Page 1

Owner/ Operator Manual

WARNING

!

!

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

WARNING

!

!

Before using our products, please

read this manual carefully to

understand the proper use of

your unit.

Tiller/Cultivator CV225

0706

Page 2

2

The REDMAX Tiller/Cultivator tills and weeds

precisely “to handle” your most difficult jobs. It

handles smoothly while the “bolo-tine” tines churn soil

to ten inches deep. It creates a soft smooth seed bed,

even in problem stony soil.

Once you know how to use your Precision

Tiller/Cultivator correctly, we guarantee you’ll love it.

So first, please read this manual. It shows, step by step,

how to use your Tiller/Cultivator safely.

If you have questions about any topic in this Manual

contact your local authorized REDMAX dealer.

Welcome to the World of REDMAX Ga rdening

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety Rules and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

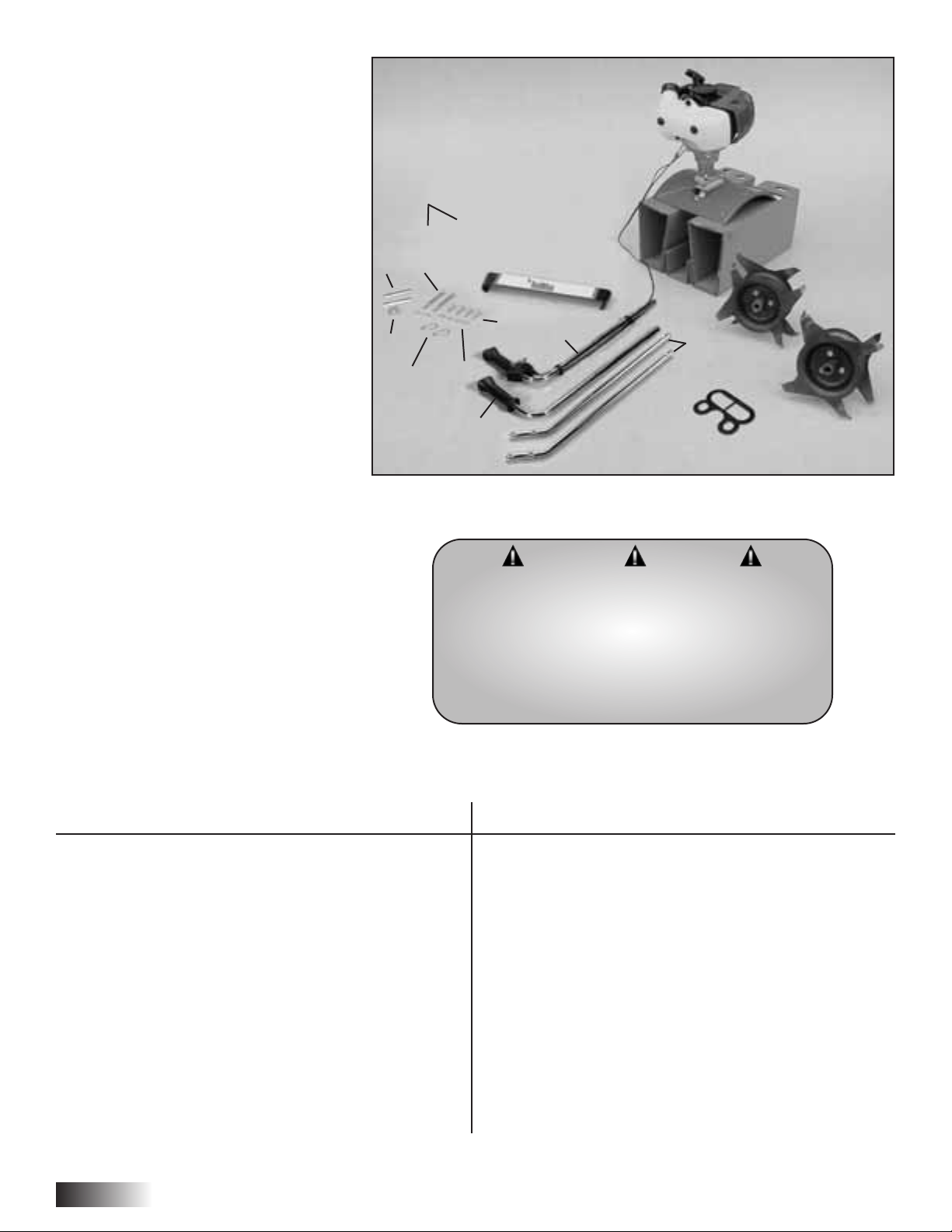

Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Fuel Mix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Starting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

What to do Just in Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Tilling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Cultivating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Cultivator Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Engine Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Emissions Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Table of Contents

Page 3

3

Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CV225

Overall Size (L x W x H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47 (1194) x 11 (280) x 38 (965) in (mm)

Dry weight w/o acc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21.5 LBS (9.8kg)

Engine Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Air cooled 2-stroke gasoline

Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Zenoah

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.4cu-in (22.5cm3)

Max. Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.08Hp at 8000rpm

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Mixture (Gasoline 50 : Oil1)

Carburetor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Walbro Diaphragm type

Spark plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RCJ6Y

Fuel tank capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20.3 fl.. oz (0.6L)

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Centrifugal clutch, Rigid driveshaft

Reduction ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42:1

Durability period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150 hrs.

Specifications are subject to change without notice.

Specifications

Page 4

4

You will notice throughout this Owners Manual

Safety Rules and Important Notes. Make sure you

understand and obey these warnings for your own

protection.

Special Safety Information

Safety and Warnings

Safety Decal Information

An important part of the safety system incorporated

in this trimmer are the warning and information

decals found on various parts of the trimmer. These

decals must be replaced in time due to abrasion, etc.

It is your responsibility to replace the decals when

they become hard to read. The location of these

decals and their part numbers for ordering are shown

below.

Safety Rules and Warnings

WARNING DANGER

ATTENTION: THIS SYMBOL POINTS OUT OUR

IMPORTANT SAFETY INSTRUCTIONS

WHEN YOU SEE THIS SYMBOL

HEED ITS WARNING! STAY ALERT!

WARNING DANGER

TO REDUCE THE POTENTIAL FOR ACCIDENTS,

COMPLY WITH THE SAFETY INSTRUCTIONS IN

THIS MANUAL. FAILURE TO COMPLY MAY

RESULT IN SERIOUS PERSONAL INJURY AND OR

EQUIPMENT AND PROPERTY DAMAGE.

WARNING DANGER

IMPROPER USE OR CARE OF THIS

TILLER/CULTIVATOR, OR FAILURE TO WEAR

PROPER PROTECTION CAN RESULT IN

SERIOUS INJURY.

READ AND UNDERSTAND THE RULES FOR SAFE

OPERATION AND ALL INSTRUCTIONS

IN THIS MANUAL.WEAR HEARING PROTECTION.

WARNING DANGER

THE ENGINE EXHAUST FROM THIS PRODUCT

CONTAINS CHEMICALS KNOWN TO THE STATE

OF CALIFORNIA TO CAUSE CANCER, BIRTH

DEFECTS OR OTHER REPRODUCTIVE HARM.

