Page 1

INSTALLATION INSTRUCTIONS

MOUNTING KIT

FORD F250/F350/F450

LD/HD/SD

6’ & 8’ Beds

DO NOT EXCEED VEHICLE MANUFACTURER’S RATING FOR 5th WHEEL TOWING

OR MAXIMUM GROSS TRAILER WEIGHT OF

DEALER/INSTALLER:

(1) Provide this Manual to end user.

(2) Physically demonstrate procedures in this Manual to end user.

(3) Have end user demonstrate that he/she understands procedures.

END USER:

(1) Read and follow this Manual every time you use Hitch.

(2) Save this Manual for future reference.

(3) Pass on copies of Manual to any other user or owner of Hitch.

18,000lb. / 8160kg.

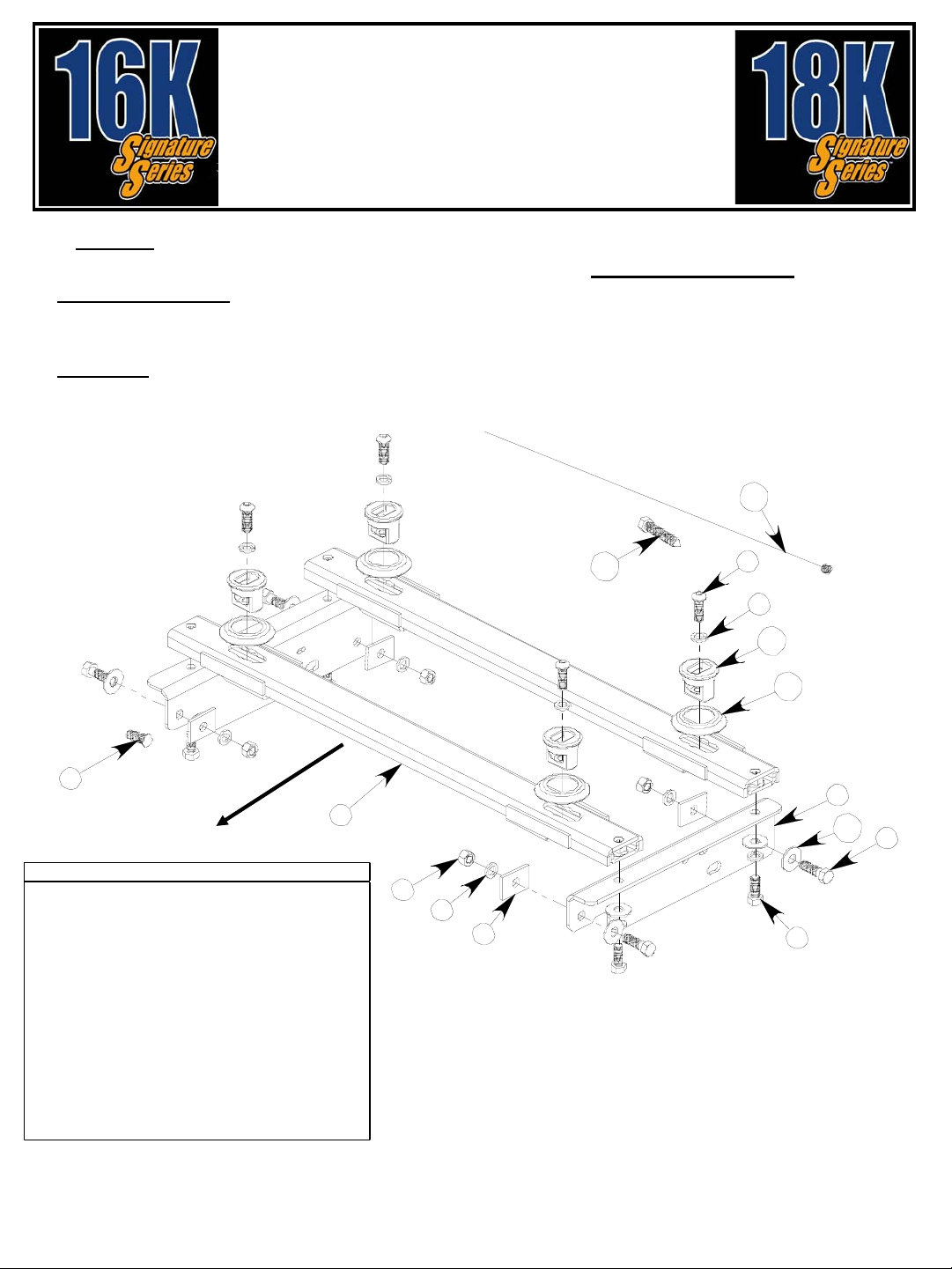

13

6

Front of

1

vehicle

PART QTY.

