Page 1

OWNER'S/OPERATOR'S

MANUAL

MODE D’EMPLOI MANUAL DE

INSTRUCCIONES

HEDGE TRIMMER

TAILLEUSE DE HAIES

CORTASETOS

848-D16-93A0 (901)

APPLICABLE SERIAL NUMBERS :

90100101 and up

NUMEROS DE SERIE APPLICABLES :

90100101 et au-delà

NÚMEROS DE SERIE APLICABLES:

90100101 y superior

WARNING

The engine exhaust from this

product contains chemicals

known to the State of California to

cause cancer, birth defects or

other reproductive harm.

WARNING

AVERTISSEMENT

AVERTISSEMENT

ADVERTENCIA

ADVERTENCIA

Before using our products,

please read this manual carefully

to understand the proper use of

your unit.

Los gases de escape del motor de

este producto contienen

sustancias químicas conocidas

por el Estado de California como

causantes de cáncer,

malformaciones en recién nacidos

y otros problemas de

reproducción.

Les échappements du moteur de

ce produit contiennent des

produits chimiques connus par

l’Etat de Californie comme étant

responsables de cancers,

d’anomalies congénitales et

d’autres atteintes à l’appareil

reproducteur.

Antes de usar nuestros productos,

lea detenidamente este manual a

fin de familiarizarse con el uso

correcto de este aparato.

Avant d’utiliser cette

ce produit

,

veuillez lire attentivement ce

manuel afin de bien comprendre le

bon fonctionnement de cet

appareil.

CHT2250

U

S

F

R

E

S

Page 2

Page 3

US-1

CHT2250

U

S

OWNER'S/OPERATOR'S

MANUAL

HEDGE TRIMMER

848-D16-93A0 (901)

APPLICABLE SERIAL NUMBERS :

90100101 and up

WARNING

The engine exhaust from this

product contains chemicals

known to the State of California to

cause cancer, birth defects or

other reproductive harm.

WARNING

Before using our products,

please read this manual carefully

to understand the proper use of

your unit.

CHT2250

Page 4

US-2

CHT2250

SAFETY FIRST

Instructions contained in warnings within this

manual marked with a symbol concern critical

points which must be taken into consideration to

prevent possible serious bodily injury, and for this

reason you are requested to read all such

instructions carefully and follow them without fail.

■ WARNINGS IN THE MANUAL

This mark indicates instructions which must be followed

in order to prevent accidents which could lead to serious

bodily injury or death.

This mark indicates instructions which must be followed,

or it leads to mechanical failure, breakdown, or damage.

This mark indicates hints or directions useful in the use

of the product.

NOTE

1. Parts location......................................................................3

2. Specifications .....................................................................3

3. Warning labels on the machine ..........................................4

4. Symbols on the machine ....................................................4

5. For safe operation ..............................................................5

6. Fuel.....................................................................................8

7. Operation..........................................................................10

8. Maintenance .....................................................................12

9. Storage .............................................................................14

10. Disposal............................................................................14

11. Troubleshooting guide ......................................................14

Contents

WARNING

IMPORTANT

Page 5

US-3

CHT2250

U

S

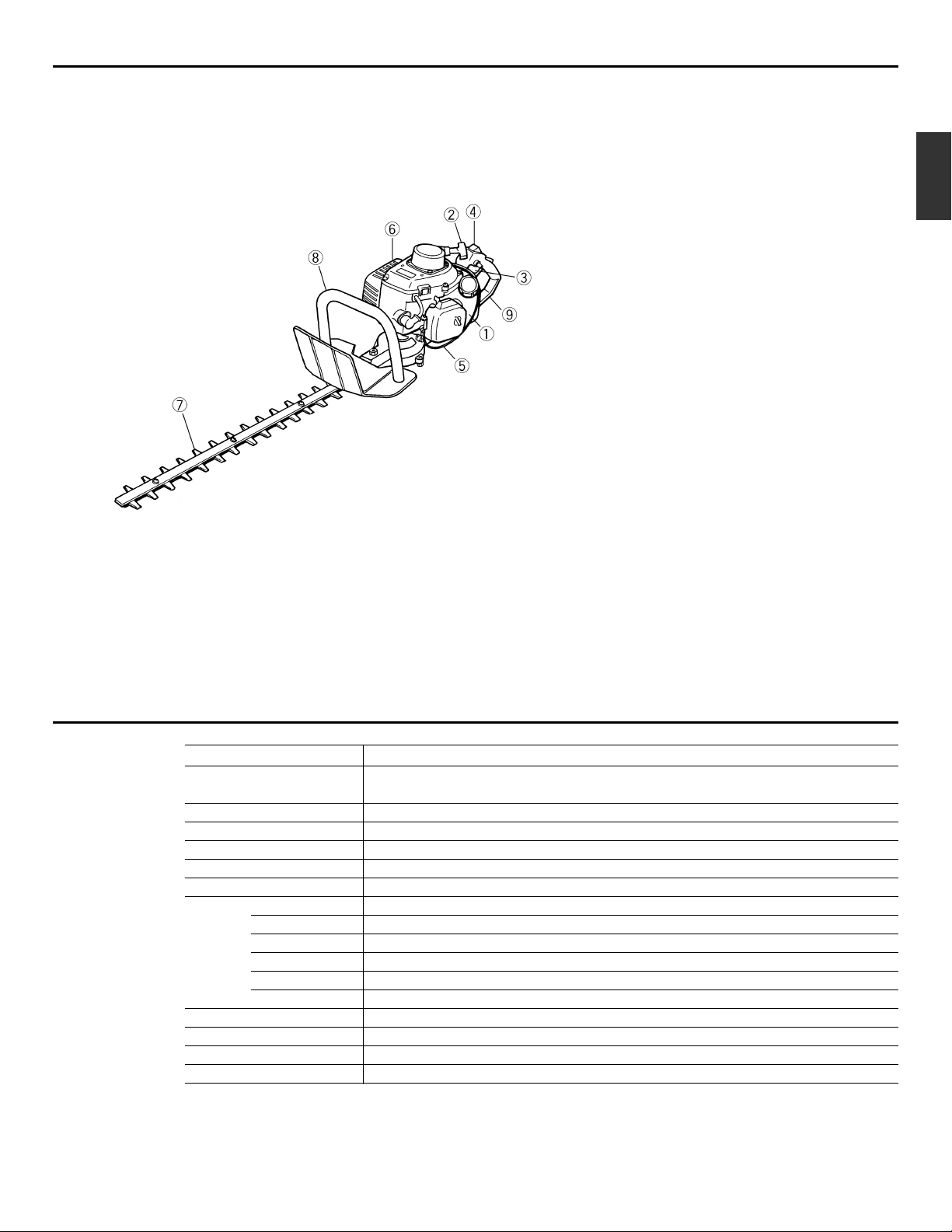

1. Parts location

1. Fuel tank

2. Starter

3. Throttle lever

4. Ignition switch

5. Throttle Cable

6. Muffler

7. Blade

8. Front handle

9. Rear handle

2. Specifications

Model CHT2250

Type Reciprocating

double-sided dual blades

Dry weight 4.6(kg)/10.1(lbs)

Blade size 550(mm)/22(in)

Blade pitch 35(mm)/1.38(in)

Transmission Centrifugal clutch, Cam-crank

Reduction ratio 4.25

Engine Type Air-cooled 2-stroke gasoline

Mode G23LH

Displacement

22.5(cm3)/1.37(cu-in)

Max. output 0.68Hp(0.51kW)at 6500/min

-

1

(rpm)

Idle speed 2800±200/min

-

1

(rpm)

Fuel mixture(Gasoline 50:Oil 1)(when using RedMax/ZENOAH genuine oil)

Carburetor Walbro Diaphragm type

Spark plug CHAMPION RCJ6Y

Fuel tank capacity 0.59(litter)/20.0(fl.oz)

Durability period 50(hrs.)

Specifications are subject to change without notice.

Page 6

US-4

CHT2250

3. Warning labels on the machine

For safe operation and maintenance, symbols

are carved in relief on the machine. According

to these indications, please be careful not to

take a mistake.

(a) The port to refuel the "MIX GASOLINE"

Position:

FUEL TANK CAP

(b) The direction to close the choke

Position:

AIR CLEANER COVER

(c) The direction to open the choke

Position:

AIR CLEANER COVER

(1) Read owner's manual before operating

this machine.

(2) Wear head, eye and ear protection.

(3) Handling this machine improperly

could result in accidents causing

serious injury or death. Read this

manual carefully and practice using the

hedge-trimmer until you are fully

acquainted with all operations and

have learned to use it correctly.

(4) This is extremely sharp and can easily

cause cuts.

If warning label peel off or become soiled and

impossible to read, you should contact the

dealer from which you purchased the

product to order new labels and affix them in

the required location(s).

Never modify your hedge trimmer.

We won’t warrant the machine, if you use

the remodeled hedge trimmer or you don’t

observe the proper usage written in the

manual.

WARNING

4. Symbols on the machine

*1: The year will be changed every year of manufacturing.

*2: The initial number will be changed every year of

manufacturing.

*3: SP : Sealed tank made of HDPE or PE.

■ EMISSION CONTROL

An emission control label is located on the machine.

USE JASO FD OR ISO L-EGD GRADE 50:1 OIL

MANUFACTURED:

THIS ENGINE MEETS U.S. EPA AND CALIFORNIA

EXH/EVP REGS FOR 2009*1 S.O.R.E.

ENGINE FAMILY :

9HQZS.0234BM*2 DISPL.:

23cc

EMISSION CONTROL SYSTEM :

EXH;EM/EVP;SP*

3

COMPLIANCE PERIOD : 50 HOURS

REFER TO OPERATOR'S MANUAL FOR MAINTENANCE, SPECIFICATIONS AND ADJUSTMENTS.

EMISSION CONTROL INFORMATION

ZENOAH AMERICA INC.

IMPORTANT

Page 7

US-5

CHT2250

U

S

1. THIS MACHINE CAN CAUSE

SERIOUS INJURIES. Read this manual

carefully until you completely

understand and follow all safety and

operating instructions. Also, know how

to stop the machine quickly in an

emergency.

2. Keep this manual handy so that you

may refer to it later whenever any

questions arise. Also note, if you have

any questions which cannot be

answered herein, contact the dealer

from whom you purchased the product.

3. Always be sure to include this manual

when selling, lending, or otherwise

transferring the ownership of this

product.

4. Never allow children or anyone unable

to fully understand the directions given

in the manual to use the machine.

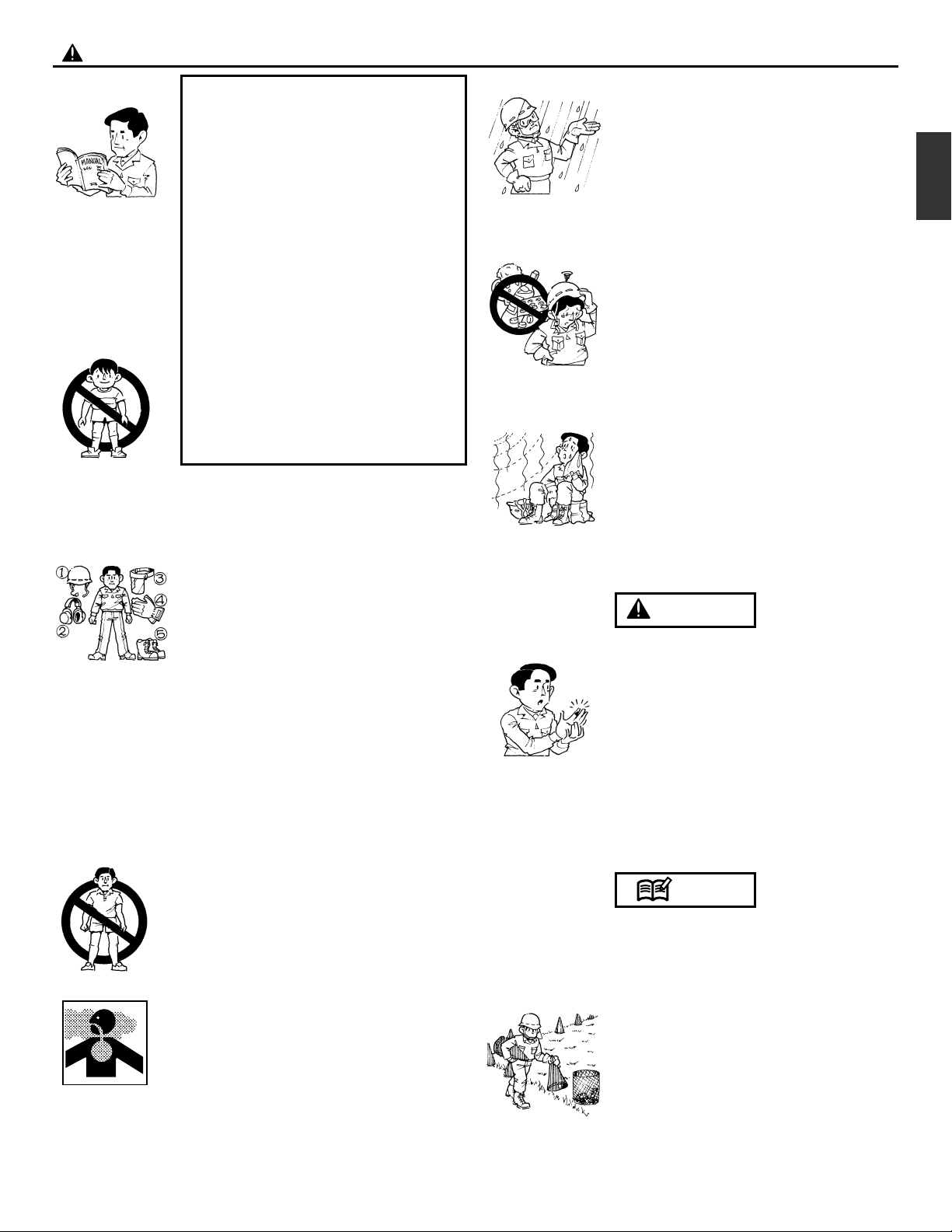

■ WORKING CONDITION

1. When using the product, you should wear

proper clothing and protective equipment.