Page 5

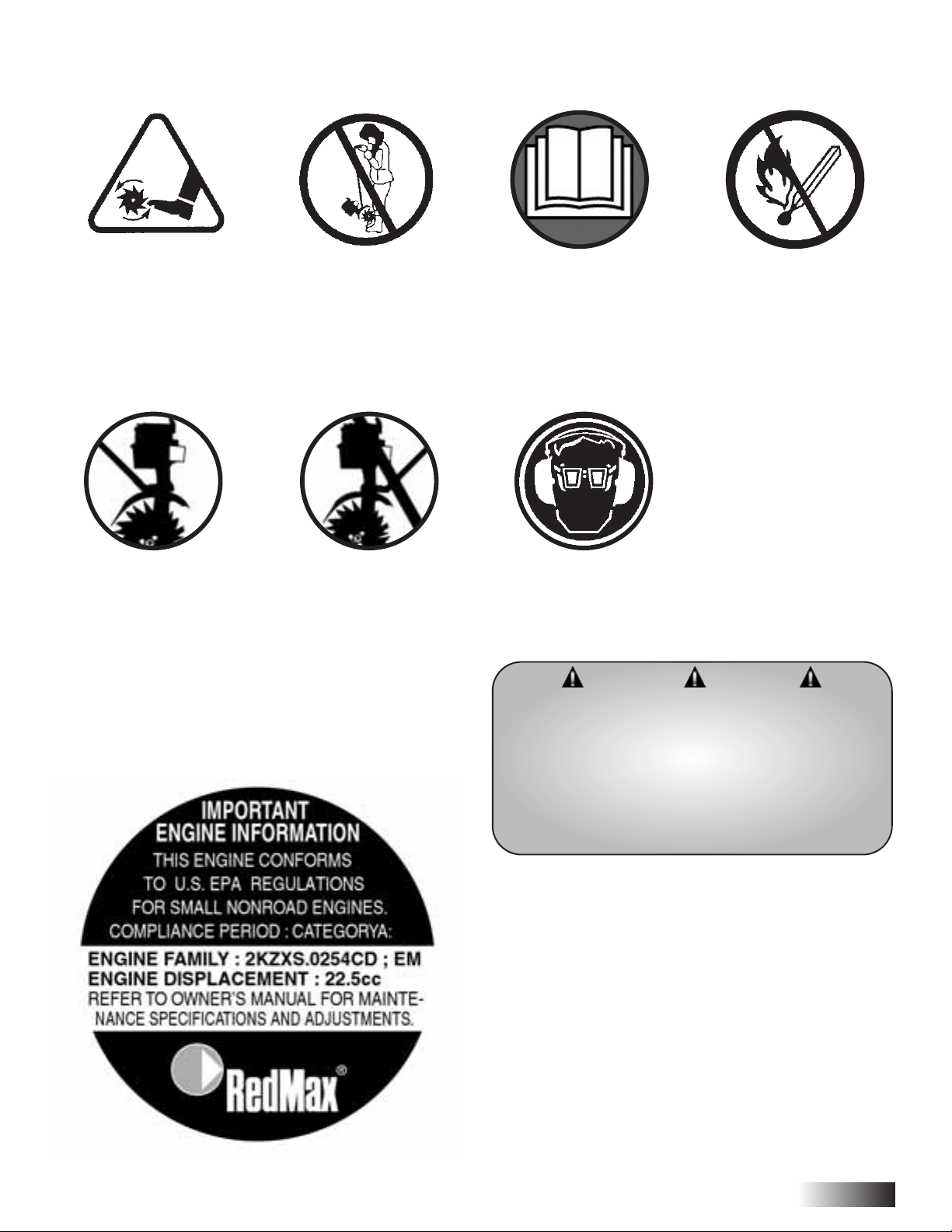

WEAR EAR AND EYE

PROTECTION.

CUTTING HAZARD; KEEP

FEET AND HANDS AWAY

FROM ROTATING TINES.

DO NOT CARRY THE

TILLER/CULTIVATOR IN

THIS POSITION.

READ OWNER’S MANUAL

BEFORE USING

TILLER/CULTIVATOR, OR

PERFORMING ANY REPAIR

OR MAINTENANCE. KEEP

OWNERS MANUAL IN A

SAFE PLACE.

DON’T FUEL, REFUEL, OR

CHECK FUEL WHILE

SMOKING, OR NEAR AN

OPEN FLAME OR OTHER

IGNITION SOURCE.

CAUTION: WHEN

ASSEMBLING THE

HANDLES, MAKE SURE

FUEL TANK FACES AWAY

FROM OPERATOR. THIS IS

THE REAR OF THE

TILLER/CULTIVATOR,

REFER TO ASSEMBLY

INSTRUCTION ON PAGE 8.

INCORRECT ASSEMBLY.

Safety Decal Information cont.

Warnings - Do’s

1. Always keep a firm grip on both handles while

the tines are moving and/or the engine is

running. BE AWARE!! The tines may coast after

throttle trigger is released. Make sure tines have

come to a complete stop and engine is off before

letting go of the Tiller/Cultivator.

2. Always maintain a firm footing and good

balance. Do not overreach while operating the

Tiller/Cultivator. Before you start to use the

Tiller/Cultivator, check the work area for

obstacles that might cause you to lose your

footing, balance or control of the machine.

3. Thoroughly inspect the area where equipment is

to be used and remove all objects, that can be

thrown by the machine.

WARNING DANGER

IF THE TILLER/CULTIVATOR PRECAUTIONS

ARE NOT FOLLOWED, THE USER RISKS

SERIOUS INJURY TO THEMSELVES

AND OTHERS.

READ AND UNDERSTAND THIS MANUAL

BEFORE ATTEMPTING TO OPERATE THIS

TILLER/CULTIVATOR.

5

Page 6

6

Warnings - Do’s cont.

4. Always keep area clear of children, pets, and

bystanders.

5. Always stay alert. Watch what you are doing and

use common sense. Do not operate unit when

fatigued.

6. Always dress properly. Do not wear loose

clothing or jewelry, they might get caught in

moving parts. Use sturdy gloves. Gloves reduce

the transmission of vibration to your hands.

Prolonged exposure to vibration can cause

numbness and other ailments.

7. While working, always wear substantial footwear

and long trousers. Do not operate the equipment

when barefoot or wearing open sandals.

8. Always wear ear and eye protection. Eye

protection must meet ANSI Z 87.1. To avoid

hearing damage, we recommend hearing

protection be worn whenever using the

equipment.

9. To reduce fire hazard, keep the engine, and

petrol/gas storage area free of vegetative material

and excessive grease.

10. Start the engine carefully, according to the

manufacturer’s instructions and with feet well

away from tool(s).

11. Keep all nuts, bolts and screws tight to be sure

the equipment is in safe working condition.

12. Use extreme caution when reversing or pulling

the machine towards you.

13. Work only in daylight or good artificial light.

14. Always be sure of your footing on slopes.

15. Exercise extreme caution when changing

direction on slopes.

16. Always keep a safe distance between two or

more people when working together.

17. Always inspect your unit before each use and

ensure that all handles, guards and fasteners are

secure, operating, and in place.

18. Always maintain and examine your

Tiller/Cultivator with care. Follow maintenance

instructions given in manual.

19. Always store Tiller/Cultivator in a sheltered area

(a dry place), not accessible to children. The

Tiller/Cultivator as well as fuel should not be

stored in a house.

Warnings - Don’ts

Don’t use Tiller/Cultivator with one hand. Keep both

hands on handles with fingers and thumbs encircling

the handles, while tines are moving, and engine is

running.

Don’t overreach. Keep a good footing at all times.

Don’t run with the machine, walk.

Don’t work on excessively steep slopes.

Don’t attempt to clear tines while they are moving.

Never try to remove jammed material before

switching the engine off and making sure the tines

have stopped completely.

Don’t allow children or incapable people to operate

this Tiller/Cultivator.

Don’t operate while under the influence of alcohol or

drugs.

Don’t attempt to repair this Tiller/Cultivator. Have

repairs made by a qualified dealer or repairman.

WARNING DANGER

FOR SAFE OPERATION AND MAINTENANCE,

SYMBOLS ARE CARVED IN RELIEF ON THE

MACHINE. ACCORDING TO THOSE INDICATIONS,

PLEASE BE CAREFUL NOT TO MAKE A MISTAKE.

THE PORT TO REFUEL THE “MIX GASOLINE”

POSITION: FUEL TANK CAP.

WARNING DANGER

IMPORTANT ENGINE INFORMATION

THIS ENGINE MEETS U.S. EPA PH1 AND 2001

CALIFORNIA EMISSION REGULATIONS FOR

SMALL OFF-ROAD ENGINES WITH AN EMISSION

DURABILITY PERIOD OF 300 HRS

ENGINE FAMILY : 1KZXS. 0254CD

ENGINE DISPLACEMENT : 22.5CC

REFER TO OWNER’S MANUAL FOR

MAINTENANCE SPECIFICATIONS

AND ADJUSTMENTS.

Page 7

Engine/ Fuel - Warnings - Do’s

Always use fresh gasoline. Stale gasoline can cause

damage.

Always store fuel in containers specifically designed

for this purpose.

Always pull starter cord slowly until resistance is felt.

Then pull cord rapidly to avoid kickback and prevent

arm or hand injury.

Always operate engine with spark arrestor installed

and operating properly. The use of spark arrestor

mufflers is required by law in the state of California

(Section 4442 of the California Public Resources

Code), as well as in other states or municipalities.

Federal laws apply on federal lands.

Stop the engine whenever you leave the machine.

Allow the engine to cool before storing in any

enclosure.

If the fuel tank needs to be drained, this should be

done outdoors.

Engine/ Fuel Warnings - Don’ts

Don’t fuel, refuel or check fuel while smoking, or

near an open flame or other ignition source. Stop

engine and be sure it is cool before refueling.

Don’t leave the engine running while the

Tiller/Cultivator is unattended. Stop engine before

putting the Tiller/Cultivator down or while

transporting from one place to another.

Don’t refuel, start or run this Tiller/Cultivator indoors

or in an improperly ventilated area.

Don’t run engine when electrical system causes spark

outside the cylinder. During periodic checks of the

spark plug, keep plug a safe distance from cylinder to

avoid burning of evaporated fuel from cylinder.

Don’t check for spark with spark plug or plug wire

removed. Use an approved tester.

Don’t crank engine with spark plug removed unless

spark plug wire is disconnected. Sparks can ignite

fumes.

Don’t run engine when the odor of gasoline is present

or other explosive conditions exist.

Don’t operate the unit if gasoline is spilled. Clean up

spill completely before starting engine.

Don’t operate your Tiller/Cultivator if there is an

accumulation of debris around the muffler, and

cooling fins.

Don’t touch hot mufflers, cylinders or cooling fins as

contact may cause serious burns.

Don’t change the engine governor setting or over

speed the engine.

7

WARNING DANGER

HANDLE FUEL WITH CARE, IT IS HIGHLY

FLAMMABLE. FUELING A HOT ENGINE OR NEAR

AN IGNITION SOURCE CAN CAUSE A FIRE AND

RESULT IN SERIOUS PERSONAL INJURY

AND/ OR PROPERTY DAMAGE.

WARNING DANGER

DO NOT MODIFY YOUR TILLER/CULTIVATOR .

WARRANTY WILL BE VOIDED IF YOU

USE THE REMODELED TILLER/CULTIVATOR

OR IF YOU DO NOT OBSERVE THE PROPER

USAGE WRITTEN IN THE MANUAL.

