Page 1

Page 2

AMF

APPAREL

GENERAL

EQUIPMENT

OPERATING

DIVISION

PRECAUTIONS

Equipment

and

manufactured

has

been

devoted

providing

Any

piece

improperly

are

highly

our

equipment

portion

and

this

will

of

training

equipment.

be

expected

described

to

to

effective

of

machinery

operated

skilled

and

which

installation

of

your

It

to

in

this

our

high

convenience

hazard

quality

protection

can

or

poorly

competent

is

installed

supervision

personnel

is

incumbent

operate

or

manual

standards.

of

operation

for

become

dangerous

maintained.

in

operation

under

in

the

upon

maintain

their

time

operation

you

this

has

been

while

operating

Our

and

supervision.

is

devoted

that

equipment

carefully

Special

simultaneously

personnel.

to

personnel

service

maintenance

to

and

maintenance

all

personnel

designed

attention

when

personnel

of

A

major

instruction

who

be

required

of

to

participate

Our

Service

maintenance

their

proper

personnel.

services

maintenance

in

these

Department

of

our

equipment.

on a regular

of

training

your

equipment,

is

highly

It

and

preferably

and

instruction

skilled

is

recommended

and

sessions.

in

the

that

periodic

competent

operation

you

call

basis

to

training

and

on

insure

of

your

Page 3

APPAREL

What

is

Covered

90

day

warranty

defects

Warranty

tion

One

feels

prepaid,

part,

be

customer.

in

workmanship

period

date.

year

warranty

is

defective,

to

AMF

defective,

EQUIPMENT

WARRANTY

on

shall

customer

AMF

will

Richmond.

inspect

it

will

both

service

or

materials.

begin

on

on

parts.

must

and

if

be

replaced

POLICY

and

completed

Any

ON

parts

part

customer

return,

Upon

the

receiving

part

is

found

at

no

charge

AMF

NEW

AND

due

to

installa

freight

the

to

to

RECONDITIONED

What

is

not

Coveted

Normal

not

the

Cleaning

Parts

to

Shipping

adjustments

be

covered.

customer.

and

lubrication

found

neglect

to

or

or

delivery

improper

EQUIPMENT

and

This

is

of

be

altered,

installation

charges.

routine

the

maintenance

sole

responsibility

equipment.

broken

or

or

will

of

damaged

due

application,

WHAT

The

satisfaction

Manufacturer's

is

not

handled

1.

Discuss

2.

Contact

and

goodwill

Representatives

to

your

the

problem

the

customer

TO

DO

IF

THERE

of

owners

and

satisfaction,

with

Service

the

the

nearest

Manager

and

AMF

following

AMF

Apparel

2115

Richmond,

Telephone:

IS A QUESTION

lessee's

Apparel

at

the

AMF

W.

of

Equipment

steps

are

Manufacturer's

address

Equipment

incorporated

Laburnum

Virginia

804/355-7961

REGARDING

AMF

Equipment

Division.

suggested:

Representative.

below:

Division

Avenue

23227

are

In

the

WARRANTY

of

primary

event

that a warranty

concern

to

matter

AMF

Page 4

Decorative

Stitching

Machine

APPAREL

To

hsip

insure

maintenance

Daily

1.

Clean

2.

Remove

Weekly

1.

Clean

2.

Check

3.

Make

EQUIPMENT

smooth

should

bottom

any

and

oil

for

worn,

sure

needle

operation

be

performed

looper

thread

both

roller,

and

needle

retaining

stops

roller

lint

from

bars.

rings

are

clean.

of

the

AMF

daily,

weekly

must

thread

and

pins.

MAINTENANCE

Decorative

and

monthly

turn

freely.

drum.

Stitching

as

indicated:

Machine,

CHECKS

CLASS59•DIVISION

the

following

preventative

83

4.

5.

6.

7.

8.

9.

Make

sure

Reset

needle

Clean

top

Check

Check

grove

Oil

belts

tension

or

machine

needle

and

stop

release.

bottom

for

proper

finger

burs.

and-igreaoo

springs

loopers,

tension

timing

goarci

are

clean

check

and

and

clean

i

and

not

broken.

timing.

alignment.

wax

from

same.

Should

be

polished

or

replaced

if

there

is

a

Page 5

PAGE

CLASS

INSTRUCTIONS

IB

59

DIVISIOI

This

To

where

references

AMF

All

called

catalog

locate

page

numbers

Parts

Part

numbers

the

listing

standard

and

illustrated

parts - refer

the

individual

are

shown

to

page

commercial

out

by a rectangular

number

If

quantity

of

can

any

item

the

machine.

be

in

wanted,

Example: 2 parts,

is

Issued

for

various

in

assist

are

called

immediately

and

semi-standard

in

for

parts

exploded

in

this

hardware

found

in

this

catalog

the

the

part

Stitching

to

"MECHANISM

units - such

are

illustrated

views

locating

out

nuineridally

following

stitqh

catalog.

is

illustratedL

shaped

Machines

INDEX"

as

in

the

vj.ew8

of

the

parts,

on

balBoon.

"Commercial rarts

is

wanted,

number,

descripti^

59-83-1041D,

it

Type

on

Page

Handwheel

and

listed.

general

mating

where

illustration

the

sequence

parts.

practicable

also

proper^pfige

Usingx^is

Lis^,

Ji^y

be

ordered

of

part,

Sprf^g,

2,

3, & 4,

SB,

3C,

or

and

Cam

Shaft,

of

assembly

and

on

which

commercial

j^rts,

of

its

item

number

beginning

by

specifying

and

the

for

Serial

Serial

5D

will

No.

which

Clutch,

with

be

found

they

use

appear.

are

and

the

on

Page

2000C.

serial

No.

number

1419

1409 & up,

lists

etc.

on

listed

is

part

the

the

-

To

expedite

Disregard

-Model*-

model

if

possible,

or

the

and

information

Individual

dowels,

ferred

without

Parts are

or

freight

Post

shipments

moulded

following

due

to

incomplete

parts

keys,

in

most

holes,

shipped

shipments

shipments - Paints

Example: 2 parts,

1

part , 39-83-1406A3,

number

number

length

the

spring

cases

as

must

of

stitch,

complete

part

number,

as

requested

are

furnished

post,

from

they

must

F.O.B.

must

be

filed

our

should

59-83-1041D,

on

castings

indicates

needle

number

the

in

without

clamp

the

part

be

transferred

factory.

be

filed

through

be

as

part

size,

usually

serial

notes

on

screws,

studs,

being

Claims

with

us.

listed

in\consecutive

Spring,

Cam , fpr

patterns

number

stamped

number

pages

washers,

replaced.

from

local

is

etc.

of

illustrating

nuts,

etc.,

parts

for

agent.

^or

Serial

Serial

may

be

used

incomplete

Customer

on

the

part

the

stitching

taper

as

these

Certain

on

the

damage

to

Claims

order.

No.

No.

for

other

as

the

should

the

pins,

parts

machine.

or

on

furnish,

being

machine

parts.

cotter

can

are

loss

Insured

1419

1419

parts.

parts

replaced

pins,

be

trans

furnished

of

express

Parcel

Page 6

PAGE

2B

CLASS

INSTRUCTIONS

59

DIVISION

83

Parts

tags

Any

o£

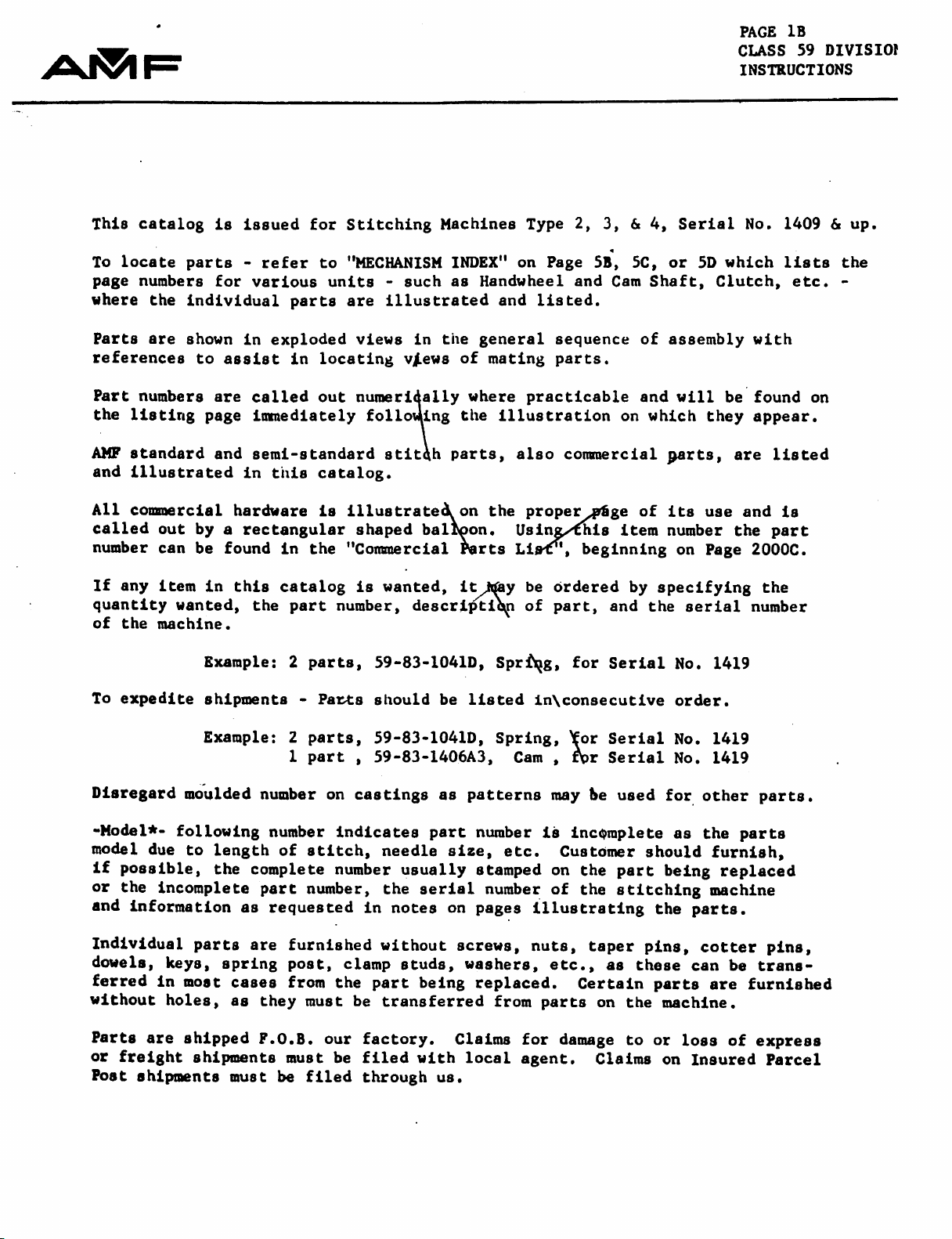

Stitches

SADDLE

should

give

your

material

returned

made

STITCH

Type 2 Machine

not

be

returned

order

or

returned

material

on

the

should

59-83

(Identified

is

used

without

our

invoice

without

be

PARTS

APPAREL

AMF

2115

RICHMOND.

STITCHING

SHORT

by

for

Saddle

our

Return

number

tag

will

sent

INCORPORATED

WEST

serial

to:

DEPARTMENT

EQUIPMENT

LABURNUM

VIRGINIA

MACHINE

-

LOMG

number

be

stored

STITCH

against

DIVISION

AVENUE

23227

are:

with

Stitch & Short - Long

Material

which

at

your

ANGLE

PICK

suffix

12,

Stitch.

Tag.

parts

risk.

STITCH

example

When

are

All

OR

requesting

shipped.

shipments

#1299-12)

Type 3 Machine

(identified

is

Stitch.

Type 4 Machine

(identified

is

used

used

for

for

by

serial

Saddle

by

serial

Saddle

number

Stitch,

number

Stitch

with

with

Short-Long

with

suffix

Stitch & Angle

suffix

improved

11,

example

14,

example

features.

