Redring PURE 8.5kW, PURE 7.5kW, PURE 9.5kW, PURE 10.5kW, Vital RVLS7 Installation And User Manual

...

IMPORTANT:

This booklet should be left with the user after

installation and demonstration

7.5/8.5/9.5/10.5kW

PURE

Installation and User Guide

2

1 – Pack Contents 3

2 – Installation Check List 3

3 – Important Safety Information 4

4 – General Installation Layout Guide 5

5 – Important Installation Information 6

6 – Fixing the Shower to the Wall 6

7 – Product Positioning Guide 7

8 – Plumbing Connections 8

9 – Electrical Connections 9-10

10 – Fitting the Front Cover 10

11 – Riser Rail Fitting Instructions 11

12 – Commissioning the Shower 12

13 – Troubleshooting Checklist for the Installer 13

1 – Important Safety Information 14

2 – Operating the Shower 15

3 – How Your Shower Works 16

4 – Routine Maintenance 16

5 – Troubleshooting and FAQs 17

6 – Troubleshooting Checklist for the Installer 18

7 – Energy Related Product Directive (ErP) 19

User Guide

Installation Guide

Contents

Installation Guide

IMPORTANT: This appliance can be used by children aged from 3

years and above and persons with reduced physical, sensory or

mental capabilities or lack of experience and knowledge if they

have been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved.

The shower spray head MUST be cleaned regularly to remove

scale and debris. The frequency of the cleaning will vary according

to the local water quality. If the water outlet temperature becomes

hot and you are unable to obtain cooler water, immediately check

the shower handset for blockage. See section 4 for cleaning

instructions.

Do not operate shower if frozen, or suspected of being frozen. It

must thaw out before using.

3

Installation Guide

Shower Unit

Shower Handset

Riser Rail Tube

Riser Rail Brackets x 2

Riser Rail Height Adjuster

Flexible Shower Hose

Screw Pack

Installation and User Instructions

Please make sure ALL components are included before starting the installation.

1. Pack Contents

2. Installation Check List

Check that the water supply will satisfy requirements

Check that water & cable entry points of the unit meet requirements

Check that the electric supply will satisfy requirements

Select a suitable position for the shower

Follow plumbing installation section

Follow electrical installation section

Fit to the wall & connect the shower supplies

Commission the shower in the way described

Fit the front cover & aligning the controls

Familiarise yourself with the user operating instructions

4

Installation Guide

Products manufactured by Redring Xpelair Group are safe and without risk

provided they are installed, used and maintained in good working order in

accordance with our instructions and recommendations.

3. Important Safety Information

MAINS SERVICE CONNECTIONS: The shower unit is supplied

for right hand entry, please see Section 8 & 9 for “Plumbing

Connections” & "Electrical Connections" for installation information.

IMPORTANT: To comply with water regulations, building

regulations or any specic local water company regulations and in

accordance with BS EN 806 a double check valve should be tted

where it is possible that the shower head may come into contact

with used water, for example in the bath or a shower tray.

IMPORTANT: Check that there are no hidden cables or pipes

before drilling holes for the wall plugs. Choose a at piece of wall

to avoid the possibility of distorting the back plate and making

the front cover a poor t. Exercise great care when using power

tools near water. The use of a residual current device (RCD) is

recommended.

IMPORTANT: Before connecting the water supply to the shower

unit the water supply pipe should be ushed out to remove all

debris. After ushing the pipework make the connection to shower

inlet and ensure the shower is positioned squarely on the wall and

all xing screws are tightened.

IT IS VERY IMPORTANT: To ensure that the terminal block

screws are fully tightened and that no cable insulation is trapped

under screws, and tighten periodically in accordance with BS

7671. The earth continuity conductor of the electrical installation

must be effectively connected to all exposed metal parts of other

appliances and services in the room in which the shower unit is

installed to conform with BS 7671. The unused supply terminal

block must not be used for any other purpose.

