Page 1

INSTRUCTION & OPERATION MANUAL

You can take it with you.

20K - Fifth Wheel Hitch

DEALER/INSTALLER:

(1) Provide this Manual to end user.

(2) Physically demonstrate hitching and unhitching

procedures in this Manual to end user.

(3) Have end user demonstrate that he/she

understands procedures.

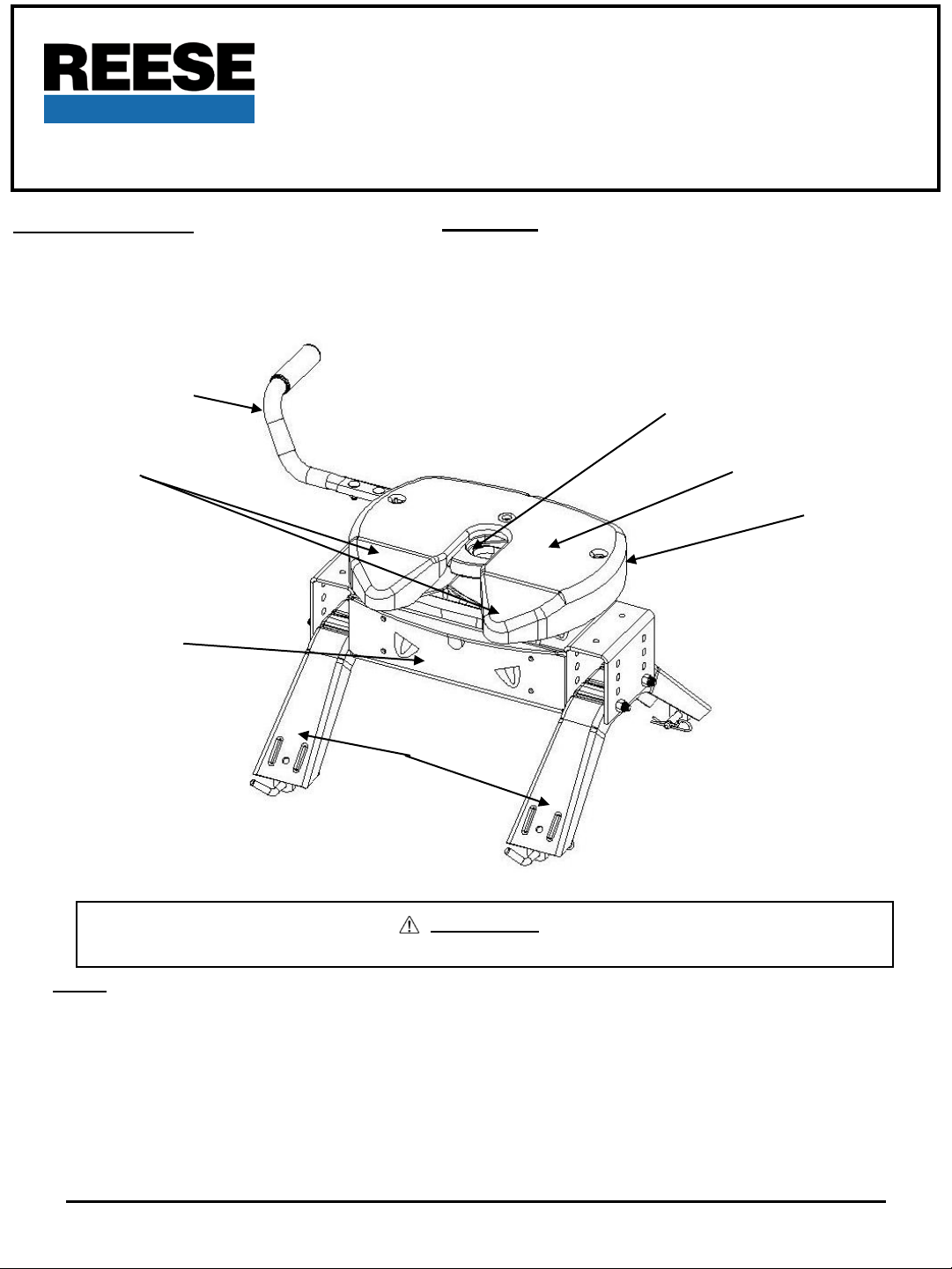

HANDLE

RAMP

END USER:

(1) Read and follow this Manual every time you use hitch.

(2) Save this Manual and Hitch Warning Hang Tag for future reference.

(3) Pass on copies of Manual and Hitch Warning Hang Tag to any other

user or owner of hitch.

(4) Never remove hitch warning decals as shown on the cover of this

manual. If damaged, contact Cequent Performance Products (1-

800-632-3290) for free replacement.

JAW TO HOLD

KING PIN

SKID PLATE

HEAD

ASSEMBLY

CENTER SECTION

SIDE BRACKETS

WARNING:

Failure to follow all of these instructions may result in death or serious injury