#1224-11)

or

Pick

#1684-14)

Page 7

PAGE

CLASS

INSTRUCTIONS

4

59

DIV.

i

0

I

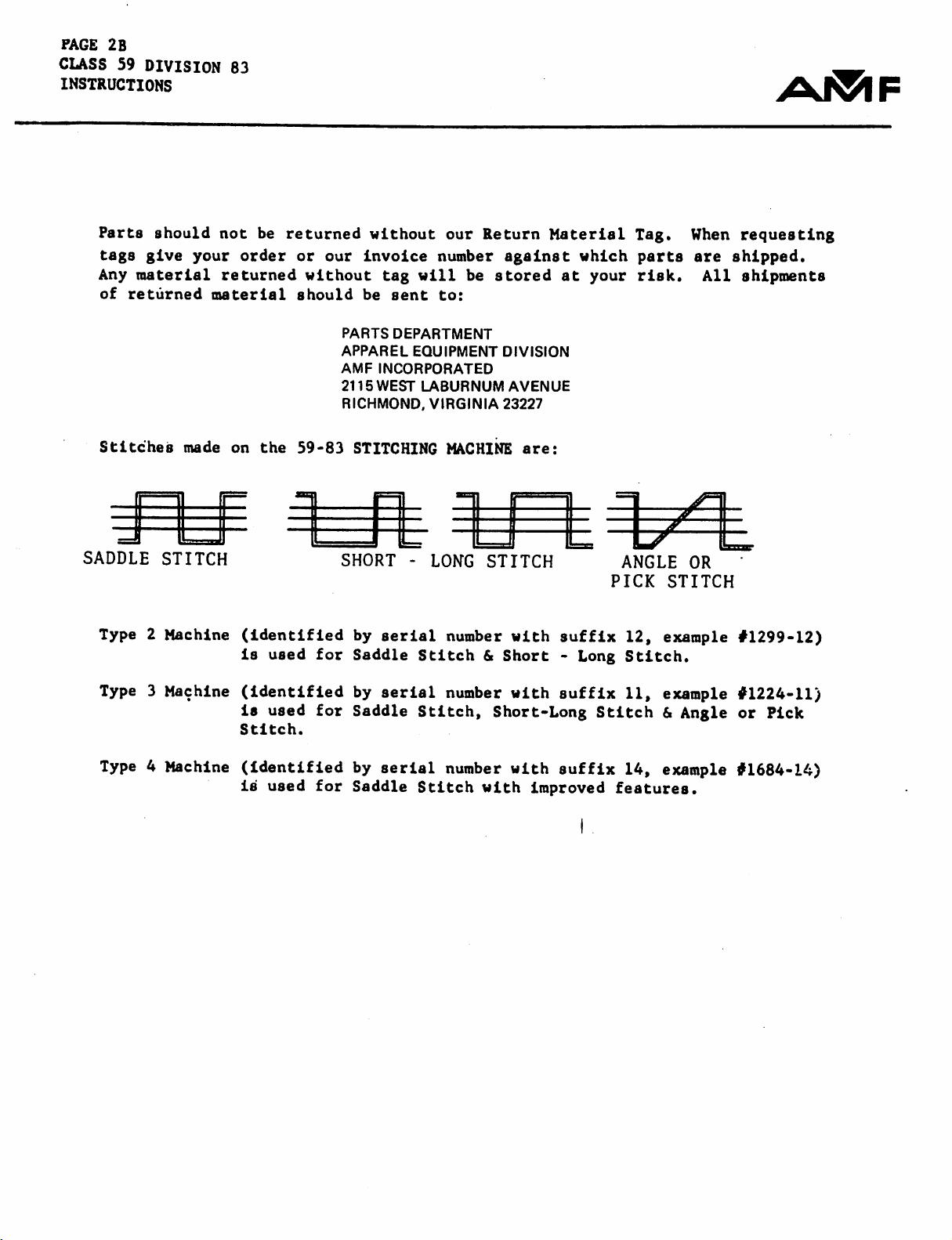

Fig.

Fig.

Fig.

T

Fig-

1

Slotted

2

Hexagon

3

Slotted

Machine

SCREW

t

TYPES

2

Set

Socket

Round

Screw

AND

(D

Fig.

Screw

Set

Head

SIZES

3

Fig.

Screw

USED

4

ON

AMF

STITCHING

©

o

11

Fig.

Fig. 5 Hexagon

Fig.

Fig.

5

6

Hexagon

7

Slotted

Machine

Fig.

6

MACHINES

(ID

t

Fig.

Socket

Head

Oval

Screw

Cap

Head

7

Hd.

Screw

CD

I

Fig.

Cap

8

Scre^^

Fig.

4

Slotted

Machine

SIZE

2-56

3-48

4-40

5-40

6-32

6-40

8-32

8-36

10-24

10-32

1/4-20

1/4-28

5/16-18

5/16-24

Flllester

Screw

Head

NOMINAL

.086"

.099"

.112"

.125"

.138"

.138"

.164"

.164"

.190"

.190"

.250"

.250"

.313"

.313"

Fig.

DIA

8

Slotted

Machine

Flat

Screw

THREADS

Head

PER

56

48

40

40

32

40

32

36

24

32

20

28

18

24

INCH

Page 8

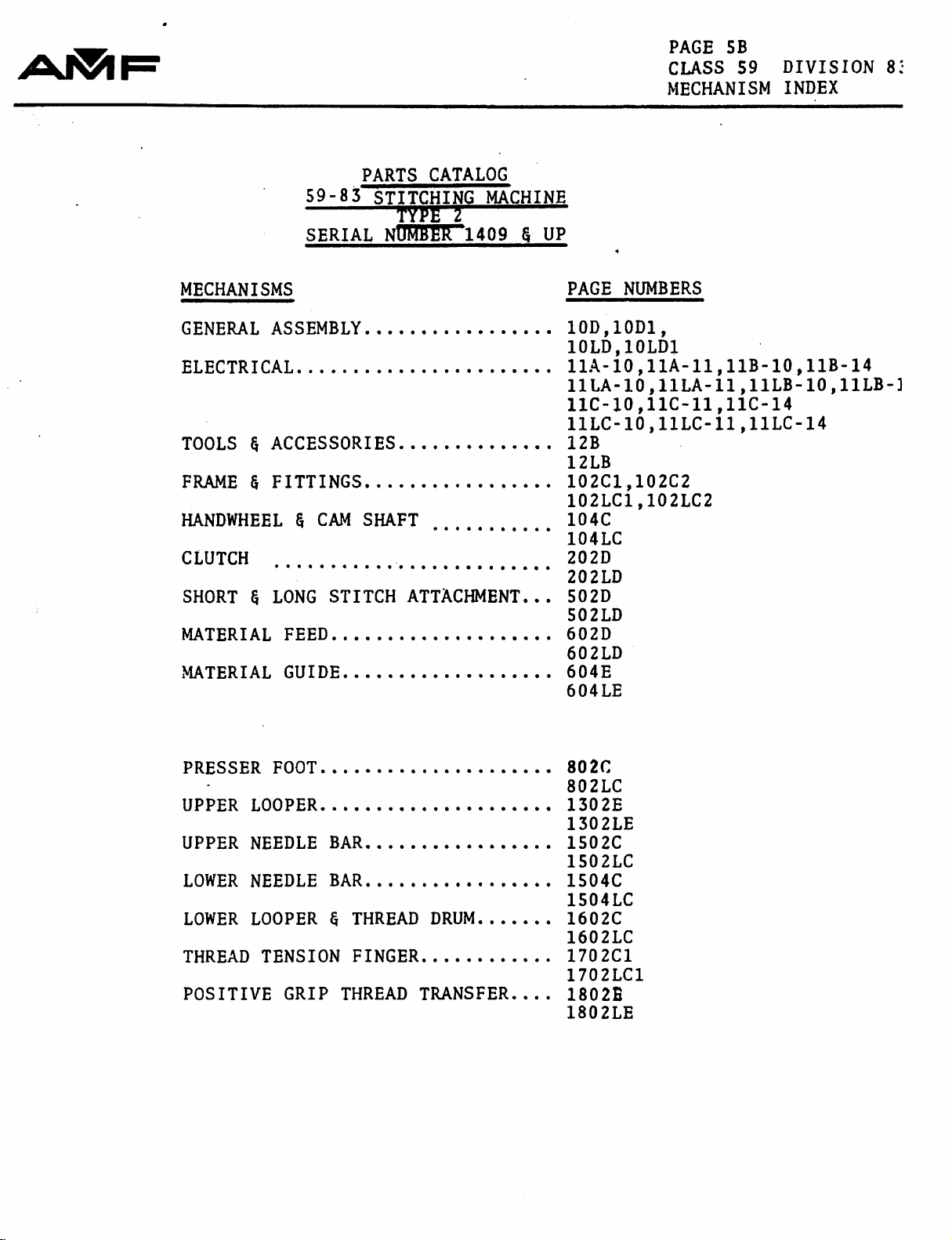

PAGE

CLASS

MECHANISM

SB

S9

DIVISION

INDEX

S;

59-83

SERIAL

MECHANISMS

GENERAL

ASSEMBLY

ELECTRICAL

TOOLS

FRAME § FITTINGS

HANDWHEEL

CLUTCH

SHORT

MATERIAL

MATERIAL

§

ACCESSORIES

§

CAM

§

LONG

STITCH

FEED

GUIDE

PARTS

CATALOG

STITCHING

TVPE

number

SHAFT

ATTACHMENT...

MACHINE

I

1409 S UP

PAGE

NUMBERS

10D,10D1,

lOLD.lOLDl

IIA-10 , llA-11,

IIB-10 , HE-14

11LA-10,11LA-11,11LB-10,11LB-]

