Page 1

INSTALLATION INSTRUCTIONS

Product No.

MULTI-FIT PICK-UP

You can take it with you.

PLYMOUTH, MICH.

WARNING: DO NOT LUBRICATE THREADS, BOLT FAILURE MAY

OCCUR DUE TO OVER TIGHTENING.

WARNING: DO NOT DRILL OR WELD TO THIS HITCH.

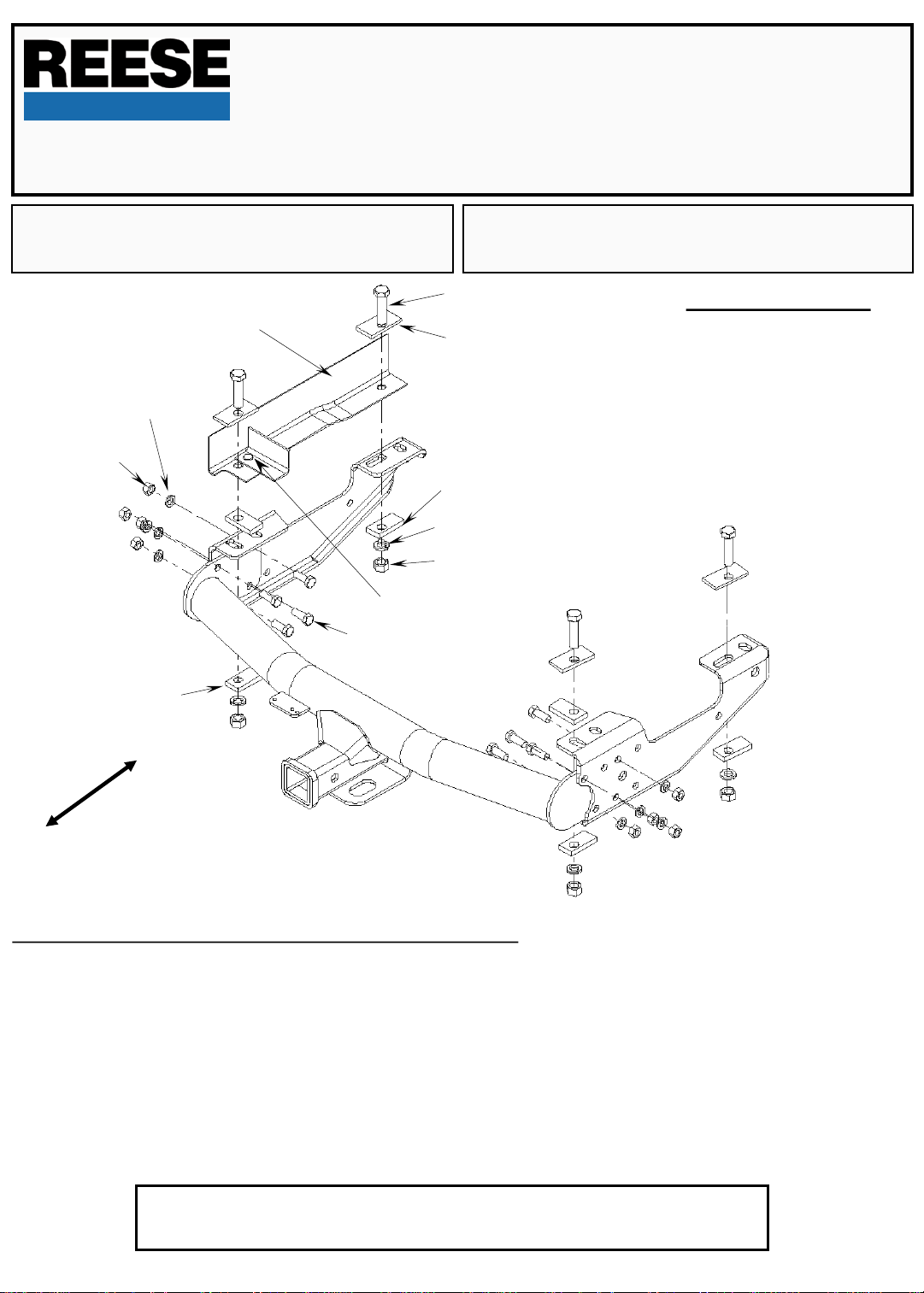

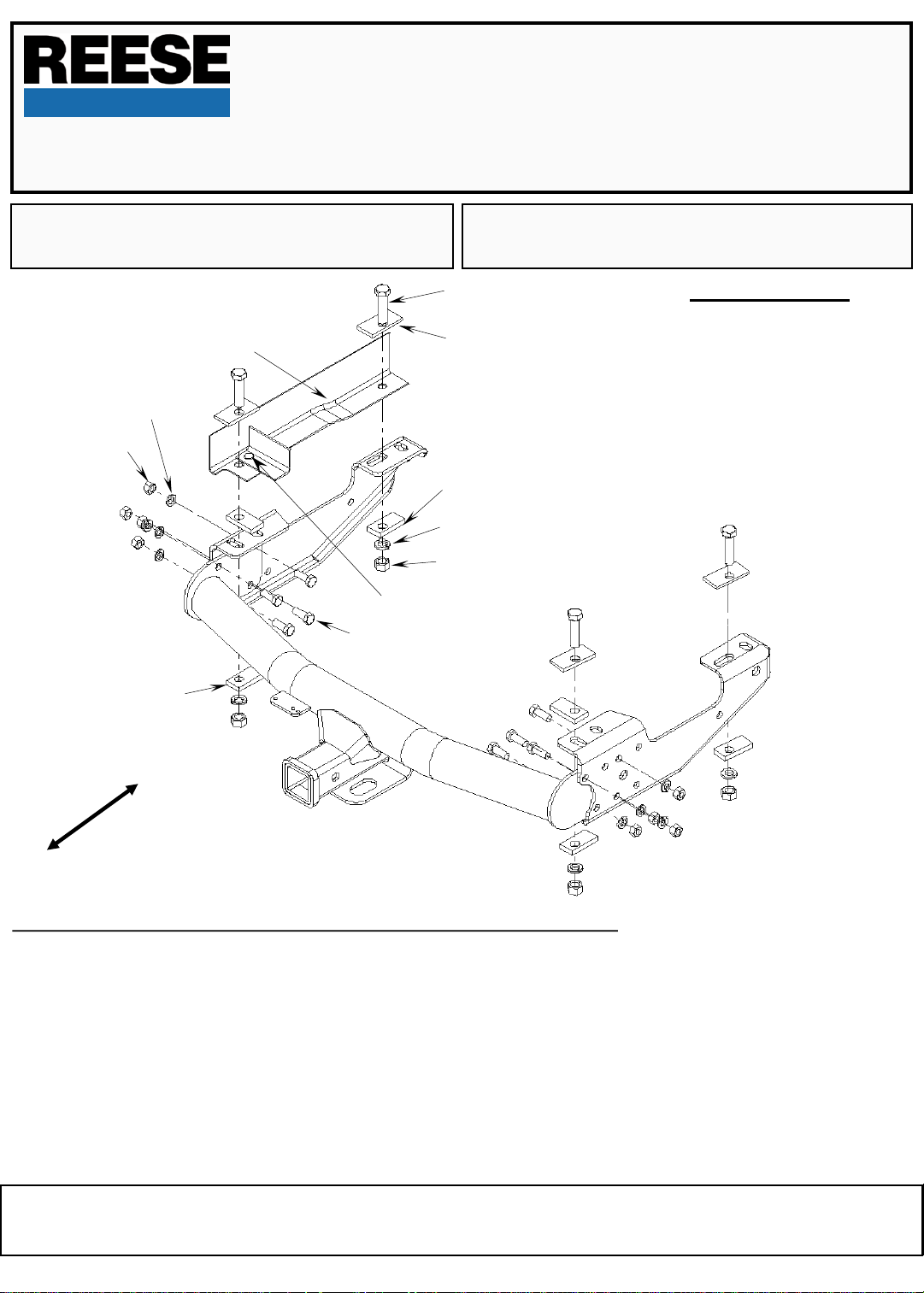

FRAME

1/2” LOCK WASHER

1/2” NUT

RIVET IN FRAME

37034

SMALL PARTS

PACKAGE 37424

USE ONLY REESE SUPPLIED OR APPROVED BOLTS, LOCKNUTS,

AND WASHERS TO INSTALL THIS HITCH

5/8” BOLT

1/4 BOLT PLATE

3/8” SPACER

5/8” LOCK WASHER

5/8” NUT

IMPORTANT NOTES

TOOLS REQUIRED

5/8” DRILL BIT

15/16” SOCKET

15/16” WRENCH

3/4” SOCKET

3/4” WRENCH

2 CLAMPS

TORQUE WRENCH

1/2” BOLT

3/8” SPACER

FRONT

REAR

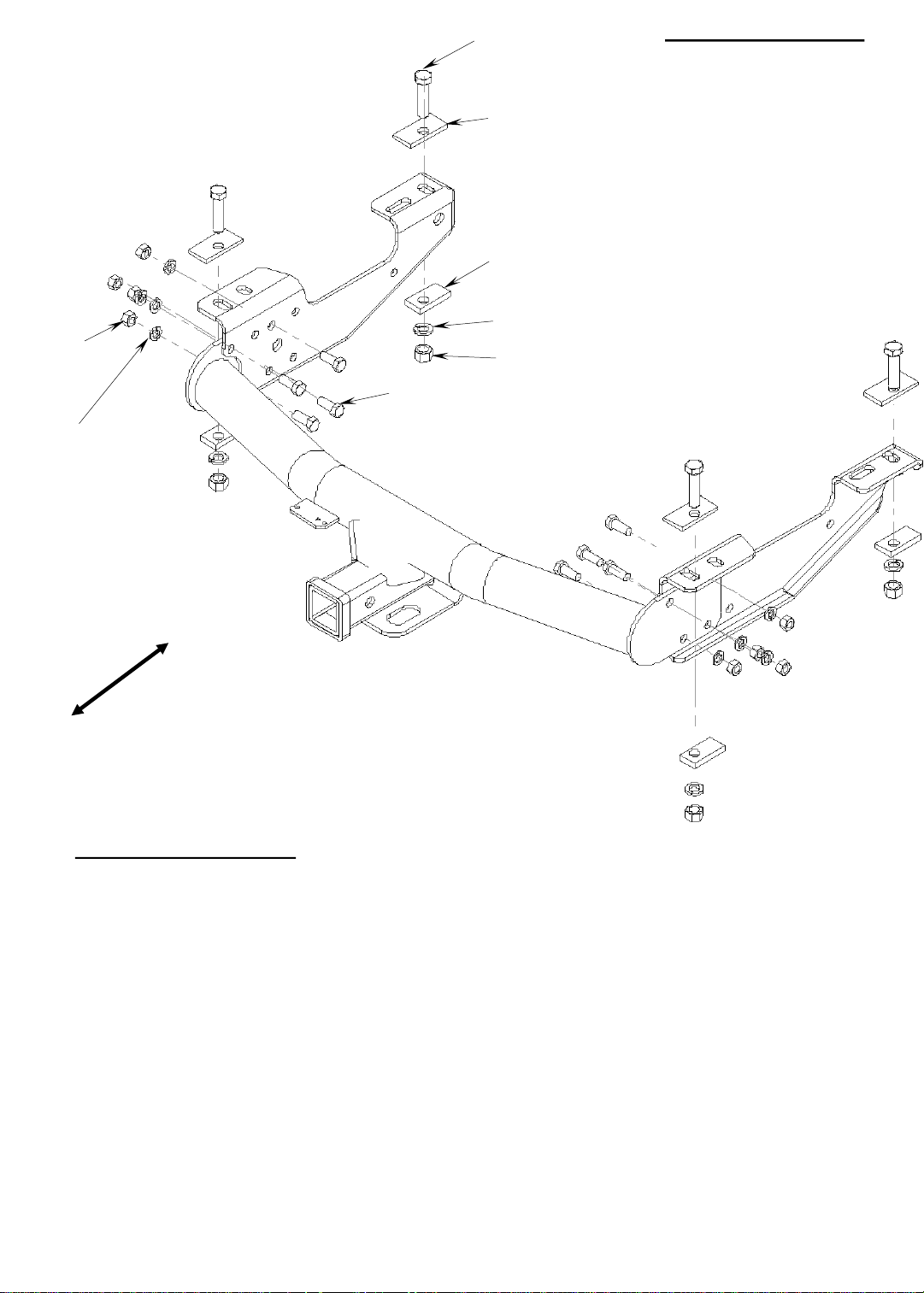

1973-1996 Ford Full Size Pickup & 1997 F-250 Heavy Duty / F-350 Heavy Duty:

1. Assemble the three pieces of the hitch together on the floor before attaching it to the truck. Using 1/2” bolts, lock washers and nuts, bolt the

brackets to the center section as shown. Place the brackets on the outside of the center section. Bolt through the holes shown in the

illustration. Leave the bolts loose enough to center brackets on truck frame. NOTE: Be sure to use four holes to bolt each bracket to the center

section.

2. Clamp the hitch to the frame with a 3/8” thick spacer between the hitch and the frame at the rear. Align the ends of the brackets with the end

of the frame as shown.

3. Using the holes in the bracket as a guide, drill 5/8” diameter holes into the frame at the locations shown.

4. Insert 5/8” bolts with bolt plates down through the frame and into the bracket. Place a 3/8” thick spacer between the frame and the bracket at

the rear mounting hole. Install a 3/8" thick spacer, lock washer and nut on each bolt.

5. Tighten the nuts in the following order: First torque the 1/2" nuts to 70 ft•lb. Then torque the 5/8" nuts to 115 ft•lb.