INDEX

1. ASSEMBLY INSTRUCTIONS

2. BEFORE EACH TRIP P. 2

3. HITCHING PROCEDURE P. 3

4. PULL TEST P. 6

5. UNHITCHING PROCEDURE P. 6

6. MAINTENANCE P. 7

7. FIVE YEAR LIMITED WARRANTY P. 9

8. APPENDIX A (Guidelines for matching hitch, truck, and trailer) P. 10

9. APPENDIX B (Guideline for center section orientation) P. 14

For Installation Assistance or Technical Help, Call 1-888-521-0510

30081N-7 July10 F PCN13787 ©2010 CEQUENT PERFORMANCE PRODUCTS, INC LITHO IN USA

FOR KITS: 30081, 40261 & 50181

Page 2

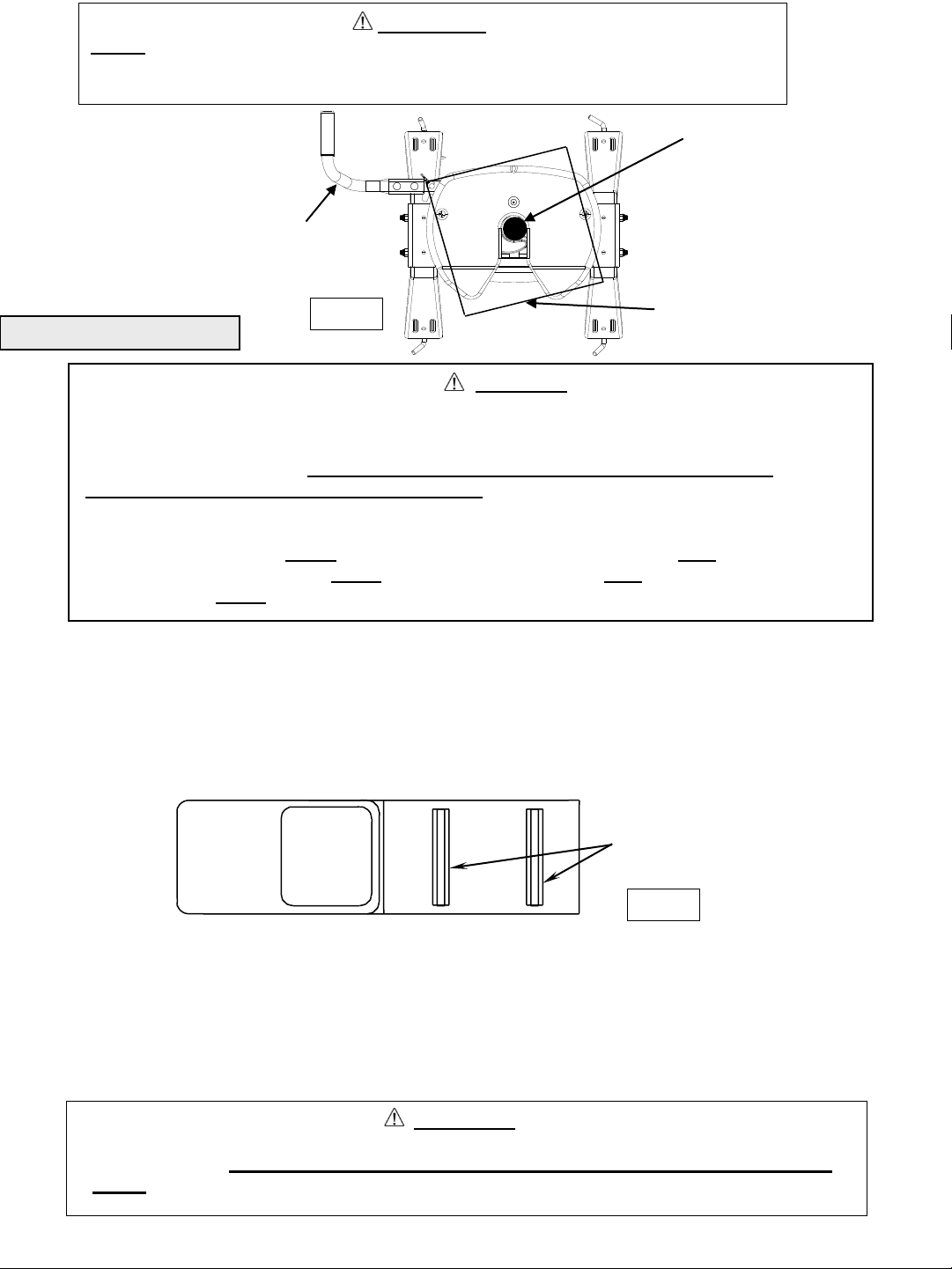

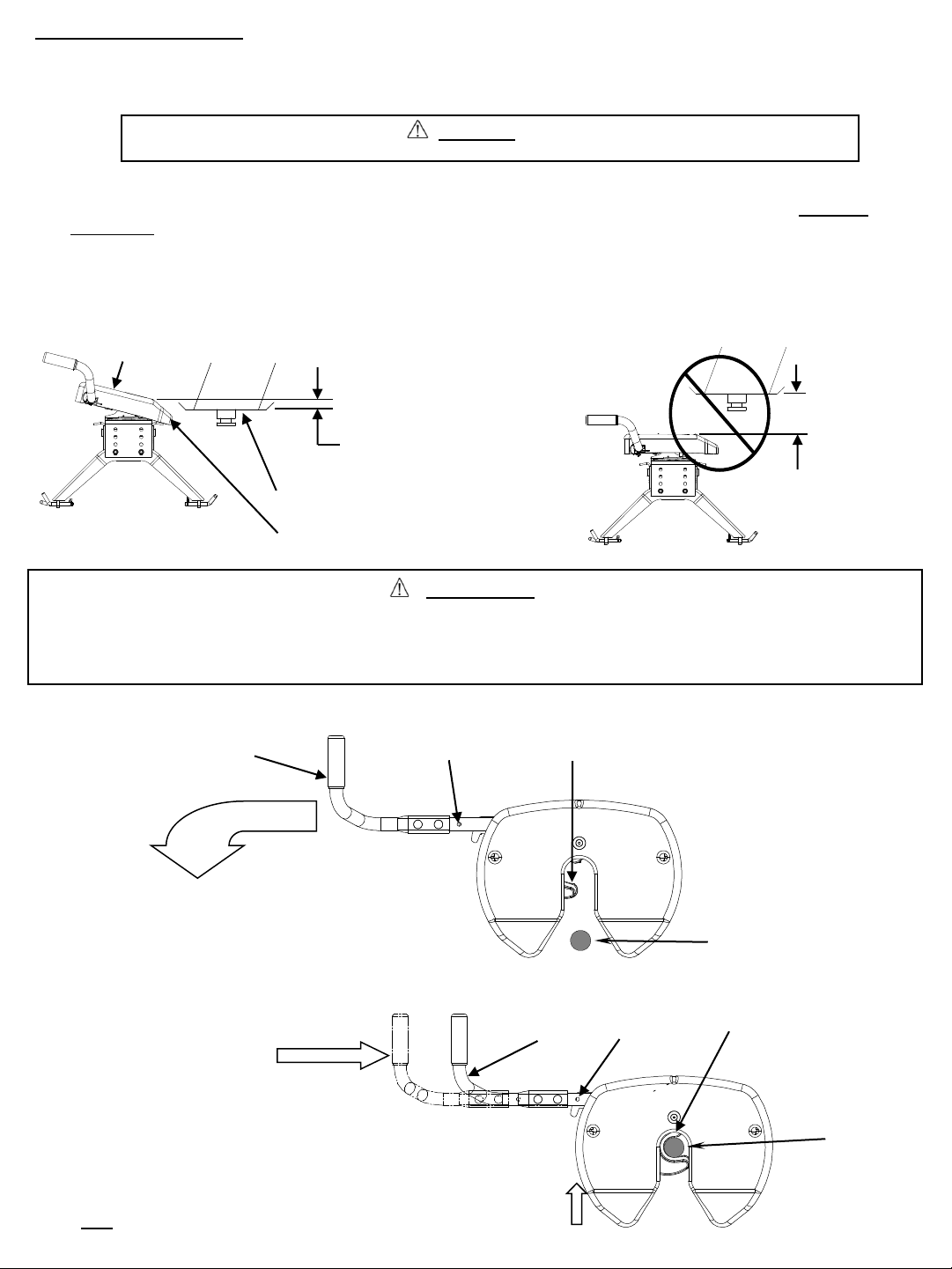

WARNING:

Do Not use this hitch for towing a trailer with a pin box that could come into contact with

or interfere with the latch for the hitch handle when turning! (See Fig. A) If the pin box

contacts the hitch handle or its latch when turning, the trailer may become unhitched.

KING PIN

LATCH

Fig. A

ASSEMBLY INSTRUCTIONS

BOTTOM OF PIN BOX

WARNING:

Connection for trailer wiring should be in the side of the truck bed between the driver’s

seat and the wheel well for the back truck axle

Installation of connection rearward of the wheel well may result in user placing body

between truck and trailer. WHENEVER POSSIBLE, AVOID PUTTING BODY UNDER

TRAILER OR BETWEEN TRUCK AND TRAILER!

If you need to place any part of your body under trailer or between truck and trailer:

All trailer tires MUST be blocked in front and behind each tire AND

Trailer landing gear MUST be resting on firm ground AND

Truck MUST be stationary, in park, with emergency brake on!

1. Reference Fig. 11 on page 8.

2. 5th Wheel Kit is contained in three cartons. Unpack and become familiar with parts on parts list. Base rails, brackets and

hardware are in separate kit (part no. 30035) with separate Installation Instructions for Fifth Wheel Rail Mounting Kit.

3. Place two base rails across bed of truck (See Fig. B). Select one side bracket and place tabs through the centermost

rectangular slot in the base rails. Slip long pull pins through holes in base rails. Repeat. Secure pull pins with spring retaining

clips.

BASERAILS

Fig. B

4. Select 20K Center Section and install on leg aligning holes for hitch height desired. (Lowest position 13" highest 17").

Install four 1/2-13 x 4.5" Hex bolts, (with heads toward inside as shown) and lock nuts. (See Appendix B for center

section orientation)

5. Torque 1/2" nuts to 75 lb. ft.

6. Install base rails and mounting brackets as described in "Installation Instructions for 5th Wheel Rail Mounting Kit,” Part #

30035.

WARNING

Base rails must be bolted through the floor of the pickup to the brackets that attach to

the truck frame. DO NOT INSTALL BY FASTENING TO THE FLOOR OF THE PICKUP BOX

ONLY. The floor alone is not strong enough to carry the loads imposed by the trailer.