11C-10,11C-11,11C-14

11LC-10,11LC-11,11LC-14

12B

12LB

102C1,102C2

102LC1,102LC2

104C

104LC

202D

202LD

502D

502LD

602D

602LD

604E

604LE

PRESSER

UPPER

UPPER

LOWER

LOWER

THREAD

POSITIVE

FOOT

LOOPER

NEEDLE

NEEDLE

LOOPER

TENSION

GRIP

BAR

BAR

§

THREAD

FINGER

THREAD

DRUM

TRANSFER

802C

802LC

1302E

1302LE

1502C

1502LC

1504C

1504LC

1602C

1602LC

170

2C1

1702LC1

1802E

1802LE

Page 9

PAGE

CLASS

NECHANISN

5C

59

DIVISION

INDEX

83

MECHANISMS

GENERAL

ASSEMBLY

ELECTRICAL

TOOLS S ACCESSORIES

FRAME & FITTINGS

HANDWHEEL

CLUTCH

ANGLE

&

STITCH

CAM

FEED

SHAFT

ADJUSTER

59-83

SERIAL

PARTS

CATALOG

SYItCHrNO

TYPE

NUMBER

HACHINE

3

1409

ii

UP

PAGE

lOE,

llA-lOJlA-n

NUMBERS

lOEl,

IDLE,

lOLEl

,118-10,118-14

11LA-10,11LA-11,11L8-10,11L8-14

11C-10,11C-11,11C-14

11LC-10,11LC-11,11LC-14

128,

12L8

102C1,102C2

102LC1,

104C,

202D,

402C,

102LC2

104LC

202LD

402LC

MATERIAL

MATERIAL

ANGLE

STITCH

PRESSER

PRESSER

UPPER

UPPER

LOWER

LOWER

ANGLE

LOOPER

NEEDLE

NEEDLE

LOOPER & THREAD

STITCH

THREAD

POSITIVE

FEED

GUIDE

MECHANISM

FOOT & SWIVEL

FOOT

BAR

BAR

MECHANISM

TENSION

GRIP

FINGER

THREAD

TOE

DRUM

&

TRANSFER

602D,

604F,

7028,

704C,

802C,

1302E,

1502C,

1504C,

1602C,

1702F,

1802E,

602LD

604LF

702L8

704LC

802LC

1302LE

1502LC

1504LC

1602LC

1702LF

1802LE

Page 10

PAGE

CLASS

SD

59

MECHANISM

DIVISION

INDEX

8

PARTS

59 - 8 3 STlTCHINfl

SERIAL

MECHANISMS

GENERAL

ASSEMBLY

ELECTRICAL

TOOLS § ACCESSORIES

FRAME 8 FITTINGS

HANDWHEEL

CLUTCH

STITCH

MATERIAL

MATERIAL

PRESSER

UPPER

UPPER

LOWER

LOWER

THREAD

POSITIVE

8

8

CAM

SHAFT

FEED

LOOPER

NEEDLE

NEEDLE

ADJUSTMENT

FEED

GUIDE

FOOT

BAR

BAR

LOOPER 8 THREAD

TENSION

GRIP

CLAMP

FINGER

THREAD

FINGERS

CATALOG

TYPE

NUMBER

DRUM

TRANSFER

machine

4

1684

5

UP

PAGE

NUMBER

lOF.lOFl

lOLF.lOLFl

llA-11,11B-10,11B-14

11LA-11,11LB-10.llLB-14

11C-10,11C-11,11C-14

11LC-10,11LC-11,11LC-14

12B

12LB

102C1,102C2

102LC1,102LC2

104C

104LC

202D

202LD

404A

404LA

602E

602LE

604E

604LE

802C

802LC

1302E

1302LE

1502C

1502LC

1504C

•1504LC

1602C

1602LC

1702C

1702LC

1802E

1802LE

Page 11

4ii[

I !B

t—-f-1-i

ill

R-

r

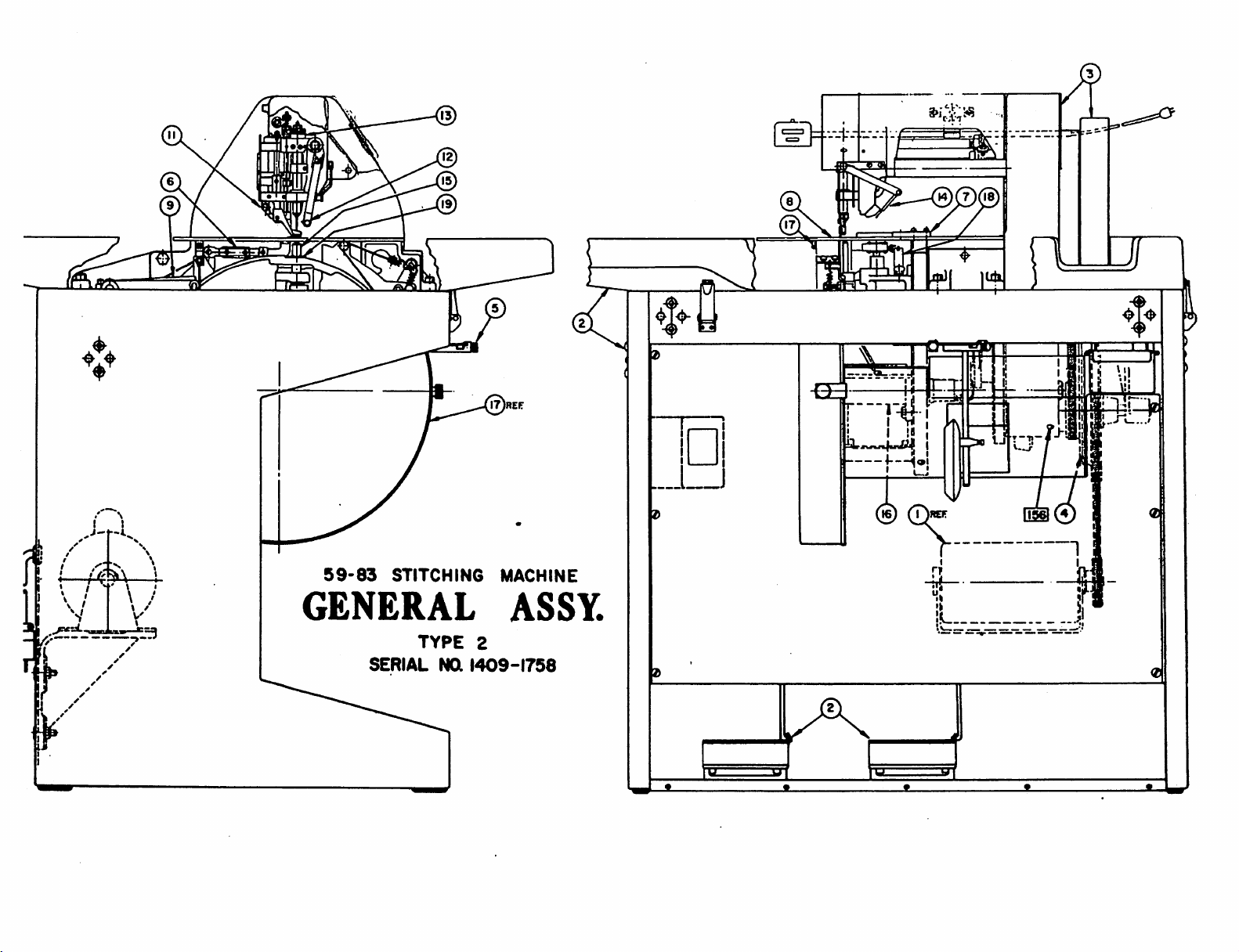

59-83

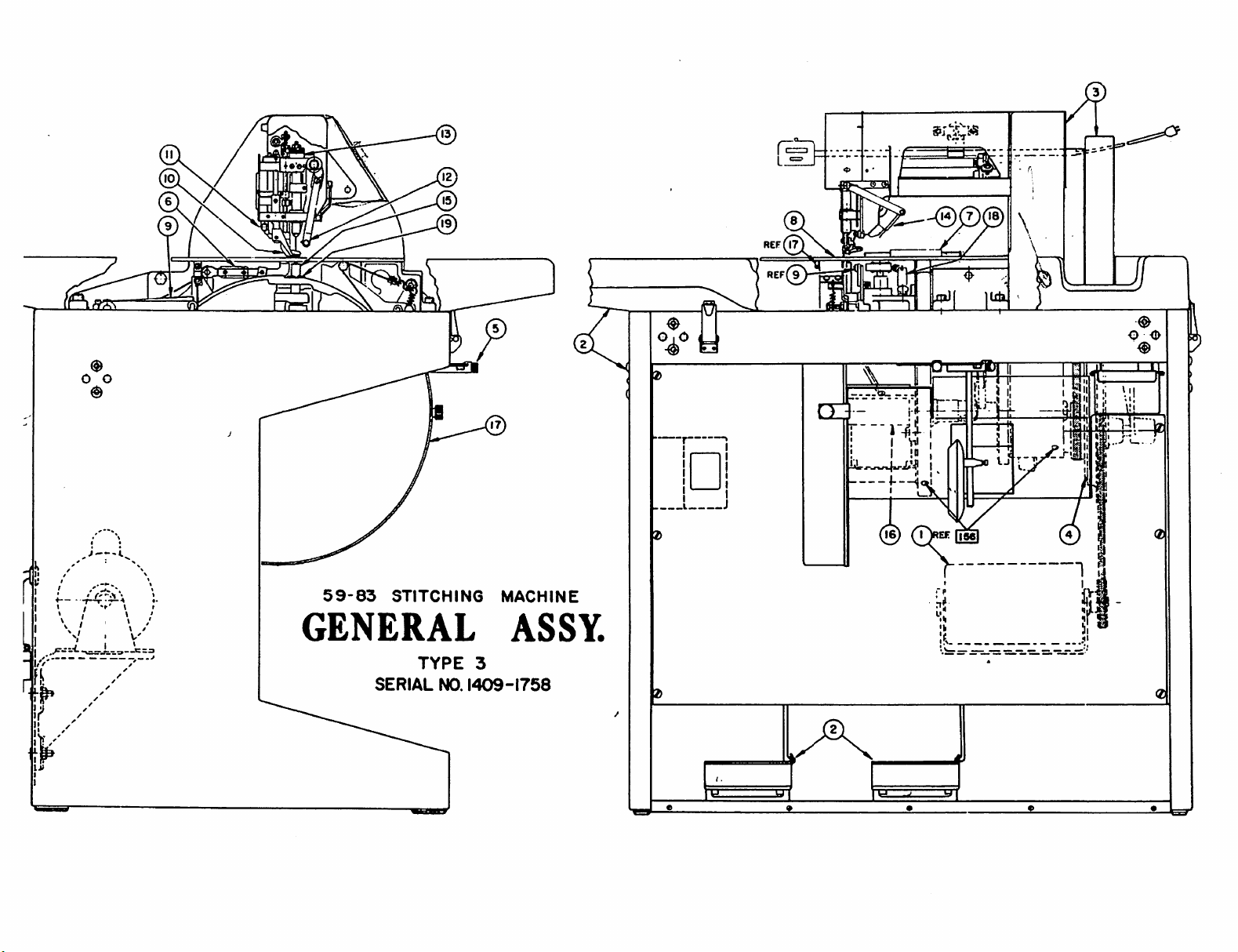

GENERAL

STITCHING

TYPE

SERIAL

2

Na

1409-1758

MACHINE

ASSY.

Page 12

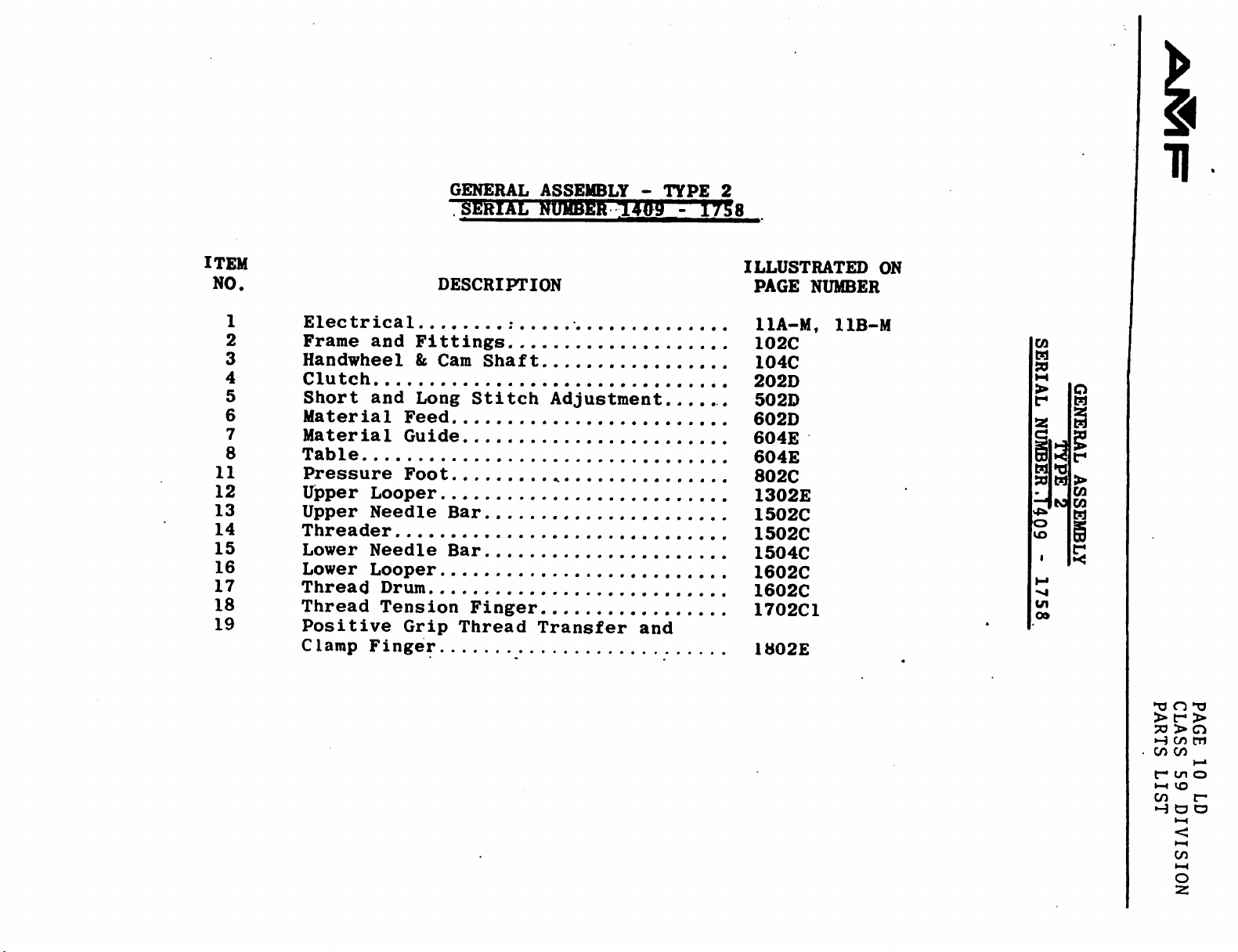

GENERAL

SEhlAL

ASSEHBLT

MUmJiR

-

TYPE

2

IJfta - 1758

Tl

ITEM

NO.

2

3

4

5

6

7

8

11

12

13

14

15

16

17

18

19

ILLUSTRATED

DESCRIPTION

1

Electrical

Frame

Handwheel

and

Fittings

&

Cam

Shaft

Clutch

Short

Material

Material

and

Long

Feed

Guide

Stitch

Adjustment

Table

Pressure

Upper

Upper

Foot

Looper

Needle

Bar

Threader

Lower

Lower

Thread

Thread

Positive

Clamp

Needle

Looper

Drum

Tension

Grip

Finger.

Bar

Finger

Thread

Transfer

and

PAGE

IIA-M.

102C

104C

202D

502D

602D

604E

604E

802C

1302E

1502C

1502C

1504C

1602C

1602C

1702C1

1802E

NUMBER

IIB-M

ON

z

:a

4k

O

CO

n

M

>

r

g

M

•0

>

H

09

CO

a

vo

M

tf

i

09

^ n 'ra

>

c-

>

>

Ci

H

c/5

m

Ol

CO

•—I

r*

to

o

►—«

vo

CO

r-

H o o

•—I

<

»—»

CO

o

z

Page 13

59-83

STITCHING

MACHINE

GENERAL

TYPE

SERIAL

NO.

2

17598

ASSY.

UP

I

)REF

Page 14

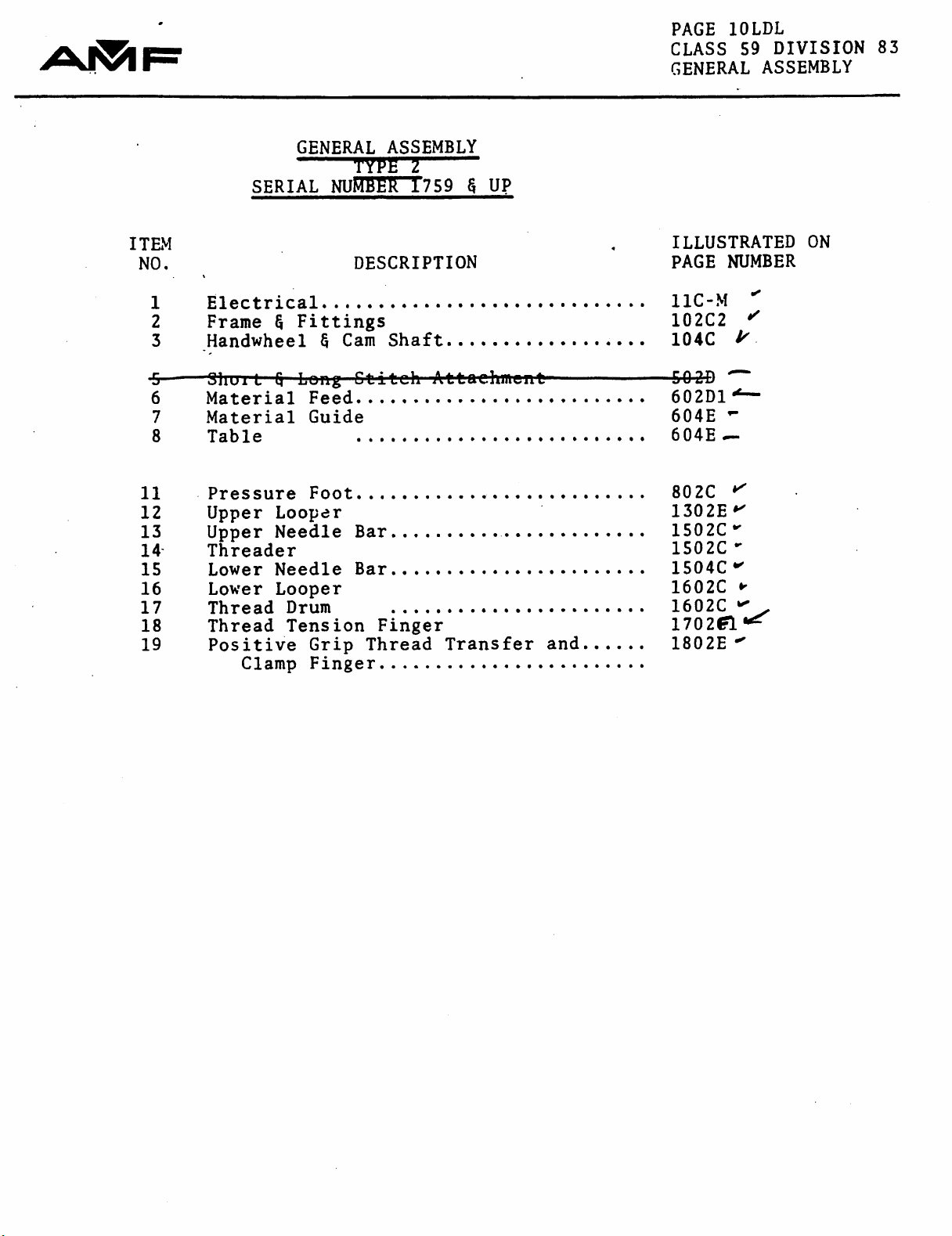

PAGE

CLASS

GENERAL

lOLDL

59

DIVISION

ASSEMBLY

83

ITEM

NO.

