caution. Check the function of all doors and sunroof before driving. For lost key replacement or other service items call customer service:

1-800-632-3290 or visit:

A number of accessories for carrying special loads are available. Only use NON-STRETCH tie down straps.

www.rolaproducts.com Please have lock core number or part numbers available.

.

Ensure bars are parallel and jaws are tightened against the side rails.

Perform a check by tugging on the cross bars.

Locking Jaw firmly

pressed against

the vehicle rail

Fig 3a Inset

59897-8-9N Date: 6/3/2011

Pg2 of 6

Printed In China

Page 3

INSTRUCTIONS D’INSTALLATION :

Rail universel 30095

PIÈCE NO :

59897 / 59898

/ 59899 / 59711

Capacité maximale de charge : 75 kg (165 lb)

(Consulter le manuel du propriétaire pour obtenir les

spécifications de charge du toit)

Étape 1 : Ajustement du support d’extrémité à la traverse

A. Dégager complètement les fixations de verrouillage de chaque

support d’extrémité avant l’assemblage. (Fig. 1b). Un mécanisme

verrouillé résistera au tournage si les fixations de verrouillage

sont complètement déclenchées. NE PAS INVERSER.

B. Insérer les supports d’extrémités dans la barre stabilisatrice

(Fig. 1c). Remarque : Les fixations de verrouillage doivent être

poussées pour permettre le mouvement du support d’extrémité

et les fixations de verrouillage de la traverse poussées vers

l’avant. (Fig. 1b Enclenchement).

C. Insérer les capuchons de verrouillage de traverse dans la traverse

et tourner le dispositif de verrouillage situé sur la face de

l’extrémité pour fixer le tout (Fig. 1c). Insérer la bande de

protection en poussant vers le devant de la traverse puis replacer

le capuchon d’extrémité.

D. Pour ajuster les traverses aux rails de toit, tourner la mâchoire de

blocage de chaque support vers l’intérieur de manière à

permettre l’ajustement de chaque traverse sur les rails du toit.

(Fig. 1c Enclenchement).

ÉTAPE 2 : Installation des traverses sur les rails de toit.

A. Ajuster approximativement la largeur des supports d’extrémité

avec les traverses latérales du toit. Les traverses peuvent

maintenant être abaisser sur les rails de toit.

B. Pousser les supports d’extrémité contre les traverses de toit

(Fig. 2b et 2b Enclenchement) en s’assurant que la distance

excédentaire des traverses est égale des deux côtés. (Mesurer

la distance de l’extrémité de la traverse et l’extrémité du

support de chaque côté du toit et ajuster pour obtenir une

distance égale). (Fig. 2c)

Suite à la page 2

Fig 1a.

Capuchon

d’extrémité

Support

d’extrémité

Manette de

blocage

Fig 1b.

Engagée

Fig 1c.

Dispositifs de

verrouillage

Traverse

Dégagée

Bande de protection

Bandes de protection

Fxations de verrouillage

Manette en position de dégagement

complet

Fig 1b Enclenchement

Tourner pour permettre l’ouverture

complète.

59897-8-9N Page 3 de 6

Fig 1c Dégagement

Vue latéral de l’ensemble de traverse et du rail de toit.

1. Abaisser la

traverse sur les

rails du véhicule.

2. Pousser

l’extrémité du

support contre le

rail de toit.

Fig 2b. Fig 2a.

Rail de toit

Pousser la mâchoire vers

l’avant pour asseoir

l’assemblage sur les rails de

toit.

Fig 2b

Empattement

Rail de toit

Page 4

INSTRUCTIONSD’INSTALLATION :

Rail universel

PIÈCE NO :

59897 / 59898

/ 59899 / 59711

C. La distance avant-arrière des traverses doit être d’au moins

700 mm (27 ½ po) (Fig. 2c).

D. Tourner la manette de blocage dans le sens des aiguilles d’une

montre pour serrer le support d’extrémité aux rails de toit.

(Fig. 2d). La manette doit être serrée fermement à un couple

équivalant à 5 Nm (44 po/lb) pour permettre une fixation

solide. Tourner toujours la manette dans le sens des aiguilles

d’une montre pour aligner le verrou avec la position de

verrouillage interne. Au même moment, la mâchoire se serre

contre le support d’extrémité et fixe la position de la bride de

la traverse. Répéter cette procédure pour tous les supports

d’extrémité.

Remarque : Pour dégager la traverse du rail de toi, tourner

simplement le mécanisme de verrouillage dans le sens

contraire des aiguilles d’une montre. Bouger manuellement la

mâchoire pour aider au dégagement du support d’extrémité.