(1) Helmet

(2) Ear protectors

(3) Protection goggles or face protector

(4) Thick work gloves

(5) Non-slip-sole work boots

2. And you should carry with you.

(1) Attached tools

(2) Properly reserved fuel

(3) Spare blade

(4) Things to notify your working area

(rope, warning signs)

(5) Whistle (for collaboration or emergency)

(6) Hatchet or saw (for removal of

obstacles)

3. Do not wear loose clothing, jewelry, short

trousers, sandals, or go barefoot. Do not

wear anything which might be caught by a

moving part of the unit. Secure hair so it is

above shoulder length.

■ WORKING CIRCUMSTANCE

1. Never start the engine inside a closed

room or building. Exhaust gases contain

dangerous carbon monoxide.

2. Never use the product,

a. when the ground is slippery or when

you can’t maintain a steady posture.

b. At night, at times of heavy fog, or at any

other times when your field of vision

5. For safe operation

might be limited and it would be difficult

to gain a clear view of the working area.

c. During rain storms, during lightning

storms, at times of strong or gale-force

winds, or at any other times when

weather conditions might make it

unsafe to use the product.

■ WORKING PLAN

1. You should never use the product when

under the influence of alcohol, when

suffering from exhaustion or lack of sleep,

when suffering from drowsiness as a result

of having taken cold medicine or at any

other time when a possibility exists that

your judgment might be impaired or that

you might not be able to operate the

product properly and in a safe manner.

2. When planning your work schedule, allow

plenty of time to rest. Limit the amount of

time over which the product is to be used

continuously to somewhere around 30 ~ 40

minutes per session, and take 10 ~ 20

minutes of rest between work sessions.

Also try to keep the total amount of work

performed in a single day under 2 hours or

less.

1. If you don’t observe the working time,

or working manner (See “USING THE

PRODUCT”), Repetitive Stress Injury

(RSI) could occur.

If you feel discomfort, redness and

swelling of your fingers or any other

part of your body, see a doctor before

getting worse.

2. To avoid noise complaints, in general,

operate product between 8 a.m. and 5

p.m. on weekdays and 9 a.m. to 5 p.m.

on weekends.

Check and follow the local regulations as to

sound level and hours of operations for the

product.

■ BEFORE STARTING THE ENGINE

1. The area within a perimeter of 15 m (50 ft)

of the person using the product should be

considered a hazardous area into which no

one should enter. If necessary, yellow

warning rope, warning signs should be

placed around the perimeter of the area.

When work is to be performed

simultaneously by two or more persons,

care should also be taken to constantly

NOTE

WARNING

Page 8

look around or otherwise check for the

presence and locations of other people

working so as to maintain a distance

between each person sufficient to ensure

safety.

2. Check the condition of working area to

avoid any accident by hitting hidden

obstacles such as stumps, stones, cans, or

broken glass.

Remove any obstacle before beginning work.

3. Inspect the entire unit for loose fasteners

and fuel leakage. Make sure that the

cutting attachment is properly installed and

securely fastened.

■ STARTING THE ENGINE

1. Keep bystanders especially children, and

animals at least 15 m (50 ft) away from the

operating point. If you are approached,

immediately stop the engine.

2. The product is equipped with a centrifugal

clutch mechanism, so the cutting

attachment might begin to rotate as soon

as the engine is started. When starting the

engine, place the product onto the ground

in a flat clear area and hold it firmly in

place so as to ensure that neither the

cutting part nor the throttle come into

contact with any obstacle when the engine

starts.

Never place the throttle into the highspeed position when starting the engine.

3. After starting the engine, check to make

sure that the cutting attachment stops

rotating when the throttle is moved fully

back to its original position. If it continues

to rotate even after the throttle has been

moved fully back, turn off the engine and

take the unit to your authorized RedMax

servicing dealer for repair.

■ USING THE PRODUCT

Cut only materials recommended by the

manufacturer. And use only for tasks

explained in the manual.

1. Grip the handles firmly with both hands

using your whole hand. Place your feet

IMPORTANT

US-6

CHT2250

5. For safe operation

slightly apart (slightly further apart than the

width of your shoulders) so that your

weight is distributed evenly across both

legs, and always be sure to maintain a

steady, even posture while working.

2. Keep cutting attachment below waist level.

3. Maintain the speed of the engine at the

level required to perform cutting work, and

never raise the speed of the engine above

the level necessary.

4. If the unit starts to shake or vibrate, turn off

the engine and check the whole unit. Do

not use it until the trouble has been

properly corrected.

5. Keep all parts of your body away from

rotating cutting attachment and hot

surfaces.

6. Never touch the muffler, spark plug, or

other metallic parts of the engine while the

engine is in operation or immediately after

shutting down the engine. Doing socould

result in serious burns or electrical shock.

7. While operating the machine be always

sure of a safe and secure operating

position especially when using steps or a

ladder.

• IF SOMEONE COMES

1. Guard against hazardous situations at all

times. Warn adults to keep pets and

children away from the area. Be careful if

you are approached. Injury may result from

flying debris.

2. If someone calls out or otherwise interrupts

you while working, always be sure to turn

off the engine before turning around.

■ MAINTENANCE

1. In order to maintain your product in proper

working order, perform the maintenance

and checking operations described in the

manual at regular intervals.

2. Always be sure to turn off the engine

before performing any maintenance,

checking procedures or working on the

machine.

(1) Check ok!

The metallic parts reach high

temperatures immediately after stopping

the engine.

3. When replacing the cutting attachment or

any other part, or when replacing the oil or

any lubricant, always be sure to use only

RedMax products or products which

WARNING

IMPORTANT

WARNING

Page 9

US-7

CHT2250

U

S

5. For safe operation

have been certified by RedMax for use

with the RedMax product.

4. In the event that any part must be replaced

or any maintenance or repair work not

described in this manual must be

performed, please contact a representative

from the store nearest RedMax authorized

servicing dealer for assistance.

5. Do not use any accessory or attachment

other than those bearing the RedMax mark

and recommended for the unit.

6. Under no circumstances should you ever

take apart the product or alter it in any

way. Doing so might result in the product

becoming damaged during operation or the

product becoming unable to operate

properly.

■ HANDLING FUEL

1. The engine of the RedMax product is

designed to run on a mixed fuel, which

contains highly flammable gasoline. Never

store cans of fuel or refill the tank of the

unit in any place where there is a boiler,

stove, wood fire, electrical sparks, welding

sparks, or any other source of heat or fire

which might ignite the fuel.

2. Never smoke while operating the unit or

refilling its fuel tank.

3. When refilling the tank, always turn off the

engine and allow it to cool down. Take a

careful look around to make sure that there

are no sparks or open flames anywhere

nearby before refueling.

(1) Refill after cooling the engine.

4. Wipe spilled fuel completely using a dry

rag if any fuel spillage occurs during

refueling.

5. After refueling, screw the fuel cap back

tightly onto the fuel tank and then carry the

unit to a spot 3 m or more away from

where it was refueled before turning on the

engine.

6. Do not inhale fuel fumes as they are toxic.

■ TRANSPORTATION

1. When hand-carrying the product, cover

over the cutting part if necessary, lift up the

product and carry it paying attention to the

blade.

2. Never transport the product over rough

roads over long distances by vehicle

without removing all fuel from the fuel tank.

If doing so, fuel might leak from the tank

during transport.

Page 10

US-8

CHT2250

lines or fuel tank of the engine.

• Failures caused by operating engines on gasoline with octane

rating lower than 89 are not covered

by the RedMax Two-

Stroke engine warranty.

•Alternative Fuels (Not Gasoline)

Alternative fuels, such as E-15 (15% ethanol), E-20 (20%

ethanol), E-85 (85% ethanol) are NOT classified as gasoline

and are NOT approved for use in RedMax 2-stroke gasoline

engines. Use of alternative fuels will cause major engine

performance and durability problems such as: improper

clutch engagements, overheating, vapor lock, power loss,

lubrication deficiency, deterioration of fuel lines, gaskets

and internal carburetor components, etc... Alternative fuels

cause high moisture absorption into the fuel/oil mixture

leading to oil and fuel separation.

■ OIL REQUIREMENTS

• Use only RedMax "Max Life", Synthetic blend Premium AirCooled two-stroke engine oil or oil certified to ISO-L-EGD

(ISO/CD1378) standard AND

one that is JASO-FD

registered.

RedMax Air-Cooled "Max Life", Synthetic blend Premium two

stroke engine oil and ISO-L-EGD

(ISO/CD1378) AND

JASO-FD

oils are fully compatible

with gasoline's containing 10% Ethanol.

RedMax Air-Cooled "Max Life", Synthetic blend Premium two

stroke engine oil and ISO-L-EGD

(ISO/CD1378) AND

JASO-FD

oils are Universal and should be mixed at 50:1 ratio for all 2

stroke air cooled engines sold in the past regardless of mixing

ratios specified in those manuals.

• If the oil is registered with JASO, the JASO Logo with FD

and

registration number

will be displayed on the container. The

highest JASO rating is "FD", which equals the ISO-L-EGD

rating. Lower ratings are "FC", "FB", and "FA".

• Engine problems due to inadequate lubrication caused by

failure to use ISO-L-EGD

certified and JASO FD registered oil

such as "MaxLife", RedMax Synthetic blend Premium 2-stroke

oil WILL VOID THE REDMAX TWO-STROKE ENGINE

WARRANTY.

• Do not use NMMA (National Marine Manufacturers

Association), BIA (Boating Industry Association), and TCW (two

cycle water cooled) oils designed for MoPeds or Outboard,

water cooled Marine Engines. Do not use API (American

Petroleum Institute), TC (Two Cycle) labeled oils. The API-TC

WARNING

6. Fuel

FUEL

• Gasoline is very flammable. Avoid smoking or bringing any

flame or sparks near fuel. Make sure to stop the engine and

allow it cool before refueling the unit. Select outdoor bare

ground for fueling and move at least 10 ft (3 m) away from

the fueling point before starting the engine.

■ GASOLINE REQUIREMENTS

• All 2-Stroke RedMax Products are powered by Zenoah

Professional-Commercial Duty, Hi-Performance, Hi-RPM, Air

Cooled 2-Stroke engines.

RedMax/Zenoah – Hi-Performance 2-stroke engines produce

higher HP outputs as compared to standard Home Owner Duty

or Light Commercial Duty production engines offered by most

manufacturers.

• Exhaust emission are controlled by the fundamental engine

parameters and components (eq., carburation, ignition timing

and port timing) without addition of any major hardware or the

introduction of an inert material during combustion.

• The RedMax/Zenoah Engines are registered and certified with

CARB (California Air Resources Board) and EPA

(Environmental Protection Agency) to operate on CLEAN Midgrade 89 octane or Premium, unleaded (lead-free) gasoline and

RedMax Air-Cooled "Max Life", Synthetic blend Premium twostroke engine oil mixed at 50:1 ratio.

• Unleaded gasoline is recommended to reduce the

contamination of the air for the sake of your health and the

environment.

• This Hi-Performance Air Cooled 2-stroke Engine requires the

use of Minimum

89 Octane (Mid grade or Premium)

clean gasoline. Gasoline may contain maximum of 10% Ethanol

(grain alcohol) or up to 15% MTBE (Methyl tertiary-butyl ether).

Gasoline containing Methanol (Wood Alcohol) is NOT

approved.

• IF octane rating of the Mid Grade

gasoline in your area is lower

than 89 Octane use Premium Unleaded Gasoline. The majority

of all 2-stroke engine manufacturers in the USA and Canada

recommend using gasoline with 89 Octane or higher.

• Gasoline with an octane rating lower than 89 will greatly

increase the engines operating temperature. Low octane

gasoline will cause detonation (knock) resulting in piston

seizures and major internal engine components damage.

• Poor quality gasolines or oils may damage sealing rings, fuel

WARNING

[ R+M ]

2

WARNING

NOTE

WARNING

NOTE

Page 11

US-9

CHT2250

U

S

6. Fuel

test standard has been discontinued by API in 1995 and it no

longer exists.