1

2

3

•5

6

7

8

11

12

13

14

15

16

17

18

19

GENERAL

ASSEMBLY

TYPE

SERIAL

Electrical

Frame 8 Fittings

Handwheel

31iui I Q—Long

Material

Material

Table

Pressure

Upper

Upper

Threader

Lower

Lower

Thread

Looper

Needle

Needle

Looper

Thread

Positive

Clamp

number

DESCRIPTION

8

Cam

Stiteh

Feed

Guide

Foot

Bar

Bar

Drum

Tension

Grip

Finger

Thread

Shaft

Finger

2

1759 8 UP

Attachment

Transfer

and

,

ILLUSTRATED

PAGE

IIC-M

NUMBER

''

102C2

104C

502D

602D1

604E

604E

802C

^

^

1302E'^

1502C*'

1502C

1S04C*^

1602C

1602C

"

^

1702^*^

1802E

"

ON

Page 15

OiO

(„

□

s-d

!»

rl

,

1!^

59-83

GENERAL

STITCHING

TYPE

SERIAL

NO.

MACHINE

ASSY.

3

1409-1758

Page 16

GENERAL

SERIAL

ASSEMBLY

NUMBER

-

1409

TYPE

-

3

1758

ITEM

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Electrical

Frame

Handwheel

Clutch

Angle

Material

Material

Table

Angle

and

Stitch

Stitch

Pressure

Pressure

Upper

Upper

Looper

Needle

Threader

Lower

Lower

Thread

Angle

Needle

Looper

Drum

Stitch

Thread

Positive

Clamp

Finger

DESCRIPTION

Fittings

&

Cam

Shaft

Feed

Adjuster

Feed

Guide

Mechanism

Foot & Swivel

Foot

Bar

Bar

Mechanism

Tension

Grip

Finger

Thread

Toe

and

Transfer

and

ILLUSTRATED

PAGE

NUMBER

11A-M,11B-M

102C

104C

202D

402C

602D

604F

604F

702B

704C

802C

1302E

1502C

1502C

1504C

1602C

1602C

1702F

1802E

ON

TI

CO

H

ta

HH

>

t-

O

g

IT"

W

>

CO

CO

CO

M

o

(O

5

'vj

tn

CO

^3 n "ra

>

r-*

>

>

£75

H

CO

m

cn

CO

r-

cn

o

►—(

to

CO

tr

H o m

H-l

<

»—I

CO

t-H

o

z

Page 17

Page 18

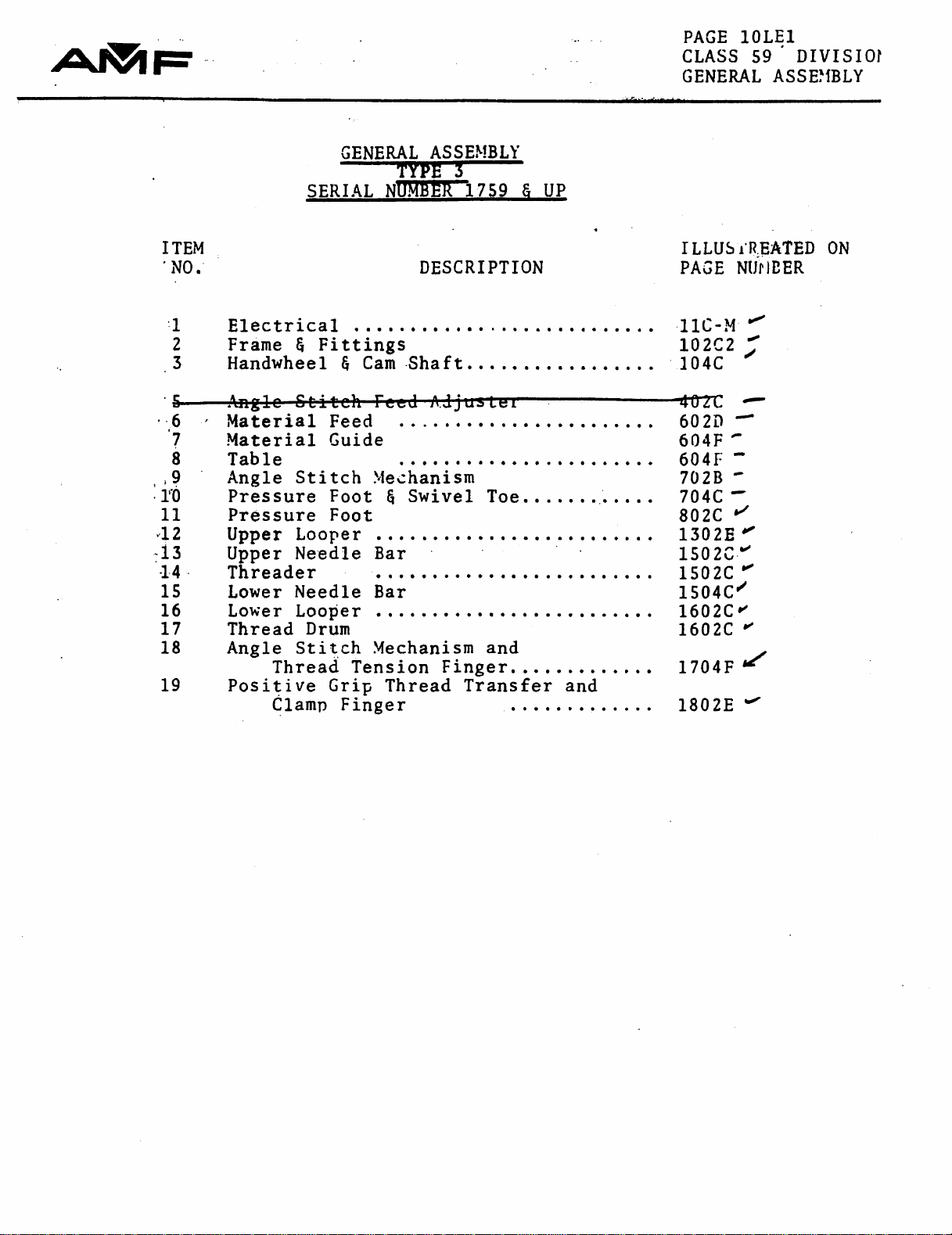

PAGE

CLASS

GENERAL

lOLEl

59 ■ DIVISIOf

ASSEMBLY

ITEM

NO.

1

2

3

S

• 6

7

8

,9

ro

11

•

12

13

14

15

16

17

18

19

GENERAL

SERIAL

Electrical

Frame 5 Fittings

Handwheel

i\nglG

'

Material

Material

Table

Angle

Pressure

Pressure

Upper

Upper

Threader

Lower

Lower

Thread

Angle

Positive

Thread

Clamp

§

Cam

Stitch

Feed

Guide

Stitch

Foot § Swivel

Foot

Looper

Needle

Needle

Looper

Drum

Stitch

Tension

Grip

Finger

ASSEMBLY

TYPE

number

Shaft

Teed

S

1759 S UP

DESCRIPTION

AJJuAlei

Mechanism

Toe

Bar

Bar

Mechanism

Thread

and

Finger

Transfer

and

ILLUSiREATED

PAGE

IIC-M

102C2

104C

402C

602D

604F

604F

702B

7040"^

802C

NUMBER

^

—"

"

"

"

'

1302E

1502C*^

1502C

1S04C'^

1602C*'

1602C

^

1704F

1802E

ON

Page 19

REro

Km

1

-fH-

I

"

111

I '1

I

'

/

f£^'y

\

V

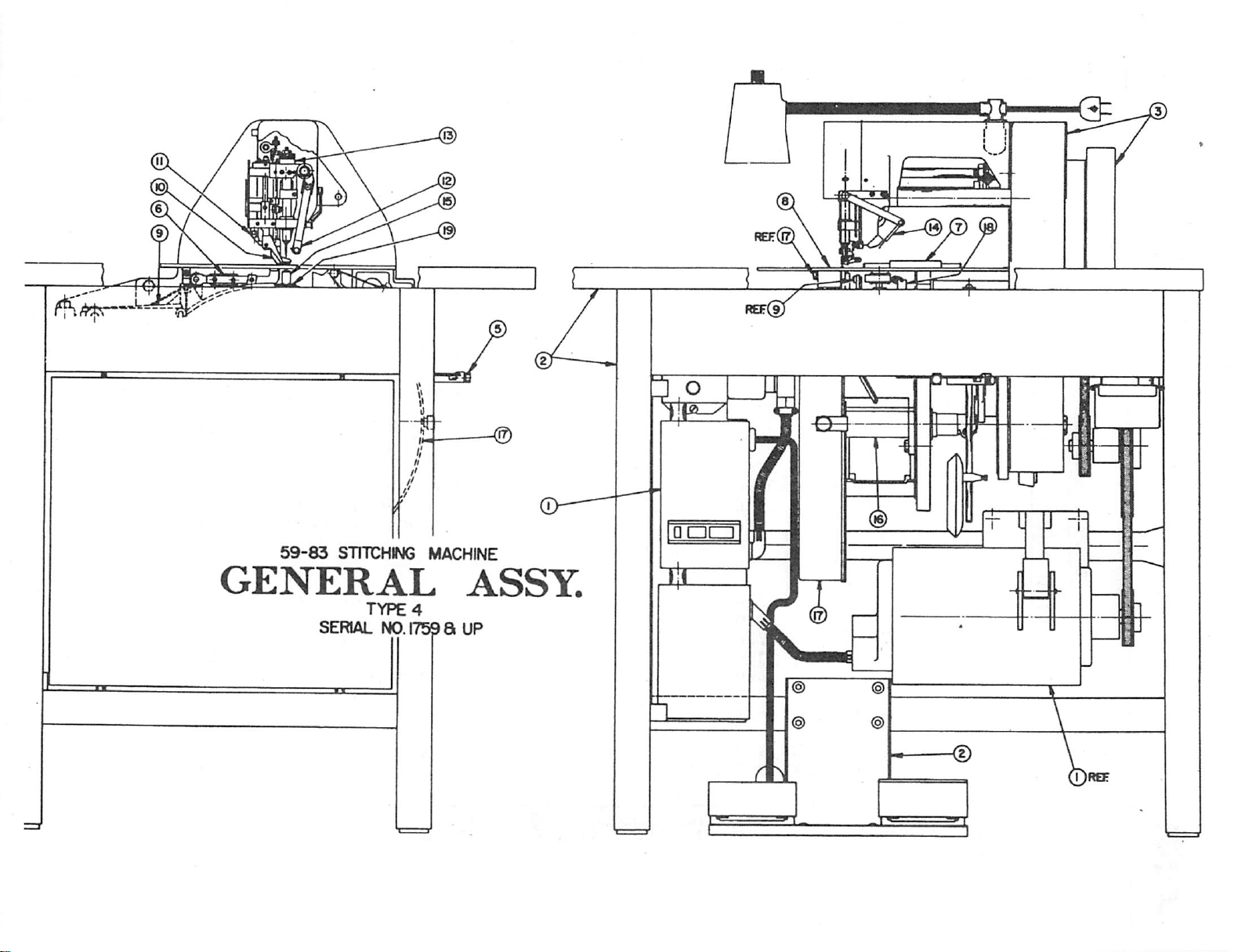

59-83

STITCHING

GENERAL

TYPE

SERIAL

4

NO.

1684-1758

MACHINE

ASSY.

Page 20

GENERAL

SERIAL

ASSEMBLY

NUMfeER

-

TYPE

.1654

4

3

-

ITEM

NO.

11

12

13

14

15

16

1

2

3

4

5*

6

7

8

Electrical

Frame

and

Handwheel

Clutch

Stitch

Feed

Material

Material

Table

Pressure

Upper

Upper

Looper

Needle

Threader

Lower

Lower

Thread

Th;

r^s;?

ead

live

^

Needle

Looper

Drum

Tension

Clamp

DESCRIPTION

Fittings

&

Cam

Adjustment

Feed

Guide

Foot

Bar

Bar

Grip

Thread

Finger

Shaft

Finger

Transfer

ILLUSTRATED

PAGE

IIA-M.

102C

104C

202D

404A

602E

604E

604E

802C

1302E

1502C

i502C

15U4C

1602C

1602C

1702C

.

