Page 1

Slim Line (SL/SLX) Series

Industrial Ethernet Switches

& Media Converter

Hardware Manual

Drawing No. LPO977

Revision: 28 April 2016

Page 2

Section 1

General Information

Page 4

Section 2

LED Indicators

Page 7

Section 3

Installation / Mounting

Page 9

Section 4

Power Wiring

Page 21

Section 5

Communication Wiring

Page 27

Section 6

Technical Specifications

Page 31

Section 7

Service Information

Page 35

Table of Contents

This manual applies to the following products:

• SL-2ES-# 2-port unmanaged Ethernet media converter

• SLX-3ES-# 3-port unmanaged Ethernet media converter

• SLX-3EG-1 3-port unmanaged Gigabit Ethernet converter

• SLX-5EG-1 5-port unmanaged Gigabit Ethernet switch

• SLX-5EG-2SFP 5-port unmanaged Gigabit Ethernet switch with 2 fiber SFPs

• SL/SLX- 5ES-# 5-port unmanaged Ethernet switch with 5 10/100 ports

• SL/SLX- 5MS-# 5-port managed Ethernet switch with 5 10/100 ports

• SL/SLX-5MS-MDM-1 5-port managed Ethernet land-line modem with 5 10/100 ports

• SL/SLX- 6ES-# 6-port unmanaged Ethernet switch

• SL/SLX- 8ES/9ES-# 8/9-port unmanaged Ethernet switch with 8 or 9 10/100 ports

• SL/SLX- 8MS-# 8-port managed Ethernet switch with 8 10/100 ports

• SL/SLX- 8MG-1 8-port managed Ethernet switch with 8 Gigabit ports

• SLX-10MG-1 10-port managed Gigabit Ethernet switch with 10 ports

• SLX-16MS-1 16-port managed Ethernet switch with 16 10/100 ports

• SLX-18MG-1 18-port managed Gigabit Ethernet switch with 18 ports

Slim Line Switch Hardware Manual Page 2 of 35

Page 3

Note: All information in this document is subject to change without notice.

Red Lion Statement of Limited Warranty - (a) Red Lion Controls Inc., Sixnet Inc., N-Tron

Corporation, or Blue Tree Wireless Data, I nc. ( the “Company”) warrants that all Product s shall be

free from defects in materi al and workmanship under norm al use f or t he per i od of time provided in

“Statement of Warranty Periods” (available at www.redlion.net) cur rent at the time of shipment of

the Products (the “Warranty Period”). EXCEPT FOR THE ABOVE-STAT ED WARRANTY, COMPANY

MAKES NO WARRANTY WHATSO EVER WIT H RESPECT TO THE PRODUCTS, INCLUDING ANY (A)

WARRANTY OF MERCHANTABILITY; (B) WARRANTY O F F I TNESS FOR A PARTICULAR PURPOSE;

OR (C) WARRANTY AGAINST INFRINGEMENT OF I NTELLECTUAL PROPERTY RIGHTS OF A THIRD

PARTY; WHETHER EXPRESS OR IMPLIED BY LAW, COURSE OF DEALING, COURSE OF

PERFORMANCE, USAGE OF TRADE OR OT HERWISE. Cust omer shall be responsible for

determining that a Product is sui t abl e f or Cust om er 's use and t hat such use complies with any

applicable local, state or f eder al l aw. (b) The Company shall not be liable for a br each of t he

warranty set forth in paragraph ( a) if (i) the defect is a r esul t of Customer's failure to st ore, install,

commission or maintain the Product accor di ng t o speci fications; (ii) Custom er al t er s or r epai r s

such Product without t he prior writt en consent of Company. (c) Subject t o par agr aph ( b) , with

respect to any such Product during the Warranty Period, Company shall, in its sole di scr et ion,

either (i) repair or replace the Product; or (ii) credi t or refund the price of Product provided that , i f

Company so requests, Customer shall, at Company's expense, return such Product to Company. (d)

THE REMEDIES SET FORTH IN PARAGRAPH ( c ) SHAL L BE THE CUSTOMER'S SOLE AND

EXCLUSIVE REMEDY AND COMPANY'S ENTIRE LIABILITY FOR ANY BREACH OF THE LIMITED

WARRANTY SET FORTH IN PARAGRAPH (a) .

FCC Statement - This equipment has been tested and found to comply with the limits for a Class B dig it al

device, pursuant to Part 15 of the FCC Rules. T hese limit s ar e designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not inst alled and used in accor dance with the instructions, may cause

harmful interferenc e t o r adio com munications. However, there is no guarantee that inter ference will not

occur in a particular installation. If t his equipment does cause harmful inter ference to radio or television

reception, which can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interfer ence by one or m or e of the following measures: Reorient or r elocat e the receiving

antenna; Increase the separation between the equipm ent and r ec eiver; Connect the equipment into an

outlet on a circuit different from that to which the receiver is connected; Consult the dealer or an

experienced radio/TV technician for help.

Copyright & Trademarks - Copyright 2014-2016 Red Lion Controls. All Rig hts Reserved.

Slim Line Switch Hardware Manual Page 3 of 35

Page 4

Section 1

General Information

This manual will help you install and maintain these industrial Ethernet switches.

Note: This manual only covers the installation and wiring of the se switches. For

IGMP, VLANs, security, port mirroring and much more.

Unlike an Ethernet hub that broadcasts all messages out all ports, these industrial Ethernet

one or more fiber optic ports for making noise immune connections up to 120 km.

These general specifications apply to these industrial Ethernet switches. Refer to Section 7

Number of ports

2,3, 5, 6, 8, 9, 10, 16 or 18 Ethernet ports

Ethernet Switch Type

Unmanaged (ES/EG models) or managed (MS models)

Ethernet Switch Mode

Store and forward, wire-speed, non-blocking

Ethernet Protocols

All standard IEEE 802.3 protocols supported

RJ45 Ports Speed

10/100 or 10/100/1000 Mbps

RJ45 Ports Operation

Auto-negotiation, auto-mdi/mdix-crossover and auto-polarity

Fiber Optic Port Speed

100 Mbps (SC or ST) or 1000 Mbps (SFP/LC)

Fiber Optic Type

Multimode, singlemode, long-haul or special application

Note: This Equipment is Suitabl e for Use in Class I, Division 2, Groups A, B, C, D

or Non Hazardous Locations Only

Overview

Operation

Installation of these switches is very easy and they will begin to operate as soon as they are

powered up. For the unmanaged models (denoted by ES in their part number) there are no

user settings so they are truly plug and play. The managed models (denoted by MS in their

part number) will act as unmanaged switches until they are configured otherwise. Refer to

the managed switch software manual for configuration of advanced network functionality.

the managed models refer to the separate Software User Manuals for details on

configuring and using any of the management functions suc h as SNMP, RSTP,

switches wil l intelligently route Ethernet messages only out the appropriate port. The major

benefits of this are increased bandwidth and speed, reduction or elimination of message

collisions, and deterministic performance when tied with real-time systems.

These industrial Ethernet switches can support 10BaseT (10 Mbps), 100BaseT (100 Mbps)

and 1000BaseT (100 Mbps) on their RJ45 ports (depending on the model). Each of these

ports will independently auto-sense the speed/duplex, mdi/mdix-crossover and polarity

allowing you to use straight, crossed or even mis-wired cables. Some models also have

Performance

Specifications

Safety

Standards

for complete technical specifications.