1. BASE RAIL (2)

2. FRAME BRACKET (2)

3. 5/8-11 BUTTON HEAD SCREW (4)

4. 5/8-11 GR8 BOLT 1 1/2" LONG (4)

5. 5/8-11 GR8 BOLT 2" LONG* (3,4)

6. 5/8-11 GR8 KNURL BOLT* (1)

7. 5/8-11 GR8 NUT (4)

8. 5/8 LOCK WASHER (12)

9. SPACER* (3,4)

10. TRIM RING (4)

11. PUCK (4)

12. 5/8 FLAT WASHER (8)

13. 5/8-11 PULL WIRE* (2)

14. 5/8-11 X 3 1/2" WITH POINT (1)

* FOR 2005 SUPER DUTY KNURL BOLT AND PULL WIRE

REPLACE ONE EACH OF BOLT AND SPACER

7

14

3

8

11

10

2

12

5

8

9

Figure 1

4

For Customer Support

Call 1-800-632-3290

30073N – 13DEC06D PCN9360 ©2006 CEQUENT TOWING PRODUCTS, INC. Litho in USA

Page 2

WARNING:

Failure to follow all of these instructions may result in death or serious injury!

INDEX

1. GUIDELINES FOR MATCHING TOW VEHICLE AND TRAILER P. 2-4

2. ASSEMBLY INSTRUCTIONS P. 5-9

3. CEQUENT TOWING PRODUCTS SEVEN YEAR LIMITED WARRANTY P. 10

GUIDELINES FOR MATCHING HITCH TRUCK AND TRAILER

WARNING:

Failure to check and follow tow ratings could result in tow vehicle

damage or truck and trailer separation while towing.