NOTE: SIDE BRACKETS WILL DEFLECT WHEN TIGHTENED

For Installation Assistance or Technical Help, See our Web Site at

www.reeseprod.com or call 1-800-428-7303

37034IN 9-5-07 rev_H PCN9924 © 2007 Cequent Towing Products Printed in Mexico

Page 2

TOOLS REQUIRED

15/16” SOCKET

15/16” WRENCH

3/4” SOCKET

3/4” WRENCH

5/8" DRILL BIT

TORQUE WRENCH

1/2” NUT

1/2” LOCK WASHER

3/8” SPACER

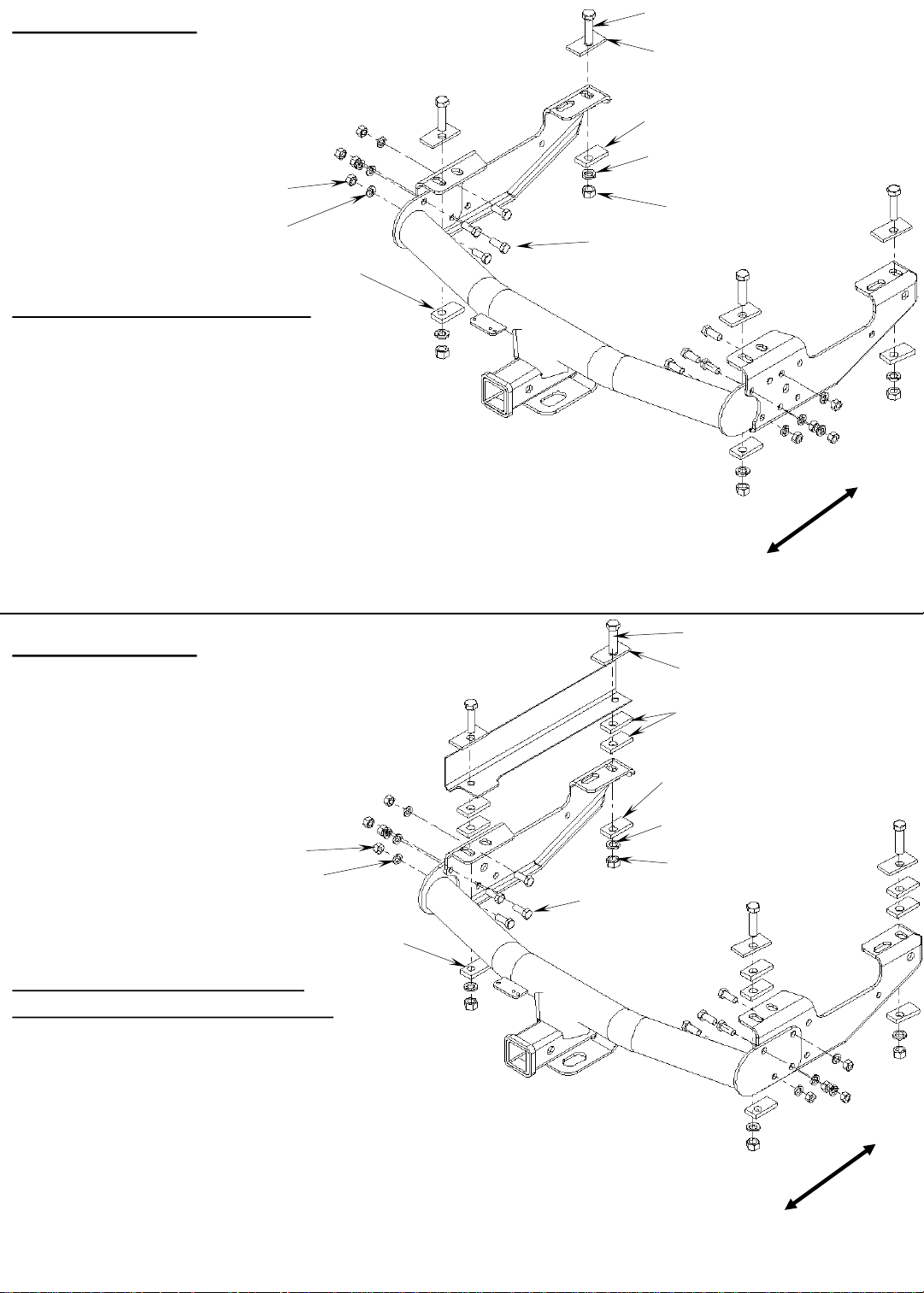

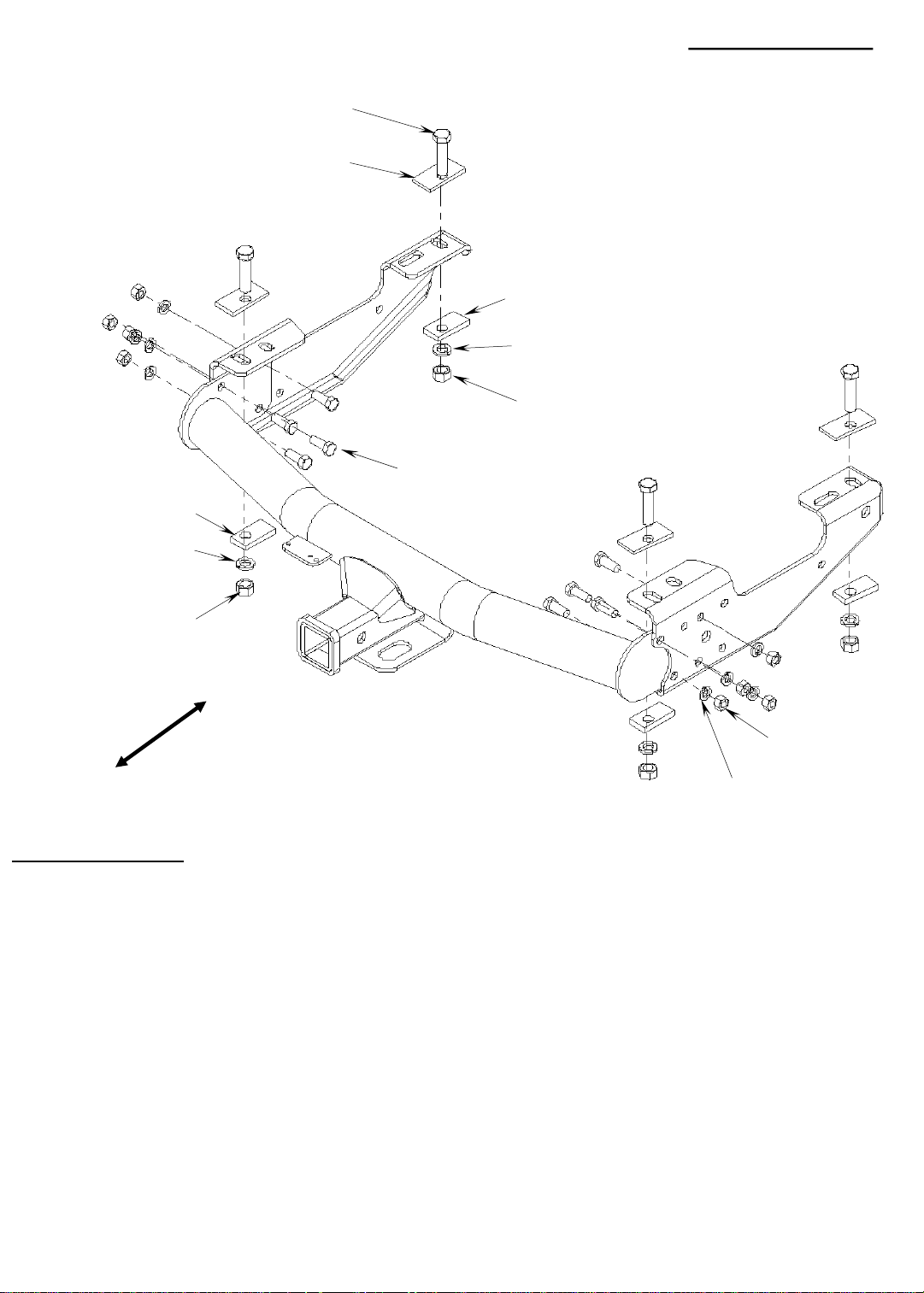

1998-2004 FORD F-250 & F-350 SUPER DUTY:

1. Align the bracket with the rear edge of the frame. Attach the

brackets to the frame as shown with 5/8” bolts and bolt plates

down through rear holes in the frame. Install 3/8" thick spacers,

5/8" lock washers, and nuts on these bolts. Leave the nuts loose

at this time.

2. Install the center section of the hitch as shown with the frame

brackets on the outside of the center section. Bolt through the

holes shown. Use the 1/2” bolts with lock washers and nuts.

NOTE: Be sure to use four holes to bolt the brackets to the

center section. Tighten enough for the brackets to make full

contact with the center section.

3. With the 5/8” drill, drill the two forward holes. Install fasteners as

shown. Install 3/8” thick spacers, 5/8” lock washers and nuts on

the bolts. Leave the nuts loose at this time.

4. Tighten the nuts in the following order: First torque the 1/2" nuts

to 70 ft•lb. Then torque the 5/8" nuts to 115 ft•lb.

5/8” BOLT

1/4” BOLT PLATE

3/8” SPACER

5/8” LOCK WASHER

5/8” NUT

1/2” BOLT

FRONT

REAR

TOOLS REQUIRED

15/16” SOCKET

15/16” WRENCH

3/4” SOCKET

3/4” WRENCH

TORQUE WRENCH

1/2” NUT

1/2” LOCK WASHER

3/8” SPACER

1997-2003 FORD F-150 & LIGHT DUTY F-250:

2004 FORD F-150 HERITAGE (OLD BODY STYLE)

1. Align the bracket with the rear edge of the frame. Place 3/8" thick

spacers between the bracket and the frame as shown. Attach

brackets to the frame as shown with 5/8” bolts and bolt plates down

through the frame, spacers, and bracket. Bolt into the first and last

holes in the bracket. Install 3/8” thick spacer with 5/8” lock washer

and nut on the each bolt. Leave the nuts loose at this time.

2. Install the center section of the hitch as shown with the frame

brackets on the inside of the center section. Use the 1/2” bolts with

lock washers and nuts. NOTE: Be sure to use four holes to bolt

each bracket to the center section.

3. Tighten the nuts in the following order:

First torque the 1/2" nuts to 70 ft•lb.

Then torque the 5/8" nuts to 115 ft•lb.