IMPORTANT: Ensure that the temperature control knob is

turned to MIN temperature (FULL ow) and the commissioning

instructions are followed before switching the unit on. This will

make sure that the unit is full of water when rst activated.

IMPORTANT: The shower unit MUST be full of water before the

heat settings are changed.

IMPORTANT: The shower unit MUST be tted with a WRAS

(Water Regulations Advice Scheme) listed mains water isolating

valve.

5

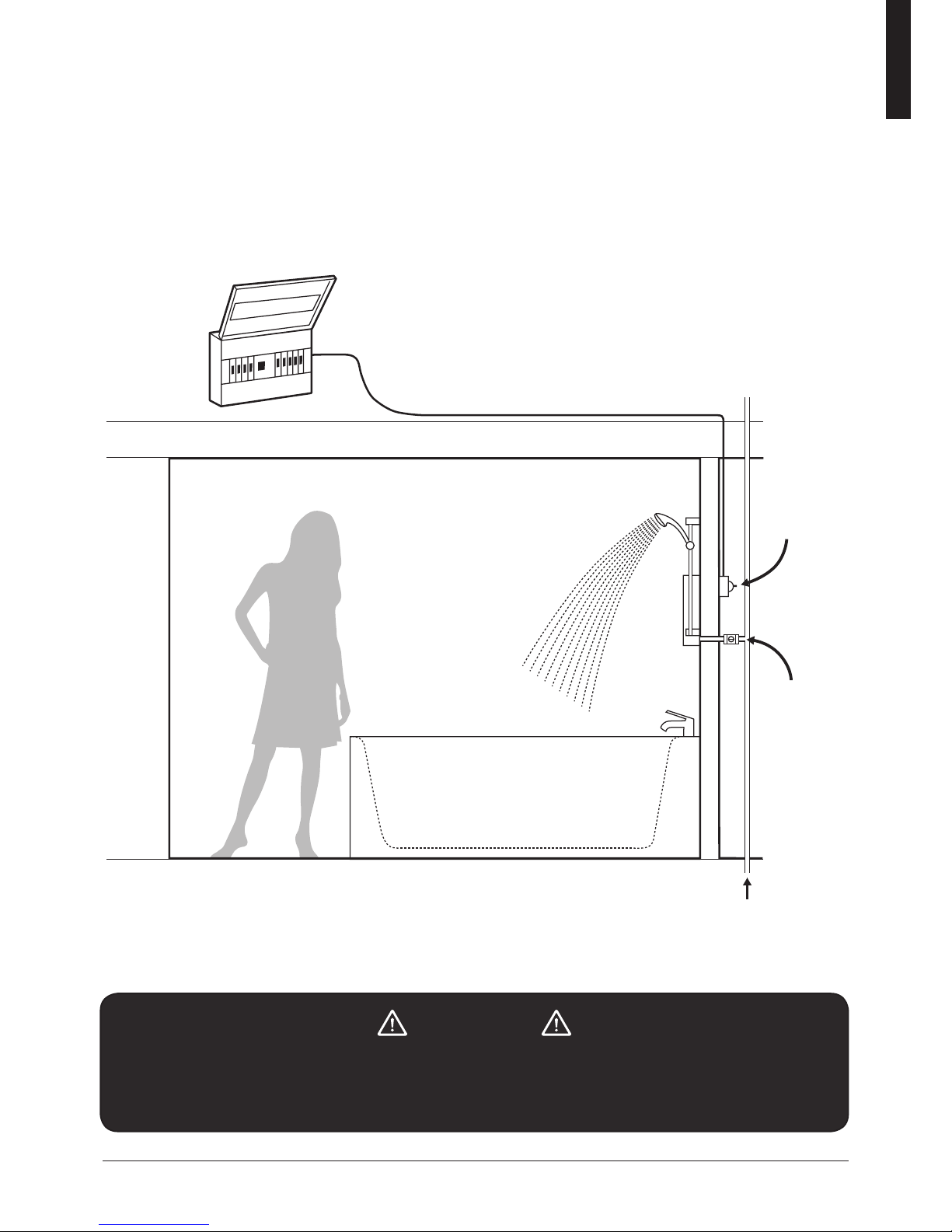

Installation Guide

• For example the mains feed to a toilet as

this may cause a drop in pressure to a level

that is too low for the shower unit to work

correctly.

