Page 1

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

MODEL ZMH - HEAVY DUTY LENGTH SENSOR

HEAVY DUTY INDUSTRIAL CONSTRUCTION

QUADRATURE OUTPUT

BUILT-IN SPRING TENSIONING

VERTICAL, HORIZONTAL, OR UPSIDE-DOWN MOUNTING

EASY INSTALLATION

VARIOUS MEASURING WHEELS AVAILABLE

VARIOUS MOUNTING CONFIGURATIONS

Bulletin No. ZMH-A

Drawing No. LP0845

Released 03/14

DESCRIPTION

Designed for heavy duty sensing applications, the Heavy Duty Length

Sensor, Model ZMH, is versatile and easy-to-use.

It features a built-in spring-loaded torsion arm that provides a simple-toadjust torsion load, allowing the unit to be mounted in almost any orientation,

including upside down. Using a properly selected wheel, the ZMH can be used

on almost any surface, while operating at speeds up to 3000 feet per minute.

Whether you need to measure speed, position, or distances, the Model ZMH is

the ideal solution.

Open Collector Output Wiring

The ZMH sensors have open collector outputs. An open collector output

brings the uncommitted collector of the encoder switching device to the external

world. Because the collector element is not associated with the sensor supply

voltage, the sensor output collector may be “pulled up” to external voltages

different than the encoder supply voltage (30 VDC maximum). NPN open

collector outputs are current sinking devices. An output signal will not be

generated unless a pull-up resistor is connected from the open-collector to the

positive side of an external supply. The same supply can be used for powering

the unit and for the pull-up resistor.

ORDERING INFORMATION

MODEL NO. DESCRIPTION PPR PART NUMBER

250 ZMH0250B

ZMH *

MBZM

* Mounting shaft not included.

Heavy Duty Length Sensor

with Quadrature Output

Mounting Bracket and Shaft N/A MBZM0001

Double Wheel Pivot Mount and Shaft N/A MBZM0002

500 ZMH0500B

1000 ZMH1000B

2000 ZMH2000B

2500 ZMH2500B

LENGTH SENSOR MEASUREMENT ACCURACY

Factors which affect measurement accuracy include Measuring Wheel

accuracy and wear, and material conditions. Ideally, materials which are hard,

thin and strong provide good readings, conversely, soft, thick and elastic

materials can present problems in obtaining true readings. Where this effect is

consistant, Counter or Rate Indicators with “input scaling” can compensate for

Measuring Wheel wear and material elastic and compliance errors. In addition,

English/Metric conversions may also be accomplished.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

literature or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

CAUTION: Read complete

instructions prior to installation

and operation of the unit.

CAUTION: Risk of electric shock.

SPECIFICATIONS

ELECTRICAL SPECIFICATIONS

1. INPUT VOLTAGE: 4.75 to 28 VDC.

2. INPUT CURRENT: 100 mA max (65 mA typical) with no output load

3. OUTPUTS: NPN Open Collector Transistor, VOH = 30 VDC max.; 20 mA

max. current. Incremental - Two square waves in quadrature with A leading

B for clockwise rotation, as viewed from the wheel side.

