Page 1

INSTALLATION INSTRUCTIONS

MOUNTING KIT

FORD F250/F350/F450

PART NUMBER

30126

HD/SD

6’ and 8’ Beds

DO NOT EXCEED VEHICLE MANUFACTURER’S RATING FOR FIFTH WHEEL TOWING

OR MAXIMUM GROSS TRAILER WEIGHT OF 25,000lb. / 11,340kg AND A MAXIMUM

KING PIN WEIGHT OF 6,250lb. / 2,835kg.

*Please read and understand these instructions prior to installation.

DEALER/INSTALLER:

END USER:

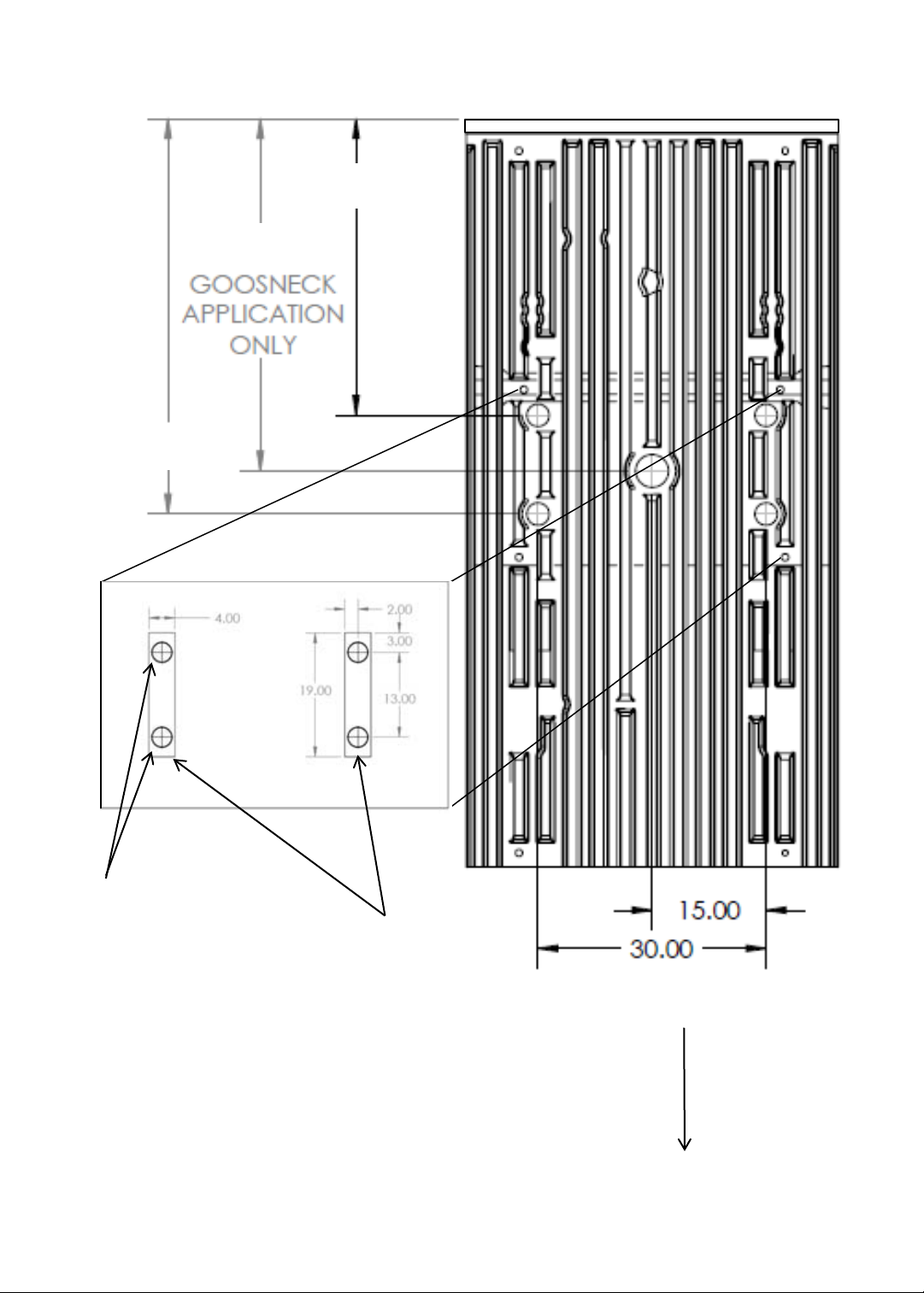

(1) Provide this Manual to end user.

(2) Physically demonstrate procedures in this Manual to end user.

(3) Have end user demonstrate that he/she understands procedures.

(1) Read and follow this Manual every time you use Hitch.

(2) Save this Manual for future reference.

(3) Pass on copies of Manual to any other user or owner of Hitch.

Front of

vehicle

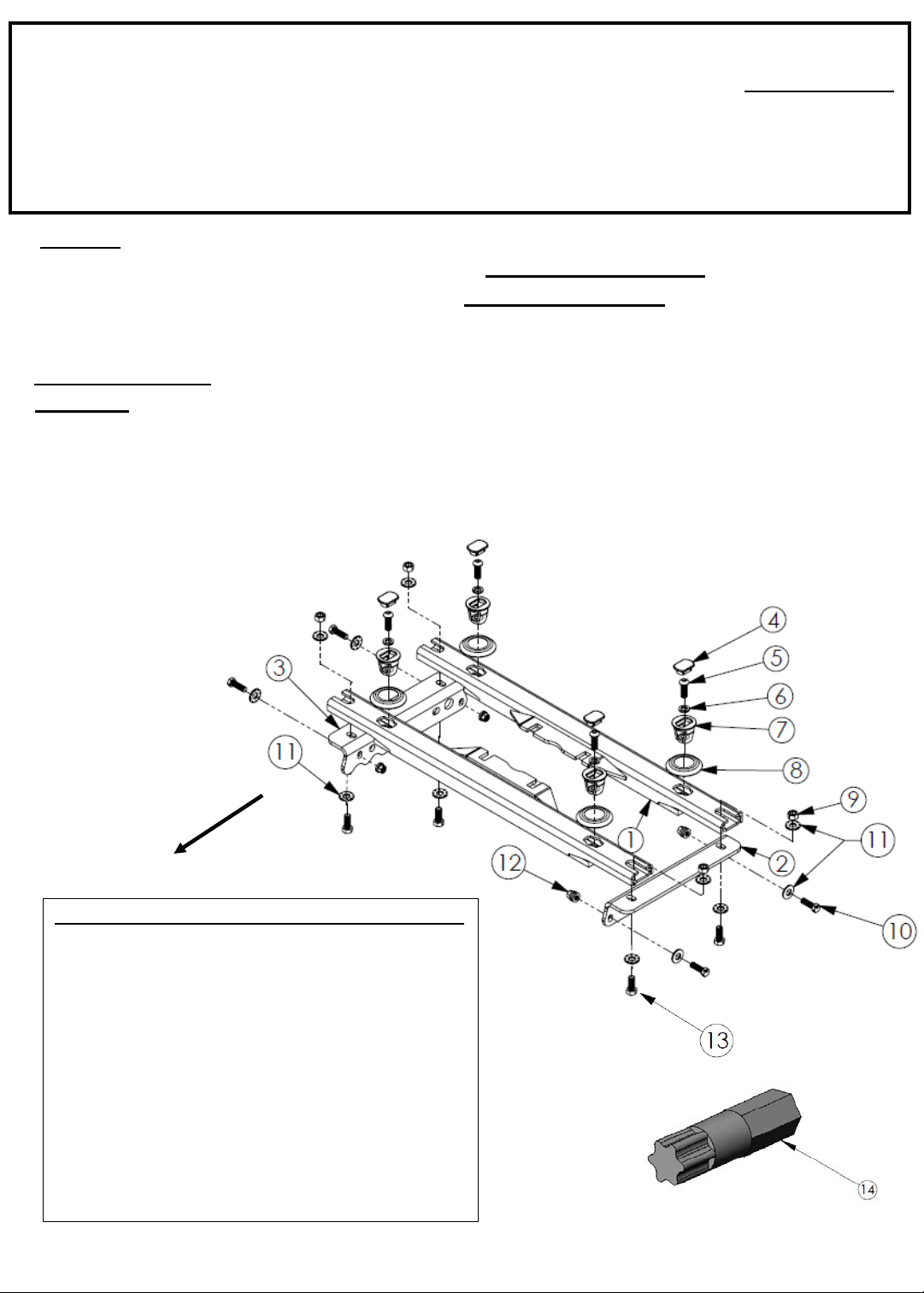

PART QTY.

1. BASE RAIL (2)

2. FRAME BRACKET (DRIVERS SIDE) (1)

3. FRAME BRACKET (PASSENGER SIDE) (1)

4. PUCK PLUG (4)

5. 5/8-11 x 1-3/4 BUTTON HEAD SCREW (4)

6. 5/8 LOCK WASHER (4)

7. PUCK (4)

8. TRIM RING (4)

9. 5/8-11 GRADE 8 HEXHEAD NUT (4)

10. M14 X 1.5 X 45 BOLT CL10.9 (4)

11. 5/8 CONNICAL WASHER (12)

12. NUT, M14 X 1.5 FLANGE (4)

13. 5/8-11 x 1-3/4 GRADE 8 HEX HEAD BOLT (4)

14. Torx T50 IP BIT (1)

Figure 1

For Customer Support Call 1-888-521-0510

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

Page 2

WARNING:

Failure to follow all of these instructions may result in death or serious injury!

INDEX

1. GUIDELINES FOR MATCHING TOW VEHICLE AND TRAILER P. 2-4

2. ASSEMBLY INSTRUCTIONS P. 5-9

3. CEQUENT PERFORMANCE PRODUCTS , INC. SEVEN YEAR LIMITED WARRANTY P. 10

GUIDELINES FOR MATCHING HI TCH TRUCK AND TRAILE R

WARNING:

Failure to check and follow tow ratings could result in tow vehicle

damage or truck and trailer separation while towing.

•Trailer and its contents together must not exceed truck, hitch and/or trailer tow

ratings.

•Towing vehicle must have a manufacturer’s rated towing capacity equal to or

greater than the gross trailer weight (dry weight of the trailer plus payload of the

trailer). (Figure 2)

•Gross weight of trailer must not exceed fifth wheel hitch rating.

•King pin weight must not exceed fifth wheel rating (Figure 3). If in doubt have king

pin weight measured by a qualified technician.

FACTORY TRAILER + FULL LIQUID

AND GAS TANKS + CARGO, ETC.

= GROSS TRAILER WEIGHT

Enter total below

Figure 2

1. Maximum Gross Trailer Weight of : 25,000 lb / 11,340kg.

Vehicle tow rating: _______________.

Total calculated Gross Trailer Weight (Figure 2):______________.

*Trailer weight should be the lowest of these recorded ratings for safe towing conditions.

2. Cequent Performance Products, Inc. hitches are designed for use with recreat i onal fifth wheel trailers only. Hitch applications

other than recreational fifth wheel trailers must be approved in writing by the Cequent Performance Products, Inc. Engineering

Department.

3. Use only a SAE 2-inch kingpin with your REESE

4. Approximately 15%-25% of trailer weight should be on hit ch (Pin Weight)(Figure 3).

Figure 3

™

Elite

®

Series Fifth Wheel Hitch.