1802E

NUMBER

IIB-M

ON

a*

•vj

11

CO

n

w

M

>

o

r

n

•Tj

>

31

m

W

CO

W

00

5

cn

CO

-a n >73

>

33

xn

Hco

m

CO

CO

r"

'-n

o

cn

tr-

H o -n

•—<

<

CO

•—4

o

z

Page 21

Page 22

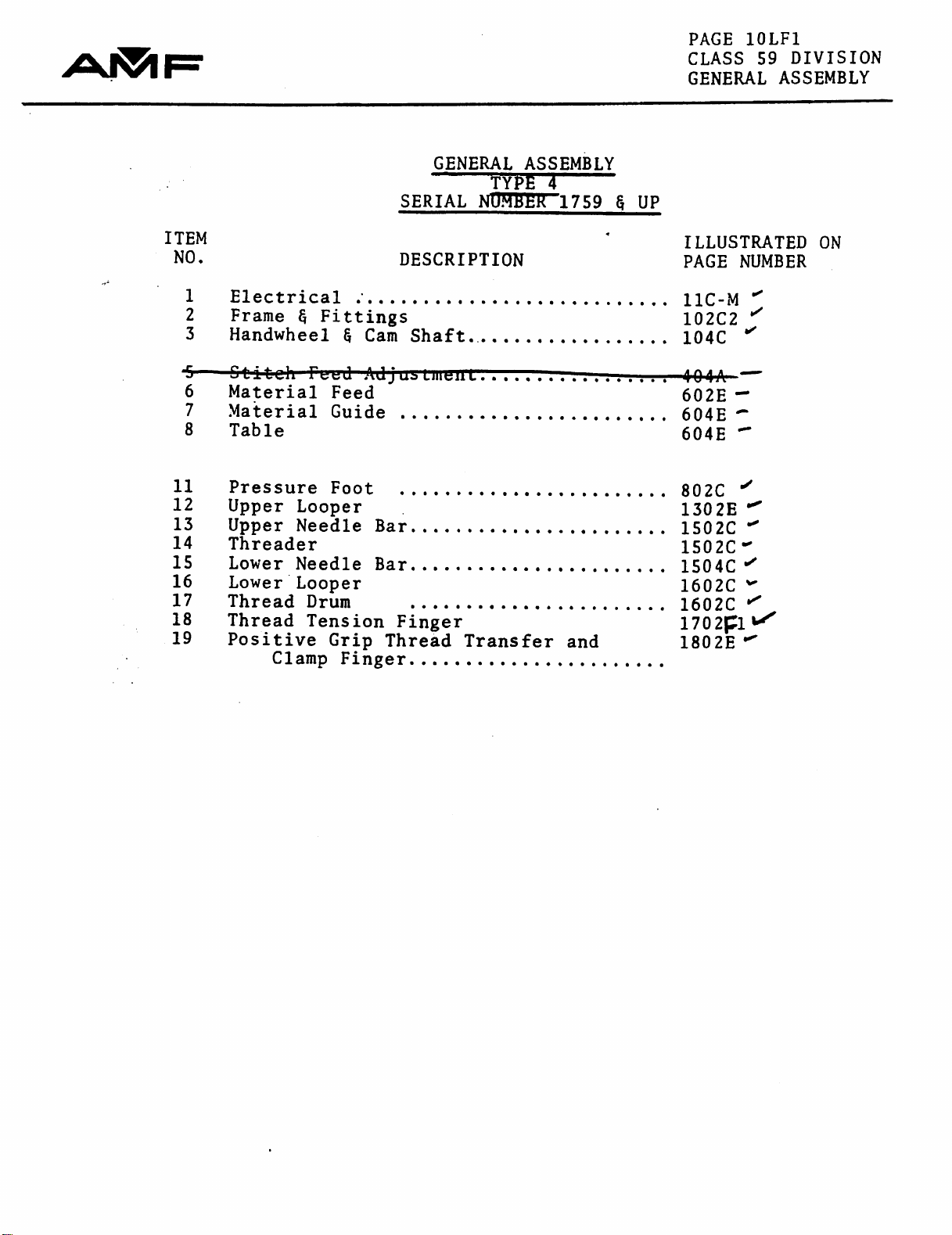

PAGE

CLASS

GENERAL

lOLFl

59

DIVISION

ASSEMBLY

ITEM

NO.

1

3

11

12

13

14

15

16

17

18

19

Electrical

2

Frame 6 Fittings

Handwheel

Stitch

Feed

Material

Material

Table

Pressure

Upper

Upper

Looper

Needle

Threader

Lower

Lower

Thread

Thread

Needle

Looper

Drum

Tension

Positive

Clamp

SERIAL

DESCRIPTION

§

Cam

Shaft.

AdjusLmeill

Feed

Guide

Foot

Bar

Bar

Finger

Grip

Thread

Finger

GENERAL

NUMBER

Transfer

TYPE

ASSEMBLY

4

1759 § UP

and

ILLUSTRATED

PAGE

NUMBER

IIC-M

102C2

104C

4

04A

602E

—

—

604E

604E

802C

1302E

1502C

1502^

1504C

1602C

^

1602C

1702pl^

1802E

ON

Page 23

EE3ni3

TO

S9-S5-20IBI

OUTER

ITEM

PAGE

4

20EC

DISC

CAM

mnn

lOtM'

59-83

220^4408

380V.

McKS'iwiKN

BZn-2RQ2

■uTTM

nrrrcN

NStOe

C>H

STMTOI

MM-NMOST

SCHEMATIC

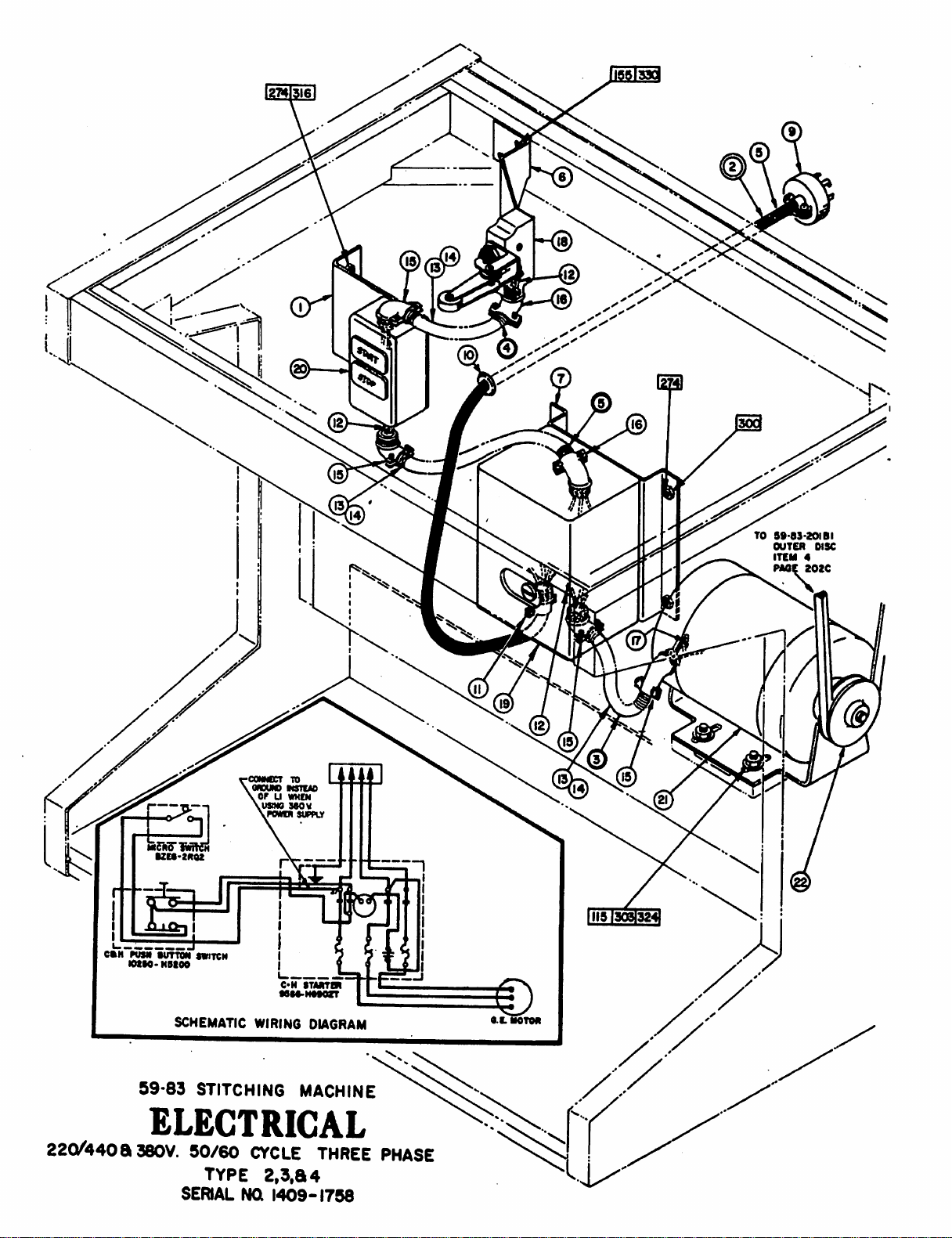

STITCHING

WIRING

DIAGRAM

MACHINE

ELECTRICAL

50/60

SERIAL

type

CYCLE

2,3,84

NO

1409-1758

THREE

PHASE

©

4.1.

(3.

DtltEES]

MOTOR

•X

Page 24

ITEM

NO.

220/440 & 380

TYPE

SERIAL

ELECTRICAL

VOLTS - 50/60

2.

3. & 4

NO.

1409-1758

DESCRIPTION

CYCLE 3 PH,

PAGE

CLASS

PARTS

PART

11

59

LIST

NUMBER

LAI-11

DIVISION

10

11

12

13

14

15

16

17

18

19

20

21

22

1

2

3

4

5

6

7

8

9

Mounting

Power

Motor

Thread

Starter

Switch

Starter

G.

Hubble

H-C

T & B

Solid

Flex.

E.

Snap

Black

Steel

Cable

Cable

Drum

Cable

Bracket

Mounting

Rubber

Cap

Squeeze

Anti-Short

T & B

T & B

Ideal

Micro

C-H

C-H

G.E.

For

Squeeze

Squeeze

Wire

Switch

Magnetic

Push

Motor

For

230/460

220/440

Browning

Bracket

(See

(See

Switch

(See

Cord

Bushing

Conn.

Wire

Conduit

Bushing

Conn.

Conn

Nut

Starter

Button

1/4

V-60Cyc.-3

V-60Cyc.-3

Pulley

Note

Note

Bracket

Switch

h.p.

#1)

#2)

Cable

Note

.

.... .

(See

#3)

PH.

PH.

Note

. .

Use

Use

.

59-83-3029B2

59-83-303lA-11

#3)

.

59-83-3031C1-11

59-83-3040A-11

59-83-3040B

59-83-3040F

59-83-3041A

Type

#9967

#SB-875-10

#3302

#14

3/8"

#2

#265

#266

#74B

SO

Type

#14-4

Cond.

"T"

#BZE6-2RQ2

#9586-H6902T

#10250-H5200

#5K36EG513

#5K36GG566

#AS-34

Type

IF

Notes

#1 - Item

#2 - Item

#3 - Items # 4 & 5

#2

consists

#3

consists

of

Items

of

Items

consists

of

8,

9,

12,

13.

Items

10, & 11.

14,

16, & 17.

12,

13, 14, 15, & 16

Page 25

^

f

'P

TO

99-8S-20IBI

OUTER

ITEM

DISC

4

TO

PLUG

llOV

BO'^

1^

-Cff

CONN.

SCHEMATIC

59-83

1

[

BOX

WIRING

STITCHING

SWITCH

DIAGRAM

MACHINE

ELECTRICAL

110

V.

60

CYCLE

220V.