These industrial Ethernet Switches meet the following standards plus others:

Note: Some ratings may be pending on newer models. Contact Red Lion for latest info.

Electrical safety –

• CE per Low Voltage Directive and IEC61010-1

• UL508

• CSA per C22.2/142

See warnings below.

Slim Line Switch Hardware Manual Page 4 of 35

Install the Managed Switches in accordance with local and national electrical codes.

Page 5

Lightning Danger: Do not work on equipment during periods of lightning activity.

Do not connect a telephone line into one of the Ethernet RJ45 connectors.

RoHS

EMC (emissions and immunity) –

• CE per the EMC directive, EN 55022, EN 61000-6-2/4

• FCC part 15 and ICES 003; Class B. See FCC statement on previous page.

Marine, maritime and offshore –

These devices, when installed in an appropriately IP rated enclosure, comply with the ABS

standards which is similar to DNV No. 2.4 and equivalent Lloyds. Please reference

product datasheet for individual specifications and agency certifications.

See warning below.

For marine and maritime compliance, do not install this product within 5 meters of a

standard or a steering magnetic compass.

WEEE compliance –

These devices comply with the WEEE directive. Do not throw away these devices in the

standard trash. Contact Red Lion regarding proper disposal.

RoHS compliance –

These devices comply with the RoHS directive and are consider lead and other hazardous

substance free.

Hazardous Locations –

• CE per ATEX directive and IEC60079-0,-15 (Zone 2)

• ISA12.12.01 (Class I, Div. 2), Groups A,B,C,D

• CSA per C22.2/213 (Class 1, Div. 2), Groups A,B,C,D

See warnings below.

Slim Line Switch Hardware Manual Page 5 of 35

Page 6

INSTALLATION AND HAZARDOUS AREA WARNINGS :

DANS LES ENDROITS DANGEREUX OU POTENTIELLEMENT

CONNEXIONS INTERNES.

These products should not be used to replace proper safety interlocking. No sof tware-based device (or any

other solid-state device) should ever be designed to be responsible f or t he maintenance of consequential

equipment or personnel safety. I n par ticular, Red Lion disclaims any responsibility for damages, ei t her

direct or consequential, that r esul t from the use of this equipment in any application.

All power, input and output (I/O) wiring must be in accor dance with Class I, Division 2 wiring methods and in

accordance with the authority having jurisdiction. This eq uipment is suitable for use in Class I, Division 2,

Groups A, B, C, D or non-hazardous locations only.

WARNING (EXPLOSION HAZARD)

WARNING (EXPLOSION HAZARD)

WARNING (EXPLOSION HAZARD)

WARNING (EXPLOSION HAZARD)

SUBSTITUTION OF ANY COMPONENTS MAY IMPAIR SUITABILITY

FOR CLASS 1, DIVISION 2 (ZONE 2).

WHEN IN HAZARDOUS LOCATIONS, DISCONNECT POWER BEFORE

REPLACING OR WIRING UNITS.

DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NONHAZARDOUS.

IN HAZARDOUS OR POTENTIALLY HAZARDOUS LOCATIONS, DO

NOT SEPARATE ANY PART OF THE UNIT WHEN ENERGIZED. USE

THE UNIT FOR INTERNAL CONNECTIONS ONLY.

INSTRUCTIONS D’INSTALLATION ET D’UTILISATI O N:

Ces produits ne doivent pas être utilisés pour rem placer le verrouillage de sécurité approprié. Aucun

dispositif basé sur un logiciel (ou tout autre dispositif à l' ét at solide) devraient jamais être conçus pour être

responsable de l'entretien de l'équipement consécutifs ou la sécurité du personnel. En particulier, Red Lion

décline toute responsabilité pour les dommages, directs ou indirects, résultant de l'utilisation de c et

équipement dans n'importe q uelle application.

Tout courant, câblage ent r ée et sortie (I / O) doit être conforme aux méthodes de câblage à la Classe I,

Division 2 et conformément à l'autorité compétente. Cet équipement est adapté à une utilisation en Classe

I, Division 2, Groupes A, B, C, D ou environnements non-danger eux seulement.

AVERTISSEMENT (RISQUE D’EXPLOSION)

AVERTISSEMENT (RISQUE D’EXPLOSION)

AVERTISSEMENT (RISQUE D’EXPLOSION)

AVERTISSEMENT (RISQUE D’EXPLOSION)

LA SUBSTITUTION DE TOUT COMPOSANT PEUT NUIRE À LA

CONFORMITÉ DE CLASSE I, DIVISION 2 (ZONE 2).

LORSQUE DANS DES ENDROITS DANGEREUX, DÉBRANCHEZ LE

CORDON D’ALIMENTATION AVANT DE REMPLACER OU DE

BRANCHER DES MODULES.

NE DÉBRANCHEZ PAS L’ÉQUIPEMENT PENDANT QUE LE CIRCUIT

EST DIRECT OU À MOINS QUE L’ENVIRONNEMENT SOIT CONNU

POUR ÊTRE LIBRE DE CONCENTRATIONS INFLAMMABLES.

