Page 1

OWNER'S/OPERATOR'S

MANUAL

MODE D’EMPLOI MANUAL DE

INSTRUCCIONES

HEDGE TRIMMER

TAILLEUSE DE HAIES

CORTASETOS

115 43 11-49 (105)

WARNING

The engine exhaust from this

product contains chemicals

known to the State of California to

cause cancer, birth defects or

other reproductive harm.

WARNING

AVERTISSEMENT

AVERTISSEMENT

ADVERTENCIA

ADVERTENCIA

Before using our products,

please read this manual carefully

to understand the proper use of

your unit.

Los gases de escape del motor de

este producto contienen

sustancias químicas conocidas

por el Estado de California como

causantes de cáncer,

malformaciones en recién nacidos

y otros problemas de

reproducción.

Les échappements du moteur de

ce produit contiennent des

produits chimiques connus par

l’Etat de Californie comme étant

responsables de cancers,

d’anomalies congénitales et

d’autres atteintes à l’appareil

reproducteur.

Antes de usar nuestros productos,

lea detenidamente este manual a

fin de familiarizarse con el uso

correcto de este aparato.

Avant d’utiliser cette

ce produit

,

veuillez lire attentivement ce

manuel afin de bien comprendre le

bon fonctionnement de cet

appareil.

CHT220

CHT220L

U

S

F

R

E

S

This spark ignition system complies with

the Canadian standard ICES-002.

Ce système d’allumage par étincelle de véhicule

est conforme à la norme NMB-002 du Canada.

Este sistema de ignición por chispa de vehículo

es conforme con la norma ICES-002 del Canadá.

Page 2

Page 3

US-1

CHT220/CHT220L

U

S

OWNER'S/OPERATOR'S

MANUAL

HEDGE TRIMMER

115 43 11-49 (105)

WARNING

The engine exhaust from this

product contains chemicals

known to the State of California to

cause cancer, birth defects or

other reproductive harm.

WARNING

Before using our products,

please read this manual carefully

to understand the proper use of

your unit.

CHT220

CHT220L

This spark ignition system complies with

the Canadian standard ICES-002.

Page 4

US-2

CHT220/CHT220L

SAFETY FIRST

Instructions contained in warnings within this

manual marked with a symbol concern critical

points which must be taken into consideration to

prevent possible serious bodily injury, and for this

reason you are requested to read all such

instructions carefully and follow them without fail.

■ WARNINGS IN THE MANUAL

This mark indicates instructions which must be followed

in order to prevent accidents which could lead to serious

bodily injury or death.

This mark indicates instructions which must be followed,

or it leads to mechanical failure, breakdown, or damage.

This mark indicates hints or directions useful in the use

of the product.

NOTE

The engine is switched off by moving the stop switch to

the stop position.

CAUTION! The stop switch automatically returns to the

start position. In order to prevent unintentional starting,

the spark plug cap must be removed from the spark

plug when assembling, checking and/or performing

maintenance.

Always wear approved protective gloves.

Regular cleaning is required.

Visual check.

Protective goggles or a visor must be worn.

WARNING

IMPORTANT

Page 5

US-3

CHT220/CHT220L

U

S

Contents

■ NOTE THE FOLLOWING BEFORE STARTING:

Please read the operator’s manual carefully.

WARNING! Long-term exposure to noise can result

in permanent hearing impairment. So always use

approved hearing protection.

WARNING! Under no circumstances may the

design of the machine be modified without the

permission of the manufacturer. Always use

genuine accessories. Non-authorized modifications

and/or accessories can result in serious personal

injury or the death of the operator or others.

Your warranty may not cover damage or liability

caused by the use of non-authorized accessories

or replacement parts.

WARNING! Incorrect or careless use of a hedge

trimmer can turn it into a dangerous tool that can

cause serious or even fatal injury. It is extremely

important that you read and understand the

contents of this operator’s manual.

1. Parts location......................................................................4

2. Specifications .....................................................................4

3. Symbols..............................................................................5

4. Emission control .................................................................5

5. For safe operation ..............................................................6

6. Fuel.....................................................................................9

7. Starting and stopping........................................................11

8. Working techniques ..........................................................12

9. Maintenance .....................................................................14

10. Storage .............................................................................18

11. Disposal............................................................................18

12. Troubleshooting guide ......................................................18

WARNING

The engine exhaust from this product

contains chemical known to the State

of California to cause cancer, birth

defects or other reproductive harm.

Page 6

US-4

CHT220/CHT220L

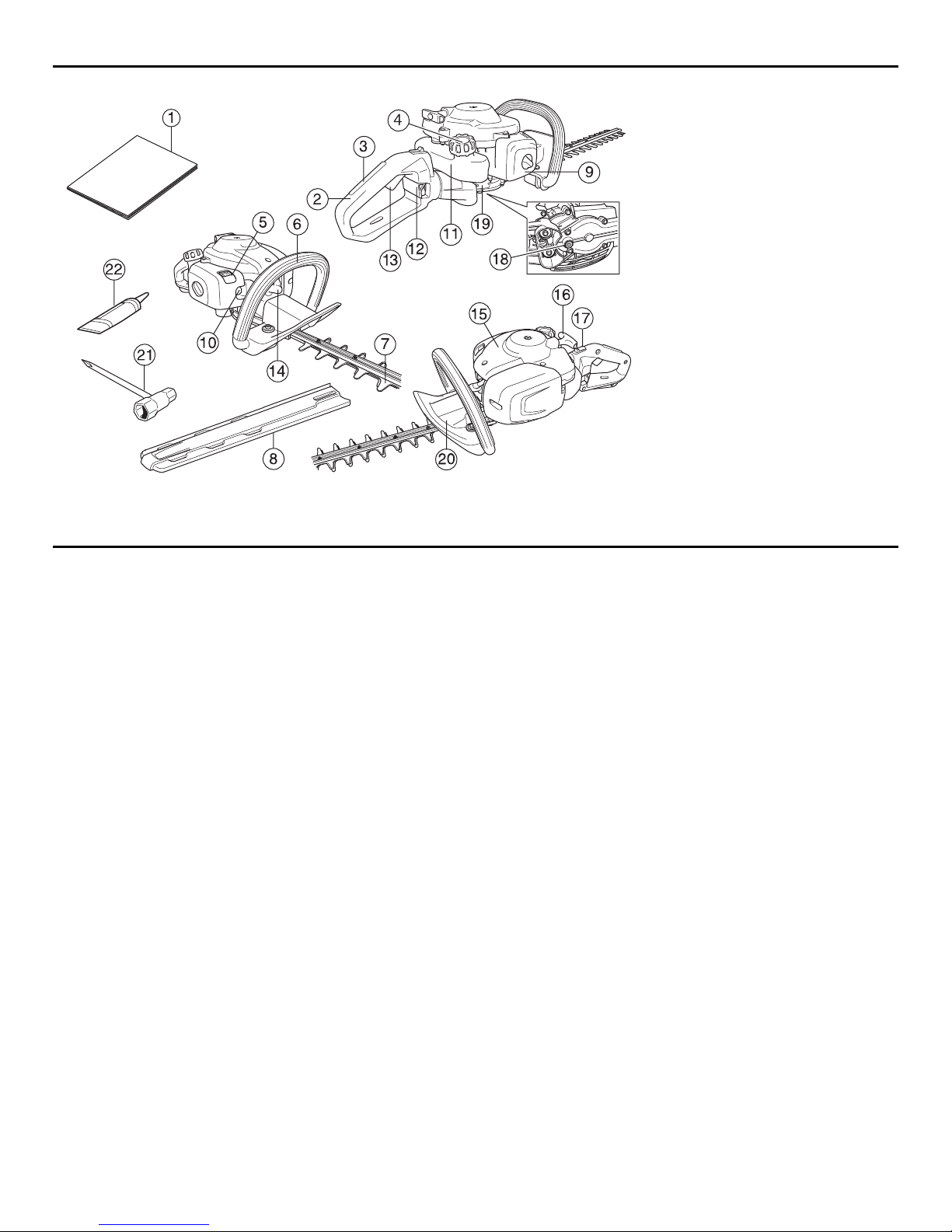

1. Parts location

1 Operator's manual

2 Handle

3 Throttle lock

4 Fuel cap

5 Choke control

6 Front handle

7 Blade and blade guard

8 Transport guard

9 Air filter cover

10 Air purge

11 Fuel tank

12 Lock for handle CHT220L

13 Throttle control

14 Spark plug cap and spark plug

15 Cylinder cover

16 Starter handle

17 Stop switch

18 Lubricant filler cap, gear

19 Gear

20 Hand guard

21 Combination spanner

22 Tube of grease

2. Specifications

Model name CHT220 CHT220L

Engine

Cylinder displacement, cu.in/cm

3

21,7 21,7

Cylinder bore, inch/mm 1,26/32 1,26/32

Stroke, inch/mm 1,06/27 1,06/27

Idle speed, rpm 2900 2900

Recommended max. speed, rpm 9000 9000

Max. engine output, acc. to ISO 8893, kW/ rpm 0,6/7800 0,6/7800

Catalytic converter muffler Yes Yes

Speed-regulated ignition system Yes Yes

Ignition system

Spark plug NGK CMR6A NGK CMR6A

Electrode gap, inch/mm 0,02/0,5 0,02/0,5

Fuel and lubrication system

Fuel tank capacity, US pint/litre 0,3 0,3

Weight

Weight without fuel, Lbs/kg 10,3/4,7 10,8/4,9

Sound levels

(see note 1)

Equivalent sound pressure level at the operator's ear,

measured according to EN ISO 10517, dB(A): 93 5, 7/94

Vibration levels

(see note 2)

Equivalent vibration levels (ahv,eq) at handles,

measured according to EN ISO 10517, m/s

2

Front/rear handles: 2,9/4,9 4,1/3,6

Blades

Type Double sided Double sided

Length, mm 450 590

Blade speed, cuts/min 4050 4050

Note 1: Reported data for equivalent sound pressure level for the machine has a typical statistical dispersion (standard

deviation) of 1 dB (A).

Note 2: Reported data for equivalent vibration level has a typical statistical dispersion (standard deviation) of 1 m/s

2

.

Page 7

US-5

CHT220/CHT220L

U

S

3. Symbols

WARNING! Incorrect or careless use of a hedge trimmer can turn

it into a dangerous tool that can cause serious or even fatal injury.

It is extremely important that you read and understand the

contents of this operator’s manual.

Please read the operator’s manual carefully and make sure you

understand the instructions before using the machine.

Always wear:

• Approved hearing protection

• Approved eye protection

Always wear approved protective gloves.

Wear sturdy, non-slip boots or shoes.

Starting instructions See the instructions under the heading Start

and stop.

Other symbols/decals on the machine refer to special

certification requirements for certain markets.

4. Emission control

The Emissions Compliance Period referred to on the Emission

Compliance label indicates the number of operating hours for

which the engine has been shown to meet Federal emissions

requirements.

An emission control label is located on the machine.

Page 8

US-6

CHT220/CHT220L

1. THIS MACHINE CAN CAUSE

SERIOUS INJURIES. Read this manual

carefully until you completely

understand and follow all safety and

operating instructions. Also, know how

to stop the machine quickly in an

emergency.

2. Keep this manual handy so that you

may refer to it later whenever any

questions arise. Also note, if you have

any questions which cannot be

answered herein, contact the dealer

from whom you purchased the product.