30081N-7 July10 F PCN13787 ©2010 CEQUENT PERFORMANCE PRODUCTS, INC LITHO IN USA

FOR KITS: 30081, 40261 & 50181

Page 3

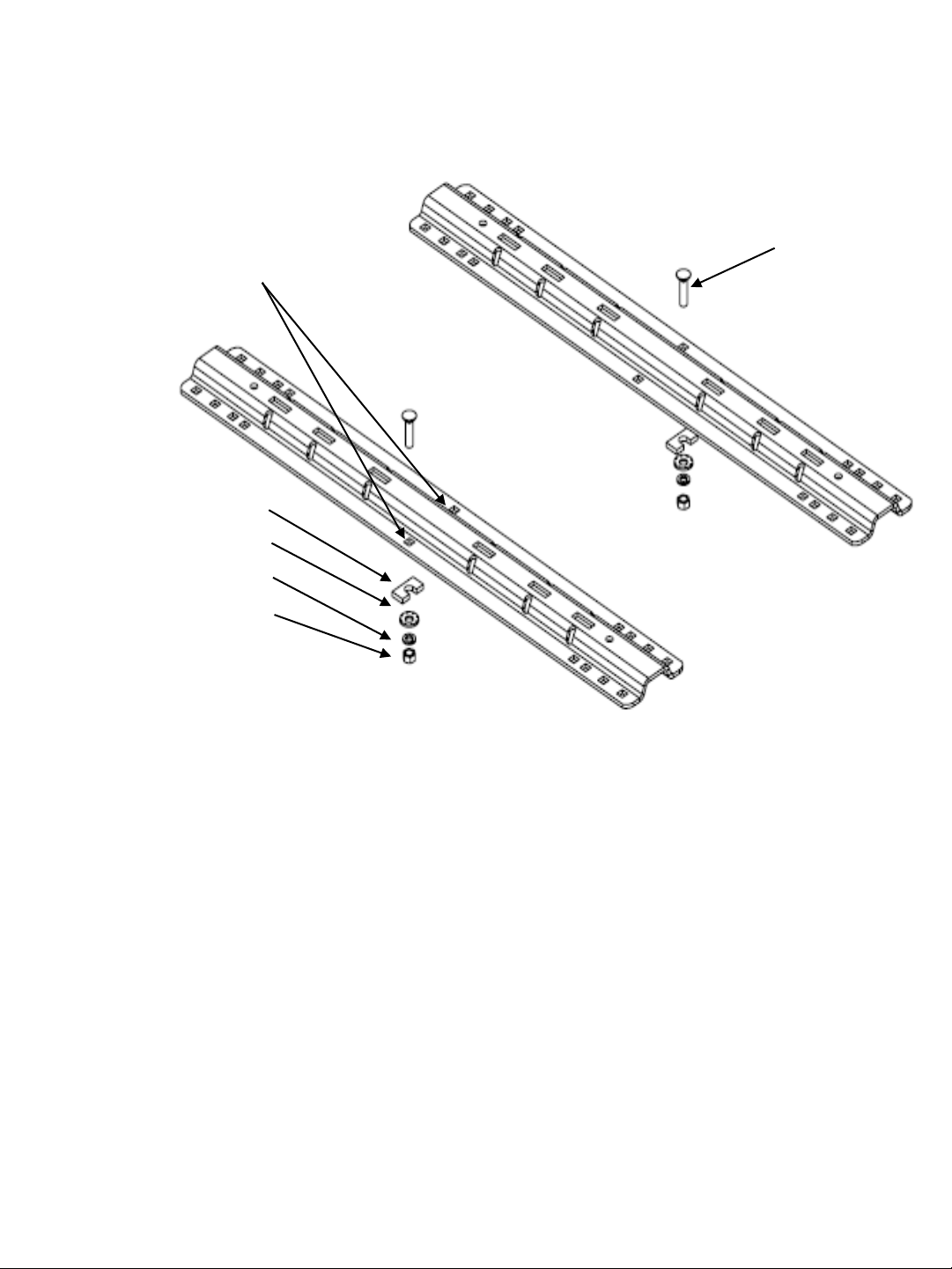

SUPPLEMENT TO 30095N

INSTALL BOLT IN EITHER POSITION WHICHEVER

IS CLOSER TO UNDER BED SUPPORT

SPACER (30)

SERRATED WASHER (31)

LOCK WASHER (32)

½” CARRIAGE BOLT (29)

½” HEX NUT (33)

ADDITIONAL MOUNTING INSTRUCTIONS:

Install base rails as instructed in base rail instructions. The instruction below is for the

addition of the 2 center bolts for applications using 30095.

1. Place base rails in accordance with base rail mounting instructions.

2. BEFORE DRILLING ANY HOLES, CHECK FOR CLEARANCE AROUND THE GAS TANK.

3. Using the center hole in the base rail as a guide, drill a ½” hole through the truck bed.

4. Insert ½” carriage bolt (29) into the hole. Install ½” serrated washer (31), ½” lock washer (32) and ½”

nut (33).

5. Insert spacer (30) between the truck bed and the base rail. It will go in between at the corrugation of the

bed. To keep bed from crushing when the bolt is tightened.

6. Repeat for the other base rail.

7. Torque the ½” nuts to 75 ft/lbs.

30081N-7 July10 F PCN13787 ©2010 CEQUENT PERFORMANCE PRODUCTS, INC LITHO IN USA

FOR KITS: 30081, 40261 & 50181

3

Page 4

GUIDELINES FOR MATCHING HITCH TRUCK AND TRAILER

If preparing to tow a 5th wheel trailer which you have not rating checked previously, please

consult Appendix A of 5th Wheel Kit assembly instructions.