• Gasoline/Oil mixture Storage Recommendations

Store your gasoline or gasoline/oil mixture in a cool dry area in

a tightly sealed approved container to limit the entry of moisture

and additional air (oxygen). Moisture and air cause the

development of varnish and gum, making the fuel stale. Stored

gasoline and gasoline/oil mixture ages and loses its octane

rating and volatility. Do not mix more gasoline/oil than you

intend to use in 30 days, and 60 days when fuel stabilizer is

added. RedMax Air-Cooled "Max Life" Synthetic blend

Premium two-stroke engine oil "Contains fuel stabilizer"

and

will automatically extend your gasoline/oil mixture life up to 60

days.

■ HOW TO MIX FUEL

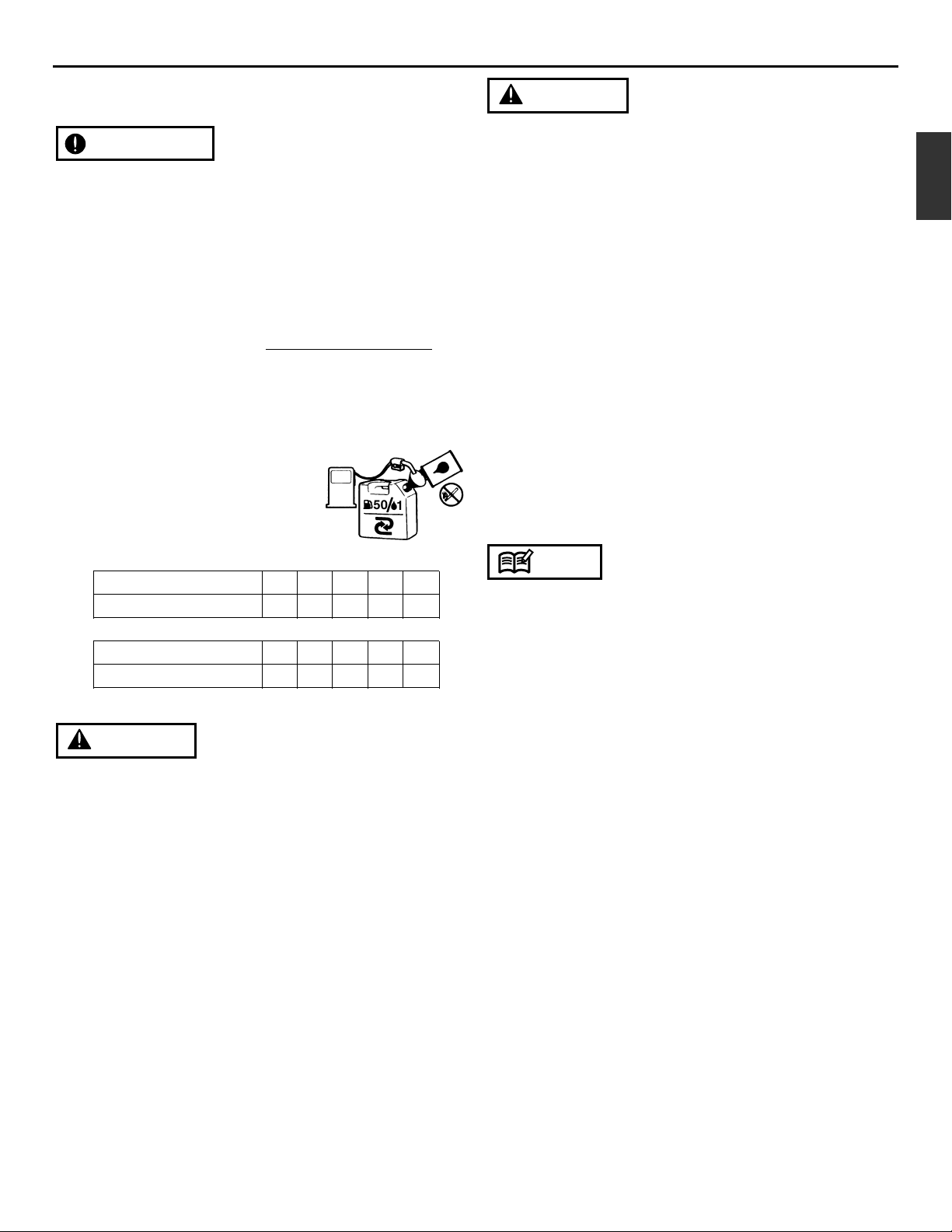

RECOMMENDED MIXING RATIO

GASOLINE 50 : OIL 1

(when using RedMax Air-Cooled "Max

Life")

• Pay attention to agitation.

1. Measure out the quantities of gasoline and oil to be mixed.

2. Put some of the gasoline into a clean, approved fuel container.

3. Pour in all of the oil and agitate well for 10seconds.

4. Pour in the rest of gasoline and agitate again for at least one

minute. As some oils may be difficult to agitate depending on oil

ingredients, sufficient agitation is necessary. Be careful that, if

the agitation is insufficient, there is an increased danger of early

piston seizure due to abnormally lean mixture.

5. Place a clear indication on the outside of the container to avoid

mixing up with gasoline or other containers that dont contain oil.

6. Indicate the contents on outside of container for easy

identification.

■ FUELING THE UNIT

1. Untwist and remove the fuel cap. Rest the cap on a clean

surface.

2. Put fuel into the fuel tank to 80% of the full capacity.

3. Fasten the fuel cap securely and wipe up any fuel spillage

around the unit.

WARNING

1. Select flat and bare ground for fueling.

2. Move at least 10 feet (3 meters) away from the fueling point

before starting the engine.

3. Stop the engine before refueling the unit. At that time, be

sure to sufficiently agitate the mixed gasoline in the

container.

■ FOR YOUR ENGINE LIFE, AVOID

1. FUEL WITH NO OIL (RAW GASOLINE) – It will cause severe

damage to the internal engine parts very quickly.

2. GASOHOL – It can cause deterioration of rubber and/or plastic

parts and disruption of engine lubrication.

3. OIL FOR 4-CYCLE ENGINE USE – It can cause spark plug

fouling, exhaust port blocking, or piston ring seizure.

4. Mixed fuels which have been left unused for a period of

one month or more may clog the carburetor and result in the

engine failing to operate properly.

5. In the case of storing the product for a long period of time,

clean the fuel tank after rendering it empty. Next, Start the

engine and run the carburetor dry residual fuel.

6. In the case of scrapping the used mixed oil container, scrap it

only at an authorized depository site.

• As for details of quality assurance, read the description in the

section Limited Warranty carefully. Moreover, normal wear and

change in product with no functional influence are not covered

by the warranty. Also, be careful that, if the usage in the

instruction manual is not observed as to the mixed gasoline,

type of oil or fuel to be used. described therein, it may not be

covered by the warranty.

NOTE

50:1 MIXING CHART

GASOLINE gal. 1 2 3 4 5

2-CYCLE OIL fl.oz 2.6 5.2 7.8 10.4 13

GASOLINE liter 1 2 3 4 5

2-CYCLE OIL ml 20 40 60 80 100

IMPORTANT

WARNING

Page 12

US-10

CHT2250

pulling the rope or remove the spark

plug and dry it.

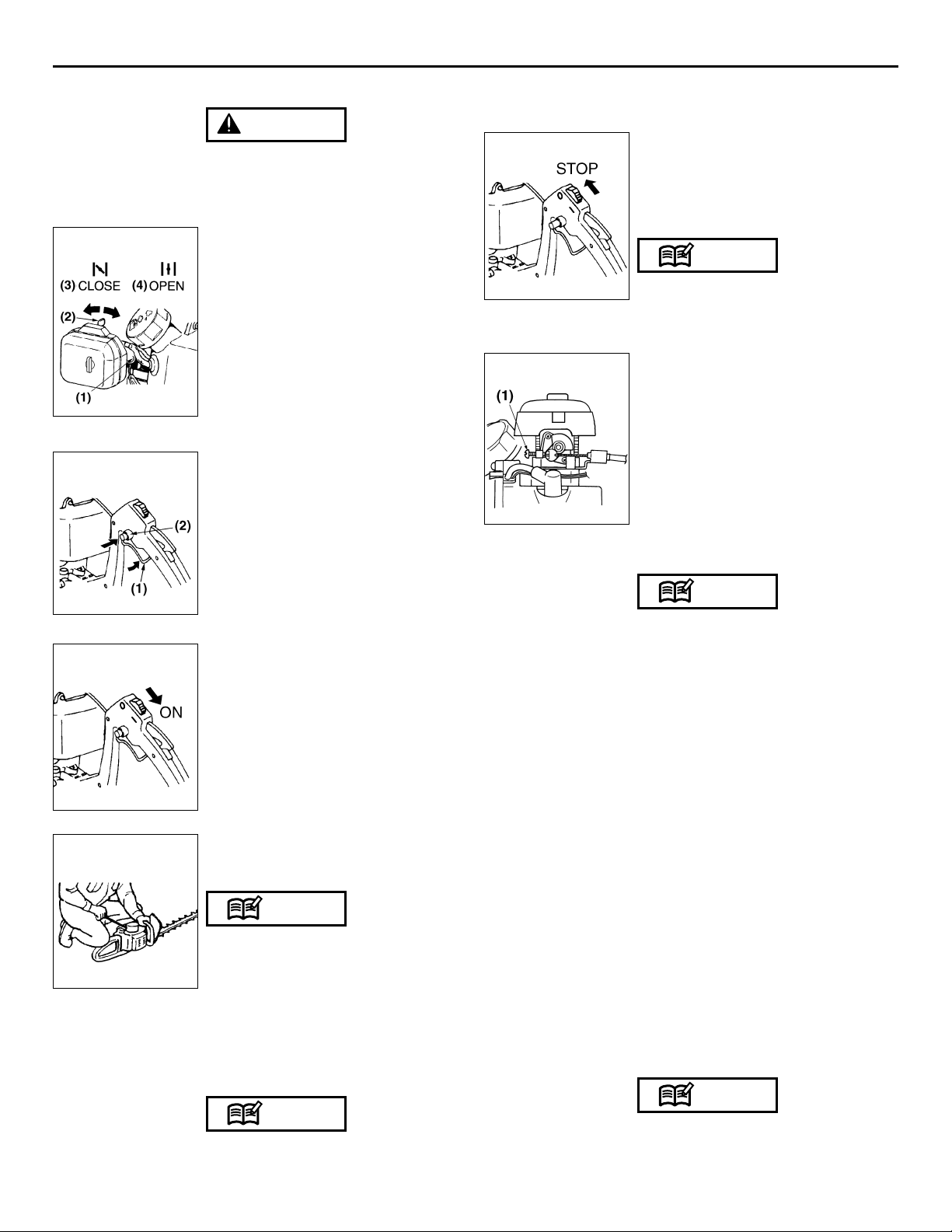

■ STOPPING ENGINE

1. Release the throttle lever and run the

engine at idling speed for a half minute.

2. Slide the ignition switch to the STOP

position.

• Except for an emergency, avoid

stopping the engine while running it at

high speed.

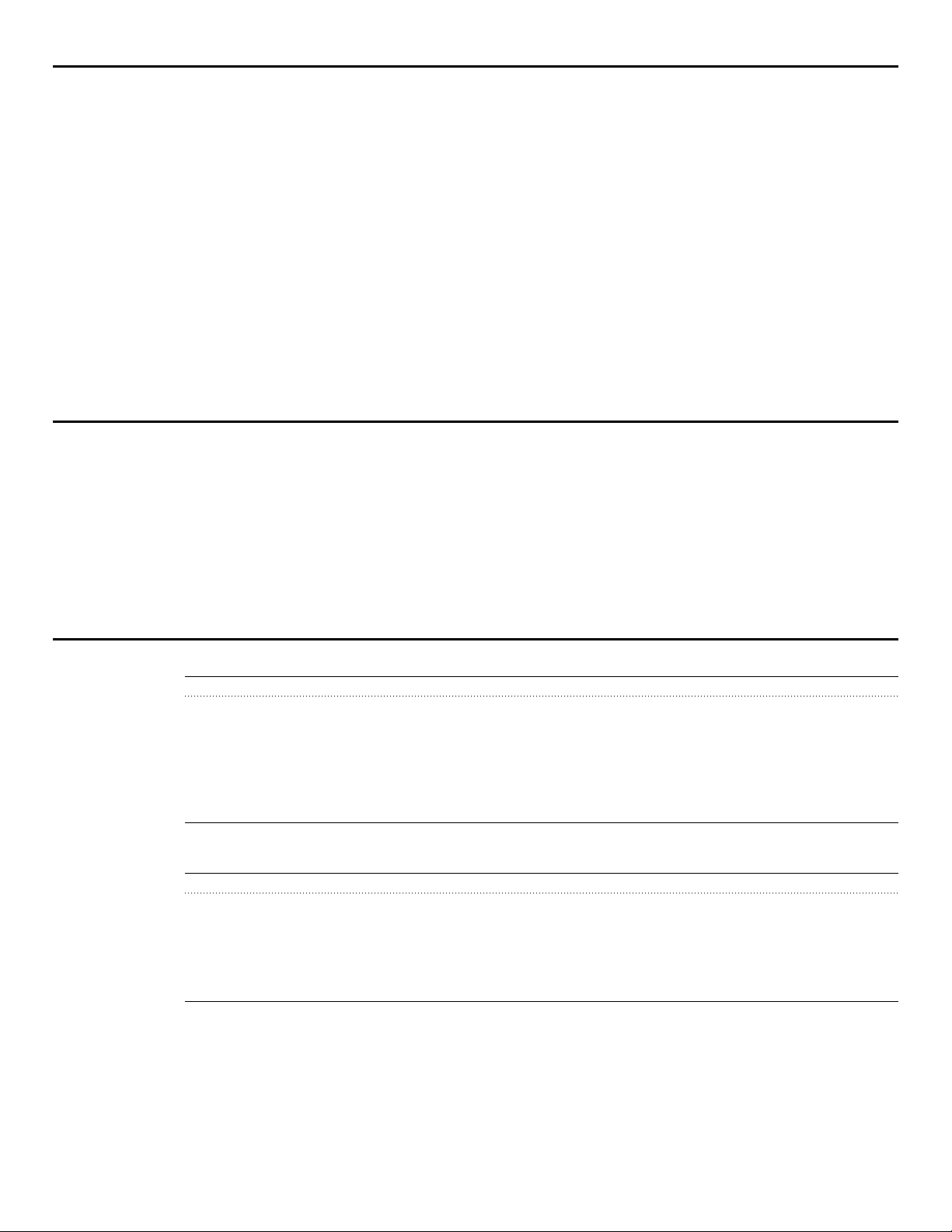

■ ADJUSTING IDLING SPEED

1. When the engine tends to stop

frequently at idling mode, turn the idle

set screw clock-wise.

