Reece S-4000_CAED Parts Book

MODEL S-4000 CAED Omron

CUT AFTER EDGE

PARTS AND SERVICE MANUAL

MACHINE SERIAL No.:

AMF is trademark of AMF Group, Inc.

PART NUMBER 97.2430.1.001

This manual is valid from the machine serial number M241429

01/2010

MODEL S-4000 CAED Omron

CUT AFTER EDGE

PARTS AND SERVICE MANUAL

MACHINE SERIAL No.:

AMF is trademark of AMF Group, Inc.

PART NUMBER 97.2430.1.001

This manual is valid from the machine serial number M241429

01/2010

97.2430.1.001

CUT AFTER EDGE

97.2430.1.001

CUT AFTER EDGE

97.2430.1.001

CUT AFTER EDGE

97.2430.1.001

CUT AFTER EDGE

97.2430.1.001

CUT AFTER EDGE

97.2430.1.001

CUT AFTER EDGE

Omron

S-4000 CAED

S-4000 CAED

Omron

Omron

S-4000 CAED

S-4000 CAED

Omron

Omron

S-4000 CAED

S-4000 CAED

Omron

LIMITED W ARRANTY ON NEW AMF REECE EQUIPMENT

Warranty pr ovisions:

A ninety (90) day limited service labor warranty to correct defects in installation, workmanship, or material without charge for

labor. This portion of the warranty applies to machines sold as ”installed” only.

A one (1) year limited material warranty on major component parts to replace materials with defects. Any new part believed

defective must be returned freight prepaid to AMF Reece, Inc. for inspection. If, upon inspection, the part or material is deter -

mined to be defective, AMF Reece, Inc. will replace it without charge to the customer for parts or material.

Service labor warranty period shall begin on the completed installation date. Material warranty shall begin on the date the

equipment is shipped from AMF Reece, Inc.

Exclusions:

Excluded from both service labor warranty and material warranty are: (1) Consumable parts which would be normally considered

replaceable in day-to-day operations. These include parts such as needles, knives, loopers and spreaders. (2) Normal adjustment

and routine maintenance. This is the sole responsibility of the customer . (3) Cleaning and lubrication of equipment. (4) Parts

found to be altered, broken or damaged due to neglect or improper installation or application. (5) Damage caused by the use of

non-Genuine AMF Reece parts. (6) Shipping or delivery charges.

There is no service labor warranty for machines sold as ”uninstalled”.

Equipment installed without the assistance of a certified technician (either an AMF Reece Employee, a Certified Contractor, or

that of an Authorized Distributor) will have the limited material warranty only . Only the defective material will be covered. Any

charges associated with the use of an AMF Reece Technician or that of a Distributor to replace the defective part will be the

customer’s responsibility .

NO OTHER WARRANTY , EXPRESS OR IMPLIED, AS TO DESCRIPTION, QUALITY , MERCHANT ABILITY, and FITNESS FOR

A P ARTICULAR PURPOSE, OR ANY OTHER MATTER IS GIVEN BY SELLER OR SELLER’S AGENT IN CONNECTION HERE-

WITH. UNDER NO CIRCUMSTANCES SHALL SELLER OR SELLER’S AGENT BE LIABLE FOR LOSS OF PROFITS OR ANY

OTHER DIRECT OR INDIRECT COSTS, EXPENSES, LOSSES OR DAMAGES ARISING OUT OF DEFECTS IN OR F AILURE OF

THE EQUIPMENT OR ANY P AR T THEREOF.

WHAT TO DO IF THERE IS A QUESTION REGARDING W ARRANTY

If a machine is purchased through an authorized AMF Reece, Inc. distributor , warranty questions should be first directed to that

distributor. However , the satisfaction and goodwill of our customers are of primary concern to AMF Reece, Inc. In the event that

a warranty matter is not handled to your satisfaction, please contact the appropriate AMF Reece of fice:

Prostejov, Czech Republic

Phone:

Fax:

e-mail:

(+420) 582-309-275

(+420) 582-360-608

service@amfreece.cz

Warranty Registration Card

(Please Fax or Mail immediately after installation)

Note: All W arranty Claims V oid, unless Registration Card on file at AMF Reece HQ

Machine model number:

(S101, S100, S104, S31 1, Decostitch, S4000 BH, etc)

Manufacturer‘s serial or production number:

Installation Site Information:

Customer‘s Name:

Customer‘s Mailing Address:

Customer‘s T elephone Number:

Supervising Mechanic‘s or Technician‘s Name:

Signature of Supervising Technician:

AMF Reece T echnician‘s Name:

AMF Reece T echnician‘s Signature:

Type of garment produced at this location?

Average Daily Production Expected from this machine?

(number of buttonholes, jackets sewn, pants produced, buttons sewn, etc)

Any special requirements required at this location?

What other AMF Reece Machines are at this location?

How can we serve you better?