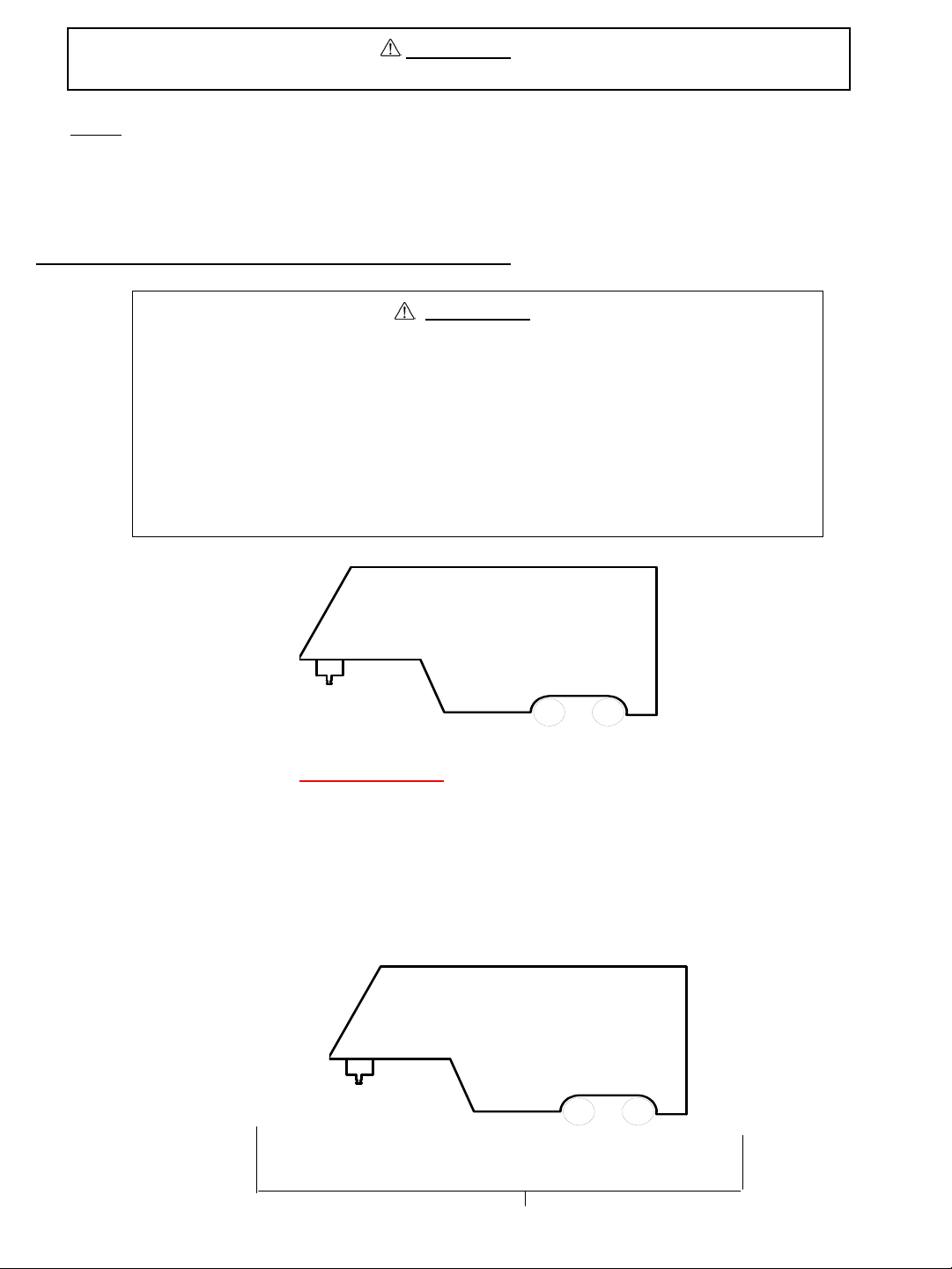

•Trailer and its contents together must not exceed truck, hitch and/or trailer tow

ratings.

•Towing vehicle must have a manufacturer’s rated towing capacity equal to or

greater than the gross trailer weight (dry weight of the trailer plus payload of the

trailer). (Figure 2)

•Gross weight of trailer must not exceed fifth wheel hitch rating.

•King pin weight must not exceed fifth wheel rating (Figure 3). If in doubt have king

pin weight measured by a qualified technician.

FACTORY TRAILER + FULL WATER

TANKS + CARGO, ETC.

= GROSS TRAILER WEIGHT

Enter total below

Figure 2

1. Maximum Gross Trailer Weight of : 18,000 lb / 8160kg.

Vehicle tow rating: _______________.

Total calculated Gross Trailer Weight (Figure 2):______________.

*Trailer weight should be the lowest of these recorded ratings for safe towing conditions.

2. Cequent Towing Products hitches are designed for use with recreational fifth wheel trailers only. Hitch applications other than

recreational fifth wheel trailers must be approved in writing by Cequent Towing Products’ Engineering Department.

3. Use only a SAE 2-inch kingpin with your Signature Series Fifth Wheel Hitch.

4. Approximately 15%-25% of trailer weight should be on hitch (Pin Weight)(Figure 3).

Figure 3

15-25%

GROSS TRAILER

WEIGHT

(PIN WEIGHT)