4. MAX FREQUENCY: 200 KHz

5. NOISE IMMUNITY: Tested to BS EN61000-6-2; BS EN50081-2; BS

EN61000-4-2; BS EN61000-4-3; BS EN61000-4-6, BS EN500811

6. SYMMETRY: 180º (±18º) electrical

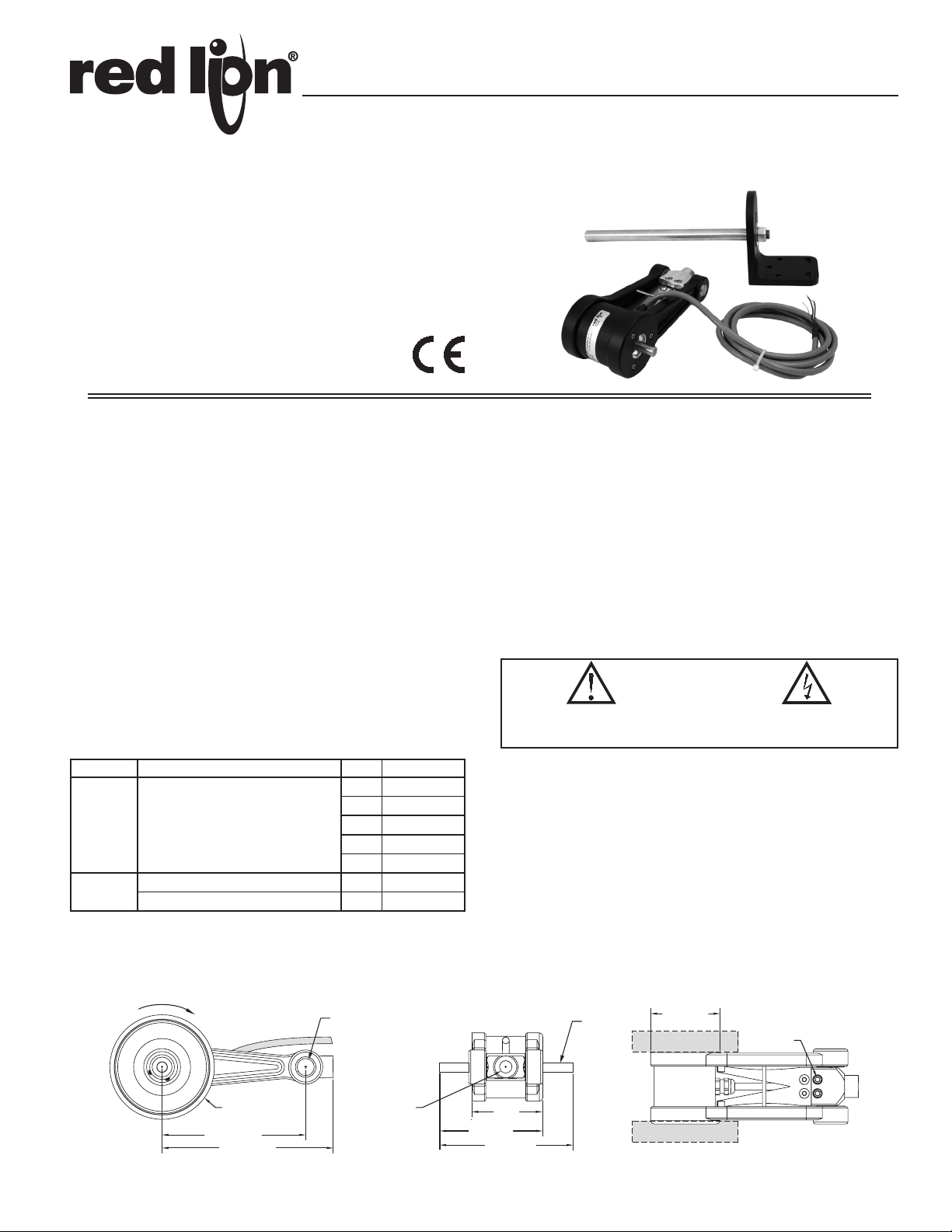

DIMENSIONS In inches (mm)

A LEADS B FOR

CW ROTATION

12" CIRC.

WHEEL SHOWN

5.25 (133.4)

6.25 (158.8)

Note: All dimensions are in inches with a tolerance of +0.01" unless otherwise specified.

FOR MOUNTING ON

+0.000

A ø0.625 SHAFT

-0.005

1/2-20, .500"

DEEP

3.85 (97.8)

2.75

(69.9)

5.00 (127.0)

1

1

ø0.375

(ø9.53)

SHAFT

2.50 (63.5)

BODY DIA.

5/32" HEX SOCKET

FOR SHAFT CLAMP

Page 2

7. QUAD. PHASING: 90º (±22.5º) electrical

8. MIN. EDGE SEP: 67.5º electrical

9. ACCURACY: Within 0.017º mechanical or 1 arc-minute from true position.

(for PPR>189)

MECHANICAL SPECIFICATIONS

1. MAXIMUM MECHANICAL SPEED: 3000 RPM

2. SHAFT MATERIAL: Stainless Steel

3. SHAFT SIZE: 0.375"

4. RADIAL SHAFT LOAD: 10 lb. max. controlled by spring torsion.

5. STARTING TORQUE: 1.0 oz-in typical

6. ELECTRICAL CONNECTION: 2 meter Cable, (foil and braid shield, 24

AWG conductors).