T ovární 837, 796 25 Prostìjov, Czech Republic

Fax: +420 582 360 606, e-mail: service@amfreece.cz, website: www.amfreece.com

A - INTRODUCTION

1. Basic information ............................................................................................ 1-1

2. Safety device and labels ................................................................................ 1-2

3. General machine parts description ................................................................ 1-3

4. Specifications .................................................................................................. 1-4

5. Instructions for operator safety and maintenance....................................... 1-5

6. Special accessories.......................................................................................... 1-6

B - MACHINE ASSEMBLY

1. Content of the shipping box .......................................................................... 1-8

2. Accessories ...................................................................................................... 1-8

3. Power and air connection .............................................................................. 1-9

4. Head pmeumatic ............................................................................................. 1-10

5. Installation of thread holder .......................................................................... 1-11

C - PROPER APPLICATION

1. Power Up/ Home position ............................................................................. 1-12

2. Needle installation .......................................................................................... 1-13

3. Threading ......................................................................................................... 1-14

S4000 CAED Omron

TABLE OF CONTENTS

D - MACHINE CONTROLS

1. Progress of sewing.......................................................................................... 1-15

2. Operator control panel push buttons and switches .................................... 1-16

3. Control panel information.............................................................................. 1-17

4. The programming menu ................................................................................. 1-17

5. Tests .................................................................................................................. 1-20

6. Program version .............................................................................................. 1-22

7. Schema of programming ................................................................................ 1-23

8. Parameter checklist ......................................................................................... 1-24

E - MACHINE ADJUSTMENTS

1. Machine home position .................................................................................. 1-25

2. Adjustment of the shifter ............................................................................... 1-25

3. Principles for machine adjustment ................................................................ 1-25

4. Needle bar ....................................................................................................... 1-26

5. Bite ................................................................................................................... 1-27

6. Feeding ............................................................................................................. 1-29

7. Clutch ............................................................................................................... 1-30

8. Stitch Density .................................................................................................. 1-30

Released 10/2009

e-mail: service@amfreece.cz; parts@amfreece.cz, website: www.amfreece.com

Phones: +420 582 309 146 (Service), +420 582 309 286 (Spare Parts); Fax: +420 582 360 606

S4000 CAED Omron

E - MACHINE ADJUSTMENTS

9. Looper adjustments ........................................................................................ 1-31

10. Home position of the clamp plate ............................................................... 1-34

11. Clamp plate adjustment ............................................................................... 1-35

12. Trimming mechanism adjustment ................................................................ 1-35

13. Adjustment of the clamp plate change-over.............................................. 1-36

14. Adjustment of machine head clamping foot .............................................. 1-37

15. Thread draw off ............................................................................................ 1-37

16. Thread tension ............................................................................................... 1-38

17. Thread trimming............................................................................................ 1-38

18. Cuts-off blow off .......................................................................................... 1-39

19. Thread blow off (special accessory) .......................................................... 1-40

20. Adjustment of stop sensor position ........................................................... 1-40

21. Replacement of the belt ............................................................................... 1-41

22. Protection during voltage fluctuation (special accessory) ....................... 1-42

23. Optical sensor - Adjustment........................................................................ 1-43

TABLE OF CONTENTS

F - MACHINE MAINTENANCE

1. Cleaning and maintenance of the machine .................................................. 1-44

2. List of regular services ................................................................................... 1-46

3. Schema of group lubrication ......................................................................... 1-47

4. Machine lubrication ........................................................................................ 1-48

5. Disposal measures .......................................................................................... 1-50

G - PNEUMATIC DIAGRA

Pneumatic diagram .............................................................................................. 1-51

H - ELECTRICAL DIRAGRAM

Electrical diagram................................................................................................ 1-52

Released 10/2009

e-mail: service@amfreece.cz; parts@amfreece.cz; website: www.amfreece.com

Phones: +420 582 309 146 (Service), +420 582 309286 (Spare Parts); Fax: +420 582 360 606

S-4000 CAED Omron

A - INTRODUCTION

1. BASIC INFORMATION

The sewing machines S-4000 CAED are designed and produced to be very reliable. Important design goals

have been achieved to provide a safe machine that is simple and inexpensive to maintain.

The patented rotary needle bar shaft drive, a major benefit, delivers longer needle bar life. The added

benefits of lower vibration and less noise, translate into less operator fatigue.

Simple buttonhole length adjustment located outside the machine, eliminates the need for tilt back, while the

quick stop repair function delivers safety and makes repairs easier.

A halogen work light is included with the S-4000 CAED and LS, to enhance operator safety and product

quality.

Special electronic and mechanical safety dev

power lock out switch that permits the machine to be locked in the off position, so that it cannot be cycled

accidentally. There is an emergency off switch. There is a low air pressure detector that will not permit

machine operation if air pressure is dangerously low.

There are safety-warning labels on the machine in all areas that require special care. These must not be

removed. If they are lost replace them immediately.

You are the most important safety equipment of all. Be sure you understand the proper operation of the

machine. Never remove safety mechanisms or labels. We have made every effort to provide the safest

possible machine, but without complete knowledge of how this machine operates, and the use of proper care

by the operator, this machine can cause serious injury or death. That is why there are safety warnings

throughout these instructions that carry one of these messages.

DANGER! Possible loss of life.

WARNING! Possible serious injury or machine damage.

NOTICE! Possible injury or machine damage.

We recommend that service workers from AMF Reece oversee the installation and initial training of your

mechanics and operators.

The most effective safety precaution is a well-managed safety program. Be sure those who use this machine

are properly trained. Never disable safety equipment.

ices protect the operator and the machine. There is a special

Always wear safety goggles when operating or servicing the machine.