50

CYCLE

TYPF

SINGLE

SINGLE

9 A ^

PHASE

PHASE

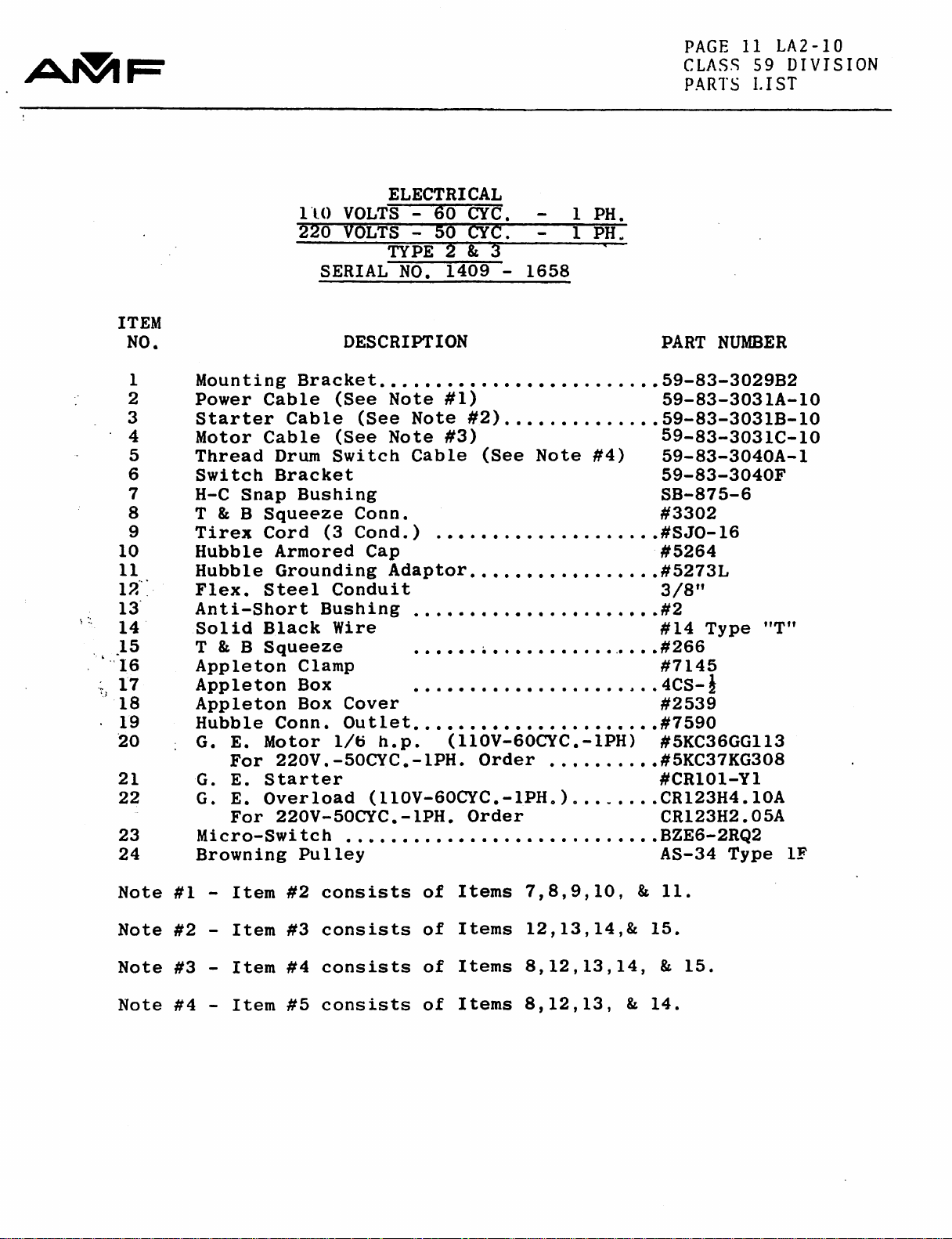

Page 26

ITEM

NO.

110

VOLTS

220

VOLTS - 50

SERIAL

DESCRIPTION

ELECTRICAL

-

60

TYPE

NO.

2 & 3

1409

CYC.

CYC.

-

-

=

1658

1

1

PH.

PH.

^

PAGE

CLASS

PARTS

PART

11

59

LIST

NUMBER

LA2-10

DIVISION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

,15

16

17

18

19

20

21

22

23

24

Mounting

Power

Starter

Motor

Thread

Switch

H-C

Snap

Bracket

Cable

Cable

Cable

Drum

Bracket

Bushing

T & B Squeeze

Tirex

Hubble

Hubble

Flex.

Anti-Short

Solid

T & B

Appleton

Appleton

Appleton

Hubble

0.

G.

G.

Micro-Switch

Browning

Cord

(3

Armored

Grounding

Steel

Bushing

Black

Squeeze

Clamp

Box

Box

Conn.

E.

Motor

For

220V.-50CYC.-1PH.

E.

Starter

E.

Overload

For

220V-50CYC.-1PH.

Pulley

(See

(See

Switch

(See

Note

Note

Note

Cable

#1)

#2)

#3)

Conn.

Cond.)

Cap

Adaptor

Conduit

Wire

Cover

Outlet

1/6

h.p.

(110V-60CYC.-1PH)

(110V-60CYC.-1PH,)

Order

(See

Order

Note

#4)

59-83-3029B2

59-83-303lA-IO

59-83-3031B-10

59-83-3031C-10

59-83-3040A-1

59-83-3040F

SB-875-6

#3302

#SJ0-16

#5264

#5273L

3/8"

#2

#14

Type

"T"

.#266

#7145

4CS-J

#2539

#7590

#5KC36GG113

#5KC37KG308

#CR101-Y1

CR123H4.10A

CR123H2.05A

BZE6-2RQ2

AS-34

Type

IF

Note

Note

Note

Note

#1 - Item

#2 - Item

#3 - Item

#4 - Item

#2

consists

#3

consists

#4

consists

#5

consists

of

of

of

of

Items

Items

Items

Items

7,8,9,10,

12,13,14,&

8,12,13,14,

8,12,13,

&

&

11.

15.

&

14.

15.

Page 27

mm

IB3E2

4-!

WTH

tMS

-4

CO.

NCUOED

vi^i

M

niaKaUTTON

^OSaO-HflMO

SHTTtM

59-83

STITCHING

Ll

MACHINE

Ei

ELECTRICAL

IIOV.

60CYCLE.SMGIE

...type

2,3.84

PHASE

iI3fc33^

Page 28

ITEM

NO.

110

VOLTS

SERIAL

ELECTRICAL

-

60

TYPE

NO.

DESCRIPTION

CYCLE

2

-

SINGLE

165r-l758

PHASE

PAGE

CLASS

PARTS

PART

11

59

LIST

NUMBER

LB-10

DIVISION

i

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

fl:7

18

19

'2

0

21

22

23

24

25

26

27

28

29

30

Mounting

Power

Motor

Thread

Starter

Switch

Starter

C-H

Magnetic

C-H

Thermal

:

-

Micro

H-C

C-H

G.

E.

C-H

Snap

Magnetic

Pushbutton

Browning

Scotchlok

Electrical

Appleton

Hubble

Cond.

Cond.

T & B

T

8e B 3/8-45

T & B

Black

Black

Tirex

Hubble

Flex.

Anti-Short

Bracket

Cable

Cable

Drum

(See

(See

Switch

Cable

Bracket

Mounting

Overloads

Switch

Bushing

Motor

Pulley

Wire

Box

Cover

Outlet

Chase

Locknuts

Squeeze

3/8-90

Insul.

Insul.

Cord

Steel

(3

Grounding

Cond.

Bushing

(See

Coil

Starter

Switch

Nut

Nipple

Conn.

Conn

Conn.

Wire

Wire

Cond.)

Note

Note

#1)

#2)

Cable

Note

Bracket

(Type

(Type

Adaptor

(See

#4)

"T")

"F")

Note

. .

#3)

. .

59-83-3029B2

59-83-3031A-

59-83-3031C2

59-83-3040A59-83-3040B

59-83-3040F

59-83-3041A1

#1945-1

#H1028

#BZE6-2RQ2

#SB-875-6

#AIOAGO-A

#5KC36GG113EX

#10250-H5200

#AS34

Type

(Type

"Y"

#4CSi

#2539

#5261

1/2"

1/2"

#3302

#265

#266

14

Ga.

14

Ga.

#SJ0-16

#5273L

3/8

#2

10

-10

11

IF)

Notes

#1 - Item

#2 - Item

#3 - Item

#4 - Item

#2

#3

ffA

#5

consist

consist

consist

consist

of

of

of

of

items

items

items

items

II,

24,25,

23, 24,

23, 24, 26,

22, 27, & 28

29, & 30

26, 29, & 30

29, & 30

Page 29

"A

m

m

now

•OCJCU

!♦

59-83

STITCHING

Hij-jj

MACHINE

■5E!f-ets^

C-N

■rm

SlMTERtei004

IMB-t

COL

NOIOD

ELECTRICAL

fiftrwj

*i-v/ei-v

rwrt

c

culiai

c

ouacc

Page 30

Af^

ITEM

NO.

220

VOLTS

-

50/60

TYPE

SERIAL

ELECTRICAL

CYCLE

2,

3.

NO.

1659-1758

DESCRIPTION

-

&

SINGLE

4

PHASE

PAGH

CLASS

PARTS

PART

11

59

LIST

NUMBER

I.B-14

niVISION

10

11

13

14

15

16

17

18

19

20

21

22

23

24

25

12

1

2

3

4

5

6

7

8

9

Mounting

Power

Motor

Thread

Cable

Cable

Drum

Starter

Switch

Bracket

Starter

C-H

Magnetic

C-H

Thermal

Micro

H-C

C-H

G.E.

C-H

Switch

Snap

Magnetic

Motor

Pushbutton

Browning

Scotchlok

T & B

T & B

T & B

Black

Black

Tirex

Hubble

Flex.

Squeeze

3/8-45

3/8-90

Insul.

Insul.

Cord

Grounding

Steel

Anti-Short

Bracket

(See

(See

Switch

Cable

(See

Mounting

Coil

Overloads

Bushing

Starter

Pulley

Wire

Conn

Conn,

Conn

Wire

Wire

(3

Cond.)

Cond.

Bushing

Note

Note

Bracket

Switch

Nut

(Type

(Type

Adaptor

#1)

P2)

Cable

Note

(See

#4)

"T")

"F")

Note

. .

.

#3)

.

59-83-3029B2

59-83-3031A59-83-3031C2

59-83-3040A59-83-3040B

59-83-3040F

59-83-3041A1

#1945-2

#H1025

#BZE6-2RQ2

#SB-875-6

#A10AG0-B

(See

Note

#AS-34

Type

#3302

#265

#266

14

14

#SJ0-16

#5273L

3/8

#2

"Y"

Ga.

Ga.

#5)

(Type

10

-10

11

IF)

Notes

#I

-

Item

#2 - Item

#3

-

Item

#4

-

Item

'

For

1/4

ff2

consist

#3

consist

#4

consist

consist

50

cycle

operation

H.P., 1425

of

items

of

Items

of

items

of

items

R.P.M,

II,

*19,

18,

18,

use

Single

17

20

19

19

G.E.

Phase

22,

24

21,

21,

Motor

&

23

&

25

24, & 25

24, & 25

#5KC38MG339/:

Page 31

REF-99-63-1004AI2-II

NEEDLE

BAR

ITEM 4 PAGE

HEAD

I02C2

(U)

SiJfeiHlOTOR

ITEM

93

MT3.

RAGE

I02C2

BKT

A

SM U U

\

H0il

STOP-STMrr

59-03

ELECTRICAL

10/120

V.

50/60

TYPE

SERIAL

STITCHING

MACHINE

CYC..SINGLE

2,3,84

NO.

1759 8 UP

PHASE

WtRING

OABRAJyi

■UTTONt

N

AKMai-A

irWTCR

Page 32

110/120

ELECTRICAL

v.

.

50/60

TYPE

SERIAL

NUMBEr'i759 & UP

CYCLE.

2

3

&

SINGLE

4

PHASE

PAGE

CLASS

Electri

IILC-IO

59

cal

DIV.

ITEM

1

'

2

3

4

5

6

7

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

NO.

Power

Switch

Electrical

Cable

Bracket

Capacitor

Counter

Switch

Motor

Shaft

Cable

Cable

Browning

Browning

Browning

Browning

Appleton

Appleton

Hubbell

Conduit

Conduit

Conduit

Micro

C-H

C-H

C-H

AMCO

Moffatt

Moffatt

Moffatt

T & B

ASA

Scotchlok

G.

E.

Outlet

Chase

Nipple

Locknuts

Switch

Magnetic

Thermal

Magnetic

Series

Multi-Lamp

Right

Steel

Knockout

Woodruff

Ajiipliance

DESCRIPTION

Bracket

Box

Bracket

Pulley

Pulley

Pulley

"V"

Belt

Box

Cover

Nipple

Starter

Overloads

Coi1

TE

Clutch

Angle

Mtg.

Plug

Key

Wire

Nuts

Bulb

Motor...

Shelf

Button

Bkt,

PART

59-83-3031A1-10

59-83-34648-006

59-83-34762-009

59-83-35654-021

59-83-42721-010

59-83-46314-010;

59-83-467n-013'

Note

#AK34-5/8

#AK84-5/8

#4L390

#4CS-l/2

#2539

#5261

1/2

NUMBER

#1

B

Bore

1/2 X 1-3/4

1/2

#BZEG-2RQ2

#A10AG1-

#H1030

#2

—

"3

—

#1945-1

Note

#A0615-PI^

#MLRA

#G0EM

#1451

#606

Type

#40A1!

ore

e

Use

Notes:

1.

2.

#AK39-3/4"

for

50

Use

#AK34-3/4"

for

60

AMCO

Series

IIOV.,

120V.,

HZ

HZ

50

60

Machines

Machines

TE

HZ

HZ

Bore

Bore

Clutch

Single

Single

Browning

Browning

Motor

Phase

Phase

Pulley

Pulley

1/2

1450

1750

H.P.

R.P.M

R.P.M

Page 33

f.

•.<>

mi

REF-99-e3-l004AI2-ll

NEEDLE

BAR

O-M-32

AMOO

ITEM

HEAD

I02C2

53

item 4 RVGE

REF-

(U)

MCmOR

nX6E

MTG

I02C2

.BKT

7i

A

C-H

STARTER

/jMCRO-SWITCH

/

BZE6-2RQ2

1

AOA6

\

LSAMP

aSE

hEJ"

WIRING

START-STOP

OtAGRAM

BirrmN

AMCO

CUnCH

SERES

MOTOR

TE

59-83

ELECTRICAL

220/380

STfTCHING

V,

50/60

TYPE

SERIAL

CYC.,

2,3,84

NO.

1759 8 UP

MACHINE

THREE

PHASE

Page 34

ITEM

NO.

220/380

ELECTRICAL

V

» 50/60

TYPE

SERIAL'^UfeBfe''l7S5"'S

UESCRIPTION

CYCLE.

2.3.

i'4

THREE

UP

PHASE

PAGE

11

CLASS

ELECTRICAL

PART

NUMBER

LC-11

59

DIVISION

1

2

3

4

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

'

Power

Cable

Spacer

Switch

Electrical

Counter

Switch

Motor

Bracket

Cable

Cable

Browning

Browning

Browning

Browning

Buss

Buss

Fuse

Fuse

Appleton

Appleton

Hubbell

Conduit

Conduit

Conduit

G.