Page 8

8

Qty Description *Key #

1 Upper Handle 4

1 Upper Handle Throttle Side 5

2 Lower Handles 6

1 Pair Cultivator Tines 39/40

1 Engine Assembly

(includes Fender Guard

& Worm-Gear Transmission) 21, 20, 50

1 Handle Brace 8

1 Plastic Carrying Handle 42

Qty Description *Key #

1 Bag of Hardware Containing:

4 Cap Screws 52

6 Lock Nuts 53

2 Bolts (3 1/4" long) 54

2 Tine Retaining Pins 41

2 Transmission Bracket 47

1 Throttle Clip 13

Your REDMAX Precision

Tiller/Cultivator comes partially

assembled. You must install only the

handlebars, the carrying handle, and

the tines. This will take just a few

minutes if you follow the directions.

First, take all items out of the

carton. But do not remove the

cardboard from around the

Tiller/Cultivator’s base.

The list below, shows the parts that

come with your Tiller/Cultivator.

Check to make sure you have them.

The bag of hardware is packed in the

plastic bag containing the owner’s

manual.

To assemble your REDMAX

Tiller/Cultivator, you’ll need two 7/16"

wrenches or two adjustable wrenches.

We suggest that you install all nuts and

bolts only “finger tight” — that is, onehalf to one full turn — until you’ve

completed assembly. The nuts are self

locking, but you must use a wrench

to tighten them completely.

Assembly Instructions

WARNING DANGER

IMPROPER ASSEMBLY OF THIS

TILLER/CULTIVATOR CAN RESULT IN

SERIOUS INJURY.

MAKE SURE TO FOLLOW ALL INSTRUCTIONS

CAREFULLY. IF YOU HAVE ANY QUESTIONS

CONTACT YOUR LOCAL REDMAX DEALER.

4

6

5

47

41

40

39

42

8

21

13

54

53

52

6

Page 9

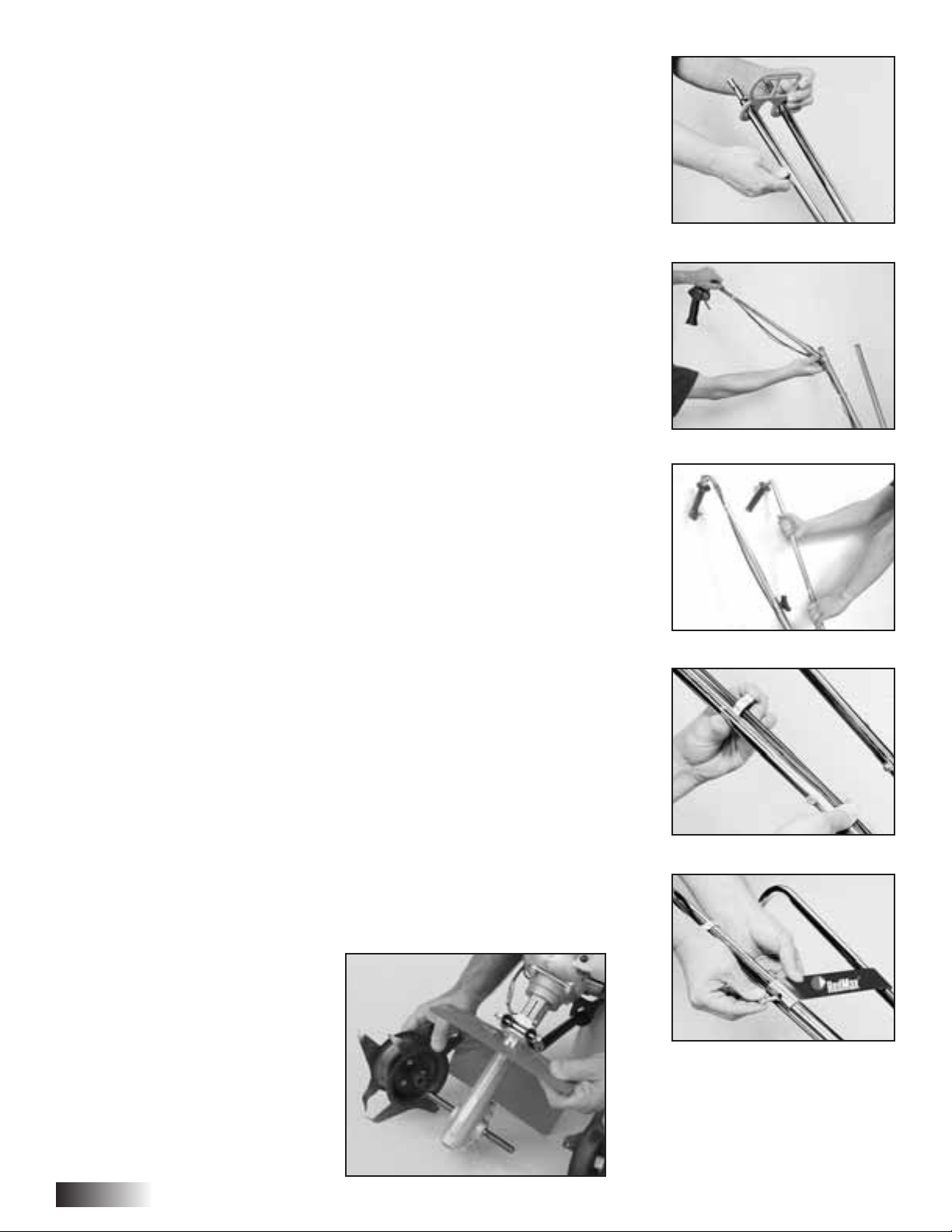

II. How to Assemble Lower Handles

To identify part numbers, see page 8.

1. Use the protective cardboard sleeve to stabilize your

Tiller/Cultivator. Stand the engine assembly up.

2. Lay the handle parts within easy reach. You’ll need the transmission

bracket (#47) and one of the lower handles (#6). Note that the lower

handles have a short leg on one end. (Picture 1)

3. Fit the transmission bracket along the outside of the short leg. Line

up the holes on the clamp and the leg.

4. Using one of the two 3 1/4" bolts (#54), slide it through the hole of

the transmission bracket (#47) and lower handle (#6) closest to the

elbow. (Picture 2) The fit will be tight.

5. Now slide the bolt completely through the second lower handle and

transmission bracket. (Picture 2) Add a nut (#53) and tighten finger

tight.

6. Locate the worm-gear housing. It starts just above — and extends

down through — the Tiller/Cultivator’s red fender. You’ll notice that

there’s a recessed channel on either side of the housing’s top.

7. Take the lower handles that you’ve just put together. Slide them into

the two recessed channels.

Make sure you insert them from the rear of the Tiller/Cultivator

(gasoline tank faces away from the operator) . . . so that the bolt fits

along the back of the housing.

8. Slide the second 3 1/4" bolt through the second hole in the short

legs. Add a nut (#53) and tighten finger tight. (Picture 4)

NOTE: THE NUTS ARE SELF

LOCKING, BUT YOU MUST

USE A WRENCH TO TIGHTEN

THEM COMPLETELY.

Picture 1

Picture 4

Picture 3

Picture 2

9

Page 10

Assembling the Tines for Tilling

1. Remove the cardboard from around your Tiller/Cultivator’s base.

2. Slide the tines onto the axle shafts. The “D” hole goes on the outside.

3. Make sure you’ve installed the tines properly for cultivating. Liken

the tines to your fingers. When your palm faces the ground, your

fingers curl down. Stand behind the Tiller/Cultivator and hold your

hand next to the tines. Do the tine blades curl down, as your fingers

do? If so, they are in the tilling position. (To switch to the cultivating

position, see page 16.)

4. To secure each tine to the axle,

insert a tine retaining pin.

IMPORTANT NOTE:

Before you use your REDMAX

Tiller/Cultivator, read the Safety

Rules & Warnings on pages 4-7.

Picture 5

Picture 4

How to Assemble Upper Handles and Plastic Carrying Handle

1. Lightly squeeze the lower handles (#3) toward one another so that they line

up with the two smaller holes on the carrying handle (#29). Then slide the

carrying handle over and down the lower handles. It will rest about four to

six inches above the engine. (Picture 1)

2. Gently pull the lower handles out to their original position.

3. Attach the upper handle assembly (#1) – the handle with the throttle cable

and ground wire – onto the right handle, and secure with the handle knob

(#40) and 1 round head bolt (#39) (Picture 2). Be sure you have proper

throttle movements and that the throttle cable is not wrapped or twisted

around the handle bar. Squeeze trigger and let go. The triangle must click

in both directions. If there is any doubt, remove air filter and visually check

that the throttle triangle hits both the idle screw and the full open stop. THIS

MUST BE DONE BEFORE STARTING THE ENGINE.

4. Follow the same steps to install the left upper handle onto the other lower

handle. (Picture 3)

5. Use the clip (#6) to secure the throttle cable and wire in place on the lower

handle. (Picture 4)

6. Now install the Handle Brace. Line it up with the holes on the upper handles.

Then insert a Cap Screw (#34) and a Lock Nut (#35) on either side (Picture 5)

7. Use a wrench to tighten Cap Screws and Lock Nuts.

8. Now use wrench to tighten all nuts and bolts firmly and securely.

IMPORTANT NOTE:

Make sure you have installed the handles properly. When you stand behind

your Tiller/Cultivator, holding the handles, gasoline tank should be in front of

the unit.

Picture 1

Picture 2

Picture 3

10

Page 11

11

Your REDMAX Tiller/Cultivator is powered by a

commercial two stroke, air cooled engine which

requires a fuel mixture of gasoline and lubricating oil.