Revised 10/2009

e-mail: service@amfreece.cz; parts@amfreece.cz; website: www.amfreece.com

Phone: +420 582 309 146 (Service), +420 582 309 286 (Spare Parts); Fax: +420 582 360 606

1-1

S-4000 CAED Omron

Ì

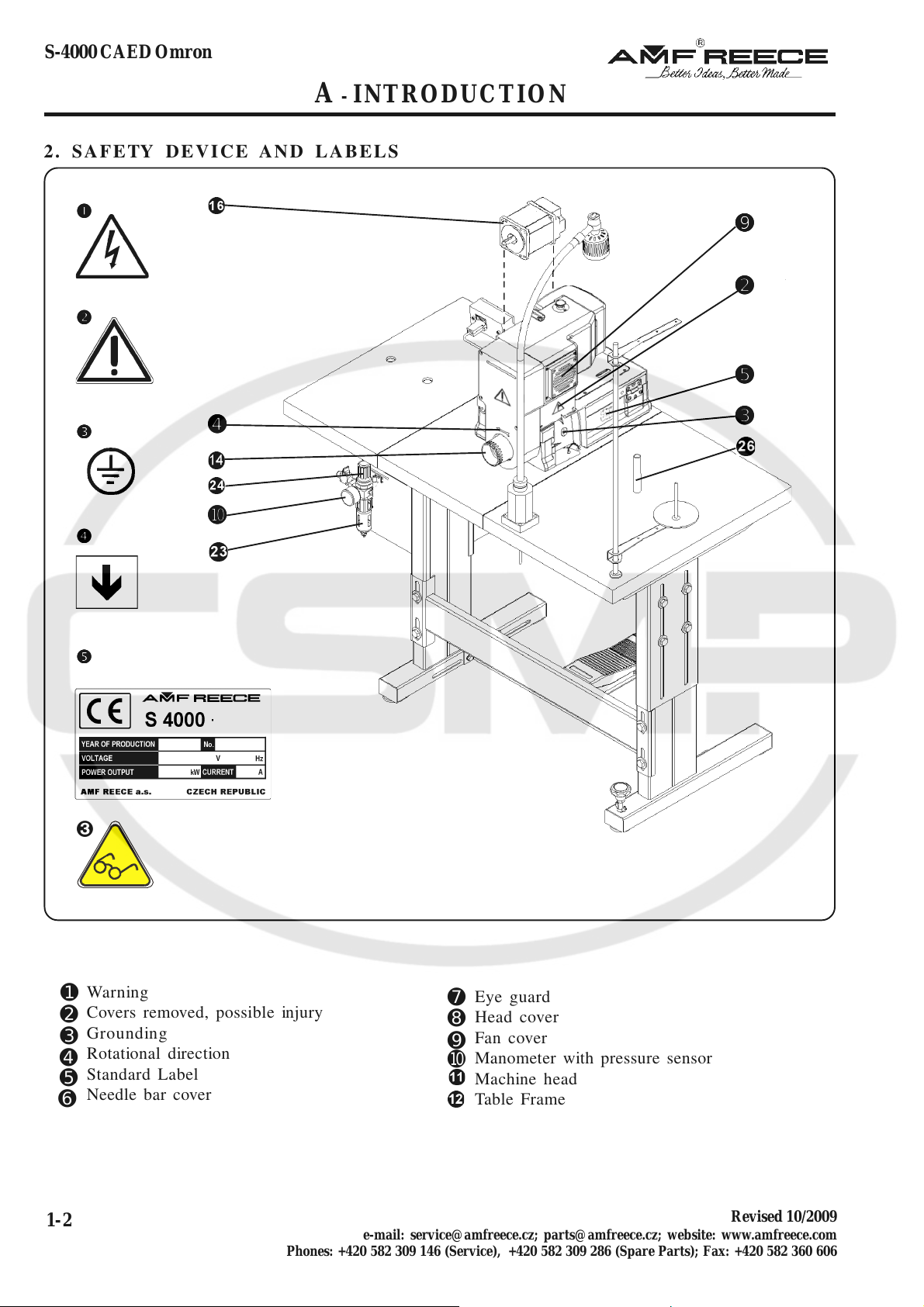

A - INTRODUCTION

2. SAFETY DEVICE AND LABELS

➍➍

➍

➍➍

➒➒

➒

➒➒

➋➋

➋

➋➋

➎➎

➎

➎

➎

➌➌

➌

➌➌

➓➓

➓

➓➓

Warning

➊

Covers removed, possible injury

➋

Grounding

➌

Rotational direction

➍

Standard Label

➎

Needle bar cover

➏

1-2

Eye guard

➐

Head cover

➑

Fan cover

➒

Manometer with pressure sensor

➓

Machine head

Table Frame

Revised 10/2009

e-mail: service@amfreece.cz; parts@amfreece.cz; website: www.amfreece.com

Phones: +420 582 309 146 (Service), +420 582 309 286 (Spare Parts); Fax: +420 582 360 606

A - INTRODUCTION

27

3. GENERAL MACHINE PARTS DESCRIPTION

➑➑

➑

➑➑

➏➏

➏

➏

➏

S-4000 CAED Omron

➐➐

➐

➐➐

➊➊

➊

➊➊

Control box

Hand wheel

Emergency Stop Button

Motor

Table Top

Thread Stand

Control Panel

Revised 10/2009

e-mail: service@amfreece.cz; parts@amfreece.cz; website: www.amfreece.com

Phone: +420 582 309 146 (Service), +420 582 309 286 (Spare Parts); Fax: +420 582 360 606

Main switch

Foot pedal

Clamps Up/Down button

Air pressure regulator

Air pressure adjustment knob

Halogen Lamp

Rest Pin

Warning: when opening the cover, mind

your eyes!