Étape 3 : Installation des bandes de protection

A. Pousser la manette du mécanisme de verrouillage dans le

support d’extrémité et sécuriser en tournant le dispositif de

verrouillage. Mesurer l’espace à l’avant et à l’arrière des

supports d’extrémité de la traverse. Couper les bandes de

protection en utilisant des ciseaux selon la longueur mesurée

(Fig. 3a) et insérer d’abord dans la rainure puis pousser l’autre

côté en s’assurant qu’elle est appuyée correctement en

terminant l’installation.

Remarque : L’installation des bandes de protection est facultative,

mais celles-ci réduisent le bruit occasionné par le vent.

Fig 2c.

Fig 2d.

Engagé

44 po/lbs

Glisser la traverse

vers l’avant ou

l’arrière pour égaliser

les extrémités libres.

Mesurer les

extrémités libres

des deux côtés.

Rail de toit

Dégagé

Assemblage

final

Fig. 2d Enclenchement

Vérifier la solidité en empoignant la traverse et en la forçant

vers l’avant et sur les côtés. Si la traverse ne reste pas

fermement en place, répéter les étapes 2b et 2c et en serrant

davantage la manette. Inspecter visuellement la mâchoire

pour s’assurer qu’elle est fermement appuyée contre les rails

de toit et aux quatre supports d’extrémité. (Fig. 3a)

Remarque : Si une trousse de verrouillage de sécurité doit être

ajoutée, veuillez consulter les instructions d’installation de la

trousse de verrouillage de sécurité. Il est conseillé d’inscrire la

combinaison du verrou afin de pouvoir commander des clés de

rechange en cas de perte.

No de clé : _ _ _

VÉRIFIER RÉGULIÈREMENT LA SOLIDITÉ DES FIXATIONS DE

VERROUILLAGE.

Les charges doivent être distribuées également et bien arrimées.

Toute charge transportée sur le véhicule modifiera sa tenue de route lors d’un vent frontal ou latéral et doit donc être conduit avec prudence. Vérifier le fonctionnement de

tous les portières et du toit ouvrant avant de quitter. Appeler le Service à la clientèle pour obtenir des clés ou des articles de rechange au 1-800-632-3290 ou visiter

www.rolaproducts.com Veuillez avoir le numéro du cylindre ou des pièces à portée de main.

Des accessoires pour le transport de charges spéciales sont offerts. Utiliser uniquement des courroies inextensibles.

Fig 3a

Devant Derrière

Enclencher fermement les

fixations de verrouillage

contre le véhicule.

S’assurer que les traverses sont parallèles et que les mâchoires sont appuyés

fermement contre les rails de toit. Vérifier en appuyant brusquement sur les

traverses.

Fig 3a Enclenchement

59897-8-9N Date : 6/3/2011

Page 4 de 6

Imprimé en Chine

Page 5

INSTRUCCIONES DE AJUSTE:

Barra larguero universal

(RBU)

Número de parte:

59897 / 59898

/ 59899 / 59711

Capacidad máxima de carga: 75 kgs/ 165 lbs

(consulte el manual del propietario para las especificaciones

de carga en el techo)

PASO 1: Ajuste del soporte extremo al travesaño

A. Libere completamente las mordazas de bloqueo en cada

soporte extremo antes del ensamble (fig. 1b). El mecanismo

de bloqueo resistirá el giro cuando las mordazas de bloqueo

estén completamente liberadas. NO GIRE EN EXCESO.

B. Inserte los soportes extremo dentro del travesaño (Fig 1c).

Nota: Con el fin de permitir el movimiento del soporte

extremo mientras está en el travesaño la mordaza de bloqueo

debe empujarse al interior (Fig 1b. Recuadro).

C. Ajuste la tapa de bloqueo del travesaño en el travesaño y gire

el mecanismo de bloqueo en la cara frontal de la tapa extremo

para sujetar (Fig 1c). Comprima la correa de

amortiguamiento hacia el interior a lo largo del travesaño al

mismo tiempo que reemplaza la tapa extremo.

D. Para ajustar los travesaños a los largueros laterales del

vehículo, rote la mordaza de bloqueo de cada soporte hacia el

interior de manera que permita que el ensamble del

travesaño encaje sobre los largueros laterales del vehículo (Fig

1c. Recuadro).

PASO 2: Colocación de los travesaños

en los largueros laterales del vehículo

A. Ajuste los soportes extremo al ancho apropiado de los

largueros laterales del vehículo. Ahora, los travesaños se

pueden bajar sobre los largueros laterales del vehículo.

B. Empuje los soportes extremo contra los largueros

laterales del vehículo (Recuadro Fig 2b y 2b) verificando

que el travesaño tenga un saliente igual más allá de los

soportes extremo (mida la distancia del extremo del

travesaño hasta el soporte extremo en cualquier lado del

vehículo y ajuste hasta que queden iguales (Fig 2c.)

Continúa en la Pág. 2

Fig 1a.

Tapa extremo

Soporte extremo

Manija de

bloqueo

Travesaño

Fig. 1b.