FUNCTION CABLE WIRE COLOR

+VDC Red

Com Black

A White

B Green

Shield Bare

7. MOUNTING: 5/8" diameter thru hole with clamp

8. HOUSING: powder coated aluminum.

9. WEIGHT:

ZMH: 2.15 lb. (0.975 Kg)

MBZM0001: 1.5 lb. (0.68 Kg)

MBZM0002: 0.15 lb.. (68.04 g)

ENVIRONMENTAL SPECIFICATIONS

1. OPERATING TEMPERATURE: -20°C to 85°C

2. STORAGE TEMPERATURE: -25°C to +85°C

3. HUMIDITY: 98% RH non-condensing

4. VIBRATION: 10 g @ 58 to 500 Hz

5. SHOCK: 80 g @ 11 msec duration

6. SEALING: IP50

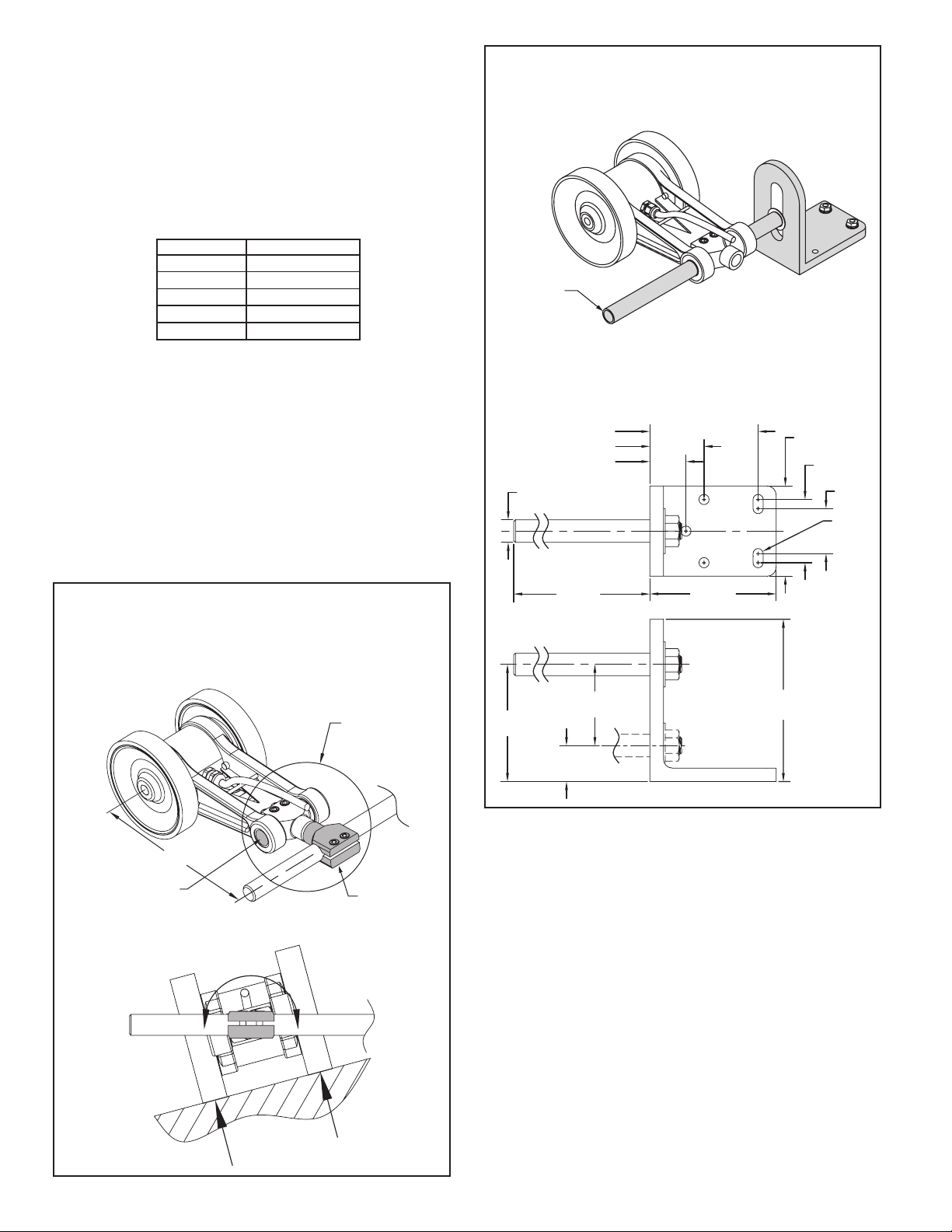

MOUNTING BRACKET - MBZM0001

This accessory angle mounting bracket allows for a variety of mounting

positions and makes installation of the ZMH even easier. Mounting shaft

included with mounting bracket.