30073N – 13DEC06D PCN9360 ©2006 CEQUENT TOWING PRODUCTS, INC. Litho in USA

75-85%

GROSS TRAILER

WEIGHT

2

Page 3

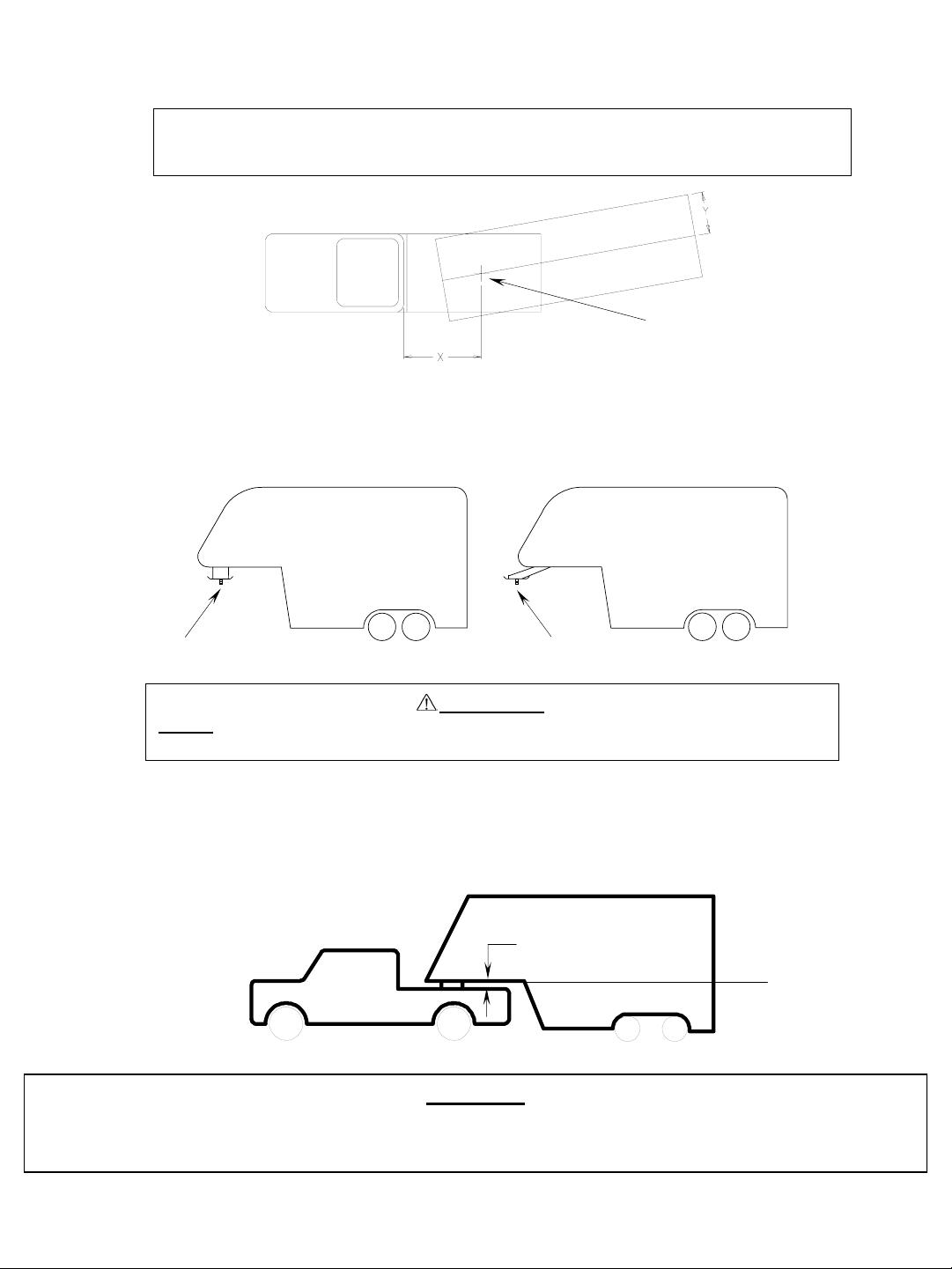

5. Trucks come in many different configurations. Cequent Towing Products’ hitches are designed for use in light trucks such as the

Ford F-Series, the Chevy Silverado and the Dodge Ram. Cequent Towing Products recommends the use of long bed (8ft) light

trucks for the best combination in truck - trailer turning clearance.

Rule of thumb: The distance from the back of the truck cab to the center of the rear truck

axle (“X” in Figure 4), should be approximately 4 inches greater than one-half

the trailer width (“Y” in Figure 4)

RV TRAILER

Figure 4

TRUCK

6. If a short bed pickup (less than 8 ft. but longer than 6 ft.) is to be used for towing, Cequent Towing Products recommends the

trailer be equipped with an extended pin box to help gain additional truck - trailer turning clearance (See trailer manufacturer for

options) (Figure 5). It also may be helpful to add a

speed, non-highway maneuvering.

Figure 5

Conventional Pin Box

Signature Series Slider (Part # 30070) for increased turning clearance for low

Extended Pin Box

KING PIN

WARNING:

Do Not install this fifth wheel hitch on or attempt to tow with a short bed pickup

truck that has a bed shorter than 6 ft.!

7. The height of the hitch and the pin box should be adjusted so the trailer is approximately level as it is towed. Allow

approximately 6 inches clearance between the top of the pickup walls and the underside of the front of the trailer for pitch and

roll of the trailer. (Figure 6). Allow more clearance between pickup walls and trailer for off road use.

Figure 6

Approximately 6 Inches

Level Trailer

CAUTION:

The measurements above are guidelines. If your measurements are close to these numbers re-check clearances. If

vehicle and/or trailer has any added bed vicinity accessories (i.e. fairings, air dams, ground effects, bed rails, etc.).

Additional dimensioning and clearance checks have to be made.