1-3

S-4000 CAED Omron

Sewing length

S 4000 CAED

electronical sewing machine for clothing parts

stitching with cutting after

Knife length 55 mm

Machine type

Air pressure

Machine db level

Machine head dimension

Machine head length

Description

Sewing speed

Stitch density

Machine clamp foot height

1NPE~60Hz 230V/TN-S (according to EN 60204-1)

1NPE~50Hz 230V/TN-S (according to EN 60204-1)

10A charakteristic C (according to EN 60947-2)

16A charakteristic B (according to EN 60947-2)

340 mm (height) x 470 (width) x 250 mm (length)

62 kg

700 mm (height) x 600 mm (width) x 1100 mm (length)

Angle adjustable

semi-automatic

according to IEC 364-3, IEC 364-5-51 temperature from +5°C to 40°C,

relative air humidity from 30 to 80 %

0.55 MPa (80 PSI)

Laeg = 74dB; LWA = 87dB; LpC, peak = 103dB

Line Circuit Breaker

1500-3800 stitches/min

3-14 stitches/cm

12.7 mm (1/2")

to 4 mm (5/32")

7-50 mm

1,7 - 3,0 mm

thread size 80, 100, 120 (Tex 40-60)

Needle 750 SC 90/14, 70/10 (it is possible to order 80/12)

Table dimension

Table type

Electrical Requirements

Maximum work thickness

Bite size

Recommended thread

Needle system

Lubrication

Operating Conditions

4. SPECIFICATIONS

A - INTRODUCTION

1-4

Phones: +420 582 309 146 (Service), +420 582 309 286 (Spare Parts); Fax: +420 582 360 606

e-mail: service@amfreece.cz; parts@amfreece.cz; website: www.amfreece.com

Revised 10/2009

S-4000 CAED Omron

A - INTRODUCTION

5. INSTRUCTIONS FOR OPERATOR SAFETY AND MAINTENANCE

When installing the machine we recommend the minimum clearances noted above around the machine.

Read all of the instructions that follow. DO NOT PUT THE MACHINE INTO OPERATION UNTIL YO

ARE COMPLETELY FAMILIAR WITH ALL INSTALLATION AND OPERATING INSTRUCTIONS.

DANGER!

- Before connecting the machine to the power supply, be positive that all safety covers are correctly

installed.

- Always engage the power lockout switch, or disconnect the main power supply, before removing

any safety covers.

WARNING!

- Locate the Emergency Stop button. Be sure you know how to use it.

- Be sure that you have a reliable and uniform power supply.

- Be sure that all electrical supply lines are in good condition and have no signs of damage to avoid

electrical shock.

- If any covers become damaged, they must be repaired or replaced immediately.

- Do not touch moving parts of the machine while it is operating.

- Keep clear of the needle.

- Always switch off the main power before changing the needle.

- Before cleaning the machine or performing service to the machine, engage the power lock out switch

or disconnect the main power supply.

- When the machine is not in use engage the power lock out switch or disconnect the main power supply.

- When this machine is used incorrectly, or is incorrectly maintained, it can be dangerous.

Everyone who uses this machine, or maintains this machine, must be completely familiar with this

manual.

U

Revised 10/2009

e-mail: service@amfreece.cz; parts@amfreece.cz; website: www.amfreece.com

Phone: +420 582 309 146 (Service), +420 582 309 286 (Spare Parts); Fax: +420 582 360 606

1-5

S-4000 CAED Omron

A - INTRODUCTION

CAUTION!

- Perform all regular service as described in this manual.

- If there is any problem with the power supply, turn off the main power switch.

- Do not remove, paint over, damage or in any way change safety labels. If a safety label cannot be

easily read, replace it.

- Long hair and loose clothing may be dangerous near any machinery. Always contain long hair

and avoid loose clothing, so that it cannot be caught by machinery and cause injury.

- Never use this machine while under the influence of drugs or alcohol.

- If anything seems to be operating incorrectly in the machine call for maintenance assistance

immediately.

- Be sure that there is adequate light for safe operation. A normal minimum light level is 750 lux.

6. SPECIAL ACCESSORIES

- machine device, which is not included in the standard equipment of the machine and can be ordered by

the customer

Voltage guard - relay HRN 35 06.2400.0.004

The machine operation is ensured when the power supply is in range AC 230V

± 10 % (EN 60204-1). It is possible to equip the machine with the relay HRN-35 in case

of larger fluctuation of power supply.

It prevents the machine from damage and in case of large decrease of power supply, the

operator is informed by error message.

If the power supply range is exceeded - max 255V and min 185V the voltage guard -

relay HRN-35 which ensures that machine does not start. After the power supply is in

required range, it is possible to start the machine.

The manufacturer recommends to use the external stabilizer in case of large fluctuation of power supply.

Needles 750 SC 80/12, 90/14

- the manufacturer recommends to use these needles when sewing thin material

- part numbers 02.0750.2.100 (80/12), 02.0750.2.110 (90/14)

1-6

Revised 10/2009

e-mail: service@amfreece.cz; parts@amfreece.cz; website: www.amfreece.com

Phones: +420 582 309 146 (Service), +420 582 309 286 (Spare Parts); Fax: +420 582 360 606

S-4000 CAED Omron

A - INTRODUCTION

Connector Ø 8 Ê

- order it if the connecting tube has the inner diameter 8 mm.

The connector Ø 10 is supplied with the machine.

- part number is 12.0008.3.607

Reduction Ë

- place an order in case you use connections with inch threads

(order number 12.0008.3.081)

Hand valve Ì

- to dissipate any air from the machine, order it (air circuit is bled). It is necessary to order the

connectors (see below) to the hand valve for connection to the air tubes.