3. Always be sure to include this manual

when selling, lending, or otherwise

transferring the ownership of this

product.

4. Never allow children or anyone unable

to fully understand the directions given

in the manual to use the machine.

■ WORKING CONDITION

1. When using the product, you should wear

proper clothing and protective equipment.

(1) Helmet

(2) Ear protectors

(3) Protection goggles or face protector

(4) Thick work gloves

(5) Non-slip-sole work boots

2. And you should carry with you.

(1) Attached tools

(2) Properly reserved fuel

(3) Spare blade

(4) Things to notify your working area

(rope, warning signs)

(5) Whistle (for collaboration or emergency)

(6) Hatchet or saw (for removal of

obstacles)

(7) First-aid kit

3. Do not wear loose clothing, jewelry, short

trousers, sandals, or go barefoot. Do not

wear anything which might be caught by a

moving part of the unit. Secure hair so it is

above shoulder length.

■ WORKING CIRCUMSTANCE

1. Never start the engine inside a closed

room or building. Exhaust gases contain

dangerous carbon monoxide.

2. Never use the product,

a. when the ground is slippery or when

you can’t maintain a steady posture.

b. At night, at times of heavy fog, or at any

5. For safe operation

other times when your field of vision

might be limited and it would be difficult

to gain a clear view of the working area.

c. During rain storms, during lightning

storms, at times of strong or gale-force

winds, or at any other times when

weather conditions might make it

unsafe to use the product.

■ WORKING PLAN

1. You should never use the product when

under the influence of alcohol, when

suffering from exhaustion or lack of sleep,

when suffering from drowsiness as a result

of having taken cold medicine or at any

other time when a possibility exists that

your judgment might be impaired or that

you might not be able to operate the

product properly and in a safe manner.

2. When planning your work schedule, allow

plenty of time to rest. Limit the amount of

time over which the product is to be used

continuously to somewhere around 30 ~ 40

minutes per session, and take 10 ~ 20

minutes of rest between work sessions.

Also try to keep the total amount of work

performed in a single day under 2 hours or

less.

1. If you don’t observe the working time,

or working manner (See “USING THE

PRODUCT”), Repetitive Stress Injury

(RSI) could occur.

If you feel discomfort, redness and

swelling of your fingers or any other

part of your body, see a doctor before

getting worse.

2. To avoid noise complaints, in general,

operate product between 8 a.m. and 5

p.m. on weekdays and 9 a.m. to 5 p.m.

on weekends.

Check and follow the local regulations as to

sound level and hours of operations for the

product.

■ BEFORE STARTING THE ENGINE

1. The area within a perimeter of 15 m (50 ft)

of the person using the product should be

considered a hazardous area into which no

one should enter. If necessary, yellow

warning rope, warning signs should be

placed around the perimeter of the area.

When work is to be performed

simultaneously by two or more persons,

NOTE

WARNING

Page 9

US-7

CHT220/CHT220L

U

S

care should also be taken to constantly

look around or otherwise check for the

presence and locations of other people

working so as to maintain a distance

between each person sufficient to ensure

safety.

2. Check the condition of working area to

avoid any accident by hitting hidden

obstacles such as stumps, stones, cans, or

broken glass.

Remove any obstacle before beginning work.

3. Inspect the entire unit for loose fasteners

and fuel leakage. Make sure that the

cutting attachment is properly installed and

securely fastened.

■ STARTING THE ENGINE

1. Keep bystanders especially children, and

animals at least 15 m (50 ft) away from the

operating point. If you are approached,

immediately stop the engine.

2. The product is equipped with a centrifugal

clutch mechanism, so the cutting

attachment might begin to rotate as soon

as the engine is started. When starting the

engine, place the product onto the ground

in a flat clear area and hold it firmly in

place so as to ensure that neither the

cutting part nor the throttle come into

contact with any obstacle when the engine

starts.

• Never place the throttle into the high-

speed position when starting the

engine.

• Never start the engine at the cutting

attachment side.

3. After starting the engine, check to make

sure that the cutting attachment stops

rotating when the throttle is moved fully

back to its original position. If it continues

to rotate even after the throttle has been

moved fully back, turn off the engine and

take the unit to your authorized RedMax

servicing dealer for repair.

■ USING THE PRODUCT

Cut only materials recommended by the

manufacturer. And use only for tasks

IMPORTANT

5. For safe operation

explained in the manual.

1. Grip the handles firmly with both hands

using your whole hand. Place your feet

slightly apart (slightly further apart than the

width of your shoulders) so that your

weight is distributed evenly across both

legs, and always be sure to maintain a

steady, even posture while working.

2. Maintain the speed of the engine at the

level required to perform cutting work, and

never raise the speed of the engine above

the level necessary.

3. If the unit starts to shake or vibrate, turn off

the engine and check the whole unit. Do

not use it until the trouble has been

properly corrected.

4. Keep all parts of your body away from

rotating cutting attachment and hot

surfaces.

5. Never touch the muffler, spark plug, or

other metallic parts of the engine while the

engine is in operation or immediately after

shutting down the engine. Doing socould

result in serious burns or electrical shock.

6. While operating the machine be always

sure of a safe and secure operating

position especially when using steps or a

ladder.

• IF SOMEONE COMES

1. Guard against hazardous situations at all

times. Warn adults to keep pets and

children away from the area. Be careful if

you are approached. Injury may result from

flying debris.

2. If someone calls out or otherwise interrupts

you while working, always be sure to turn

off the engine before turning around.

■ MAINTENANCE

1. In order to maintain your product in proper

working order, perform the maintenance

and checking operations described in the

manual at regular intervals.

2. Always be sure to turn off the engine

before performing any maintenance,

checking procedures or working on the

machine.

(1) Check ok!

The metallic parts reach high

temperatures immediately after stopping

the engine.

3. When replacing the cutting attachment or

WARNING

IMPORTANT

WARNING

Page 10

US-8

CHT220/CHT220L

5. For safe operation

any other part, or when replacing the oil or

any lubricant, always be sure to use only

RedMax products or products which

have been certified by RedMax for use

with the RedMax product.

4. In the event that any part must be replaced

or any maintenance or repair work not

described in this manual must be

performed, please contact a representative

from the store nearest RedMax authorized

servicing dealer for assistance.

5. Do not use any accessory or attachment

other than those bearing the RedMax mark

and recommended for the unit.

6. Under no circumstances should you ever

take apart the product or alter it in any

way. Doing so might result in the product

becoming damaged during operation or the

product becoming unable to operate

properly.

■ HANDLING FUEL

1. The engine of the RedMax product is

designed to run on a mixed fuel, which

contains highly flammable gasoline. Never

store cans of fuel or refill the tank of the

unit in any place where there is a boiler,

stove, wood fire, electrical sparks, welding

sparks, or any other source of heat or fire

which might ignite the fuel.

2. Never smoke while operating the unit or

refilling its fuel tank.

3. When refilling the tank, always turn off the

engine and allow it to cool down. Take a

careful look around to make sure that there

are no sparks or open flames anywhere

nearby before refueling.

(1) Refill after cooling the engine.

4. Wipe spilled fuel completely using a dry

rag if any fuel spillage occurs during

refueling.

5. After refueling, screw the fuel cap back

tightly onto the fuel tank and then carry the

unit to a spot 3 m or more away from

where it was refueled before turning on the

engine.

6. Do not inhale fuel fumes as they are toxic.

■ TRANSPORTATION

1. When hand-carrying the product, cover

over the cutting part if necessary, lift up the

product and carry it paying attention to the

blade.

2. Never transport the product over rough

roads over long distances by vehicle

without removing all fuel from the fuel tank.

If doing so, fuel might leak from the tank

during transport.

Page 11

US-9

CHT220/CHT220L

U

S

lines or fuel tank of the engine.

• Failures caused by operating engines on gasoline with octane

rating lower than 89 are not covered

by the RedMax Two-

Stroke engine warranty.

•Alternative Fuels (Not Gasoline)

Alternative fuels, such as E-15 (15% ethanol), E-20 (20%

ethanol), E-85 (85% ethanol) are NOT classified as gasoline

and are NOT approved for use in RedMax 2-stroke gasoline

engines. Use of alternative fuels will cause major engine

performance and durability problems such as: improper

clutch engagements, overheating, vapor lock, power loss,

lubrication deficiency, deterioration of fuel lines, gaskets

and internal carburetor components, etc... Alternative fuels

cause high moisture absorption into the fuel/oil mixture

leading to oil and fuel separation.

■ OIL REQUIREMENTS

• Use only RedMax "Max Life", Synthetic blend Premium AirCooled two-stroke engine oil or oil certified to ISO-L-EGD

(ISO/CD1378) standard AND

one that is JASO-FD

registered.

RedMax Air-Cooled "Max Life", Synthetic blend Premium two

stroke engine oil and ISO-L-EGD

(ISO/CD1378) AND

JASO-FD

oils are fully compatible

with gasoline's containing 10% Ethanol.

RedMax Air-Cooled "Max Life", Synthetic blend Premium two

stroke engine oil and ISO-L-EGD

(ISO/CD1378) AND

JASO-FD

oils are Universal and should be mixed at 50:1 ratio for all 2

stroke air cooled engines sold in the past regardless of mixing

ratios specified in those manuals.