• A WRAS (Water Regulations Advice

Scheme) listed isolating valve must be

tted between the rising main and the

unit to comply with water regulations and

to allow for routine maintenance and

servicing.

• Plan your installation carefully. Check on

the nearest and most accessible rising

main water supply, this may be beneath

the bath or in the loft, where it feeds the

water storage tank. Use only the cold rising

water main.

• If possible avoid connecting the shower

unit where it will be affected by water

drawn off by another appliance.

ELECTRICAL

ISOLATION

SWITCH IN

ACCORDANCE

WITH I.E.T BS

7671

MAINS WATER

ISOLATING

TAP

COLD WATER

MAINS SUPPLY

SEPARATE PERMANENTLY

CONNECTED CONSUMER UNIT

FLOOR

BATH

BATHROOM

CEILING JOISTS

4. General Installation Layout Guide

IMPORTANT!

This appliance can be used by children aged from 3 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge

if they have been given supervision or instruction concerning use of the appliance in a

safe way and understand the hazards involved.

6

Installation Guide

• This shower unit is designed to be

connected to a 15mm cold water mains

supply.

• To make sure the heating elements are

activated the shower must be connected

to mains water supply with a minimum

static pressure of 0.1MPa (15lb/sq in) – 1

bar at a minimum ow rate of 8 litres per

minute. The maximum static pressure is

1MPa (145lb/sq in) 10 bar.

• The shower unit must not be tted where it

may be exposed to frost, for example, in an

outdoor area. The shower must not be used

if suspected of being frozen. Frost damage

is not covered by the guarantee.

NOTE: For the 9.5 & 10.5kW model, the

minimum running pressure must be obtained

at 9 L/min.

• Position your shower on a FLAT section of wall,

ensuring that it will NOT be in the direct water spray

from the shower handset when xed.

• The shower unit should be positioned so that the

shower handset cannot be immersed in the bath or

shower tray when hanging down.

• Remove the four front cover xing screws and lift the

cover off complete with the control knobs and start /

stop push button.