DANGEREUX, NE PAS SÉPARER UNE PARTIE DE L'UNITÉ SOUS

TENSION. SEULEMENT UTILISEZ L'APPAREIL POUR LES

Slim Line Switch Hardware Manual Page 6 of 35

Page 7

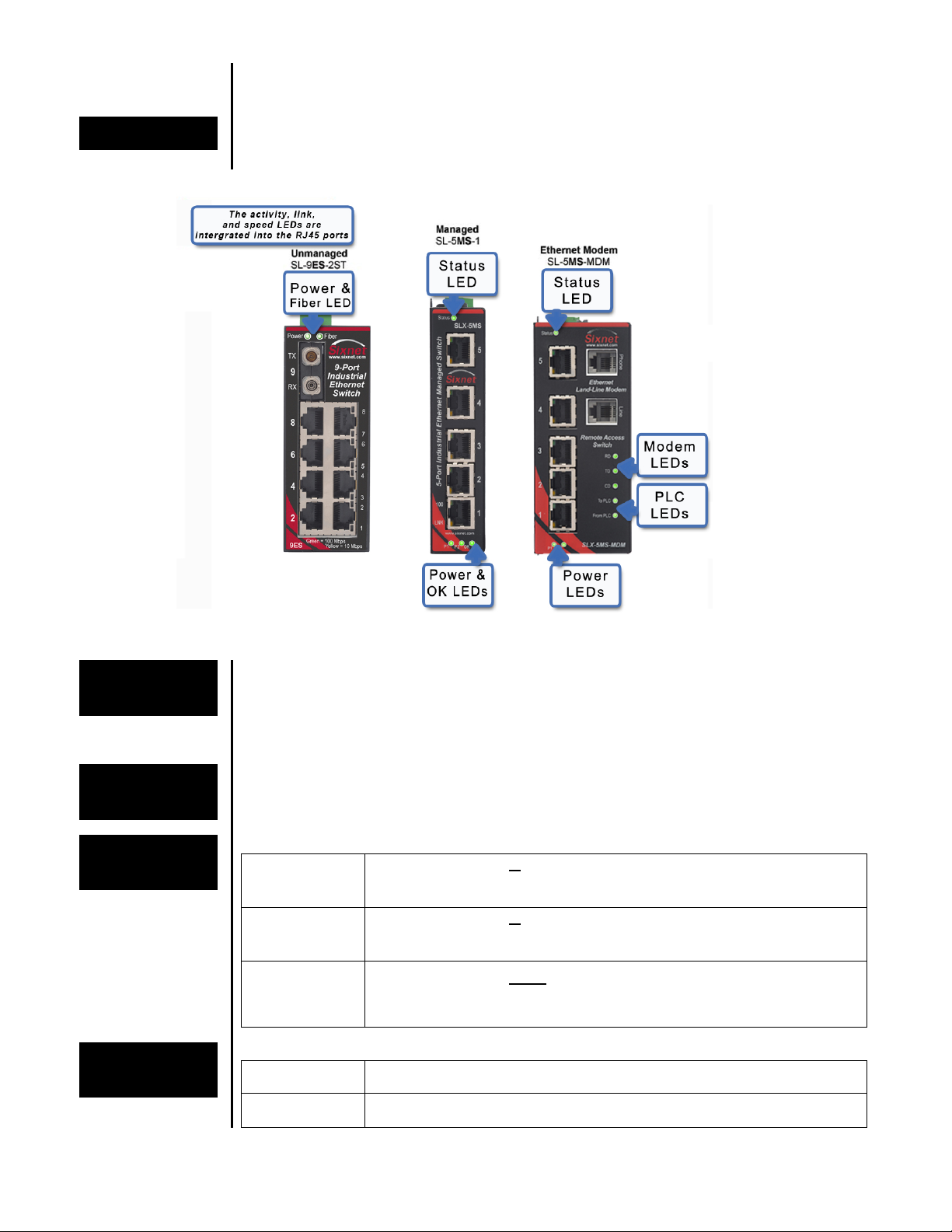

Section 2

LED Indicators

All these industrial Ethernet switches have 1 or 2 communication LEDs for each port and a

power LEDs. Refer to the sample pictures below for the location of these LEDs.

Typical LED Location (varies with model)

Managed Models Only: The Status LED indicates the overall health of the switch. It is

contact Red Lion for support.

On unmanaged models there is typically one power LED that is ON if either power input (P1

This is the Yellow LED on models with two LEDs per RJ45 port.

Indicates that there is a proper Ethernet connection (Link) between the

detected.

Indicates that there is a proper Ethernet connection (Link) between the

activity.

This is the Green LED on models with two LEDs per RJ45 port.

Overview

power LED. The managed models also have an “OK” output LED, a status LED and dual

Status LED

Power LED

normally ON solid indicating that no internal CPU or software problems are detected. It will

flash when loading firmware and briefly on power up or reset. Otherwise, if it is OFF or

flashing for an extended period of time then a problem is detected. In this case, please

or P2) has power applied to it. On the managed models (and some unmanaged models)

there are two Power LEDs that indicate if there is power applied to the respective input.

ACT / LNK

LED

Speed 10/100

LED

ON (yellow)

(not flashing)

ON (yellow)

(flashing)

OFF

ON (green)

OFF

port and another Ethernet device, but no communications activity is

port and another Ethernet device, and that there is communications

Indicates that there is not a proper Ethernet connection (Link) between

the port and another Ethernet device. Make sure the cable has been

plugged securely into the ports at both ends.

A 100 Mbps (100BaseT) connection is detected.

A 10 Mbps (10BaseT) connection is detected.

Slim Line Switch Hardware Manual Page 7 of 35

Page 8

This is a bi-color (green and yellow or orange) LED on models with one LED per RJ45

Indicates that there is a proper Ethernet connection (Link) between the

detected.

Indicates that there is a proper Ethernet connection (Link) between the

activity.

On 10/100 ports, a 100 Mbps connection is detected.

On 10/100/1000 ports, a 1000 Mbps connection is detected.

Yellow or

Orange

No valid Powered Device (PD) is detected or the connected device is

then power will be sourced.

Error Code

Blink

Managed Models and Some Unmanaged Models: This LED indicates the status of the

the switch software is not running.

From PLC

5MS-MDM Models Only: This LED indicates status of the Discrete “From PLC” input on

voltage is applied the LED will be OFF.

To PLC

5MS-MDM Models Only: This LED can indicate Power Status or Modem Connection

the CD LED is ON and will be OFF when the CD LED is OFF.

CD LED

5MS-MDM Models Only: The CD LED indicates when there is a carrier (successful

connection is not established, and when ON the Carrier is established.

RD LED

5MS-MDM Models Only: The RD LED flashes when the SL-5MS-MDM is receiving data

will indicate communication coming in from the remote device.

TD LED

5MS-MDM Models Only: The TD LED will flash on as the SL-5MS-MDM transmits data

communications between the SL-5MS-MDM and device connected to the other modem.

ACT / LNK /

Speed LED

PoE LED

port.

ON Solid

(not flashing)

Flashing

Green

OFF

ON

OFF

Periodically

Blinks ON

port and another Ethernet device, but no communications activity is

port and another Ethernet device, and that there is communications

On 10/100 ports, a 10 Mbps connection is detected.

ON 10/100/100 ports, a 10 or 1000 Mbps connection is detected.

Indicates that there is not a proper Ethernet connection (Link) between

the port and another Ethernet device. Make sure the cable has been

plugged securely into the ports at both ends.

A valid Powered Device(PD) is detected and the switch is sourcing

power on this port.

No valid Powered Device(PD) is detected and no power is sourced.

drawing too little current (<10 mA) so no power is being sourced. Once

the connected device is loaded and draws more than 10 or 15 mA

If you see the same sequence of blinks repeatedly then contact Red

Lion for more information.

OK LED

Input LED

Output LED

power inputs. There is an output screw terminal that can be connected as shown in the

wiring diagram. The output voltage from the screw terminal marked ‘OK’ will be the same

as the applied switch input voltage. The output will be ON when both the PI and P2

terminals have power applied to them. It will be OFF if either input does not have power or

the modem. There is an input screw terminal that can be connected as shown in the

diagram. When voltage is applied to the From PLC input the LED will be ON. When no

status. There is an output screw terminal. That can be connected as shown in the wiring

diagram. . The output voltage from the screw terminal marked ‘OK’ will be the same as the

applied switch input voltage. In “OK output” mode the output will be ON when both P1 and

P2 terminals have power applied to them. It will be OFF if either input does not have power

or the switch software is not running. In “Carrier Detect” mode the output will be ON when

connection) established between the SL-5MS-MDM and another modem. When OFF the

Slim Line Switch Hardware Manual Page 8 of 35

from the phone line port. Flashing on this LED when the CD LED is OFF could indicate a

Ring coming in from a calling device. When the CD LED is ON and the RD LED is flashing

out to the modem. The flashing of TD LED while the CD LED is ON will indicate

Page 9

Section 3

Installation

These industrial Ethernet switches can be snapped onto a standard DIN rail (EN50022) or

Note: Make sure to allow enough room to route your Ethernet copper or fiber optic cables.

Mounting

Removal

1

Recommended DIN rail mounting steps:

Recommended DIN rail removal steps:

Overview

screwed directly to a flat panel. Refer to the mechanical drawings below to properly mount

your switch.