Use a mixture of 50 parts unleaded regular gasoline

and 1 part two-stroke oil (50:1.) Make sure to use

gasoline with a minimum octane number of 90 ROZ

(USA/Canada: pump octant Min. 87)

The REDMAX engines are lubricated by oil specially

formulated for air-cooled 2-cycle gasoline engine use.

If REDMAX oil is not available, use an anti-oxidant

added quality oil expressly labeled for air-cooled 2

cycle-engine use. (JASO FC GRADE OIL or ISO

EGC GRADE)

Recommended mixing ratio

Gasoline 50: Oil 1

Exhaust emission are controlled by the fundamental

engine parameters and components (eq., carburators,

ignition timing and port timing) without addition of

any major hardware or the introduction of an inert

material during combustion.

How to mix fuel:

1. Pour 1/2 of the gasoline into a safe container. Do

not mix the fuel and oil in the engine fuel tank.

2. Add 2.6 ounces (.077 liters) of two-cycle engine

oil to the gasoline and mix. Then add the rest of

the gasoline.

3. Screw the cap onto the gasoline can. Then swirl

the can to blend the oil and gas.

Fueling the unit:

1. Carefully pour the fuel mix into the `

Tiller/Cultivator’s fuel tank.

2. Put fuel into the fuel tank to 80% of the

full capacity.

3. Fasten the fuel cap securely and wipe up any fuel

spillage around the unit.

IMPORTANT: Two stroke fuel separates and ages.

Do not mix more than you will use in a month. Using

old fuel can cause difficult starting or engine damage.

Shake fuel container to thoroughly mix fuel before

each use. Do not attempt to run your engine on

gasoline only, use proper fuel mixture.

Need pre-measured engine oil? Contact your local

authorized REDMAX dealer.

Remember …

• Always mix two-cycle oil with gasoline before

fueling your Tiller/Cultivator. Never, ever run your

Tiller/Cultivator on gasoline alone. This will ruin

your engine and void all warranties.

• Always use a clean gas can and always use

unleaded gas.

• Never try to mix the oil and gasoline in the engine

fuel tank.

• Always mix oil and gas in the proper proportions:

2.6 ounces (.077 liters) of two-cycle engine oil to

one gallon (3.785 liters) of unleaded gasoline.

• Gasohol - It can cause deterioration of rubber

and/or plastic parts and disruption of

engine lubrication.

• Oil for 4-cycle engine use or water coded 2-cycle

engine use - it can cause spark plug fouling,

exhaust port blocking, or piston ring sticking.

IMPORTANT NOTE:

Do Not use old or stale oil/gasoline mixture.

Always use the proper oil/gasoline mixture. If you

do not, your engine will suffer rapid, permanent

damage. And you will void the engine warranty.

Fuel Mix

WARNING DANGER

FUEL IS EXTREMELY FLAMMABLE. HANDLE IT

WITH CARE. KEEP AWAY FROM IGNITION

SOURCES. DO NOT SMOKE WHILE FUELING

YOUR EQUIPMENT.

Gasoline liter 1234 5

2-cycle oil ml 20 40 60 80 100

Gasoline gal. 1234 5

2-cycle oil fl. oz 2.6 5.2 7.8 10.4 13

Page 12

Starting Your Tiller/Cultivator for the First Time

1. Fill the fuel tank with the proper oil/gasoline mixture.

(See previous section.)

2. Hand tighten the gasoline cap just until it’s snug.

3. Place the o/I switch into the I “start/on” position. (Picture 1)

4. Pull the choke button all the way out, to completely close the choke.

(Picture 2)

5. Locate the purge bulb on the upper right of the engine, in front of the

fuel tank. (See Picture 3) It sends fuel into the carburetor, for easy

starting. Press the purge bulb until you see fuel flow through the clear

fuel return line. Since you’re starting “cold,” you may need to press six

to eight times. As soon as fuel starts flowing through the clear fuel line,

stop pressing! (Picture 3)

6. Don’t press the throttle trigger during the starting of the engine.

7. Pull the starter cord (Picture 4) until resistance is felt. Then give the

recoil starter cord a few

brisk pulls until the engine fires. Note: Pull the

starter cord about 12" to 18".

During cold starting, you may need to pull

at least three or four times before the engine fires.

NOTE: When the choke is closed, never pull the cord more than four or

five times. Overpulling may cause flooding. Also, bear in mind that,

when the engine fires, it only coughs or sputters, and will not run on

choke.

8. Push the choke button in, all the way, to open the choke. (Picture 5)

9. Then pull the starter cord again. The engine should start and run. Let

the engine warm up two to three minutes before using.

Follow these steps whenever you are starting the engine “cold”, or

when the engine has run dry and you have just added fuel. Remember,

always use short, brisk pulls. Don’t give the cord a long, forceful yank.

And, do not let the cord snap back into the starter housing.

Starting Instructions

WARNING DANGER

NEVER USE STARTING FLUIDS AS THEY WILL

CAUSE PERMANENT ENGINE DAMAGE. USING

THEM WILL VOID THE WARRANTY.

BEFORE YOU USE THE TILLER/CULTIVATOR,

READ THE SAFETY WARNING

RULES ON PAGES 4-7.

Picture 1

Picture 5

Picture 4

Picture 3

Picture 2

12

Page 13

13

Starting a Warm Engine

1. Slide ignition switch to START position.

2. Move the choke lever to the Open (Run) position.

3. If there is no fuel in the clear return line, push

primer bulb 3-4 times or until fuel is visible in the

line.

4. Pull starter rope using short pulls, 1/2 to 2/3 of the

rope length.

5. If engine fails to start in 4 pulls, use “First Time”

starting procedure on page 14.

6. With engine running, and both hands on the

handles, squeeze throttle trigger gradually to

increase the engine speed and engage the tines.

Additional Information

How to Stop the Engine

Simply push the o/

I switch into the I “stop”

position. This will stop the engine instantly. If it

should ever fail to do so, just pull out the choke

button. The engine will stop at once.

About the Choke

The choke controls the amount of air drawn into the

engine. Your Tiller/Cultivator will run only if the

choke is open — that is, if the choke is pushed in.

A Special Feature (with the idle set properly and

the engine running)

Even when the engine is running, the tines won’t

turn unless you press the throttle lever on the

handlebars. And, when you release the throttle lever,

the tines will stop.

A Tip for Extending Your Engine’s Life

After you start the engine, let your Tiller/Cultivator

warm up for two to three minutes before you use it.

Then, before you put your Tiller/Cultivator away, let

it idle for a minute to give the engine a chance to

cool down.

WARNING DANGER

AVOID ACCIDENTAL BLADE ENGAGEMENT.

DO NOT SQUEEZE THE THROTTLE TRIGGER WHEN

STARTING. MAINTAIN PROPER IDLE

SPEED ADJUSTMENT (220 - 2300 RPM).

WARNING DANGER

IF ENGINE DOES NOT STOP WHEN SWITCH IS

PUT IN THE STOP POSITION, RELEASE THE

THROTTLE. ALLOW ENGINE TO IDLE.

PUT THE TILLER/CULTIVATOR DOWN, AND

PULL THE CHOKE BUTTON OUT TO COLD

START (CLOSED) POSITION.

CHECK AND RETURN IGNITION SWITCH TO ON

POSITION BEFORE STARTING ENGINE AGAIN.

Page 14

What to do Just in Case

If you follow the normal starting procedure, you

should have no problem starting your

Tiller/Cultivator. But, just in case you do have

problems, here’s what to do.

Make sure the start/stop switch is on “start.” You’d be

surprised how many people forget to push the switch

into the “start” position.

If the switch was on “stop” when you pulled the cord,

you may have flooded the engine.

• First, examine the spark plug. Use a 3/4" (19 mm)

inch spark plug wrench.

• Remove the cap over the spark plug. (Picture 1)

IMPORTANT NOTE:

To avoid possible damage to the threads, do not try

to remove the plug from a hot aluminum cylinder

head.

• Unscrew the spark plug. (Picture 2)

Starting a Flooded Engine

1. If the end of the spark plug is wet, the engine may

be flooded. Make sure the switch is in the stop

position, disconnect spark plug wire and

remove plug. Use a paper towel or a clean rag

to dry the spark plug, then, with the spark

plug out of the engine, pull the starter cord

several times. Shake the fuel out of the inside of

the plug and air dry. Next, replace the spark

plug. Use the wrench to tighten it and replace the

cap. Next, put the switch in the start position and

pull the choke button out. Pull the starter cord

three or four times until the engine coughs or

sputters. Open the choke (push the choke button

in) and pull the cord a few times. The engine

should start and run.

2. If the end of the spark plug is dry, check to see if

the fuel line is blocked. The fuel line runs from

the fuel tank to the carburetor. Pull it off at the

carburetor end. Fuel should drip slowly from the

line. Wipe off any excess or spilled fuel.

If fuel does not drip from the line, check the line

for any bends or pinches. (Picture 3) Kinks in the

line restrict the flow of fuel to the engine. Just

straighten out the line. Reconnect. Then follow

the normal starting procedure.

If fuel drips too freely, the line may be

disconnected from the fuel filter. You’ll find the

fuel filter inside the fuel tank. Just re-attach the

line to the filter, and put the filter back in the tank.

Then follow the normal starting procedure.

WARNING DANGER

MAKE SURE THE START/STOP SWITCH IS

IN THE STOP POSITION.