- part number 12.0008.3.463

Connectors

➍ 12.0008.3.464 Ø 8 for connection to the tube with inner Ø 8 mm

➎ 12.0008.3.466 Ø 10 for connection to the tube with inner Ø 10 mm

Ï 12.0008.3.467 Ø 12 for connection to the tube with inner Ø 12 mm*

Ð 12.0008.3.465 Ø 16 for connection to the tube with inner Ø 16 mm*

* To connect the tube with inner Ø 12 and Ø 16, it is also necessary to order Ø 10.

Thread Blow - Off Kit 03.5524.0.023

Thread Draw - Off Kit 03.5524.0.004

- the device enables thread tail at

- order this device if

you would like to use

the machine for both,

sewing and trimming.

the needle to be caught above the clamping

feet

without

trimming

with trimming

Revised 10/2009

e-mail: service@amfreece.cz; parts@amfreece.cz; website: www.amfreece.com

Phone: +420 582 309 146 (Service), +420 582 309 286 (Spare Parts); Fax: +420 582 360 606

1-7

S-4000 CAED Omron

B - MACHINE ASSEMBLY

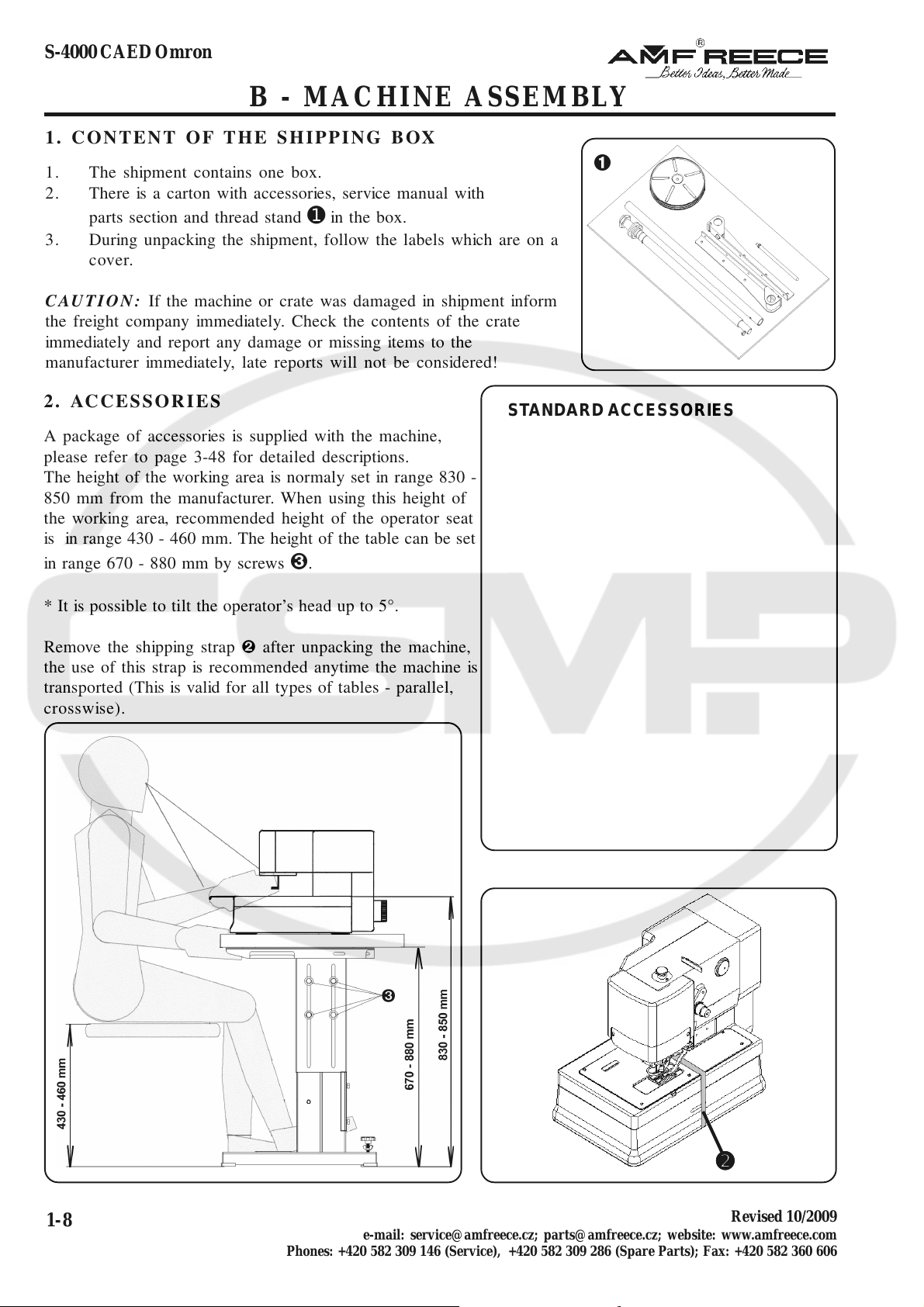

1. CONTENT OF THE SHIPPING BOX

1. The shipment contains one box.

2. There is a carton with accessories, service manual with

parts section and thread stand ➊ in the box.

3. During unpacking the shipment, follow the labels which are on a

cover.

CAUTION: If the machine or crate was damaged in shipment inform

the freight company immediately. Check the contents of the crate

immediately and report any damage or missing items to the

manufacturer immediately, late reports will not be considered!

2. ACCESSORIES

A package of accessories is supplied with the machine,

please refer to page 3-48 for detailed descriptions.