15-25%

GROSS TRAILER

WEIGHT

(PIN WEIGHT)

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

75-85%

GROSS TRAILER

WEIGHT

2

Page 3

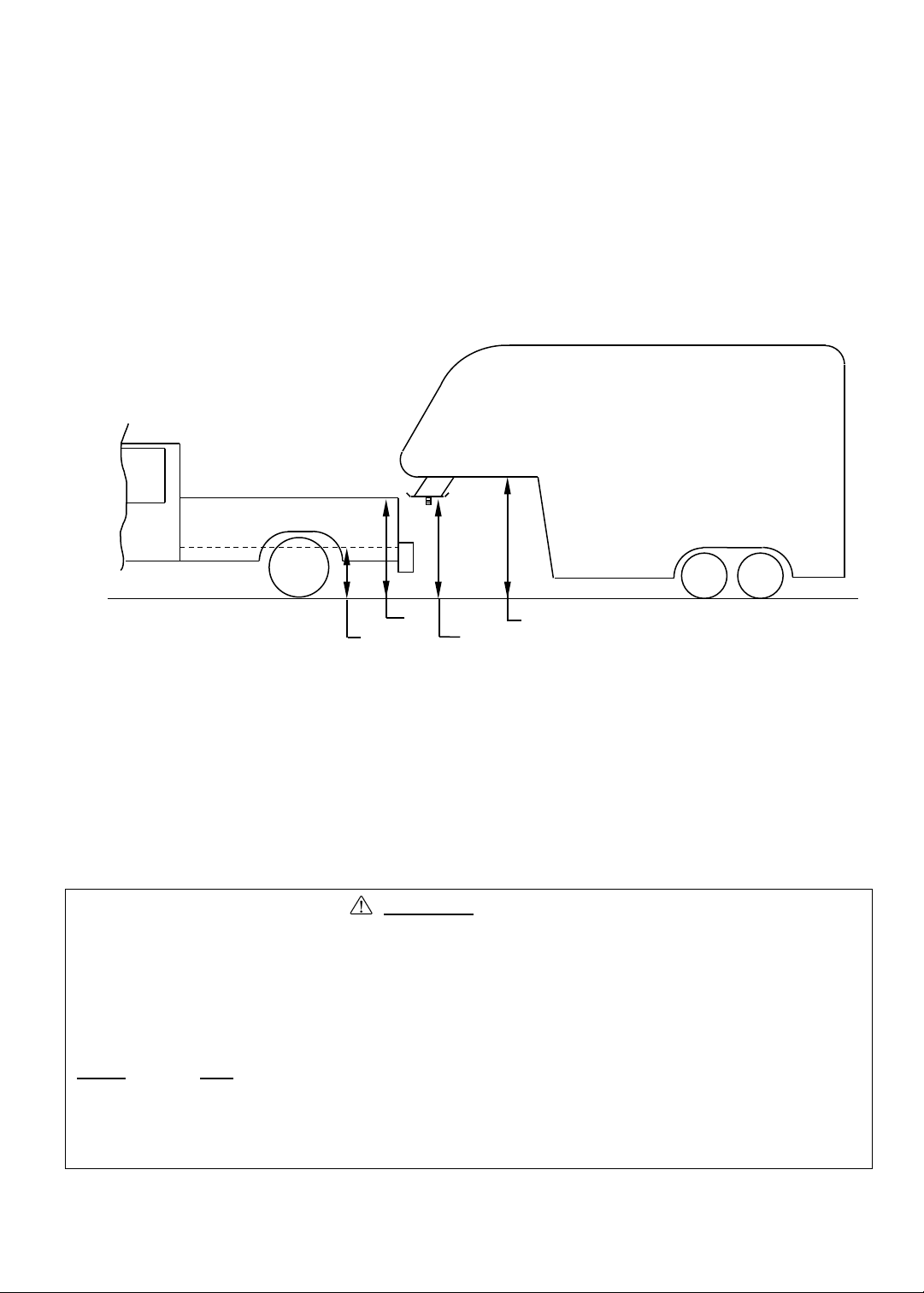

5. Trucks come in many different configurations. Cequent Performance Products, Inc. hitches are designed for use in light trucks

such as the Ford F-Series, the Chevy Silverado and the Dodge Ram. Cequent Performance Products, Inc. recommends the

use of light trucks with beds 6ft. long or longer for the best combination in truck - t rail er tur ning clear ance. See website for

vehicle application.

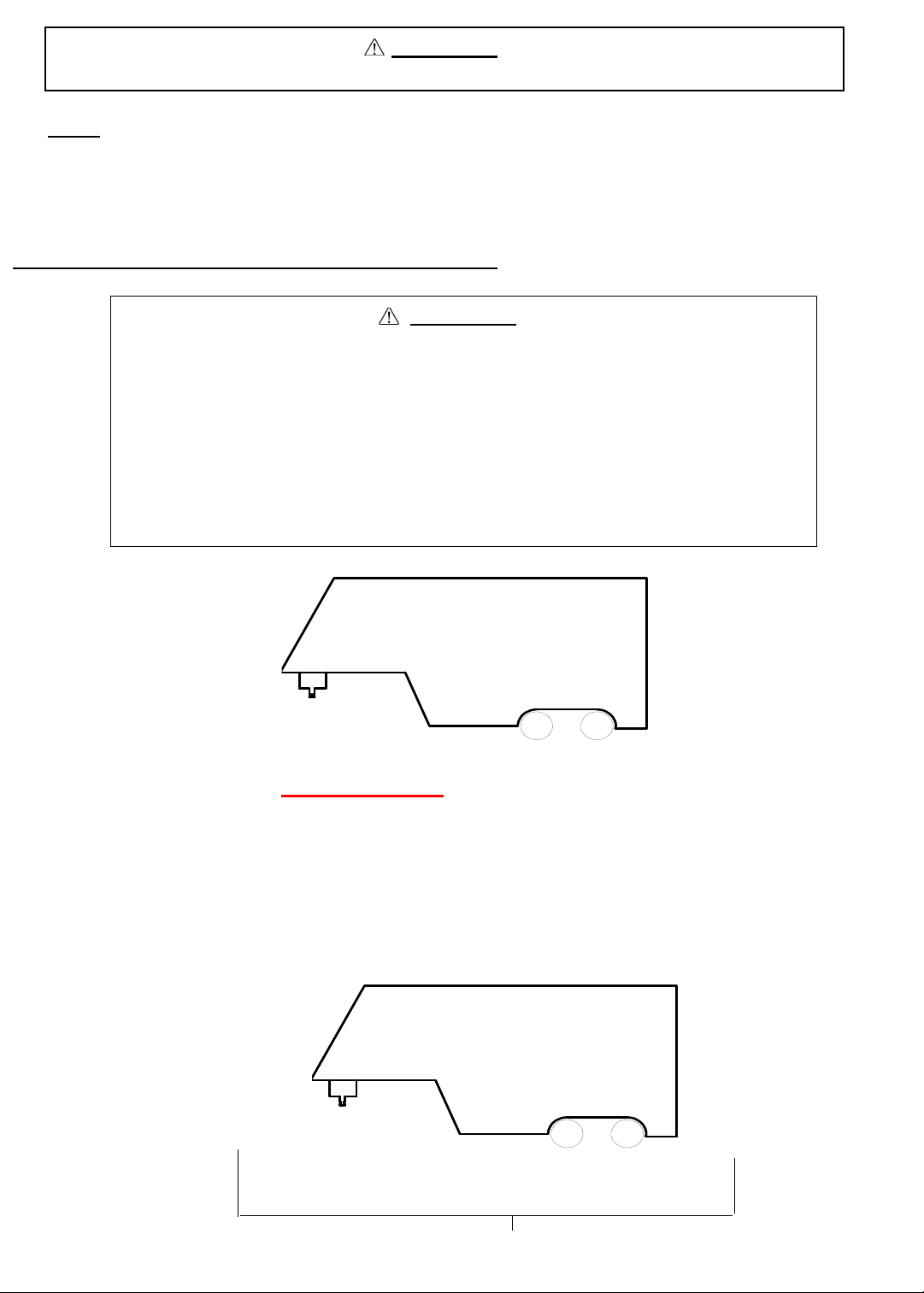

NOTE: To prevent the trailer from hitting t he c ab with the trailer turned 90°, the center of the hitch should be at least 52in. from the

back of the cab when using a long bed truck. (Actual distance required will depend on trailer width and king pin location.) S hort

bed (Minimum 38in. from back cab to axle center li ne) trucks require a minimum of 13in. extended pin box (Figure 5) or a

SIDEWINDER

6. The height of the hitch and the pin box should be adjusted s o the trailer is approximately level as i t is towed. Allow

approximately 6 in. - 9 in. clearance between the top of the bed rails and the underside of the front of the trailer for pitch and roll

of the trailer. (Figure 6). Allow more clearance between pickup walls and trailer for off road use.

TM

Pin box or slider hitch assembly for regular maneuvers.

Rule of thumb: The distance from the back of the truck cab to the center of the rear truck

axle (“X” in Figure 4), should be approximately 4 in. greater than one-half

the trailer width (“Y” in Figure 4)

Figure 4

Figure 5

Conventional Pin Box

TRUCK

Extended Pin Box

RV TRAILER

KING PIN

WARNING:

Do Not install this fifth wheel hitch on or attempt to tow with a short bed pickup

truck that has a bed shorter than 6 ft. unless trailer is equipped with a Sidewinder

pin box!

Figure 6

TM

Approximately 6-9 in.

Level Trailer

CAUTION:

The measurements above are guidelines. If your measurements are close to these numbers re-check clearances. If

vehicle and/or trailer has any added bed vicinity accessories (i.e. fairings, air dams, ground effects, bed rails, fuel-cells,

toolbox, etc.), additional dimensioning and clearance checks have to be made.