KEEP PLUG WIRE AWAY FROM ENGINE TO

AVOID UNINTENTIONAL SPARK.

Picture 1 Picture 2

14

Page 15

15

What to do Just in Case cont.

Here’s Another Way to Start your REDMAX

Tiller/Cultivator

If you follow the steps above and your engine still

won’t start, try this:

1. Push the switch to “start.”

2. Move the choke lever to open the choke.

3. Press the plastic bubble a few times.

4. Give the starter cord a few short, quick pulls. The

engine should start and run.

5. If the engine does not start, then move the choke

lever to close the choke. Pull the starter cord four

to five times. The engine should sputter or cough.

6. After the engine sputters, push the choke button in.

Then pull the starter cord. The engine should start

and run.

7. If the engine still does not start, repeat steps 2

through 6.

IMPORTANT NOTE:

Never use starting fluids. Starting fluids will cause

permanent engine damage. Using them will void

the warranty.

IMPORTANT NOTE:

Before you use your REDMAX Tiller/Cultivator,

read the Safety Rules & Warnings on pages 4-7.

Tilling

Now You’re ready to Use Your REDMAX

Tiller/Cultivator.

If you’ve seen other Tiller/Cultivators, your REDMAX

Tiller/Cultivator may surprise you. It tills best when you

pull it backward! You see, when you pull your

REDMAX Tiller/Cultivator backward, you give extra

resistance to the tines, so they dig deeper.

What’s more when you go backward, you erase your

footprints, So your soil stays light and fluffy. With other

Tiller/Cultivators, by contrast, you walk right over the

soil you’ve just cultivated, packing it down, so it’s less

plantable.

Run Your REDMAX Tiller/Cultivator like a Vacuum

Cleaner.

Place your Tiller/Cultivator at the head of the row or

area you want to cultivate. Start it up. Then use an easy

rocking motion. First, pull your Tiller/Cultivator

backward. Then use an easy rocking motion. Again, pull

your Tiller/Cultivator backward. Then, let it move

forward just a little bit. Then pull it backward again.

This will help you cultivate deeper.

Keep repeating these steps until you’ve tilled an entire

row. Start again on the next row. It’s much like running a

vacuum cleaner! (Picture 2)

You Can Even Control Depth.

For Deeper Cultivating:

Move your Tiller/Cultivator slowly back and forth, as

you would a vacuum cleaner. Work the same area over

and over until you’ve dug to your desired depth.

For Shallow Cultivating:

Switch the tines to the cultivating position. (See page 16

to learn how.) Then move your Tiller/Cultivator quickly

over your soil surface.

For Big Weeds or Tough Roots:

Let your Tiller/Cultivator rock back and forth over the

tough spot, until the tines slice through the weed or root.

WARNING DANGER

THE OPERATOR OF THIS TILLER/CULTIVATOR IS

RESPONSIBLE FOR ACCIDENTS OR HAZARDS

OCCURRING TO HIMSELF, OTHER PEOPLE,

OR THEIR PROPERTY.

Page 16

Cultivating

How to Switch From Tilling to Cultivating Position

1. Make sure your Tiller/Cultivator is off.

2. Remove the retaining pins from the tines.

3. Remove the tines from the axle.

4. Place the right-side tine onto the left-side axle. Place the left side

tine onto the right-side axle. The “D” hole should be to the outside.

5. Here is how to make sure you’ve installed the tines properly. Stand

behind the Tiller/Cultivator and hold your hand, palm up, next to the

tines. Do the tine points curl up, as your fingers do? If so, they are in

the correct cultivating position.

6. Reinsert the pins.

WARNING DANGER

IF YOUR TINES GET JAMMED OR ENTANGLED,

SHUT OFF THE ENGINE AT ONCE.

REMOVE THE OBSTRUCTION WHILE THE

ENGINE IS OFF.

NEVER TRY TO REMOVE AN OBSTRUCTION

WHILE THE ENGINE IS RUNNING. SERIOUS

INJURY CAN RESULT.

Now You’re Ready to Cultivate or Weed.

Guide your Tiller/Cultivator where you want to weed and start it up. Pull

your Tiller/Cultivator backward slowly, then let it move forward a bit, in a

gentle rocking motion. Watch it slice, shred, and bury those weeds!

Got tough weeds? Lighten your pressure on the throttle to slow your

Tiller/Cultivator down. Then work back and forth until your

Tiller/Cultivator chops up the weeds. It’s easy and effective!

Remember, any Tiller/Cultivator will tangle in tall grass, stringy vines, or

super-big weeds. So, if you have a “backyard jungle,” first use a knife,

pruner, or brush cutter to chop up the overgrowth. If the tines become

tangled anyway, turn the engine off completely before trying to clear

them.

Tilling Position

Tine teeth point in the same direction as the rotation of the tine; or toward

the front of the Tiller/Cultivator, away from the operator.

Cultivating Position

Tine teeth point in the opposite direction as the rotation of the tine. Tines

point toward the back of the Tiller/Cultivator, or toward the operator.

Back Front

Tine

Rotation

Tine

Teeth

Back Front

Tine

Rotation

Tine

Teeth

16

Page 17

17

Maintenance

How to Check, Clean and Change the Air Filter

Check the air filter every 25 hours of use or more frequently if used

under dusty conditions. A clogged air filter may increase fuel

consumption while cutting down the engine power. Never operate the

blower without the air filter or with a deformed filter element because

unfiltered dusty air will quickly ruin the engine.

Cleaning air filter

1. Remove the air cleaner cover by pulling the tab on side and take out

the 2 filter element.

2. Use neutral detergent and warm water to clean the filter elements.

After cleaning, air dry the element completely and moisten with a

small amount of motor oil.

3. Place the filter element into the air cleaner housing and press the

cover against the housing until it clicks.

Idle Speed Adjustment

1. Warm up engine before adjusting idle speed.

2. The idle speed adjustment screw controls the throttle opening at idle

position.

3. When the engine tends to stop frequently at idling mode, turn the

adjusting screw clock wise.

4. If the tines continue to rotate after releasing the trigger, turn the

adjusting screw counter-clockwise.

Clear Blockages From the Fuel Line & Filter

After you’ve used your Tiller/Cultivator for a few seasons, check for

blockages in the fuel tank and fuel filter. Such blockages can keep your

Tiller/Cultivator from starting.

Clear any blockages you see in the tank, fuel filter, or fuel line.

Remember: The fuel filter is located inside the tank. (See Picture 3)

Then use the normal starting procedure to start your Tiller/Cultivator.

Spark Plug

1. Starting failure and mis-firing are often caused by a fouled spark

plug. Clean the spark plug and check the that the plug gap is in the

correct range. (Picture 4) (.025., 0.65 mm)

2. CAUTION: Do not over tighten the spark plug. To install the spark

plug first turn the plug until it is finger tight, then tighten it a quarter

turn more with a socket wrench.

3. For a replacement plug, use the correct type specified by RedMax.

The replacement plug is Champion RCJ6Y (5602-73110)

Picture 1

Picture 2

Picture 3

Picture 4

Page 18

How to Reseat the Flange

At some point, you may find that the tines won’t turn when you press

the throttle. This may mean the engine isn’t sitting all the way down on

the worm-gear housing.

Perhaps you’ve been using your Tiller/Cultivator for several years. The

flange bolt (Key #22) may have come loose and lifted the engine up.

If this happened you’ll notice a gap between the bottom of the engine

flange (Key #24) and the top of the wormgear housing. (Picture 1)

To fix this, loosen the flange bolt. Take the engine off the wormgear

housing. Notice the hex head on top of the drive shaft (Key #28). Inside

the flange housing, you’ll find the clutch drum (Key #25). Make sure

the hex head lines up with the clutch drum inside the flange housing.

Then put the engine back on the wormgear housing. Make sure the

plastic carrying handle is not under the fuel tank.

If you’ve followed these steps properly, there will be no gap between the

engine flange and the wormgear housing. (Picture 2) Make sure you

tighten the flange bolt!

How to Check the Grease Level Inside

the Worm-Gear Housing

When we built your REDMAX Tiller/Cultivator, we lubricated the

worm-gear housing thoroughly.

It is imperative that you inspect the grease level once a year. Simply

remove the cover plate on the worm-gear housing. (Picture 1) Then

check to make sure the grease comes almost to the top of the housing. If

it doesn’t, add lithium #0 grease. This is the only way to add grease to

the worm-gear housing. (Picture 3) To purchase grease, contact your

local authorized REDMAX dealer.

Please do not overfill. Too much grease can create pressure, which

could cause seals to fail or the clutch to slip.

Maintenance cont.

Picture 1

Picture 2

Picture 3

18

Page 19

19

Muffler

• Inspect periodically, the muffler for loose fasteners,

any damage or corrosion. If any sign of exhaust

leakage is found, stop using the machine and have it

repaired immediately.

• Note that failing to do so may result in the engine

catching on fire.

Spark Arrester

• The muffler is equipped with a spark arrester to

prevent red hot carbon from flying out of the

exhaust outlet. Periodically inspect and clean as

necessary with a wire brush. In the State of

California it is required by law (Section 4442 of the

California Public Resources Code) to equip a spark

arrester when a gas powered tool is used in any

forest covered, brush covered, or grass covered

unimproved land.

Intake Air Cooling Vent

• Never touch the cylinder, muffler, or spark plugs

with your bare hands immediately after stopping the

engine. The engine can become very hot when in

operation, and doing so could result in severe burns.