30073N – 13DEC06D PCN9360 ©2006 CEQUENT TOWING PRODUCTS, INC. Litho in USA

3

Page 4

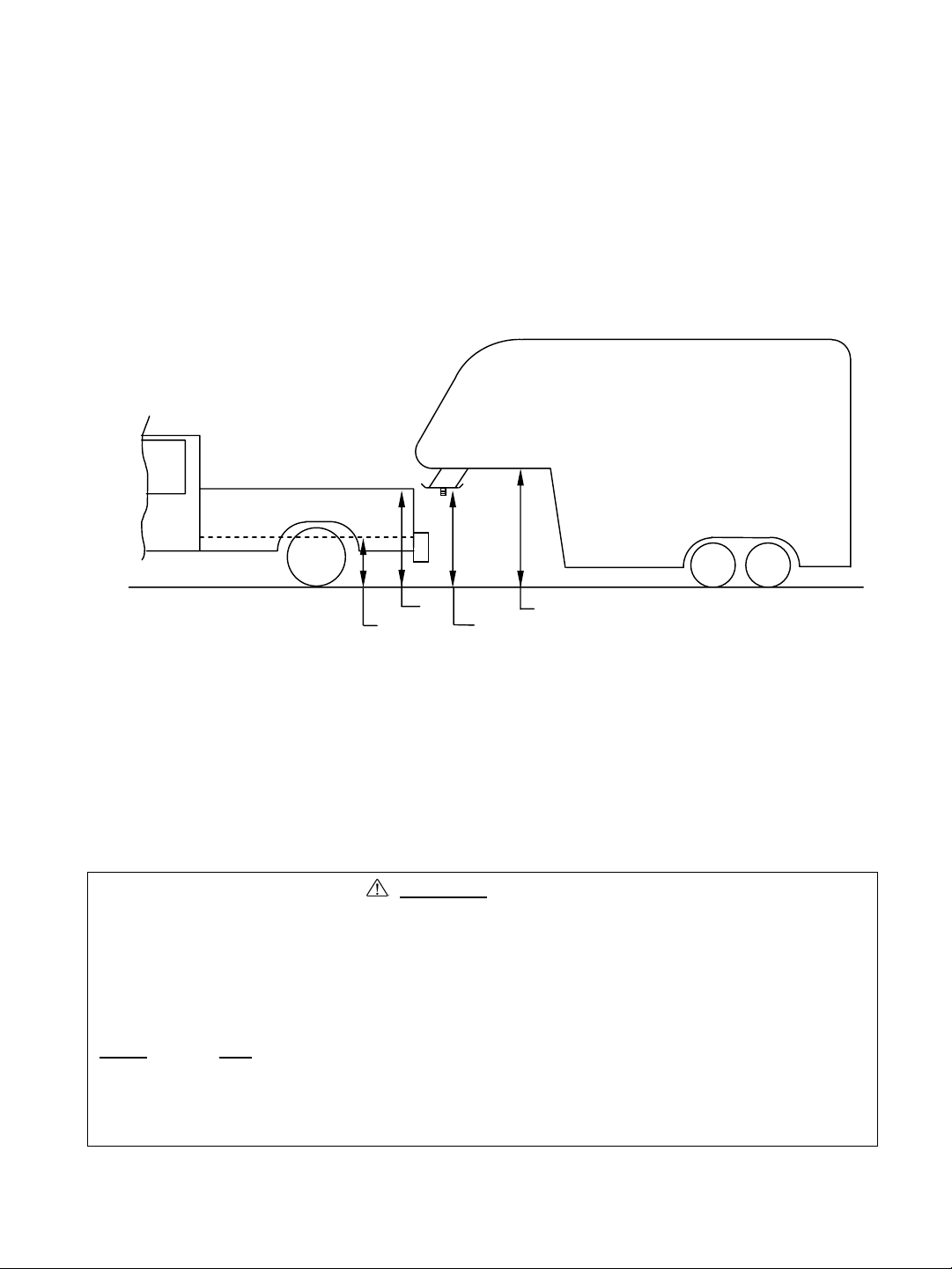

8. Hitch height determination:

With trailer leveled and on level ground measure from the ground to the king pin box (“A” in Figure 7). Secondly measure from

the height of the inside of the truck bed (“B” in Figure 7). Determine the amount of clearance over the side rails ( “C” and “D” in

Figure 7), as mentioned in Note 7.

Hitch Height = A – B + 2”

The 2” value is an estimate of suspension compression due to king pin weight of the trailer. This compression could range

between 1”-5” depending on the truck being used and the trailer being towed.

D – C + 2” > 6” as in Note 7.