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

3

Page 4

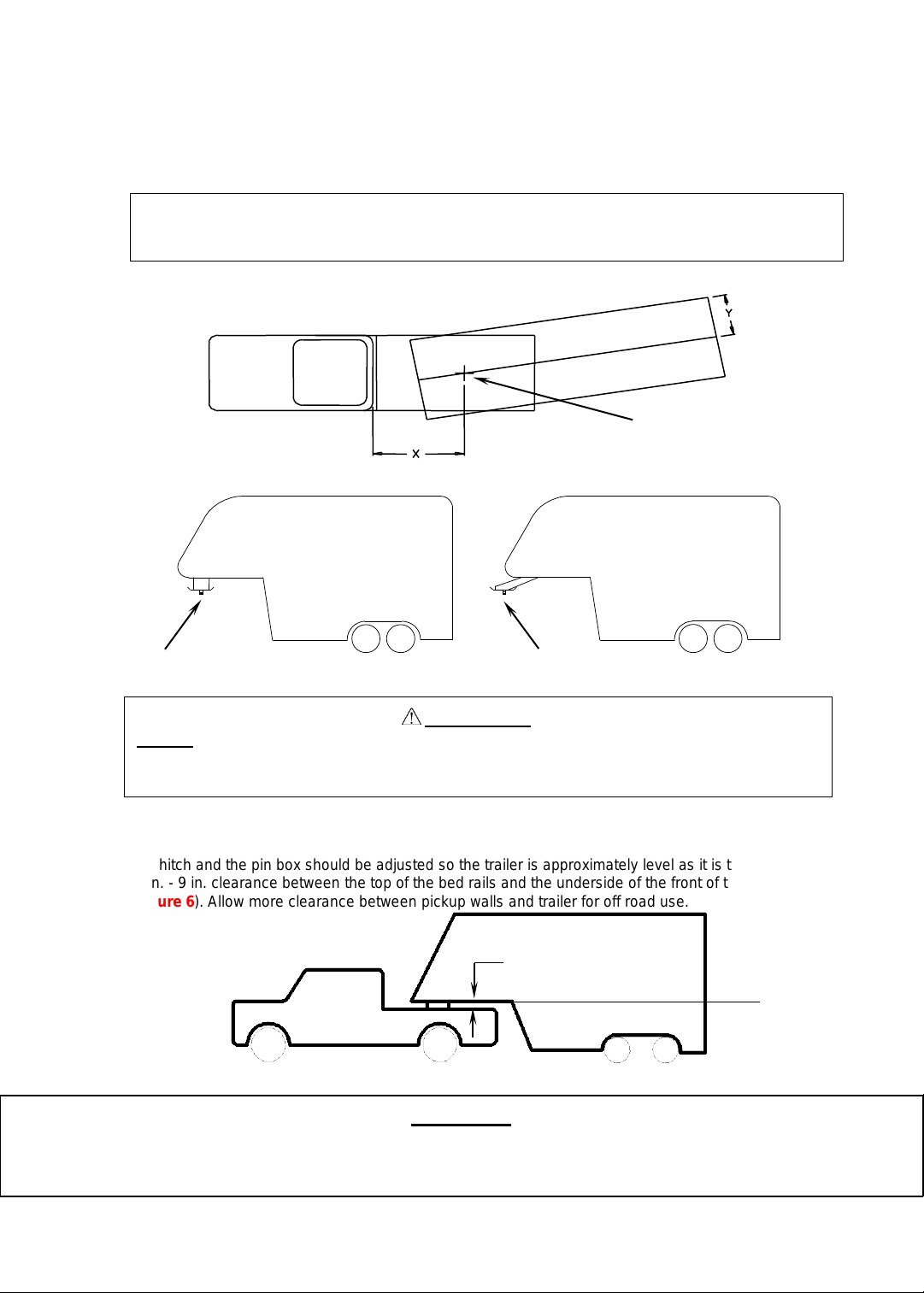

7. Hitch height determination:

With trailer leveled and on level ground measure from the ground to the bottom of the king pin box (“A” in Figure 7). Secondly

measure the height of the inside of the truck bed to the ground (“B” in Figure 7). Determine the amount of clearance ov er the

side rails ( “C” and “D” in Figure 7).

Hitch Height = A – B + 2” **

** The 2” value is an estimate of suspension compression due to king pin weight of the trailer. This compression could range

between 1”-5” depending on the truck being used and the trailer being towed.

D – C + 2” > 6”

C

B

8. If a lube plate is to be used with a REESE™ Elite® Fifth Wheel it must be at least 12” in diameter. Cequent Performance

Products, Inc. offers this optional lube plate as part # 83001.

A

Figure 7

D

*MEASURED WITH TRAILER LEVEL,

ON LEVEL GROUND

WARNING:

•Connection for trailer wiring must be located at the side of the truck bed between the driver’s

seat and the rear wheel to prevent operators from working between the truck and trailer.

•Avoid putting any part of your body under the trailer or between the truck and trailer.

Unexpected or accidental movement of the truck or the trailer can cause serious injury or death

•If you must place any part of your body under the trailer or between the truck and trailer you

perform ALL of the following steps:

MUST

•Check that the truck transmission is in park

•Check that the emergency brake is on

•Block in front of and behind all trailer tires

•Check that the trailer landing gear are resting on firm ground

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

4

Page 5

GENERAL INSTRUCTIONS FO R FI FTH WHEEL INS TALLATI ON

TOOLS

1/8" Drill Bit 15/16" Socket & Open End Wrench

Torx T50IP Bit (Supplied with Kit) 200 lb-ft Torque Wrench

Rubber Mallet 2-3/4” Hole Saw

21mm Socket or Open End Wrench 19mm Socket or Open End Wrench

1/2” Drive Swivel Head Ratchet 3/8” Allen Wrench Socket

CAUTION!

Read pages 2-4 of these instructions before starting installation. Failure to do so could result in significant vehicle damage!

9. The following instructions should be used to mount the fifth wheel mounting kit. Care and attention to detail will

ensure a quick quality installation. Check parts against parts list to become familiar with parts in kit. (Figure 1)

10. If extra clearance is needed to install the frame brackets, raise the rear of the truck high enou gh to allow the rear

tires to hang down freely. This will provide the maximum room to install the fifth wheel brackets.

WARNING:

If the truck is raised, be sure that the truck is properly blocked and restrained to prevent the truck from falling.

11. Remove plastic bed liner if applicable. Plastic drop-in bed liners will be cut later. (See Figure 15) Spray-in bed

liners and bed mats less than 1/4” thick will work with normal installation instructions. Note: Consult installer for

recommended curing time on spray-in liner before cutting holes through bed.

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural

members, etc. CEQUENT PERFORMANCE P RODUCTS, In c. does its best to communicate tow vehicle

manufacturer changes; however, it is ultimately the responsibility of the installer to prevent damage due to

12. Use only CEQUENT PERFORMANCE PRODUCTS, Inc. supplied bolts, nuts, and washers to install this kit. All

bolts and nuts are Grade 8 unless specified otherwise.

13. These instructions are intende d for 2011 Ford Supe r Duty with 6 to 8 foot bed. Each frame bracket must be bolted

to the vehicle frame with two bolts.

Failure to do so may result in the truck suddenly falling, causing death or serious injury.

CAUTION:

installation.

CAUTION:

These instructions are guidelines only. Actual installation is the responsibility of the installer and the owner.

Always measure truck and trailer before installing hitch to be sure that there is cl ear anc e at the cab and at the

bumper to allow for turns.

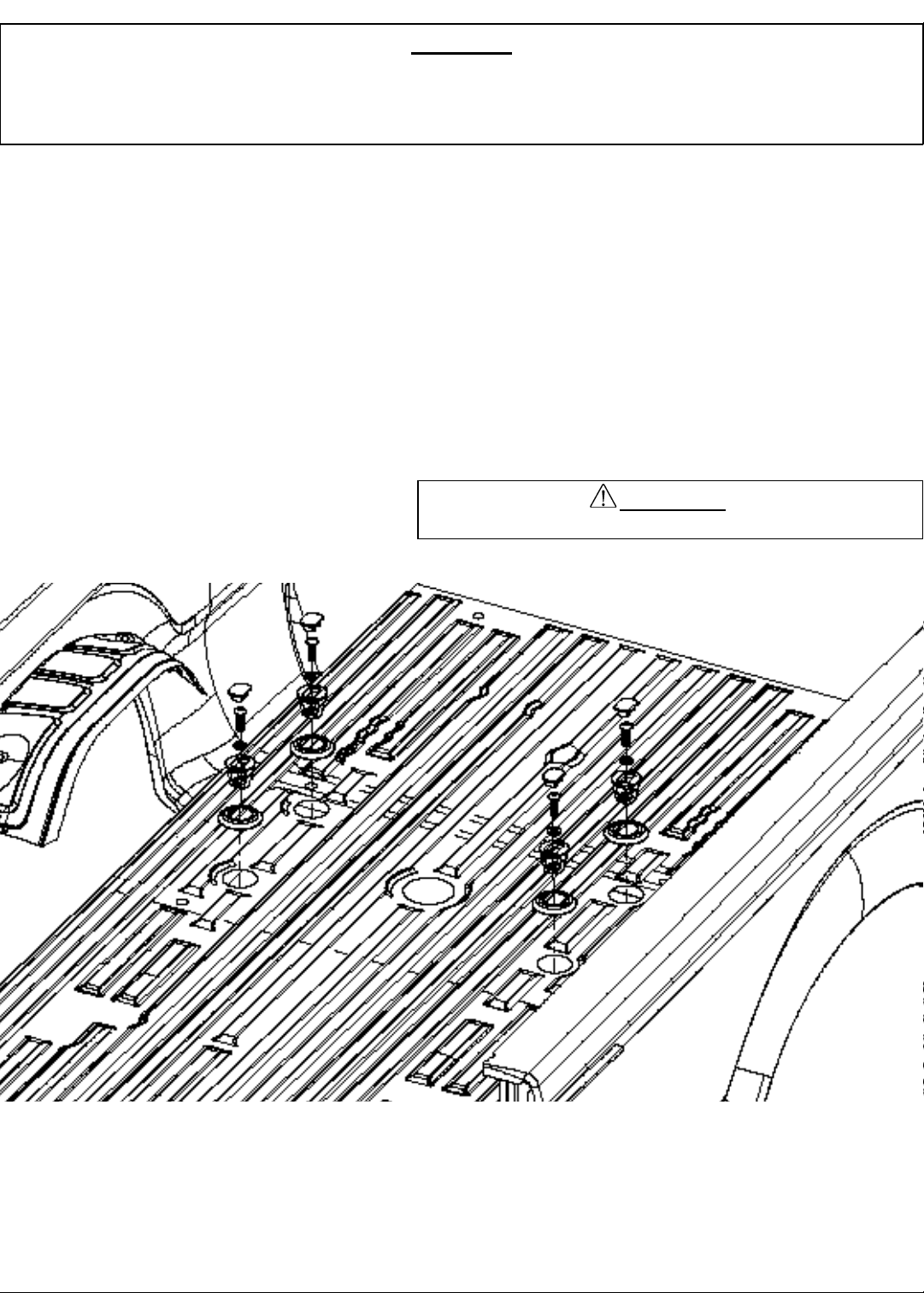

14. Drill 1/8”pilot holes in truck bed at outer dimpled locations (approximate dimensions of Figure 15). The middle

dimple is for the goose ball only. (See gooseneck instructions if applicable.) These dimpled locations are placed by

the factory. If dimples are not present, refer to (Figure 15) located on page 9. Use a 2 ¾” hole saw to cut hole at

pilot holes. Note: Consult installer for recommended curing time on spray in liner before cutting holes through bed.

Optional: Spray under coating around 2 ¾” holes to prevent rusting.