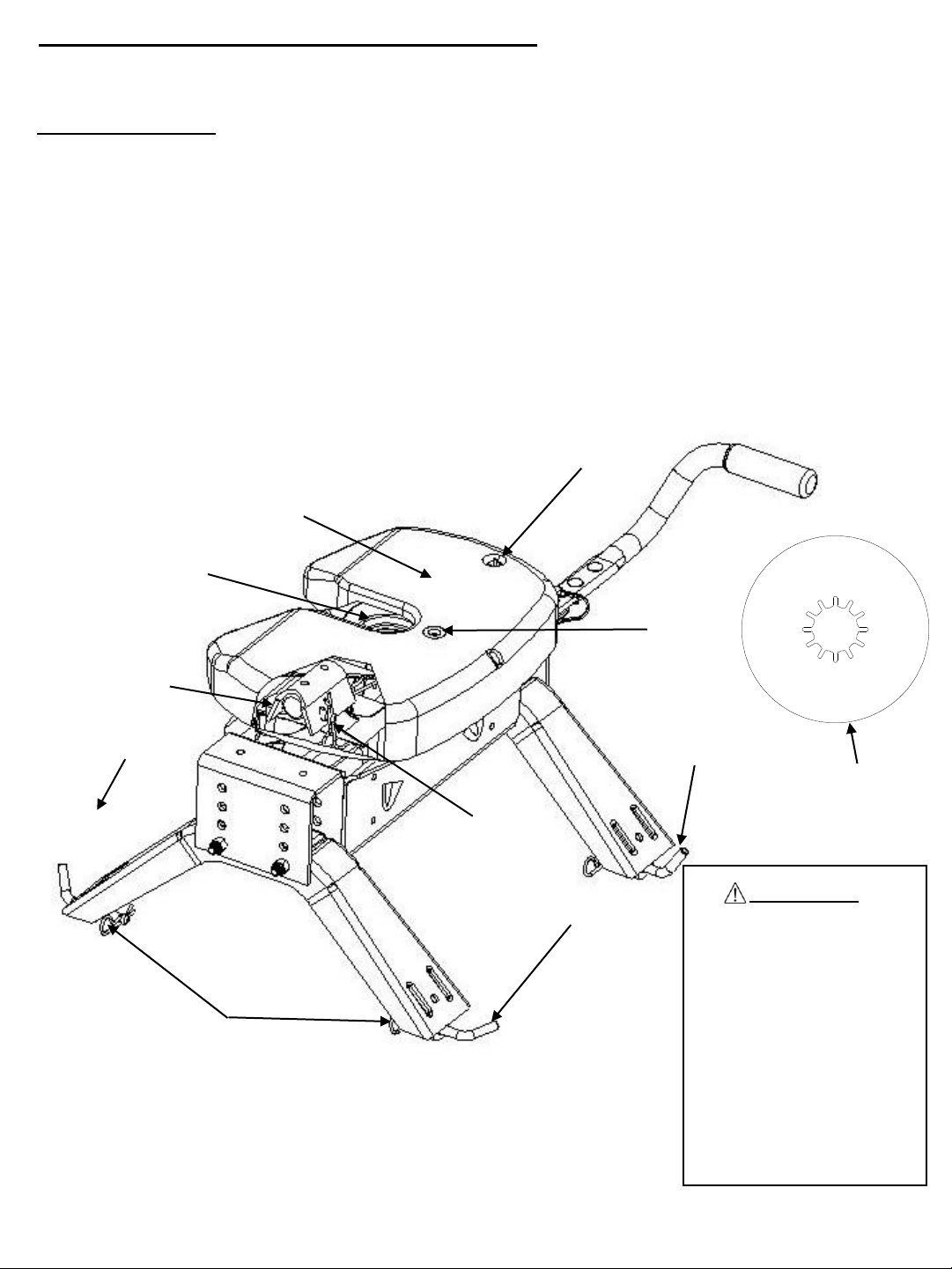

BEFORE EACH TRIP:

1.Lubricate skid plate surface of the hitch and pivot pin grease fitting (see Figure on cover of Manual) with automotive type

chassis grease or use a plastic lube plate to provide a lubricated surface. Use lithium grease to lubricate pivot points of

moving parts within the hitch.

2. Plastic lube plates (Performance Products No. 83001/40001) can be used to avoid messy grease. The plastic lube plate

must not exceed 3/16 of an inch in thickness to ensure hitch will operate properly. Lube plates must be 12 inches in

diameter or larger to properly distribute king pin weight.

3. Before each trip or maneuver, operate the handle and check that the jaw opens and closes freely.

4. See that all hitch pull pins (#7 (P/N 30434) & #12 (P/N 110974), Figure 11) are in place and the spring retaining clips (#4,

Figure 11) are installed (Figure 1). Note that hitch pull pins used to attach the head assembly to the center section for the 5th

Wheel Kit Hitch are 90 degree bent pins and if replacements are needed, please contact Customer Service at (800) 632-

3290. Check that all four anchor assembly pins are pinned and have the retaining clips attached.

Sight Hole

Lube Skid Plate

(With No Lube Plate)

Lube Jaw

Pull Pin 90°

Pull Pin

Retaining Clip

Retaining Clip

Figure 1 : Pin and Clip (Skid Plate cut away view)

Pull Pin

Grease Fitting

Pull Pin

Lube Plate

(Optional)

WARNING:

To prevent tilting head

detachment and or

separation of hitch you must

make sure that the anchor

assemblies are properly

installed and pinned, and

the spring retaining clip is

properly installed onto the

½” pull pin before towing.

The spring retaining clip can

easily be seen through the

site holes in the top of the

head.

30081N-7 July10 F PCN13787 ©2010 CEQUENT PERFORMANCE PRODUCTS, INC LITHO IN USA

FOR KITS: 30081, 40261 & 50181

Page 5

HITCHING PROCEDURE:

IMPORTANT: YOU ARE RESPONSIBLE FOR SAFE HITCHING AND UNHITCHING OPERATIONS. DO NOT RELY ON

OTHERS TO PERFORM THESE DUTIES. YOU MUST PERSONALLY MAKE SURE THE FOLLOWING

STEPS ARE PERFORMED IN THE FOLLOWING ORDER!

WARNING:

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN DEATH OR SERIOUS INJURY.

1. Place blocks (sometimes called “chocks”) firmly against front and rear of each trailer wheel to prevent any possible

forward or rearward motion. DO NOT REMOVE BLOCKS UNTIL EACH OF THE FOLLOWING STEPS AND THE

PULL TEST HAVE BEEN COMPLETED. Lower tailgate if necessary. Clearance of the lowered tailgate to the trailer needs

to be monitored during hookups as some manufacturer combinations of truck and trailer have little or no clearance.

2. Using trailer jacks, adjust trailer height following the directions in the trailer manual so that bottom of trailer pin box (“A” in

Figure 2) is ½ to 1 inch below skid plate (See “B” in Figure 2). During the hitching maneuver, the bottom of the trailer pin

box should come in contact with skid plate ramp (“C” in Figure 2).

Hitch Skid Plate (B)

Figure 2

CORRECT

Bottom of Pin Box (A)

1/2 To 1 Inch Below

Hitch Skid Plate (B)

Bottom of Pin Box (A)

Skid Plate Ramp (C)

Figure 3

WRONG

Bottom of

Pin

Box Above

Hitch Skid

Plate

WARNING:

Failure to follow this instruction may result in king pin being too high and coming to rest on top of the closed jaw

or not completely inside jaw. (See Figure 6 & 7). This could result in trailer separating from hitch. Trailer

separation may result in death or serious injury if anyone is under the trailer or between truck and trailer when

separation occurs.

3. Remove bail pin from bail pin hole (see Figure 4). Then pull handle out and rearward to hold open

NOTE: Hitch jaw must be in the open position for king pin to enter the hitch.