C

B

9. If a lube plate is to be used with a Signature Series 5thWheel it must be at least 12” in diameter. Cequent Towing Products offers

this optional lube plate as part # 83001 / 40001.

A

Figure 7

D

*MEASURED WITH TRAILER LEVEL,

ON LEVEL GROUND

WARNING:

•Connection for trailer wiring must be located at the side of the truck bed between the driver’s

seat and the rear wheel to prevent operators from working between the truck and trailer.

•Avoid putting any part of your body under the trailer or between the truck and trailer.

Unexpected or accidental movement of the truck or the trailer can cause serious injury or death

•If you must place any part of your body under the trailer or between the truck and trailer you

MUST

perform ALL of the following steps:

•Check that the truck transmission is in park

•Check that the emergency brake is on

•Block in front of and behind all trailer tires

•Check that the trailer landing gear are resting on firm ground

30073N – 13DEC06D PCN9360 ©2006 CEQUENT TOWING PRODUCTS, INC. Litho in USA

4

Page 5

GENERAL INSTRUCTIONS FOR FIFTH WHEEL INSTALLATION

TOOLS

3/16" Drill 15/16" Socket & Open End Wrench

21/32" Drill 200 lb-ft Torque Wrench

3/8” Hex socket 2-1/2” Hole Saw

Rubber Mallet 5/8-11 x 3 1/2” w/point

Vice grips or pliers

Optional for 2005 Super Duty: 5/8-11 Pull Wire

CAUTION!

Read pages 2-4 of these instructions before starting installation. Failure to do so could result in significant vehicle damage!

1. The following instructions should be used to mount the 5th wheel. Care and attention to detail will ensure a quick

quality installation. Check parts against parts list to become familiar with parts in kit. (Figure 1)

2. Raise rear of truck high enough to allow jack stands to be placed under rear spring hanger bracket of truck. This

will provide maximum room to install the 5th wheel brackets.

WARNING:

If the truck is raised, be sure that the truck is properly blocked and restrained to prevent the truck from falling.

Failure to do so may result in the truck suddenly falling, causing death or serious injury.

3. Remove plastic bed liner if applicable. Plastic drop-in bed liners will be cut later. Spray-in bed liners and bed

mats less than 1/4” thick will work with normal installation instructions. Note: Consult installer for recommended

curing time on spray-in liner before cutting holes through bed.

CAUTION:

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural

members, etc. CEQUENT TOWING PRODUCTS does its best to communicate tow vehicle manufacturer

changes; however, it is ultimately the responsibility of the installer to prevent damage due to installation.

4. Use only CEQUENT TOWING PRODUCTS supplied bolts, nuts, and washers to install this kit. All bolts and nuts

are grade 8 unless specified otherwise.

5. These instructions are intended for a specific group of trucks. If these instructions do not apply to your vehicle,

contact Technical Service to get proper instructions. Each frame bracket must be bolted to the vehicle frame with

two bolts.

6. On older models a metal heat shield runs underneath truck bed. Remove and discard heat shield from

beneath truck bed if applicable. Heat shield adhered to bottom of bed on newer models does not need to

be removed.

CAUTION:

These instructions are guidelines only. Actual installation is the responsibility of the installer and the owner.

Always measure truck and trailer before installing hitch to be sure that there is clearance at the cab and at the

bumper to allow for turns.

7. Locate the area where the base rails will be inserted above the wheel on the drivers side. There are two hat

channels supporting the truck bed over the wheel. The base rails will be inserted at the location behind the forward

hat channel. The edge of the truck bed is flanged down. To create clearance for inserting the rails there are two

options. Either loosen truck bed bolts to lift truck bed, or the flanged area must be bent out using pliers or vice

grips. (Figure 8) To prevent scratching the paint on the flange cover the flange with a soft cloth before gripping

with pliers or vice grips.

Truck bed

Section of flange

to bend out

Front

of

vehicle

Front of wheel

hat channel

30073N – 13DEC06D PCN9360 ©2006 CEQUENT TOWING PRODUCTS, INC. Litho in USA

Wheel

well

Figure 8

Rear of wheel

hat channel

5

Page 6

8. Insert rails as shown in the following steps (Figures 9 through 11). Rails should be inserted flat side up.

Front Hat Channel

Fuel

Cell

Step 1 : Insert the first rail from the

drivers side wheel well above the

frame. Rest the rail on both chassis

frame rails (Figure 9).

Forward

F

r

a

m

e

Rear Hat Channel

Figure 9

Step 2 : Slide the rail rearward,

parallel with axle, resting on both

frame rails, and as close as possible

to the rear hat channel (Figure 10).