5/8” BOLT

1/4” BOLT PLATE

3/8” SPACER

3/8” SPACER

5/8” LOCK WASHER

5/8” NUT

1/2” BOLT

FRONT

REAR

Page 3

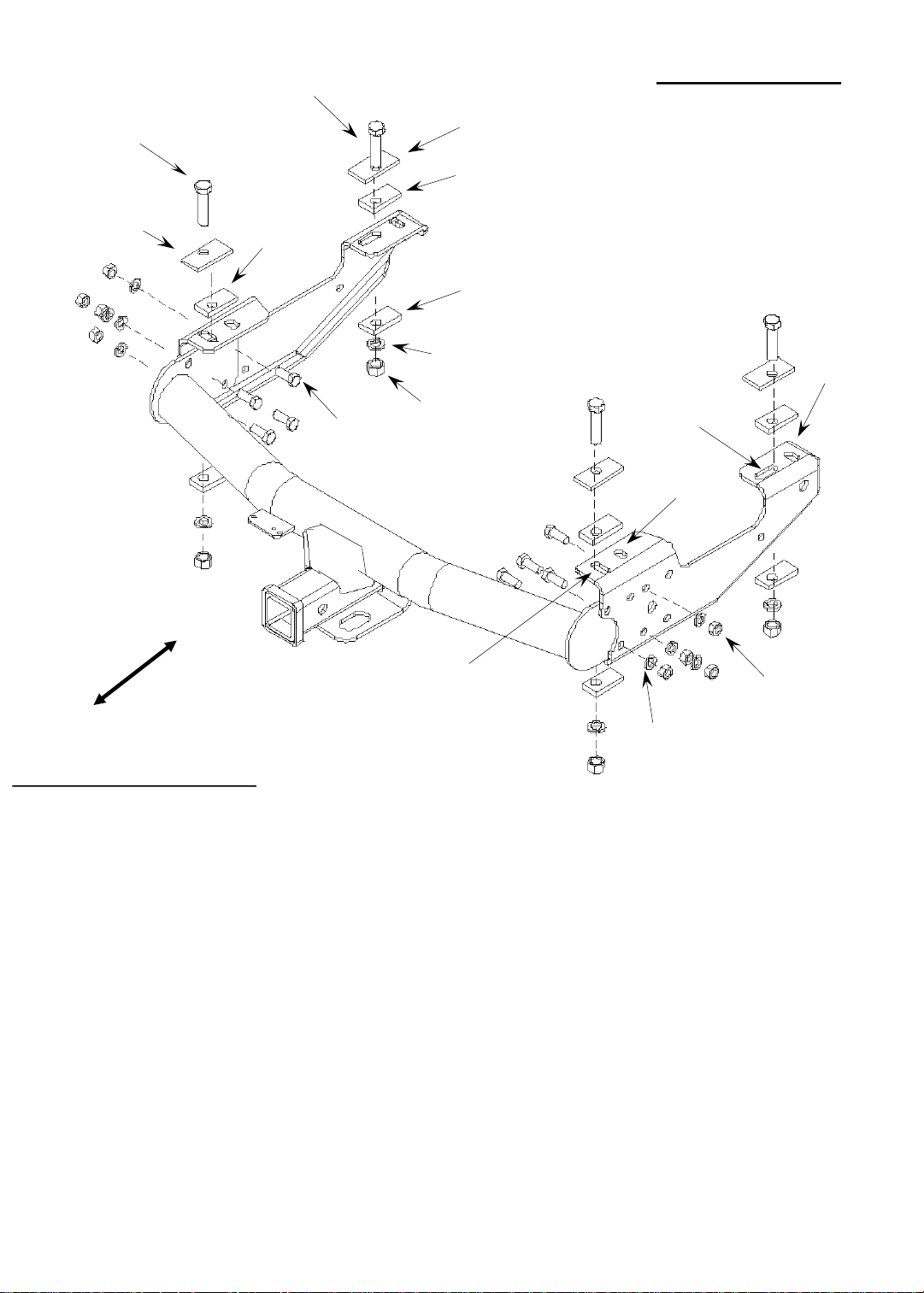

5/8” BOLT

1/4” BOLT PLATE

5/8” BOLT

3/8” SPACER

1/4” BOLT PLATE

3/8” SPACER

3/8” SPACER

TOOLS REQUIRED

15/16” SOCKET

15/16” WRENCH

3/4” SOCKET

3/4” WRENCH

19MM WRENCH

19MM SOCKET

15MM SOCKET

15MM WRENCH

5/8” DRILL

TORQUE WRENCH

1/2” BOLT

5/8” LOCK WASHER

5/8” NUT

Hole

3

Hole 2

Hole 4

FRONT

Hole 1

1/2” NUT

REAR

1/2” LOCK WASHER

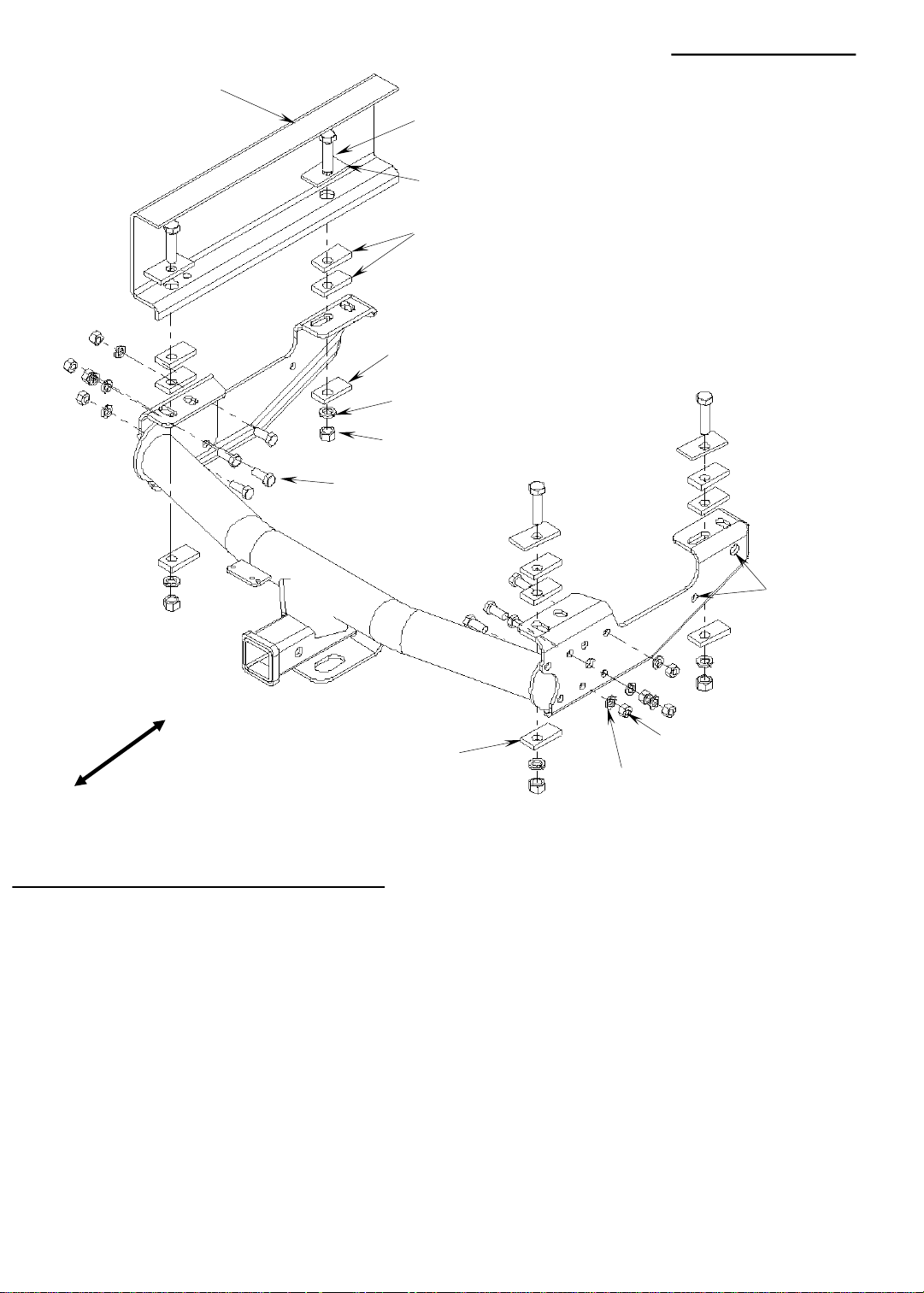

1988-2000 CHEVY & GMC (CLASSIC):

1. The 12mm diameter bolts and weld nuts at the end of the frame must be removed. ( Wear Eye Protection) Method 1) Back out the

12mm diameter bolt halfway. Drive the bolt upward by striking the bolt head with a ball peen hammer to break the nut loose. Ream out the

bolt hole to 5/8” diameter. Method 2) Remove the 12mm bolt and discard. Using a 5/8” drill bit, drill out the nut. Then remove the remainder

with a hammer and chisel. Some vehicles have an additional 8mm diameter bolt on the passenger’s side. Remove the bolt and reinstall it with

the head on the bottom of the frame.

2. If your vehicle has rivets on the bottom of the frame or the 8mm bolt, you will need to install one 3/8” thick spacer between the frame and the

bracket at each bolting location. These are needed for clearance between the bracket and the rivet head or 8mm bolt. The bracket can not be

bolted directly against the rivets or 8mmbolt.

3. Using the supplied hardware, insert 5/8” diameter bolt with bolt plate down through the hole created from the removal of the 12mm nut. Fasten

the bracket to the frame. See the illustration. For short bed use hole 2. On long bed use hole 1. NOTE: SOME DUAL PIPE EXHAUST

SYSTEMS WILL HIT THE BRACKET. THE EXHAUST WILL NEED TO BE MODIFIED. Attach with 3/8” spacer, 5/8” lock washer, and 5/8’nut.

4. (Short Beds): Insert 5/8” bolts with bolt plates down through the 1” diameter holes in the frame and into holes (4) in the brackets. Install a 3/8”

thick spacer, 5/8” lock washer, and nut on each bolt. Leave the nuts loose at this time.

5. (Long Beds): Insert 5/8” bolts with bolt plates down through the 1” diameter holes in the frame and into holes (3) in the brackets. If the forward

holes are only 1/2" diameter, use the 5/8" drill bit to enlarge them. Install a 3/8” thick spacer, 5/8” lock washer and nut on each bolt. Leave the

nuts loose at this time.

6. Place the center section between the brackets as shown. The spare tire may need to be loosened. Bolt through the center section and the

bracket with 1/2” bolts, lock washers and nuts. NOTE: Be sure to use four holes to bolt the brackets to the center section.

7. Tighten the nuts in the following order:

First torque the 1/2" nuts to 70 ft•lb.

Then torque the 5/8" nuts to 115 ft•lb.

8. Retighten the spare tire if it was loosened.

9. Be sure that the spare tire is not rubbing against the brake hose. If needed, bend the bracket that the hose mounts to a little so that you have

clearance between the tire and the brake hose.

Page 4

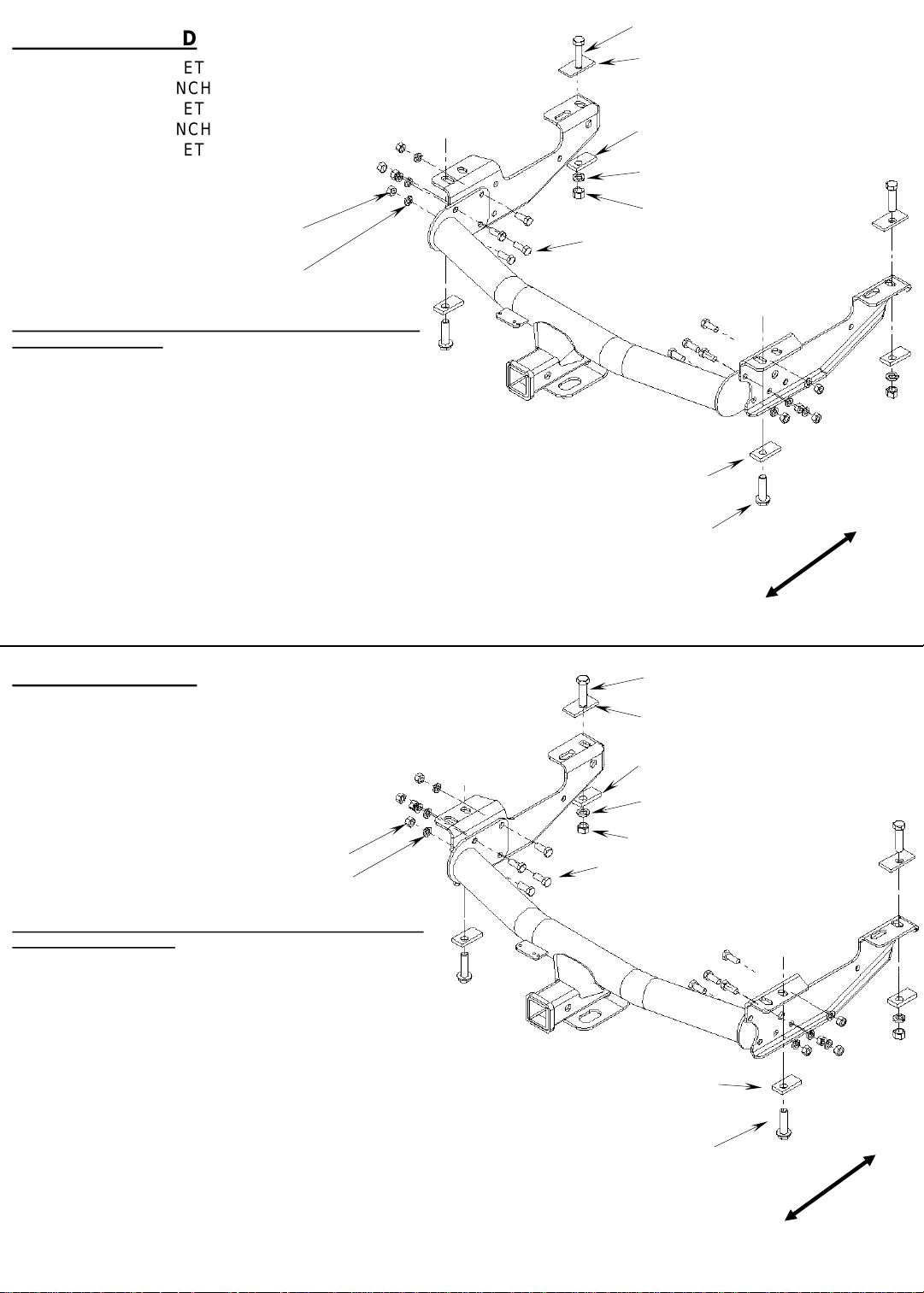

TOOLS REQUIRED

15/16” SOCKET

15/16” WRENCH

3/4” SOCKET

3/4” WRENCH

21MM SOCKET

TORQUE WRENCH

1/2” NUT

1/2” LOCK WASHER

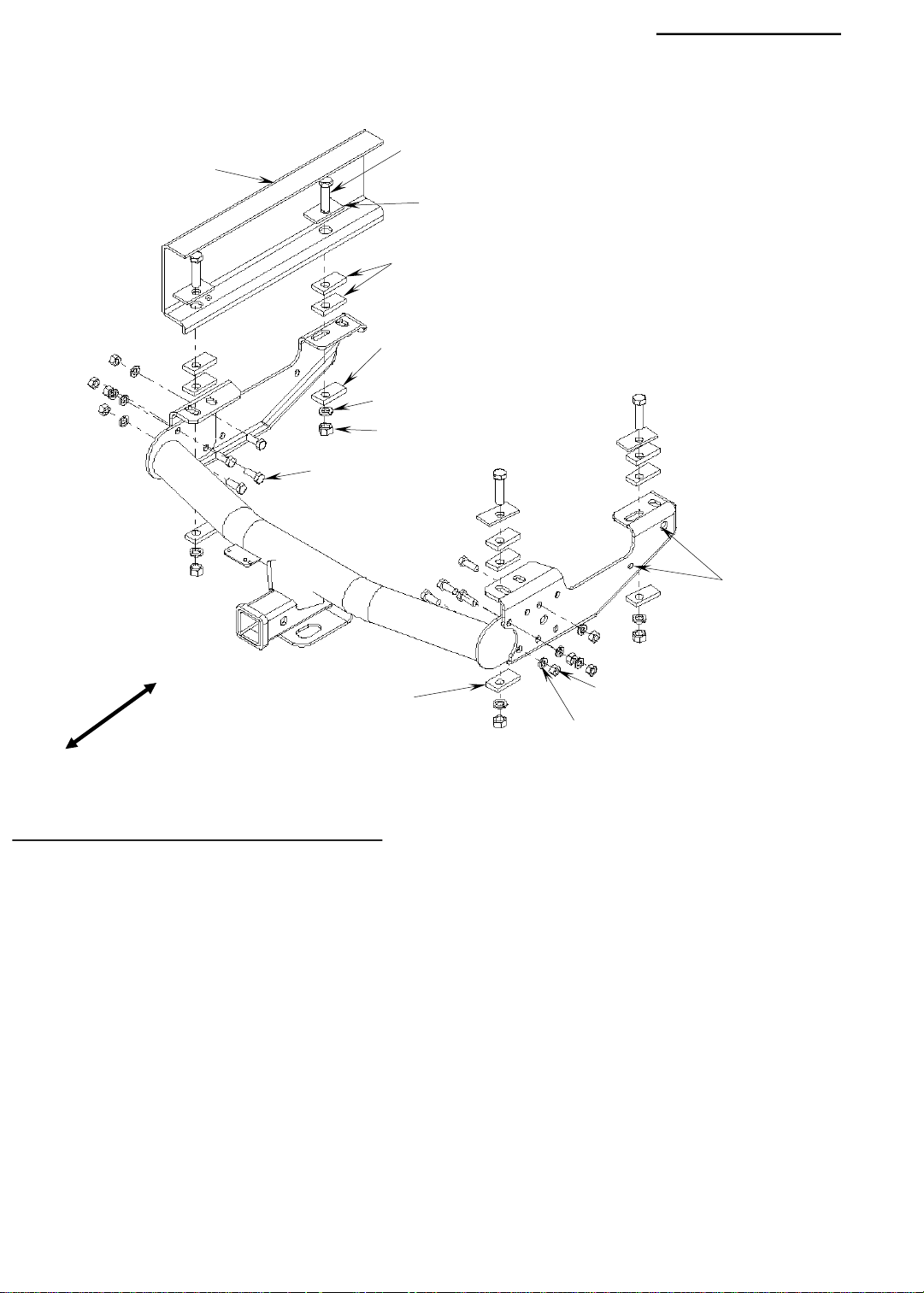

1999-2007 1500,1999-2004 2500LD CHEVY SILVERADO & GMC

SIERRA (LONG BEDS):

1. Remove the 14mm bolt from the bottom of the frame with a

21mm socket.

2. Bolt the brackets on with the 14mm bolt that was just removed

and a 3/8” thick spacer into the hole shown. Insert a 5/8” bolt

with a 1/4" bolt plate through the large hole in the frame and

into the bracket as shown. Install 3/8” thick spacers, 5/8” lock

washers and nuts on the bolts. Leave the bolts loose.

3. Install the center section between the brackets as shown. Use

the bolting location indicated. Install 1/2” bolts through the

center section and the bracket as shown. Install 1/2” lock

washers and nuts on the bolts. NOTE: Be sure to use four

holes to bolt the brackets to the center section.

4. Tighten the nuts in the following order:

First torque the 1/2" nuts to 70 ft•lb.

Then torque the5/8" nuts to 115 ft•lb, and the 14mm bolts to 85 ft-lb.

5/8” BOLT

1/4” BOLT PLATE

3/8” SPACER

5/8” LOCK WASHER

5/8” NUT

1/2” BOLT

3/8” SPACER

EXISTING FACTORY

FLANGE BOLT

FRONT

REAR

TOOLS REQUIRED

15/16” SOCKET

15/16” WRENCH

3/4” SOCKET

3/4” WRENCH

21MM SOCKET

TORQUE WRENCH

1/2” NUT

1/2” LOCK WASHER

1999-2007 1500, 1999-2004 2500LD CHEVY SILVERADO & GMC

SIERRA (SHORT BEDS):

1. Remove the 14mm bolt from the bottom of the frame with a

21mm socket.

2. Bolt the brackets on with the 14mm bolt that was just removed

and a 3/8” thick spacer into the hole shown. Insert a 5/8” bolt

with a 1/4" bolt plate through the large hole in the frame and into

the bracket as shown. Install 3/8” thick spacers, 5/8” lock

washers and nuts on the bolts. Leave the bolts loose.