Mounting

Shaft

DIMENSIONS In inches (mm)

3.00 (76.2)

1.50 (38.1)

1.00 (25.4)

Ø0.625

(Ø15.86

+0.000

-0.005

+0.01

-0.13

)

2.50

(63.5)

(44.4)

1.75

1.25

(31.7)

Ø0.281

(Ø7.14)

THRU

5x

DOUBLE WHEEL PIVOT MOUNT - MBZM0002

This accessory allows the unit to rotate freely to maintain equal pressure

on both wheels, accomodating uneven/angled surfaces and mounting

misalignment. Pivot mounting shaft included with MBZM0002. For

installation of unit, use the mounting bracket and shaft included with

MBZM0001.

Pivot Joint

7.5

Pivot Mounting

Shaft

Pivot

Mounting

Clamp

3.25

(82.6)

8.95

(227.3)

ADJUSTABLE

HEIGHT

1.00

(25.4)

3.50

(88.9)

4.50

(114.3)

2

Page 3

LENGTH SENSOR ACCESSORIES

SEPARATE LENGTH MEASURING WHEELS - DIMENSIONS In Inches (mm)

WHEEL

CODE

8-32 UNF

Set Screw

.376"

(9.6)

Bore

+.001"

-.000"

Cast

Alum.

3/8"

(9.5)

OR

Round Section Replaceable

Tire .210" Section Dia.

Black Neoprene

FOR USE ON: Metal, paper,

foil, film and hard plastics.

Line contact on material

being measured,

convenient when available

measuring track is narrow

or for measuring on end of

roller beside passing

material.

Max. Speed: 600 RPM

WHEEL

CODE

.376"

(9.6)

Bore

+.001"

-.000"

OF

(25.4)

Alum.

1"

Tan, Smooth Polyurethane

Tread

10-32 UNF

Set Screw

Cast

FOR USE ON: Soft, smooth

materials such as soft

paper, matting, cardboard,

fine weave textiles. Broad

wheel tread minimizes

contact pressure and tan

polyurethane tread

minimizes marking.

Max. Speed: 600 RPM

Balanced version of 1ft.

circumference available.

Balanced to ANSI S2.191989 Quality Grade 6.3 @

3000 RPM.

WHEEL

CODE

.376"

(9.6)

Bore

+.001"

-.000"

OK

(25.4)

Diamond Knurled Aluminum

Tread

Cast

Alum.

1"

10-32 UNF

Set Screw

FOR USE ON: Rubber,

coarse weave fabrics,

rough wood surfaces,

foam, insulation.

Max. Speed: 600 RPM

Balanced version of 1ft.

circumference available.

Balanced to ANSI S2.191989 Quality Grade 6.3

@ 3000 RPM.

SELECTING APPROPRIATE WHEEL SIZE & PPR (Pulses Per Rev.) OF ROTARY PULSE GENERATOR

When the desired output of a length sensor and wheel combination is either in feet or inch units, selection

of the proper combination is relatively straight forward. For example, with a 1-foot wheel circumference, a

1 PPR Rotary Pulse Generator will deliver 1 pulse/ft, 12 PPR would deliver 12 pulses/ft (1 pulse/inch); 100

PPR would yield 100 pulses/ft; and 120 PPR would permit measuring to 1/10th of an inch (1/120th of a foot).

WHEELS & REPLACEMENT TIRES FOR CODE OR WHEELS

ORDERING INFORMATION

TOLERANCEWHEEL CODE CIRCUMFERENCE PART NUMBER

1 foot (1/3 yd) ±0.40% WF1000OR

OR

1/3 meter ±0.40% WM0333OR

4/10ths yard ±0.40% WY0400OR

4/10ths meter ±0.40% WM0400OR

1 foot (1/3 yd) ±0.35% WF1000OF

OF

1/3 meter ±0.30% WM0333OF

4/10ths yard ±0.30% WY0400OF

4/10ths meter ±0.30% WM0400OF

BF (Balanced) 1 foot (1/3 yd) ±0.40% WF1000BF

Note: After installation of measuring wheels, ensure guards,shields or other

devices are in place to protect personnel from rotating equipment.

