After Sales Service

We offer a technical advisory service on the telephone to installers and other customers with problems

in the field.

RING 0844 372 7766 (UK ONLY)

Remember to quote type of shower, as written on the front of the shower and on this leaflet.

The model and serial number are located on the bottom face of the shower.

Make a note of those numbers here, and be sure to quote them if you call for advice.

Model Number: 53--__________________ / Serial Number:____________________

Note: You may be charged for a service call if you do not have the serial number.

I

I

I

I

Full details of terms and conditions are available on request from:-

Redring Xpelair Group, Newcombe House,

Newcombe Way, Orton Southgate, Peterborough, PE2 6SE

Website: www.redring.co.uk

16

A3:567-2450-01 Rev B

We, Redring Xpelair Group Ltd., guarantee this product for domestic use only, for the period of 24

months from the date of purchase.

Within the guarantee period we will resolve, free of charge, any manufacturing defects in the product

resulting from faulty workmanship or material on the condition that:

I

I

I

A) The appliance has been correctly installed in accordance with our instructions and is being used on the supply

circuit or voltage printed on the rating plate.

B) The appliance has been used in accordance with these instructions and has not been tampered with or

otherwise subject to misuse, neglect or accident.

C) The appliance has not been taken apart, modified or repaired except by a person authorised by us.

D) Evidence of the date of purchase in the form of an invoice or receipt will be required in order to qualify for an

in-guarantee repair.

E) The guarantee period for the products used in commercial applications will be limited to 12 months.

F) For the service work to be undertaken free of charge, the work must be only undertaken by

Redring Xpelair Group Limited, or our approved agents.

G) Service under guarantee has no effect on the expiry date. The guarantee on any exchanged parts or product

ends when the original guarantee period ends.

EXCLUSIONS

This guarantee DOES NOT cover damage or defects arising from poor or incorrect installation, improper use or lack of maintenance,

including build-up of limescale. It is the responsibility of the installer to check that the installation parameters meet the requirements

of the product, and any relevant regulations.

If we are called out to a fault, which is subsequently identified as being an installation fault, we will make a charge. It is important

that the routine checks are completed before calling us out, as many issues can be simply diagnosed and resolved.

We make no guarantees as to response times for repairs. We will endeavour to achieve the most timely response possible but while

we indicate an average response time, this should not be taken as a guarantee.

The guarantee applies to a repair or replacement (at our discretion) of the product subject to the conditions above, and DOES NOT

cover compensation for the loss of the product or consequential loss of any kind

The guarantee does not apply to the repair or replacement of pressure relief devices, sprayheads, hoses, accessories, isolating

switches, electrical cable, fuses and/or circuit breakers.

This guarantee does not affect your statutory rights.

I

I

I

I

I

I

I

I

I

I

I

GUARANTEE

Terms and Conditions for UK (outside UK contact your local distributor)

IMPORTANT

This booklet should be given to the customer after installation and demonstration

Thermostatic Instantaneous Electronic Shower

Handbook

Xpressions

User

Information

How To Start Your Shower

How To Operate Your Shower

How your shower works

Handset Operation

Routine Maintenance

Periodical Maintenance

Trouble Shooting (User)

Guarantee

Contents

Installer

Information

Installation Instructions

Plumbing Connections

Electrical Connections

Commissioning

Trouble Shooting (Installer)