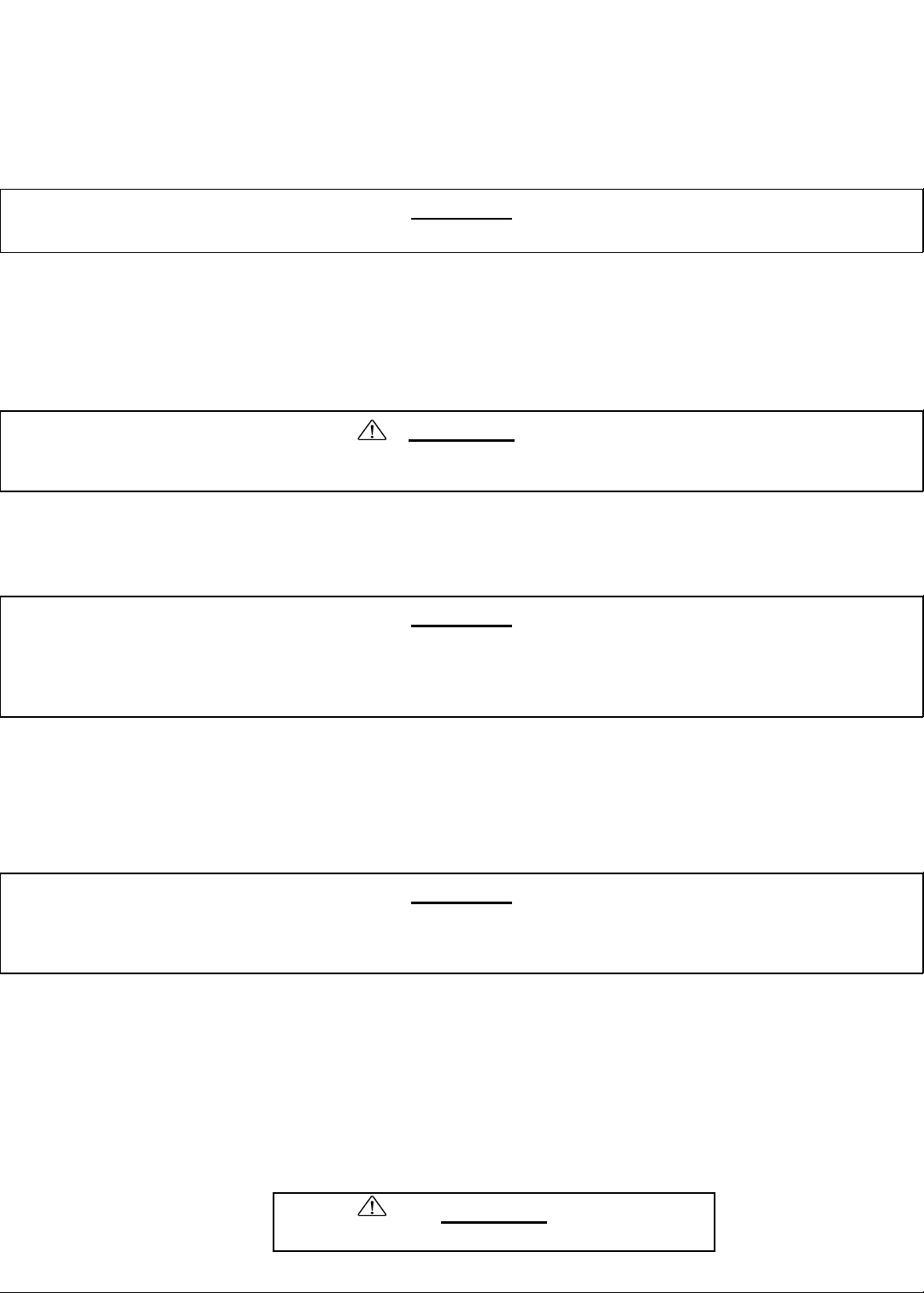

15. Locate the area where the base rails will be inserted above the rear wheel on the passengers side. There are two

hat channels supporting the truck bed over the rear wheel. The base rails will be inserted at the location behind

the forward hat channel (FIGURE 8) located on page 6. To create clearance for inserting the rails remove

passengers side bed bolts, loosen drivers side bed bolts with T50 torx bit (#14) (Figure 1), and block up

passengers side bed.

WARNING:

Be careful of fuel fill line and wiring while lifting.

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

5

Page 6

Front

Rail positions

Figure 8

of

vehicle

16. Insert rails (#1) as shown in the following steps (Figures 9 through 11). Rails should be inserted flat side up.

F

r

a

m

e

Fuel

Cell

Fuel

Cell

Front Hat Channel

Figure 9

Rear Hat Channel

Figure 10

m

F

r

a

e

Step 16A : Insert the first rail fro m th e

passengers side rear wheel well

above the frame. Rest the rail on

both chassis frame rails (Figure 9).

Vehicle

Forward

Step 16B : Slide the rail rearward,

parallel with axle, resting on both

frame rails, and as close as possible

to the rear hat channel (Figure 10).

Fuel

Cell

Figure 11

Step 16C : Insert the second rail from

the passengers side rear wheel well

above the frame. Rest the rail on both

chassis frame rails (Figure 11).

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

6

Page 7

Step 16D : One rail should be facing rearward and the other rail facing forward after the

installation. The rails should be centered with both ends of each rail resting

evenly on the frame.

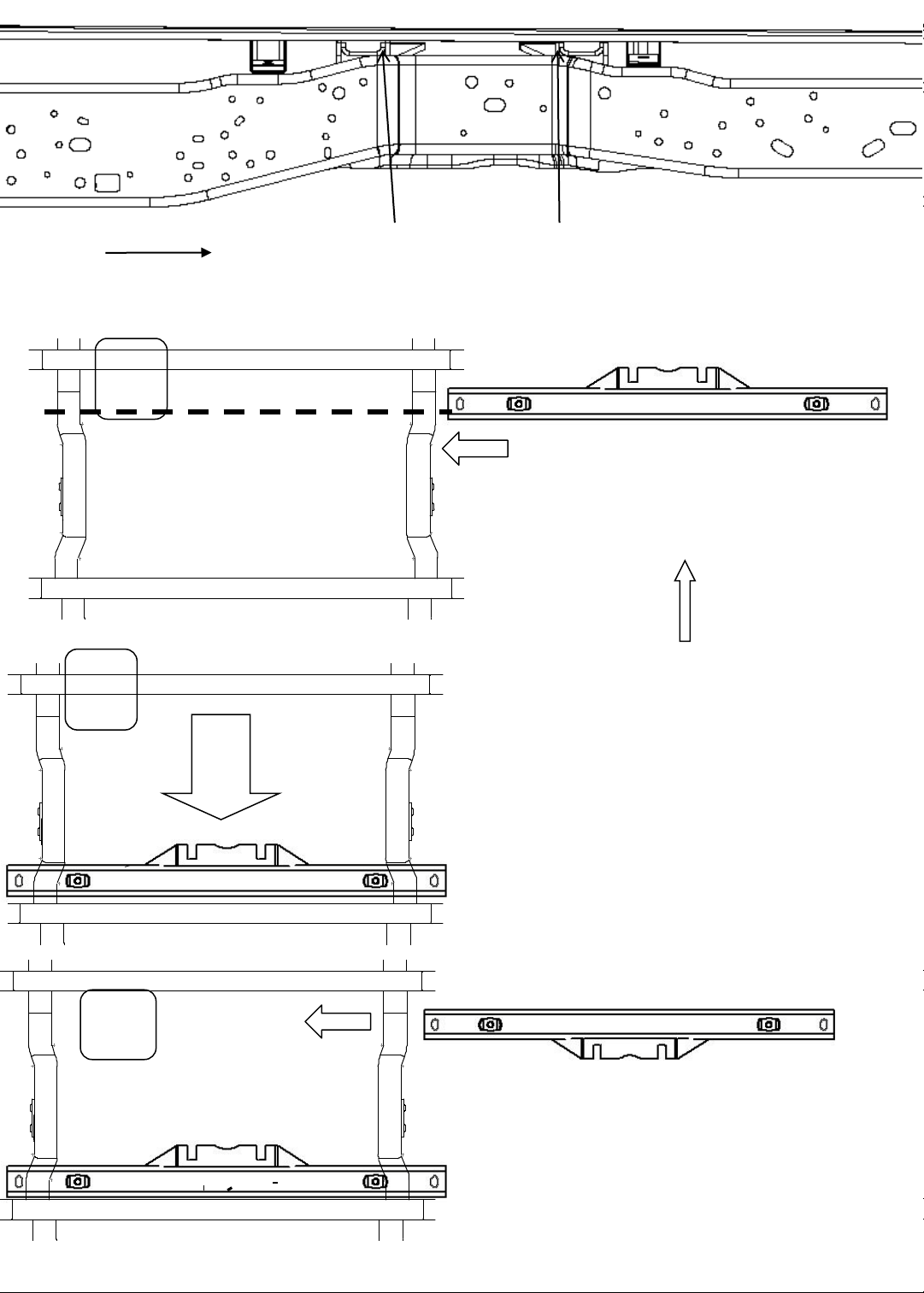

17. Loosely attach frame brackets (#2 & 3) (Figure 1) to mounting kit rails using 5/8” X 1 3/4” (#10) (Figure 1) long

bolts, conical washer (#11) (Figure 1) (below bracket), conical washer (#11) (inside rail), and 5/8” nut (inside rail)

(#9) (Figure 12). Tighten all mounting kit bolts to hand tight.

WARNING:

DO NOT lubricate bolt threads. It may cause bolt failure.

Figure 12

CAUTION:

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural

members, etc. CEQUENT PERFORMANCE P RODUCTS, In c. does its best to communicate tow vehicle

manufacturer changes; however, it is ultimately the responsibility of the installer to prevent damage due to

installation.

18. Loosely attach frame bracket to existing holes in chassis frame using M14 1.5 x 45 bolts (#10), conical washer

(#11) (Figure 1), and flange nut (#12) (Figure 1). Tighten to hand tight (Figure 13). Lifting truck bed gives easier

access to the driver’s side nut and bolt.

Front

Figure 13

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

7

Page 8

CAUTION:

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural

members, etc. CEQUENT PERFORMANCE P RODUCTS, In c. does its best to communicate tow vehicle

manufacturer changes; however, it is ultimately the responsibility of the installer to prevent damage due to

installation.

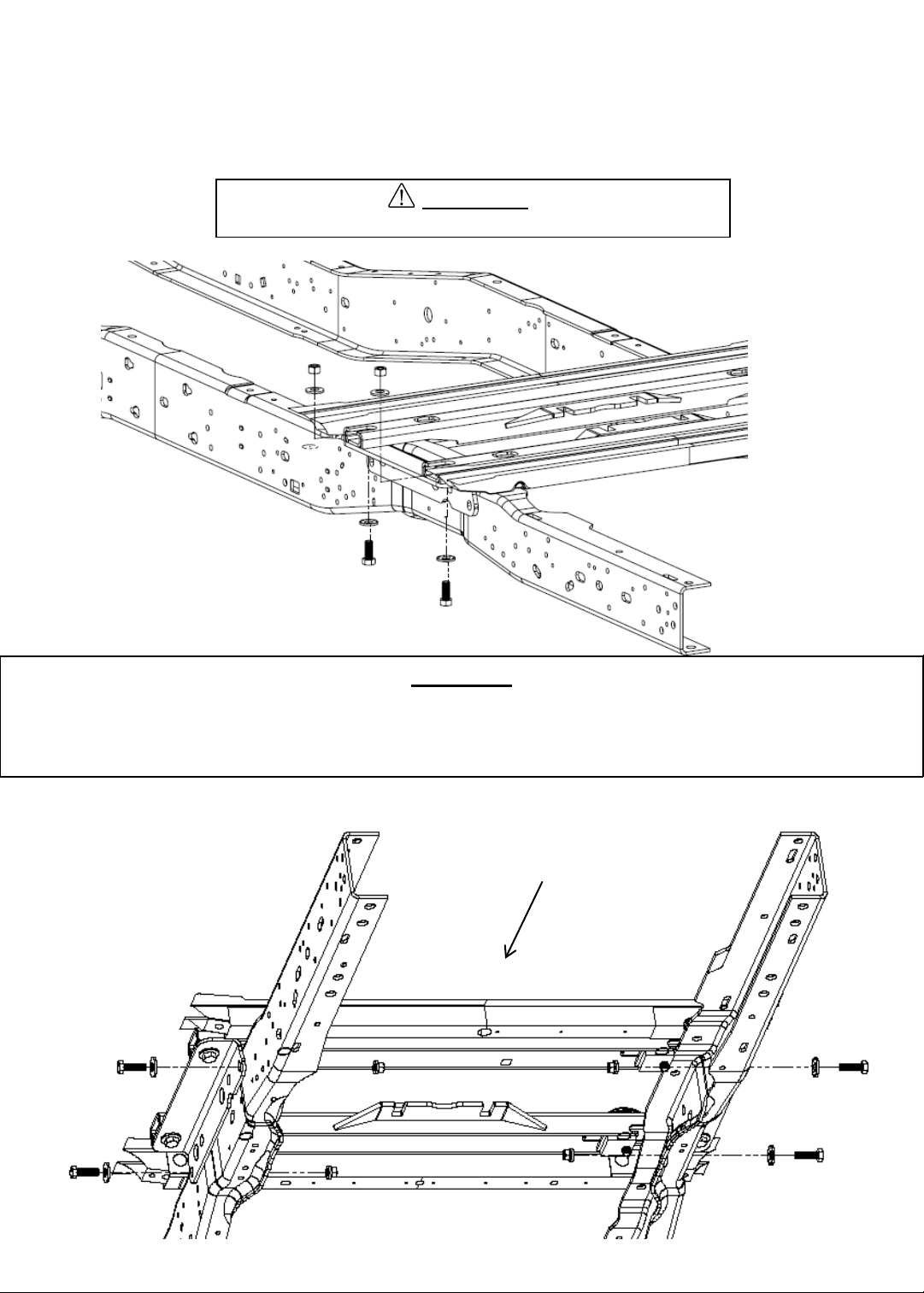

19. Lower bed and align bed, bolts, and holes for pucks as needed.

20.