WHEEL CODE CIRCUMFERENCE TOLERANCE PART NUMBER

1 foot (1/3 yd) ±0.35% WF1000OK

OK

1/3 meter ±0.30% WM0333OK

4/10ths yard ±0.30% WY0400OK

4/10ths meter ±0.30% WM0400OK

BK (Balanced) 1 foot (1/3 yd) ±0.35% WF1000BK

1 foot (1/3 yd) TORF1000

Replacement Tires

for OR Wheels

1/3 meter TORM0333

4/10ths yard TORY0400

4/10ths meter TORM0400

ZMH INSTALLATION

INSTALLATION:

1. Slide ZMH over a fixed Ø5/8" (Ø0.625 +0/-0.005") shaft. The optional ZMH

Mounting Bracket (MBZM0001) is shown in the picture.

2. While rotating the ZMH clamp to apply a spring load, securely tighten the two

clamp bolts with a 5/32" (supplied) or 4 mm hex “L” key.

Note 1: A 1/2 – 20 bolt can be threaded into the end of the clamp to aid in

loading the spring as shown. If a 1/2 – 20 bolt is not handy, then a Ø0.45"or

smaller rod, bolt, screw driver etc. works as well.

Note 2: The spring should not be preloaded too much or it may come in

contact with the spring limit pins and the ZMH will not have sufficient

travel to accommodate variations in the surface height of the material

being measured. For most applications, the spring setting in its mid-range

(5-6 lbs.) is sufficient.

3

Page 4

DOUBLE WHEEL PIVOT INSTALLATION

(MBZM0002):

Note: It is recommended that double wheel ZMH’s be installed with the optional

Double Wheel Pivot. The pivot allows the unit to rotate freely to maintain

equal pressure on both wheels, accommodating uneven/angled surfaces and

mounting misalignment.

1. Thread the pivot clamp into the end of the ZMH’s clamp by hand until the

threads just bottom out then back out approximately 1 revolution to allow for

rotation after installation.

2. Slide the pivot clamp over a fixed Ø5/8" (Ø0.625 +0/-0.005") shaft. The

optional ZMH Mounting Bracket (MBZM0001) is shown in the picture.

3. While applying a load to the spring, securely tighten the two clamp bolts with

a 5/32" (supplied) or 4mm hex “L” key.

Pivot

Clamp

Threaded

Joint

Apply Load

CONNECTOR EXIT ORIENTATION ADJUSTMENT:

1. Slide the ZMH over a Ø5/8" (Ø0.625 +0/-0.005") shaft and tighten the clamp

bolts with the supplied 5/32" hex “L” key.

2. Remove the measuring wheel(s) using the supplied 3/32" hex “L” wrench to

loosen the set screws.

3. Remove 6 screws (3 on each side) from the side plates using the supplied

7/64" hex “L” key.

4. Rotate body of encoder to desired orientation, aligning bolt pattern with one

of six unique positions (see inset drawing).

5. Replace side plate screws and measuring wheel(s), making sure to tighten

screws securely.

Rotate

Body

Red Lion Controls

Headquarters

20 Willow Springs Circle

York PA 17406

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

The Company warrants the products it manufactures against defects in materials and workmanship

LIMITED WARRANTY

for a period limited to two years from the date of shipment, provided the products have been stored,

handled, installed, and used under proper conditions. The Company’s liability under this limited

warranty shall extend only to the repair or replacement of a defective product, at The Company’s

option. The Company disclaims all liability for any affirmation, promise or representation with

respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against

damages, claims, and expenses arising out of subsequent sales of RLC products or products

containing components manufactured by RLC and based upon personal injuries, deaths, property

damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be

to any extent liable, including without limitation penalties imposed by the Consumer Product Safety

Act (P.L. 92-573) and liability imposed upon any person pursuant to the Magnuson-Moss Warranty

Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except

those expressly contained herein. The Customer acknowledges the disclaimers and limitations

contained herein and relies on no other warranties or affirmations.

Red Lion Controls

Europe

Softwareweg 9

NL - 3821 BN Amersfoort

Tel +31 (0) 334 723 225

Fax +31 (0) 334 893 793

Red Lion Controls

India

201-B, 2nd Floor, Park Centra

Opp 32 Mile Stone, Sector-30

Gurgaon-122002 Haryana, India

Tel +91 984 487 0503

Red Lion Controls

China

Unit 302, XinAn Plaza

Building 13, No.99 Tianzhou Road

ShangHai, P.R. China 200223

Tel +86 21 6113 3688

Fax +86 21 6113 3683

4

Loading...

Loading...