Spares

Page

Page

2

3

5

7

14

15

8

9

10

12

12

13

13/14

16

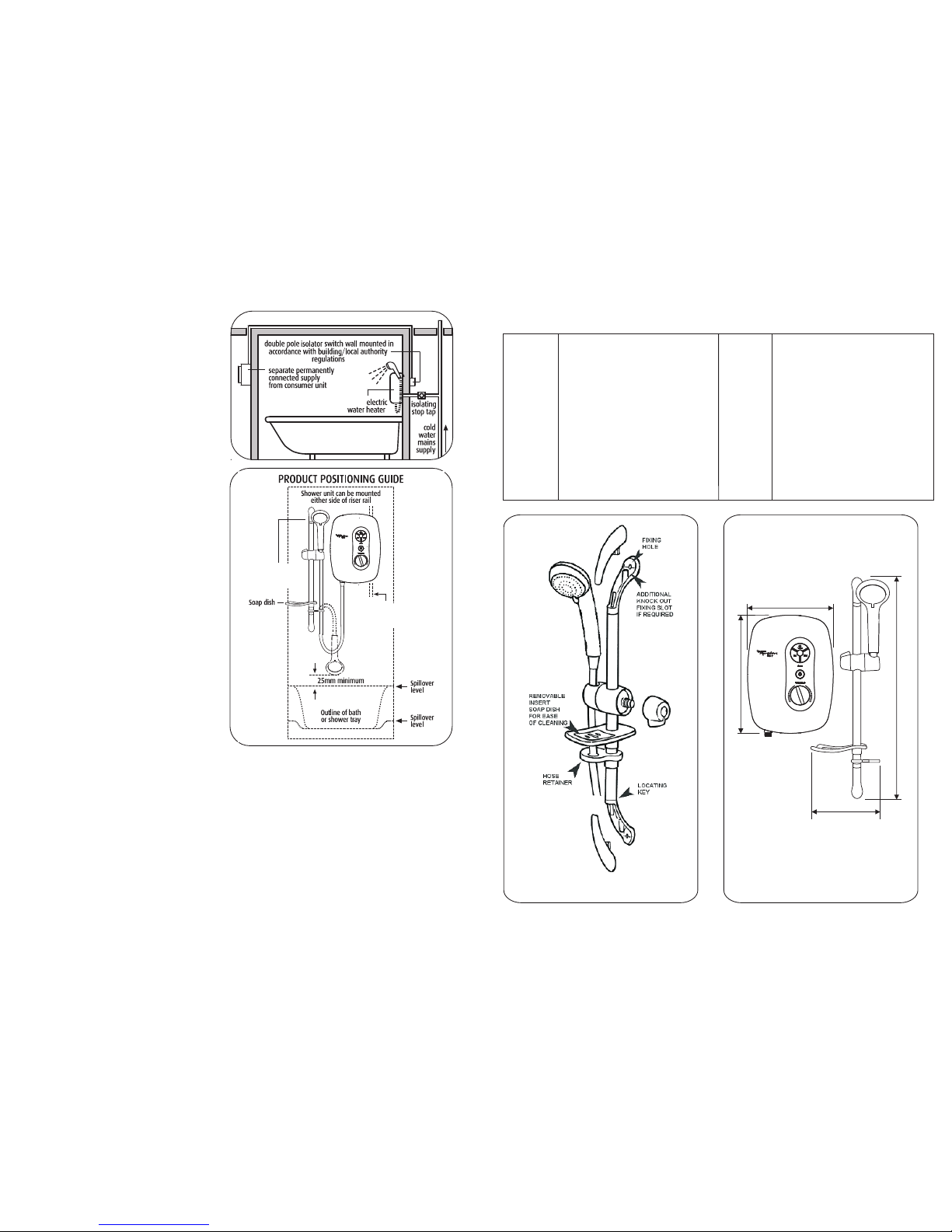

A TYPICAL INSTANTANEOUS ELECTRIC SHOWER INSTALLATION

Mains cold water supply

(either top, bottom

or rear entry)

Height of spray head

and shower to suit

user’s requirements

2

Installation Instructions

ALL WIRING AND INSTALLATION MUST BE

SUPERVISED BY A SUITABLY QUALIFIED

PERSON.

We recommend that the installation be done in

the following sequence: -

a) Fix the shower to the wall

b) Plumbing

c) Electrical connections

d) Commissioning

Warning! Do Not Install The Shower In A

Room Where It May Be Subject To Freezing

a) Fix The Shower To The Wall

When deciding where to place the unit a few

things need to be taken into consideration: -

1) The unit MUST NOT be mounted directly

in the path of the spray from the handset

2) The handset could be used over a sink for

hair washing.

3) The handset does not come into contact

with the used water in the cubicle, bath or

basin.

A hose retainer is supplied with the

Accessories (See Diagram 22).

4) The unit can be mounted at a lower level for

less able users combined with optional

extended hose and riser rail.

The installation must comply with BS 8300:

2001.(Design of buildings and their

approaches to meet the needs of disabled

people. Code of practice).Remembering to

Adhere to point 1.

5) Choose a flat piece of wall to avoid the

possibility of distorting the backplate and

making the front cover a poor fit.