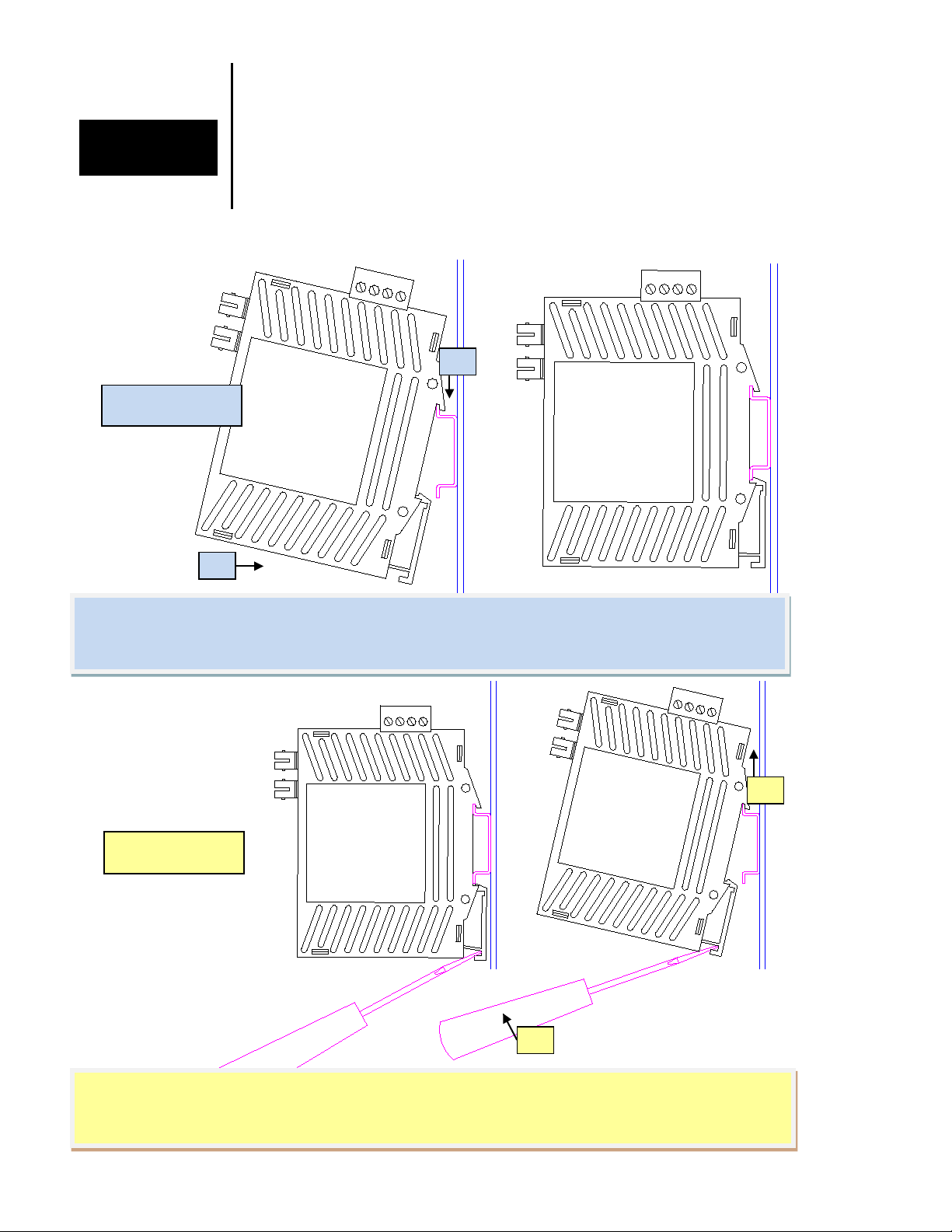

SL- or SLX-#ES models in Lexan case:

1. Hook the top back of the unit over the DIN rail.

2. Push the bottom of the unit towards the DIN rail until it snaps into place.

A. Insert screwdriver into DIN clip and pry until the bottom of the unit releases from the din rail.

B. Unhook the top of the unit and remove it from the DIN rail.

Slim Line Switch Hardware Manual Page 9 of 35

Page 10

SL- or SLX-#ES models in metal case:

Mounting

Removal

Recommended DIN rail mounting steps:

Recommended DIN rail removal steps:

C

1. Hook the top back of the DIN rail clip on the unit over the din rail.

2. Push the bottom of the unit towards the DIN rail until it snaps into place.

A. Push the whole unit down to free the bottom of the DIN rail clip. See blue circle area.

B. Pull the bottom of the unit away from the DIN rail.

C. Unhook the top of unit and remove it from the DIN rail.

Slim Line Switch Hardware Manual Page 10 of 35

Page 11

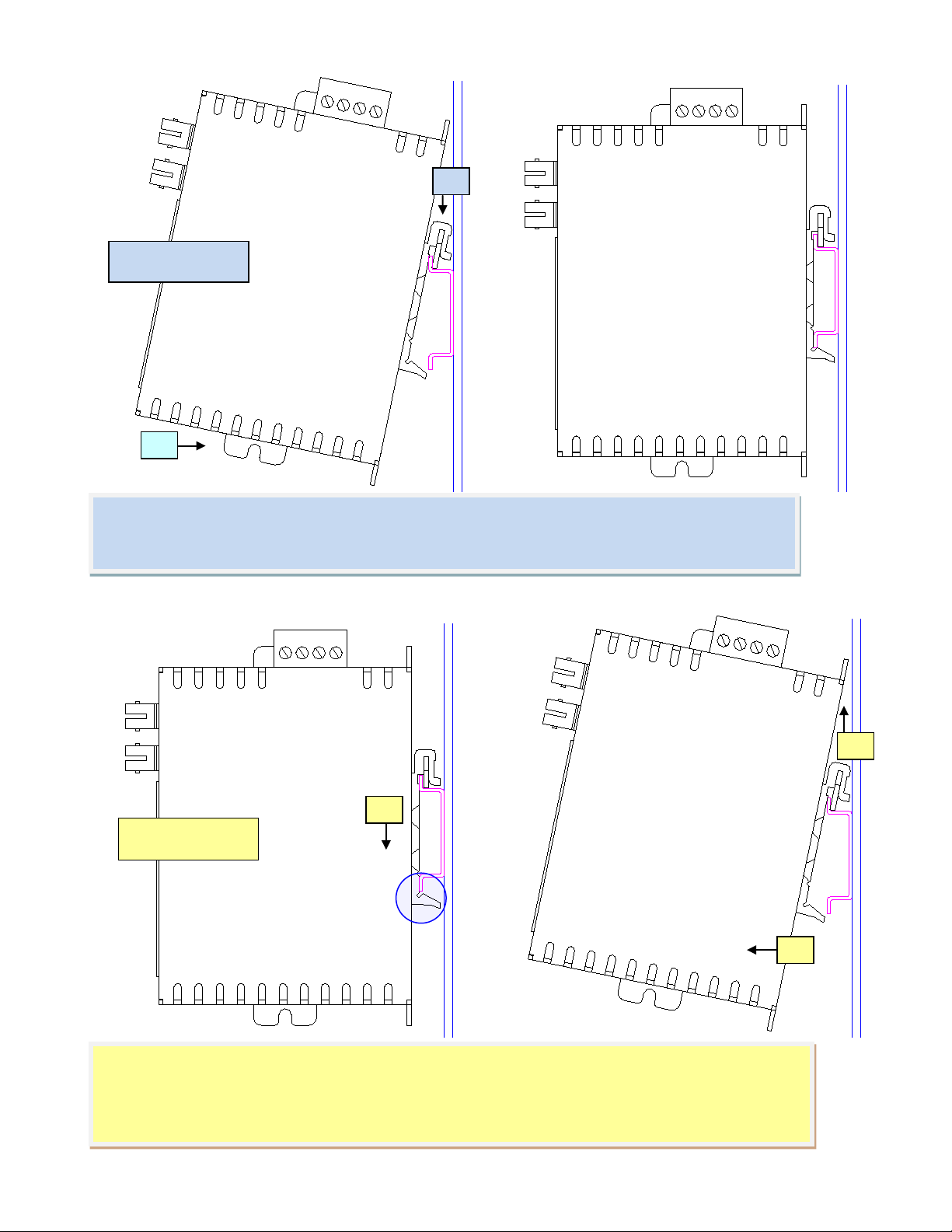

SL- or SLX-#MS models in metal case with plastic DIN rail clip (older models):