(1) Idle set screw

2. When the cutting blades keep moving

after releasing the throttle trigger, turn

the idle set screw counter-clockwise.

• Warm up the engine before adjusting

the idling speed.

■ HOW TO USE

• This machine is designed so as to

cut twigs upto 8 mm (0.3 inches)

thick. Cutting too thick twigs or

metal wires can not only break the

blade teeth but also give damage to

the drive mechanism.

• When trimming leaves and thin twigs,

guide the blades as drawing a half

circle on the surface, and you will get a

better finish.

• Running the engine at high speed with

the blades Jammed up can shorten the

life of clutch parts. When the blades

have been jammed by thick twigs, stop

operation at once and draw your unit

off the objects after stopping the

engine. When clipping comparatively

thick twigs, move your unit slowly back

and forth like a saw, and they can be

cut to a fine finish.

• When a new unit is first operated, in the

first few minutes grease may come out

of the gear case. But, since this is

NOTE

7. Operation

■ STARTING ENGINE

Keep the blades clear of the

surrounding as they will start moving

upon starting of the engine.

1. When first starting up after putting fuel

into the machine, push the priming

pump until fuel runs out in the clear

tube. Then close the choke. Choking

may not be necessary when re-starting

right after stopping the engine. (OP1)

(1) Primer pump

(2) Choke lever

(3) CLOSE

(4) OPEN

2. Pull the throttle lever and push the lock

button to set the lever in the START

position. (OP2)

(1) Throttle lever

(2) Lock button

3. Slide the ignition switch to the engine

side to set it in the ON position. (OP3)

4. Rest the unit on a firm place. Pull the

starter knob quickly. (OP4)

• Avoid pulling the rope to its end or

returning it by releasing the knob. Such

actions can cause starter failures.

5. When the engine has started, gradually

open the choke.

6. Allow the engine to warm up for a half

minute before starting operation.

• If the engine won't start after several

attempts, open the choke and repeat

NOTE

OP1

OP2

OP3

OP4

OP5

OP6

WARNING

NOTE

NOTE

NOTE

Page 13

US-11

CHT2250

U

S

7. Operation

OP7

OP8

excess grease, there is no cause for

alarm. For next use just wipe it off with

the engine stopped.

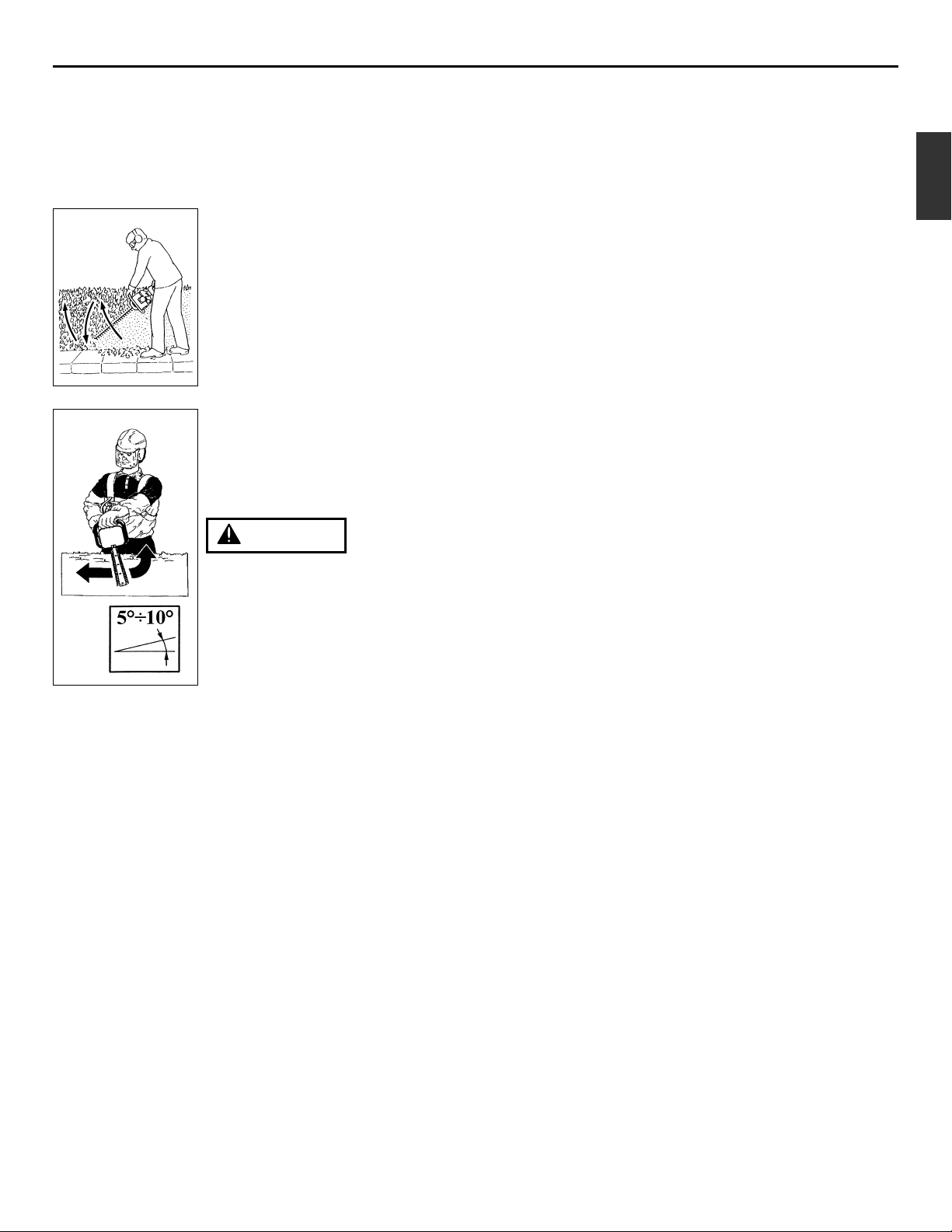

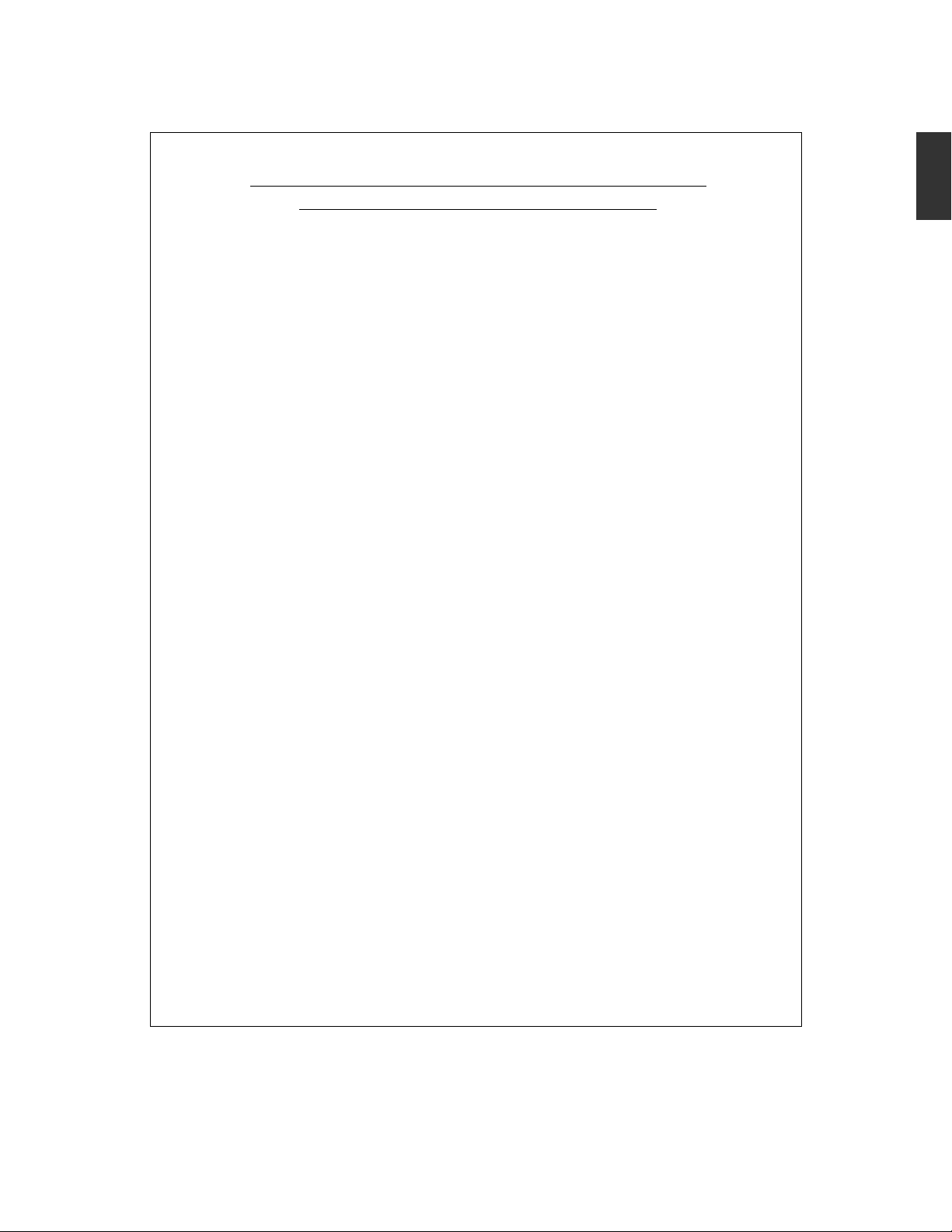

HEDGE TRIMMING TECHNIQUES

Trim sides of a hedge first, and then the

top.

Vertical cut:

• With the 2-sided blade model CHT2250

use an arcing cut from the bottom

upwards, then downwards to use both

sides of the blades (OP7).

Horizontal cut:

• In order to get the best cutting results,

slightly tilt the blade (5÷10°) towards

the cutting direction (OP8).

Cut slowly, specially with thick hedges.

Always follow the safety precautions.

The hedge-trimmer must only be used

to trim hedges or small bushes. It is

forbidden to cut other types of

material. Do not use the hedge-trimmer

as a lever to lift, move or break

objects, nor lock it on fixed supports. It

is forbidden to apply tools or

applications that are not the ones

indicated by the manufacturer onto the

hedge-trimmer’s power take-off. Do not

use it for pruning trees or cutting

grass.