21. Place fifth wheel in rail kit and secure in place.

22. Torque all 5/8” rail kit hex bolts to 150ft./lbs first. Then torque all M14 bolts to 140 ft./lbs. Note: Use swivel

23. Replace any brake lines and spare tire that may have been removed/relocated.

24. Torque the bed bolts that were loosened in step 14 to 75ft./lbs with T50 TORX BIT (#14) (FIGURE 1).

From truck bed attach pucks (#7) (Figure 1) and trim rings (#8) (Figure 1) to rails as shown in Figure 14

below using 5/8” button head screw (#5) and lock washer (#6) using 3/8in. Allen socket. Tighten to 110ft.lbs.

torque.

head ratchet to access front driv er’s side nut from over fram e.

DO NOT lubricate bolt threads. It may cause bolt failure.

WARNING:

Figure 14

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

8

Page 9

46-3/8”

52-1/16”

39-1/16”

Puck placement

Cut rectangles

out of plastic

removable bed

liner.

FRONT/ FORWARD

Figure 15

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

9

Page 10

NOTES

SEVEN YEAR LIMITED WARRANTY

Hitches - Custom Receiver s

Cequent Performance Products, Inc. warrants the REESE

from date of purchase against defects in material and workmanship under normal use and service,

ordinary wear and tear excepted, for 7 years of ownership to the original consumer purchaser

when a Cequent Performance Products, Inc. mounting kit is used.

Cequent Performance Products, Inc. will replace FREE OF CHARGE any part(s) which proves

defective in material or workmanship when presented to any Cequent Performance Products, Inc.

dealer, Cequent Performance Products, Inc. Warehouse or returned to factory. TRANSPORTATION

CHARGES PREPAID, at the address below. THIS WARRANTY IS LIMITED TO DEFECTIVE PARTS

REPLACEMENT ONLY. LABOR CHARGES AND/OR DAMAGE INCURRED IN INSTALLATION OR

REPLACEMENT AS WELL AS INCIDENTAL AND CONSE QUENT IAL DAMAGES CONNECTED

THEREWITH ARE EXCLUDED.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclus i on may not apply to you.

Any damage to the Fifth Wheel Hitch as a result of misuse, abuse, neglect, accident, improper

installation, or any use violating of instructions furnished by us, WILL VOID THE WARRANTY.

This warranty gives you specific legal ri ghts, and y ou may also have other rights which v ary from

state to state. In the event of a problem with warranty service or performance, you may be able to

go to a small claims court, or a federal district court.

™

Elite® Series Fifth Wheel Mounting Kit

Cequent Performance Products, Inc.

47912 Halyard Dr, #100

Plymouth, MI 48170

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

10

Page 11

INSTRUCTIONS D'INSTALLATION

NÉCESSAIRE DE MONTAGE

FORD F250/F350/F450HD/SD

Plateformes de 6 et 8 pieds

NE PAS EXCÉDER LES SPÉCIFICATIONS DE CHARGE DU FABRICANT DU VÉHICULE

POUR LES ATTELAGES À SELLETTE, NI UN POI DS BRUT MAXIMAL DE REMORQUE DE

25 000lb / 11 340 kg ET UN POIDS MAXIMAL AU PIVOT D'ATTELAGE DE 6 250lb / 2 835 kg.

*Veuillez lire et comprendre toutes les instructions avant de procéder à l’installation.

CONCESSIONNAIRE/INSTALLATEUR :

UTILISATEUR FINAL :

(1) Remettre ce manuel à l'utilisateur final.

(2) Démontrer physiquement les procédures de c e m anuel à l'utilisateur final.

(3) Demander à l'utilisateur final de démontr er sa compréhension des procédures.

(1) Lire et observer les instructions de ce manuel à chaque utilisation de l'attelage.

(2) Conserver ce manuel pour consultation ultér ieure.

(3) Remettre des copies du manuel à tout autre utilisateur ou propriétaire de l'attelage.

Numéro de pièce

30126

Avant du

véhicule

PIÈCE QTÉ

1. TRAVERSE DE MONTAGE (2)

2. SUPPORT DE CADRE (CÔTÉ CONDUCTEUR) (1)

3. SUPPORT DE CADRE (CÔTÉ PASSAGER) (1)

4. BOUCHON (4)

5. VIS À TÊTE RONDE 5/8-11 x 1-3/4 (4)

6. RONDELLE FREIN 5/8 (4)

7. RÉCEPTACLE (4)

8. ANNEAU DE GARNITURE (4)

9. ÉCROU À TÊTE HEX. 5/8-11 GRADE 8 (4)

10. BOULON M14 X 1.5 X 45 CL10.9 (4)

11. RONDELLE CONIQUE 5/8 (12)

12. ÉCROU À EMBASE M14 X 1.5 (4)

13. ÉCROU À TÊTE HEX. 5/8 x 1-3/4 GRADE 8 (4)

14. EMBOUT Torx T50 (1)

Figure 1

Pour l'assistance à la clientèle, composez le 1-888-521-0510.

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

Page 12

AVERTISSEMENT :

L'omission d'observer toutes les instructions

peut causer des blessures sévères, voire la mort !

SOMMAIRE

1. DIRECTIVES CONCERNANT LE JUMELAGE DU VÉHICULE ET DE LA CARAVANE Pgs 2 à 4

2. INSTRUCTIONS DE MONTAGE Pgs 5 à 9

3. GARANTIE LIMITÉE DE SEPT ANS DE CEQUENT PERFORMANCE PRODUCTS, INC. Pg 10

DIRECTIVES CONCERNANT LE JUMELAGE DU VÉHICULE ET DE LA CARAVANE

AVERTISSEMENT :

L'omission de vérifier et respecter les capacités de charge nominales peut

causer l'endommagement du véhicule ou la séparation du véhicule et de la

caravane pendant le remorquage.

• Le poids de la caravane et de son contenu ne doit pas dépasser les capacités de charge du

véhicule, de l'attelage et/ou de la caravane.

• La capacité de charge du véhicule spécifiée par le fabricant doit être égale ou supérieure au

poids brut de la caravane (poids à vide de la caravane plus sa charge utile). (Figure 2)

• Le poids brut de la caravane ne doit pas dépasser la capacité de charge nominale de

l'attelage à sellette.

• Le poids du pivot d'attelage ne doit pas dépasse r la capacité de charge nominale de la sellette

(Figure 3). En cas de doute, faire peser le pivot d'att ela ge par un t echnicie n spécialisé .

CARAVANE À VIDE + RÉSERVOIRS

DE LIQUIDE ET DE GAZ PLEINS

+ BAGAGES, ETC.

= POIDS BRUT DE LA CARAVANE

Inscrire le total ci-dessous.

Figure 2

1. Poids brut max. de la remorque : 25 000 lb / 11 340 kg.

Capacité de remorquage du véhicule : ______________.

Total du poids brut calculé de la caravane (Figure 2) : ______________.

*Pour s'assurer de conditions de remorquage sécuritaires, le poids de la caravane ne doit pas dépasser la capacité de charge la

plus basse inscrite ci-dessus.

2. Les attelages Cequent Performance Products, Inc. sont conçus pour une utilisation avec caravane à sellette récréative

seulement. Toute utilisation de l'attelage qui ne s'applique pas à une caravane récréative à sellette doit être approuvée par écrit

par le service d'ingénierie de Cequent Performance Products, Inc.

3. Utiliser seulement un pivot d'attelage de 2 pouces SAE avec votre attelage à sellette REESE

4. Environ 15 % à 25 % du poids de la caravane doit reposer sur l'attelage (poids au pi v ot) (Figure 3).

Figure 3

™

Elite

®

Series.

15 à 25 % DU POIDS

BRUT DE LA CARAVANE

(POIDS AU PIVOT)

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

75 à 85 % DU POIDS BRUT

DE LA REMORQUE

12

Page 13

5. Les camionnettes sont fabriquées selon des configurations v ariées. Les att elages Cequent Perf orm ance Pr oduct s, Inc . sont

conçus pour des camionnettes légères, telles que les modèles Ford F-Series, Chevy Silverado et Dodge Ram. Cequent

Performance Products, Inc. recommande d'utiliser des camionnettes légères à plateforme de 6 pi ou plus pour obtenir le m ei ll eur

dégagement véhicule-caravane dans les virages. Visiter le site Web pour les applications sur différents véhicules.

NOTA : Pour éviter que la cabine ne soit heurtée par l a remorque lorsque celle-ci se trouve à un angle de 90°, le centre de l'attelage

doit être à une distance d'au moins 52" (132 cm) de l'arrière de la cabine s'il s'agit d'une camionnette à platefor me longue. (La

distance réelle requise dépendra de la largeur de la remorque et de l'emplacement du pivot d'attelage.) Les camionnettes à

plateforme courte (minimum de 38 po / 97 cm entr e l'arrière de cabine et la ligne de centre de l'essieu) exigent l'un des trois

dispositifs suivants pour les manoeuvres régulières : carter de pivot allongé d'un minimum de 13 po / 33 cm (Figure 5) ; carter de

pivot SIDEWINDER

6. La hauteur de l’attelage et du carter de pivot doit être ajustée de façon que la caravane soit à peu près de niveau lors du

remorquage. Laisser environ 6 à 9 pouces de dégagement entre le dessus des traverses de montage et le dessous de l'avant

de la caravane en prévision du tangage et du roulis de la caravane. (Figure 6). Laisser un dégagement supplément aire ent re

les parois de la camionnette et la caravane dans l e cas d'une utilisation hors route.

Figure 4

Figure 5

TM

; ou encore un attelage à curseurs.

Méthode empirique : La distance entre l'arrière de la cabine de la camionnette et le c entre de l'essieu

arrière de la camionnette (“X” de la Figure 4) doit être supérieure d'environ 4 pouces à la dem ilargeur de la caravane (“Y” de la Figure 4).

CARAVANE

CAMIONNETTE

Carter de pivot conventionnel

Carter de pivot allongé

PIVOT D'ATTELAGE

AVERTISSEMENT :

Ne pas installer cet attelage à sellette (ni tenter de remorquer avec celle-ci) sur une

camionnette à plateforme courte inférieure à 6 pieds, à moins que la caravane ne soit

équipée d'un carter de pivot Sidewinder

TM

!