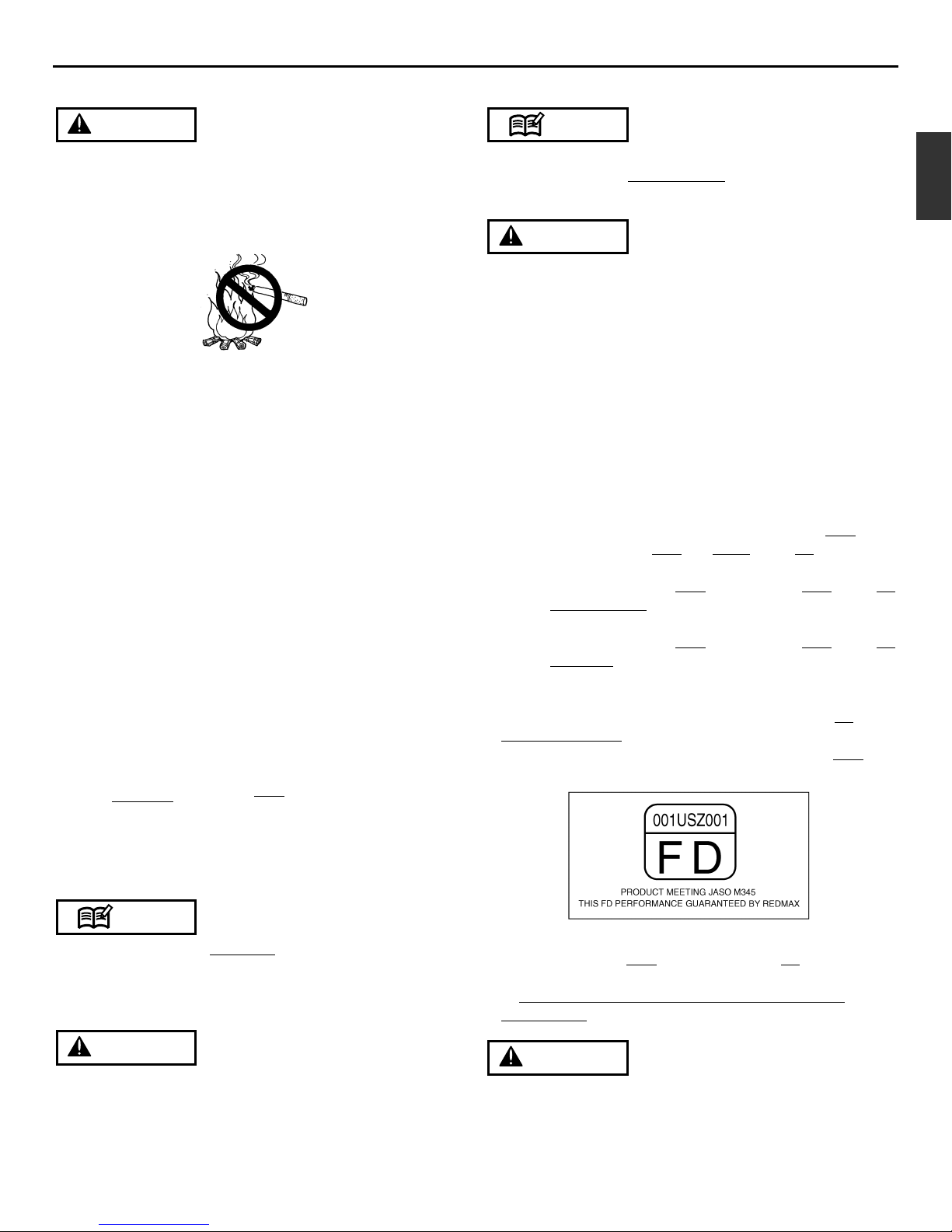

• If the oil is registered with JASO, the JASO Logo with FD

and

registration number

will be displayed on the container. The

highest JASO rating is "FD", which equals the ISO-L-EGD

rating. Lower ratings are "FC", "FB", and "FA".

• Engine problems due to inadequate lubrication caused by

failure to use ISO-L-EGD

certified and JASO FD registered oil

such as "MaxLife", RedMax Synthetic blend Premium 2-stroke

oil WILL VOID THE REDMAX TWO-STROKE ENGINE

WARRANTY.

• Do not use NMMA (National Marine Manufacturers

Association), BIA (Boating Industry Association), and TCW (two

cycle water cooled) oils designed for MoPeds or Outboard,

water cooled Marine Engines. Do not use API (American

Petroleum Institute), TC (Two Cycle) labeled oils. The API-TC

WARNING

6. Fuel

FUEL

• Gasoline is very flammable. Avoid smoking or bringing any

flame or sparks near fuel. Make sure to stop the engine and

allow it cool before refueling the unit. Select outdoor bare

ground for fueling and move at least 10 ft (3 m) away from

the fueling point before starting the engine.

■ GASOLINE REQUIREMENTS

• All 2-Stroke RedMax Products are powered by RedMax

Professional-Commercial Duty, Hi-Performance, Hi-RPM, Air

Cooled 2-Stroke engines.

RedMax – Hi-Performance 2-stroke engines produce higher HP

outputs as compared to standard Home Owner Duty or Light

Commercial Duty production engines offered by most

manufacturers.

• Exhaust emission are controlled by the fundamental engine

parameters and components (eq., carburation, ignition timing

and port timing) without addition of any major hardware or the

introduction of an inert material during combustion.

• The RedMax Engines are registered and certified with CARB

(California Air Resources Board) and EPA (Environmental

Protection Agency) to operate on CLEAN Mid-grade 89 octane

or Premium, unleaded (lead-free) gasoline and RedMax AirCooled "Max Life", Synthetic blend Premium two-stroke engine

oil mixed at 50:1 ratio.

• Unleaded gasoline is recommended to reduce the

contamination of the air for the sake of your health and the

environment.

• This Hi-Performance Air Cooled 2-stroke Engine requires the

use of Minimum

89 Octane (Mid grade or Premium)

clean gasoline. Gasoline may contain maximum of 10% Ethanol

(grain alcohol) or up to 15% MTBE (Methyl tertiary-butyl ether).

Gasoline containing Methanol (Wood Alcohol) is NOT

approved.

• IF octane rating of the Mid Grade

gasoline in your area is lower

than 89 Octane use Premium Unleaded Gasoline. The majority

of all 2-stroke engine manufacturers in the USA and Canada

recommend using gasoline with 89 Octane or higher.

• Gasoline with an octane rating lower than 89 will greatly

increase the engines operating temperature. Low octane

gasoline will cause detonation (knock) resulting in piston

seizures and major internal engine components damage.

• Poor quality gasolines or oils may damage sealing rings, fuel

WARNING

[ R+M ]

2

WARNING

NOTE

WARNING

NOTE

Page 12

US-10

CHT220/CHT220L

6. Fuel

test standard has been discontinued by API in 1995 and it no

longer exists.

• Gasoline/Oil mixture Storage Recommendations

Store your gasoline or gasoline/oil mixture in a cool dry area in

a tightly sealed approved container to limit the entry of moisture

and additional air (oxygen). Moisture and air cause the

development of varnish and gum, making the fuel stale. Stored

gasoline and gasoline/oil mixture ages and loses its octane

rating and volatility. Do not mix more gasoline/oil than you

intend to use in 30 days, and 60 days when fuel stabilizer is

added. RedMax Air-Cooled "Max Life" Synthetic blend

Premium two-stroke engine oil "Contains fuel stabilizer"

and

will automatically extend your gasoline/oil mixture life up to 60

days.

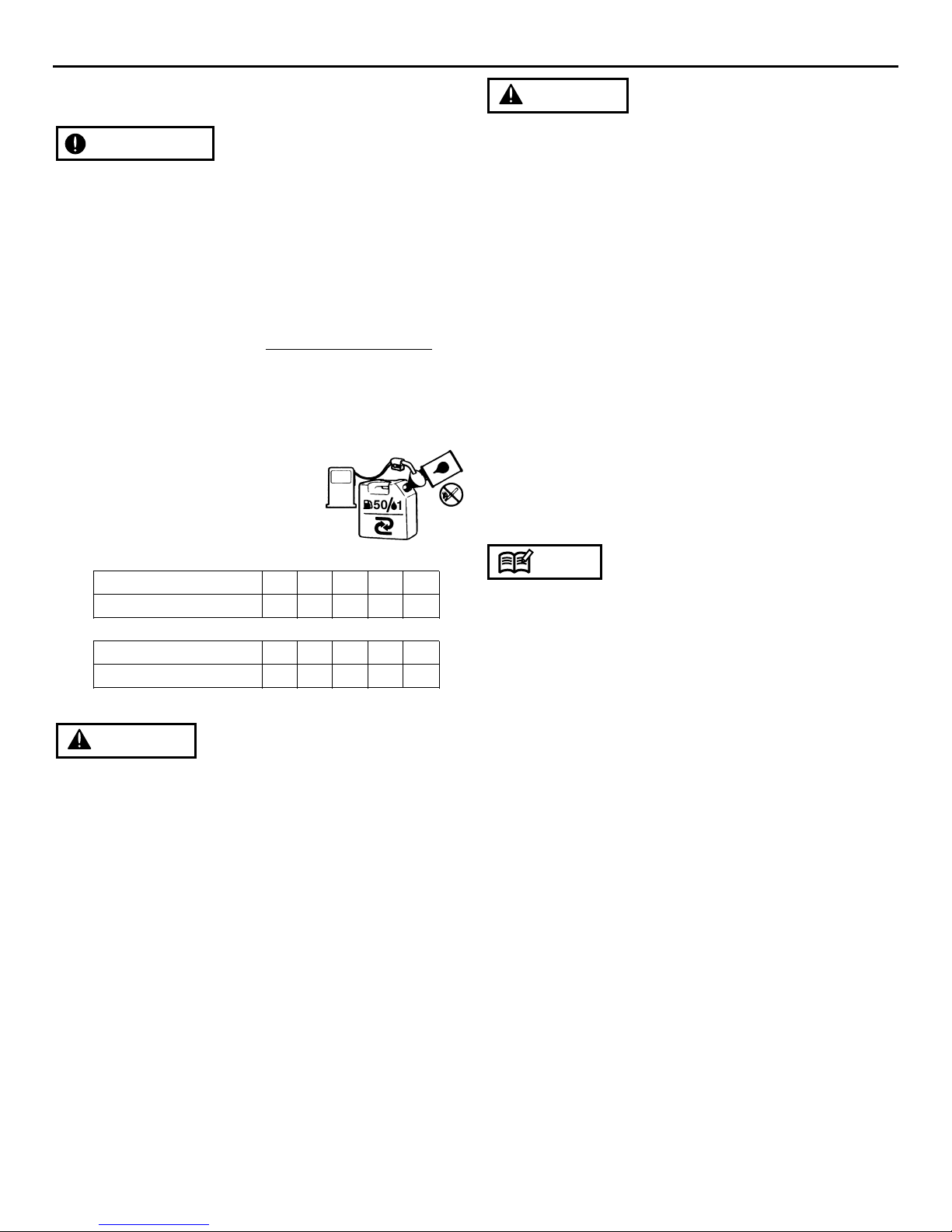

■ HOW TO MIX FUEL

RECOMMENDED MIXING RATIO

GASOLINE 50 : OIL 1

(when using RedMax Air-Cooled "Max

Life")

• Pay attention to agitation.

1. Measure out the quantities of gasoline and oil to be mixed.

2. Put some of the gasoline into a clean, approved fuel container.

3. Pour in all of the oil and agitate well for 10seconds.

4. Pour in the rest of gasoline and agitate again for at least one

minute. As some oils may be difficult to agitate depending on oil

ingredients, sufficient agitation is necessary. Be careful that, if

the agitation is insufficient, there is an increased danger of early

piston seizure due to abnormally lean mixture.

5. Place a clear indication on the outside of the container to avoid

mixing up with gasoline or other containers that dont contain oil.

6. Indicate the contents on outside of container for easy

identification.

■ FUELING THE UNIT

1. Untwist and remove the fuel cap. Rest the cap on a clean

surface.

2. Put fuel into the fuel tank to 80% of the full capacity.

3. Fasten the fuel cap securely and wipe up any fuel spillage

around the unit.

WARNING

1. Select flat and bare ground for fueling.

2. Move at least 10 feet (3 meters) away from the fueling point

before starting the engine.

3. Stop the engine before refueling the unit. At that time, be

sure to sufficiently agitate the mixed gasoline in the

container.

■ FOR YOUR ENGINE LIFE, AVOID

1. FUEL WITH NO OIL (RAW GASOLINE) – It will cause severe

damage to the internal engine parts very quickly.

2. GASOHOL – It can cause deterioration of rubber and/or plastic

parts and disruption of engine lubrication.

3. OIL FOR 4-CYCLE ENGINE USE – It can cause spark plug

fouling, exhaust port blocking, or piston ring seizure.

4. Mixed fuels which have been left unused for a period of

one month or more may clog the carburetor and result in the

engine failing to operate properly.

5. In the case of storing the product for a long period of time,

clean the fuel tank after rendering it empty. Next, Start the

engine and run the carburetor dry residual fuel.

6. In the case of scrapping the used mixed oil container, scrap it

only at an authorized depository site.

• As for details of quality assurance, read the description in the

section Limited Warranty carefully. Moreover, normal wear and

change in product with no functional influence are not covered

by the warranty. Also, be careful that, if the usage in the

instruction manual is not observed as to the mixed gasoline,

type of oil or fuel to be used. described therein, it may not be

covered by the warranty.