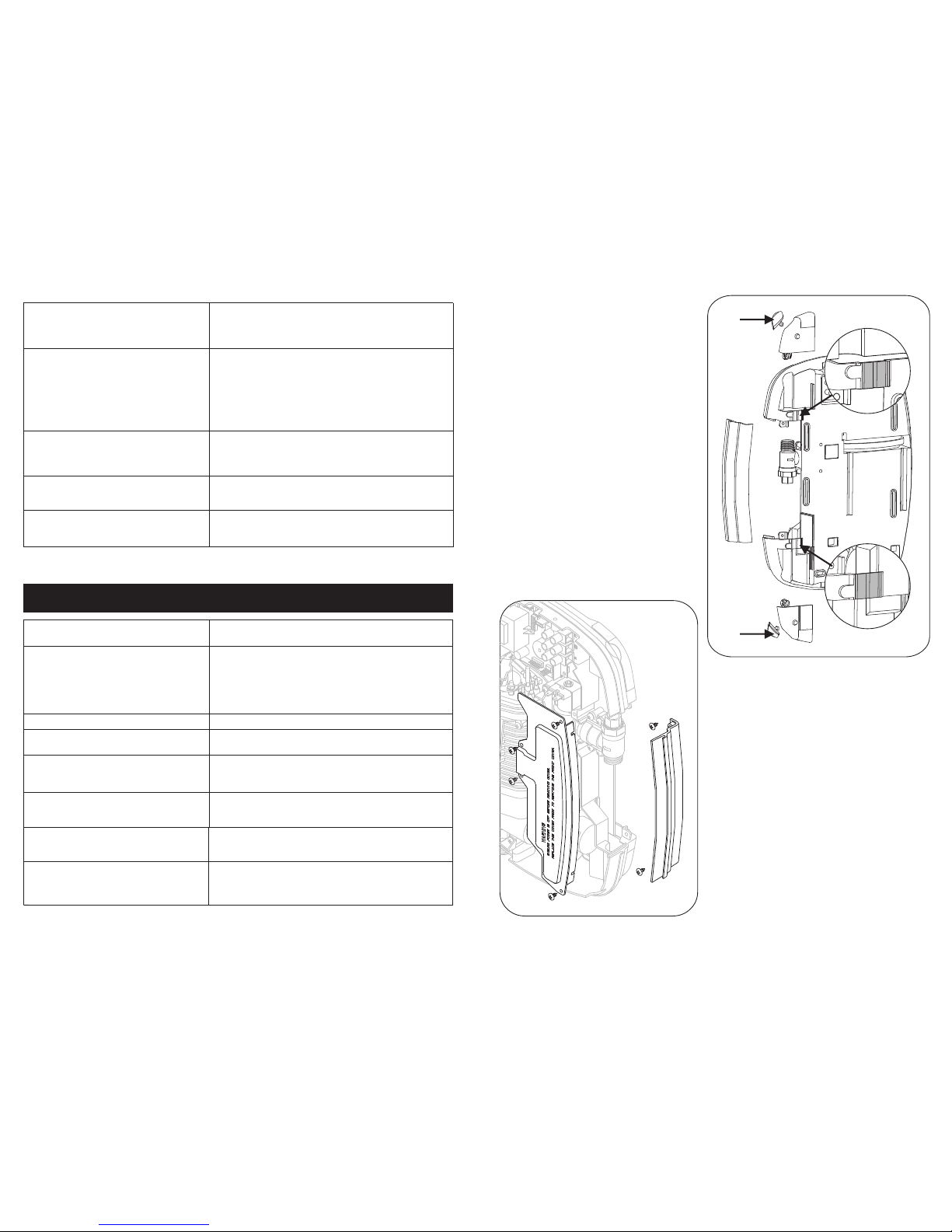

Remove the four cover screws and lift the cover

off.

Remove the four inlet cover screws and remove

inlet cover - also the two side access trimplate

section screws and remove complete with seal.

Hold the shower vertically against the wall and

mark the top hole first.

Having determined the direction of the inlet

water mains supply and cable approach for the

installation (Top, Bottom, or Rear or any

combination) - it is necessary to remove the

appropriate section inserts. See Plumbing

Connections and Electrical Installation

sections (Pages 3 and 5) for detailed guidance.

Drill the hole to take the rawl plug provided (taking

care to keep dust away from the shower).

Put the top screw in first leaving it proud by 5mm

approximately. The shower can now be hung on this

screw.

Position the shower so that it is vertical then mark

and drill the other two holes. Then fix the Shower to

the wall.

Assemble the accessories as shown in Diagram 22.

Remove the four cover screws and lift the

cover off.

Spares (Ring 0844 372 7750 UK ONLY)

Description

Triac PCB

Flow Valve Assembly (no PCB)

Flow Transducer

Heat Exchanger 7.2kW

Heat Exchanger 8.5kW

Heat exchanger 9.5kW

Thermal Cut-Out c/w Cables

Cable/Pipe Entry Set

PRV Housing Complete

Front Cover Complete white

Front Cover Complete Black

Front Cover Complete SIlver

Front Cover Complete Atlas Chrome

Part No,

93594158

93594159

93594160

93594161

93594162

93594163

93594117

93594164

93594165

93594166

93594139

93594141

93594142

Description

Backplate Rubber Seal Set

Solenoid Valve c/w Seals

6-Mode Handset White/Grey

1.25m Long Chrome Shower Hose

Wall Bracket Set

22mm x 455mm Bright Riser Rail

Height Adjuster Assy

Main Logic Board

Valve Rotation sensor PCB + wheel

Inlet Thermistor

Inlet Filter Housing Complete

Backplate Trimplate

Backplate Side Section

Part No.