Figure 6

Environ 6 à 9 pouces

Caravane de niveau

ATTENTION :

Les mesures ci-dessus apparaissent à titre indicatif. Si vos mesures se rapprochent de ces valeurs, vérifiez

les dégagements de nouveau. Si le véhicule et/ou la caravane sont équipés d’accessoires dans la zone de la

plateforme (carénage, jupe, effet de sol, traverse de plateforme, réservoirs de carburant, coffre d'outil, etc.), il

faut procéder à des mesures et vérifications de dégagement additionnelles.

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

13

Page 14

7. Détermination de la hauteur de l'at telage :

Caravane de niveau et reposant sur un sol plat, mesurer la distance entre le sol et l e bas du carter du pivot d'attelage et le

coupleur (dimension “A” de la Figure 7). Mesurer ensuite la distance entre l'intérieur de la plateforme de cam ionnett e et le sol

(dimension “B” de la Figure 7). Calculer le dégagement au-dessus des longerons de caisse de la camionnette ( “C” et “D” à

la Figure 7).

Hauteur de l'attelage = A – B + 2 po **

** La valeur de 2 po est une évaluation de la compression de la suspension causée par le poids du pivot d'attelage de la

caravane. Cette compression peut mesurer entre 1 et 5 po selon la camionnette et la caravane utilisées.

D – C + 2 po > 6 po

C

B

8. Si une plaque lubrifiante doit être utilisée avec la sellette REESE™ Elite®, son diamètre doit mesurer au

moins 12 po. Cequent Performance Products, Inc. offre cette plaque lubrifiante en option (pièce #83001).

A

Figure 7

D

*MESURÉ AVEC LA CARAVANE DE

NIVEAU ET UN SOL PLAT

AVERTISSEMENT :

• La connexion pour le câblage de la caravane doit être située sur le côté de la plateforme de la

camionnette, entre le siège du conducteur et la roue arrière, afin d'empêcher les opérateurs de travailler

entre le véhicule et la caravane.

• Éviter de placer une partie du corps sous la caravane ou entre la camionnette et la caravane. Un

mouvement imprévu ou accidentel de la camionnette ou de la caravane peut causer des blessure s

sévères, voire la mort.

• Si l'on place une partie du corps sous la caravane ou entre le véhicule et la caravane, il FAUT

exécuter TOUTES

les étapes suivantes :

• S'assurer que la transmission de la camionnette est en position de stat ionne ment .

• S'assurer que le frein de secours est appliqué.

• Placer des cales à l'avant et l'arrière des pneus de la caravane.

• S'assurer que la béquille de la caravane repose sur un sol ferme.

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

14

Page 15

INSTRUCTIONS GÉNÉRALES POUR L'INSTALLATION DE LA SELLETTE

OUTILS

Mèche 1/8" Clé ouverte et douille 15/16"

Embout Torx T50 (fourni) Clé dynamométrique 200 lb-pi

Maillet en caoutchouc Scie-cloche 2-3/4”

Douille ou clé ouverte 21 mm Douille ou clé ouverte 19mm

Pince-étau (vise-grip) ou pince Clé à cliquet à tête pivotante 1/2”

MISE EN GARDE !

Lire attentivement les pages 2 à 4 de ces instructions avant de commencer l’installation. Le défaut d’observe r ce

conseil peut causer des dommages importants au véhicule !

9. Les instructions suivantes doivent être suivies pour installer le nécessaire de montage de la sellette. Un travail

soigné et une attention aux détails procurera une install ation rapide de qualité . Comparez les pièces avec celles

qui sont énumérées dans la liste pour vous familiariser avec les éléments du montage. (Figure 1)

10. Soulevez l'arrière de la camionnette à une hauteur suff isante pour pl acer les vérins sous le support de ressort

arrière de la camionnette. Vous disposerez ainsi du maximum d'espace pour installer les supports de sellette.

AVERTISSEMENT :

Si la camionnette est soulevée, s'assurer qu'elle est adéquat ement bloquée et retenue pour prévenir sa chute.

L’omission de procéder ainsi peut entraîner la chute de la camionnette et causer des blessures sévères, v oire la mort.

11. Retirer la doublure de caisse en plastique s'il y a lieu. La doublure amovible en plastique sera décou pé e plus tard.

(Voir Figure 15) Les doublures de caisse à vaporiser et les tapis de caisse inférieurs à 1/4 po d'épaisseur sont

compatibles avec les instructions d'installation normales. Nota : Consulter l'installate ur pour connaît re le temps de

durcissement recommandé des doublure s à vaporiser avant de percer des trous dans le plancher de caisse.

S'assurer qu'il n'y a pas d'obstacles avant de percer. L’omission d’observer ce conseil peut causer l'endomma gemen t

des conduites de carburant ou de frein, des éléments structuraux, etc. CEQUENT PERFORMANCE PRODUCTS, Inc.

fait de son mieux pour communiquer les modifications des constructeurs des véhicules de remorquage ; cepend ant, il

12. Utiliser seulement les boulons, écrous et rondelles fournis par CEQUENT PERFORMANCE PRODUCTS, Inc. pour

13. Ces instructions sont destinées au modèle Ford Super Duty 2011 à plateforme de 6 à 8 pi. Chaque support de

est ultimement de la responsabilité de l'installat eur de prévenir les dommages associés à l'installation.

installer ce produit. Tous les boulons et les écrous sont de grade 8 sauf indication contraire.

cadre doit être boulonné au cadre du véhicule à l'aide de deux boulons.

ATTENTION :

ATTENTION :

Ces instructions servent à vous guider seulement. L'installation relève de la responsabili té de l’installateur et du

propriétaire. Toujours mesurer la camionnette et la remorque avant d'installer l'attelage pour s'assurer que le

dégagement à l a cabine et au pare-chocs est suffisant pour permettre les virages.

14. Percer des trous de guidage de 1/8 po dans la platefo rme de la camionnet te au niveau des empreinte s

(dimensions approx. à la Figure 15). L'empreinte du centre ne sert que pour les attelage s col-de-cygne. (Voir les

instructions concernant l'att elage col-de-cygn e s'il y a lieu.) Les empreinte s sont f aites en usine. Si les empreintes

sont absentes, se reporter à la Figure 15 de la page 9. Utiliser une scie-cloche 2 ¾ po pour percer aux

emplacements des trous de guidage. Nota : Consulter l'installateur pour connaître le temps de durcissement

recommandé des doublures à vaporiser avant de percer des trous dans le plancher de caisse.

Facultatif : Vaporiser sous le revêtement autour des trous de 2 ¾ po afin de prévenir la corrosion.

15. Repérer l'endroit où les traverses de montage seront insérées au-dessus de la roue arrière côté conducteur. Deux

profilés en forme d'oméga supportent la plateforme au-dessu s de la roue arrière. Les traverses de montage seront

insérées derrière le profilé oméga situé à l'avant, FIGURE 8 à la page 6. Pour créer le déga gement permettant

d'insérer les traverses, retirer les boulons de plateforme côté conducteur, desserrer les boulons de plateform e côté

passager à l'aide d'un embout T50 torx (n

cales.

o

14) (Figure 1), et soulever la plateforme côté conducteur à l'aide de

AVERTISSEMENT :

Surveiller la conduite d'esse n ce et le câblage lors du soulèvement.

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

15

Page 16

Avant du véhicule

Position des

Figure 8

traverses

16. Insérer les traverses (#1) selon les étapes suivantes (Figures 9 à 11). Insérer les traverses côté plat vers le haut.

Profilé oméga avant

Étape 16A : Insérer la première traverse de

montage depuis la roue arrière côté

conducteur, bien au-dessus du cadre.

Appuyer la traverse sur les deux longerons

de châssis (Figure 9).

Avant du

véhicule

Réservoir de

carburant

Réservoir

C

a

d

r

e

de

carburant

Profilé oméga arrière

Figure 9

Étape 16B : Faire glisser la traverse vers

l'arrière, parallèlement à l'essieu,

toujours en appui sur les deux longerons

et aussi près que possible du profilé

oméga arrière (Figure 10).

Figure 10

C

a

d

r

e

Étape 16C : Insérer la deuxième

traverse de montage depuis la roue

Réservoir de

carburant

arrière côté conducteur, bien au-dessus

du cadre. Appuyer la traverse sur les

deux longerons de châssis (Figure 11).

Figure 11

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

16

Page 17

Étape 16D : Après l'installation, une traverse de montage doit faire face à l'arrière et l'autre, à

l'avant. Les traverses doivent être centrées avec leurs deux extrémités reposant

uniformément sur le cadre.

17. Fixer sans trop serrer les supports de cadre (#2 et 3) (Figure 1) aux traverses de montage à l'aide de boulons

longs 5/8” X 1 3/4” (#10) (Figure 1) , de rondelles coniques (#11) (Figure 1) (sous le support), de rondelles

coniques (#11) (à l'intérieur de la traverse) et d'écrous 5/8” (#9) (à l'intérieur de la traverse) (Figure 12). Serrer

tous les boulons de montage à la main.

AVERTISSEMENT :

NE PAS lubrifier les filets des boulons. Cela peut causer la défaillanc e des boulon s.

Figure 12

ATTENTION :

Assurez-vous qu'il n'y a pas d'obst acle s avant de percer. Le défau t d’obse rver ce conseil peut endommag er des

conduites de carburant ou de frein, des éléments structurau x, etc. CEQUENT PERFORMANCE PRODUCTS, Inc. fait

de son mieux pour communiquer les modifications des constructeurs de véhicules ; cependant , il est ultimement de la

responsabilité de l'installateur de prévenir les dommages associé s à l'installation.

18. Sans trop serrer, fixer les supports de cadre dans les trous existants du cadre de châssis à l'aide de boulons M14

1.5 x 45 (#10), de rondelles coniques (#11) (Figure 1) et d'écrous à embase (#12) (Figure 1). Serrer à la main

(Figure 13). Le soulèvement de la plateforme de la camionnette facilitera l'accès aux écrous et boulons côté

conducteur.

Avant

Figure 13

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

17

Page 18

ATTENTION :

Assurez-vous qu'il n'y a pas d'obst acle s avant de percer. Le défau t d’obse rver ce conseil peut endommag er des

conduites de carburant ou de frein, des éléments structurau x, etc.CEQUE NT P ERFORMANCE PRODUCTS, I nc. fait

de son mieux pour communiquer les modifications des constructeurs des véhicules de remorquage ; cependant, il est

ultimement de la responsabilité de l'installateur de prévenir les dommages associés à l'installat ion.

19. Abaisser puis aligner la plateforme, ainsi que les boulons et les trous des réceptacles .

20. Depuis la plateforme de la camionnette, fixer les réceptacles (#7) (Figure 1) et les anneaux de garniture (#8)

(Figure 1) sur les traverses, comme illustré à la Figure 14 ci-dessous , à l'aide de vis à tête ronde 5/8 po (#5),

de rondelles freins (#6) et d'une douille Allen 3/8 po. Serrer au couple de 110 lb-pi.

21. Placer la sellette sur les traverses et fixer en place.

22. Serrer d'abord tous les boulons hex. 5/8 po des traverses au couple de 150 lb-pi. Puis serrer tous les boulo ns

M14 au couple de 140 lb-pi. Nota : Utiliser un cliquet à tête pivotante pour accéder à l'écrou côté conducteur

depuis le dessus du cadre.

23. Remettre en place toute conduite de frein ou tout pneu de secours qui a pu être enlevé ou déplacé.

24. Serrer les boulons de plateforme qui ont été dess errés à l'étap e 14 au couple de 75 lb-pi à l'aide d'un embout

TORX T50 (#14) (FIGURE 1).