NOTE

50:1 MIXING CHART

GASOLINE gal. 1 2 3 4 5

2-CYCLE OIL fl.oz 2.6 5.2 7.8 10.4 13

GASOLINE liter 1 2 3 4 5

2-CYCLE OIL ml 20 40 60 80 100

IMPORTANT

WARNING

Page 13

US-11

CHT220/CHT220L

U

S

Primer bulb: Press the air purge diaphragm repeatedly

until fuel begins to fill the diaphragm (about 6 times). The

diaphragm need not be completely filled.

Starting

Hold the body of the machine on the ground using your left

hand (CAUTION! Not with your foot!). Grip the starter

handle, slowly pull out the cord with your right hand until

you feel some resistance (the starter pawls grip), now

quickly and powerfully pull the cord. Never wrap the

starter cord around your hand.

Push the choke control back to its original position as soon

as the engine fires, and continue trying to start until the

engine starts.

CAUTION! When the choke control is pushed back to its

original position, the engine runs at a heightened speed,

the so called start throttle position, and the blades then

move. Start throttle position is released by throttling using

the throttle lever.

CAUTION! Do not pull the starter cord all the way out and

do not let go of the starter handle when the cord is fully

extended. This can damage the machine.

7. Starting and stopping

■ CHECK BEFORE STARTING

• Inspect the working area. Remove any objects that could

be thrown out.

• Check the cutting attachment. Never use blades that are

dull, cracked or damaged.

• Check that the machine is in perfect working order.

Check that all nuts and screws are tight.

• Make sure the gear housing is lubricated correctly.

See instructions under the heading Gear housing.

• Check that the cutting attachment always stops when

the engine is idling.

• Only use the machine for the purpose it was intended

for.

• Make sure that the handle and safety features are in

good working order. Never use a machine that lacks a

part or has been modified outside its specifications.

• All covers must be correctly fitted and undamaged

before you start the machine.

■ STARTING AND STOPPING

WARNING! The complete gear housing must

be fitted before the machine is started,

otherwise the clutch may loosen and cause

personal injury.

Always move the machine about 3 metres

from the refuelling position before starting.

Place the machine on a firm surface.

Remember that the blades may start to move

when the engine is started. Make sure the

blades cannot come into contact with any

object. Make sure that no unauthorised

persons are in the working area, otherwise

there is a risk of serious personal injury. The

safety distance is 15metres.

Cold engine

Choke:

Set the choke control in the choke position.

Page 14

US-12

CHT220/CHT220L

7. Starting and stopping

Warm engine

Hold the body of the machine on the ground using your left

hand (CAUTION! Not with your foot!). Grip the starter

handle, slowly pull out the cord with your right hand until

you feel some resistance (the starter pawls grip), now

quickly and powerfully pull the cord. Never wrap the

starter cord around your hand.

Stopping

The engine is switched off by moving the stop switch to the

stop position.

CAUTION!

The stop switch automatically returns to the start position.In

order to prevent unintentional starting, the spark plug cap

must be removed from the spark plug when assembling,

checking and/or performing maintenance.

■ GENERAL WORKING INSTRUCTIONS

IMPORTANT!

This section takes up the basic safety precautions for

working with a hedge trimmer.

If you encounter a situation where you are uncertain how

to proceed you should ask an expert. Contact your

dealer or your service workshop.

Avoid all usage which you consider to be beyond your

capability.

WARNING! The machine can cause serious

personal injury. Read the safety instructions

carefully. Learn how to use the machine.

WARNING! Cutting tool. Do not touch the

tool without first switching off the engine.

Safety instructions regarding the surroundings

• Never allow children to use the machine.

• Observe your surroundings and make sure that there is

no risk of people or animals coming into contact with the

cutting equipment.

• Ensure that no-one comes closer than 15 m while you

are working.

• Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

operator's manual.

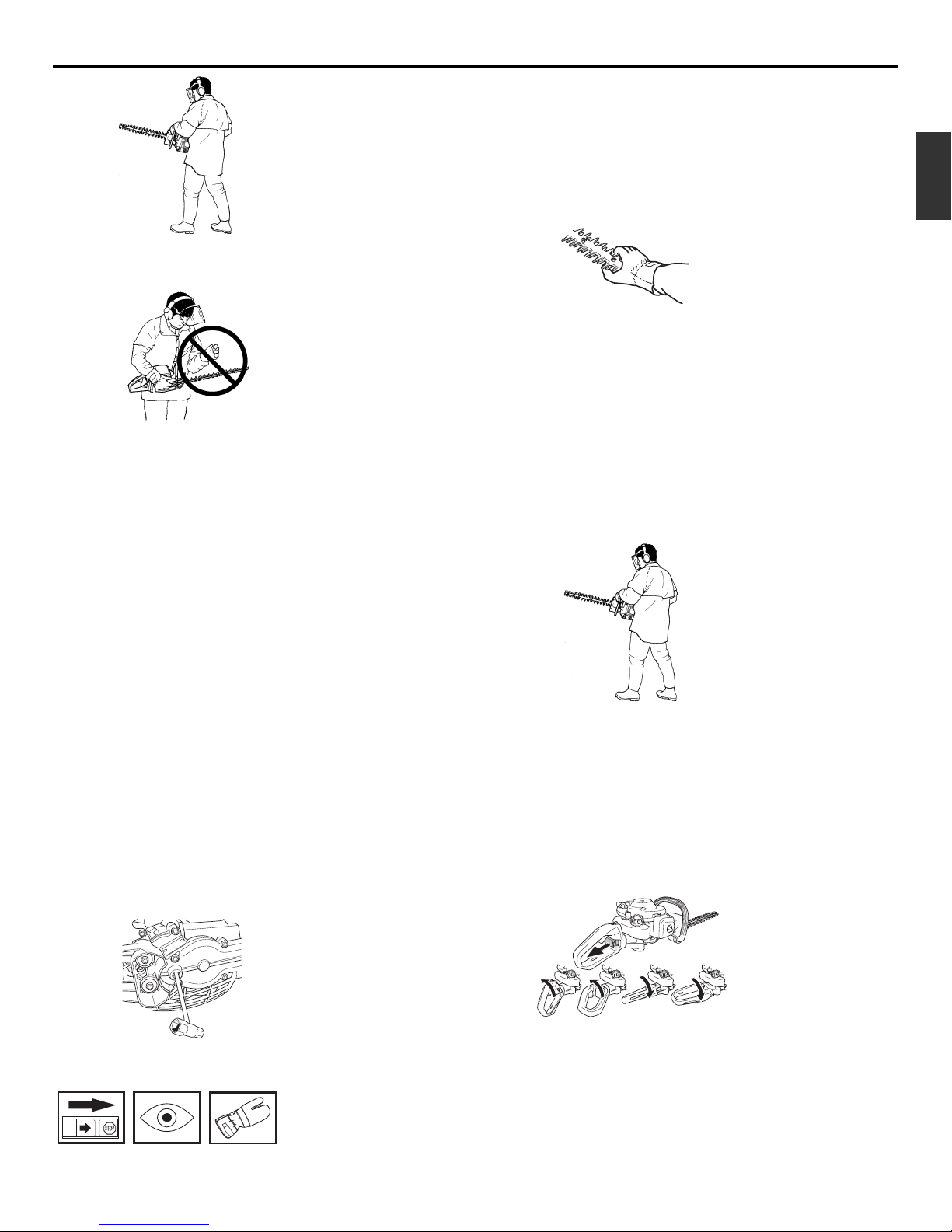

• Never work from a ladder, stool or any other raised

position that is not fully secured.

• Keep in mind that the operator is responsible for

accidents or hazards occuring to other people or their

property.

Safety instructions while working

• Always ensure you have a safe and stable working

position.

• Never leave the machine unsupervised with the motor

running.

• Always use both hands to hold the machine. Hold the

machine in front of your body.

8. Working techniques

Page 15

US-13

CHT220/CHT220L

U

S

8. Working techniques

cutting attachment when the machine is not in use.

• Make sure the cutting attachment has stopped before

cleaning, carrying out repairs or an inspection.

Disconnect the HT lead from the spark plug.

• Always wear heavy-duty gloves when repairing the

cutting attachment. This is extremely sharp and can

easily cause cuts.

• Store the machine out of reach of children.

• Use only original spare parts for repairs.

Basic working techniques

• Work with a swinging action from the bottom upwards

when trimming sides.

• Adjust the throttle setting to suit the load.

• When trimming a hedge the engine should always face

away from the hedge.

• Hold the machine as close to your body as possible to

get the best balance.

• Make sure that the tip does not touch the ground.

• Do not rush the work, but work steadily until all the

branches have been cut back cleanly.

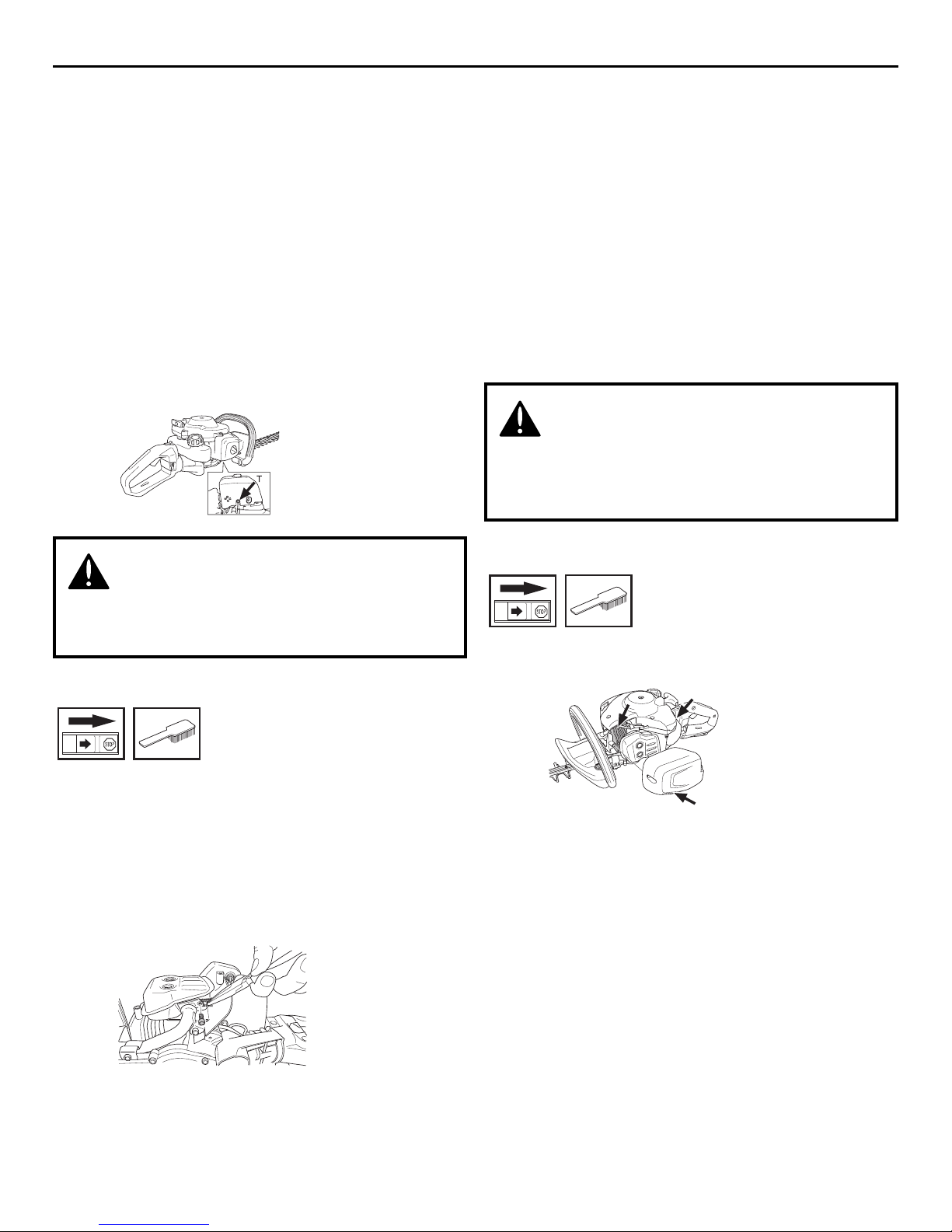

CHT220L

The hedge trimmer's rear handle can be set in five

positions by pulling out the catch. See figure. When the

handle is adjusted, the hedge trimmer must be idling or not

running.