Mounting

Removal

2

Recommended DIN rail mounting steps:

Recommended DIN rail removal steps:

1. Hook the top back of the unit over the DIN rail.

2. Push the bottom of the unit towards the DIN rail until it snaps into place.

A. Insert screwdriver into DIN clip and pry until the bottom of the unit releases from the din rail.

B. Unhook the top of the DIN clip and remove the unit from DIN rail.

Slim Line Switch Hardware Manual Page 11 of 35

Page 12

SL/SLX-#MS and -#MG models in metal case with metal DIN rail clip:

Mounting

Removal

B

Recommended DIN rail mounting steps:

Recommended DIN rail removal steps:

1. Hook the top back of the DIN rail clip on the unit over the din rail.

2. Push the bottom of the unit towards the DIN rail until it snaps into place.

A. Push the whole unit down to free the bottom of the DIN rail clip. See blue circle area.

B. Pull the bottom of the unit away from the DIN rail.

C. Unhook the top of unit and remove it from the DIN rail.

Slim Line Switch Hardware Manual Page 12 of 35

Page 13

Dia. 0.15"

(0.38 cm)

Use f or dire ct

panel mounting

to a f lat surface

3.95"

[10.03 cm]

1.98"

[5.02 cm]

1.98"

[5.02 cm]

1.00"

[2.54 cm]

1.50"

[3.81 cm]

3.26"

[8.28 cm]

4.20"

[10.67 cm]

0.40" (1.02 cm)

Ty pica l f or

SC or ST fiber

Removable Scre w Bloc k

Snaps t o st anda rd

DIN rail EN5 0 0 22

(3 5 mm)

2/3/5

Ports

6/8/9

Ports

1.01"

[2.57 cm]

1.01"

[2.57 cm]

0.06"

[0.15 cm]

2.90"

[7.35 cm]

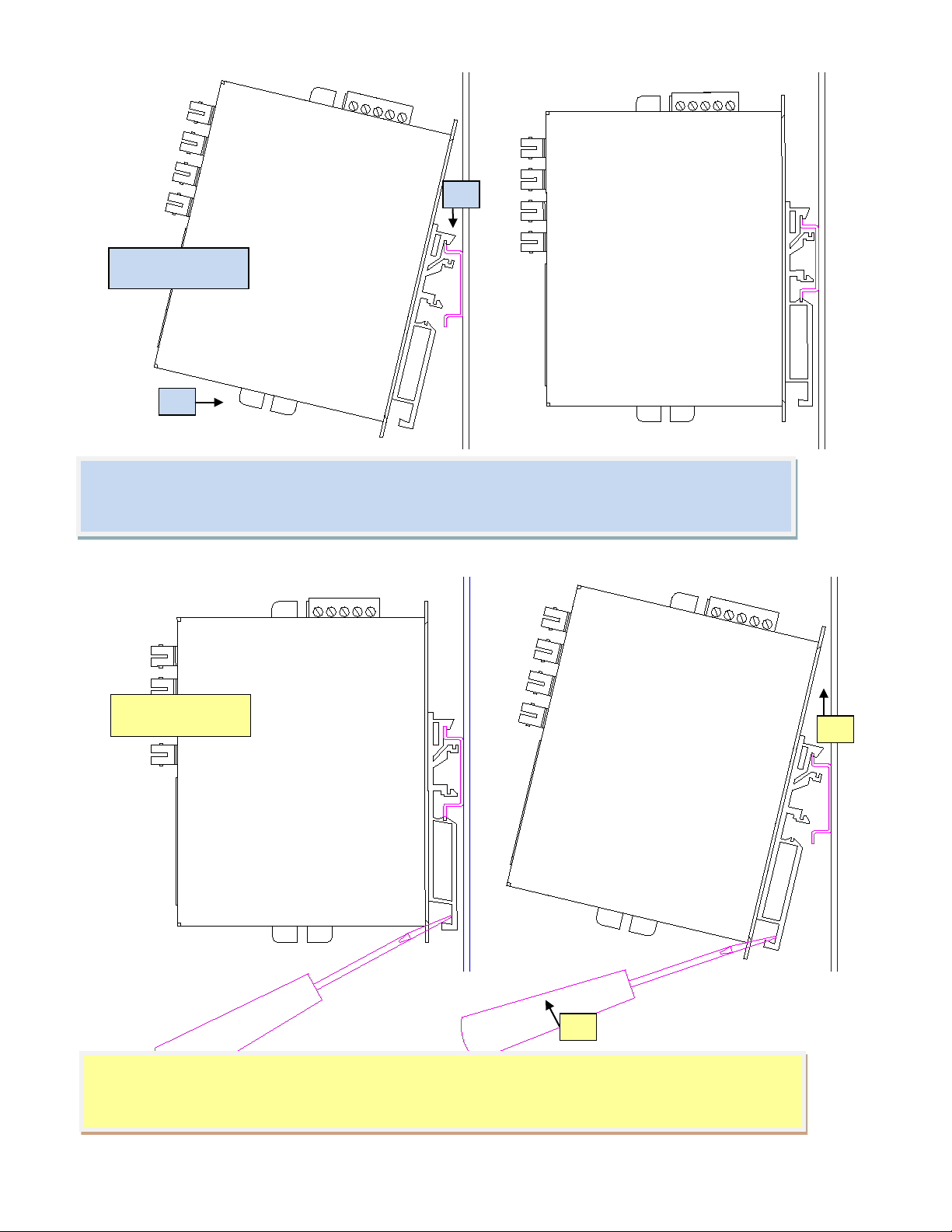

Mechanical Dimensions for SL-2/3/5/6/8/9ES-1/2/3

in Lexan Packaging

Use f or dire ct pa nel

mount ing t o a f lat

surfac e with up t o

# 8 scre w for older

units or up to #12

for ne we r unit s

(see guide t o right)

4.00"

[10.16 cm]

4.50"

[11.43 cm]

4.35"

[11.05 cm]

2.25"

[5.71 cm]

2.25"

[5.71 cm]

Ty pical for

SC or ST fiber

0.40" (1.02 cm)

Snaps t o st andard

DIN rail EN5 002 2

(3 5 mm)

Removable Screw Block

1.50"

[3.81 cm]

3.00"