NE PAS lubrifier les filets des boulons. Cela peut causer la défaillanc e des boulon s.

AVERTISSEMENT :

Figure 14

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

18

Page 19

Pour attelage

col-de-cygne

seulement

Mise en place

des réceptacles

Découper des rectangles

dans la doublure de caisse

amovible en plastique.

Figure 15

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

AVANT

19

Page 20

REMARQUES

GARANTIE LIMITÉE DE SEPT ANS

Attelages - Récepteurs sur mesure

Cequent Performance Products, Inc. garantit, pendant une période de 7 ans à compter de la date d'achat,

ses attelages à sellette REESE

de l'usure normale) apparus dans le cadre d'un usage et d'un entretien normaux, et ce à condition que le

propriétaire soit l'acheteur d'origine et qu'un ensemble de montage Cequen t Performance Products, Inc.

ait été utilisé.

Cequent Performance Products, Inc. remplacera SANS FRAIS toute pièce qui s’avère défectueuse suite à

un vice de matériau ou de fabrication et qui est retournée au concessionnaire Cequent Performance

Products, Inc., ou à l’entrepôt ou l’usine Cequent Performance Products, Inc. PORT PAYÉ, à l’adresse cidessous. CETTE GARANTIE SE LIMITE AU REMPLACEMENT DES PIÈCES DÉFECTUEUSES

SEULEMENT. ELLE NE COUVRE NI LES FRAIS DE MAIN-D’ŒUVRE, NI LES DOMMAGES SUBIS

LORS DE L’INSTALLATION OU DU REMPLACEMENT, Y COMPRIS LES DOMMAGES ACCESSOIRES

OU INDIRECTS.

Certains États ou provinces ne permettant pas d’exclure ou de restreindre les dommages accessoires ou

indirects, il se peut que la restriction ou l’exclusion ci-dessus ne vous concerne pas.

Tout dommage à l’attelage à sellette attribuable à une mauvaise utilisation, un usage abusif, la

négligence, un accident, une installation inadéquate, ou à toute utilisation contraire aux instructions

fournies par nous, ANNULERA LA GARANTIE.

Certains droits particuliers vous sont dévolus en vertu de la présente garantie et peuvent s'accompagner

d'autres droits qui varient selon votre lieu de résidence. Dans l'éventualité d'un problème av ec le service

de la garantie ou le rendement du produit, il se peut que vous puissiez recourir à la cour des petites

créances ou une cour d'une autre juridiction.

™

Elite® Series contre les vices de matières et de fabrication (à l'exception

Cequent Performance Products, Inc.

47912 Halyard Dr, #100

Plymouth, MI 48170

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

20

Page 21

INSTRUCCIONES DE INSTALACIÓN

KIT DE MONTAJE

FORD F250/F350/F450

HD/SD

Bases de 6' y 8'

NO SUPERE LA CALIFICACIÓN DEL FABRICANTE DEL VEHÍCULO PARA EL

REMOLQUE DE QUINTA RUEDA O EL PESO BRUTO MÁXIMO DEL REMOLQUE DE

25,000lb. / 11,340kg Y UN PESO MÁXIMO

DEL KING PIN DE 6,250lb. / 2,835kg.

*Lea y entienda estas instrucciones antes de la instalación.

CONCESIONARIO/INSTALADOR:

USUARIO FINAL:

(1) Entregue este manual al usuario final.

(2) Demuestre físicamente los procedimientos en este manual al usuario final.

(3) Pida al usuario final que le demuestre que entiende los procedimientos.

(1) Lea y siga este manual todas las veces que use su enganche.

(2) Guarde este Manual para referencia futura.

(3) Distribuya copias de este manual a cualquier otro usuario o propietario del enganche.

NÚMERO DE

PARTE

30126

Frente del

vehículo

PARTE CANT.

1. LARGUERO BASE (2)

2. SOPORTE DEL BASTIDOR (LADO CONDUCTOR) (1)

3. SOPORTE DEL BASTIDOR (LADO PASAJERO) (1)

4. TAPÓN DE DISCO (4)

5. TORNILLO CABEZA DE BOTÓN 5/8-11 x 1-3/4 (4)

6. ARANDELA DE BLOQUEO 5/8 " (4)

7. DISCO (4)

8. ARO DECORATIVO (4)

9. TUERCA HEXAGONAL GRADO 8 5/8"-11 (4)

10. PERNO M14 X 1.5 X 45 CL10.9 (4)

11. ARANDELA CÓNICA 5/8” (12)

12. TUERCA CON REBORDE – M14 x 1.5 (4)

13. PERNO HEXAGONAL GRADO 8 5/8" x 1-3/4 (4)

14. BROCA Torx T50 (1)

Figura 1

Para Servicio al Cliente llame al 1-888-521-0510.

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

Page 22

ADVERTENCIA:

¡No seguir estas instrucciones puede resultar en la muerte o en lesiones serias!

ÍNDICE

1. PAUTAS PARA AJUSTAR EL VEHÍCULO DE REMOLQUE Y EL REMOLQUE P. 2-4

2. INSTRUCCIONES DE ENSAMBLE P . 5-9

3. GARANTÍA LIMITADA DE SIETE AÑOS DE CEQUENT PERFORMANCE PRODUCTS, INC P. 10

PAUTAS PARA AJUSTAR EL VEHÍCULO DE ENGANCHE Y EL REMOLQUE

ADVERTENCIA:

No revisar o no seguir las calificaciones de remolque podría resultar en daño al

vehículo de remolque o separación del vehículo y remolque durante el desplazamiento.

•El remolque y su contenido combinados no deben exceder las calificaciones del vehículo, enganche y/o

remolque.

•El vehículo de remolque debe tener una capacidad de remolque establec ida por el fabricante que sea

igual o superior al peso bruto del remolque (peso seco del remolque más la carga útil del remolque).

(Figura 2)

•El peso bruto del remolque no debe superar la calificación del enganche de quinta rueda.

•El peso del king pin no debe superar la calificación de la quinta rueda (Figura 3). Si tiene dudas haga que

un técnico calificado pese el king pin.

REMOLQUE DE FÁBRICA + TANQUES

LLENOS DE AGUA Y COMBUSTIBLE +

CARGA, ETC. = PESO BRUTO DEL

REMOLQUE

Indique el total abajo

Figura 2

1. Peso máximo bruto del remolque: 25,000 lb / 11,340kg.

Calificación del remolque del vehículo: _______________.

Peso bruto total calculado del rem ol que (Figura 2):______________.

*El peso del remolque debe ser el inferior de estas calificaci ones registradas para unas condiciones seguras.

2. Los enganches de Cequent Performance Products, Inc. están diseñados para uso con remolques de recreación de quinta r ueda

únicamente. Las aplicaciones de enganche diferentes a los remolques con quinta rueda recreacional deben ser aprobadas por

escrito por el departamento de Ingeniería de Cequent Performance Products, Inc.

3. Use únicamente un king pin SAE de 2 pul gadas con su Enganche de Quinta Rueda REESE

4. Aproximadamente 15%-25% del peso del remolque debe estar en el enganche (peso del Pin)(Figura 3).

Figura 3

™

Elite

®

Series

15-25%

PESO BRUTO

DEL REMOLQUE

(PESO DEL PIN)

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

75-85%

PESO BRUTO

DEL REMOLQUE

22

Page 23

5. Los vehículos vienen en muchas configuraciones diferentes. Los enganches de Cequent Performance Products, Inc. están

diseñados para uso en vehículos livianos como la serie Ford F, los Chevy Silverado y los Dodge Ram. Cequent Performance

Products, Inc. recomienda el uso de vehículos livianos con bases de 6 pies de largo o mayores para l a m ej or combinación en el

despeje de giros de vehículo - remolque. Consulte el s itio Web para la aplicación del vehí culo.

NOTA: Para evitar que el remolque golpee la cabina con un giro de 90°, el centro del enganche debe estar al menos a 52 pulgadas

desde la parte posterior de la cabina cuando se us e un vehículo de base larga. (La distancia real requerida dependerá del

ancho del remolque y de la ubicación del king pin.) Los vehículos de base m ás corta (mínimo 38 pulgadas desde la cabina

posterior hasta la línea del eje central) requier en una caja conectora extendida de un mínimo de 13 pulgadas (Figura 5) o una

caja conectora SIDEWINDER

6. La altura del enganche y de la caja de conectores se debe ajustar de manera que el remolque esté nivelado aproximadamente

a medida que se remolca. Permita aproximadamente 6 - 9 pulgadas de despeje entre la parte superior de los largueros base y

la parte inferior del frente del remolque para el c abeceo y rollido del remolque. (Figura 6) Permita más despeje entr e l as

paredes de la camioneta y el remolque para uso f uer a de la carretera.

Figura 5

Regla de oro: La distancia desde la parte posterior de la cabina del vehículo hasta el centro del eje

del vehículo posterior (“X” en la Figura 4), debería ser aproximadamente 4 pulgadas mayor que la

mitad del ancho del remolque (Y” en la Figura 4)

Figura 4

Caja conectora convencional

¡No instale este enganche de quinta rueda ni intente remolcar con un vehículo tipo

pickup de base corta inferior a 6 pies, a menos que el remolque esté equipado con

una caja conectora Sidewinder

TM

o ensamble de enganche con deslizador para maniobras normales.

REMOLQUE RV

VEHÍCULO

Caja conectora extendida

KING PIN

ADVERTENCIA:

TM

!

Figura 6

Aproximadamente 6-9 pulg.

Remolque nivelado

PRECAUCIÓN:

Las medidas anteriores son pautas. Si sus medidas están cercanas a estos números, vuelva a revisar los despejes.

Si el vehículo y/o el remolque tiene cualquier accesorio agregado cerca a la base (por ejemplo protectores de faros,

desviadores de aire, efectos en el piso, largueros base, celdas de combustible, caja de herramientas, etc.), se deben

hacer revisiones adicionales de despeje y dimensionamiento.

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

23

Page 24

7. Determinación de la altura del enganche:

Con el remolque nivelado y sobre terreno plano mida desde el piso hasta la base de la caja del king pin (“A” en la Figura 7).

Luego, mida la altura del interior de la base del v ehículo hasta el piso (“B” en la Figura 7). Determine la cantidad de despeje

sobre los largueros laterales ( “C” y “D” en l a Figura 7).

Altura del enganche = A – B + 2” **

** El valor de 2” es un estimado de la compresión de suspensión debido al peso del king pin del remolque. Esta compr esión

podría oscilar entre 1”-5” dependiendo del v ehículo y remolque que se usen.

D – C + 2” > 6”

(C)

B

8. Si se va a usar una placa de lubricación con una Quinta Rueda REESE™ Elite® debe tener al menos 12” de diámetro. Cequent

Performance Products, Inc. ofrece esta placa de lubricación opcional como parte No. 83001.

A

Figura 7

*MEDIDO CON EL NIVEL DEL REMOLQUE,

D

SOBRE TERRENO NIVELADO

ADVERTENCIA:

•La conexión del cableado del remol que deb e ser en el costado de la base del v ehícu lo entre el asiento

del conductor y la rueda posterior para evitar que los operadores trabajen entre el vehículo y el

remolque.

•Evite colocar cualquier parte de su cuerpo debajo del remolque o entre el vehícul o y el remolque. El

movimiento no esperado o accidental del vehículo o el remolque puede causar lesiones serias o muerte.