• While working the handle should always be facing

upwards irrespective of how the hedge trimmer is

directed.

• Make sure that your hands and feet do not come near

the cutting attachment when the engine is running.

• When the engine is switched off, keep your hands and

feet away from the cutting attachment until it has

stopped completely.

• Watch out for stumps of branches that can be thrown out

during cutting.

• Do not cut too close to the ground. Stones and other

objects can be thrown out.

• Check the working area for foreign objects such as

electricity cables, insects and animals, etc, or other

objects that could damage the cutting attachment, such

as metal items.

• If any foreign object is hit or if vibrations occur stop the

machine immediately. Disconnect the HT lead from the

spark plug. Check that the machine is not damaged.

Repair any damage.

• If anything jams in the blades while you are working,

switch off the engine and wait until it has stopped

completely before cleaning the blades. Disconnect the

HT lead from the spark plug.

If the blades get stuck, they can be loosened by sticking

the combination spanner into the gear housing. Remove

the lubricant plug and stick the combination spanner into

the gearing and turn it back and forth.

Safety instructions after completing work

• The transport guard should always be fitted to the

Page 16

US-14

CHT220/CHT220L

9. Maintenance

■ CARBURETOR

Adjustment of the idle speed

Before any adjustments are made, make sure that the air

filter is clean and the air filter cover is fitted. Make sure the

start throttle position is disengaged.

Adjust the idle speed using the idle adjustment screw T, if it

is necessary to readjust. First turn the T screw clockwise

until the cutting attachment starts to move. Then turn the

screw anticlockwise until the cutting attachment stops.

The idle speed is correctly adjusted when the engine runs

smoothly in every position. The idle speed should also be

well below the speed at which the cutting attachment starts

to move.

Rec. idle speed: See the Technical data section.

WARNING! If the idle speed cannot be

adjusted so that the cutting attachment

stops, contact your dealer/service workshop.

Do not use the machine until it has been

correctly adjusted or repaired.

■ MUFFLER

CAUTION! Some mufflers are fitted with a catalytic

converter. See chapter on Technical data to see whether

your machine is fitted with a catalytic converter.

The muffler is designed to reduce the noise level and to

direct the exhaust gases away from the operator. The

exhaust gases are hot and can contain sparks, which may

cause fire if directed against dry and combustible

material.

Some mufflers are equipped with a special spark arrestor

mesh. If your machine has this type of muffler, the mesh

must be cleaned. This is best done with a wire brush.

On mufflers without a catalytic converter, the mesh should

be cleaned or replaced if necessary once a week. If the

mesh is damaged it must be replaced. If the mesh is

frequently blocked, this can be a sign that the carburetor is

incorrectly adjusted or that too much oil has been mixed

with the petrol.

On mufflers fitted with a catalytic converter, the mesh must

be checked, and if necessary cleaned, monthly. If the mesh

is damaged it must be replaced. If the screen is frequently

blocked, this can be a sign that the performance of the

catalytic converter is impaired.

Contact your dealer to inspect the muffler. A blocked

screen will cause the machine to overheat and result in

damage to the cylinder and piston.

CAUTION! Never use a machine with a defective muffler.

WARNING! Mufflers fitted with catalytic

converters get very hot during use and

remain so for some time after stopping. This

also applies at idle speed. Contact can result

in burns to the skin.

Remember the risk of fire!

■ COOLING SYSTEM

To keep the working temperature as low as possible the

machine is equipped with a cooling system.

The cooling system consists of:

1 Cooling fins on the cylinder.

2 Cylinder cover (directs cold air over the cylinder).

3 Air intake through the crankcase (inside the tank).

Clean the cooling system with a brush once a week,more

often in demanding conditions. A dirty or blocked cooling

system results in the machine overheating which causes

damage to the piston and cylinder.

Page 17

US-15

CHT220/CHT220L

U

S

9. Maintenance

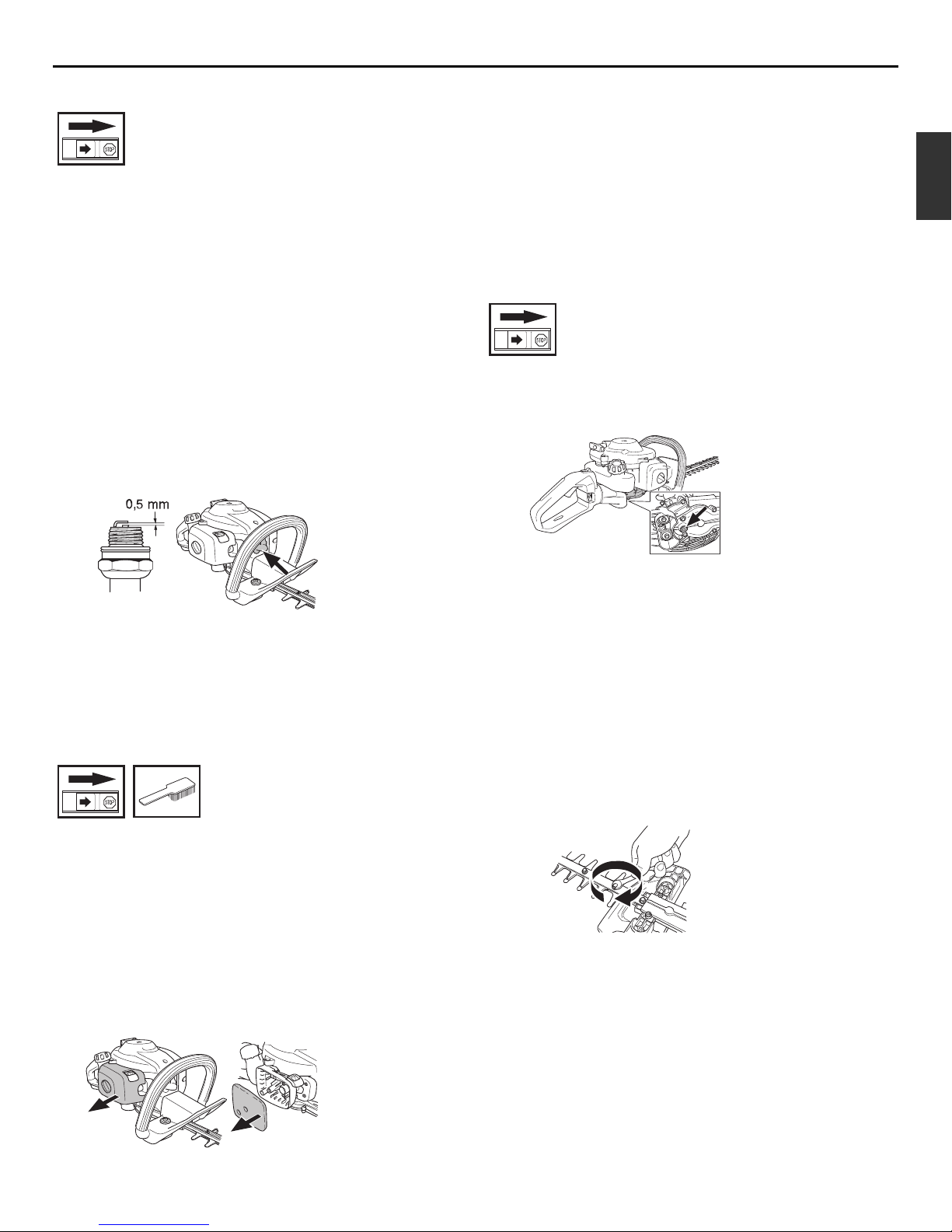

■ SPARK PLUG

The spark plug condition is influenced by:

• Incorrect carburetor adjustment.

• An incorrect fuel mixture (too much or incorrect type of

oil).

• A dirty air filter.

These factors cause deposits on the spark plug electrodes,

which may result in operating problems and starting

difficulties.

If the machine is low on power, difficult to start or runs

poorly at idle speed: always check the spark plug first

before taking any further action. If the spark plug is dirty,

clean it and check that the electrode gap is 0,5 mm

(0,020"). The spark plug should be replaced after about a

month in operation or earlier if necessary.

CAUTION! Always use the recommended spark plug type!

Use of the wrong spark plug can damage the

piston/cylinder. Check that the spark plug is fitted with a

suppressor.

■ AIR FILTER

The air filter must be regularly cleaned to remove dust and

dirt in order to avoid:

• Carburetor malfunctions

• Starting problems

• Loss of engine power

• Unnecessary wear to engine parts

• Excessive fuel consumption.

Clean the filter every 25 hours, or more regularly if

conditions are exceptionally dusty.

Cleaning the air filter

Remove the air filter cover and take out the filter. Wash it

clean in warm, soapy water. Allow the filter to dry and then

oil it in according to the instructions.

An air filter that has been in use for a long time cannot be

cleaned completely. The filter must therefore be replaced

with a new one at regular intervals. A damaged air filter

must always be replaced.

■ GEAR

There is a plug for filling lubricant on the gear housing.

Use the grease tube to fill with grease and repeat every 25

hours. Use RedMax special grease.

CAUTION! The gear housing must not be filled completely

with grease. The grease expands as the machine heats up

during operation. If the gear housing was completely filled

with grease it could damage the seals and lead to leakage

of grease.

The grease in the bevel gear does not normally need to be

changed except if repairs are carried out.

■ CUTTING UNIT

Check that the cutting units' screws are fitted correctly.

Tighten them with a tightening torque of 7-10 Nm.

Page 18

US-16

CHT220/CHT220L

9. Maintenance

■ CLEANING AND LUBRICATION

Clean any resin and plant residue from the blades using

cleaning agent 531 00 75-13 (UL22) before and after using

the machine.

Check that the blade edges are not damaged or deformed.

File away any burrs.

Check that the blades move freely. Remove the lubrication

plug in the gear housing and stick in the combination

spanner and turn back and forth.

Lubricate the blade bars with special grease, part no.

531 00 75-12 (UL 21) before long periods of storage.

IMPORTANT! Use only RedMax replacement parts.

Use of other brands of replacement parts can

cause damage to your unit or injury to the operator

or others. Your warranty does not cover damage or

liability caused by the use of accessories and/or

attachments not specifically recommended by

RedMax.