3. Install the center section between the brackets as shown. Use

the bolting location indicated. Install 1/2" bolts through the

center section and the bracket as shown. Install 1/2” lock

washers and nuts on the bolts. NOTE: Be sure to use four holes

to bolt the brackets to the center section.

5/8” BOLT

1/4” BOLT PLATE

3/8” SPACER

5/8” LOCK WASHER

5/8” NUT

1/2” BOLT

3/8” SPACER

EXISTING FACTORY

14MM FLANGE BOLT

FRONT

4. Tighten the nuts in the following order:

First torque the 1/2" nuts to 70 ft•lb.

Then torque the5/8" nuts to 115 ft•lb, and the 14mm bolts to 85 ft-lb.

REAR

Page 5

1/2” NUT

1/2” LOCK WASHER

1/2” BOLT

5/8” BOLT

1/4” BOLT PLATE

3/8” SPACER

5/8” LOCK WASHER

5/8” NUT

TOOLS REQUIRED

15/16” SOCKET

15/16” WRENCH

3/4” SOCKET

3/4” WRENCH

21MM SOCKET

TORQUE WRENCH

SAFETY GLASSES

FRONT

REAR

2000-2006 TOYOTA TUNDRA :

1. Ream existing hole at the rear of the frame to except a 5/8” bolt and install the 5/8” bolts through the bolt plates and into

the frame. With the 3/8” spacer, 5/8” lock washer, and 5/8” nut bolt the brackets to the frame. Leave the bolts loose

enough to center bracket on frame of truck. Do not install fasteners in the forward hole in the brackets at this time.

2. Install the center section to the brackets as shown. Use the bolting location indicated. Install 1/2” bolts through the center

section and the bracket as shown. Install 1/2” lock washers and nuts on the bolts.

3. Using the forward most holes in the brackets as a guide drill a 5/8” hole and install the 5/8” bolts with 1/4” bolt plates

through the frame and brackets. Then install the 3/8” spacer, 5/8” lock washer, and 5/8” nuts.

NOTE: Be sure to use four holes to bolt the brackets to the center section.

4. Tighten the nuts in the following order:

First torque the 1/2" nuts to 70 ft•lb.

Then torque the 5/8" nuts to 115 ft•lb.

NOTE: SIDE BRACKETS MAY DEFLECT WHEN TIGHTENED

Page 6

3/8” SPACER

5/8” BOLT

1/4” BOLT PLATE

TOOLS REQUIRED

15/16” SOCKET

15/16” WRENCH

3/4” SOCKET

3/4” WRENCH

5/8" DRILL BIT

TORQUE WRENCH

3/8” SPACER

5/8” LOCK WASHER

5/8” NUT

1/2” BOLT

5/8” LOCK WASHER

5/8” NUT

FRONT

1/2” NUT

REAR

1971-1993 Dodge Pick Up:

1. Insert a 5/8” bolt with a 1/4” bolt plate down through the 1” diameter hole at the end of the frame. Do this on both sides. Fasten the frame

brackets as shown, to the frame with 3/8" thick spacers, lock washers and nuts. Leave the bolts loose enough to center bracket on frame of

truck.

2. Install the center section between the brackets as shown. Bolt through the center section and the brackets with 1/2” bolts, lock washers and

nuts. Use the holes shown. Leave the nuts finger tight at this time. Some spare tire carriers may need to be modified if the hitch hits the

carrier. NOTE: Be sure to use four holes to bolt the brackets to the center section.

3. Using the hole in the bracket as a guide, drill a 5/8” diameter hole through the frame. Use the farthest front hole. Do this on both sides.

4. Insert 5/8” bolts with 1/4” bolt plates down through the frame and the bracket. Install 3/8” thick spacers, 5/8” lock washers and nuts on the

bolts.

5. Tighten the nuts in the following order:

First torque the 1/2" nuts to 70 ft•lb.

Then torque the 5/8" nuts to 115 ft•lb.

1/2” LOCK WASHER

NOTE: SIDE BRACKETS WILL DEFLECT WHEN TIGHTENED

Page 7

FRAME

3/8” SPACER

5/8” LOCK WASHER

5/8” NUT

1/2” BOLT

5/8” BOLT

1/4” BOLT PLATE

3/8” SPACER

TOOLS REQUIRED

5/8” DRILL BIT

3/8” DRILL BIT

15/16” SOCKET

15/16” WRENCH

3/4” SOCKET

3/4” WRENCH

13MM SOCKET

9/16” SOCKET

9/16” WRENCH

TORQUE WRENCH

RE-ATTATCH

EXHAUST

HANGER IN ONE

OF THESE HOLES

FRONT

3/8” SPACER

1/2” NUT

1/2” LOCK WASHER

REAR

1994-2001 and 2002 2500/3500 Dodge Pick Up Short Bed:

1. The spare tire may need to be loosened for installation.

2. Bolt the brackets to the frame as shown with a 5/8” bolt and 1/4” bolt plate inserted through the 1” diameter hole in the end of the frame. Install

two 3/8” thick spacers between the frame and brackets at the rear bolting locations. Install 3/8" thick spacers, lock washers and nuts on the

bolts. NOTE: For some models, the exhaust hanger will need to be unbolted from the frame.

3. Install the center section between the brackets as shown. Use the hole pattern that works best for your truck. Insert 1/2" bolts through the

center section and the brackets. Install 1/2” lock washers and nuts on the bolts. Finger tighten the bolts at this time. NOTE: Be sure to use four

holes to bolt each bracket to the center section.

4. Using the hole in the bracket as a guide, drill a 5/8" hole through the frame. Use the hole shown in the diagram. Install 5/8” bolts with bolt

plates into the holes. Be sure to insert two 3/8” thick spacers between the frame and the brackets. Install 3/8” thick spacers, lock washers and

nuts on the bolts.

5. If the exhaust hanger was removed, drill a 3/8” hole through the hanger and attach it to the hitch bracket in one of the holes indicated. Use the

3/8" hardware provided to re-attach the exhaust hanger.

6. Tighten the nuts in the following order:

First torque the 1/2" nuts to 70 ft•lb.

Then torque the 5/8" nuts to 115 ft•lb.

7. If the spare tire was loosened, retighten it now.

Page 8

FRAME

1/2” BOLT

5/8” BOLT

1/4” BOLT PLATE

3/8” SPACER

3/8” SPACER

5/8” LOCK WASHER

5/8” NUT

TOOLS REQUIRED

3/8” DRILL BIT

15/16” SOCKET

15/16” WRENCH

3/4” SOCKET

3/4” WRENCH

13MM SOCKET

9/16” SOCKET

9/16” WRENCH

TORQUE WRENCH

RE-ATTATCH EXHAUST

HANGER IN ONE OF

THESE HOLES

FRONT

3/8" SPACER

1/2” NUT

1/2” LOCK WASHER

REAR

1994-2001 and 2002 2500/3500 Dodge Pick Up Long Bed:

1. The spare tire may need to be loosened for installation.

2. Bolt the brackets to the frame as shown with a 5/8” bolt and 1/4” bolt plate inserted through the 1” diameter hole in the end of the frame. Install

two 3/8” thick spacers between the frame and brackets at the rear bolting locations. Install 3/8" thick spacers, lock washers and nuts on the

bolts. NOTE: For some models, the exhaust hanger will need to be unbolted from the frame.

3. Install the center section between the brackets as shown. Use the hole pattern that works best for your truck. Insert 1/2” bolts through the

center section and the brackets. Install 1/2” lock washers and nuts on the bolts. Finger tighten the bolts at this time. NOTE: Be sure to use four

holes to bolt each bracket to the center section.

4. Insert a 5/8” bolt with a 1/4" bolt plate through the 1” hole in the frame and into the bracket as shown. Insert two 3/8” thick spacers between

the frame and the bracket. Install a 3/8” thick spacer, 5/8” lock washer and nut on the bolt. Do this on both sides.

5. If the exhaust hanger was removed, drill a 3/8” hole through the hanger and attach it to the hitch bracket in one of the holes indicated. Use the

3/8" hardware provided to re-attach the exhaust hanger.

6. Tighten the nuts in the following order:

First torque the 1/2" nuts to 70 ft•lb.

Then torque the 5/8" nuts to 115 ft•lb.

7. If the spare tire was loosened, retighten it now.

Page 9

Vous pouvez tout apporter.

PLYMOUTH, MICH.

INSTRUCTIONS D’INSTALLATION

ATTELAGE POLYVALENT

POUR CAMIONNETTES

NO DE PRODUIT

37034

PAQUET DE

PETITES PIÈCES 37424

AVERTISSEMENT: Ne lubrifiez pas les filets; serrer excessivement les

boulons pourrait les endommager ou les briser.

AVERTISSEMENT: Ne percez ni soudez cet attelage.

CADRE

RONDELLE DE

BLOCAGE DE 1/2”

ÉCROU DE 1/2”

RIVET AU CADRE

BOULON DE 1/2”

CALE DE 3/8”

Utilisez seulement les boulons, les écrous et les rondelles fournis ou

approuvés par Reese pour installer cet attelage.

BOULON DE 5/8”

PLAQUE DE BOULON

DE 1/4"

NOTES IMPORTANTES

OUTILS REQUIS

5/8" FORET

15/16" DOUILLE

15/16" CLÉ

3/4" DOUILLE

3/4" CLÉ

SERRE-JOINTS (2)

CLÉ DYNAMOMÉTRIQUE

CALE DE 3/8”

RONDELLE DE BLOCAGE DE 5/8”

ÉCROU DE 5/8”

AVANT

ARRIÈRE

1973-1996 Ford Camionnette de plein grandeur et 1997 F-250 Heavy Duty / F-350 Heavy Duty:

1. Assemblez les trois pièces de l'attelage au sol avant de l'attacher à la camionnette. Utilisez les boulons striés, les rondelles de blocage, et

les écrous de 1/2" pour boulonner les supports à la section centrale comme illustré. Mettez les supports à l'extérieur de la section centrale.

Mettez les boulons à travers les trous comme montré au diagramme. Gardez les boulons assez desserrés pour pouvoir centrer les supports

par rapport au cadre du véhicule. NOTE : soyez certain d'utiliser trois trous pour boulonner chaque support à la section centrale.

2. Serrez l'attelage au cadre avec une cale de 3/8" d'épaisseur entre l'attelage et le cadre à l'arrière. Alignez les extrémités des supports avec

l'extrémité du cadre comme montré.

3. Utilisez les trous des supports comme guide pour percer des trous de 5/8" de diamètre dans le cadre aux points montrés.

4. Insérez les boulons de 5/8" avec les plaques de boulon vers le bas à travers le cadre et le support. Mettez une cale de 3/8" d'épaisseur

entre le cadre et le support au trou de montage arrière. Installez les cales de 3/8" d'épaisseur, les rondelles de blocage, et les écrous aux

boulons.

5. Serrez les écrous dans l’ordre suivant : d’abord les écrous de 1/2" au couple de 70 pi•lb, puis les écrous de 5/8" au couple de 115 pi•lb.

REMARQUE : LES SUPPORTS LATÉRAUX FLÉCHISSENT AU SERRAGE

Si une assistance ou aide technique est nécessaire pour une installation,

composez le www.reeseprod.com ou appel 1-800-428-7303

37034IN 9-5-07 rev_H PCN9924 © 2007 Cequent Towing Products - Imprimé au Mexique

Page 10

OUTILS REQUIS

15/16” DOUILLE

15/16” CLÉ

3/4” DOUILLE

3/4” CLÉ

5/8" FORET

CLÉ DYNAMOMÉTRIQUE

BOULON DE 5/8”

PLAQUE DE BOULON DE 1/4”

CALE DE 3/8”

RONDELLE DE BLOCAGE DE 5/8”

ÉCROU DE 1/2”

RONDELLE DE BLOCAGE DE 1/2”

CALE DE 3/8”

1998-2004 FORD F-250 & F-350 SUPER DUTY:

1. Alignez le support avec le rebord arrière du cadre. Attachez les

supports au cadre comme montré, en insérant les boulons de 5/8"

avec les plaques de boulons vers le bas à travers les trous arrière du

cadre. Installez les cales de 3/8" d'épaisseur, les rondelles de

blocage de 5/8", et les écrous. Ne serrez pas encore les écrous.

2. Installez la section central de l'attelage comme montré, les supports à l'extérieur de la section centrale.

Boulonnez à travers les trous indiqués. Utilisez les boulons de 1/2" avec les rondelles de blocage et les

écrous. NOTE : utilisez quatre trous pour boulonner chaque support à la section centrale. Serrez les écrous

assez pour que les supports fassent un bon contact avec la section centrale.

3. Utilisez le foret de 5/8" pour percer les deux trous de devant. Installez les boulons de 5/8" avec les plaques

de boulon comme montré. Installez les cales de 3/8" d'épaisseur, les rondelles de blocage et les écrous de

5/8" aux boulons.

4. Serrez les écrous dans l'ordre suivant : Premièrement serrez les écrous de 1/2" au couple de 70 pi•lb.

Ensuite, serrez les écrous de 5/8" au couple de 115 pi•lb.

BOULON DE 1/2”

OUTILS REQUIS

15/16” DOUILLE

15/16” CLÉ

3/4” DOUILLE

3/4” CLÉ

CLÉ DYNAMOMÉTRIQUE

ÉCROU DE 5/8”

AVANT

ARRIÈRE

BOULON DE 5/8”

PLAQUE DE BOULON DE 1/4”

CALE DE 3/8”

CALE DE 3/8”

ÉCROU DE 1/2”

RONDELLE DE BLOCAGE DE 1/2”

BOULON DE 1/2”

CALE DE 3/8”

1997-2003 FORD F-150 et F-250 LÉGER:

HÉRITAGE 2004 DE FORD F-150 (VIEILLE CARROSSERIE)

1. Alignez le support avec le rebord arrière du cadre. Mettez les cales

de 3/8" d'épaisseur entre le support et le cadre comme montré.

Attachez les supports au cadre comme montré au moyen des

boulons de 5/8" et les plaques de boulon installés vers le bas à

travers le cadre, les cales, et les supports. Installez les boulons

dans les premiers et les derniers trous des supports. Installez les

cales de 3/8" d'épaisseur avec les rondelles de blocage de 5/8" et

les écrous aux boulons. Ne serrez pas encore les écrous.

2. Installez la section central de l'attelage comme montré, les supports à l'intérieur de la section centrale.

Utilisez les boulons de 1/2" avec les rondelles de blocage et les écrous. NOTE : utilisez quatre trous pour

boulonner chaque support à la section centrale.

3. Serrez les écrous dans l'ordre suivant : Premièrement serrez les écrous de 1/2" au couple de 70 pi•lb.

Ensuite, serrez les écrous de 5/8" au couple de 115 pi•lb.