Figure 10

F

r

a

m

e

Step 3 : Insert the second rail from

the drivers side wheel well above the

frame. Rest the rail on both chassis

frame rails (Figure 11).

Figure 11

Step 4 : One rail should be rearward and the other rail forward. The rails should be

centered with both ends of each rail resting evenly on the frame. After rails are

inserted and in place the flanged area of the bed liner can be straightened with

vice grips or pliers, be sure to use a soft cloth before gripping flange to

prevent scratching. If flanged area is scratched immediately follow

manufacturer’s recommended method of touching up scratched area to

prevent rust or other corrosion.

30073N – 13DEC06D PCN9360 ©2006 CEQUENT TOWING PRODUCTS, INC. Litho in USA

6

Page 7

9. If there is a brake cable bracket located above the rear axle on the driver’s side of the frame, then disassemble and

remove the brake cable bracket (Figure 12). Do not discard the brake cable bracket it will be re-attached later.

Truck bed

Frame mounting rails

Existing slot on older

model truck frames.

Front of

vehicle

10. If brake cable bracket was removed in previous step, then re-locate brake cable bracket to rail bracket through hole

given in the frame rail bracket using the original brake cable bracket hardware, tighten brake cable hardware with a

wrench (Figure 13). Do not attempt to re-attach brake cable bracket through chassis rail.

Figure 12

Brake cable bracket

Aligns with existing slot on

older models, hole must be

drilled in frame for 2008 and

newer models.

Front of

vehicle

Frame bracket

Figure 13

Brake cable bracket

WARNING:

DO NOT lubricate threads. It may cause bolt failure.

11. Loosely attach frame brackets to mounting kit rails using 5/8” X 1 1/2” long bolts, flat washer, and lock washers

(Figure 14). Tighten all mounting kit bolts to hand tight.

5/8” flat washer

4 places

5/8” lock washer

4 places

5/8” X 1 1/2”

long bolt

4 places

Front of

Figure 14

vehicle

30073N – 13DEC06D PCN9360 ©2006 CEQUENT TOWING PRODUCTS, INC. Litho in USA

7

Page 8

CAUTION:

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural

members, etc. CEQUENT TOWING PRODUCTS does its best to communicate tow vehicle manufacturer

changes; however, it is ultimately the responsibility of the installer to prevent damage due to installation.

12. Align hole in bracket with hole in chassis for 2007 and earlier models. After checking to ensure that rails are square with each

other, at forward mount hole location, drill pilot hole in frame using frame bracket as a template. For 2008 and newer models,

position complete assembly near or against truck bed hat channel towards rear of vehicle and drill a pilot hole in frame, both

sides. Enlarge pilot holes to 21/32” diameter holes (Figure 15). Optional: Spray undercoating around drilled holes to prevent

rusting.

Front of

For 2008 & newer models,

Drill frame mounting hole

vehicle

Drill frame

mounting hole

13A. Loosely attach frame bracket to chassis frame using 5/8” X 2” bolts, washer, spacers, lock washers, and nut.

Tighten to hand tight (Figure 16). With 2005 and newer super duty models, suspension components may block

access to the front drilled hole on the passenger side of the vehicle. Use supplemental instruction 13B for use of

the knurl bolt in the forward passenger side hole.

Figure 15

Align bracket hole with hole in

chassis frame 2007 and earlier

models

WARNING:

DO NOT lubricate threads. It may cause bolt failure.

5/8 X 2” bolt

3 or 4 places

5/8 washer

5/8 lock washer

4 places

5/8 nut

4 places

4 places

Spacer

3 or 4 places

Front of

vehicle

Figure 16

Optional: 5/8” knurl bolt and pull wire inserted here and

pulled through chassis rail and mounting hole in bracket

13B. With 2005 and newer super duty models where suspension components block access to the front drilled hole on

the passenger side of the vehicle thread 5/8” x 1 1/2” knurl bolt onto pull wire (Figure 17). From the inside of the

chassis rails insert straight end of pull wire into drilled hole. Pull wire out through drilled hole and mounting hole in

bracket (Figure 16), unthread pull wire from knurl bolt. Thread washer, lock washer, and nut onto knurl bolt from

the outside of chassis rails and tighten until hand tight.

Note: Standard bolt and spacer will not be used in this case.