WARNING

Page 14

US-12

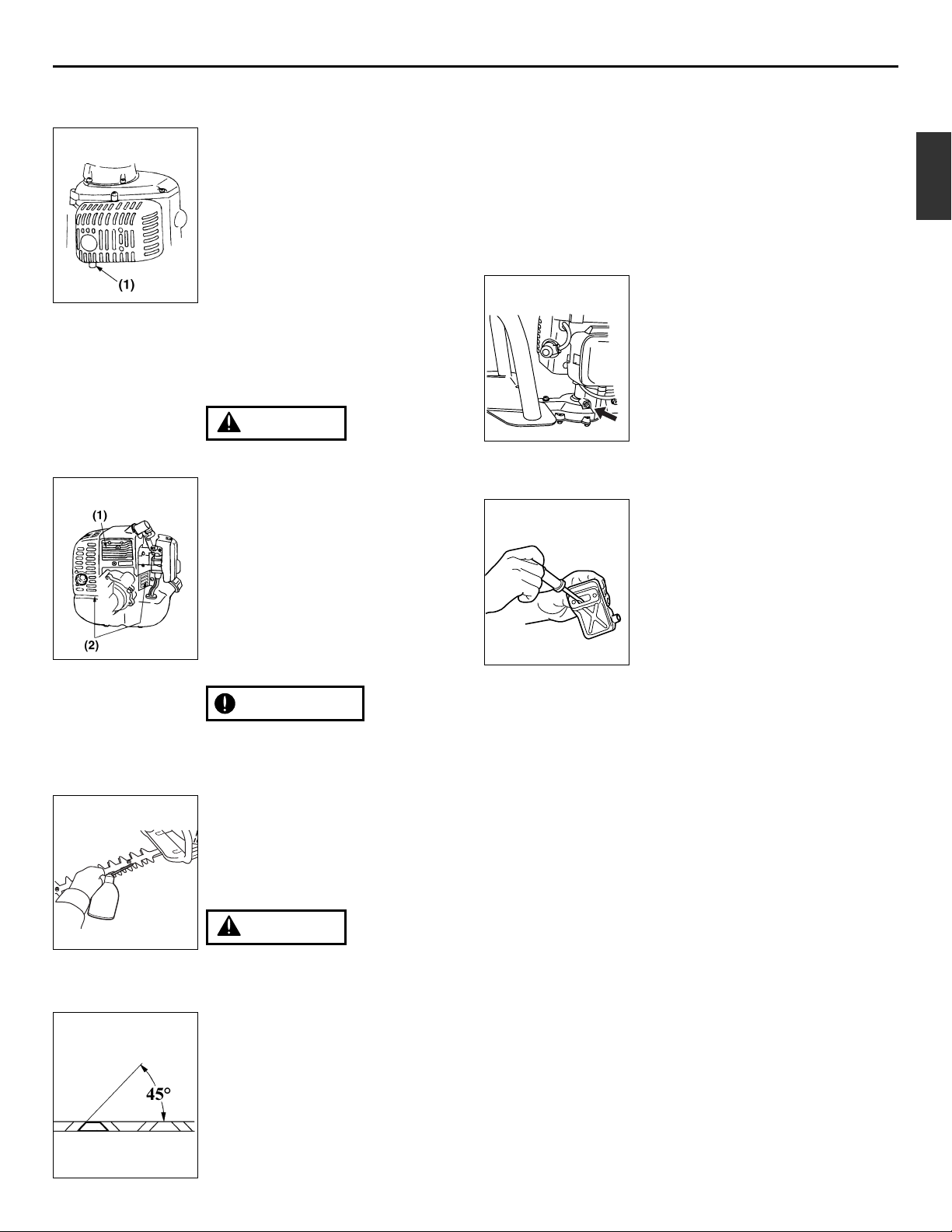

CHT2250

MA1

.025 in

0.655mm

MA3

MA2

Maintenance, replacement, or repair of the emission control device and

systems may be performed by any non-road engine repair establishment or

individual.

8. Maintenance

specified by RedMax. (MA3)

• REPLACEMENT PLUG IS

CHAMPION RCJ6Y OR NGK

BPMR7A.

• Note that using any spark plug other

than those designated may result in the

engine failing to operate properly or in

the engine becoming overheated and

damaged.

• To install the spark plug, first turn the

plug until it is finger tight, then tighten it

a quarter turn more with a socket

wrench.

TIGHTENING TORQUE:

87~121 in-lbs

(9.8~13.7 N.m.)

■ MUFFLER

• Inspect periodically, the muffler for

loose fasteners, any damage or

corrosion. If any sign of exhaust

leakage is found, stop using the

machine and have it repaired

immediately.

•Note that failing to do so may result

in the engine catching on fire.

WARNING

• Make sure that the engine has

stopped and is cool before

performing any service to the

machine. Contact with moving

cutting head or hot muffler may

result in a personal injury.

■ AIR FILTER

• The air filter, if clogged, will reduce the

engine performance. Check and clean

the filter element in warm, soapy water

as required. Dry completely before

installing. If the element is broken or

shrunk, replace with a new one. (MA1)

(1) Air filter

■ FUEL FILTER

• When the engine runs short of fuel

supply, check the fuel cap and the fuel

filter for blockage. (MA2)

(1) Fuel filter

■ SPARK PLUG

• Starting failure and mis-firing are often

caused by a fouled spark plug. Clean

the spark plug and check that the plug

gap is in the correct range. For a

replacement plug, use the correct type

WARNING

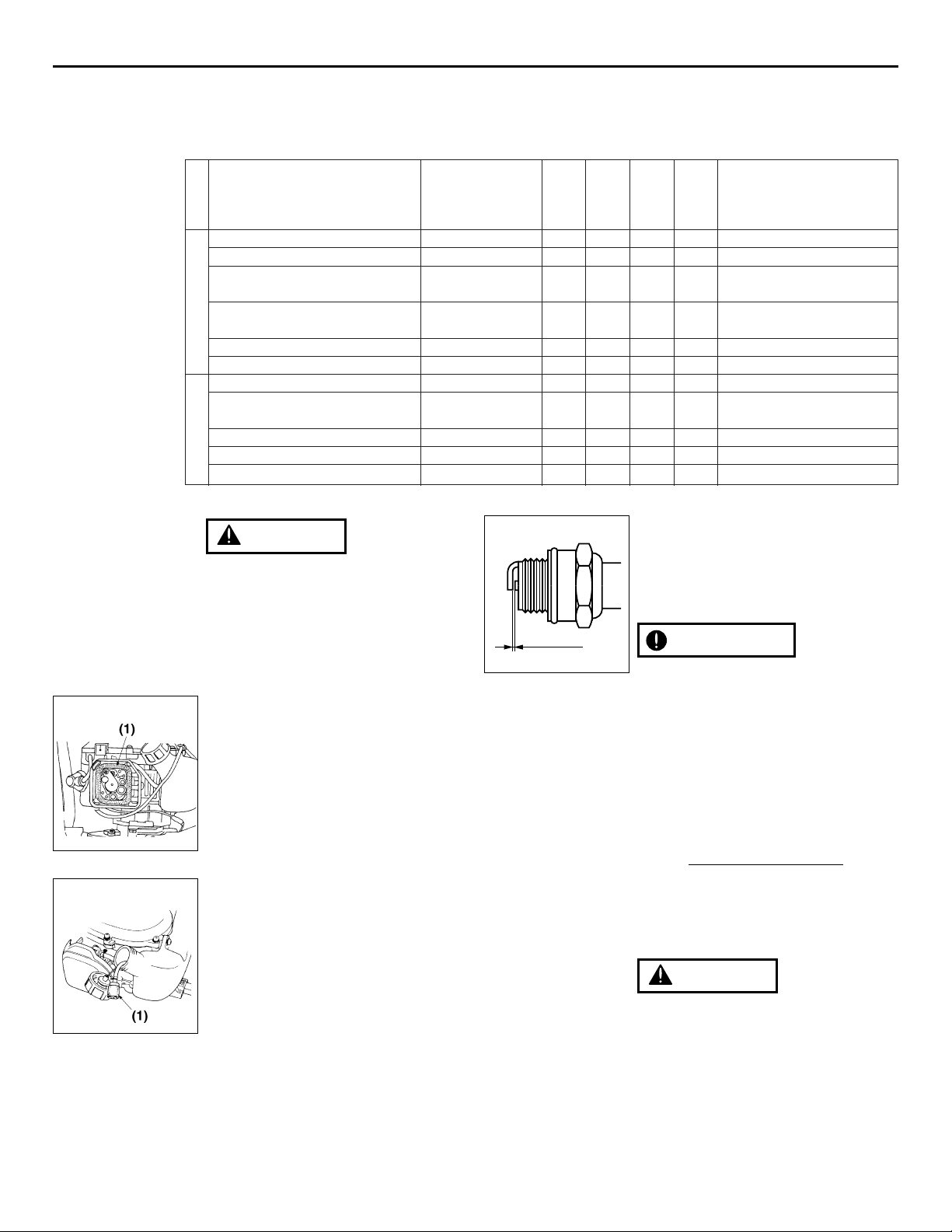

■ MAINTENANCE CHART

Every Every Every

25 50 100

System/components Procedure

Before hours hours hours

Note

use after after after

fuel leaks, fuel spillage wipe out ✔

fuel tank, air filter, fuel filter inspect/clean ✔✔ replace, if necessary

idle adjusting screw

see adjusting

✔

replace carburetor

idling speed if necessary

spark plug

clean and readjust

✔

GAP : 0.6 ~ 0.7 mm

plug gap replace, if necessary

cylinder fins, intake air cooling vent clean ✔

muffler, spark arrester, cylinder exhaust port

clean ✔

throttle lever, ignition switch check operation ✔

cutting parts

replace if

✔

something’s wrong

gear case grease ✔

screws/nuts/bolts tighten/replace ✔✔not adjusting screws

debris guard make sure to attach ✔

ENGINE

SHAFT

IMPORTANT

Page 15

US-13

CHT2250

U

S

■ SPARK ARRESTER (MA4)

• The muffler is equipped with a spark

arrester to prevent red hot carbon from

flying out of the exhaust outlet.

Periodically inspect and clean as

necessary with a wire brush.

In the State of California it is required

by law (Section 4442 of the California

Public Resources Code) to equip a

spark arrester when a gas powered tool

is used in any forest covered, brush

covered, or grass covered unimproved

land.

(1) Spark arrester

■ INTAKE AIR COOLING VENT

• Never touch the cylinder, muffler, or

spark plugs with your bare hands

immediately after stopping the

engine. The engine can become very

hot when in operation, and doing so

could result in severe burns.

• Clean the cylinder fins with

compressed air or a brush. (MA5)

(1) Cylinder

(2) Intake air cooling vent (back)

• If waste gets stuck and causes

blockage around the intake air cooling

vent or between the cylinder fins, it may

cause the engine to overheat, and that

in turn may cause mechanical failure

on the part of the hedge-trimmer.

■ BLADES

Oil blades each gas tank filling. (MA6)

• Make sure that the blade bolts are

well tightened.

• The blade assembly is designed to

automatically compensate for any

play between the blades.

■ Sharpening (MA7)

Always keep the file or sharpener at an

angle of 45° to the blade, and:

• Always grind in the direction of the

cutting edge;

• Note: files cut only in one direction; lift

WARNING

MA4

MA5

MA6

MA7

MA8

MA9

8. Maintenance

the file from the blade when returning

to start a new pass;

•Remove all burr from the edge of the

blade with a slip stone;

• Remove as little material as possible;

• Before refitting the sharpened blades,

remove filings and then apply grease.

Do not try to sharpen a damaged blade:

change it or take it to a Service dealer.

■ REDUCTION GEARBOX

Refill gear housing every 25 working

hours.

Use greese pump. Feed greese until it

comes out of the base of blades. (MA8)

■ PROCEDURES TO BE PERFORMED

AFTER EVERY 100 HOURS OF USE

1. Remove the muffler, insert a

screwdriver into the vent, and wipe

away any carbon buildup. Wipe away

any carbon buildup on the muffler

exhaust vent and cylinder exhaust port

at the same time.

2. Tighten all screws, bolts, and fittings.

3. Check to see if any oil or grease has

worked its way in between the clutch

lining and drum, and if it has wipe it

away using oil-free, lead-free gasoline.

WARNING

IMPORTANT

Page 16

US-14

CHT2250

1. Oil the blade to prevent rust.

2. Empty the fuel tank and put the cap

back on.

3. Remove the spark plug, pour a small

amount of oil into the cylinder.

4. Rotate the crankshaft several times

using the starting rope in order to

distribute the oil. Put the spark plug

back in.

5. Wrap the engine with a plastic sheet.

6. Store the trimmer in a dry place,

preferably not in direct contact with the

floor and away from heat sources.

9. Storage

10. Disposal

• When disposing your machine, fuel or

oil for the machine, be sure to allow

your local regulations.

11. Troubleshooting guide

Case 1. Starting failure

CHECK PROBABLE CAUSES ACTION

fuel tank ➞ incorrect fuel ➞ drain it and with correct fuel

fuel filter ➞ fuel filter is clogged ➞ clean

carburetor adjustment screw ➞ out of normal range ➞ adjust to normal range

sparking (no spark) ➞ spark plug is fouled/wet ➞ clean/dry

➞ plug gap is incorrect ➞ correct (GAP: 0.6 – 0.7 mm)

spark plug ➞ disconnected ➞ retighten

Case 2. Engine starts but does not keep running/Hard re-starting.

CHECK PROBABLE CAUSES ACTION

fuel tank ➞ incorrect fuel or staled fuel ➞ drain it and with correct fuel

carburetor adjustment screw ➞ out of normal range ➞ adjust to normal range

muffler,cylinder (exhaust port) ➞ carbon is built-up ➞ wipe away

air cleaner ➞ clogged with dust ➞ wash

cylinder fin, fan cover ➞ clogged with dust ➞ clean

When your unit seems to need further service, please consult with our service shop in your area.