RONDELLE DE BLOCAGE

DE 5/8 ”

ÉCROU DE 5/8”

AVANT

ARRIÈRE

Page 11

BOULON DE 5/8"

PLAQUETTE DE

BOULON 1/4"

BOULON DE 5/8"

ENTRETOISE

DE 3/8"

PLAQUETTE DE

BOULON 1/4"

ENTRETOISE

DE 3/8"

ENTRETOISE

DE 3/8"

RONDELLE DE

BLOCAGE DE 5/8"

OUTILS REQUIS

DOUILLE 15/16"

CLÉ 15/16"

DOUILLE 3/4"

CLÉ 3/4"

CLÉ 19 mm

DOUILLE 19 mm

DOUILLE 15 mm

CLÉ 15 mm

PERCEUSE 5/8"

CLÉ DYNOMOMÉTRIQUE

Trou 4

ÉCROU DE 5/8"

BOULON DE 1/2"

Trou 3

Trou 2

AVANT

Trou 1

ARRIÈRE

CHEVROLET ET GMC (CLASSIC) (1988-2000) :

1. Vous devez retirer les boulons de 12 mm et les boulons soudés à l'extrémité du cadre (portez des lunettes de protection). 1ère méthode :

retirez à moitié le boulon de 12 mm. Faites monter le boulon en tappant dessus avec un marteau à panne ronde, de manière à décoller

l’écrou. Élargissez le trou du boulon à 5/8" de diamètre. 2ème méthode : retirez le boulon de 12 mm et jetez-le. Percez l’écrou à l’aide d’un

foret de 5/8". Retirez ensuite la partie restante avec un marteau et un burin. Certains véhicules sont équipés d’un boulon supplémentaire de 8

mm du côté passager. Ôtez le boulon et replacez-le, la tête au bas du cadre.

2. Si votre véhicule est équipé de rivets ou d’un boulon de 8 mm dans le bas du cadre, vous devrez insérer une entretoise de 3/8" entre le cadre

et le support, à chaque point de boulonnage. Elles permettent de créer un espace entre le support et la tête du rivet ou du boulon de 8 mm.

Vous ne devez pas boulonner le support directement contre les rivets ou contre le boulon de 8 mm.

3. À l’aide de la quincaillerie fournie, insérez un boulon de de 5/8" de diamètre avec plaquette dans le trou formé par le retrait de l’écrou de

12 mm. Fixez le support sur le cadre (voir illustration). Sur les caisses courtes, utilisez le trou 2. Sur les caisses longues, utilisez le trou 1.

NOTE : CERTAINS SYSTÈMES À ÉCHAPPEMENT DOUBLE PEUVENT COINCER LE SUPPORT. VOUS DEVEZ ALORS MODIFIER

L’ÉCHAPPEMENT. Fixez le support avec une entretoise de 3/8", une rondelle de blocage de 5/8" et un écrou de 5/8".

4. (Caisses courtes) : insérez les boulons de 5/8" avec les plaques de boulons vers le bas à travers les trous de 1" de diamètre dans le cadre, et

dans les trous (4) au support. Installez une cale de 3/8" d'épaisseur, une rondelle de blocage de 5/8", et un écrou à chaque boulon. Ne serrez

pas encore les écrous.

5. (Caisses longues) : insérez les boulons de 5/8" avec les plaques de boulons vers le bas à travers les trous de 1" de diamètre dans le cadre, et

dans les trous (3) au support. Si les trous de devant sont du diamètre de 1/2", utilisez le foret de 5/8" pour les élargir. Installez une cale de 3/8"

d'épaisseur, une rondelle de blocage, et un écrou de 5/8" à chaque boulon. Ne serrez pas encore les écrous.

6. Mettez la section centrale entre les supports comme montré. Il peut être nécessaire de desserrer le pneu de rechange. Boulonnez à travers la

section centrale et les supports, en utilisant les boulons, les rondelles de blocage, et les écrous de 1/2". NOTE : utilisez quatre trous pour

boulonner chaque support à la section centrale.

7. Serrez les écrous dans l'ordre suivant : premièrement serrez les écrous de 1/2" au couple de 70 pi•lb. Ensuite, serrez les écrous de 5/8" au

couple de 115 pi•lb.

8. Resserrer le pneu de rechange s'il a été desserré.

9. Assurez-vous que le pneu de rechange ne frotte pas le tuyau de freins. Si nécessaire, pliez un peu le support de montage du tuyau de freins

pour qu'il y ait suffisamment d'espace entre le pneu et le tuyau de freins.

RONDELLE DE

BLOCAGE DE 1/2"

ÉCROU DE 1/2"

Page 12

OUTILS REQUIS

15/16” DOUILLE

15/16” CLÉ

3/4” DOUILLE

3/4” CLÉ

21MM DOUILLE

CLÉ DYNAMOMÉTRIQUE

BOULON DE 5/8”

PLAQUE DE BOULON DE 1/4”

CALE DE 3/8”

RONDELLE DE BLOCAGE DE 5/8”

ÉCROU DE 1/2”

RONDELLE DE BLOCAGE DE 1/2”

1999-2007 1500, 1999-2004 2500LD CHEVY SILVERADO ET

GMC SIERRA (CAISSES LONGUES) :

1. Retirez le boulon de 14mm du bas du cadre, en utilisant une

douille de 21mm.

2. Attachez les supports en insérant les boulons de 14mm

retirés à l'étape 1 et une cale de 3/8" d'épaisseur dans les

trous indiqués. Insérez un boulon de 5/8" avec une plaque

de boulon de 1/4" à travers le grand trou du cadre et dans le

support comme montré. Installez les cales de 3/8"

d'épaisseur, les rondelles de blocage, et les écrous de 5/8"

aux boulons. Ne serrez pas les boulons.

3. Installez la section centrale entre les supports comme

montré. Utilisez les trous de boulon indiqués. Installez les

boulons de 1/2" à travers la section centrale et le support

comme montré. Installez les rondelles de blocage et les

écrous de 1/2" aux boulons. NOTE: utilisez quatre trous

pour boulonner chaque support à la section centrale.

4. Serrez les écrous dans l'ordre suivant : Premièrement serrez les écrous de 1/2" au couple de 70 pi•lb.

Ensuite, serrez les écrous de 5/8" au couple de 115 pi•lb, et les boulons de 14mm au couple de 85 pi•lb.

BOULON À EMBASE EXISTANT

BOULON DE 1/2”

CALE DE 3/8”

OUTILS REQUIS

15/16” DOUILLE

15/16” CLÉ

3/4” DOUILLE

3/4” CLÉ

21MM DOUILLE

CLÉ DYNAMOMÉTRIQUE

ÉCROU DE 1/2”

RONDELLE DE BLOCAGE DE 1/2”

BOULON DE 1/2”

ÉCROU DE 5/8”

AVANT

ARRIÈRE

BOULON DE 5/8”

PLAQUE DE BOULON DE 1/4”

CALE DE 3/8”

RONDELLE DE BLOCAGE DE 5/8”

ÉCROU DE 5/8”

1999-2007 1500, 1999-2004 2500LD CHEVY SILVERADO ET

GMC SIERRA (CAISSES COURTES) :

1. Retirez le boulon de 14mm du bas du cadre, en utilisant une

douille de 21mm.

2. Attachez les supports en insérant les boulons de 14mm retirés

à l'étape 1 et une cale de 3/8" d'épaisseur dans les trous

indiqués. Insérez un boulon de 5/8" avec une plaque de boulon

de 1/4" à travers le grand trou du cadre et dans le support

comme montré. Installez les cales de 3/8" d'épaisseur, les

rondelles de blocage, et les écrous de 5/8" aux boulons. Ne

serrez pas les boulons.

3. Installez la section centrale entre les supports comme montré.

Utilisez les trous de boulon indiqués. Installez les boulons de

1/2" à travers la section centrale et le support comme montré.

Installez les rondelles de blocage et les écrous de 1/2" aux

boulons. NOTE: utilisez quatre trous pour boulonner chaque

support à la section centrale.

4. Serrez les écrous dans l'ordre suivant : Premièrement serrez les écrous de 1/2" au couple de 70 pi•lb.

Ensuite, serrez les écrous de 5/8" au couple de 115 pi•lb, et les boulons de 14mm au couple de 85 pi•lb.

BOULON À EMBASE EXISTANT

CALE DE 3/8”

AVANT

ARRIÈRE

Page 13

ÉCROU DE 1/2"

RONDELLE DE BLOCAGE

DE 1/2"

BOULON DE 5/8"

PLAQUETTE DE 1/4"

ENTRETOISE DE 3/8"

RONDELLE DE BLOCAGE DE 5/8"

ÉCROU DE 5/8"

BOULON DE 1/2"

OUTILS REQUIS

DOUILLE 15/16"

CLÉ 15/16"

DOUILLE 3/4"

CLÉ 3/4"

DOUILLE 21mm

CLÉ DYNAMOMÉTRIQUE

LUNETTES DE SÉCURITÉ

AVANT

ARRIÈRE

TOYOTA TUNDRA (2000-2006) :

1. Élargissez le trou pratiqué à l’arrière du cadre et insérez les boulons de 5/8" dans le cadre, à travers les plaquettes. À l’aide de

l’entretoise de 3/8", de la rondelle de blocage et de l’écrou de 5/8", fixez les supports au cadre. Gardez les boulons assez desserrés

pour pouvoir centrer les supports par rapport au cadre du véhicule. N’installez pas de boulon dans le trou avant des supports pour le

moment.

2. Raccordez la section centrale aux supports comme illustré. Utilisez les emplacements de boulonnage indiqués. Insérez les

boulons de 1/2" dans la section centrale et les supports, comme illustré. Posez les rondelles de blocage et les écrous de 1/2" sur les

boulons.

3. En vous servant des trous avant extrêmes comme guides, percez un trou de 5/8" et insérez les boulons de 5/8" dans le cadre

et les supports, à travers les plaquettes de 1/4". Placez l’entretoise de 3/8", la rondelle de blocage et les écrous de 5/8".

REMARQUE : assurez-vous de bien utiliser les quatre trous pour le boulonnage des supports sur la section centrale.

4. Serrez les écrous dans l’ordre suivant :

d’abord les écrous 1/2" à 70 pi•lb.

puis les écrous 5/8" à 115 pi•lb.

REMARQUE : LES SUPPORTS LATÉRAUX FLÉCHISSENT AU SERRAGE

Page 14

BOULON DE 5/8”

PLAQUE DE BOULON DE 1/4”

CALE DE 3/8”

OUTILS REQUIS

15/16” DOUILLE

15/16” CLÉ

3/4” DOUILLE

3/4” CLÉ

5/8" FORET

CLÉ DYNAMOMÉTRIQUE

CALE DE 3/8”

RONDELLE DE BLOCAGE DE 5/8”

ÉCROU DE 5/8”

BOULON DE 1/2”

RONDELLE DE BLOCAGE

ÉCROU DE 5/8”

DE 5/8”

AVANT

ARRIÈRE

1971-1993 Camionnette Dodge :

1. Insérez un boulon de 5/8" avec une plaque de boulon vers le bas à travers le trou de 1" de diamètre à l'extrémité du cadre. Faites ceci des

deux côtés. Attachez les supports au cadre comme montré, en utilisant les cales de 3/8" d'épaisseur, les rondelles de blocage de 5/8", et les

écrous. Gardez les boulons assez desserrés pour pouvoir centrer les supports par rapport au cadre du véhicule.

2. Installez la section centrale entre les supports comme montré, en insérant les boulons de 1/2" à travers la section centrale et les supports.

Installez les rondelles de blocage et les écrous de 1/2". Utilisez les trous indiqués. Serrez légèrement à la main. Certains porteurs de pneu de

rechange peuvent avoir besoin d'être modifiés si l'attelage contacte le porteur. NOTE : utilisez quatre trous pour boulonner chaque support à

la section centrale.

3. En utilisant le trou du support comme guide, percez un trou de 5/8" à travers le cadre. Utilisez le trou le plus vers l'avant. Faites ceci des deux

côtés.

4. Insérez les boulons de 5/8" avec les plaques de boulon de 1/4" vers le bas à travers le cadre et les supports. Installez les cales de 3/8"

d'épaisseur, les rondelles de blocage, et les écrous de 5/8" aux boulons.

5. Serrez les écrous dans l'ordre suivant :

Premièrement serrez les écrous de 1/2" au couple de 70 pi•lb.

Ensuite, serrez les écrous de 5/8" au couple de 115 pi•lb.

ÉCROU DE 1/2”

RONDELLE DE BLOCAGE

DE 1/2”

REMARQUE : LES SUPPORTS LATÉRAUX FLÉCHISSENT AU SERRAGE

Page 15

CADRE

BOULON DE 5/8”

PLAQUE DE BOULON DE 1/4”

CALE DE 3/8”

CALE DE 3/8”

RONDELLE DE BLOCAGE DE 5/8”

ÉCROU DE 5/8”

BOULON DE 1/2”

OUTILS REQUIS

5/8” FORET

3/8” FORET

15/16” DOUILLE

15/16” CLÉ

3/4” DOUILLE

3/4” CLÉ

13MM DOUILLE

9/16” DOUILLE

9/16” CLÉ

CLÉ DYNAMOMÉTRIQUE

RATTACHEZ LE

SUPPORT

D'ÉCHAPPEMENT

DANS UN DE CES

TROUS

AVANT

CALE DE 3/8”

ÉCROU DE 1/2”

RONDELLE DE BLOCAGE DE 1/2”

ARRIÈRE

1994-2001 et 2002 2500/3500 Camionnette Dodge à caisse courte :

1. Il peut être nécessaire de desserrer le pneu de rechange pendant l'installation.

2. Attachez les supports au cadre comme montré en utilisant un boulon de 5/8" et une plaque de boulon insérés à travers le trou de 1" de

diamètre à l'extrémité du cadre. Installez deux cales de 3/8" d'épaisseur entre le cadre et les supports aux points de montage arrière. Installez

les cales de 3/8" d'épaisseur, les rondelles de blocage de 5/8", et les écrous aux boulons. NOTE : sur certains modèles, il faut déboulonner le

support de l'échappement du cadre.

3. Installez la section centrale entre les supports comme montré. Utilisez les trous qui donnent le meilleur positionnement pour votre véhicule.

Insérez les boulons de 1/2" à travers la section centrale et les supports. Installez les rondelles de blocage et les écrous de 1/2" aux boulons.

Serrez légèrement à la main. NOTE : utilisez quatre trous pour boulonner chaque support à la section centrale.

4. En utilisant les trous des supports comme guide, percez des trous de 5/8" au cadre. Utilisez les trous indiqués au diagramme. Installez les

boulons de 5/8" avec les plaques de boulon aux trous. Il faut insérer deux cales de 3/8" d'épaisseur entre le cadre et les supports. Installez les

cales de 3/8" d'épaisseur, les rondelles de blocage, et les écrous de 5/8" aux boulons.