[7.62 cm]

0.30"

[0.76 cm]

0.39"

[0.99 cm]

2/3/5

Ports

6/8/9

Ports

C

Removable

for direct pane l

mounting

1.10"

[2.79 cm]

0.55"

[1.40 cm]

1.60"

[4.06 cm]

0.80"

[2.03 cm]

0.175"

[0.44 cm]

SLX

Panel mount ing ea rs on

new er models accept

up t o a #1 2 scre w

Direct to pa nel

mount ing guide

Mechanical Dimensions for SLX-2/3/5/6/8/9ES-1/2/3

in Metal Packaging

Slim Line Switch Hardware Manual Page 13 of 35

Page 14

Mechanical Dimensions for SL/SLX-5/8MS-1/4/5 with up to 2 Fiber P orts

5.05"

Removable

Screw Block

Console

Port(s)

C

# 6 screw

# 8 screw

#10 screw

#12 screw

Direc t t o pa nel

mount ing guide

f or newer models

Panel mount ing ea rs on

new er models accept

up t o a #1 2 screw

[12.83 cm]

For #6 screw: 5.05"

[12.95 cm]

For #8 screw: 5.10"

[13.08 cm]

For #10 screw: 5.15"

[13.21 cm]

For #12 screw: 5.20"

0.39"

[0.99 cm]

3.82"

[9.70 cm]

2.00"

[5.08 cm]

1.00"

[2.54 cm]

5.20"

[13.21 cm]

4.70"

[11.93 cm]

[12.83 cm]

2.60"

[6.60 cm]

2.60"

[6.60 cm]

1.92"

[4.88 cm]

1.90"

[4.83 cm]

0.15"

[0.38 cm]

Snaps t o

standard

DIN Rail

EN50022

(35 mm)

Removable DI N clip f or

direct pa nel mount ing

Panel mounting ears accept

up t o a #6 screw on older

models (see to th e right f or

new er models)

Mechanical Dimensions for SL/SLX-5MS-MDM-1

SC Fiber

ST Fib er

Removable DI N clip for

direct pa nel mounting

Removable

Screw Block

Panel mount ing ea rs acc ept up

t o a #6 screw on older models

w/ pla st ic D IN clip ( see t o the

right f or ne wer models)

5 Por t

Snaps t o

standard

DIN Rail

EN50022

(35 mm)

8 Por t

Console

Port(s)

M e t al D I N C lip (ne wer models)

Plastic D I N C lip (older m odels)

C

0.39"

[0.99 cm]

1.60"

[4.07 cm]

4.70"

[11.94 cm]

5.20"

[13.21 cm]

0.51"

[1.29 cm]

1.07"

[2.71 cm]

0.40"

[1.02 cm]

1.92"

[4.88 cm]

0.53"

[1.36 cm]

2.60"

[6.60 cm]

2.60"

[6.60 cm]

0.43"

[1.10 cm]

3.82"

[9.70 cm]

0.80"

[2.04 cm]

1.90"

[4.83 cm]

0.15"

[0.38 cm]

For #12 screw: 5.20"

[13.21 cm]

For #10 screw: 5.15"

[13.08 cm]

For #8 screw: 5.10"

[12.95 cm]

For #6 screw: 5.05"

[12.83 cm]

Panel mount ing ears on

newer models (w/ meta l DI N clip)

accept up t o a # 1 2 screw

Direct t o panel

mount ing guide

f or newer models

# 12 screw

# 10 screw

#8 screw

#6 screw

Ty p. for S C or ST Fiber

5.05"

[12.83 cm]

Slim Line Switch Hardware Manual Page 14 of 35

Page 15

2.60"

[6.60 cm]

2.60"

[6.60 cm]

3.82"

[9.70 cm]

5.05"

[12.83 cm]

f or #6

screw

Removable

Screw Block

1.60"

[4.07 cm]

5.20"

[13.21 cm]

0.80"

[2.04 cm]

0.40"

[1.02 cm]

typical

0.15"

[0.38 cm]

0.39"

[0.99 cm]

1.92"

[4.88 cm]

1.90"

[4.83 cm]

#6 scre w

#8 scre w

# 10 screw

# 12 screw

Direct to panel

mount ing guide

for new er models

Panel mount ing ea rs on

new er models accept

up t o a #1 2 screw

[12.83 cm]

For #6 screw: 5.05"

[12.95 cm]

For #8 screw: 5.10"

[13.08 cm]

For #10 screw: 5.15"

[13.21 cm]

For #12 screw: 5.20"

Console

Port(s)

Snaps t o

standard

DIN Rail

EN50022

(35 mm)

SC Fiber

ST Fi be r

Removable DIN clip for

direct pa nel mounting

Panel mounting ears accept

up t o a #6 scre w on older

models (see t o t he right for

new er models)

Mechanical Dimensions for SL/SLX-8ES-6/7 with 3 Fiber Ports

2.60"

[6.60 cm]

2.60"

[6.60 cm]

3.82"

[9.70 cm]

5.05"

[12.83 cm]

f or #6

screw

Removable

Screw Block

1.60"

[4.07 cm]

5.20"

[13.21 cm]

0.80"

[2.04 cm]

0.40"

[1.02 cm]

typical

0.15"

[0.38 cm]

1.92"

[4.88 cm]

1.90"

[4.83 cm]

For #12 screw: 5.20"

[13.21 cm]

For #10 screw: 5.15"

[13.08 cm]

For #8 screw: 5.10"

[12.95 cm]

For #6 screw: 5.05"

[12.83 cm]

Panel mount ing ea rs on

new er models accept

up t o a #1 2 screw

Direct to panel

mount ing guide

for new er models

# 12 screw

# 10 screw

#8 scre w

#6 scre w

SC Fiber

ST Fi be r

Snaps t o

standard

DIN Rail

EN50022

(35 mm)

Removable DIN clip for

direct pa nel mounting

Panel mounting ears accept

up t o a #6 scre w on older

models (see t o t he right for

new er models)

Console

Port(s)

0.39"

[0.99 cm]

Mechanical Dimensions for SL/SLX-8MS-8/9 wi t h 4 Fiber Ports

Slim Line Switch Hardware Manual Page 15 of 35

Page 16

0.15"

[0.38 cm]

5.20"

[13.21 cm]

0.35"

[0.88 cm]

# 6 screw

# 8 screw

#10 screw

#12 screw

Direc t t o pa nel

mount ing guide

f or newer models

Panel mount ing ea rs on

newer models

acce pt up t o a #12 screw

[12.83 cm]

For #6 screw: 5.05"

[12.95 cm]

For #8 screw: 5.10"

[13.08 cm]

For #10 screw: 5.15"

[13.21 cm]

For #12 screw: 5.20"

2.60"

[6.60 cm]

2.60"

[6.60 cm]

Ty pica l f or SFP X cv rs

1.92"

[4.88 cm]

0.39"

[0.99 cm]

3.80"

[9.65 cm]

5.05"

[12.83 cm]

SFP F ib e r

Ports

Removable DI N clip

f or direct panel mount ing

Removable

Screw Block

Panel mount ing ea rs

accept up t o a # 6

screw on earlier models

and up t o a #1 2 screw

on newer models.