Page 17

US-15

CHT2250

U

S

The California Air Resources Board and ZENOAH AMERICA, INC. are pleased to explain the

emission control system warranty on your 2007 and later small off-road engine. In California,

new small off-road engines must be designed, built and equipped to meet the state’s stringent

anti-smog standards. ZENOAH AMERICA, INC. must warrant the emission control system on

your small off-road engine for the periods of time listed below provided there has been no abuse,

neglect or improper maintenance of your small off-road engine.

Your emission control system may include parts such as the carburetor, fuel tank and the ignition

system.

Where a warrantable condition exists, ZENOAH AMERICA, INC. will repair your small off-road

engine at no cost to you including diagnosis, parts and labor.

Manufacturer’s warranty coverage:

The 2007 and later small off-road engines are warranted for two years. If any emissionrelated part on your engine is defective, the part will be repaired or replaced by ZENOAH

AMERICA, INC.

Owner’s warranty responsibilities:

– As the small off-road engine owner, you are responsible for the performance of the

required maintenance listed in your owner’s manual. ZENOAH AMERICA, INC.

recommends that you retain all receipts covering maintenance on your small off-road

engine, but ZENOAH AMERICA, INC. can not deny warranty solely for the lack of

receipts or for your failure to ensure the performance of all scheduled maintenance.

– As the small off-road engine owner, you should be aware, however, that ZENOAH

AMERICA, INC. may deny you warranty coverage if your small off-road engine or a part

has failed due to abuse, neglect, improper maintenance or unapproved modification.

– You are responsible for presenting your small off-road engine to a ZENOAH AMERICA,

INC. distribution center as soon as a problem exists. The warranty repairs should be

completed in e reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should

contact ZENOAH AMERICA, INC. at (770)-381-5147 or you can write to

ZENOAH AMERICA, INC.

1100 Laval Blvd. Suite 110

Lawrenceville, Georgia 30043

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

Page 18

US-16

CHT2250

ZENOAH AMERICA, INC.

1100 Laval Blvd. Suite 110

Lawrenceville, Georgia 30043

EMISSION-RELATED PARTS, FOR TWO (2) YEARS FROM THE DATE OF ORIGINAL DELIVERY OF THE UNIT,

RedMax / ZENOAH AMERICA, INC., THROUGH ANY RedMax DEALER, WILL REPAIR OR REPLACE, FREE OF CHARGE,

FOR THE ORIGINAL AND EACH SUBSEQUENT PURCHASER, ANY PART OR PARTS FOUND TO BE DEFECTIVE IN

MATERIAL AND/OR WORKMANSHIP.

EMISSION-RELATED PARTS ARE:

THE CARBURETOR ASSEMBLY, COIL ASSEMBLY, ROTOR, SPARKPLUG,

AIR FILTER, FUEL FILTER, INTAKE MANIFOLD, AND THE GASKETS

ALL OTHER PARTS EXCEPT ABOVE PARTS, FOR TWO (2) YEARS OF HOME USE AND 180 DAYS COMMERCIAL USE,

FROM THE DATE OF ORIGINAL PURCHASE, THE COMPANY, THROUGH ANY RedMax DEALER, WILL REPAIR OR

REPLACE, FREE OF CHARGE, FOR THE ORIGINAL PURCHASER, ANY PART OF PARTS FOUND TO BE DEFECTIVE IN

MATERIAL AND/OR WORKMANSHIP. THIS IS THE EXCLUSIVE REMEDY.

THE PURCHASER SHALL BEAR COSTS OF TRANSPORTING THE UNIT TO AND FROM THE RedMax DEALER.

THE PURCHASER SHALL NOT BE CHARGED FOR DIAGNOSTIC LABOR WHICH LEADS TO THE DETERMINATION

THAT A WARRANTED PART IS DEFECTIVE, IF THE DIAGNOSTIC WORK IS PERFORMED AT THE RedMax DEALER.

THE PURCHASER OR OWNER IS RESPONSIBLE FOR THE PERFORMANCE OF THE REQUIRED MAINTENANCE AS

DEFINED BY THE MANUFACTURER IN THE OWNER/OPERATOR MANUAL.

ANY WARRANTED PART WHICH IS NOT SCHEDULED FOR REPLACEMENT AS REQUIRED MAINTENANCE, OR

WHICH IS SCHEDULED ONLY FOR REGULAR INSPECTION TO THE EFFECT OF "REPAIR OR REPLACE AS

NECESSARY" SHALL BE WARRANTED FOR THE WARRANTY PERIOD. ANY WARRANTED PART WHICH IS

SCHEDULED FOR REPLACEMENT AS REQUIRED MAINTENANCE SHALL BE WARRANTED FOR THE PERIOD OF

TIME UP TO THE FIRST SCHEDULED REPLACEMENT POINT FOR THE PART.

ANY REPLACEMENT PART THAT IS EQUIVALENT IN PERFORMANCE AND DURABILITY MAY BE USED IN NONWARRANTY MAINTENANCE OR REPAIRS, AND SHALL NOT REDUCE THE WARRANTY OBLIGATION OF THE

COMPANY.

THE COMPANY IS LIABLE FOR DAMAGES TO OTHER ENGINE COMPONENTS CAUSED BY THE FAILURE OF A

WARRANTED PART STILL UNDER WARRANTY.

THE WARRANTY DOES NOT APPLY TO THOSE UNITS WHICH HAVE BEEN DAMAGED BY NEGLIGENCE OF

INSTRUCTION LISTED IN THE OWNER/OPERATOR MANUAL FOR PROPER USE AND MAINTENANCE OF THE UNITS,

ACCIDENTAL MISHANDLING, ALTERATION, ABUSE, IMPROPER LUBRICATION, USE OF ANY PARTS OR ACCESSORIES

OTHER THAN THOSE SPECIFIED BY THE COMPANY, OR OTHER CAUSES BEYOND THE COMPANY'S CONTROL.

THIS WARRANTY DOES NOT COVER THOSE PARTS REPLACED BY NORMAL WEAR OR HARMLESS CHANGES IN

THEIR APPEARANCE.

THERE ARE NO OTHER EXPRESS WARRANTIES.

IMPLIED WARRANTIES INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

LIMITED TO TWO (2) YEARS OF HOME USE AND 180 DAYS COMMERCIAL USE, FROM THE ORIGINAL DELIVERY DATE.

LIABILITIES FOR INCIDENTAL OR CONSEQUENTIAL DAMAGE UNDER ANY AND ALL WARRANTIES

ARE EXCLUDED.

SOME STATES DO NOT ALLOW LIMITATION ON HOW LONG AN IMPLIED WARRANTY LASTS OR EXCLUSION OR

LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY

NOT APPLY TO YOU.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY

FROM STATE TO STATE.

IF YOU NEED TO OBTAIN INFORMATION ABOUT THE NEAREST SERVICE CENTER, PLEASE CALL RedMax / ZENOAH

AMERICA, INC. AT (770)-381-5147.

IMPORTANT: YOU WILL RECEIVE A WARRANTY REGISTRATION CARD AT TIME OF PURCHASE.PLEASE FILL

OUT THE CARD AND SEND IT TO RedMax / ZENOAH AMERICA WITHIN SEVEN (7) DAYS. BE SURE TO KEEP A COPY

FOR YOUR RECORDS.

LIMITED WARRANTY

Page 19

FR-1

CHT2250

F

R

MODE D’EMPLOI

TAILLEUSE DE HAIES

848-D16-93A0 (901)

NUMEROS DE SERIE APPLICABLES :

90100101 et au-delà

AVERTISSEMENT

AVERTISSEMENT

Les échappements du moteur de

ce produit contiennent des

produits chimiques connus par

l’Etat de Californie comme étant

responsables de cancers,

d’anomalies congénitales et

d’autres atteintes à l’appareil

reproducteur.

Avant d’utiliser cette

ce produit

,

veuillez lire attentivement ce

manuel afin de bien comprendre le

bon fonctionnement de cet

appareil.

CHT2250

Page 20

FR-2

CHT2250

SECURITE

Les instructions contenues dans les mises en garde

de ce mode d’emploi portant le symbole

concernent les points critiques qui doivent être pris

en considération pour éviter les blessures

corporelles graves, c’est pourquoi ces précautions

doivent être rigoureusement suivies.

■ DIFFERENTS TYPES D’AVERTISSEMENT DE CE

MODE D’EMPLOI

Les instructions repérées par ce symbole doivent être

rigoureusement suivies afin d’éviter tout accident

pouvant entraîner des blessures corporelles graves ou

la mort.

Les instructions repérées par ce symbole doivent être

suivies afin d’éviter tout incident mécanique, panne ou

endommagement de la débroussailleuse.

Remarques utilisées dans des instructions ou conseils

supplémentaires pour l’utilisation de cette

débroussailleuse.

REMARQUE

1. Emplacement des composants ..........................................3

2. Caracteristiques..................................................................3

3. Etiquettes d’avertissement placées sur la machine............4

4. Symboles utilises sur la machine .......................................4

5. Consignes de securite ........................................................5

6. Carburant............................................................................8

7. Fonctionnement................................................................11

8. Entretien ...........................................................................13

9. Rangement .......................................................................15

10. Mise au rebut....................................................................15

11. Guide de localisation des pannes.....................................15

Tables des matieres

AVERTISSEMENT

IMPORTANT

Page 21

FR-3

CHT2250

F

R

1. Emplacement des pieces

1. Réservoir de carburant

2. Démarreur

3. Levier d’accélération

4. Bouton d’allumage

5. Câble d’accélérateur

6. Silencieux

7. Lame de coupe

8. Manette avant

9. Manette arrière

2. Fiche technique

Model CHT2250

Type Lames jumelées

double face à va-et-vient

Poids à vide 4,6(kg)/ 10,1(lbs)

Taille de la lame 550(mm)/22(in)

Angle de la lame 35(mm)/1,38(in)

Transmission Embrayage centrifuge, arbre à cames / vilebrequin

Rapport de réduction 4,25

Moteur Type Moteur à 2 temps à refroidissement par air

Modèle G23LH

Cylindrée

22,5(cm3)/1,37(cu-in)

Cadence max. 0,68Hp(0,51kW)à 6500 /min

-

1

(rpm)

Vitesse de ralenti

2800±200/min

-

1

(rpm)

Carburant Mélange(essence 50:huile 1)(

Lors de l’utilisation de la véritable huile RedMax/ZENOAH

)

Carburateur Walbro Type à Diaphragme

Bougie d’allumage CHAMPION RCJ6Y

Contenance du réservoir de carburant

0,59(litter)/20,0(fl.oz)

Période de durabilité 50(hrs.)

Ces spécifications peuvent être modifiées sans préavis.

Page 22

FR-4

CHT2250

Des symboles en relief ont été placés sur la

machine pour assurer la sécurité à l’usage et

faciliter l’entretien. Prendre soin d’observer les

indications suivantes afin d’éviter les erreurs.

(a) Emplacement de remplissage du

“MELANGE”

Emplacement:

BOUCHON DU RESERVOIR DE

CARBURANT

(b) Position fermée du starter

Emplacement:

CAPOT DU FILTRE A AIR

(c) Position ouverte du starter

Emplacement:

CAPOT DU FILTRE A AIR

3. Etiquettes d’avertissement sur la machine

4. Symboles utilises sur la machine

*1: L'année changera chaque année de la fabrication.

*2: Le nombre initial changera chaque année de la fabrication.

*3: SP : Réservoir hermétique en HDPE ou PE.

■ MESURES DE LUTTE CONTRE LES EMISSIONS

Une étiquette de mesures de lutte contre les émissions se trouve

sur le machine.

Utilise JASO FD ou ISO L-EGD 50:1 Huile.

Fabrique Par:

Ce moteur est conforme aux règlements sur les émissions

de gaz U.S. EPA et californie EXH/EVP pour

2009*1

S.O.R.E.

Type de moteur :

9HQZS.0234BM*2 Cylindree :

23cc

Système de contrôle des émissions :

EXH;EM/EVP;SP*

3

Période de conformité : 50 heures

Se référer au manuel de l’opérateur pour l’entretien,

les spécifications et les réglages.

ZENOAH AMERICA INC.

Information de controle des émissions

(1) Lire le mode d’emploi avant d’utiliser

cette machine.

(2) Porter un casque et des lunettes de

sécurité, un casque antibruit.

(3) Une manipulation incorrecte de cette

machine peut provoquer des accidents

graves ou mortels. Lisez attentivement

ce mode d’emploi et entraînez-vous à

utiliser le tailleuse de haies jusqu’à ce

que vous maîtrisiez parfaitement toutes

les opérations et que vous ayez appris

à vous en servir correctement.

(4) Il est très tranchant et peut facilement

provoquer des coupures.

Si les étiquettes d’avertissement se décollent,

deviennent sales ou impossible à lire,

commander de nouvelles étiquettes auprès

du revendeur pour les remplacer.