5. Si le support de l'échappement a été enlevé, percez un trou de 3/8" dans le support et attachez-le au support d'attelage à un des trous

indiqués. Utilisez la quincaillerie de 3/8" pour rattacher le support de l'échappement.

6. Serrez les écrous dans l'ordre suivant :

Premièrement serrez les écrous de 1/2" au couple de 70 pi•lb.

Ensuite, serrez les écrous de 5/8" au couple de 115 pi•lb.

7. Si le pneu de rechange a été desserré, resserrez-le maintenant.

Page 16

CADRE

BOULON DE 5/8”

CALE DE 3/8”

CALE DE 3/8”

RONDELLE DE BLOCAGE DE 5/8”

ÉCROU DE 5/8”

BOULON DE 1/2”

PLAQUE DE BOULON DE 1/4”

OUTILS REQUIS

3/8” FORET

15/16” DOUILLE

15/16” CLÉ

3/4” DOUILLE

3/4” CLÉ

13MM DOUILLE

9/16” DOUILLE

9/16” CLÉ

CLÉ DYNAMOMÉTRIQUE

RATTACHEZ LE

SUPPORT

D'ÉCHAPPEMENT

DANS UN DE CES

TROUS

AVANT

CALE DE 3/8”

ÉCROU DE 1/2”

RONDELLE DE BLOCAGE DE 1/2”

ARRIÈRE

1994-2001 et 2002 2500/3500 Camionnette Dodge à caisse longue :

1. Il peut être nécessaire de desserrer le pneu de rechange pendant l'installation.

2. Attachez les supports au cadre comme montré en utilisant un boulon de 5/8" et une plaque de boulon insérés à travers le trou de 1" de

diamètre à l'extrémité du cadre. Installez deux cales de 3/8" d'épaisseur entre le cadre et les supports aux points de montage arrière. Installez

les cales de 3/8" d'épaisseur, les rondelles de blocage de 5/8", et les écrous aux boulons. NOTE : sur certains modèles, il faut déboulonner le

support de l'échappement du cadre.

3. Installez la section centrale entre les supports comme montré. Utilisez les trous qui donnent le meilleur positionnement pour votre véhicule.

Insérez les boulons de 1/2" à travers la section centrale et les supports. Installez les rondelles de blocage et les écrous de 1/2" aux boulons.

Serrez légèrement à la main. NOTE : utilisez quatre trous pour boulonner chaque support à la section centrale.

4. Insérez un boulon de 5/8" avec une plaque de boulon de 1/4" à travers le trou de 1" au cadre et à travers le support comme montré. Insérez

deux cales de 3/8" d'épaisseur entre le cadre et le support. Installez cale de 3/8" d'épaisseur, une rondelle de blocage de 5/8", et un écrou au

boulon. Faites ceci des deux côtés.

5. Si le support de l'échappement a été enlevé, percez un trou de 3/8" dans le support et attachez-le au support d'attelage à un des trous

indiqués. Utilisez la quincaillerie de 3/8" pour rattacher le support de l'échappement.

6. Serrez les écrous dans l'ordre suivant :

Premièrement serrez les écrous de 1/2" au couple de 70 pi•lb.

Ensuite, serrez les écrous de 5/8" au couple de 115 pi•lb.

7. Si le pneu de rechange a été desserré, resserrez-le maintenant.

Page 17

Llévalo contigo.

PLYMOUTH, MICH.

INSTRUCCIONES DE INSTALACIÓN

ENGANCHE MULTICOMPATIBLE

PARA CAMIONETAS

Producto No.

37034

PAQUETE DE PIEZAS

PEQUEÑAS 37424

ADVERTENCIA: No lubrique las roscas; los tornillos pueden romperse

debido a una torsión excesiva.

ADVERTENCIA: No taladre ni suelde en este enganche.

CONVERSIÓN

1/4" = 6,25 mm

3/8" = 9,5 mm

1/2" = 12,7 mm

5/8" = 15,875 mm

ARANDELA DE

PRESIÓN DE 1/2”

TUERCA DE 1/2”

SEPARADOR DE 3/8”

ESTRUCTURA

REMACHE EN

LA ESTRUCTURA

TORNILLO DE 1/2”

Use solamente tornillos, contratuercas y arandelas suministrados o

aprobados por REESE para instalar este enganche.

NOTAS IMPORTANTES

EQUIPO

TORNILLO DE 5/8”

CHAPA DE TORNILLO

DE 1/4"

SEPARADOR DE 3/8”

ARANDELA DE PRESIÓN DE 5/8”

TUERCA DE 5/8”

NECESARIO

5/8” BROCA

15/16” DADO

15/16” LLAVE

3/4” DADO

3/4” LLAVE

2 SUJETADORES

LLAVE DE TORSIÓN

FRENTE

TRASERA

1973-1996 Camioneta Ford de Tamaño Completo & 1997 F-250 Trabajo Pesado / F-350 Trabajo Pesado

1. En el suelo, ensamble las tres piezas del enganche antes de unirlas a la camioneta. Use los tornillos de 1/2”, las arandelas de presión y las

tuercas para atornillar los soportes a la sección central, así como se ilustra. Coloque los soportes en la parte exterior de la sección central.

Atornille a través de los agujeros que se muestran en la ilustración. Deje los tronillos lo suficientemente sueltos para centrar los soportes en el

marco de la camioneta. NOTA: Asegúrese de usar los cuatro agujeros para atornillar cada soporte a la sección central.

2. Usando un sujetador, una el enganche a la estructura, coloque un separador de 3/8” de grosor en la parte trasera, entre el enganche y la

estructura. Alinee las terminaciones de los soportes con la terminación de la estructura, así como se ilustra.

3. Usando los agujeros del soporte como guía, taladre agujeros de 5/8” en la estructura, en las localidades que se muestran.

4. Inserte tornillos de 5/8” junto con chapas de tornillo a través de la estructura y del soporte. Coloque una separador grueso de 3/8” entre la

estructura y el soporte en el agujero de montaje trasero. Instale los separadores gruesos de 3/8", las arandelas de presión, y las tuercas en los

tornillos.

5. Apriete las tuercas en el orden siguiente: Apriete primero las tuercas de 1/2" a 70 pies•lb. Luego apriete las tuercas de 5/8" a 115 pies•lb.

NOTA: LOS SOPORTES LATERALES SE COMBARÁN AL APRETARLOS

Si Necesita Ayuda para la Instalación o Ayuda Técnica, Llame al

www.reeseprod.com o 1-800-428-7303

37034IN 9-5-07 rev_H PCN9924 © 2007 Cequent Towing Products

- Impreso en México

Page 18

EQUIPO

NECESARIO

15/16” DADO

15/16” LLAVE

CONVERSIÓN

1/4" = 6,25 mm

3/8" = 9,5 mm

1/2" = 12,7 mm

5/8" = 15,875 mm

TORNILLO DE 5/8”

CHAPA DE TORNILLO

DE 1/4"

3/4” DADO

3/4” LLAVE

5/8" BROCA

LLAVE DE TORSIÓN

TUERCA DE 1/2”

ARANDELA DE PRESIÓN DE 1/2”

SEPARADOR DE 3/8”

1998-2004 FORD F-250 & F-350 "SUPER DUTY"

1. Alinee el soporte con el borde trasero de la estructura. Pase los

tornillos de 5/8” junto con chapas de tornillo a través de los

agujeros traseros de la estructura para así unir los soportes a la

misma, así como se ilustra. Instale en estos tornillos separadores

de 3/8” de grosor, arandelas de presión y tuercas. Por ahora, deje

éstas tuercas flojas.

2. Instale la sección central del enganche así como se ilustra, con los soportes de la estructura en la parte

exterior de la sección central. Atornille a través de los agujeros así como se ilustra. Use tornillos de 1/2”

con arandelas de presión y tuercas. NOTA: Asegúrese de usar los cuatro agujeros para atornillar los

soportes a la sección central. Apriete lo suficiente como para hacer que los soportes entren en contacto

directo con la sección central.

3. Con la broca de 5/8”, taladre los dos agujeros delanteros. Instale fijadores así como se ilustra. Instale

separadores de 3/8” de grosor, arandelas de presión de 5/8” y tuercas en los tornillos. Por ahora, deje

estas tuercas flojas.

4. Apriete las tuercas en el orden siguiente: Apriete primero las tuercas de 1/2” a una torsión de 70 pies•libra

(95 N•m). Luego apriete las tuercas de 5/8” a 115 pies•libra (156 N•m).

TORNILLO DE 1/2”

SEPARADOR DE 3/8”

ARANDELA DE PRESIÓN DE 5/8”

TUERCA DE 5/8”

FRENTE

TRASERA

EQUIPO

NECESARIO

15/16” DADO

CONVERSIÓN

1/4" = 6,25 mm

3/8" = 9,5 mm

1/2" = 12,7 mm

5/8" = 15,875 mm

15/16” LLAVE

3/4” DADO

3/4” LLAVE

LLAVE DE TORSIÓN

TUERCA DE 1/2”

ARANDELA DE PRESIÓN DE 1/2”

SEPARADOR DE 3/8”

1997-2003 FORD F-150 & F-250 PARA TRABAJO LIVIANO

HERENCIA 2004 DE FORD F-150 (VIEJA CARROCERÍA)

1. Alinee el soporte con el borde trasero de la estructura. Coloque

separadores de 3/8” de grosor entre el soporte y la estructura, así como se

ilustra. Pase los tornillos de 5/8” junto con chapas de tornillo a través de la

estructura, los separadores y el soporte. Atornille en el primero y último

agujero del soporte. Instale un separador grueso de 3/8” junto con una

arandela de presión y tuerca de 5/8” en cada tornillo. Por ahora, deje estas

tuercas flojas.

2. Instale la sección central del enganche con los soportes de la estructura en

la parte interior de la sección central, así como se ilustra. Use tornillos de

1/2” con arandelas de presión y tuercas. NOTA: Asegúrese de usar los

cuatro agujeros para atornillar cada soporte a la sección central.

3. Apriete las tuercas en el orden siguiente:

Apriete primero las tuercas de 1/2” a una torsión de 70 pies•libra (95 N•m).

Luego apriete las tuercas de 5/8” a 115 pies•libra (156 N•m).

TORNILLO DE 5/8”

CHAPA DE TORNILLO

DE 1/4"

SEPARADOR DE 3/8”

SEPARADOR DE 3/8”

ARANDELA DE PRESIÓN

DE 5/8”

TUERCA DE 5/8”

TORNILLO DE 1/2”

FRENTE

TRASERA

Page 19

HERRAMIENTAS

TORNILLO DE 5/8"

PLACA DE

TORNILLOS DE 1/4"

TORNILLO DE 5/8"

ESPACIADOR

DE 3/8"

TORNILLO DE 1/2"

PLACA DE TORNILLOS

DE 1/4"

ESPACIADOR DE 3/8"

ESPACIADOR DE 3/8"

ARANDELA DE

SEGURIDAD DE 5/8"

TUERCA DE 5/8"

REQUERIDAS

COPA DE 15/16"

LLAVE DE 15/16"

COPA DE 3/4"

LLAVE DE 3/4"

LLAVE DE 19MM

COPA DE 19MM

COPA DE 15MM

LLAVE DE 15MM

TALADRO DE 5/8"

LLAVE DE TORQUE

Agujero 4

Agujero 3

Agujero 2

ADELANTE

Agujero 1

ATRÁS

1988-2000 CHEVY & GMC (CLÁSICO)

1. Los tornillos de 12mm de diámetro y las tuercas soldadas al final del marco deben ser removidos. (Use Protección de Ojos)

Método 1) Afloje el tornillo de 12mm hasta la mitad. Empuje el tornillo hacia arriba golpeándolo en la cabeza con un martillo de bola

para reventar la tuerca. Amplíe el agujero del tornillo hasta 5/8" de diámetro. Método 2) Retire y descarte el tornillo de 12mm.

Utilizando una broca de 5/8", taladre la tuerca hasta que caiga. Luego, retire los sobrantes con cincel y martillo. Algunos vehículos

tienen un tornillo de 8mm adicional en el lado del pasajero. Retire el tornillo y reinstálelo con la cabeza en la parte inferior del marco.

2. Si su vehículo tiene remaches en la parte inferior del marco o tornillo de 8mm, usted necesitará instalar un espaciador de 3/8" de grueso

entre el marco y el soporte en cada punto de anclaje. Estos se necesitan para dar holgura entre el soporte y la cabeza del remache o del

tornillo de 8mm. El soporte no puede ser atornillado directamente contra los remaches o el tornillo de 8mm.

3. Utilizando los herrajes suministrados, inserte un tornillo de 5/8" de diámetro con placa de tornillo hacia abajo a través del agujero creado

al retirar la tuerca de 12mm. Asegure el soporte al marco. Vea la ilustración. Para platón corto use el agujero 2. En platón largo use

agujero 1. NOTA: ALGUNOS SISTEMAS DE ESCAPE DOBLES GOLPEARÁN EL SOPORTE. EL ESCAPE NECESITARÁ SER

MODIFICADO. Fije con espaciador de 3/8", arandela de seguridad de 5/8" y tuerca de 5/8".

4. (Cabina Corta): Inserte los tornillos de 5/8"junto con chapas de tornillo a través del agujero de 1"de diámetro que se encuentra en la

estructura y a través del agujero (4) del soporte. Instale un separador de 3/8"de grosor, arandela de presión de 5/8", y tuerca en cada

tornillo. Por ahora, deje estas tuercas flojas.

5. (Cabina Larga): Inserte los tornillos de 5/8"junto con chapas de tornillo a través del agujero de 1"de diámetro que se encuentra en la

estructura y a través del agujero (3) del soporte. Si los agujeros delanteros sean de diámetro de 1/2", use la broca de 5/8" para

agrandarlos. Instale un separador de 3/8"de grosor, arandela de presión de 5/8", y tuerca en cada tornillo. Por ahora, deje estas tuercas

flojas.

6. Coloque la sección central entre los soportes, así como se ilustra. Es posible que sea necesario aflojar la llanta de repuesto. Atornille a

través de la sección central y el soporte usando tornillos de 1/2", arandelas de presión y tuercas. NOTA: Asegúrese de usar los cuatro

agujeros para atornillar los soportes a la sección central.

7. Apriete las tuercas en el orden siguiente:

Apriete primero las tuercas de 1/2"a una torsión de 70 pies•libra (95 N•m).

Luego apriete las tuercas de 5/8"a 115 pies•libra (156 N•m), y los tornillos de 12mm a 75 pies•libra (102 N•m).

8. Apriete nuevamente la llanta de repuesto, si fue aflojada.

9. Asegúrese de que la llanta de repuesto no esté rozando con la manguera de freno. Si es necesario, doble un poquito el soporte en el

cual la manguera está instalada para así crear un espacio libre entre la llanta y la manguera de freno.