Snaps t o

standard

DIN Rail

EN50022

(3 5 mm)

1.88"

[4.78 cm]

Console

Ports

4.70"

[11.94 cm]

0.50"

[1.27 cm]

1.37"

[3.49 cm]

2.75"

[6.98 cm]

Mechanical Dimensions for SL/SLX-8M G with 8 Gigabit Ports

#6 scre w

#8 scre w

# 10 screw

# 12 screw

Panel mounting ears

accept up t o a # 12 screw

Direct to panel

mount ing guide

Snaps t o

standard

DIN Rail

EN50022

(35 mm)

Removable

Screw Block

Removable DIN

clip f or direc t

panel m ount ing

Panel mount ing e ars

acce pt up to

a #12 screw

2.76"

[7.01 cm]

2.76"

[7.01 cm]

0.35"

[0.88 cm]

0.39"

[0.99 cm]

5.52"

[14.02 cm]

2.15"

[5.46 cm]

2.15"

[5.46 cm]

Ty pica l f or SFP X cv rs

0.50" [1.27 cm]

6.02"

[15.29 cm]

1.63"

[4.13 cm]

Mechanical Dimensions for SLX -10MG-1

Slim Line Switch Hardware Manual Page 16 of 35

Page 17

# 6 screw

# 8 screw

# 10 screw

# 12 screw

Panel mount ing ea rs

accept up t o a # 12 screw

Direct to panel

mount ing guide

Sna ps to

standard

DIN Rail

EN50022

(35 mm)

Removable

Screw Block

Removable DI N

clip f or direc t

panel mounting

Panel mount ing ea rs

accept up t o

a #12 screw

2.76"

[7 .01 cm]

2.76"

[7 .01 cm]

0.35"

[0 .88 cm]

0.39"

[0 .99 cm]

5.52"

[14.02 cm]

2.15"

[5 .46 cm]

2.15"

[5 .46 cm]

Ty pica l f or SFP X cv rs

0.50" [1.27 cm]

6.02"

[15.29 cm]

2.13"

[5 .40 cm]

Mechanical Dimensions for SLX-16MS-1

2.88"

[7.31 cm]

# 6 screw

# 8 screw

# 10 screw

# 12 screw

Panel mount ing ea rs

acce pt up t o a #12 screw

Direct to pane l

mount ing guide

Snaps t o

standard

DIN Rail

EN50022

(35 mm)

Removable

Screw Block

Removable DIN

clip f or direc t

panel mounting

Panel mount ing ea rs

accept up to

a #12 screw

2.76"

[7.01 cm]

2.76"

[7.01 cm]

0.35"

[0.88 cm]

0.39"

[0.99 cm]

5.52"

[14.02 cm]

2.15"

[5.46 cm]

2.15"

[5.46 cm]

Ty pical for S FP Xc vrs

0.50" [1.27 cm]

6.02"

[15.29 cm]

Mechanical Dimensions for SLX -18MG-1

Slim Line Switch Hardware Manual Page 17 of 35

Page 18

Mechanical Dimensions for SLX-3EG-1SFP

Mechanical Dimensions for SLX-5EG-2SFP

Slim Line Switch Hardware Manual Page 18 of 35

Page 19

Mechanical Dimensions for SLX-5EG-1

Slim Line Switch Hardware Manual Page 19 of 35

Page 20

The metal packaged models allow you to choose the mounting method that best fits your requirements. (Note:

Not all methods are available on all models. Refer to the mechanical diagrams for details.)

Vertical snap-on DIN rail

Vertical screw-to-

Flat screw-to-panel mounting

Overview of Optional M ount ing Methods

from the case to the mounting surface.

Important Notes about

Thermal Performance:

mounting for quickest

installation and optimal

utilization of your rail space.

The Slim Lines switches with metal cases use an

innovative technique to remove excess heat from

the product and its components. This technique

effectively utilizes the heavy-gauge all-aluminum

case as a large heat-sink. Therefore, you may

notice the case becoming warm during operation

(especially with large loads such as all ports

linked and active). This is normal operation. For

best performance it is recommended that a DIN

rail spacer (such as an end clamp) be used

between the switch and adjacent devices. This

will leave an air gap for best heat dissipation off

For best thermal performance when direct panel

mounting to a metal surface, you may use a

thermal compound or pad between the mounting

face and the mounting surface. This will reduce

any air gaps and optimize the transfer of heat

the case.

panel mounting for

better shock and

vibration resistance.

for low profile orientation

in shallow boxes plus best

shock and vibration resistance.

Slim Line Switch Hardware Manual Page 20 of 35

Page 21

Section 4

Power and Output Wiring

These industrial Ethernet switches can be powered from the same DC source that is used

Overview

to power your other devices. A voltage in the range of 10 to 30 VDC needs to be applied

between the P1 (plus) terminal and the Minus terminal as shown in the diagrams on the

next page. The chassis screw terminal should be tied to panel or chassis ground. To

reduce down time resulting from power loss, these industrial Ethernet switches can

optionally be powered redundantly with a second power supply as shown in the diagrams.

The managed models also have an “OK” output that can be tied to a PLC input or other

device to indicate when there is a power loss. When ON, this output will source the same

voltage that is applied to the switches power terminals. See the wiring diagrams on the next

page.

Models with PoE accepts power in the range of 12 to 48 VDC and can source 48 VDC

power to four PoE devices. For PoE sourcing (PSE) operation, the power must be in the

range of 45 to 50 VDC. Otherwise, the switch will function properly as an industrial Ethernet

switch but will not source any PoE power. For PoE operation, make sure your 48 VDC

supply is rated for at least 16 Watts per PoE channel being sourced, plus some overhead

for the switch. It is recommended that a supply with 75 Watts or more of power be used.

PoE switchs support dual power inputs allowing you to connect a backup power source.

The backup power should have the same voltage as the primary power.

The PoE ports when sourcing power will put out 48 VDC* (see note below) over the signal

pair of the RJ45 connection:

o V+ on RX lines 1 and 2

o V- on TX lines 3 and 6

o Lines 4, 5, 7 and 8 are unused

* Note: When the supply voltage is 45 to 47 VDC then the power output for the PoE will be

the same as the supply voltage. For example, if the supply voltage is 45 VDC then the PoE

output will also be 45 VDC. If the supply voltage is 48 to 50 VDC then the PoE output will be

regulated at 48 VDC.

Screw Torque

WIRING

WARNINGS

When tightening the screws be careful to tighten to a max. torque of 5 in/lb (0.57 Nm).

BEFORE PERFORMING ANY WIRING TO THESE SWITCHES MAKE SURE …

• THE AREA IS CURRENTLY NONHAZARDOUS (ESPECIALLY WHEN

WORKING IN CLASS I, DIV 2 OR ZONE 2 HAZARDOUS LOCATIONS)

• TO TURN OFF THE POWER TO THE SWITCH

• TO UNPLUG THE SCREW TERMINAL BLOCK (This is especially important on

the units that have a metal case as shown below. Connecting or disconnecting

wires to the screw block when it is in place and the power is turned on can allow

the screwdriver to short the power to the case.)

Slim Line Switch Hardware Manual Page 21 of 35

Page 22

To meet the requirements for UL you must do one of the following:

2. Use a Class 2 rated power supply to power the switch.

ANY WIRING!