• When checking the machine to make sure that it is

okay before using it, check the area around the

muffler and remove any debris. Failing to do so

could cause the muffler to become overheated, and

that this in turn could cause the engine to catch on

fire. Always make sure that the muffler is clean and

free of debris before use.

• Check the intake air cooling vent and the area

around the cylinder cooling fins after every 25

hours of use for blockage. Note that it is necessary

to remove the engine cover in order to view the

upper part of the cylinder.

1. Remove the muffler, insert a screwdriver into the

vent, and wipe away any carbon buildup. Wipe

away any carbon buildup on the muffler exhaust

vent and cylinder exhaust port at the same time.

2. Tighten all screws, bolts, and fittings.

3. Check to see if any oil or grease has worked its way

in between the clutch lining and drum, and if it has,

wipe it away using oil-free, lead-free gasoline.

Maintenance cont.

WARNING DANGER

IF WASTE GETS STUCK AND CAUSES

BLOCKAGE AROUND THE INTAKE AIR

COOLING VENT OR BETWEEN THE CYLINDER

FINS, IT MAY CAUSE THE ENGINE TO

OVERHEAT, AND THAT IN TURN MAY

CAUSE MECHANICAL FAILURE ON THE

PART OF THE TILLER/CULTIVATOR.

Picture 1

Picture 2

Procedures to be Performed After Every 100 Hours of Use

Page 20

20

System/ Component

Fuel Leaks, Fuel

Spillage

Fuel Tank, Air Filter,

Fuel Filter

Idle Adjusting Screw

Spark Plug

Cylinder Fins, Intake

Air Cooling Vent

Muffler, Spark

Arrester, Cylinder

Exhaust Port

Procedure

Wipe out

Inspect, clean

see Adjusting

Idling Speed

(pg. 9)

Clean and

readjust plug gap

Clean

Clean

Before

Use

Every 25

Hours

Every 50

Hours

Every 100

Hours

Note

Replace if

necessary

Replace

carburetor if

necessary

GAP: .025"

(0.6 - 0.7 mm)

replace if

necessary

IMPORTANT: Time intervals shown are maximum. Actual use and your experience will determine the frequency of

required maintenance.

ENGINE

Maintenance cont.

Page 21

21

Storage

Each fall — or before you store your REDMAX

Tiller/Cultivator for any long period — be sure to

take these measures:

1. Do not store your Tiller/Cultivator with fuel still

in it. Even under ideal conditions, stored fuel

containing ethanol or MTBE can start to go stale

in 30 days. And, since stale fuel has a high gum

content, it can clog the carburetor, this, in turn,

will restrict fuel flow. So, when you’re ready to

store your Tiller/Cultivator, or will not be

using it for more than 2 weeks, drain the fuel

tank completely.

2. Next, restart the engine to make sure no fuel is

left in the carburetor. Then run the engine until it

stops. This will prevent gum deposits, forming

inside of the carburetor and possible engine

damage.

3. Disconnect spark plug wire and remove the spark

plug. (Use a 19mm or 3/4" spark-plug wrench.)

Pour about a teaspoon of clean, air-cooled, twocycle oil through the spark-plug hole into the

combustion chamber. Slowly pull the starter cord

two or three times to coat the inside of the

cylinder wall.

4. Inspect the spark plug, and, if necessary, clean it.

If you need to replace it, buy a Champion

RCJ6Y (5602-73110)

5. Install the spark plug, but leave the spark plug

wire disconnected.

6. Clean the air filter as described on page 17.

7. Clean dirt, grass, and other materials from the

entire machine.

8. Wipe the tines with oil or spray them with WD40, to prevent rusting.

9. Oil the throttle cable and all visible moving parts.

(Do not remove the engine cover.)

10. Check the grease level in the wormgear housing,

as described on page 18.

11. Order new parts to replace any that are badly

worn or broken. Just contact your local

authorized REDMAX dealer. But do it early, so

you’ll have the parts well before the next

gardening season starts.

12. Store your Tiller/Cultivator — in an upright

position — in a clean, dry place.

13. Do you have fuel left over from last season?

Dispose of it properly. Buy fresh oil and gasoline

next season.

How to Prepare Your REDMAX Tiller/Cultivator

for Restarting

In the Spring, when you take your Tiller/Cultivator

out of storage, remove the spark plug. Pull the starter

cord three or four times to clean oil from the

combustion chamber. Wipe oil from the spark plug.

Place the spark plug back into the cylinder. Reconnect the spark plug wire back on the spark plug.

Then follow the steps on pages 12 to refuel and

restart your Tiller/Cultivator.

Again, Check the Carburetor.

If your Tiller/Cultivator won’t restart in the Spring

— or if it lacks its usual power — the carburetor

may need attention.

Check the Spark Plug Too.

If your Tiller/Cultivator won’t restart, or if it lacks

full power, the spark plug may be at fault. Check to

see if the plug is fouled with oily black deposits.

Clean or replace it if it is.

Also, check whether the center electrode is rounded

at the end, or if the ground electrode is worn. If

either is the case, you should replace it with a

Champion RCJ6Y spark plug. Use a 19mm or a 3/4"

spark-plug wrench to install it. Adjust the plug gap to

.025 in. (0.65 mm)

To Install the spark plug first turn the plug until it is

finger tight, then tighten it a quarter turn more with a

socket wrench.

IMPORTANT NOTE:

To avoid possible damage to the threads, do not

try to remove the plug from a hot aluminum

cylinder head.

Page 22

Check

Fuel Tank

Fuel Filter

Carburetor Adjustment Screw

Sparking (no spark)

Spark Plug

Probable Causes

Incorrect fuel

Fuel filter is clogged

Out of normal range

Spark plug is fouled/ wet

Plug gap is incorrect

Disconnected

Action

Drain it and fill with correct fuel

Clean

Adjust to normal range

Clean/ dry

Correct (GAP: 0.6 ~ 0.7 mm)

Retighten

When your unit seems to need further service, please consult with our RedMax service shop in your area.

Troubleshooting Guide

Case 1. Starting failure

Check

Fuel Tank

Carburetor Adjustment Screw

Muffler, Cylinder (exhaust port)

Air Cleaner

Cylinder Fin, Fan Cover

Probable Causes

Incorrect fuel

Out of normal range

Carbon is built-up

Clogged with dust

Clogged with dust

Action

Drain it and fill with correct fuel

Adjust to normal range

Wipe away

Wash

Clean

Case 2. Engine starts but does not keep running/ hard re-starting.

22

Page 23

23

Parts List

NOTE :

1. Use REDMAX genuine parts as specified in the parts list for repair and/or replacement.

2. REDMAX does not warrant the machines, which have been damaged by the use of any parts other than

those specified by the company.

3. When placing parts orders for repair and/or replacement, check if the model name and the serial number

are applicable to those specified in the parts list, then use parts number described in the parts list.

4. The contents described in the parts list may change due to improvement.

5. The parts for the machine shall be supplied seven (7) years after the machine is discontinued. [It is

possible that some specific parts may be subject to change of their delivery term and list price within the

limit of seven (7) years after the machine is discontinued. It is also possible that some parts may be

available even after the limit of seven (7) years.]

CV225

Tiller/Cultivator

Page 24

24

RedMax Cultivator Assembly

21

7

8

47

61

62

63

6

51

54

50-A

60

64

52

48

42

53

48

4

13

13

50

46

55

5

20

50-P

50-O

50-Q

50-B

50-M

50-F

50-G

50-R

50-K

50-O

50-H

50-L

50-I

50-J

50-P

50-Q

50-N

44

41

50-C

50-D

41

40

39

50-E

Page 25

Key# Part Number Q'ty Description

4 400255 1 Upper Handle

5 400260 1 Upper Handle Throttle Side

6 400224 2 Lower Handle

7 400613 1 Brace Label

8 148 1 Handle Brace

13 478 2 Throttle Clip

20 465 1 Fender Guard

21 1 Engine Assembly

39 400210 1 Tine Assembly - LT

40 400211 1 Tine Assembly - RT

41 418-1 2 Tine Retaining Hair Pin

42 400133 1 Carrying Handle

44 400609 1 Tine Label

46 400615 1 RedMax Label

47 410 2 Bolt 1/4-20 x 1

48 972 4 Lock Nut 1/4-20

50 400010 1 Transmission w/ Drive Shaft

50-A 468 1 Drive Shaft

50-B 466 1 Worm Gear Housing

50-C 436 1 Gasket

50-D 437A 1 Housing Cover

50-E 651 4 Rd. Hd Self Tapping Screw

50-F 423 1 Roller Bearing

50-G 425 2 Worm Bearing Race

50-H 424 1 Worm Thrust Bearing

50-I 422 1 Worm Shaft

50-J 426 1 Worm Disk

50-K 428 1 Retaining Ring

50-L 429 1 Worm Gear

50-M 431 1 Tine Shaft

50-N 430 2 Worm Gear Thrust Washer

50-O 432 2 Worm Gear Bearing

50-P 434 2 Bearing Seal

50-Q 435 2 Bearing Seal Retainer

50-R 458 1 Roller Bearing

51 377 2 Handle Clamp

52 400509 2 Capscrew 1/4-20 x 1” lg

53 400523 2 Lock Nut 1/4-20

54 4049 2 1/4-20 x 3 1/4” Bolt

55 140 2 Bolt 1/4-20 x 3/8”