Handle

Pull handle out

and latch to the

rear to open

hitch jaw

4. With handle in the open position (See Figure 4), back truck slowly into trailer. As king pin

completely enters head, jaw will spring closed around king pin and handle will return to the closed

position. If the handle does not return to the

closed position, then

try to push the handle back to the

closed position. If handle does

not return to the closed position

then move the truck slightly forward

or rearward until the handle returns

to the closed position. (See Figure 5)

Bail Pin Hole

Figure 4

Hitch Jaw (Shown in open position)

King pin

Handle

Bail Pin Hole

Hitch Jaw

King pin

5. Use only the method described above for hitching.

30081N-7 July10 F PCN13787 ©2010 CEQUENT PERFORMANCE PRODUCTS, INC LITHO IN USA

FOR KITS: 30081, 40261 & 50181

Figure 5

Page 6

6. With all trailer wheels still firmly blocked, landing gear still resting on firm ground and supporting trailer weight, and

truck stationary and in park with emergency brake on: visually check that bottom of pin box is resting on top of the

hitch. THERE SHOULD BE NO SPACE BETWEEN THESE SURFACES (see Figure 6). If space exists, (see

Figure 7) trailer has not been properly hitched. DO NOT TOW! Instead, repeat above steps until trailer is properly

hitched. DO NOT PLACE BODY UNDER TRAILER TO PERFORM THIS INSPECTION!

No Space

GAP

Figure 6

CORRECT

7. Place bail pin through bail pin holes in the handle and the base plate to make sure the hitch jaw is locked closed. IF

FLAG BLOCKS HOLE FOR BAIL PIN, TRAILER HAS NOT BEEN PROPERLY CONNECTED TO HITCH. DO NOT

TOW! Repeat above steps until trailer is properly hitched. (see Figure 8)

Bail pin placement

Bail Pin

Handle

Hole for bail pin

Figure 7

WRONG

High Pin

King Pin

Flag

Base plate

Figure 8

8. With:

•All trailer wheels still firmly blocked in front and behind each tire, and

•Truck stationary with the emergency brake on, and

•Trailer landing gear still resting on firm ground and supporting trailer weight; and

Connect electrical cable between truck and trailer, connect breakaway switch cable from pin box to a permanent

part of truck, and raise tailgate of truck. Do not tow trailer until the Pull Test has been successfully completed.

30081N-7 July10 F PCN13787 ©2010 CEQUENT PERFORMANCE PRODUCTS, INC LITHO IN USA

FOR KITS: 30081, 40261 & 50181

Jaw closed

Page 7

WARNING:

Do not attempt to hitch by using trailer jacks to lower trailer and king pin. This could result in king pin

coming to rest on top of skid plate instead of within hitch opening where jaws are located. King pin could

slide off hitch and trailer could drop, resulting in death or serious injury (see Figure 9).

Figure 9

WRONG

WARNING:

Connection for trailer wiring should be in the side of the truck bed between the driver’s

seat and the wheel well for the back truck axle

Installation of connection rearward of the wheel well may result in user placing body

between truck and trailer. WHENEVER POSSIBLE, AVOID PUTTING BODY UNDER TRAILER

OR BETWEEN TRUCK AND TRAILER!

If you need to place any part of your body under trailer or between truck and trailer:

All trailer tires MUST be blocked in front and behind each tire AND

Trailer landing gear MUST be resting on firm ground AND

Truck MUST be stationary, in park, with emergency brake on!

PULL TEST

WARNING:

Failure to perform pull test may result in death or serious injury

1. With all trailer wheels still firmly blocked, and

2. Trailer landing gear still resting on firm ground and supporting trailer weight and,

3. Truck stationary and with emergency brake on:

4. Make sure no one is between truck and trailer, Return to cab of truck and release truck’s emergency brake. Apply trailer

brakes. Try to pull trailer slowly forward with the truck. If the trailer is properly hitched, the wheel blocks and trailer brakes

should keep the truck from moving forward.

NOTE: If trailer is not properly hitched, trailer will separate from hitch and truck will move forward leaving trailer behind. If

you followed all previous steps, the trailer will not drop or fall and you will easily be able to repeat the attachment

steps.

WARNING:

Failure to keep wheels blocked and landing gear down could result in trailer suddenly moving or

falling. This could result in death or serious injury!

5. After successfully performing above steps, fully raise trailer landing gear (see trailer manual).

6. Check and inspect all electrical circuits for proper operation. (Clearance lights, turn signals, stop lights, etc.).

7. Remove and store all trailer wheel blocks.

30081N-7 July10 F PCN13787 ©2010 CEQUENT PERFORMANCE PRODUCTS, INC LITHO IN USA

FOR KITS: 30081, 40261 & 50181

Page 8

UNHITCHING PROCEDURE:

PERFORM THE FOLLOWING IN THIS ORDER:

1. Make sure truck is in park with emergency brake on.

2. Place blocks firmly against front and rear of each trailer wheel to prevent any possible forward or rearward motion.

3. Using trailer jacks, lower trailer landing gear following the directions in the Trailer Manual until feet of landing gear are

resting on firm ground.

WARNING:

Trailers that are not stable or properly hitched can fall and cause death or serious injury!

To avoid death or serious injury:

• All trailer tires MUST be blocked in front and behind each tire AND

• Trailer landing gear MUST be resting on firm ground AND

• Truck MUST be stationary, in park, with emergency brake on!

4. Lower truck tail gate.

5. Disconnect power cable and breakaway switch cable between truck and trailer.

6. Remove bail pin from hole in handle.

7. Pull hitch handle out completely until it latches in open position so that king pin is no longer

securely grasped by hitch jaws (see Figure 4). Trailer is now free from hitch and truck. If handle does not pull out,

there is probably pressure against the jaw. To relieve this pressure, back the truck slightly or pull the truck slightly

forward. Reset truck emergency brake. Then pull hitch handle out completely until it latches in open position.