The height of the working area is normaly set in range 830 -

850 mm from the manufacturer. When using this height of

the working area, recommended height of the operator seat

is in range 430 - 460 mm. The height of the table can be set

in range 670 - 880 mm by screws Ì.

* It is possible to tilt the operator’s head up to 5°.

STANDARD ACCESSORIES

Ê

Remove the shipping strap Ë after unpacking the machine,

the use of this strap is recommended anytime the machine is

transported (This is valid for all types of tables - parallel,

crosswise).

1-8

➋➋

➋

➋➋

Revised 10/2009

e-mail: service@amfreece.cz; parts@amfreece.cz; website: www.amfreece.com

Phones: +420 582 309 146 (Service), +420 582 309 286 (Spare Parts); Fax: +420 582 360 606

S-4000 CAED Omron

B - MACHINE ASSEMBLY

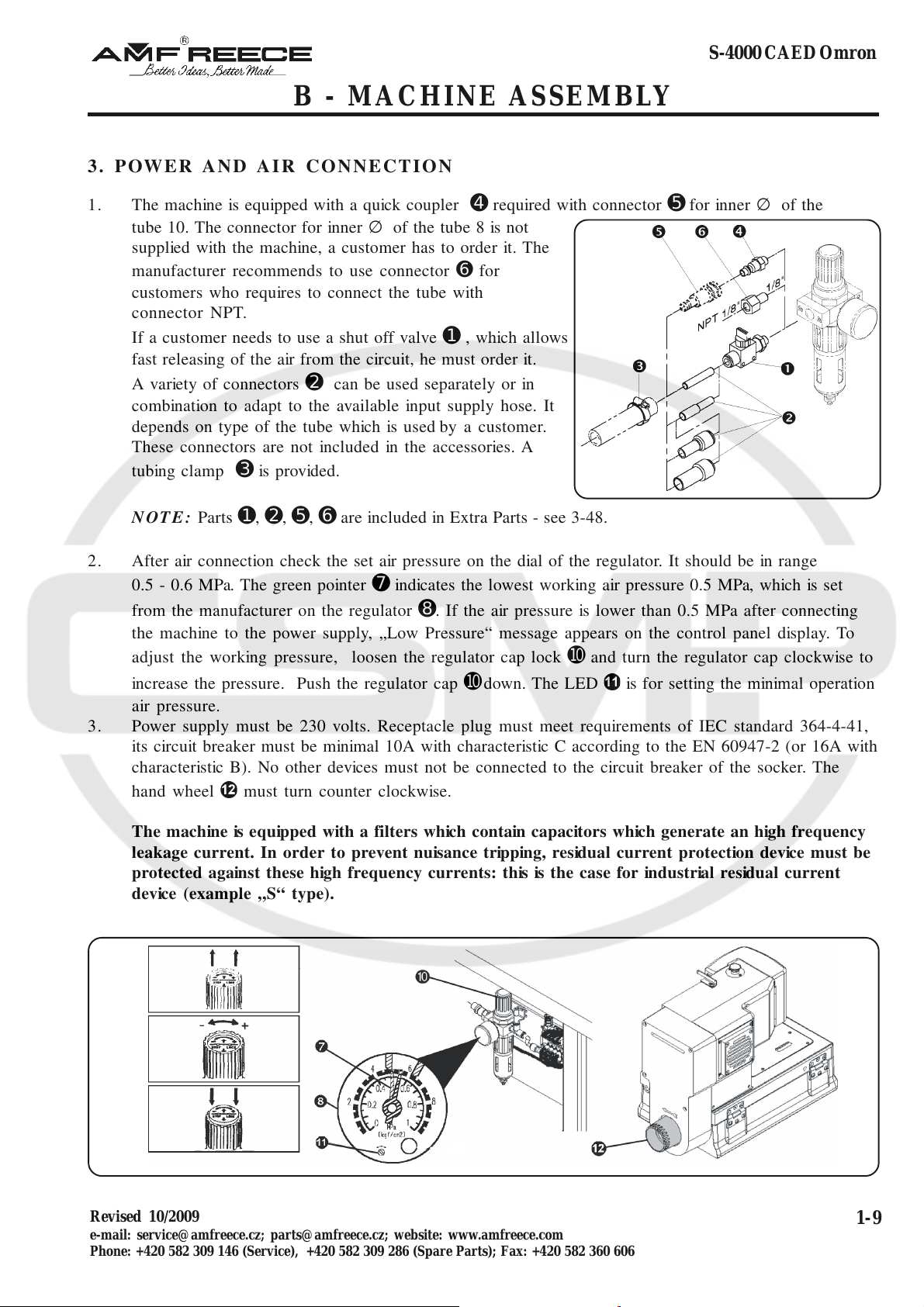

3. POWER AND AIR CONNECTION

1. The machine is equipped with a quick coupler ➍ required with connector ➎for inner ∅ of the

tube 10. The connector for inner ∅ of the tube 8 is not

supplied with the machine, a customer has to order it. The

manufacturer recommends to use connector ➏ for

customers who requires to connect the tube with

connector NPT.

If a customer needs to use a shut off valve ➊ , which allows

fast releasing of the air from the circuit, he must order it.

A variety of connectors ➋ can be used separately or in

combination to adapt to the available input supply hose. It

depends on type of the tube which is used by a customer.

These connectors are not included in the accessories. A

tubing clamp ➌ is provided.

NOTE: Parts ➊, ➋, ➎, ➏ are included in Extra Parts - see 3-48.