Apriete

Libere

FIG. 1c.

Mecanismos de

bloqueo

Correa de

amortiguamiento

Mordaza de

bloqueo

Mordaza de bloqueo en posición

completamente liberada

Recuadro Fig. 1b.

Rote para permitir la apertura

máxima

Cubiertas

inferiores

59897-8-9N Pg 5 de 6

Recuadro Fig. 1c.

Vista lateral del ensamble del travesaño y larguero lateral del

vehículo

1. Baje el

travesaño sobre

los largueros del

vehículo

2. Empuje el

soporte extremo

contra el larguero

del vehículo.

Larguero del

Fig. 2b. Fig 2a.

vehículo

Empuje la mordaza de

bloqueo hacia el interior

para acomodar el ensamble

en los largueros del vehículo

Recuadro Fig.

1b.

Larguero del

vehículo

Page 6

INSTRUCCIONES DE AJUSTE:

Barra larguero universal

(RBU)

Número de parte:

59897 / 59898

/ 59899 / 59711

C. Cerciórese de que la distancia entre los travesaños desde el

frente hasta atrás es al menos 700.0mm (27 ½”) Fig 2c.

D. Gire la manija de bloqueo en el sentido del reloj para apretar

el soporte extremo a los largueros laterales del vehículo (Fig

2d). La manija debe estar firmemente girada (Equivalente a

Fig. 2c.

Deslice el

travesaño hacia

atrás o adelante

hasta que el

saliente sea igual

5Nm ó 44 pulg./ lbs) para alcanzar un ajuste positivo y firme.

Siempre gire la manija en el sentido del reloj hasta que

quede horizontal para alinear el cierre con la posición de

bloqueo interna. Al mismo tiempo que la mordaza de

bloqueo se aprieta el soporte extremo fijará el travesaño en

su posición. Repita este procedimiento en todos los

soportes extremo.

Mida el saliente

en ambos

lados.

Nota: Para liberar el travesaño de los largueros laterales del

vehículo, simplemente rote la manija del mecanismo de

bloqueo en sentido contrario al reloj. Un movimiento

adicional de la mordaza de bloqueo con la mano ayudará a

liberar el soporte extremo.

PASO 3: Colocación de cubierta inferior

A. Empuje la manija del mecanismo de bloqueo hacia atrás

contra el soporte extremo y asegure al girar el

mecanismo de bloqueo. Mida el espacio debajo de las

barras al frente y detrás de los soportes extremo. Con

tijeras corte las tiras de cubierta inferior según la

longitud medida (Fig 3a) y empuje la cubierta inferior

Fig 2d.

Apriete

44 pulg.lbs

Larguero del

vehículo

Libere

dentro del canal insertando un lado primero y luego

empujando el otro lado en su lugar verificando que

quede plana cuando se instale correctamente.

Recuadro Fig. 2d

Vista de

ensamble

final

Nota: Instalar las cubiertas inferiores es opcional pero

reducirá el ruido potencial del viento.

Revise que el ajuste quede seguro al agarrar el

travesaño y aplicar fuerzas en movimientos hacia arriba

Fig 3a.

y hacia los lados. Si ocurre cualquier movimiento repita

los pasos 2b y 2c al mismo tiempo que aprieta la manija

aún más. Revise visualmente para ver que la mordaza

de bloqueo esté firmemente presionada contra los

largueros laterales del vehículo en todos los cuatro

soportes extremo (Fig. 3a).

Nota: Si se va a agregar un Kit de bloqueo de seguridad

Frente

Detrás

remítase a las instrucciones de nuestro Kit de bloqueo para

su instalación. Se recomienda registrar la combinación de

la llave para que se puedan ordenar repuestos en caso de

pérdida.

Número de llave: _ _ _

REVISE CON FRECUENCIA LA FIRMEZA DE LAS MORDAZAS DE BLOQUEO

Las cargas deben distribuirse de manera uniforme y asegurarse

Cualquier peso del vehículo afectará de manera adversa su manipulación especialmente en las esquinas o con el viento en contra, por lo cual el vehículo se debe

conducir con mayor precaución. Revise la función de todas las puertas y del techo corredizo al conducir. Para el reemplazo de llaves perdidas u otras piezas de

servicio llame a servicio al cliente: 1-800-632-3290 o visite

Tenemos disponibles una variedad de accesorios para cargas especiales. Use únicamente correas de amarre que NO ESTIREN.

www.rolaproducts.com Tenga a mano el número de candado o números de partes.

.

Verifique que las barras estén paralelas y que las mordazas estén

apretadas contra los largueros laterales. Revise halando los travesaños.

Mordaza de bloqueo

firmemente

presionada contra el

larguero del vehículo

Recuadro Fig. 3a

59897-8-9N Date: 6/3/2011

Página 6 de 6

Impreso en China

Loading...

Loading...