•Si debe colocar cualquier parte de su cuerpo debajo del remolque o entre el v ehículo y el remolque,

usted DEBE realizar TODOS los pasos siguientes:

•Revise que la transmisión del v ehículo esté en posici ón de estac iona mi ento

•Revise que el freno de emergencia esté activado

•Coloque bloques al frente y detrás de todas las llantas del remolque

•Revise que el tren de apoyo del remolque esté apoyado en terreno firme

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

24

Page 25

INSTRUCCIONES GENERALES PARA LA INSTALACIÓN DE LA QUINTA RUEDA

HERRAMIENTAS

Broca 1/8" Llave abierta y de tubo 15/16"

Broca Torx T50IP (suministrada con el kit) Llave de torsión 200 lb-pies

Mazo de goma Sierra de copa 2-3/4”

Llave abierta y de tubo 21mm Llave abierta y de tubo 19mm

Alicates de sujeción Trinquete de cabeza giratoria 1/2”

¡PRECAUCIÓN!

Lea las páginas 2-4 de estas instrucciones antes de empezar la instalación. ¡No hacerlo podría resultar en daños significativos al

vehículo!

9. Las siguientes instrucciones se deberán usar para instalar el kit de montaje de la quinta rueda. La atención a los

detalles garantizará una instalación rápida de calidad. Revise las partes contra la lista para familiarizarse con las

partes del kit. (Figura 1)

10. 10. Levante la parte posterior del vehículo lo suficiente para permitir que las bases del gato se coloquen debajo

del soporte colgante posterior de resorte del vehículo. Esto permitirá espacio máximo para instalar los soportes

de la quinta rueda.

ADVERTENCIA:

Si el vehículo se levanta, verifique que el vehícul o esté correcta mente bl oqueado y restringido para ev itar que

se caiga. No hacerlo podría resultar en la caída repentina del vehículo, y causar la muerte o lesiones serias.

11. Retire el forro plástico de la base si corresponde. Los forros plásticos de aplicación directa de la base se

recortarán después. (Ver Figure 15) Los forros y alfombras de la base de aplicación con spray de menos de 1/4”

de espesor funcionarán según las instrucciones normales de instalación . Nota: Consulte con el instalador los

tiempos de curado recomendados para los forros aplicados con spray antes de recortar los orificios en la base.

Revise en busca de obstrucciones antes de perforar. No hacerlo podría resultar en daños a las líneas de

combustible o frenos, miembros estructurales etc. CEQUENT PERFORMANCE PRODUCTS, Inc. in tenta al

máximo comunicar los cambios del fabricante del v ehículo de remol que; sin embargo, es finalmente

12. Use únicamente los pernos, tuercas y arandelas suminist rados por CEQUENT PERFORMANCE PRODUCTS, Inc.

para instalar este kit. Todos los pernos y tuercas son Grado 8 a menos que se especifique lo contrario.

13. Estas instrucciones están diseñadas para el Ford Super Duty 2011 con bases de 6 a 8 pies. Cada soporte del

bastidor se debe atornillar al bastidor del vehículo con dos pernos.

responsabilidad del instalador evitar daños por causa de la instalación.

PRECAUCIÓN:

PRECAUCIÓN:

Estas instrucciones son pautas únicamente. La instalación real es responsabilidad del instalador y del

propietario. Siempre mida el vehículo y el remolque antes de instalar el enganche para verificar que haya

espacio en la cabina y en el parachoques para permitir los giros.

14. Perfore orificios piloto de 1/8” en la base del vehículo en las ubicacione s hend ida s en el exterior (dimension es

aproximadas de Figura 15). La hendidura del medio es para la bola de ganso únicam ente . (Ver las instrucciones

del cuello de ganso si corresponde) Estas ubicaciones hendida s se colocan en la fábrica. Si no hay hendiduras

presentes, consulte la (Figura 15) que se encuen tra en la página 9. Use una sierra de copa de 2 3/4” para cortar

el orificio en los orificios piloto. Nota: Consulte con el instalador los tiempos de curado recomend ado s para los

forros aplicados con spray antes de recortar los orificios en la base. Opcional: Rocíe deba jo de las capas

alrededor de los orificios de 2 ¾” para evitar la corrosión.

15. Localice el área donde se insertarán los largueros base por encima de la rueda posterior en el lado del conductor.

Hay dos canales de perfil que apoyan la base del vehículo sobre la rueda posterior. Los largueros base se

insertarán en la ubicación detrás del canal de perfil delantero (FIGURA 8) que se encuentra en la página 6. Para

crear distancia para insertar los largueros retire los pernos de la base del lado del conductor, afloje los pernos de

la base del lado del pasajero con una broca Torx T50 (#14) (Figura 1), y bloquee la base del lado del conductor.

ADVERTENCIA:

Tenga cuidado con la línea de combustible y cables mientras se esté elevando.

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

25

Page 26

Frente del

vehículo

16. Inserte los largueros (#1) como se muestra en los siguientes pasos (Figuras 9 hasta 11). Los largueros se deben

insertar con el lado plano hacia arriba.

Posiciones de

los largueros

Celda de

combusti

ble

Canal de perfil frontal

Figura 8

Paso 16A : Inserte el primer larguero

desde la rueda trasera del lado del

conductor bien por encima del bastidor.

Apoye el larguero en ambos largueros

del bastidor del chasis (Figura 9).

Frente

del vehículo

Celda

de

combus

tible

B

a

st

id

o

r

Canal de perfil trasero

Figura 9

Paso 16B : Deslice el larguero hacia

atrás, paralelo con el eje, apoyando

en ambos largueros del bastidor, y lo

más cerca posible al canal de perfil

posterior (Figura 10).

Figura 10

B

a

st

id

o

r

Celda de

combusti

ble

Paso 16C : Inserte el segundo

larguero desde la rueda trasera del

lado del conductor bien por encima

del bastidor. Apoye el larguero en

ambos largueros del bastidor del

chasis (Figura 11).

Figura 11

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

26

Page 27

Paso 16D : Un larguero debería estar orientado hacia atrás y el otro hacia adelante de la

instalación. Los largueros se deben centrar con ambos extremos de cada

larguero apoyados de manera uniforme en el bastidor.

17. Sin apretar instale los soportes del bastidor (#2 y 3) (Figura 1) a los largueros del kit de montaje, usando pernos

de 5/8” X 1 3/4” (#10) (Figura 1) de largo y arandela s cónicas (#11) (Figura 1) (debajo del soporte), arandelas

cónicas (#11) (larguero interior), y tuerca de 5/8” (larguero interior) (#9) (Figura 12). Apriete a mano todos los

pernos del kit de montaje.

ADVERTENCIA:

NO lubrique las roscas. Podría causar falla de los pernos.

Figura 12

PRECAUCIÓN:

Revise en busca de obstrucciones antes de perforar. No hacerlo podría resultar en daños a las líneas de

combustible o frenos, miembros estructurales etc. CEQUENT PERFORMANCE PRODUCTS, Inc. in tenta al

máximo comunicar los cambios del fabricante del v ehículo de remol que; sin embargo, es finalmente

responsabilidad del instalador evitar daños por causa de la instalación.

18. Sin apretar instale el soporte del bastidor a los orificios existentes del bastidor del chasis usando pernos M14 1.5 x

45 (#10), arandelas cónicas (#11) (Figura 1), y tuerca mariposa (#12) (Figura 1). Apriete a mano (Figura 13).

Levantar la base del vehículo permite un acceso más fácil a la tuerca y perno del lado del conductor.

Frente

Figura 13

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

27

Page 28

PRECAUCIÓN:

Revise en busca de obstrucciones antes de perforar. No hacerlo podría resultar en daños a las líneas de

combustible o frenos, miembros estructurales etc. CEQUENT PERFORMANCE PRODUCTS, Inc. in tenta al

máximo comunicar los cambios del fabricante del v ehículo de remol que; sin embargo, es finalmente

responsabilidad del instalador evitar daños por causa de la instalación.

19. Baje y alinee la base, los pernos y los orificios para los discos, si es necesario.

20.

Desde la base del vehículo instale los discos (#7) (Figura 1) y aros decorativos (#8) (Figura 1) a los largueros

como se muestra en la Figura 14 abajo usando un tornillo cabeza de botón de 5/8” (#5) y arandela de

bloqueo (#6) usando 3/8in. Llave ALLEN Apriete a torsión a 110 pies-lbs..

21. Coloque la quinta rueda en el kit de largueros y asegure en su lugar.

22. Apriete a torsión todos los pernos hexagonales de 5/8" del kit de largueros a 150 pies-libras primero. Luego,

apriete a torsión todos los pernos M14 a 140 pies-libras. Nota: Use un trinquete con cabeza giratoria para

tener acceso a la tuerca delantera del lado del conductor desde el bastidor.

23. Reemplace cualquier línea de frenos y llanta de repuesto que se haya retirado/reub icado.

24. Apriete a torsión los pernos de la base que se aflojaron en el paso 14 a 75 pies-lbs con una BROCA TORX

T50 (#14) (FIGURA 1).

NO lubrique las roscas. Podría causar falla de los pernos.

ADVERTENCIA:

Figura 14

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

28

Page 29

APLICACIONES

DE CUELLO DE

GANSO

ÚNICAMENTE

Colocación del

disco

Corte

rectángulos del

forro de la base

plástica

Figura 15

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

desmontable.

ADELANTE/FRENTE

29

Page 30

NOTAS:

GARANTÍA LIMITADA DE SIETE AÑOS

Enganches - Receptores a la medida

™

Cequent Performance Products, Inc. garantiza el Ki t de Montaje de Quinta Rueda Ser ie REESE

®

desde la fecha de compra contra defectos en los materiales y mano de obra bajo

Elite

condiciones normales de uso y servicio, excepto por el desgaste normal, por 7 años de propiedad

al comprador consumidor original cuando se use un kit de montaje de Cequent Performance

Products, Inc.

Cequent Performance Products, Inc. reemplazará SIN COSTO cualquier parte que resulte

defectuosa en materiales o mano de obra cuando se presente a cualquier concesionario de

Cequent Performance Products, Inc., a una bodega de Cequent Performance Products, Inc. o a la

fábrica. CARGOS POR TRANSPORT E PREPAGADOS, a la dirección a continuación. ESTA

GARANTÍA ESTÁ LIMITADA A LA REPOSICIÓN DE PARTES DEFECTUOSAS ÚNICAMENTE. SE

EXCLUYEN LOS CARGOS DE MANO DE OBRA Y /O DAÑOS I NCURRIDOS EN LA INSTALACIÓN O

REEMPLAZO ASÍ COMO LOS DAÑOS CONSECUENCIALE S O INCIDENTALES RELACIONADOS.

Algunos estados no permiten la exclusión o limitación de los daños incidentales o

consecuenciales, por lo que la exclusión o limitación anterior podría no corresponderle.

Cualquier daño al enganche de quinta rueda como resultado del mal uso, abuso, negligencia,

accidente, instalación incorrecta, o cualquier uso en contra de las instrucciones entregadas por

nosotros INVALIDARÁ LA GARANTÍA.

Esta garantía le otorga derechos legales. Usted también podría tener otros derechos que v arían d e

estado a estado. En el evento de un problema con el servicio de garantía o desempeño, usted

puede acudir a una corte de demandas menores, una corte estatal, o una corte federal del distrito.

Cequent Performance Products

47912 Halyard Dr. #100

Plymouth, MI 48170

30126N 03/16/11 REV E PCN15022 ©2011 CEQUENT PERFORMANCE PRODUCTS, INC. PRINTED IN USA

30

Loading...

Loading...