Page 19

US-17

CHT220/CHT220L

U

S

9. Maintenance

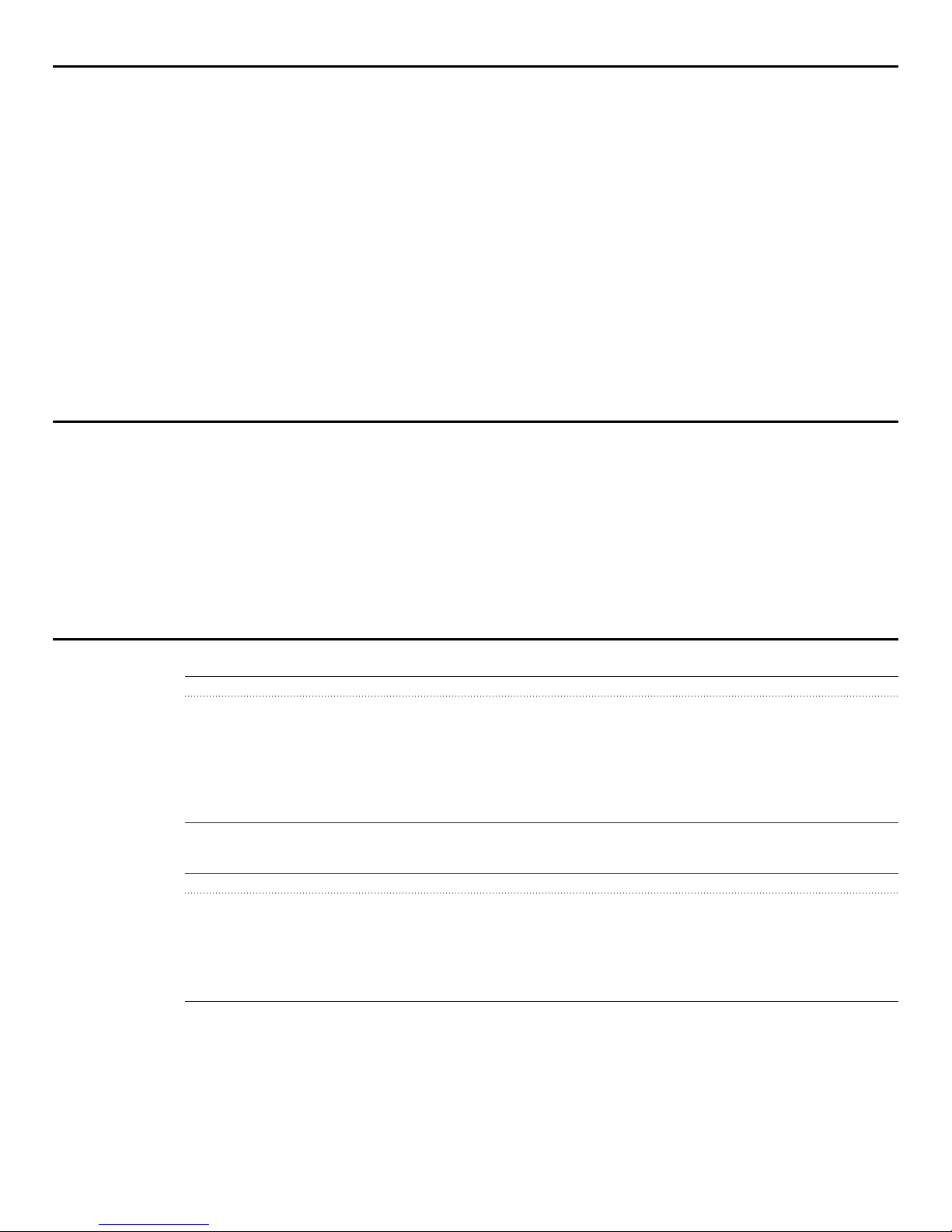

■ MAINTENANCE SCHEDULE

The following is a list of the maintenance that must be performed on the machine. Most of the items are described in the

Maintenance section. The user must only carry out the maintenance and service work described in this manual. More

extensive work must be carried out by an authorized service workshop.

Clean the outside of the machine.

Make sure the throttle trigger lock and the throttle function correctly

from a safety point of view.

In order to reduce the risk of fire, dirt, leaves and surplus lubricant, etc

must be cleaned from the muffler, exhaust pipe and engine.

Check that the stop switch works correctly.

Check that the blades do not move when the engine is idling.

Check that the blades are undamaged and show no signs of cracking

or other damage. Replace the blades if necessary.

Check that the blade guard is not damaged or distorted. Replace the

blade if the blade guard is bent or damaged.

Replace the cutting unit if it is bent or damaged.

Check that the hand guard is not damaged. Replace the guard if

damaged.

Check that nuts and screws are tight.

Check that there are no fuel leaks from the engine, tank or fuel lines.

Clean the air filter.

Clean more often if conditions are exceptionally dusty.

Check the starter and starter cord.

Check that the vibration damping elements are not damaged.

Clean the outside of the spark plug. Remove it and check the

electrode gap. Adjust the gap to 0.5 mm (.20"), or replace the spark

plug. Check that the spark plug is fitted with a suppressor.

Clean the machine's cooling system.

Clean the outside of the carburetor and the space around it.

Fill the gear housing with grease. This should be carried out

approximately every 25 working hours.

Check that the screws that hold the blades together are correctly

tightened.

Check and clean the spark arrestor screen on the muffler (only applies

to mufflers fitted with a catalytic converter).

Clean the inside of the fuel tank.

Check the inside of the fuel filter for any dirt or if the fuel hose has any

cracks or other defects. Replace if necessary.

Check all cables and connections.

Check the clutch, clutch springs and the clutch drum for wear. Replace

if necessary by an authorized service workshop.

Replace the spark plug. Check that the spark plug is fitted with a

suppressor.

After 40 After 100

Maintenance Before use:

hours in use hours in use

After each time the machine is used

(25 tim).

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Page 20

US-18

CHT220/CHT220L

1. Oil the blade to prevent rust.

2. Empty the fuel tank and put the cap

back on.

3. Remove the spark plug, pour a small

amount of oil into the cylinder.

4. Rotate the crankshaft several times

using the starting rope in order to

distribute the oil. Put the spark plug

back in.

5. Wrap the engine with a plastic sheet.

6. Store the trimmer in a dry place,

preferably not in direct contact with the

floor and away from heat sources.

10. Storage

11. Disposal

• When disposing your machine, fuel or

oil for the machine, be sure to allow

your local regulations.

12. Troubleshooting guide

Case 1. Starting failure

CHECK PROBABLE CAUSES ACTION

fuel tank ➞ incorrect fuel ➞ drain it and with correct fuel

fuel filter ➞ fuel filter is clogged ➞ clean

carburetor adjustment screw ➞ out of normal range ➞ adjust to normal range

sparking (no spark) ➞ spark plug is fouled/wet ➞ clean/dry

➞ plug gap is incorrect ➞ correct (GAP: 0.5 mm)

spark plug ➞ disconnected ➞ retighten

Case 2. Engine starts but does not keep running/Hard re-starting.

CHECK PROBABLE CAUSES ACTION

fuel tank ➞ incorrect fuel or staled fuel ➞ drain it and with correct fuel

carburetor adjustment screw ➞ out of normal range ➞ adjust to normal range

muffler,cylinder (exhaust port) ➞ carbon is built-up ➞ wipe away

air cleaner ➞ clogged with dust ➞ wash

cylinder fin, fan cover ➞ clogged with dust ➞ clean

When your unit seems to need further service, please consult with our service shop in your area.

Page 21

US-19

CHT220/CHT220L

U

S

The EPA (U.S. Environmental Protection Agency), CARB (California Air Resources Board), Environment

Canada and RedMax are pleased to explain the emissions control system's warranty on your 2009 and later

small off-road engine. In U.S. and Canada, new equipment that use small off-road engines must be designed,

built, and equipped to meet the applicable Federal or Californian stringent anti-smog standards. RedMax must

warrant the emissions control system on your small off-road engine for the period listed below provided there

has been no abuse, neglect or improper maintenance of your equipment. Your emissions control system may

include parts such as carburetor, ignition system, catalytic converter, fuel tank, filters and other associated

components. Also, included may be hoses, belts, connectors, sensors, and other emission-related assemblies.

Where a warrantable condition exists, RedMax will repair your small off-road engine at no cost to you including

diagnosis, parts and labor.

MANUFACTURER'S WARRANTY COVERAGE

This emissions control system is warranted for two years or if the product qualifies for a longer warranty period

resulting from the type of use, that period shall prevail. If any emissions-related part on your equipment is

defective, the part will be repaired or replaced by RedMax.

OWNER'S WARRANTY RESPONSIBILITIES

As the small off-road engine owner, you are responsible for performance of the required maintenance listed in

your Owner's Manual. RedMax recommends that you retain all receipts covering maintenance on your small offroad engine, but RedMax cannot deny warranty solely for the lack of receipts or your failure to ensure the

performance of all scheduled maintenance. As the small off-road engine owner, you should however be aware

that the RedMax may deny you warranty coverage if your small off-road engine or a part has failed due to

abuse, neglect, or improper maintenance or unapproved modifications.

You are responsible for presenting your small off-road engine to a RedMax distribution center or service center

as soon as the problem exists. The warranty repairs should be completed in a reasonable amount of time, not to

exceed 30 days. If you have any questions regarding your warranty coverage, you should contact RedMax at 1800-291-8251 or via e-mail at service@redmax.com.

WARRANTY COMMENCEMENT DATE

The warranty period begins on the date the engine or equipment is delivered to an ultimate purchaser.

LENGTH OF COVERAGE

RedMax warrants to the ultimate purchaser and each subsequent owner that the engine or equipment is

designed, built, and equipped so as to conform with all applicable regulations adopted by EPA and CARB, and

is free from defects in materials and workmanship that causes the failure of a warranted part for a period of two

years.

WHAT IS COVERED

REPAIR OR REPLACEMENT OF PARTS Repair or replacement of any warranted part under the warranty

must be performed at no charge to the owner at a warranty station. Warranty services or repairs will be provided

at all RedMax distribution centers that are franchised to service the subject engines. Throughout the emissions

warranty period of two years, RedMax must maintain a supply of warranted parts sufficient to meet the expected

demand for such parts.

WARRANTY PERIOD Any warranted part that is scheduled for replacement as required in the maintenance

schedule, is warranted for the period of time prior to the first scheduled replacement point for that part. If the

part fails prior to the first scheduled replacement, the part will be repaired or replaced by RedMax at no cost.

Any such part repaired or replaced under warranty is warranted for the remainder of the period prior to the first

scheduled replacement point for the part. Any warranted part that is not scheduled for replacement as required

in the maintenance schedule, is warranted for two years or if the product qualifies for a longer warranty period

resulting from the type of use, that period shall prevail. If any such part fails during the period of warranty

coverage, it will be repaired and replaced by RedMax at no cost. Any such part repaired or replaced under the

FEDERAL AND CALIFORNIA EMISSIONS CONTROL WARRANTY

STATEMENT YOUR WARRANTY RIGHTS AND OBLIGATIONS

Page 22

US-20

CHT220/CHT220L

warranty is warranted for the remaining warranty period. Any warranted part that is scheduled only for regular

inspection in the maintenance schedule will be warranted for a period of two years. A statement in such written

instructions to the effect of "repair or replace as necessary" will not reduce the period of warranty coverage. Any

such part repaired or replaced under warranty will be warranted for the remaining warranty period.