2. After air connection check the set air pressure on the dial of the regulator. It should be in range

0.5 - 0.6 MPa. The green pointer ➐ indicates the lowest working air pressure 0.5 MPa, which is set

from the manufacturer on the regulator ➑. If the air pressure is lower than 0.5 MPa after connecting

the machine to the power supply, „Low Pressure“ message appears on the control panel display. To

adjust the working pressure, loosen the regulator cap lock ➓ and turn the regulator cap clockwise to

increase the pressure. Push the regulator cap ➓down. The LED is for setting the minimal operation

air pressure.

3. Power supply must be 230 volts. Receptacle plug must meet requirements of IEC standard 364-4-41,

its circuit breaker must be minimal 10A with characteristic C according to the EN 60947-2 (or 16A with

characteristic B). No other devices must not be connected to the circuit breaker of the socker. The

hand wheel must turn counter clockwise.

The machine is equipped with a filters which contain capacitors which generate an high frequency

leakage current. In order to pre

protected against these high frequency currents: this is the case for industrial residual current

device (example „S“ type).

vent nuisance tripping, residual current protection device must be

Revised 10/2009

e-mail: service@amfreece.cz; parts@amfreece.cz; website: www.amfreece.com

Phone: +420 582 309 146 (Service), +420 582 309 286 (Spare Parts); Fax: +420 582 360 606

1-9

S-4000 CAED Omron

J6A

J6B

J5A

B - MACHINE ASSEMBLY

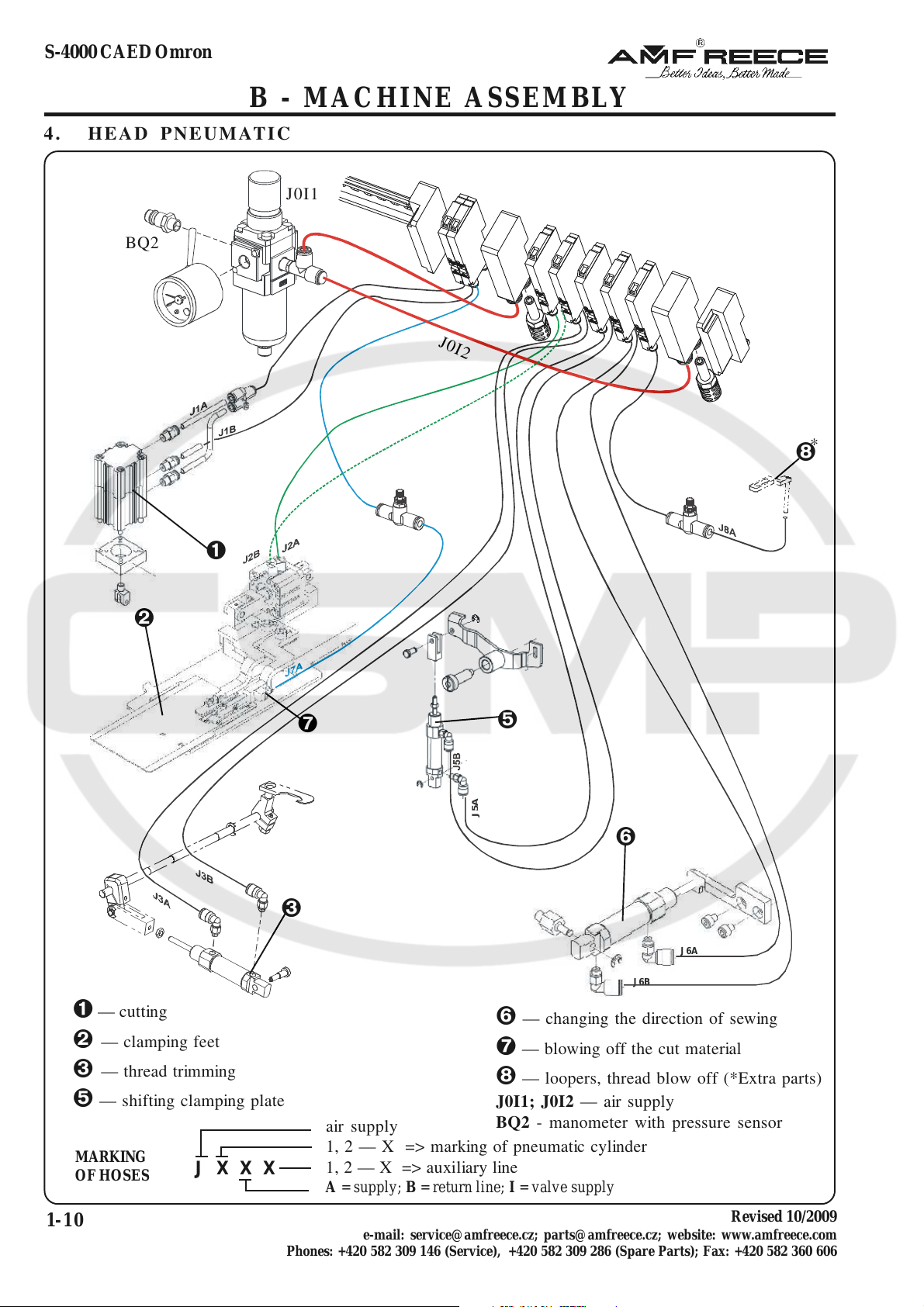

4. HEAD PNEUMATIC

BQ2

J0I1

J0I2

Ñ

*

Ë

Ê

Ì

Ð

Î

Ï

Ê — cutting

Ë — clamping feet

Ì — thread trimming

Î — shifting clamping plate

MARKING

OF HOSES

1-10

JXXX

Ï — changing the direction of sewing

Ð — blowing off the cut material

Ñ — loopers, thread blow off (*Extra parts)