Ne pas modifier la tailleuse de haies.

la garantie sera annulée si la tailleuse de

haies a été modifiée ou utilisée de

manière non conforme aux instructions de

ce mode d’emploi.

AVERTISSEMENT

IMPORTANT

Page 23

FR-5

CHT2250

F

R

5. Consignes de securite

1. RISQUE ELEVE DE BLESSURE

GRAVE. Lire ce manuel attentivement

jusqu’à une compréhension totale et

suivre toutes les instructions de sécurité

et d’utilisation. Vous devez aussi être

capable d’arrêter la débrouss-ailleuse

très vite en cas d’urgence.

2. Conserver ce mode d’emploi à portée

de la main pour le consulter au moindre

doute. Si une question reste sans

réponse, contacter le revendeur où

vous avez acheté la débroussailleuse.

3. Ne pas oublier de donner le manuel

avec la machine en cas de revente ou

de prêt.

4. Ne pas laisser des enfants ou toute

personne incapable de comprendre les

instructions, utiliser cette machine.

■ CONDITIONS DE TRAVAIL

1. Lors de l’utilisation de cette machine, il est

nécessaire de porter des vêtements

appropriés et des équipements de

sécurité.

(1) Casque

(2) Casque antibruit

(3) Lunettes ou masque de protection

(4) Gants de travail épais

(5) Chaussures de sécurité à semelle

antidérapante

2. Les objets suivants doivent être emportés

sur le lieu de travail.

(1) Les outils fournis avec la machine

(2) Une réserve de carburant

(3) Une lame de rechange

(4) Matériel pour délimiter la zone de travail

(5) Un sifflet (pour collaborateur ou en cas

d’urgence)

(6) Une hache ou une scie (pour enlever

les obstacles)

3. Ne pas porter de vêtements larges, de

short, de bijoux, de sandales ou travailler

pieds nus. Ne pas porter quoi que ce soit

pouvant être happé par les pièces en

mouvement de la machine. Porter les

cheveux longs noués au-dessus des

épaules.

■ CONDITIONS DE TRAVAIL

1. Ne jamais mettre la machine en marche à

l’intérieur d’une pièce ou d’un bâtiment.

Les gaz d’échappement contiennent du

monoxyde de carbone dangereux.

2. Ne jamais utiliser la machine dans les

conditions suivantes :

a. Lorsque le sol est glissant ou lorsqu’il

est impossible de se maintenir dans

une position correcte.

b. La nuit, par temps de brouillard ou

lorsque la visibilité ou le champ de

vision empêche de voir clairement la

zone de travail.

c. Pendant les averses, les orages avec

éclairs, par grands vents ou toute autre

condition climatique rendant l’utilisation

de la machine dangereuse.

■ PLAN DE TRAVAIL

1. Ne jamais utiliser la machine sous

l’influence de l’alcool ou en état de

faiblesse due à la fatigue, au manque de

sommeil, à la prise de médicament ou à

tout autre moment où l’on n’est pas

réellement capable de l’utiliser

correctement et en toute sécurité.

2. Lors de l’élaboration du plan de travail,

prévoir suffisamment de temps de repos.

Limiter la durée des périodes pendant

lesquelles la machine est utilisée sans

interruption entre 30 et 40 minutes. Se

reposer de 10 à 20 minutes entre ces

périodes. Autant que possible, essayer de

limiter ce genre de travail à 2 heures par

jour.

1. Si ce plan de travail et cette méthode de

travail ne sont pas respectés, un

accident dû au stress répétitif peut se

produire (voir “UTILISATION DE LA

MACHINE”).

Si l’on ressent un malaise ou si les

doigts ou tout autre membre rougissent

et enflent, consulter un docteur avant

que cela ne s’aggrave.

2. Pour éviter les problèmes de bruit avec

le voisinage, utiliser de préférence la

machine entre 8 et 17 heures pendant la

semaine et de 9 à 17 heures les fins de

semaine.

Vérifier et suivre la réglementation locale sur

le niveau de bruit et les horaires d’utilisation

de ce type de machine.

■ AVANT DE METTRE LE MOTEUR EN

MARCHE

1. La zone dans un rayon de 15 mètres

autour de l’utilisateur est considérée

REMARQUE

AVERTISSEMENT

Page 24

FR-6

CHT2250

5. Consignes de securite

comme dangereuse et personne ne doit

s’y trouver. Si nécessaire, délimiter le

périmètre de la zone de travail avec du

ruban de marquage (rouge fluorescent et

blanc par exemple) et poser des panneaux

d’avertissement. Lorsque deux ou

plusieurs personnes travaillent ensemble

ou à proximité, chacune doit constamment

faire attention et garder ses distances par

rapport aux autres pour assurer une

sécurité satisfaisante.

2. Vérifier constamment l’état de la zone de

travail pour éviter tout accident dû aux

impacts avec des obstacles tels que les

souches, les pierres, les boîtes de

conserves ou débris de verre.

Retirer tout obstacle avant de commencer le

travail.

3. Vérifier que la machine ne comporte aucun

élément desserré ou qu’il n’y a pas de fuite

de carburant. S’assurer que l’outil de

coupe est monté correctement et bien

serré.

4. S’assurer que le cache de protection antidébris est fermement attaché.

5. Utiliser toujours la machine avec son

harnais. Le régler pour un confort maximal

avant de mettre le moteur en marche. Il

doit être ajusté pour que la main gauche

puisse tenir confortablement la poignée

environ à hauteur de la taille.

■ DEMARRAGE DU MOTEUR

1. Ne laissez personne approcher à moins de

15 m du lieu de travail, en particulier les

enfants et les animaux. Si quelqu’un

s’approche trop près, arrêter aussitôt le

moteur.

2. Cette débroussailleuse est équipée d’un

embrayage centrifuge : les lames

s’activent dès que le papillon des gaz est

sur la position de démarrage et que le

moteur tourne. Pour mettre le moteur en

route, poser et maintenir fermement la

machine à plat sur le sol dans un endroit

dégagé où aucun obstacle ne peut entrer

en contact avec l’outil de coupe ou la

manette d’accélérateur une fois que le

moteur sera en marche.

Ne jamais mettre la manette de l’accélérateur à fond lors de la mise en marche.

AVERTISSEMENT

3. Une fois le moteur en marche, vérifier que

l’outil de coupe s’arrête de tourner lorsque

l’accélérateur est remis à zéro. Si l’outil de

coupe continue à tourner, arrêter le moteur

et rapporter la machine chez le revendeur

agréé RedMax pour la faire réparer.

■ UTILISATION DE LA MACHINE

Ne couper avec la machine que les

matériaux recommandés par le fabricant.

Ne l’utiliser que pour les travaux décrits

dans ce mode d’emploi.

1. Tenir les poignées de la machine

fermement des deux mains. Ecarter

légèrement les jambes (pour que les pieds

reposent sur une largeur un peu plus

importante que celle des épaules), avoir

une posture de travail stable et répartir le

poids du corps également sur chaque

jambe.

2. Maintenir les accessoires de coupe audessous de la ceinture.

3. Faire tourner le moteur à la vitesse

appropriée à la coupe sans jamais

accélérer inutilement au dessus du niveau

nécessaire.

4. Si la machine se met à vibrer ou à créer

des secousses, arrêter le moteur et

procéder à une vérification totale de la

machine. Ne pas utiliser la machine avant

que la panne ne soit réparée.

5. Se tenir à distance de l’outil de coupe ou

des parties chaudes de la machine.

6. Ne jamais toucher le silencieux, la bougie

ou toute autre partie métallique du moteur

pendant le fonctionnement ou aussitôt

après son arrêt. Dans ces circonstances,

les risques de brûlures ou d’électrocution

sont importants.

7. Veillez à ce que l’appareil soit toujours

stable et fonctionne en toute sécurité, en

particulier lorsque vous travaillez sur un

escalier ou sur une échelle.

• SI QUELQU’UN S’APPROCHE

1. Il faut se préserver des situations

dangereuses à tout moment. Avertir les

adultes de maintenir les enfants et les

animaux à distances car le risque de

recevoir des projections d’objets est

important.

2. Si quelqu’un appelle ou interrompt le

travail d’une manière ou d’une autre,

arrêter le moteur avant de se tourner vers

la personne.

IMPORTANT

IMPORTANT

Page 25

FR-7

CHT2250

F

R

5. Consignes de securite

■ ENTRETIEN

1. De manière à conserver la machine en

parfait état de marche, effectuer à

intervalles réguliers les opérations et les

vérifications d’entretien décrites dans le

mode d’emploi.

2. N’oubliez pas de couper le moteur avant

d’entreprendre une intervention d’entretien

ou de vérification de la machine.

(1) Tout est en ordre de marche!

Les pièces métalliques atteignent leur

plus haute température aussitôt après

l’arrêt de la machine.

3. Lors du remplacement de l’outil de coupe

ou d’une autre pièce, de l’huile ou du

lubrifiant, veiller à n’utiliser que des

produits RedMax ou des produits

certifiés par RedMax.

4. Pour toute pièce devant être remplacée ou

pour toute opération d’entretien ou de

réparation non décrite dans ce manuel,

contacter le centre de SAV agréé par

RedMax le plus proche pour demander

assistance.

5. Ne pas utiliser d’accessoires ou d’outils de

marque autres que RedMax ou non

agréés.

6. Ne jamais démonter ou modifier la

machine, quelles que soient les

circonstances. Dans le cas contraire, la

machine risque d’être endommagée en

cours d’utilisation ou de ne pas fonctionner

correctement.

■ MANIPULATION DU CARBURANT

1. Le moteur de la débroussailleuse RedMax

est conçu pour fonctionner avec du

mélange contenant de l’essence

hautement inflammable. Ne jamais

entreposer de bidon de carburant ou

refaire le plein de la machine dans un local

où se trouve une chaudière, un poêle, un

feu ouvert, des étincelles, un poste à

souder électrique ou toute autre source de

chaleur ou d’étincelles pouvant enflammer

le carburant.

2. Ne jamais fumer pendant l’utilisant de la

machine ou son remplissage en carburant.

3. Avant de refaire le plein de carburant,

toujours arrêter le moteur et laisser

refroidir la machine. Vérifier aussi

l’absence de flammes ou d’étincelles à

AVERTISSEMENT

proximité avant de faire le plein.

(1) Refaire le plein après avoir laissé

refroidir la débroussailleuse.

4. Essuyer avec un chiffon toute trace de

carburant renversé lors du remplissage.

5. Une fois le plein effectué, bien resserrer le

bouchon du réservoir et éloigner la

machine à plus de 3 mètres de l’endroit où

le plein a été fait avant de la remettre en

marche.

6. Les fumées de carburant sont toxiques :

ne pas inhaler.

■ TRANSPORT

1. Pour transporter la machine, couvrir la

partie coupante si nécessaire, relever la

machine et faire attention à la lame de

coupe.

2. Ne jamais transporter la machine sur

mauvaise route et sur une grande distance

sans vider complètement le réservoir de

carburant. Sinon le carburant pourrait

s’échapper du réservoir pendant le trajet.

Page 26

FR-8

CHT2250

CARBURANT

•L’essence est un produit hautement inflammable.

S’abstenir de fumer et ne tolérer aucun flamme ou source

d’étincelles à proximité de l’endroit où est entreposée

l’essence. Arrêter le moteur puis le laisser refroidir un peu

avant de remplir le réservoir. Remplir le réservoir à

l’extérieur sur une surface nue et éloigner le bidon

d’essence d’au moins 3 mètres avant de mettre le moteur

de la tronçonneuse en marche.

■ TYPES DE CARBURANTS REQUIS

• Tous les produits RedMax 2 temps disposent de moteurs 2

temps Zenoah de notre gamme professionnelle et

commerciale, à hautes performances, RPM élevées et

refroidis par air. Les moteurs 2 temps RedMax/Zenoah à

hautes performances, permettent d’obtenir plus de CV en sortie

par rapport aux moteurs des gammes standard à usage

personnel ou pour une utilisation commerciale légère offertes

par la plupart des fabricants.

• La composition des gaz d’échappement est contrôlée par les

principaux paramètres et composants du moteur (comme par

ex., la carburation, le calage de l’allumage) sans avoir besoin

d’effectuer des changements de matériel ou à introduire un

produit inerte durant la combustion.

• Les moteurs RedMax/Zenoah ont été approuvés et certifiés par

les agences gouvernementales CARB (Office Californien des

Ressources Aériennes) et EPA (Agence de Protection de

l'Environnement) pour pouvoir fonctionner avec de l’essence

PURE de type Normal ou Super à 89 octanes, essence sans

plomb et du "Max Life" RedMax refroidi à l’air, mélange

synthétique de Super et d'huile à 50:1 pour moteurs deux

temps.

• Il est préférable d’utiliser de l’essence sans plomb afin de

réduire la pollution de l’atmosphère et de participer ainsi à la

protection de l’environnement et de votre santé.

• Ce moteur 2 temps à hautes performances et refroidi à l’air a

besoin d’une essence pure à 89 octanes au minimum

(Normal ou Super). L’essence peut contenir un maximum de

10% d’éthanol (alcool) ou jusqu’à 15% de MTBE (éther

méthyltertiobutylique). Les essences contenant du méthanol ne

peuvent PAS être utilisées.