93594150

93594154

93550895

93550896

93593522

93593526

93550899

93594167

93594168

93594169

93594144

93594145

93594146

Diagram 22

Please Note:- The fitting of all spares should be supervised by a suitably qualified person

15

264 mm

364 mm

680 mm

207 mm

Product Dimensions

Plumbing Connections

Plumbing to be carried out before wiring

DO NOT use jointing compounds on any pipe

fittings for the installation.

DO NOT solder fittings near the shower unit

as heat can travel along pipework and

damage components.

Compression fittings MUST be used to

connect to the inlet of the shower.

Note: We recommended that a WRAS (Water

Regulations Advisory Scheme) listed isolating

valve be fitted between the rising main and

the unit. This will allow the unit to be serviced

without having to turn off the house water at

the stop valve.

The unit should be connected to the mains

COLD water supply. This must have a

minimum running pressure of 0.07 MPa

(0.7bar / 10 p.s.i.) and a maximum pressure

of 1MPa (10bar / 145 p.s.i.).

This unit can also be fed from a header tank

provided this has a minimum head of 7 metres

(23ft).

IMPORTANT: Before completing the

connection of the water supply to the inlet of the

shower, flush out the pipework to remove all

swarf and system debris. This can be achieved

by connecting a hose to the pipework and

turning on the mains water supply long enough

to clear the debris to waste.

A blockage in the waterways (particularly the spray

plate of the handset and solenoid valve) will prevent

the unit from working correctly.

The shower is designed to have an open outlet and

should ONLY be used with the fittings recommended

by the manufacture.

Installation Procedure

Turn off the water supply either at the mains

stopvalve or the isolating stopvalve.

For ease of access to the inlet fitting the right hand

side of the shower has a removable inlet cover. See

Diagram 1. Also remove the backplate side access

trimplate shown in Diagram 1.

Diagram 2

A

B

C

D

Diagram 1

3

d) Lights behaves erratically.

e) Water does not flow when START/STOP

buttons are pressed.

Lights ON.

No lights.

I

I

I

I

I

I

I

Switch OFF electricity at ceiling/wall isolating switch,

wait a few seconds, switch on again.

(Note: The shower should be switched OFF each

time after use at the ceiling/wall isolating switch.

Note: If there is no water flowing then the shower will

automatically switch OFF after about 5 seconds.

Check the water supply is turned ON.

Check ceiling/wall isolating switch is ON.

Check power is ON.

I

I

I

I

I

I

PROFESSIONAL SERVICE CHECK LIST

This additional checklist is provided for the benefit of the qualified service representative.

WARNING! Switch Off The Electricity At The Isolator Before Removing The Front Cover To

Make Checks.

a) Poor temperature control.

b) Water too COLD

c) Poor or no control over water flow.

d) No water when button are pressed.

e) Unit has been switched OFF using

START/STOP button but can be heard

heating the water.

f) Pressure relief valve operated.

I

I

I

I

I

Check inlet thermistor to see if it is in circuit.

Check for blockage in the inlet filter.

Check circuit through thermal cut-out.

Check circuit through all 3 elements.

Test should be done using a low voltage resistance

meter whilst the power is switched OFF at the isolating

switch.

Check working voltage.

Replace flow valve assembly.

Check water supply. Check circuit through solenoid coil.

If OK replace logic PCB.

Replace triac PCB.

Check for cause of high pressure and remove it.

Replace pressure relief valve. (Not covered under

Guarantee).

I

I

I

I

I

g) Shower has a limited temperature

adjustment range.

h) Shower runs for about 5 seconds and

then switches OFF by itself.

I

I

Unit has been set with Temperature limiter set at 43°C.

Flow transducer fault.

Check that internal blade “spins” when the water flows:

If not, replace transducer.

I

I

14

f) Shower runs on about 5 seconds after

pressing Start / Stop Button then

switches OFF.

This is normal. Unit is in phased shutdown mode

indicated by the relevant LED flashing.

Re-press the High (or Eco) button and re-adjust the

temperature dial to give the desired temperature.

Re-press the High (or Eco) button and re-adjust the

temperature dial to give the desired temperature.

g) The flow rate is too low but the

temperature is correct.

h) The temperature dial is at its hottest but

the temperature is too low.

Loading...

Loading...