DIAGNOSIS The owner must not be charged for diagnostic labor that leads to the determination that a

warranted part is in fact defective, provided that such diagnostic work is performed at a warranty station.

CONSEQUENTIAL DAMAGES RedMax is liable for damages to other engine components proximately caused

by a failure under warranty of any warranted part.

EMISSION WARRANTY PARTS LIST

1. Air-induction system*

2. Fuel system*

3. Ignition system*

4. Fuel tank, cap and lines as applicable*

*some components only covered up to point specified by maintenance schedule

WHAT IS NOT COVERED

All failures caused by abuse, neglect or improper maintenance are not covered.

ADD-ON OR MODIFIED PARTS

Add-on or modified parts that are not exempted by CARB or EPA may not be used. The use of any nonexempted add-on or modified parts will be grounds for disallowing a warranty claim. RedMax will not be liable to

warrant failures of warranted parts caused by the use of a non-exempted add-on or modified part.

HOW TO FILE A CLAIM

If you have any questions regarding your warranty rights and responsibilities, you should contact your nearest

authorized servicing dealer or contact RedMax at 1-800-291-8251 or via e-mail at service@redmax.com.

WHERE TO GET WARRANTY SERVICE

Warranty services or repairs are provided through all RedMax authorized servicing dealers.

MAINTENANCE, REPLACEMENT AND REPAIR OF EMISSION-RELATED PARTS

Any replacement part may be used in the performance of any warranty maintenance or repairs and must be

provided without charge to the owner. Such use will not reduce the warranty obligations of the manufacturer.

MAINTENANCE STATEMENT

The owner is responsible for the performance of all required maintenance, as defined in the operator's manual.

Page 23

US-21

CHT220/CHT220L

U

S

RedMax

STANDARD LIMITED WARRANTY STATEMENT

ALL Products Sold on or after 1/01/2010

All RedMax Brand Products

RedMax Limited Warranty, provides to the ORIGINAL

retail purchaser that this RedMax product is free from DEFECTS in MATERIAL and

WORKMANSHIP

under normal use and maintenance from the date of retail purchase. RedMax agrees to repair or replace at our discretion,

any defective product, free of charge at any authorized RedMax servicing dealer using original RedMax replacement parts, within the listed

below application time periods, limitations and exclusions. THIS LIMITED WARRANTY IS EXTENDED TO THE FIRST, ORIGINAL RETAIL

PURCHASER ONLY, AND IT IS NOT TRANSFERABLE TO SUBSEQUENT OWNERS. This warranty is separate from the Emission Control

Warranty Statement supplied with your new product. Please consult your Emission Control Warranty Statement for details.

PRODUCT WARRANTY PERIOD

PRODUCTS PURCHASED FOR NON-INCOME PRODUCING USE (Home Owner)

Complete units purchased for residential, or non-income producing use, will be covered by this limited warranty for two (2) years from the date

of retail

purchase. The electronic ignition module, the brush cutter/trimmer drive shafts, are warranted for the life* of the product on parts only.

PRODUCTS PURCHASED FOR COMMERCIAL, INSTITUTIONAL, AGRICULTURAL, INDUSTRIAL, OR INCOME

PRODUCING USE

Complete units used for commercial, institutional, agricultural, industrial, or income producing use will be covered by this limited warranty for a

period of two (2) years, from the date of retail

purchase. Chainsaws, BT280, BC280, TR2301S/2350S, CHT2200/2250, and Sprayers are

covered for one (1) year. Exceptions are Models: GZ400, BT250, BC250, HB250/280, and HE250F, CHT220/220L. These EXCEPTIONS

are

covered for ninety (90) days. The electronic ignition module and the brush cutter/trimmer drive shafts, are warranted for the life* of the product

on parts only.

RENTAL APPLICATION

Complete units for rental use will be covered against defects in material and workmanship for a period of 90 days from the date of purchase.

The following carry No Rental Warranty. They are: GZ400, BT250, BC250, TR2301S/2350S, HB250/280, CHT2200/2250 and

HE250F, CHT220/220L. These products have NO Rental Warranty.

RedMax liability under the "Lifetime" coverage is limited to furnishing parts only after the Standard Warranty coverage expires as specified

under the PRODUCT WARRANTY PERIOD section of this warranty statement. "Lifetime" free of charge parts is only for a period of seven (7)

years after the last date of the complete unit's final production.

This warranty does not cover damage other than that resulting from defects in material or workmanship

. RedMax DOES NOT OFFER AN

OVER THE COUNTER EXCHANGE PROGRAM. Any product sold, serviced or re-built by other than a RedMax Authorized Servicing Dealer, is

sold as is without

RedMax standard warranty coverage. Repair parts and accessories replaced under this warranty are warranted only for the

BALANCE

of the original unit or accessory warranty period.

All parts or products replaced under warranty become the property of RedMax.

PURCHASED REPAIR PARTS, SHORT BLOCKS AND ACCESSORIES

These items carry a 90-day residential, or non-income producing use, and 90-day commercial, institutional, agricultural, industrial, income

producing, or rental application warranty.

CUTTING ATTACHMENTS SUPPLIED WITH PRODUCTS

All original equipment cutting attachments used in residential, or non-income producing use, such as, but not limited to, bars, chains, sprockets,

blades, nylon trimmer heads, will be covered for failures due to defects in material or workmanship for a period of 60 days from the original

product purchase date. Any misuse from contact with, rocks, or other non-approved materials and/or structures is not covered by this warranty.

When used in a commercial, institutional, agricultural, industrial, income producing or rental application, the cutting attachment warranty is for 30

days.

All Maxtreme Series, Split Shaft attachments carry the same warranty duration as the units they are designed to fit.

DISCLAIMER OF IMPLIED WARRANTIES

Any implied warranty is limited to the duration of the limited warranty. Otherwise, this limited warranty is in lieu of all other expressed or implied

warranties, including any warranty of FITNESS FOR A PARTICULAR PURPOSE OR USE and any implied warranty of MERCHANTABILITY

otherwise applicable to this product. RedMax and its affiliated companies shall not be liable for any special incidental or consequential damage,

including lost profits. There are no warranties extended other than as provided herein. This warranty may be modified only by RedMax.

ATTENTION TWO-STROKE ENGINE POWERED PRODUCT OWNERS

RedMax – Hi-Performance 2-Stroke engines produce higher HP (horse power) outputs as compared to standard Home Owner Duty or Light

Commercial Duty production engines offered by most manufacturers. To help insure trouble free performance of the unit, it is required

to use oil

which meets the ISO-L-EGD Standard per ISO/CD 13738 and one that is registered under JASO M345/FD Standards. RedMax MaxLife

™

Synthetic blend Two-Stroke Oil is a premium two-stroke oil specifically formulated to meet ISO-L-EGD (ISO/CD 13738) and JASO M345/FD

Standards. The use of un-registered

oils designed for other applications, such as for outboard motors or lawnmowers, or low RPM, low HP

output engines, can result in severe engine damage, and void your two-stroke engine warranty. This Hi-Performance Air Cooled 2-Stroke

engine requires the use of MINIMUM 89 Octane (Mid grade or Premium) clean gasoline. If octane rating of the Mid Grade gasoline is lower

than 89 octane USE Premium Unleaded Gasoline. Warning: Gasoline with octane rating lower than 89 will greatly increase engines operating

temperature. Low octane gasoline will cause detonation (knock) resulting in piston seizures and major internal engine component damage.

U S

Page 24

US-22

CHT220/CHT220L

Engine Failures caused by operating engines on gasoline with octane rating lower

than 89 are not covered by the RedMax Two-Stroke engine

warranty.

(Emission related parts only

are covered for two years, regardless of two-stroke oil used, per the statement listed in the EPA or California

Emission Defect Warranty Explanation.)

THIS WARRANTY DOES NOT INCLUDE, OR COVER DAMAGE TO THE UNIT OR ENGINE CAUSED BY:

1. Lack of lubrication or engine failure, due to the use of two-stroke oils that do not meet the ISO-L-EGD (ISO/CD 13738) and are

not

registered to meet JASO M345/FD Standards. Engine problems due to inadequate lubrication caused by failure to use an ISO-L-EGD

compliant and JASO M345/FD Registered

oil, WILL VOID the RedMax two-stroke engine warranty. RedMax MaxLife

™ Synthetic blend

Two-Stroke Oil meets the ISO-L-EGD and is registered to JASO Standard M345/FD.

2. Damage caused by use of gasohol, containing methanol (wood alcohol), or gasoline containing LESS than 89 OCTANE

. Only use

gasolines which contain 89 octane or Higher. Gasohol which contains a maximum 10% ethanol (grain alcohol) or 15% MTBE

(methyl/tertiary/butyl/ether) is also approved. The prescribed mixing ratio of gasoline to oil is 50:1 and is listed on the RedMax oil label and

covered in your operator's manual.

3. Engine damage caused by use of ether or any starting fluids. Damage caused by pressure or steam cleaning the unit.

4. Overheating and Detonation damage caused by use of spark plugs other than those meeting emissions performance requirements listed in

the Operators Manual.

5. Damage caused by tampering with engine speed governor or emission components, or running engines above specified and

recommended engine speeds as listed in your operator's manual.

6. THIS WARRANTY DOES NOT COVER DAMAGE TO THE UNIT OR ENGINE CAUSED BY:

Operation of the unit with improperly installed/removed cutting shields, guards or safety devices.

7. Damage caused by removed/damaged air filter, dirt, abrasives, salt water, moisture corrosion, rust, varnish, stale fuel, or any adverse

reaction due to incorrect storage procedures.

8. Defects, malfunctions or failures resulting from abuse, misuse, neglect, modifications, alterations, normal wear, improper servicing, use of

unauthorized attachments, including failure to provide or perform required maintenance services as prescribed in the operators manual.

Preventative maintenance as outlined in the operator's manual is the owner's/ customer's responsibility

.

9. Failures due to improper set-up, pre-delivery service or repair service by anyone other than an authorized RedMax servicing dealer during

the warranty period.

10. Certain parts and other items are not warranted

, including but not limited to: spark plugs, filters, lubricants, starter cords, sprockets, and

debris bags. Overheating or carbon scoring failures due to restricted/clogged exhaust port, blocked spark arrester screen, or combustion

chamber.

11. Set-up and pre-delivery service, engine tune-ups, including natural discoloration due to ultraviolet light.

12. Adjustments after the first (30) thirty days of purchase and beyond, such as carburetor adjustment and throttle cable adjustment.

13. Damage to gears or gear cases caused by dirt contaminated grease, use of incorrect type of gear case grease, and/or failure to comply

with recommended greasing intervals.

14. Damage caused by sprayers pumping or spraying caustic or flammable materials, lack of or broken strainers.

15. Additional damage to parts or components due to continued use after operational problem or failure occurs.

Should operational problem or failure occur, the product should not

be used, but delivered as is to an authorized RedMax Servicing Dealer.

IMPORTANT OWNER'S RESPONSIBILITY

The owner shall demonstrate reasonable care and use

, and follow preventative maintenance, storage, fuel and oil usage as prescribed in the

enclosed operator's manual. Should a product difficulty occur within the applicable warranty period, you must, at your expense, deliver or ship

your RedMax unit to an authorized RedMax Servicing Dealer only for warranty repairs and arrange for pick-up or return of your unit after the

repairs have been made. If you do not know the location of your nearest authorized RedMax Servicing Dealer, consult your telephone yellow

pages or call RedMax, at 1-800-291-8251 during the hours of 8:00 am to 5:00 pm Eastern Standard time, or visit www.RedMax.com

. Should

you require assistance or have questions concerning this Warranty Statement, you may contact us at 1-800-291-8251 during the hours of 8:00

am to 5:00 pm Eastern Standard Time or contact us through the web at www.RedMax.com

.