• Si l’indice d’octane de l’essence normale

dans votre région est

inférieur à 89 octanes, utilisez de l'essence Super sans plomb.

La plupart des fabricants de moteurs à 2 temps aux USA et au

Canada recommandent d’utiliser de l’essence à 89 octanes ou

plus.

REMARQUE

• Toute essence avec un indice inférieur à 89 octanes risque

d’élever dangereusement la température du moteur. Les

essences à indice d’octane inférieur à cette valeur ont tendance

à provoquer des détonations (explosions), ce qui risque

d’endommager les pistons ou d’autres composants importants

du moteur.

• De l’essence ou de l’huile de basse qualité risque

d’endommager les joints, les conduites d’essence ou le

réservoir d’essence du moteur.

• Les dommages dûs à l’utilisation du moteur avec des essences

à indice inférieur à 89 octanes ne sont pas couverts

par la

garantie des moteurs RedMax deux temps.

•Carburants alternatifs (autres que l’essence)

Les carburants alternatifs, tels que l’E-15 (15% d’éthanol),

E- 20 (20% d’éthanol) et E-85 (85% d’éthanol) ne sont PAS

considérés comme des carburants, et leur utilisation n’est

PAS approuvée avec les moteurs à essence RedMax à 2

temps. L’utilisation de carburants alternatifs entraînera de

graves problèmes de fonctionnement et de durabilité du

moteur, tels que : mauvais engagements de l’embrayage,

surchauffes, blocages par vapeur, pertes de puissance,

défaillances de lubrification, dégradation des tuyaux de

carburant, des joints statiques et des composants internes

du carburateur, etc. Les carburants alternatifs ont de plus

tendance à aggraver l'absorption d'humidité dans le

mélange carburant/huile, ce qui entraîne une séparation de

ces deux composants.

■ Types d‘huiles requises

• N’utilisez que du RedMax "Max Life", du mélange synthétique

Super et huile moteur à deux temps refroidi à l'air, ou de l'huile

certifiée selon la norme ISO-L-EGD

(ISO\CD1378) ET une

certifiée JASO-FD

. Le RedMax "Max Life" refroidi à l’air, le

mélange synthétique Super et huile moteur à deux temps

refroidi à l'air, et l'huile ISO-L-EGD

(ISO\CD1378) ET

JASO-FD

sont entièrement compatibles avec de l’essence contenant 10%

d’éthanol. Le RedMax "Max Life" refroidi à l’air, le mélange

synthétique Super et huile moteur à deux temps refroidi à l'air,

et l'huile ISO-L-EGD

(ISO\CD1378) ET

JASO-FD

sont des

carburants universels et devraient être mélangés à un rapport

de 50:1 pour tous les moteurs à 2 temps refroidis à l’air déjà

commercialisés, indépendamment des rapports de mélange

mentionnés dans les modes d’emploi.

• Si l’huile en question est certifiée JASO, le logo JASO avec la

mention FD

ainsi que le numéro d'enregistrement

correspondant sera présent sur le récipient. La classe JASO la

plus élevée est "FD", qui correspond à la classe ISO-L-EGD

.

Les classes inférieures sont "FC", "FB" et "FA".

AVERTISSEMENT

6. Carburant

[ R+M ]

2

AVERTISSEMENT

AVERTISSEMENT

REMARQUE

Page 27

FR-9

CHT2250

F

R

6. Carburant

• Tout dommage ou problème du moteur, dû à une lubrification

inadéquate, suite à la non utilisation d’une huile certifiée ISOLEGD

et JASO FD, comme le "MaxLife", mélange synthétique

RedMax Super et huile à 2 temps ENTRAÎNERA

L’ANNULATION DE LA GARANTIE DU MOTEUR A DEUX

TEMPS RedMax.

•Ne pas utiliser d’huiles conçues pour les cyclomoteurs ou

les moteurs hors-bord de la NMMA (Association nationale

des constructeurs de véhicules maritimes) et les moteurs

TCW (moteur deux temps refroidis à l’eau). Ne pas utiliser

d’huiles étiquetées API (American Petroleum Institute) TC

(Deux cycles). L'étalonnage de test API-TC a été annulé par

API en 1995 et n'existe plus.

• Conseils sur le stockage du mélange carburant/huile

L’essence ou le mélange d’essence/d’huile devra être conservé

au frais et à sec, dans un récipient étanche approuvé, afin de

limiter la pénétration d’humidité et d’air (oxygène). En effet,

l’humidité ainsi que l’air ont tendance à causer le

développement d’une couche de vernis et de gomme, ce qui

entraîne l’éventement de l’essence. L’essence ou le mélange

d’essence/d’huile stockée vieillit et perd donc en indice d'octane

et en volatilité. Ne mélangez donc pas plus d'essence/d’huile

qu’une quantité pour 30 jours, ou 60 jours lorsqu’un produit

stabilisateur est utilisé. Le mélange synthétique RedMax "Max

Life" refroidi à l’air Super huile moteur à deux temps "Contient

un stabilisateur pour carburant" et prolonge donc

automatiquement la durée de vie de votre mélange

d’essence/huile à 60 jours.

■ COMMENT OBTENIR UN BON MELANGE

RAPPORT DE MELANGE

RECOMMANDE

ESSENCE 50 : HUILE 1

(Lors de l’utilisation de la véritable huile

"Max Life" RedMax refroidi à l’air)

IMPORTANT

• Faire attention à ne pas trop remuer le carburant.

1. Mesurez les volumes d’essence et d’huile à mélanger.

2. Verser un peu d’essence dans un récipient à carburant propre.

3. Verser ensuite toute l’huile, puis bien remuer le tout.

4. Verser enfin le reste de l’essence, puis bien mélanger

l’ensemble pendant une minute environ. Etant donné que

certains types d’huiles sont plus fluides que d’autres en fonction

de leur composition, un brassage énergique est nécessaire afin

de garantir une bonne marche du moteur pendant longtemps.

En effet, en cas de mélange insuffisant, un risque majeur de

problèmes au niveau des cylindres peut apparaître en raison

d’un mélange hétérogène.

5. Placer une étiquette assez grande sur le récipient afin d’éviter

de le confondre avec de l’essence ou avec d’autres récipients.

6. Indiquer les composants sur cette étiquette afin d’en faciliter

l’identification.

■ REMPLISSAGE DU RESERVOIR

1. Dévisser puis retirer le bouchon de carburant. Déposer ce

bouchon sur une surface non poussiéreuse.

2. Remplir le réservoir de carburant à 80% de sa capacité totale.

3. Visser fermement le bouchon du réservoir et essuyer toute

éventuelle éclaboussure d’essence sur l’appareil.

1. Effectuer le remplissage sur une surface nue.

2. S’éloigner d’au moins 3 mètres du point de remplissage

avant de démarrer le moteur.

3. Arrêter le moteur avant de faire le plein de l’appareil. Bien

remuer à cet instant le mélange d’essence dans le

réservoir.

■

A EVITER POUR PROLONGER LA DUREE DE VIE DU MOTEUR :

1. ESSENCE SANS HUILE (ESSENCE PURE) – L’essence pure

va endommager très rapidement les pièces du moteur.

2. ESSENCE-ALCOOL – Ce mélange risque de très rapidement

détruire les pièces en caoutchouc et/ou en plastique et

d’empêcher la lubrification du moteur.

3. UILE POUR MOTEURS 4 TEMPS – Elles risquent d’encrasser

les bougies, de bloquer l’échappement ou d’endommager les

segments des pistons.

4. Les mélanges d’huile et de carburants laissés au repos

pendant une période d’un mois ou plus risquent

sérieusement d’encrasser le carburateur et d’entraîner par

conséquent une défaillance du moteur.

5. Dans l’éventualité d’une longue période d’inactivité, nettoyer le

réservoir de carburant après l’avoir vidangé. Allumer ensuite le

moteur et vider le mélange d’essence du carburateur.

6. En cas de mise au rebut du récipient contenant le mélange

d’huile, en disposer toujours dans une décharge autorisée.

Pour plus de détails sur la garantie de qualité, lire attentivement

la section à propos de la Garantie Limitée. Il est également

important de rappeler que l’usure et les dégradations normales

de l’appareil ne sont en aucun cas couvertes par cette garantie.

AVERTISSEMENT

TABLEAU DE MELANGE 50 :1

ESSENCE gal. 1 2 3 4 5

HUILE 2 TEMPS once liquide

2.6 5.2 7.8 10.4 13

ESSENCE litre 1 2 3 4 5

HUILE 2 TEMPS ml 20 40 60 80 100

AVERTISSEMENT

AVERTISSEMENT

Page 28

FR-10

CHT2250

6. Carburant

De plus, le non-respect des instructions relatives aux

proportions des mélanges d’essence, etc. décrites dans ce

mode d’emploi risque d’entraîner un refus de couverture par la

garantie.

• As for details of quality assurance, read the description in the

section Limited Warranty carefully. Moreover, normal wear and

change in product with no functional influence are not covered

by the warranty. Also, be careful that, if the usage in the

instruction manual is not observed as to the mixed gasoline,

etc. described therein, it may not be covered by the warranty.

REMARQUE

Page 29

FR-11

CHT2250

F

R

• Si le moteur ne démarre pas après

plusieurs tentatives, ouvrez l'étrangleur

et recommencez à tirer sur la

cordelette ou retirez la bougie

d'allumage et séchez-la.

■ ARRET DU MOTEUR

1. Libérez la manette des gaz et laissez

tourner le moteur au ralenti pendant

une demi-minute.

2. Faites glisser le commutateur

d'allumage en position STOP.

• Sauf en cas d'urgence, évitez d'arrêter

le moteur pendant qu'il tourne à haute

vitesse.

■ REGLAGE DU REGIME DE RALENTI

1. Si le moteur a tendance à s'arrêter

lorsqu'il tourne au ralenti, tournez la vis

de réglage du ralenti dans le sens des

aiguilles d'une montre.

(1) Vis de reglage du ralenti

2. Si les lames de coupe continuent leur

mouvement après que vous ayez

relâché la gâchette d'accélérateur,

tournez la vis de réglage du ralenti

dans le sens inverse des aiguilles

d'une montre.

• Faites chauffer le moteur avant de

régler le régime de ralenti.

■ COMMENT UTILISER

• Cette machine est conçue pour

couper des rameaux jusqu'à 8 mm

de diamètre. Le fait de couper des

rameaux trop gros ou des fils

métalliques peut non seulement

casser les dents de la lame, mais

également endommager le

mécanisme d'entraînement.

• Lorsque vous émondez des feuillez ou

des rameaux fins, guidez la lame pour

qu'elle décrive un arc de cercle sur la

surface à émonder, vous obtiendrez

ainsi un meilleur résultat.

• Si vous faites tourner le moteur à haute

vitesse alors que les lames sont

REMARQUE

7. Fonctionnement

■ DEMARRAGE DU MOTEUR

Placez l'appareil dans un espace

dégagé car les lames commenceront à

bouger dès le démarrage du moteur.

1. Lorsque vous démarrez la machine

après y avoir mis de l'essence,

poussez la pompe d'amorçage jusqu'à

ce que l'essence sorte par le tube

incolore. Puis fermez l'étrangleur.

L'étranglement peut ne pas être

nécessaire lorsque vous redémarrez le

moteur juste après l'avoir arrêté. (OP1)

(1) Pompe d'amorçage

(2) Levier du starter

(3) Ferm

(4) Ouvert

2. Tirez la manette des gaz et poussez le

bouton de verrouillage pour régler la

manette en position START. (OP2)

(1) Manette des gas

(2) Bouton de verrouillage

3. Faites glisser le commutateur

d'allumage sur le côté du moteur pour

le régler en position ON. (OP3)

4. Posez la machine sur un endroit ferme.

Tirez rapidement sur la manette de

démarrage. (OP4)

• Evitez de tirer sur la cordelette jusqu'à

son extrémité ou de la laisser revenir

en la lâchant. De telles actions peuvent

endommager le starter.

5. Lorsque le moteur a démarré, ouvrez

l'étrangleur progressivement.

6. Laissez le moteur chauffer pendant une

demi-minute avant de commencer

l'utilisation.

REMARQUE

OP1

OP2

OP3

OP4

OP5

OP6

REMARQUE

AVERTISSEMENT

REMARQUE

Page 30

FR-12

CHT2250

7. Fonctionnement

bloquées, cela peut raccourcir la durée

de vie des pièces de l'embrayage.

Lorsque les lames sont bloquées par

des rameaux trop gros, arrêtez le

moteur et retirez l'appareil des

rameaux où il est bloqué. Lorsque vous

taillez des rameaux un peu plus gros,

déplacez lentement l'appareil de

l'arrière vers l'avant comme une scie, le

résultat sera meilleur.

• Lorsqu'un nouvel appareil est utilisé

pour la première fois, durant les

premières minutes de la graisse peut

s'échapper du réservoir de graisse.

Cette graisse étant en excédent, il n'y a