ARANDELA DE SEGURIDAD

DE 1/2"

TUERCA DE 1/2"

Page 20

EQUIPO

NECESARIO

15/16” DADO

CONVERSIÓN

1/4" = 6,25 mm

3/8" = 9,5 mm

1/2" = 12,7 mm

5/8" = 15,875 mm

TORNILLO DE 5/8”

CHAPA DE TORNILLO

DE 1/4"

15/16” LLAVE

3/4” DADO

SEPARADOR DE 3/8”

3/4” LLAVE

21MM DADO

ARANDELA DE PRESIÓN DE 5/8”

LLAVE DE TORSIÓN

TUERCA DE 5/8”

TUERCA DE 1/2”

ARANDELA DE

PRESIÓN DE 1/2”

1999-2007 1500, 1999-2004 2500LD CHEVY SILVERADO Y GMC

SIERRA (CABINA LARGA):

1. Desatornille el tornillo de 14mm que se encuentra en la parte baja

de la estructura usando un dado de 21mm.

2. Atornille los soportes usando el tornillo de 14mm que acaba de

desatornillar y un separador de 3/8" de grosor, use el agujero que

se indica. Inserte un tornillo de 5/8” junto con una chapa de 1/4” a

través del agujero grande que se encuentra en la estructura y a

través del soporte, así como se ilustra. Instale separadores de 3/8”

de grosor, las arandelas de presión de 5/8” y las tuercas en los

tornillos. Por ahora, deje estas tuercas flojas.

3. Instale la sección central entre los soportes, así como se ilustra.

Use el punto de atornillaje que se indica. Instale tornillos de 1/2” a

través de la sección central y el soporte, así como se ilustra.

Instale arandelas de presión de 1/2” y tuercas en los tornillos.

NOTA: Asegúrese de usar los cuatro agujeros para atornillar cada

soporte a la sección central.

4. Apriete las tuercas en el orden siguiente:

Apriete primero las tuercas de 1/2” a una torsión de 70 pies•libra (95 N•m).

Luego apriete las tuercas de 5/8” a 115 pies•libra (156 N•m), y los tornillos de 14mm a 85 pies•libra (115 N•m).

TORNILLO DE 14MM CON

TORNILLO DE 1/2”

SEPARADOR DE 3/8”

PESTAÑA (DE FÁBRICA)

FRENTE

TRASERA

EQUIPO

NECESARIO

15/16” DADO

15/16” LLAVE

CONVERSIÓN

1/4" = 6,25 mm

3/8" = 9,5 mm

1/2" = 12,7 mm

5/8" = 15,875 mm

TORNILLO DE 5/8”

CHAPA DE TORNILLO

DE 1/4"

SEPARADOR DE 3/8”

3/4” DADO

3/4” LLAVE

21MM DADO

LLAVE DE TORSIÓN

1999-2007 1500, 1999-2004 2500LD CHEVY SILVERADO Y GMC SIERRA

(CABINA CORTA):

1. Desatornille el tornillo de 14mm que se encuentra en la parte baja de la

estructura usando un dado de 21mm.

2. Atornille los soportes usando el tornillo de 14mm que acaba de desatornillar y

un separador de 3/8” de grosor, use el agujero que se indica. Inserte un

tornillo de 5/8” junto con una chapa de 1/4” a través del agujero grande que se

encuentra en la estructura y a través del soporte, así como se ilustra. Instale

separadores de 3/8” de grosor, las arandelas de presión de 5/8” y las tuercas

en los tornillos. Por ahora, deje estas tuercas flojas.

3. Instale la sección central entre los soportes, así como se ilustra. Use el punto

de atornillaje que se indica. Instale tornillos de 1/2” a través de la sección

central y el soporte, así como se ilustra. Instale arandelas de presión de 1/2” y

tuercas en los tornillos. NOTA: Asegúrese de usar los cuatro agujeros para

atornillar cada soporte a la sección central.

4. Apriete las tuercas en el orden siguiente:

Apriete primero las tuercas de 1/2” a una torsión de 70 pies•libra (95 N•m).

Luego apriete las tuercas de 5/8” a 115 pies•libra (156 N•m), y los tornillos de 14mm a 85 pies•libra (115 N•m).

TUERCA DE 1/2”

ARANDELA DE

PRESIÓN DE 1/2”

SEPARADOR DE 3/8”

TORNILLO DE 14MM CON

PESTAÑA (DE FÁBRICA)

ARANDELA DE PRESIÓN DE 5/8”

TUERCA DE 5/8”

TORNILLO DE 1/2”

FRENTE

TRASERA

Page 21

TORNILLO DE 5/8"

HERRAMIENTAS

REQUERIDAS

TUERCA

DE 1/2"

ARANDELA DE

SEGURIDAD DE 1/2"

PLACA DE

TORNILLO

DE 1/4"

ESPACIADOR DE 3/8"

ARANDELA DE

SEGURIDAD DE 5/8"

TUERCA DE 5/8"

TORNILLO DE 1/2"

COPA 15/16"

LLAVE 15/16"

COPA 3/4"

LLAVE 3/4"

COPA 21mm

LLAVE DE TORQUE

GAFAS DE SEGURIDAD

FRENTE

ATRÁS

TOYOTA TUNDRA 2000-2006:

1. Amplíe el agujero existente en la parte posterior del marco hasta que acepte un tornillo de 5/8" e instale los tornillos de 5/8" a

través de las placas de tornillos y en el marco. Con el espaciador de 3/8", la arandela de seguridad de 5/8", y una tuerca de

5/8" atornille los soportes al marco. Deje los tornillos lo suficientemente sueltos para centrar el soporte en el marco de la

camioneta. No instale sujetadores en los agujeros delanteros de los soportes en este momento.

2. Instale la sección central en los soportes como se muestra. Use los puntos indicados para los tornillos. Instale tornillos de 1/2" a

través de la sección central y los soportes como se muestra. Instale arandelas de seguridad y tuercas de 1/2" en los

tornillos.

3. Utilizando los agujeros delanteros en los soportes como guía, taladre un agujero de 5/8" e instale los tornillos de 5/8" con las

placas de tornillos de 1/4" a través del marco y los soportes. Instale luego el espaciador de 3/8", la arandela de seguridad de

5/8", y las tuercas de 5/8".

NOTA: Asegúrese de utilizar cuatro agujeros para atornillar los soportes a la sección central.

4. Apriete las tuercas en el siguiente orden:

Primero apriete las tuercas de 1/2" a 70 pies•libra de torque.

Luego apriete las tuercas de 5/8" a 115 pies•libra de torque.

NOTA: LOS SOPORTES LATERALES PUEDEN COMBARSE CUANDO LOS APRIETE

Page 22

CONVERSIÓN

1/4" = 6,25 mm

3/8" = 9,5 mm

1/2" = 12,7 mm

5/8" = 15,875 mm

1" = 25,4 mm

TORNILLO DE 5/8”

CHAPA DE TORNILLO

DE 1/4"

EQUIPO

NECESARIO

15/16” DADO

15/16” LLAVE

3/4” DADO

3/4” LLAVE

LLAVE DE TORSIÓN

SEPARADOR DE 3/8”

ARANDELA DE PRESIÓN DE 5/8”

TUERCA DE 5/8”

TORNILLO DE 1/2”

SEPARADOR DE 3/8”

ARANDELA DE PRESIÓN

TUERCA DE 5/8”

DE 5/8”

FRENTE

TUERCA DE 1/2”

ARANDELA DE

TRASERA

1971-1993 Dodge Camioneta :

PRESIÓN DE 1/2”

1. Inserte un tornillo de 5/8” junto con una chapa de tornillo de 1/4” a través del agujero de 1” de diámetro que se encuentra al final de la

2. Instale la sección central entre los soportes, así como se ilustra. Atornille a través de la sección central y los soportes usando tornillos de

3. Usando el agujero del soporte como guía, taladre un agujero de 5/8” de diámetro a través de la estructura. Use el agujero que se

4. Inserte tornillos de 5/8” junto con chapas de tornillo de 1/4” a través de la estructura y el soporte. Instale separadores de 3/8” de grosor,

5. Apriete las tuercas en el orden siguiente:

estructura. Haga esto en ambos lados. Fije los soportes a la estructura así como se ilustra, use separadores de 3/8" de grosor,

arandelas de presión de 5/8” y tuercas. Deje los tornillos lo suficientemente sueltos para centrar el soporte en el marco de la camionets.

1/2”, arandelas de presión y tuercas. Use los agujeros que se indican. Por ahora, apriete estas tuercas solo con la mano. Es probable

que sea necesario modificar algunos porta-llanta de repuesto si el enganche entra en contacto con el porta-llanta. NOTA: Asegúrese de

usar los cuatro agujeros para atornillar los soportes a la sección central.

encuentra más hacia el frente del vehículo. Haga esto en ambos lados.

arandelas de presión de 5/8” y tuercas en los tornillos.

Apriete primero las tuercas de 1/2” a una torsión de 70 pies•libra (95 N•m).

Luego apriete las tuercas de 5/8” a una torsión de 115 pies•libra (156 N•m).

NOTA: LOS SOPORTES LATERALES SE COMBARÁN AL APRETARLOS

Page 23

CONVERSIÓN

1/4" = 6,25 mm

3/8" = 9,5 mm

1/2" = 12,7 mm

5/8" = 15,875 mm

1" = 25,4 mm

ESTRUCTURA

TORNILLO DE 5/8”

CHAPA DE TORNILLO

DE 1/4"

SEPARADOR DE 3/8”

SEPARADOR DE 3/8”

ARANDELA DE PRESIÓN DE 5/8”

TUERCA DE 5/8”

TORNILLO DE 1/2”

EQUIPO

NECESARIO

5/8” BROCA

3/8” BROCA

15/16” DADO

15/16” LLAVE

3/4” DADO

3/4” LLAVE

13MM DADO

9/16” DADO

9/16” LLAVE

LLAVE DE TORSIÓN

FIJE DE NUEVO EL

COLGADOR DEL

SISTEMA DE

ESCAPE EN UNO DE

ESTOS AGUJEROS

FRENTE

SEPARADOR DE 3/8”

TUERCA DE 1/2”

ARANDELA DE

PRESIÓN DE 1/2”

TRASERA

1994-2001 y 2002 2500/3500 Dodge Camioneta de Cabina Corta:

1. Es probable que sea necesario aflojar la llanta de repuesto antes de comenzar la instalación.

2. Atornille los soportes a la estructura, así como se ilustra. Use un tornillo de 5/8” junto con una chapa de tornillo de 1/4” e insértelos a través del

agujero de 1” de diámetro que se encuentra al final de la estructura. Instale dos separadores de 3/8” de grosor entre la estructura y los soportes

en las localidades de atornillaje traseras. Instale separadores de 3/8” de grosor, arandelas de presión de 5/8" y tuercas en los tornillos.

NOTA: En algunos modelos, el colgador del sistema de escape tendrá que ser desatornillado de la estructura.

3. Instale la sección central entre los soportes, así como se ilustra. Use el patrón de agujeros que va mejor con su camioneta. Inserte los tornillos

de 1/2” a través de la sección central y los soportes. Instale arandelas de presión de 1/2” y tuercas en los tornillos. Por ahora, apriete éstos

tornillos con la mano. NOTA: Asegúrese de usar los cuatro agujeros para atornillar cada soporte a la sección central.

4. Usando el agujero del soporte como guía, taladre un agujero de 5/8” a través de la estructura. Use el agujero que se muestra en el diagrama.

Instale tornillos de 5/8” junto con chapas de tornillo en los agujeros. Asegúrese de insertar dos separadores de 3/8” de grosor entre la estructura

y los soportes. Instale separadores de 3/8” de grosor, arandelas de presión y tuercas en los tornillos.

5. Si el colgador del sistema de escape fue desmontado, taladre un agujero de 3/8” a través del colgador y una el colgador al soporte del

enganche usando uno de los agujeros indicados. Use las piezas de 3/8” que se proveen para atornillar seguramente el colgador del sistema de

escape.

6. Apriete las tuercas en el orden siguiente:

Apriete primero las tuercas de 1/2” a una torsión de 70 pies•libra (95 N•m).

Luego apriete las tuercas de 5/8” a una torsión de 115 pies•libra (156 N•m).

7. Si aflojó la llanta de repuesto, apriétela ahora.

Page 24

CONVERSIÓN

1/4" = 6,25 mm

3/8" = 9,5 mm

1/2" = 12,7 mm

5/8" = 15,875 mm

1" = 25,4 mm

ESTRUCTURA

TORNILLO DE 5/8”

CHAPA DE TORNILLO

DE 1/4"

SEPARADOR DE 3/8”

SEPARADOR DE 3/8”

ARANDELA DE PRESIÓN DE 5/8”

TUERCA DE 5/8”

TORNILLO DE 1/2”

EQUIPO

NECESARIO

3/8” BROCA

15/16” DADO

15/16” LLAVE

3/4” DADO

3/4” LLAVE

13MM DADO

9/16” DADO

9/16” LLAVE

LLAVE DE TORSIÓN

FIJE DE NUEVO EL

COLGADOR DEL

SISTEMA DE ESCAPE EN

FRENTE

SEPARADOR DE 3/8”

TRASERA

1994-2001 y 2002 2500/3500 Dodge Camioneta de Cabina Larga:

1. Es probable que sea necesario aflojar la llanta de repuesto antes de comenzar la instalación.

2. Atornille los soportes a la estructura, así como se ilustra. Use un tornillo de 5/8” junto con una chapa de tornillo de 1/4” e insértelos a través del

agujero de 1” de diámetro que se encuentra al final de la estructura. Instale dos separadores de 3/8” de grosor entre la estructura y los soportes

en las localidades de atornillaje traseras. Instale separadores de 3/8” de grosor, arandelas de presión de 5/8" y tuercas en los tornillos.

NOTA: En algunos modelos, el colgador del sistema de escape tendrá que ser desatornillado de la estructura

3. Instale la sección central entre los soportes, así como se ilustra. Use el patrón de agujeros que va mejor con su camioneta. Inserte los tornillos

de 1/2” a través de la sección central y los soportes. Instale arandelas de presión de 1/2” y tuercas en los tornillos. Por ahora, apriete éstos

tornillos con la mano. NOTA: Asegúrese de usar los cuatro agujeros para atornillar cada soporte a la sección central.

4. Inserte un tornillo de 5/8" junto con una chapa de tornillo de 1/4" a través del agujero de diámetro de 1" en la estructura y en el soporte, como se

muestra. Inserte dos separadores de 3/8” de grosor entre la estructura y el soporte. Instale un separador de 3/8” de grosor, una arandela de

presión y una tuerca en el tornillo. Haga esto en ambos lados.

5. Si el colgador del sistema de escape fue desmontado, taladre un agujero de 3/8” a través del colgador y una el colgador al soporte del

enganche usando uno de los agujeros indicados. Use las piezas de 3/8” que se proveen para atornillar seguramente el colgador del sistema de

escape.

6. Apriete las tuercas en el orden siguiente:

Apriete primero las tuercas de 1/2” a una torsión de 70 pies•libra (95 N•m).