60 400131 1 Clutch Drum

61 400132 1 Bearing

62 400130 1 Transmission Adapter

63 910502 1 10-32 x 3/4 Flange Bolt

64 400511 4 M6 x 12 Flange Bolt

25

REDMAX CULTIVATOR ASSEMBLY

Page 26

26

Engine Unit CV225 (S/N 108000 and up)

Page 27

27

Engine Unit CV225 (S/N 108000 and up)

Key# Description Part Number Q'ty

1 CYLINDER 5580-12110 1

2 GASKET, base 5500-12213 1

3 BOLT 1850-12130 2

4 PLUG RCJ-6Y 5602-73110 1

5 CRANKCASE-C 5500-21100 1

6 • PIN 2629-21130 3

7 GASKET 5500-21141 1

8 BEARING 06030-06001 2

9 SEAL 2169-21210 1

10 SEAL 1850-21220 1

11 SNAP RING 04065-02812 1

12 BOLT 01252-30530 3

13 GUARD 5500-22110 1

14 SCREW 0263-90514 1

15 CRANKSHAFT-C 5500-42001 1

16 PISTON 5600-41111 1

17 RING 1100-41210 2

18 PIN 1101-41310 1

19 RING 1260-41320 2

20 BEARING 5500-41410 1

21 WASHER 1101-41340 2

22 MUFFLER ASSY T1702-15100 1

23 ARRESTER 1601-15120 1

24 BOLT 01252-30550 2

25 GASKET T1600-15210 1

26 PLATE 5500-15221 1

27 SCREW 0263-90416 1

28 INSULATOR T1700-13160 1

29 GASKET, insulator 5500-13121 1

30 GASKET, carburetor 5500-13131 1

31 SCREW 0263-90520 2

32 CARBURETOR ASS'Y T1723-81000 1

33 • BODY ASS'Y 1850-81450 1

34 • • SCREEN 3306-81380 1

35 • • VALVE 3356-81310 1

36 • • SPRING 1850-81270 1

37 • • SCREW 1850-81220 1

38 • • PIN 3310-81250 1

39 • • LEVER 3310-81230 1

40 • BODY, purge 1850-81490 1

41 • COVER, pump 1850-81520 1

42 • PUMP, priming 1751-81510 1

43 • DIAPHRAGM 3310-81260 1

44 • GASKET, diaphragm 1850-81470 1

45 • DIAPHRAGM, pump 1065-81420 1

46 • GASKET, pump 1065-81410 1

47 • JET 5500-81251 1

48 • RING 1751-81240 1

49 • RING 1751-81130 1

50 • SWIVEL 1881-81140 1

52 • SCREW 1752-81110 2

53 • BRACKET 5500-81120 1

55 • RING 1881-81130 1

56 • SCREW 1850-81530 4

57 • WASHER 5500-81160 1

58 AIR CLEANER ASS'Y 1918-82001 1

59 • COVER 1918-82110 1

60 • FILTER 1918-82120 2

Key# Description Part Number Q'ty

61 • HOUSING 1918-82130 1

62 • PLATE 1918-82140 1

63 • CHOKE VALVE 1918-82150 1

64 • WASHER 1918-82160 1

65 • SLEEVE 1918-82170 2

66 • SCREEN 1918-82180 1

67 SCREW 0263-90560 2

68 COVER, fan T1815-31110 1

69 CLAMP T1600-72210 1

79 SCREW 0263-90520 4

80 COVER, engine T1815-32110 1

81 SCREW T1700-32162 1

82 SCREW 0263-90510 1

83 SHOE T1700-51110 2

84 SPRING T1700-51220 1

85 SCREW 1140-51250 2

86 WASHER 1140-51230 2

87 WASHER 1970-51241 2

88 ROTOR T1700-71110 1

89 COIL-A T1700-71201 1

90 • CAP 5500-72110 1

91 • CORD T1700-71220 1

92 • CAP 2616-71320 1

93 • GROMMET 5500-72130 1

94 • SPRING 5500-72120 1

95 BOLT 3310-72150 2

96 SPACER T1700-71260 2

97 CORD-C T1700-73200 1

98 NUT 1650-43230 1

99 KEY 1000-43240 1

100 RECOIL ASS'Y T1700-75100 1

101 • CASE-C 5500-75110 1

102 • REEL 1850-75120 1

103 • SPRING 1850-75130 1

104 • SCREW 1850-75151 1

105 • ROPE T1600-75160 1

106 • KNOB T1600-75310 1

107 • COLLAR T1600-75321 1

108 • SPRING T1600-75330 1

109 • WASHER T1600-75210 1

110 PULLEYASS'Y 1850-75201 1

111 • RATCHET 1850-75221 1

112 • SPRING 1850-75230 1

113 SCREW T1700-32162 4

114 TANK ASS'Y T1700-85001 1

115 • CAP ASS'Y 5607-85201 1

116 • • HOLDER ASS'Y 5601-85300 1

117 • • PACKING 5500-85220 1

118 • • FILTER 5601-85260 1

119 • • STOPPER 4820-85260 1

120 • PIPE-C 5500-85300 1

121 • FILTER ASS'Y 5500-85400 1

122 • CLIP 1260-85460 1

123 SCREW 5910-85510 1

124 CLIP 1950-86120 1

125 SCREW 5500-85510 2

126 LABEL, recoil T1716-31120 1

Page 28

28

EMISSION-RELATED PARTS, FOR TWO (2) YEARS FROM THE DATE OF ORIGINAL DELIVERY OF THE MODEL

CV225 UNIT, KOMATSU ZENOAH AMERICA INC. (THE COMPANY),THROUGH ANY RedMax DEALER, WILL

REPAIR OR REPLACE, FREE OF CHARGE, FOR THE ORIGINAL AND EACH SUBSEQUENT PURCHASER, ANY

PART OR PARTS FOUND TO BE DEFECTIVE IN MATERIAL AND/OR WORKMANSHIP. EMISSION-RELATED

PARTS ARE:

THE CARBURETOR ASSY, COIL ASSY, ROTOR, SPARKPLUG,

AIR FILTER, FUEL FILTER, INTAKE MANIFOLD, AND THE GASKETS

ALL OTHER PARTS EXCEPT ABOVE PARTS, FOR TWO (2) YEARS OF HOME USE [ ONE (1) YEAR FOR ANY

OTHER USE ] FROM THE DATE OF ORIGINAL ANY DELIVERY OF THE MODEL CV225 UNIT, THE COMPANY,

THROUGH ANY RedMax DEALER, WILL REPAIR OR REPLACE, FREE OF CHARGE, FOR THE ORIGINAL

PURCHASER, ANY PART OF PARTS FOUND TO BE DEFECTIVE IN MATERIAL AND/OR WORKMANSHIP. THIS IS

THE EXCLUSIVE REMEDY.

THE PURCHASER SHALL BEAR COSTS OF TRANSPORTING THE UNIT TO AND FROM THE RedMax DEALER.

THE PURCHASER SHALL NOT BE CHARGED FOR DIAGNOSTIC LABOR WHICH LEADS TO THE

DETERMINATION THAT A WARRANTED PART IS DEFECTIVE, IF THE DIAGNOSTIC WORK IS PERFORMED AT

THE RedMax DEALER. THE PURCHASER OR OWNER IS RESPONSIBLE FOR THE PERFORMANCE OF THE

REQUIRED MAINTENANCE AS DEFINED BY THE MANUFACTURER IN THE OWNER/OPERATOR MANUAL.

ANY WARRANTED PART WHICH IS NOT SCHEDULED FOR REPLACEMENT AS REQUIRED MAINTENANCE, OR

WHICH IS SCHEDULED ONLY FOR REGULAR INSPECTION TO THE EFFECT OF "REPAIR OR REPLACE AS

NECESSARY" SHALL BE WARRANTED FOR THE WARRANTY PERIOD.ANY WARRANTED PART WHICH IS

SCHEDULED FOR REPLACEMENT AS REQUIRED MAINTENANCE SHALL BE WARRANTED FOR THE PERIOD

OF TIME UP TO THE FIRST SCHEDULED REPLACEMENT POINT FOR THE PART.

ANY REPLACEMENT PART THAT IS EQUIVALENT IN PERFORMANCE AND DURABILITY MAY BE USED IN

NONWARRANTY MAINTENANCE OR REPAIRS, AND SHALL NOT REDUCE THE WARRANTY OBLIGATION OF

THE COMPANY.

THE COMPANY IS LIABLE FOR DAMAGES TO OTHER ENGINE COMPONENTS CAUSED BY THE FAILURE OF A

WARRANTED PARTS STILL UNDER WARRANTY.

THE WARRANTY DOES NOT APPLY TO THOSE UNITS WHICH HAVE BEEN DAMAGED BY NEGLIGENCE OF

INSTRUCTION LISTED IN THE OWNER/OPERATOR MANUAL FOR PROPER USE AND MAINTENANCE OF THE

UNITS, ACCIDENT MISHANDLING, ALTERATION, ABUSE, IMPROPER LUBRICATION, USE OF ANY PARTS OR

ACCESSARIES OTHER THAN THOSE SPECIFIED BY THE COMPANY, OR OTHER CAUSES BEYOND THE

COMPANY'S CONTROL.

THIS WARRANTY DOES NOT COVER THOSE PARTS REPLACED BY NORMAL WEAR OR HARMLESS CHANGES

IN THEIR APPEARANCE.

THERE ARE NO OTHER EXPRESS WARRANTIES.