E.

Transformer

Micro

C-H

C-H

C-H

AjMCO

Switch

Magnetic

Thermal

Magnetic

Series

Moffatt

Moffatt

Moffatt

ASA

Woodruff

Scotchlok

G.

E

Appliance

Bracket

Shaft

Bracket

Pulley

Pulley

Pulley

"V"

Belt

Holder

Box

Cover

Outlet

Chase

Nipple

Nipple

Locknuts

Starter

Overload

Coil

TE

Clutch

Multi-Lamp

Right

Steel

Angle

Mtg.

Key

Wire

Nuts

Bulb

Motor

Shelf

Button

Bkt

59-83

59-83

59-8359-83

59-8359-8359-83-

Note

3031A1-11

31423-028

34648-006

34762-009

42721-010

46314-010

46711-013

#1

#AK34-5/8

#AK84-5/8

#4L390

#HKP

#MDL-1.S

MCS-1/2

#2539

#5261

1/2

1/2 X 1-3/4

1/2

Note

#2

#BZE6-2RQ/

#A10AG1-A

Note

#1945-1

Note

#A0615-PP

#MLRA

#GOEM

#606

Tyoe

#40A15

#3

#4

"Y'

Bore

Bore

Nores:

Use

#AK39-3/4*'

50

HZ

Machines.

Use

#AK34-3/4'*

60

HZ

Machines

For

208/220

For

380

For

208/220 V.,

For

220 v.,

For

380 v.,

AMCO

?nR/77n

Series

V.

V

Bore

Bore

V.

use

use

$9T51Y3009.

50

HZ

50

HZ

TE

Clutch

fin H7

60

G.

HZ

use

use

T

Browning

Borwning

E.

Transformer

use

#H1024

#H1021.

#H1117.

Motor

1/2

17Cn

Pulley

Pulley

C-'i'

-

H.P.

D D M

fur

for

#9T51Y4.

Overload.

/>-

Page 35

2X22

REF-

S9-83-I004AI2-II

NEEDLE

rrEM 4 RIVGC

BAR

HEAD

102C2

REF-^-M-32

AMOO

MOTOR

ITEM

53

(U)

MTG

RODE

BKT

I02C2

Micro

Switch

ZE6

ft

129811561

Button

59-83

STITCHING

MACHINE

WIRING

DIAGRAM

ELECTRICAL

220/240

V,

50/50

TYPE

SERIAL

CYC.,SINGLE

2,3,84

NO.

1759 8 UP

PHASE

C-H

Stortw

i/~GlE.1an*fbRn«r

5

Amp

Fum

SarMS

dul^

Motor

TE

Page 36

ITEM

NO.

220/240

ELECTRICAL

v.. 50/60

TYPE

SERIAL

DESCRIPTION

NUMBER

CYCLE.

2.3.

1759

S

SINGLE

4

S

UP

PAGE

CLASS

ELECTRICAL

PHASE

llLC-14

59

PART

DIVISION

NUMBER

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

.

Power

Spacer

Switch

Electrical

Capacitor

Counter

Switch

Motor

Cable

Bracket

Cable

Cable

Browning

Browning

Browning

Browning

Buss

Buss

Fuse

Fuse

Appleton

Appleton

Hubbell

Conduit

Conduit

Conduit

G.

E.

Transformer

Micro

C-H

C-H

C-H

AMCO

Switch

Magnetic

Thermal

Magnetic

Series

Moffatt

Moffatt

Moffatt

T § B

ASA

Scotchlok

G.

Knockout

Woodruff

Er

Appliance

Bracket

Box

Shaft

Bkt.

Pulley

Pulley

Pulley

"V"

Belt

Holder

Box

Cover

Outlet

Chase

Nipple

Nipple

Locknuts

Starter

Overloads

Coil

TE

Clutch

Multi-Lamp

Right

Steel

Angle

Mtg.

Plug

Key

Wire

Nuts

Button

.Bulb

Motor

Shelf

Bkt

59-83

59-83

59-83

59-83

59-83

59-83

59-83

59-83

Note

3031A1-10

31423-028

34648-006

34762-009

35654-021

42721-010

46314-010

46711-013

#1

#AK34-5/8"

#AK84-5/8"

#4L390

#HKP

#MDL-K5

#4CS

#2539

#5261

1/2

1/2

1/2 X 1-3/4

1/2

#9T51Y4

BZEG-2RQ2

#A10AG1-A

Note

#1945-1

Note

#A0615-PR

#MLRA

#GOEM

#1451

#606

Type

#40A15

#2

#3

-

"Y"

1/2"

Bore

Bore

Notes

:

2-

use

#AK39,

50

HZ

Machines.

Use

#AK34,

60

HZ

Machines.

For

220 V.,

For

240 v.,

AMCO

Series

220 v.,

240 v.,

50

60

3/4"

3/4"

50

60

TE

HZ,

HZ,

Bore

Bore

HZ

use

HZ

use

Clutch

Single

Single

Browning

Browning

C-H

Overload

C-H

Overload

Motor

1/2

Phase,

Phase,

Pulley

Pulley

#H102S

#H106e

H.P.

1450

1750

R.P.M.

R.P.M.

fcj

fo:-:

Page 37

I

I

Page 38

TOOLS

&

ACCESSORIES

SERIAL

NUMBER

-

TYPE

1209

2,3, & 4

&

UP

ITEM

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Spindle

Lint

Spindle

Threader

Perk

Razor

Needle

Needle

Needle

S.

Gulf

Hold

Allen

Allen

Allen

Allen

Crescent

Needle

ReMnovei*

Brush

Brush

Norton

Oil

E-Zee

Key

Key

Key

Key

Singer

Williams

Needle

Round

Needle

Needle

Oiler

DESCRIPTION

Lint.

Remover

Handle

Setting

Ne^'dlo

Tlu'eader

Bar

Cleaner

Stop

Pin

Oil

Brush

Can

Screw

Set

Thin

Nose

Nose

Pliers

Wrench

Superwrench

Stop

Stop

Pin

Spring

Gauge

Driver

Pliers

Retainer

TOOLS

PART

NUMBER

59-78-1044A

59-78-1044B

59-83-103lEl

59-83-1095F2

59-83-1503A

59-83-1503C

59-83-1503D

59-83-1503F1

59-83-1501F

#154

4

oz.

can

#TR4

#605

5/64

7/64

9/64

#J26

#1033

Across

Across

Across

#10875

#1120

59-83-1025D1

59-83-1032B1-36

59-83-1501B1

84-4-1324D

Flats

Flats

Flats

§

>

SS

o

CO

M

»

t-t

c:

w

w

to

CD

a

»d

to

CO

9P

Q

O

r

CO

>

o

n

t*5

CO

CO

O

fd

>-♦

CO

ACCESSORIES

A.

B.

C.

Needle

Steel

Skein

NOT

ILLUSTRATED

Stop

Balls

White

Thread

59-83-1501C4

11/64

Size

Dia.

A,

48"

Page 39

REF

|2T5|3331^

14 ■ l9,Rtf

2e6;322|29ek

I

AUXILIARY

REF

95-100

213

VIEW

NAME

P.A^t

KEF

59-83-30I5AI0

PATENT

PUATE

REF

S9-83-3042AI

NAME

PLATE

TO

59-83-2916El

CONN

ROD

ITEM

45

PACE

ITEM

30

PACE

59-83

FRAME

5020

7028

STITCHING

&

TYPE

2,3.84

MACHINE

FITTINGS

(3|

TO

59-83-I0I5A

ITEM

TO BE

RTVrr

pnui

USED

16

CONN

a

2020

ROD

3231332

PAGE

ON

LEFT

r*

Tircr

Page 40

PAGE

CLASS

PARTS

102LC1

S9

LIST

DIVISION

8

ITEM

NO.

1

2

3

4

6

7

8

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

27a

28

29

30

31

32

33

34

35

36

37

38

39

Frame

Needle

Light

Wire

Housing

Needle

Tie

Frame

Base

Spacer

Support

Frame

Spacer

Weldment

Support

Support

Support

Support

Inner

Inner

Frame

Frame

Corner

Foot

Motor

Tread

Tread

Tool

Tool

Pedal

Pedal

Front

Table

Table

Plunger

Lower

Middle

Frame

Frame

Bar

Bar

Pedal

Bracket

Plate

Plate

Drawer

Drawer

Arm

Arm

Panel

Hinge

Position

Control

Pedal

Pedal

Front

Pivot

Shaft

Hook

Oilite

Cam-Loc

FRAME

SERIAL

DESCRIPTION

Bar

Head

(Note

Bar

Head

Bracket

Bracket

Bracket

Bracket

Bar

Bar

(L)

(R)

Gusset

Moulding

Covering 59-83-3028D

Receiver

Extension

Extension

Holder

Position

Bracket

Bracket

Bushing

&

TYPE

2.3,&

NUMBER

(F)

(L)

#1)

(U)

(R)

(R-F)

(L-F)

(R-R)

(L-R)

(F)

(R)

Block

Block. . ,

Block

'

FITTINGS

1409-175.S

(Note

(Note

..

.

,

,

4

#1)

#1)

PART

NUMBER

59-83-101A2

59-83-102A3

59-83-104A-M

59-83-104B

59-83-1003A6

59-83-1004A10-11

59-83-1006A7

59-83-3011B2

59-83-3025A

59-83-3026C

59-83-3026D

59-83-3Q26E

59-83-3026F

59-83-3027A

59-83-3027B

59-83-3027C

59-83-3027D

59-83-3027E

59-83-3028A

59-83-3028B

59-83-30280

59-83-3028E

59-83-3028F

59-83-3029A-10

59-83-3029A-11

59-83-3029C

59-83-3030A-M

59-83-3032A

59-83-33171-032

59-83-33175-020

59-83-33175-021

59-83-34231-01'^

84-4-1407A

84-4-1407C

84-4-1453D

^10-250-lA-6'

#51L1-1-1AB

Note

items

59-83-

2,6, & 7

lOSA?

Needle

are

sold

Bar

assembled

Head

as

Assemble

Page 41

REF

Atfftjflffr

YEW

REF-5»-e3-X*5AII

(WENT

plate

•tD

BE

USED

M

PLACE

^...TggieaB*

ssB-SBflLtajBiaje

OF

n:

/SJ7

59-83

FRAME

STITCHING

TYPE

SERIAL

MACHINE

&

FITTINGS

2.3.a4

NQ

1759 a UP

TO

ra

or

BE

USED

POM.

211

OF

ON

TYPE

LEFT

I06I323I

4

Page 42

PAGE

CLASS

PARTS

102LC2

59

LIST

DIVISION

i

ITEM

1

3

4

5

6

7

8

9

10

11

13

14

15

17

18

20

22

24

26

27

28

30

32

34

36

37

38

40

41

42

44

46

48

50

51

52

53

54

55

56

5

7

NO.

2

Frame

Spacer

Needle

Housing

Needle

Tie

Frame

Frame

Pedal

Pedal

Pedal

Spacer

Arm

Arm

Spacer

Frame

Frame

Adj.

Bracket

Bracket

Position

Plunger'

Lower

Position

Middle

Platform

Pedal

Control

Table

Platform

Strut

Clip

Hook

Pedal

Main

Table

Pedal

Position

Side

Back

Front

Drawer

Tool

Table

Table

Pedal

Pedal

Angle

AMCO

Camloc

Extension

Frame

Platform

Panel

Panel

Ponlo

Drawer

Hinge

Support

Pivot

Shaft

Clip

Motor

Oilite

Roll

Grommet,

Pin

(F)

Bar

Head

(Note

Bar

Head

Extension

Extension

(Note

Holder

Position

Extension

Bracket

Bracket

Base

Slide

Bkt.

Mtg.

Latch

Bushing

(Note

Atlantic

FRAME

SERIAL

DESCRIPTION

(L)

#1)

(U)

#2)

-

Rear

-

Front

Block

Block

Block

Block

Support

Bkt.

#2)

India

S

FITTINGS

2.3.8

NUMBER

(Note

(Note

Rubber

4

1759 8 UP

#1)

#1)

Co.

PART

59-83-101A2

59-83-102A3

59-83-1003A6^

NUMBER

59-83-10U4Alil-ir

59-83-1006A7.

59-83-3011B2

59-83-3028A

59-83-3029A-10

59-83-3029A-11

59-83-31423-032

59-83-32413-052

59-83-32735-020

59-83-32783-002

59-83-33171-032

59-83-33175-020

59-83-33175-021

59-83-34125-052

59-83-34145-0

59-83-34231-017

59-83-34231-019

59-83-34264-016

59-83-34584-007^

-

20

59-83-34767-009^

59-83-35322-009

59-83-35351-060'

59-83-35441-043

59-83-35464-018

59-83-35714-009

59-83-35718-005

59-83-35778-015

59-83-36785-004'

59-83-37151-034'

-

-

59-83-41214-004^^

59-83-41441-020^

84-4—l-4^-7Arj

84-4—1"40

84-6-34272-02:

#10-M-32

#51L1-1-1AB^

#10-250-1A-64

7/32

#2902

7C

Dia. X '

Note#l

'•Jote#2

Items

2,3, § 4

59-83-103A2

For

Serial

59-83-31851-016.

are

Needle

#1759

sold

Bar

1858

assembled

Head

order

as

Assembly

Part.