8. AFTER MAKING CERTAIN NO ONE IS STANDING BETWEEN TRUCK AND TRAILER OR IN FRONT OF TRUCK,

drive truck slowly away from trailer.

WARNING

Whenever possible, avoid putting body under trailer or between truck and trailer

If you need to place any part of our body under trailer or between truck and trailer:

All trailer tires MUST be blocked in front and behind each tire AND

Trailer landing gear MUST be resting on firm ground AND

Truck MUST be stationary, in park, with emergency brake on!

9. Hitch jaw will automatically close as the king pin is removed from the jaw.

10. KEEP WHEEL BLOCKS IN PLACE. This will keep trailer from moving unexpectedly

MAINTENANCE:

1. Recheck tightness of all hardware every 1000 miles of use. All 1/2” bolts have a torque specification of

75ft.lbs.

2. See “Before each trip” section in this manual.

3. Head assembly to center section should be lubed every 12 months with grease to keep assemblies

moving freely.

WARNING:

Tilting 5thWheel head can

crush and cut. Keep hands and

fingers clear from this area at

all times (including

placement/removal of head).

Figure 10 : Head Placement

30081N-7 July10 F PCN13787 ©2010 CEQUENT PERFORMANCE PRODUCTS, INC LITHO IN USA

FOR KITS: 30081, 40261 & 50181

Page 9

19

REF # QTY.

DESCRIPTION REF # QTY DESCRIPTION

1 1 18K HEAD ASSEMBLY 13 1 HANG TAG (P/N 110795)

2 1 18K CENTER SECTION 14 1 BAIL PIN WITH LANYARD (P/N 110896)

3 2 SIDE BRACKET (P/N 30834) 15 1 LABEL, PINCH POINT (P/N 110954)

4 6 RETAIN CLIP (P/N 55515) 16 1 LABEL, OPERATION WARNING (P/N 110793)

5 4 ½” X 4 1/2 “ BOLTS (P/N 01150018) 17 2 LABEL, RATING (P/N 113145)

6 4 ½” LOCK NUTS (P/N 3376) 18 1 HANDLE TUBE (P/N 110470)

7 4 ½” DIA LONG PULL PIN (P/N 30434) 19 1 HANDLE GRIP (P/N 07417)

8 2 ¼” X 20 – 1.75 HX HEAD BOLT (P/N 55256) 20 2 3/8 CARRIAGE BOLT (P/N 01246005)

9 2 TUBE SPACER (P/N 110898) 21 2 3/8 NUT (P/N 55052)

10 2 TORSION SPRING (P/N 110787 & 110788) 22 2 3/8 LOCK WASHER (P/N 01129006)

11 2 ¼” WASHER (P/N 55546)

12 2 1/2” PULL PIN 90° (P/N 110974)

20

14

1

18

22

21

9

8

10

11

12

6

2

5

3

7

4

3

Figure 11

30081N-7 July10 F PCN13787 ©2010 CEQUENT PERFORMANCE PRODUCTS, INC LITHO IN USA

FOR KITS: 30081, 40261 & 50181

Page 10

NOTES

FIVE YEAR LIMITED WARRANTY

Fifth Wheel Hitches

Cequent Performance Products warrants the 20K 5th Wheel Hitch from date of purchase against defects

in material and workmanship under normal use and service, ordinary wear and tear excepted, for 5 years

of ownership to the original consumer purchaser when a Cequent Performance Products mounting kit is

used.

Cequent Performance Products will replace FREE OF CHARGE any part which proves defective in

material or workmanship when presented to any Cequent Performance Products dealer, Cequent

Performance Products Warehouse or returned to factory. TRANSPORTATION CHARGES PREPAID, at

the address below. THIS WARRANTY IS LIMITED TO DEFECTIVE PARTS REPLACEMENT ONLY.

LABOR CHARGES AND/OR DAMAGE INCURRED IN INSTALLATION OR REPLACEMENT AS WELL

AS INCIDENTAL AND CONSEQUENTIAL DAMAGES CONNECTED THEREWITH ARE EXCLUDED.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

Any damage to the 5th Wheel Hitch as a result of misuse, abuse, neglect, accident, improper installation,

or any use violative of instructions furnished by us, WILL VOID THE WARRANTY.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state. In the event of a problem with warranty service or performance, you may be able to go to a small

claims court, or a federal district court.

Cequent Performance Products, Inc.

2602 College Avenue

Goshen, IN 46528

30081N-7 July10 F PCN13787 ©2010 CEQUENT PERFORMANCE PRODUCTS, INC LITHO IN USA

FOR KITS: 30081, 40261 & 50181

Page 11

Appendix A

GUIDELINES FOR MATCHING HITCH, TRUCK, AND TRAILER

30081N-7 July10 F PCN13787 ©2010 CEQUENT PERFORMANCE PRODUCTS, INC LITHO IN USA

FOR KITS: 30081, 40261 & 50181

Page 12

GUIDELINES FOR MATCHING HITCH, TRUCK, AND TRAILER

WARNING:

Failure to follow all of these instructions may result in death or serious injury!

WARNING:

Failure to check and follow tow ratings could result in tow vehicle

damage or truck and trailer separation while towing.

Trailer and its contents together must not exceed truck, hitch and/or trailer tow

ratings.

Towing vehicle must have a manufacturer’s rated towing capacity equal to or

greater than the gross trailer weight (dry weight of the trailer plus payload of the

trailer). (Figure 12)

Gross weight of trailer must not exceed 20,000 pounds.

King pin weight must not exceed 5,000 pounds (Figure 13). If in doubt have king

pin weight measured by qualified facility.

FACTORY TRAILER + FULL WATER

TANKS + CARGO, ETC.

= GROSS TRAILER WEIGHT

Figure 12

1. Check Tow Ratings:

Vehicle Tow Rating:_______________________.