IMPORTANT OWNER'S RESPONSIBILITY

IT IS A CUSTOMER'S AND/OR DEALER'S RESPONSIBILITY TO COMPLETE AND RETURN WITHIN 10 DAYS OF THE DATE OF

PURCHASE, THE WARRANTY REGISTRATION CARD SUPPLIED WITH YOUR REDMAX PRODUCT.

YOUR RECEIPT OF PURCHASE INCLUDING DATE, MODEL AND ENGINE

SERIAL NUMBER MUST BE MAINTAINED AND PRESENTED

TO AN AUTHORIZED RedMax SERVICING DEALER FOR WARRANTY SERVICE. PROOF OF PURCHASE RESTS SOLELY WITH THE

OWNER-CUSTOMER. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE

LIMITATIONS MAY NOT APPLY TO YOU. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE. THIS WARRANTY IS GIVEN ONLY

BY RedMax OUR ADRESS is, 7349 Stateville Rd. Charlotte, NC 28269

1/2010

U S

Page 25

FR-1

CHT220/CHT220L

F

R

MODE D’EMPLOI

TAILLEUSE DE HAIES

115 43 11-49 (105)

AVERTISSEMENT

AVERTISSEMENT

Les échappements du moteur de

ce produit contiennent des

produits chimiques connus par

l’Etat de Californie comme étant

responsables de cancers,

d’anomalies congénitales et

d’autres atteintes à l’appareil

reproducteur.

Avant d’utiliser cette

ce produit

,

veuillez lire attentivement ce

manuel afin de bien comprendre le

bon fonctionnement de cet

appareil.

CHT220

CHT220L

Ce système d’allumage par étincelle de véhicule

est conforme à la norme NMB-002 du Canada.

Page 26

FR-2

CHT220/CHT220L

SECURITE

Les instructions contenues dans les mises en garde

de ce mode d’emploi portant le symbole

concernent les points critiques qui doivent être pris

en considération pour éviter les blessures

corporelles graves, c’est pourquoi ces précautions

doivent être rigoureusement suivies.

■ DIFFERENTS TYPES D’AVERTISSEMENT DE CE

MODE D’EMPLOI

Les instructions repérées par ce symbole doivent être

rigoureusement suivies afin d’éviter tout accident

pouvant entraîner des blessures corporelles graves ou

la mort.

Les instructions repérées par ce symbole doivent être

suivies afin d’éviter tout incident mécanique, panne ou

endommagement de la débroussailleuse.

Remarques utilisées dans des instructions ou conseils

supplémentaires pour l’utilisation de cette

débroussailleuse.

REMARQUE

Arrêter le moteur en déplaçant l’interrupteur d’arrêt en

position d’arrêt.

REMARQUE! L'interrupteur d'arrêt se remet

automatiquement en position de démarrage. Toujours

retirer le chapeau de bougie de la bougie lors du

montage, contrôle et/ou entretien, afin d'éviter tout

démarrage accidentel.

Toujours porter des gants de protection homologués.

Un nettoyage régulier est indispensable.

Examen visuel.

Porter des lunettes protectrices ou une visière.

AVERTISSEMENT

IMPORTANT

Page 27

FR-3

CHT220/CHT220L

F

R

1. Emplacement des pieces ...................................................4

2. Fiche technique ..................................................................4

3. Symboles............................................................................5

4. Mesures de lutte contre les emissions ...............................5

5. Consignes de securite ........................................................6

6. Carburant............................................................................9

7. Démarrage et arrêt ...........................................................12

8. Techniques de travail .......................................................13

9. Entretien ...........................................................................15

10. Rangement .......................................................................19

11. Mise au rebut....................................................................19

12. Guide de localisation des pannes.....................................19

Tables des matieres

■ CONTRÔLER LES POINTS SUIVANTS AVANT LA MISE EN

MARCHE:

Lire attentivement le manuel d’utilisation.

AVERTISSEMENT! Une exposition prolongée au

bruit risque de causer des lésions auditives

permanentes. Toujours utiliser des protecteurs

d'oreille agréés.

AVERTISSEMENT! Ne jamais modifier sous aucun

prétexte la machine sans l’autorisation du

fabricant. N’utiliser que des accessoires et des

pièces d’origine.

Des modifications non-autorisées et l’emploi

d’accessoires non-homologués peuvent

provoquer des accidents graves et même mortels,

à l’utilisateur ou d’autres personnes.

AVERTISSEMENT! Un taille-haie utilisé de

manière imprudente ou inadéquate peut devenir

un outil dangereux, pouvant causer des blessures

graves voire mortelles. Il est très important de lire

et comprendre le contenu de ce mode d’emploi.

Page 28

FR-4

CHT220/CHT220L

1. Emplacement des pieces

2. Fiche technique

1 Manuel d’utilisation

2 Poignée

3 Verrou d’accélérateur

4 Bouchon du réservoir de carburant

5 Commande de starter

6 Poignée avant

7 Lame et protège-lame

8 Dispositif de protection pour le

transport

9 Capot de filtre à air

10 Pompe à carburant

11 Réservoir d’essence

12 Verrou pour la poignée CHT220L

13 Commande de l’accélération

14 Chapeau de bougie et bougie

15 Capot de cylindre

16 Poignée de lanceur

17 Bouton d’arrêt

18 Bouchon de remplissage en lubrifiant,

engrenage

19 Engrenage

20 Protège-main

21 Clé universelle

22 Tube de lubrifiant

Nom du modèlele CHT220 CHT220L

Moteur

Cylindrée, po

3

/cm

3

21,7 21,7

Alésage, po/mm 1,26/32 1,26/32

Course, po/mm 1,06/27 1,06/27

Régime de ralenti, tr/min 2900 2900

Régime d’emballement maximal recommandé, tr/min 9000 9000

Puissance moteur maxi selon ISO 8893, kW/ tr/min 0,6/7800 0,6/7800

Silencieux avec pot catalytique Oui Oui

Système d’allumage réglé en fonction du régime Oui Oui

Système d’allumage

Bougie NGK CMR6A NGK CMR6A

Écartement des électrodes, po/mm 0,02/0,5 0,02/0,5

Système de graissage/de carburant

Contenance du réservoir de carburant, pint/litres 0,3 0,3

Poids

Poids, sans carburant, lb/kg 4,7 10,8/4,9

Niveaux sonores

(voir rem. 1)

Pression acoustique équivalente au niveau des oreilles

de l’utilisateur, mesurée selon EN ISO 10517, dB(A): 93 5,7/94

Niveaux de vibrations

(voir remarque 2)

Niveaux de vibrations équivalents (ahveq) mesurés au

niveau des poignées selon EN ISO 10517, en m/s

2

.

Poignées avant/arrière: 2,9/4,9 4,1/3,6

Couteaux

Type Double tranchant Double tranchant

Longueur, mm 450 590

Vitesse des couteaux, taille/min 4050 4050

Remarque 1: Les données reportées pour le niveau de pression sonore équivalent pour la machine montrent

une dispersion statistique typique (déviation standard) de 1 dB (A).

Remarque 2: Les données reportées pour le niveau de vibrations équivalent montrent une dispersion

statistique typique (déviation standard) de 1 m/s

2

.

Page 29

FR-5

CHT220/CHT220L

F

R

3. Symboles

4. Mesures de lutte contre les emissions

AVERTISSEMENT! Un taille-haie utilisé de manière imprudente

ou inadéquate peut devenir un outil dangereux, pouvant causer

des blessures graves voire mortelles. Il est très important de lire

et comprendre le contenu de ce mode d’emploi.

Lire attentivement et bien assimiler le manuel d’utilisation avant

d’utiliser la machine.

Toujours utiliser:

• Protecteurs d’oreilles homologués

• Des protège-yeux homologués

Toujours porter des gants de protection homologués.

Utiliser des bottes ou chaussures antidérapantes et stables.

Instruction de démarrage Voir les instructions au chapitre

Démarrage et arrêt.

Les autres symboles/autocollants présents sur la machine

concernent des exigences de certification spécifiques à

certains marchés.

La période de conformité des émissions à laquelle il est fait

référence sur l’étiquette de conformité des émissions indique le

nombre d’heures de fonctionnement pour lesquelles il a été établi

que le moteur répond aux exigences fédérales en matière

d’émissions.

Une étiquette de mesures de lutte contre les émissions se trouve

sur le machine.

Page 30

FR-6

CHT220/CHT220L

5. Consignes de securite

1. RISQUE ELEVE DE BLESSURE

GRAVE. Lire ce manuel attentivement

jusqu’à une compréhension totale et

suivre toutes les instructions de sécurité

et d’utilisation. Vous devez aussi être

capable d’arrêter la débrouss-ailleuse

très vite en cas d’urgence.

2. Conserver ce mode d’emploi à portée

de la main pour le consulter au moindre

doute. Si une question reste sans

réponse, contacter le revendeur où

vous avez acheté la débroussailleuse.

3. Ne pas oublier de donner le manuel

avec la machine en cas de revente ou

de prêt.

4. Ne pas laisser des enfants ou toute

personne incapable de comprendre les

instructions, utiliser cette machine.

■ CONDITIONS DE TRAVAIL

1. Lors de l’utilisation de cette machine, il est

nécessaire de porter des vêtements

appropriés et des équipements de

sécurité.

(1) Casque

(2) Casque antibruit

(3) Lunettes ou masque de protection

(4) Gants de travail épais

(5) Chaussures de sécurité à semelle

antidérapante

2. Les objets suivants doivent être emportés

sur le lieu de travail.

(1) Les outils fournis avec la machine

(2) Une réserve de carburant

(3) Une lame de rechange

(4) Matériel pour délimiter la zone de travail

(5) Un sifflet (pour collaborateur ou en cas

d’urgence)

(6) Une hache ou une scie (pour enlever

les obstacles)

(7) Boîte de secours

3. Ne pas porter de vêtements larges, de

short, de bijoux, de sandales ou travailler

pieds nus. Ne pas porter quoi que ce soit

pouvant être happé par les pièces en

mouvement de la machine. Porter les

cheveux longs noués au-dessus des

épaules.

■ CONDITIONS DE TRAVAIL

1. Ne jamais mettre la machine en marche à

l’intérieur d’une pièce ou d’un bâtiment.

Les gaz d’échappement contiennent du

monoxyde de carbone dangereux.

2. Ne jamais utiliser la machine dans les

conditions suivantes :

a. Lorsque le sol est glissant ou lorsqu’il

est impossible de se maintenir dans

une position correcte.

b. La nuit, par temps de brouillard ou

lorsque la visibilité ou le champ de

vision empêche de voir clairement la

zone de travail.

c. Pendant les averses, les orages avec

éclairs, par grands vents ou toute autre

condition climatique rendant l’utilisation

de la machine dangereuse.

■ PLAN DE TRAVAIL

1. Ne jamais utiliser la machine sous

l’influence de l’alcool ou en état de

faiblesse due à la fatigue, au manque de

sommeil, à la prise de médicament ou à

tout autre moment où l’on n’est pas

réellement capable de l’utiliser

correctement et en toute sécurité.