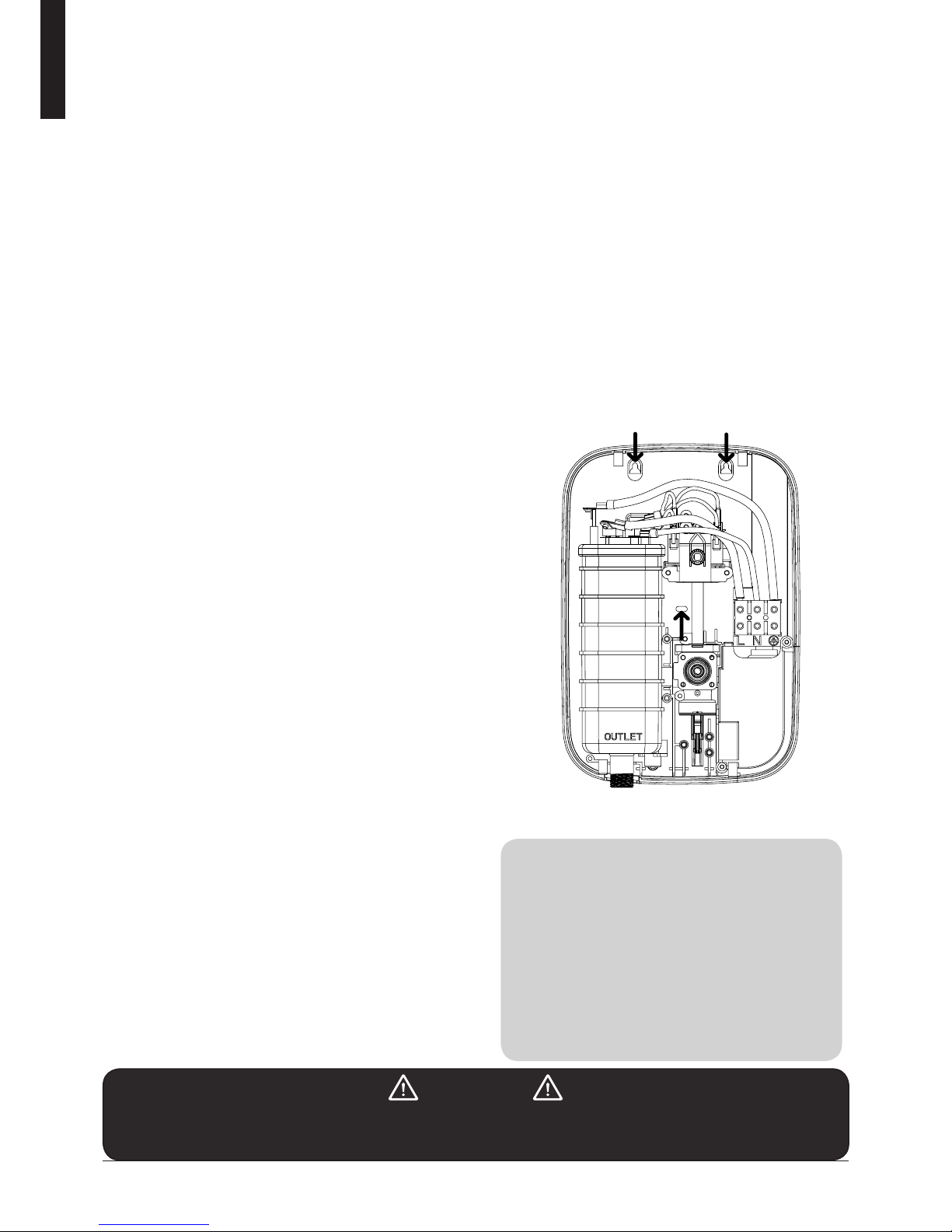

1. Having decided on the water and cable entry

points and chosen a at piece of wall, hold the

shower vertically against the wall and mark the

top two xing holes whilst ensuring the shower

is square.

2. Carefully drill the two holes as marked using

a sharp 5.5mm masonry drill after rst making

certain there are no pipes or wires behind the

proposed holes.

3. Insert the wall plugs and screws provided

leaving the screw head proud by approximately

5mm. The shower can now be hung on these

screws.

4. Make sure that the shower is positioned

vertically and square, now mark and drill the

lower slotted xing hole. Then x the shower to

the wall. Do not fully tighten the screws at this

stage

5. The shower back plate and removable corn er

mouldings have moulded cut out sections which

are clearly indicated to allow the chosen service

entry option to be cut out prior to nal x.

Shower installation must be carried out by a suitably qualied person and be in

accordance with BS 7671 (IET wiring regulations), building regulations, water regulations

and / or any specic local water company regulations in force and should be in

accordance with BS EN 806.

• Plumbers jointing compound must not

be used. In instances of difcult joints

use P.T.F.E. Tape. The use of jointing

compound will invalidate the product

guarantee.

• Do not solder ttings near the shower unit

as heat can travel along pipe work and

damage components.

• Do complete all plumbing connections

before making the electrical connections.

IMPORTANT

Under no circumstances should this shower unit be recessed (it must be tted onto the

nished wall surface) or tiled up to or sealed around the unit at this may prevent air

circulating and any condensation escaping. Shower must be installed on a at wall.

5. Important Installation Information

6. Fixing The Shower To The Wall

NOTE: The half way down screw should

only be tted during nal installation.

• A piece of insulating or masking tape

applied to the wall before marking out the

fixing holes will help stop the drill from

wandering, particularly on tiled surfaces.

• When working near a basin or bath,

insert the plug in the waste fitting so that

small parts cannot be lost.

• Take care not to drop accessories or

tools into basin or bath.

TIPS

Wall xing points

Loading...

Loading...