5th Wheel Kit Hitch Rating:_____20,000 lbs.__.

Gross Trailer Weight (Figure 12):______________.

*Trailer weight should be the lowest of these recorded ratings for safe towing conditions.

2. Cequent Performance Products hitches are designed for use with recreational fifth wheel trailers only. Hitch

applications other than recreational fifth wheel trailers must be approved in writing by Cequent Performance Products’

Engineering Department.

3. Use only a SAE 2-inch kingpin with your 20KFifth Wheel Hitch.

4. Approximately 15%-25% of trailer weight should be on hitch (Pin Weight). See Figure 13.

Figure 13

15-25%

GROSS TRAILER

WEIGHT

(PIN WEIGHT)

75-85%

GROSS TRAILER

WEIGHT

30081N-7 July10 F PCN13787 ©2010 CEQUENT PERFORMANCE PRODUCTS, INC LITHO IN USA

FOR KITS: 30081, 40261 & 50181

Page 13

5. Trucks come in many different configurations. Cequent Performance Products’ hitches are designed for use in light

trucks such as the Ford F-Series, the Chevy Silverado and the Dodge Ram. Cequent Performance Products

recommends the use of long bed (8ft) light trucks for the best combination in truck - trailer turning clearance.

Rule of thumb: The distance from the back of the truck cab to the center of the rear truck

axle (“X” in Figure 14), should be approximately 4 inches greater than one-

half the trailer width (“Y” in Figure 4)

RV TRAILER

Figure 14

TRUCK

6. If a short bed pickup (less than 8 ft. but longer than 6 ft.) is to be used for towing, Cequent Performance Products

recommends the trailer be equipped with an extended pin box to help gain additional truck - trailer turning clearance (See

trailer manufacturer for options) (Figure 15). It also may be helpful to add a Square Tube or Round Tube Slider (Part #

30048 / 50008) for increased turning clearance for low speed, non-highway maneuvering.

Figure 15

Conventional Pin Box

Extended Pin Box

KING PIN

WARNING:

Do Not install this fifth wheel hitch on or attempt to tow with a short bed pickup

truck that has a bed shorter than 6 ft.!

7. The height of the hitch and the pin box should be adjusted so the trailer is approximately level as it is towed. Allow

approximately 6 inches clearance between the top of the pickup walls and the underside of the front of the trailer for pitch

and roll of the trailer. (Figure 16). Allow more clearance between pickup walls and trailer for off road use.

Figure 16

Approximately 6 Inches

Level Trailer

CAUTION:

The measurements above are guidelines. If your measurements are close to these numbers re-check

clearances. If vehicle and/or trailer has any added bed vicinity accessories (i.e. fairings, air dams, ground effects,

bed rails, etc.). Additional dimensioning and clearance checks have to be made.

30081N-7 July10 F PCN13787 ©2010 CEQUENT PERFORMANCE PRODUCTS, INC LITHO IN USA

FOR KITS: 30081, 40261 & 50181

Page 14

8. Hitch height determination:

With trailer leveled and on level ground measure from the ground to the king pin box, “A” in Figure 17.

Secondly measure from the height of the inside of the truck bed, “B” in Figure 17. Dimensions “C” and “D” in

Figure 17 can be used to determine the amount of clearance over the side rails, as mentioned in Note 17.

The 2” value is an estimate of suspension compression due to king pin weight of the trailer. This

compression could range between 1”-5” depending on the truck being used and the trailer being towed.

Hitch Height = A – B + 2”

D – C + 2” > 6” as noted in Note 7.

C

B

9. If a lube plate is to be used with a 5thWheel Kit it must be at least 12” in diameter. Cequent Performance

Products offers this optional lube plate as part # 83001 / 40001.

A

Figure 17

D

*MEASURED WITH TRAILER LEVEL,

ON LEVEL GROUND

WARNING:

Connection for trailer wiring must be located at the side of the truck bed between the driver’s

seat and the rear wheel to prevent operators from working between the truck and trailer.

Avoid putting any part of your body under the trailer or between the truck and trailer.

Unexpected or accidental movement of the truck or the trailer can cause serious injury or death

If you must place any part of your body under the trailer or between the truck and trailer you

MUST perform ALL of the following steps:

Check that the truck transmission is in park

Check that the emergency brake is on

Block in front of and behind all trailer tires

Check that the trailer landing gear are resting on firm ground

30081N-7 July10 F PCN13787 ©2010 CEQUENT PERFORMANCE PRODUCTS, INC LITHO IN USA

FOR KITS: 30081, 40261 & 50181

Page 15

Appendix B

GUIDELINE FOR CENTER SECTION ORIENTATION

30081N-7 July10 F PCN13787 ©2010 CEQUENT PERFORMANCE PRODUCTS, INC LITHO IN USA

FOR KITS: 30081, 40261 & 50181

Page 16

NOTE: SPRINGS IN

FACTORY POSITION

HEAD

FRONT OF

VEHICLE

NOTE: SPRINGS NEED TO

BE TURNED AROUND

FROM FACTORY LOCATION

FOR REARWARD POSITION

SHOWN BELOW.

HEAD

FRONT OF

VEHICLE

CENTER SECTION

OFFSET POSITION

(POINTED VEHICLE

FORWARD)

CENTER LINE OF REAR

AXLE

FORWARD POSITION

14.5” FROM TOP OF

TRUCK BED TO TOP OF

HEAD

18.0” FROM TOP OF

TRUCK BED TO TOP OF

HEAD

CENTER LINE OF REAR

TOP OF RAIL

TOP OF TRUCK BED

AXLE

REARWARD POSITION

CENTER SECTION

OFFSET POSITION

(POINTED VEHICLE

REARWARD)

30081N-7 July10 F PCN13787 ©2010 CEQUENT PERFORMANCE PRODUCTS, INC LITHO IN USA

FOR KITS: 30081, 40261 & 50181

Loading...

Loading...