Pull wire

5/8” knurl bolt

30073N – 13DEC06D PCN9360 ©2006 CEQUENT TOWING PRODUCTS, INC. Litho in USA

Figure 17

8

Page 9

Front of

vehicle

Thread pointed bolt through welded nuts

4 places

Figure 18

14. Using pointed bolt (Figure 19), screw pointed bolt in to the nut that is welded to the rail assembly until a prick mark

is clearly visible on the truck bed (Figure 18). If access to a welded nut is obstructed by chassis components, a

fourth prick mark should be made on the bed based upon measuring from the other prick marks (Figure 20). If a

plastic bed liner is used cut 19” X 4” slots in the liner measured from prick marks in truck bed. If the Signature Series

slider fifth wheel assembly is used, then see fifth wheel slider assembly instructions for slot cut dimensions.

Figure 19

Prick mark

19"

4"

**Measure distance for

cutting plastic bed liner.

Tailgate

3"

2"

Figure 20

Cut bed liner

30"

Truck Bed

Cut bed liner

30073N – 13DEC06D PCN9360 ©2006 CEQUENT TOWING PRODUCTS, INC. Litho in USA

13"

Prick mark

9

Page 10

15. Remove 5/8” x 1 1/2“ bolts attaching frame bracket to mounting rails. Remove front rail as per instructions in

step 7. Move rear rail rearward or forward to prevent interference with hole drilling or punching of truck bed.

CAUTION:

Check for obstructions before drilling. Failure to do so could result in damaged fuel or brake lines, structural

members, etc. CEQUENT TOWING PRODUCTS does its best to communicate tow vehicle manufacturer

changes; however, it is ultimately the responsibility of the installer to prevent damage due to installation.

16. Drill pilot holes in truck bed at prick mark locations. With hole saw saw 2 1/2” hole centered at pilot holes.

Note: Consult installer for recommended curing time on spray-in liner before cutting holes through bed.

Optional: Spray under coating around 2 1/2” holes to prevent rusting.

17. Loosely reattach rails to frame bracket.

18. From truck bed attach pucks and trim rings to rails as shown in Figure 21 using 5/8” button head screw and

lock washer. Tighten to 110ft.lbs. torque.

WARNING:

DO NOT lubricate threads. It may cause bolt failure.

5/8” BUTTON HEAD

Figure 21

4 PLACES

5/8” LOCK WASHER

4 PLACES

PUCK

4 PLACES

TRIM RING

4 PLACES

Truck Bed

Puck Plug

Puck Assembly

19. Insert puck plugs in plugs whenever pucks are not in use. (Figure 22)

20. Install Signature Series 5th wheel per hitch assembly instructions.

21. Torque hitch assembly bolts per hitch instructions.

Figure 22

22. Torque all 5/8” rail kit hex bolts to 170ft.lbs

23. Replace any brake lines and spare tire that may have been removed/relocated.

30073N – 13DEC06D PCN9360 ©2006 CEQUENT TOWING PRODUCTS, INC. Litho in USA

10

Page 11

NOTES

SEVEN YEAR LIMITED WARRANTY

Hitches - Custom Receivers

Cequent Towing Products warrants the Signature Series 5th Wheel Hitch Mounting Kits from date of purchase

against defects in material and workmanship under normal use and service, ordinary wear and tear

excepted, for 7 years of ownership to the original consumer purchaser when a Cequent Towing Products

Signature Series 5th Wheel Hitch is used.

Cequent Towing Products will replace FREE OF CHARGE any part which proves defective in material or

workmanship when presented to any Cequent Towing Products dealer, Cequent Towing Products

Warehouse or returned to factory. TRANSPORTATION CHARGES PREPAID, at the address below.

THIS WARRANTY IS LIMITED TO DEFECTIVE PARTS REPLACEMENT ONLY. LABOR CHARGES

AND/OR DAMAGE INCURRED IN INSTALLATION OR REPLACEMENT AS WELL AS INCIDENTAL

AND CONSEQUENTIAL DAMAGES CONNECTED THEREWITH ARE EXCLUDED.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

Any damage to the Signature Series 5th Wheel Hitch as a result of misuse, abuse, neglect, accident, improper

installation, or any use violative of instructions furnished by us, WILL VOID THE WARRANTY.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state. In the event of a problem with warranty service or performance, you may be able to go to a small

claims court, or a federal district court.

Cequent Towing Products, Inc.

47774 Anchor Court

Plymouth, MI 48170

30073N – 13DEC06D PCN9360 ©2006 CEQUENT TOWING PRODUCTS, INC. Litho in USA

11

Loading...

Loading...