Luego apriete las tuercas de 5/8” a una torsión de 115 pies•libra (156 N•m).

7. Si aflojó la llanta de repuesto, apriétela ahora.

TUERCA DE 1/2”

ARANDELA DE

PRESIÓN DE 1/2”

UNO DE ESTOS

AGUJEROS

Page 25

For Installation Assistance or Technical Help, Call:

Pour toute assistance technique, composez le :

Si necesita ayuda para la instalación o ayuda técnica, llame al:

1-800-428-7303

This product complies with safety specification and requirements for the State of New York and VESC regulation V-5 for

connecting devices and towing systems. Weight distributing hitch rating is 12,000 lb maximum gross trailer weight and

1200 lb maximum tongue weight. Weight carrying hitch rating is 7000 lb maximum gross trailer weight and 700 lb maximum

tongue weight. Consult vehicle owners manual for towing recommendations and limitations.

Ce produit est conforme aux exigences et aux prescriptions de sécurité de l'état de New York et de la norme V-5 de la VESC

pour les dispositifs de raccordement et les attelages. La capacité de l'attelage répartiteur de charge correspond à un poids

brut de remorque maximal de 12 000 lb et à une charge maximale de 1 200 lb sur le timon. La capacité d'un attelage sans

dispositif de répartition correspond à un poids brut de remorque maximal de 7 000 lb et à une charge maximale de 700 lb

sur le timon. Reportez-vous au manuel du propriétaire afin de prendre connaissance des recommandations et des limites

dictées par le constructeur.

Este producto cumple con los requerimientos y especificaciones de seguridad del estado de Nueva York y el reglamento

VESC V-5 para dispositivos de conexión y sistemas de remolque. El enganche tipo distribuidor del peso tiene una

capacidad máxima de 12.000 lb/5.443 kg peso bruto de la remolque, y 1.200 lb/544 kg en la horquilla. El enganche tipo

llevador de peso tiene una capacidad de 7.000 lb/3.175 kg máximo (peso bruto del remolque) y la carga máxima admisible de

la horquilla es de 700 lb/317,5 kg. Para las recomendaciones y limitaciones del remolque consulte el manual del usuario del

vehículo.

THREE YEAR LIMITED WARRANTY

GARANTIE LIMITÉE DE TROIS ANS

GARANTÍA LIMITADA DE TRES AÑOS

This limited warranty covers products produced by either Cequent Consumer Products, Inc., or Cequent Towing Products, Inc.(herein collectively “Cequent”). Cequent

warrants this hitch against defects in material and workmanship under normal recreational use and service, ordinary wear and tear excepted, for three years from the

date of purchase, to the original consumer purchaser. Cequent will replace FREE OF CHARGE any part which proves defective in material or workmanship when

presented to any Cequent dealer, Cequent Warehouse or returned to factory, TRANSPORTATION CHARGES PREPAID, at the address below. THIS WARRANTY IS

LIMITED TO DEFECTIVE PARTS REPLACEMENT ONLY. LABOR CHARGES AND/OR DAMAGE INCURRED IN INSTALLATION OR REPLACEMENT AS WELL AS

INCIDENTAL AND CONSEQUENTIAL DAMAGES CONNECTED THEREWITH ARE EXCLUDED. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion may not apply to you. Any damage to the Hitch, Custom Hitch receiver or Sway Control as a result of

misuse, abuse, neglect, accident, improper installation, or any use violative of instructions furnished by us, WILL VOID THE WARRANTY.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state. In the event of a problem with warranty service or

performance, you may be able to go to a small claims court, a state court, or a federal district court.

Cette garantie limitée couvre des produits produits par Cequent Consumer Products, Inc., ou produits de remorquage de Cequent, Inc.(herein collectivement “Cequent").

Cequent garantit cet attelage contre les vices de matériau et de fabrication qui se manifestent dans les conditions normales d'utilisation et de service de récréation (ceci

ne couvrant pas l'usure normale) à compter de la date d'achat pendant trois ans de la période de propriété de l'acheteur initial.

Cequent remplacera SANS FRAIS toute pièce si un défaut de fabrication ou de matériaux vient qu’à se manifester et que l’accessoire est retourné au magasin, à

l’entrepôt ou à l’usine Cequent, PORT PAYÉ. CETTE GARANTIE EST LIMITÉE AU REMPLACEMENT DES PIÈCES DÉFECTUEUSES SEULEMENT. ELLE NE

COUVRE PAS NON PLUS LES FRAIS DE MAIN-D’OEUVRE ET LES DOMMAGES ENCOURUS PENDANT L’INSTALLATION OU LE REMPLACEMENT, Y COMPRIS

LES DOMMAGES FORTUITS OU INDIRECTS. Comme les limites de temps relatives à une garantie tacite ou l’exclusion des dommages de nature fortuite ou indirecte

n’ont pas nécessairement cours dans toutes les provinces, il se peut que lesdites limites ou exclusions ne vous concernent pas.

La garantie des attelages à barre de tirage fixe ou amovible et des stabilisateur EST ANNULÉE D’OFFICE dans le cas d’un mauvais emploi, d’un usage abusif, d’un

accident, d’une mauvaise installation ou de toute utilisation contraire aux instructions qui les accompagnent.

Certains droits particuliers vous sont dévolus en vertu de la présente garantie et peuvent s’accompagner d’autres droits en fonction de la province où vous résidez.

Esta garantía limitada cubre los productos producidos por Cequent Consumer Products, Inc., o productos del remolque de Cequent, Inc.(herein colectivamente

“Cequent"). Cequent garantiza este enganche contra defectos del material y mano de obra bajo condiciones de servicio y uso normal de recreación, exceptuando el

desgaste normal, a partir de la fecha de compra y durante tres años del período de propiedad del comprador original.

Cequent reemplazará GRATUITAMENTE cualquier pieza que resulte defectuosa en material o mano de obra cuando sea presentada a cualquier distribuidor Cequent, al

Cequent o sea devuelta a la fábrica, CON PORTE PAGADO, a la dirección indicada abajo. ESTA GARANTIA SE LIMITA SOLAMENTE AL REEMPLAZO DE PIEZAS

DEFECTUOSAS. LOS COSTOS DE MANO DE OBRA Y/O DAÑOS INCURRIDOS EN LA INSTALACION O REEMPLAZO ASI COMO LOS DAÑOS SECUNDARIOS O

CONSECUENTES RELACIONADOS CON ELLO QUEDAN EXCLUIDOS.

En algunos estados no se permite la exclusión o limitación de los daños consecuentes o indirectos, por lo tanto la limitación o exclusión anterior puede que no se

aplique en su caso. Cualquier daño al enganche, al recibidor del enganche Custom o al control contraladeo causado por mal uso, abuso, negligencia, accidente,

instalación incorrecta o cualquier uso que no cumpla con las instrucciones suministradas por nosotros, ANULARA LA GARANTIA.

Esta garantía le otorga derechos legales específicos y usted puede también tener otros derechos que varían de un estado a otro. En el caso de un problema

relacionado con servicio o rendimiento en virtud de la garantía, usted puede recurrir a la corte de pequeña cuantía, a la corte estatal o federal.

Cequent Towing Products

27070 Miles Rd.

Solon, OH 44139

37034IN 9-5-07 rev_H PCN9924 © 2007 Cequent Towing Products - Impreso en México.

Page 26

IMPORTANT INFORMATION ON TOWING

TOWING EQUIPMENT OWNERS: Make sure all operators of your equipment read and understand this information before towing.

Save for reference. This will help you properly select, use, and maintain your towing equipment. Refer to owner's manuals for your

tow vehicle, trailer, and other parts of your towing system. Learn the capabilities and limitations of each part. GROSS TRAILER

WEIGHT and TONGUE WEIGHT are two of the most important items to consider. THESE WEIGHTS MUST NEVER EXCEED THE

LOWEST RATING OF ANY PART OF YOUR TOWING SYSTEM. GROSS TRAILER WEIGHT is the weight of the trailer plus all cargo.

Measure GROSS TRAILER WEIGHT with the fully loaded trailer on a level surface. The WEIGHT is the downward force exerted on

the ball by the trailer coupler. Measure TONGUE WEIGHT with the fully loaded trailer on a level surface. The coupler must be at its

normal towing height. Use a commercial scale or a bathroom scale. Set up the bathroom scale as shown for heavy tongue weights.

2 OR 3 FT.

PIPE

BATHROOM SCALE

1 FT.

BRICK

METHOD FOR MEASURING GROSS TRAILER WEIGHT METHOD FOR MEASURING TRAILER TONGUE WEIGHT

YOUR TOWING EQUIPMENT

TRAILER HITCHES, RECEIVERS, AND BALL MOUNTS

Select these products by their gross trailer weight and tongue weight ratings.

Select hitches and receivers for specific vehicles.

HITCH BALLS

Select by gross trailer weight rating, mounting platform thickness, hole size,

and coupler socket size. Platform must be at least 3/8 inch thick. Hole

must not exceed threaded shank diameter by more than 1/16 inch. Use lock

washer. Tighten per instructions. When tightened, shank must protrude

beyond bottom of nut. Gross trailer weight rating and ball diameter are

marked on REESE balls.

TRAILER COUPLERS

The coupler socket should be smooth, clean, and lightly lubricated.

Tighten or adjust per coupler manufacturer's instructions.

SAFETY CHAINS

Connect safety chains properly EVERY TIME YOU TOW. Cross chains

under coupler. Attach securely to the hitch or tow vehicle so they can't

bounce loose. Leave only enough slack to permit full turning. Too much

slack may prevent chains from maintaining control if other connections

separate. Don't let chains drag on the road.

TRAILER LIGHTS, TURN SIGNALS, ELECTRIC BRAKES, AND

BREAK AWAY SWITCH CONNECTIONS

Make these safety-critical connections EVERY TIME YOU TOW, no matter

how short the trip. Check operation, including electric brake manual control,

before getting on the road.

SWAY CONTROLS

Sway controls can lesson the effects of sudden maneuvers, wind gusts, and

buffeting caused by other vehicles. We reccommend them for trailers with

large surface areas, such as travel trailers. Adjustable friction models can

help control trailers with low tongue weight percentage.

OTHER USEFUL EQUIPMENT

AIR SPRINGS, AIR SHOCKS, or HELPER SPRINGS are useful for some

hitch applications. A TRANSMISSION COOLER may be necessary for

heavy towing. Many states require TOWING MIRRORS on both sides.

TIRE INFLATION

Check often. Follow tow vehicle and trailer manufacturers' recommenda

tions. Improper tire inflation can cause trailer sway.

CHECK YOUR EQUIPMENT / REPLACE WORN PARTS

Check ball, coupler, chains, retaining pins and clips, and all other

connections EVERY TIME YOU TOW. Re-check at fuel and rest stops.

NO PASSENGERS IN TRAILERS!

NEVER allow people in trailers while towing, under any circum

stances.

TRAILER LOADING

Proper loading helps prevent sway. Place heavy object on the floor

ahead of the axle. Balance the load side-to-side. Secure it to

prevent shifting. Tongue weight should be 10-15 percent of gross

weight for most trailers. Too low a percentage of tongue weight can

cause sway. NEVER load the trailer rear-heavy. LOAD THE

TRAILER HEAVIER IN FRONT.

DRIVING

The additional weight of a trailer affects acceleration, braking and

handling. Allow extra time for passing, stopping, and changing lanes.

Severe bumps can damage your towing vehicle, hitch, and trailer.

Drive slowly on rough roads. STOP AND MAKE A THOROUGH

INSPECTION IF ANY PART OF YOUR TOWING SYSTEM

STRIKES THE ROAD. CORRECT ANY PROBLEMS BEFORE

RESUMING TRAVEL.

CHECK FOR EXCESSIVE SWAY AND ELIMINATE IT

Excessive sway can lead to loss of control. Sway motion should

settle out quickly. Sway tends to increase on a downgrade. Starting

slowly, increase speed in gradual steps. If sway occurs, adjust your

trailer load and equipment. Repeat until the trailer is stable at

highway speed. Do this whenever your trailer loading changes.

IF TRAILER SUDDENLY STARTS TO SWAY

Turbulence from another vehicle, a wind gust, or a downgrade can

cause sudden sway. So can a shift of the trailer's load or a trailer

tire blowout. IF THE TRAILER SWAYS, IT IS THE DRIVER'S

RESPONSIBILITY TO ASSESS THE SITUATION AND TAKE

APPROPRIATE ACTION. Below are suggestions that may apply,

depending on conditions:

DO

- Reduce your speed gradually.

- Hold the steering wheel as steady as possible.

- If your trailer has electric brakes, apply the brakes alone, without

using the tow vehicle's brakes.

DON'T

- Don't hit your brake pedal hard unless absolutely necessary. A

"jackknife" can result.

- Don't try to steer out of the sway condition. Sudden or violent steering

can make it worse.

- Don't speed up. Sway increases as you go faster.

- Don't continue towing a trailer that tends to sway. You may lose

control during an emergency maneuver or if the conditions listed above

occur.

SAFE TOWING TIPS

PIPE

WARNING

DO NOT MODIFY REESE PRODUCTS. INSTALL ONLY ON SPECIFIED VEHICLES IN GOOD CONDITION. REESE TOWING

PRODUCTS ARE DESIGNED TO TOW TRAILERS. USE ONLY FOR THIS PURPOSE. Do not attach cargo carriers, motorcycle

carriers, boat hoists, or coupler alignment devices. Do not extend the original structure. Do not use to pull or push the towing

vehicle. Do not use as a jacking point. Do not attach anything with or in place of the ball. Any exceptions to the foregoing require

written approval of REESE PRODUCTS, Inc. DO NOT TOW MULTIPLE TRAILERS. Towing one trailer behind another may cause

severe instability and loss of control. FAILURE TO HEED WARNINGS AND FOLLOW INSTRUCTIONS MAY RESULT IN VEHICLE

CRASH, PROPERTY DAMAGE AND PERSONAL INJURY

DON'T OVERLOAD ANY PART OF YOUR TOWING SYSTEM

IA69000

Page 27

PROPRIÉTAIRES D’ÉQUIPEMENT DE REMORQUAGE: Assurez-vous que tous les opérateurs de votre équipement lisent et comprennent cette information avant de

INFORMATION IMPORTANTE SUR LE REMORQUAGE

remorquer. Gardez-la pour référence. Cela vous aidera à sélectionner, utiliser et entretenir correctement votre équipement de remorquage. Référer aux manuels du

propriétaire pour votre véhicule remorqueur, remorque, et les autres composantes de votre système de remorquage. Apprendre les capacités et les limites de chaque

composante. LE POIDS AU TIMON et POIDS BRUT DE LA REMORQUE sont deux des points le plus importants à considérer. CES POIDS NE DOIVENT JAMAIS

DÉPASSER LA COTE LA PLUS BASSE DE L’ENSEMBLE DES COMPOSANTES DE VOTRE SYSTÈME DE REMORQUAGE. LE POIDS BRUT DE LA REMORQUE