IMPLIED WARRANTIES INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE LIMITED TO TWO (2) YEARS OF HOME USE [ ONE (1) YEAR FOR ANY OTHER USE ] FROM THE

ORIGINAL DELIVERY DATE.

LIABILITIES FOR INCIDENTAL OR CONSEQUENTIAL DAMAGE UNDER ANY AND ALL WARRANTIES ARE

EXCLUDED.

SOME STATES DO NOT ALLOW LIMITATION ON HOW LONG AN IMPLIED WARRANTY LASTS OR EXCLUSION

OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIONS OR

EXCLUSION MAY NOT APPLY TO YOU.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH

VARY FROM STATE TO STATE.

IF YOU NEED TO OBTAIN INFORMATION ABOUT THE NEAREST SERVICE CENTER, PLEASE CALL KOMATSU

ZENOAH AMERICA INC. AT (770)-381-5147.

IMPORTANT: You will receive a warranty registration card at time of purchase. Pease fill out the card and send it to RedMax

/ Komatsu Zenoah America Inc. within seven (7) days. Be sure to keep a copy for your records.

REDMAX Mini Tiller/Cultivator CV225 2 -Year

Limited Warranty

Page 29

29

Pièces en rapport avec les émissions de gaz d'échappement : KOMATSU ZENOAH AMERICA INC., par

l'intermédiaire de n'importe quel revendeur RedMax, réparera gratuitement ou remplacera gratuitement pour

l'acheteur initial et chaque acheteur successif toute(s) pièce(s) se révélant de constitution et/ou de montage

défectueux pendant deux (2) ans à compter de la date initiale de livraison d’une unité du modèle CV225. Les pièces

en rapport avec les émissions de gaz d'échappement sont:

l'assemblage carburateur, l'assemblage bobine, le rotor, la bougie, le filtre à air, le filtre à carburant, la tubulure

d'admission et les joints Toutes autres pièces exceptées celles mentionnées ci-dessus :

La société, par l'intermédiaire de n'importe quel revendeur RedMax, réparera gratuitement ou remplacera

gratuitement pour l'acheteur initial toute(s) pièce (s) se révélant de constitution et/ou de montage défectueux pendant

deux (2) ans en cas d’utilisation privée [un (1) an pour toute autre utilisation] à compter de la date de livraison

initiale d’une unité du modèle CV225. Telles sont les limites de la garantie.

Le coût du transport de l'unité jusqu'au revendeur RedMax et depuis celui-ci sera à la charge de l'acheteur.

L'acheteur ne supportera pas le coût de main d'oeuvre du diagnostic qui amène à la conclusion qu'une pièce garantie

est défectueuse, si ce diagnostic est effectué chez le revendeur RedMax.

L’acheteur ou propriétaire a pour responsabilité d’effectuer l’entretien obligatoire tel que défini par le fabricant dans

le manuel du propriétaire/de l'utilisateur.

Toute pièce garantie dont le remplacement n'est pas prévu dans le cadre de l’entretien obligatoire, ou pour laquelle

est seulement prévue une inspection périodique pour "remplacement ou réparation si nécessaire" sera garantie pour

la période de garantie. Toute pièce garantie arrivée à l’échéance de son premier remplacement prévu sera garantie

jusqu’à celui-ci.

Toute pièce de rechange équivalente en performance ou en durabilité peut être utilisée pour l’entretien hors-garantie

ou les réparations hors-garantie, et ce sans réduire l’obligation de garantie incombant à la société.

La société sera tenue responsable des dommages aux autres composants du moteur causés par la défaillance de

pièce(s) garantie(s) en période de garantie.

La garantie ne s'applique pas aux unités endommagées par suite de: négligence dans la mise en oeuvre des

instructions spécifiées dans le manuel du propriétaire/de l'utilisateur en vue d’une utilisation et d’un entretien

correct, fausse manœuvre accidentelle, modification, utilisation abusive, lubrification incorrecte, utilisation de pièces

ou d’accessoires autres que ceux spécifiés par la société, ou autres causes hors du contrôle de la société.

Cette garantie ne couvre pas les pièces remplacées en raison de leur usure normale ou de changements

d’apparence sans effets.

Il n'existe aucune autre garantie explicite.

Les garanties implicites, celles de négociabilité du produit et de son adaptabilité à un usage défini incluses, sont

limitées à deux (2) ans pour un usage privé [un (1) an pour toute autre utilisation] à compter de la date initiale de

livraison.

Les responsabilités pour les dommage conséquents ou incidents sont exclues de toutes les garanties.

Certaines provinces n'autorisant pas les limitations à la durée des garanties implicites, ou les exclusions ou

limitations relatives aux dommages incidents ou conséquents, la limitation indiquée ci-dessus peut ne pas vous être

applicable.

Cette garantie vous donne des droits juridiques spécifiques, et vous pouvez également jouir d’autres droits variant

d'une province à l'autre.

Si vous désirez obtenir des informations sur le centre de service le plus proche, veuillez appeler KOMATSU

ZENOAH AMERICA INC. au (770)-381-5147

Note importante: vous recevrez une carte d'enregistrement de garantie au moment de l'achat. Veuillez la remplir et

l'adresser à RedMax / KOMATSU ZENOAH AMERICA sous sept (7) jours en prenant soin de conserver une copie

pour vous.

REDMAX Mini Tiller/Cultivator Modèle CV225 Garantie limitée à 2 ans

Page 30

30

THE CALIFORNIA AIR RESOURCES BOARD AND KOMATSU ZENOAH Co. ARE PLEASED

TO EXPLAIN THE EMISSION CONTROL SYSTEM WARRANTY ON YOUR 1995 AND LATER

LAWN AND GARDEN EQUIPMENT ENGINE. IN CALIFORNIA, NEW UTILITY AND LAWN

AND GARDEN EQUIPMENT ENGINES MUST BE DESIGNED, BUILT AND EQUIPPED TO

MEET THE STATE'S STRINGENT ANTI-SMOG STANDARDS. KOMATSU ZENOAH Co, MUST

WARRANT THE EMISSION CONTROL SYSTEM ON YOUR LAWN AND GARDEN

EQUIPMENT ENGINE FOR THE PERIODS OF TIME LISTED BELOW PROVIDED THERE HAS

BEEN NO ABUSE, NEGLECT OR IMPROPER MAINTENANCE OF YOUR LAWN AND

GARDEN EQUIPMENT ENGINE. YOUR EMISSION CONTROL SYSTEM MAY INCLUDE

PARTS SUCH AS THE CARBURETOR, THE IGNITION SYSTEM, AND CATALYTIC

CONVERTER. ALSO INCLUDED MAY BE THE HOSES, BELTS, CONNECTORS AND OTHER

EMISSION-RELATED ASSEMBLIES. WHERE A WARRANTABLE CONDITION EXISTS,

KOMATSU ZENOAH Co. WILL REPAIR YOUR LAWN AND GARDEN EQUIPMENT ENGINE AT

NO COST TO YOU INCLUDING DIAGNOSIS, PARTS AND LABOR.

MANUFACTURER'S WARRANTY COVERAGE:

THE 1995 AND LATER UTILITY AND LAWN AND GARDEN EQUIPMENT ENGINES ARE

WARRANTED FOR TWO YEARS. IF ANY EMISSION-RELATED PART ON YOUR ENGINE IS

DEFECTIVE, THE PART WILL BE REPAIRED OR REPLACED BY KOMATSU ZENOAH Co.

OWNER'S WARRANTY RESPONSIBILITIES:

— AS THE LAWN AND GARDEN EQUIPMENT ENGINE OWNER, YOU ARE RESPONSIBLE

FOR THE PERFORMANCE OF THE REQUIRED MAINTENANCE LISTED IN YOUR

OWNER'S MANUAL. KOMATSU ZENOAH Co. RECOMMENDS THAT YOU RETAIN ALL

RECEIPTS COVERING MAINTENANCE ON YOUR LAWN AND GARDEN ENGINE, BUT

KOMATSU ZENOAH Co. CAN NOT DENY WARRANTY SOLELY FOR THE LACK OF

RECEIPTS OR FOR YOUR FAILURE TO ENSURE THE PERFORMANCE OF ALL

SCHEDULED MAINTENANCE.

— AS THE LAWN AND GARDEN EQUIPMENT ENGINE OWNER, YOU SHOULD HOWEVER

BE AWARE THAT KOMATSU ZENOAH Co. MAY DENY YOU WARRANTY COVERAGE IF

YOUR LAWN AND GARDEN EQUIPMENT ENGINE OR A PART HAS FAILED DUE TO

ABUSE, NEGLECT, IMPROPER MAINTENANCE OR UNAPPROVED MODIFICATION.

— YOU ARE RESPONSIBLE FOR PRESENTING YOUR LAWN AND GARDEN EQUIPMENT

ENGINE TO A KOMATSU ZENOAH Co. DISTRIBUTION CENTER AS SOON AS A

PROBLEM EXISTS. THE WARRANTY REPAIRS SHOULD BE COMPLETED IN A

REASONABLE AMOUNT OF TIME, NOT TO EXCEED 30 DAYS.

IF YOU HAVE ANY QUESTIONS REGARDING YOUR WARRANTY RIGHTS AND

RESPONSIBILITIES,YOU SHOULD CONTACT KOMATSU ZENOAH AMERICA INC. AT (770)381-5147. CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT YOUR WARRANTY

RIGHTS AND OBLIGATIONS

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

Page 31

P/N 401755

6/07

Loading...

Loading...