J0I1; J0I2 — air supply

air supply

1, 2 — X => marking of pneumatic cylinder

1, 2 — X => auxiliary line

A = supply; B = return line; I = valve supply

Phones: +420 582 309 146 (Service), +420 582 309 286 (Spare Parts); Fax: +420 582 360 606

e-mail: service@amfreece.cz; parts@amfreece.cz; website: www.amfreece.com

BQ2 - manometer with pressure sensor

Revised 10/2009

B - MACHINE ASSEMBLY

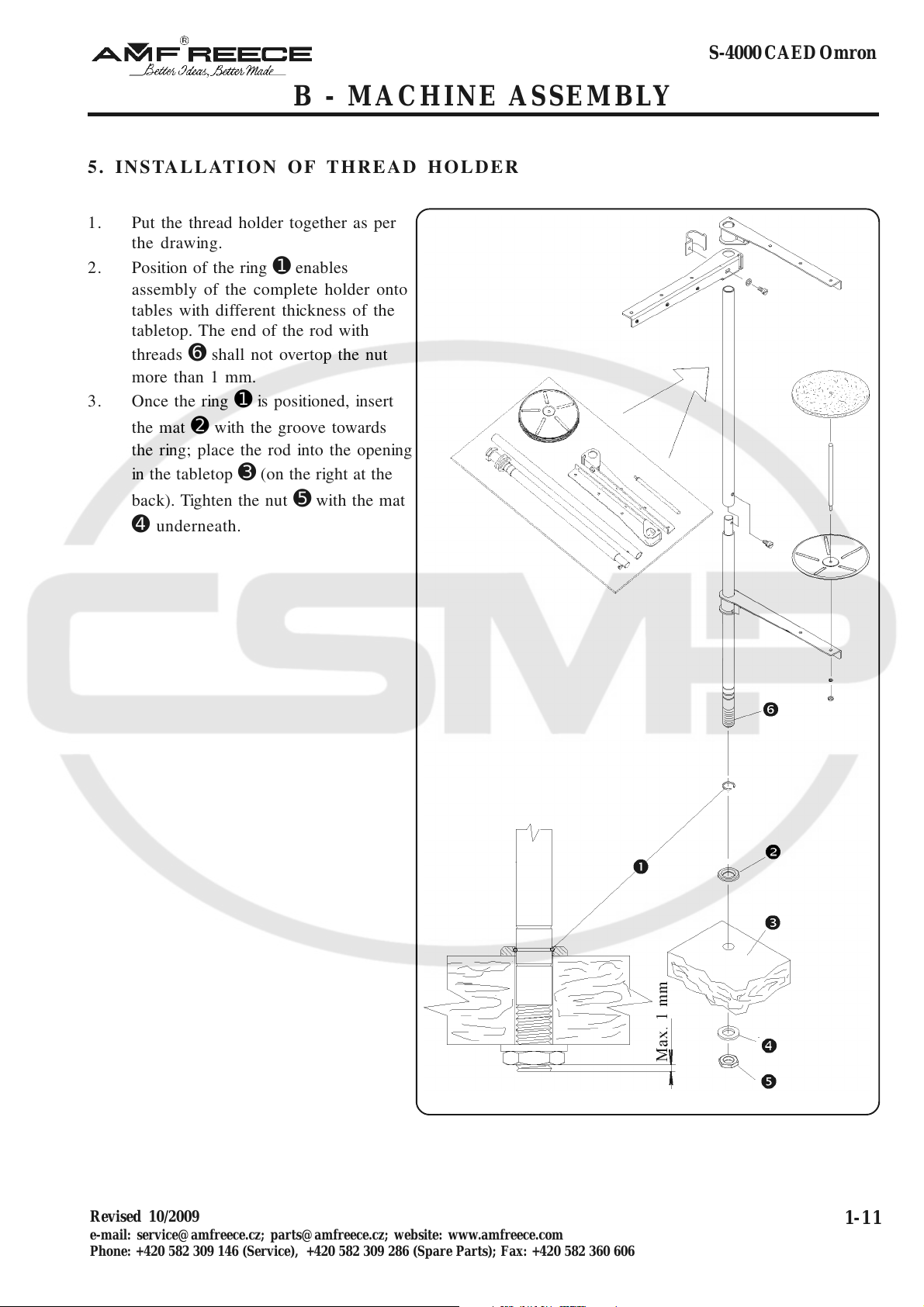

5. INSTALLATION OF THREAD HOLDER

1. Put the thread holder together as per

the drawing.

2. Position of the ring ➊ enables

assembly of the complete holder onto

tables with different thickness of the

tabletop. The end of the rod with

threads ➏ shall not overtop the nut

more than 1 mm.

3. Once the ring ➊ is positioned, insert

the mat ➋ with the groove towards

the ring; place the rod into the opening

in the tabletop ➌ (on the right at the

back). Tighten the nut ➎ with the mat

➍ underneath.

S-4000 CAED Omron

Revised 10/2009

e-mail: service@amfreece.cz; parts@amfreece.cz; website: www.amfreece.com

Phone: +420 582 309 146 (Service), +420 582 309 286 (Spare Parts); Fax: +420 582 360 606

1-11

Loading...

Loading...