No

Page 43

0

59-83-IO04AI0

NEEDLE

ITEM 7 PAGE

BAR

II

HEAD

I02C

UPPER

B3-I703C

GEAR

>0^'^

^

/'2A

—

M

IE

26

ir02F

Page 44

HANDWHEEL

SERIAL

&

CAM

SHAFT - TYPE

NUMBER

1209 fc

2.3, & 4

Ui>

ITEM

NO.

1

3

4

I

5

6

7

8

9

10

II

12

13

14

15

16

17

18

19

20

21

22

23

DESCRIPTION

Stitch

(Not

Shaft

Cam.,

used

Spacer

(Replaces

on

Types

Machines)

Angle

(Used

Cam

Housing

Drive

Decal

Needle

Handwheel

Upper

Thread

Lifter

Cam

Drive

Small

Gear

Gear

Gear

Large

Cam

Brush

Cam

Plate

on

Machine

Shim

Gear

Bar

Looper

Clamp

Hook

Shaft

Gear

Inter,

Stud

Bolt

Bushing

Inter.

Hub

Oper.

Shaft

PART

59-83

on

Type

4)

..

59-83

Item 4 Cam

2 & 4

Cam.

Type

3

.

59-83

only)

c . - . .

59-83

59-83

59-83

.

..59-83

Cam

59-83

59-83

Cam

Cam

Cam

59-83

59-83

59-83

Bearing....59-83

59-83

Gear....

59-83

59-83

59-83

59-83'

Gear...

Cam.

^

,

59-8359-83-

59-83-

59-83-

NUMBER

-503E4

r507D

-705B2

706Bli

•1003A6'^'

•1008B

1016A

1029A3

1030A4

1037A8

1066C

107IC

1072E

1072F

•«)HJt29

.

CV15

Oi^36

CK^.

^

Cka.

1073A*Cki5.

1073B5

1073C

1073D1

1073E ' CV*^.

1076B2-

1076D2

1077A2^

Ch^.

ITEM

NO.

26

27

30

31

-3«-

33

34

35

40

41

42

43

44

DESCRIPTION

Stud

Assembly

(Includes

1300B1

Ring)

Drive

StWeh

Set

Set

Hi

Oilito

Oilite

Oilite

Oilite

Boston

Tbv«>-t-

Handwheel

Belt

Front

Rear

Upper

Stud

Gear

Screw

Screw

Pro

Key......c.eco

Buohing

Bushing

Bushing

Bushing

Gear

Guard

Mtg,

Mtg.

Mtg.

PART

NUMBER

59-83-1300CT

1300A

VC-aoanJ

Collar

Collar

&

1301A

Flange,

.

59-83-1703D

10-45-lA-5'^

10

10"lA"

10—100—1100—3

10

350

. . . ^ .

10-250-lA-80

10-250-lA-83

10-250-lA-126^*/^*/f

Bearing.(^'*^#603-1/4

^

x"

#c

Covei-^•

Bkt.

..

Bkt.

Block.

59-83-103101:5

59-83-1094A-

59-83-1094B

59-83-dr094C'

59-83-1094I>

"ll^^r

lA

^

/

•

►d

M

M

to

ir-

CO

o

>

s

CO

C3

•XJ o "ra

>

c-

>

PO > (75

H

CO

m

CO CO

en

o

t—I

VD

^

CO

r-

H o n

•—t

<

•-H

CO

t-H

o

00

Page 45

TO S9-83-3027B

ITEM

FRAME

17

PAGE

i02C

TO

59-83-1029A^

PULLEY

ITEM

9

TO

59-83-3029A

PEDAL

ITEM

27

ARM

FOOT

EXTENSION

PAGE

i02C

24)2

REO

59-83

STITCHING

CLUTCH

TYPE

SERIAL

2.3.84

NO.

TO

MACHINE

1209-1758

MOTOR

ITEM

ITEM

19

20

PAGE

PAGE

IIA-10

IIA-II a IIA

I2

Page 46

CLUTCH

SERIAL

NUMBER

-

TYPE

2.3.

120^-1756

&

4

ITEM

2

3

4

5

6

7

8

9

10

12

13

14

15

16

17

20

21

23

24

25

NO.

Bracket

Inner

Outer

Clutch

Brake

Drive

Clutch

Disc

Disc

Brake

Shoe

Shaft

Yoke

Shifting.

Yoke

Shaft

Lever

Lever

Stud

Spring

Roller

Conn.

Disc

Set

Set

Oilite

Oilite

Oilite

Stud

Rod

Spring

Screw

Screw

Bushing

Bushing

Bushing...

DESCRIPTION

Lever

Collar

Collar

..c

.

_

PART

59-83-200A2

59-83-201A

59-83-20IBl

59-83-202A1

59-83-202B1

. „ c . .

. . .

59-83-202C

59-83-202D3

59-83-203A2

59-83-203B1

.

59-83-203D2

59-83-203E

59-83-203F1

59-83-204B1

_

..

.59-83-1015A

59-83-1070D4

. c .. .. . 10-45-lA-5

10-45-1A-7

10-250-lA-98

10-250-1A-100

10-250-lA-101

NUMBER

j-"

a

cn

00

w

»

tsJ

KO

M

Tl

o

r

to

•

•

CO

o

s

ftr

lU

I

28

29

Gates

Gates

Belt

Belt

.. ..

...

#2370

.#2550

Tj

n

>

r-

po > n

H

cn

cn

cn

t-

VI

•—I

VO

cn

H o a

<

cn

I—t

o

z

00

>

m

ho

o

ho

r*

Page 47

REF

99-63-lOOeAT

TIE

FRAME

ITEM

8

PACE

102

C

ANGLE

59-83

STITCHING

STITCH

MACHINE

FEED

ADJ.

REF

99-63-604

ITEM

16

PA6E602D

310

81

(33

SLIDE

BLOCK

I02A3

HEAD

SERIAL

TYPE

NO.

3

1209 a UP

ITEM

•83-1077 A 2

23

PAGE

REFI27

CAM

104C

SHAFT

281REF

REF.

99-e3-l704A4

ITEM

29

PAGE

BRACKET

1702

F

so

O-

LlllU

Page 48

ITEM

NO.

ANGLE

STITCH

SERIAL

FEED

NUMBER

DESCRIPTION

ADJUSTER

1209

&

UP

-

TYPE

3

PART

NUMBER

1

2

3

4

5

7

8

9

II

13

14

15

16

17

18

19

20

21

oo

23

24

25

26

27

28

Arm

Spacer

Arm

Head

Head

Conn.

Arm

Control

Lever

Cam

Rod

Lever

Lever

Adj.

Spring

Roller

Arm

(includes

Mounting

Setting

Large

Small

Stop

Locking

Locking

Bottom

Top

Pin

Rod

Bracket

Block

Stud

Lever

Spring

Head

Spring

Cam

Stud

Stud

Assembly

501B4

Bracket

Plate

Stud

Lever

Stud

Block

Slider

Screw

Plate

Setting

Setting

Lever

Stop & 502F7

Lever

Rod)

59-83-400A2

59-83-400B2

59-83-400C

59-83-400D

59-83-400EI

59-83-402E

59-83-500F2

59-83-501A3

59-83-50IE1

59-83-503A2

59-83-503D

59-83-503E4

59-83-505A

59-83-506E1

59-83-506F1

59-83-510A

59-83-510B

59-83-510C

59-83-51OD

59-83-510F

59-81-511

A'

si-ILsUB

59-83-511C

59-83-511D

>

25

CO

O

w

r

ia

>

CO

r

2:

H

c

O

a;

s

w

:a

w

m

M

CO

o

to

o

>

(O

o

C-i

C3

CO

a

H

w

30

31

33

34

Dowel

Pin

Spring

Clamp

Stud

Washer

Post

10-8-1100-28

10-20-1A1-63

10-25-1A1-53

10-40-1100-15

Page 49

RS;-99-03-100647

TIE

FRAME

ITEM

e

mcEiozc

REE-99-63-60401

ITEM

16

RAGE

SLBE

6020

BLOCK

STITCH

59-83

FEED

SERIAL

STITCHING

MACHINE

ADJUSTMENT

TYPE

4

NO.

1684 a UP

Page 50

ITEM

N0„

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Arm

Head

Arm

Bracket

Rod

Spring

Mounting

Setting

Large

Small

Small

Stop

Block

Locking

Locking

Top

Setting

Stitch

Plain

Stitch

Washer

Washer

Set

Screw

STITCH

SERIAL

Bracket

Plate

Stud

Lever

Stud

Screw

Plate

Adj.

Stud

Length

Collar

FEED

NUMBER

DESCRIPTION

Slider.

Lever

Conn.

Decal

ADJUSTMENT

1684

Rod

&

-

TYPE

UP

4

PART

59-83-40032

59-83-400E1

59-83-501E1

59-83-510A

59-83-510B

59-83-510C

59-83-510D

59-83-510E

59-83-510F

59-83-51lA

59-83-511B

59-83-511D

59-83-31286-009

NUMBER

CO

w

>

r

25

o3

M m

W

M

0)

00

ftp

c

><

►d

w

H-

H-l

o

x

►d

M

w

o

>

a

Cm

c

03

-3

aj

W

25

•-3

59-83-31611-045

59-83-37731-032

#10-40-1100-15

^^10-40-1100-117

io-45-lA-l

Boston

#SC25

or

Page 51

TO

S9-e3-30Z7B

FRAME

BAR

REF.

59-83

ITEM 8 PAGE

r006A7

TIE

102

FRAME

c

REE

MATERIAL

. PAGE

6020

FEED

029A

ARM

EXT

REF

59-83-1704A4

/ ITEM

29

PAGE

BRACKET

I702F

M

REF

59-83-301182

ITEM

10

PAGE

''

TIE

I02C

REE

FRAME

99-83-I02A3

NEEDLE

BAR

ITEM 2 PAGE

LOWER

HEAD

>020

59-83

SHORT

ATTACHMENT

STITCHING

&

SERIAL

MACHINE

LONG

TYPE

NO.

1209 a UP

REE

59-e3-l077A2

ITEM

2

23

STITCH

CAM

SHAFT

PAGE

I04C

<»(^REF

1 .r

TO

59-B3-2S0182-10

ARM

BEARING

ITEM

39

PAGE

BRKT.

I602C

i

"nI-'

•sto

i

I I I \

\\V-

\

Page 52

ITEM

NO.

I

2

3

4

5

6

7

9

10

11

12

13

14

15

16

17

19

20

21

22

23

24

25

26

27.

28

29

30

DESCRIPTION

Yoke

Clutch

Arm

Pin

Yoke

Hub

Adjust.

Arm

Cover

Lever

Cam

Conn.

Yoke

Rod

Stud

Lever

Rod

Spring

Spring

Control

Shift

Stud

Shift

Arm

Arm

Bracket

Lever

Stud

Shifting

Lever

Arm

Head

Pin

Shifting

Lever

Stitch

Finger

Spring

Lever

Latch

Roller

Arm

Spring

Cam

Spring

Stud

Bearing

Lever

Stud

Assembly

(Includes

&

502F7

Arm

Assembly

(Includes

&

10-67-1A--3

Arm

Shaft

Finger

Pin

501B4

Rod)

506B1

Stop

Arm

Spacer)

SHORT

&

LONG

SERIAL

PART

59-83-500A2

NUMBER

59-83-500B3

59-.83-500C2

59-83-500D2

59-83-500E1

59-83-500F2

59-83-501A3

59-83-501C3

59-83-501D1

59-83-501E1

59-83-501F1

59-83-502A3

59-83-502B

59-83-502C1

59-83-502D1

59-83-502E1

59-83-503A2

59-83-503B

59-83-503C1

59-83-503D

59-83-503E4

59-83-504C

59-83-505A

59-83-506C

59-83-506D

59-83-506E1

59-83-506F1

59-83-507B1

STITCH

NUMBER

,

ATTACHMENT

1209

ITEM

&

NO.

31

Slide

32

Shaft

33

Mounting

34

Setting

35

Large

Small

36

Smal1

37

38

Stop

39

Locking

40

Locking

41

Bottom

42

Top

43

Lever

44

Pedal

45

Conn.

46

Shaft

47

Spacer

48

Plain

49

Cam

50

Spring

51

Spring

52

Spring

54

Set

55

Cam

56

Washer

57

Washer

-

TYPE

2

UP

DESCRIPTION

Block

Spacer

Bracket..

Plate

Stud

Lever

Stud

Block

Slider

Screw

Plate

Setting

Setting

Lever

Spring

Lever

Rod

Bracket. ......

Stud

Roll

Stud

Post

Post

Post

Screw

Roller

Collar.

*

..

Lever

..

...

PART

NUMBER

. 59-83-507Ct=

59-83-507D

. 59-83-510A

59-83-510B

. 59-83-510C

59-83-510D

. 59-83-510E

59-83-510F

. 59-83-511A

. 59-83-51

IB

. 59-83-511C

. 59-83-51ID

59-83-1009D1

. 59-83-2510D2

59-83-2516E1

. 59-83-3010D1-10

59-83-3010F

. lO-l-lA-58

10-6-1A1-61

. 10-20-1A-56

10-20-1A-62

. 10-20-1A-63

. 10-45-1A-5

10-49-1A1-6

. 10-40-1100-17

10-40-1100-115

3

Tl

03

s

o

»

Ul

n

ftp

w

H-l

>

6

a;

a:

o

s

K

CO

H

w

►d

M

W

ta

to

O

h-'

to

o

>

to

H

R®

>

O

c

X

S

w

a:

H

n

•-

>

t—

>

TO > (Ti

H

c/^

m

LO

C/1

Ln

f-

tn

O

H-i

vo

tsj

cn

r-

H a —

CO

o