TO PREVENT

SHORTING THE

POWER TO THE

CASE ALWAYS

UNPLUG THE

SCREW

TERMINAL

BLOCK BEFORE

PERFORMING

UL Requirements

1. Install a 3.33 Amp maximum fuse at the input of the switch.

OR

Slim Line Switch Hardware Manual Page 22 of 35

Page 23

Alarm

Output

Load

(opt.)

Dual DC Supplies

OK

P1

P2

Single DC Power

Redundant DC Power

+

-

Back of

Switch

(DIN rail)

Front of

Switch

(connectors)

+

P2

P1

OK

Single DC Supply

Alarm

Output

Load

(opt.)

Chassis

GND

(panel)

Chassis

GND

(panel)

Chassis

GND

(panel)

Single DC Supply

P1

P2

Front of

Switch

(connectors)

Back of

Switch

(DIN rail)

Redundant DC Power

Single DC Power

P2

P1

Dual DC Supplies

Chassis

GND

(panel)

and SL-2ES Media Convert e r

Front of

Front of

(connectors)

Switch

Switch

(connectors)

Power & Alarm Wiring for

SL/SLX-5/8MS M anaged Switches

-------------------------------------------------------

Slim Line Switch Hardware Manual Page 23 of 35

Power Wiring for

SL/SLX-5/8/9ES Unmanaged Switches

Page 24

P2

+

Redundant DC Power

From

PLC

Single DC Power

OUT IN

IN

IN

IN

OUT

Back of

Switch

(DIN rail)

PLC or

Other

Device

PLC or

Other

Device

P1

+

To

PLC

OUT

IN

IN

IN

INOUT

From

PLC

P2

+

Front of

Switch

(connectors)

Single DC Supply Dual DC Supplies

Chassis

GND

(panel)

Chassis

GND

(panel)

To

PLC

P1

+

P2

P1

OK

One DC Supply

+

-

Chassis

GND

(panel)

-

+

Dual DC Supplies

OK

P1

P2

Single DC Power

Redundant DC Power

Alarm

Output

Load

+

-

Chassis

GND

(panel)

(optional)

(optional)

Alarm

Output

Load

Front of

Switch

(connectors)

Back of

Switch

(DIN rail)

SL/SLX-8MG Managed Switches

Front of

(connectors)

Front of

(connectors)

Switch

SL/SLX-5MS-MDM Ethernet Modem

Power & P LC Wiring for

-------------------------------------------------------

Switch

Power & Alarm Wiring for

Slim Line Switch Hardware Manual Page 24 of 35

Page 25

+

+

-

Alarm

Output

Load

(opt.)

Alarm

Output

Load

(opt.)

OK OK

Chassis GND is

made through the

DIN rail mounting

Single DC Supply

P1

P2

Front of

Switch

(connectors)

Back of

Switch

(DIN rail)

Redundant DC Power

Single DC Power

P2

P1

Dual DC Supplies

Single DC Supply

Front of

Switch

(connectors)

Back of

Switch

(DIN rail)

-

+

+

-

Redundant DC Power

Single DC Power

P2

P1

OK

Dual DC Supplies

Alarm

Output

Load

(opt.)

Chassis

GND

(panel)

OK

P1

P2

-

+

Alarm

Output

Load

(opt.)

Chassis

GND

(panel)

SLX-10/16/18-Mx Managed Swi tches

Front of

(connectors)

Front of

Switch

(connectors)

Power a nd Alarm Wi ring For

SL/SLX-6ES Unmanaged Switches

-------------------------------------------------------

Switch

Slim Line Switch Hardware Manual Page 25 of 35

Power a nd Alarm Wi ring for

Page 26

Power a nd Alarm Wi ring for

SLX-3EG-1 Managed Swi tches

Power a nd Alarm Wi ring for

SLX-5EG-1 Managed Swi tches

Slim Line Switch Hardware Manual Page 26 of 35

Page 27

Section 5

Communication Ports Wiring

These industrial Ethernet switches provide connections to standard Ethernet devices such

ports and a serial or USB console port for management (managed models).

Use data-quality (not voice-quality) twisted pair cable rated category 5 (or better) with

Straight-thru Cable Wiring

Cross-over Cable Wiring

Pin 1

Pin 1

Pin 1

Pin 3

Pin 2

Pin 2

Pin 2

Pin 6

Pin 3

Pin 3

Pin 3

Pin 1

Pin 6

Pin 6

Pin 6

Pin 2

Depending on the model these industrial Ethernet switches may have up to four fiber optic

See images below for typical fiber optic port placement on these switches.

Overview

RJ45

Ethernet

Wiring

For Reference

Only.

Either cable

wiring will work!

as PLCs, Ethernet I/O, industrial computers and much more. Three types of communication

ports may be found on these switches: RJ45 (copper) Ethernet ports, fiber optic Ethernet

standard RJ45 connectors. For best performance use shielded cable. Straight through or

crossover RJ45 cable can be used regardless of the device the switch is to be connected to

as all the ports are capable of auto-mdi/mdix-crossover detection.

The RJ45 Ethernet port connector bodies on these products are metallic and are connected

to the Chassis GND terminal. Therefore, shielded cables may be used to provide further

protection. To prevent ground loops, the cable shield should be tied to the metal connector

body at one end of the cable only. Electrical isolation is also provided on the Ethernet ports

for increased reliability.

Ethernet

Plug & Connector

Pin Positions

RJ45 Cable

The maximum cable length for 10/100/1000BaseT is typically 100 meters (328 ft.).

Distance

Ethernet

Fiber Wiring

Guidelines

ports. All 100 Mbps fiber ports are available with dual SC or ST style connectors. They are

also available with multimode, singlemode, long-haul (for connections up to 120+ km) or

special-application transceivers. Refer to the technical specifications for details.

All 1000 Mbps fiber ports are provided as mini-gbic SFP (small form pluggable). These

accept plug in fiber transceivers that typically have an LC style connector. They are

available with multimode, singlemode, long-haul (for connections up to 80+ km) or specialapplication transceivers. Refer to the technical specifications for details.

For each fiber port there is a transmit (TX) and receive (RX) signal. When making your

fiber optic connections, make sure that the transmit (TX) port of the switch connects to the

receive (RX) port of the other device, and the receive (RX) port of the switch connects to

the transmit (TX) port of the other device.

Use standard fiber optic wiring techniques (not covered by this manual) to make your

connections. The corresponding ACT/LNK LED will be ON solid or flashing when you have

made a proper connection.

For more fiber optic guidelines go to: www.redlion.net

Slim Line Switch Hardware Manual Page 27 of 35

Page 28

Typical Fiber

Typical Fiber

Typical Fiber

The RJ45 ports will auto-sense for Full or Half duplex operation, while the fiber ports are

models the duplex setting is software configurable.

Typical SC style

SL-5ES-2/3SC

Typical ST style

SL-5ES-2/3ST

Typical SC style

SLX-5MS-4/5SC

Typical ST style

SLX-5MS-4/5ST

Typical SC style

SLX-8xS-6/7/8/9SC

SLX-8MG with

installed

SLX-8MG with

installed

Ports on

Unmanaged

Models

Ports on

Managed

Models

connector on a

connector on a

connector on a

connector on a

connector on a

Ports on an

SL-8MG

no transceivers

Duplex

Operation

configured for full duplex operation. Note: Fiber devices with half duplex settings should still

communicate with the switch. If otherwise then please contact Red Lion. On managed

Slim Line Switch Hardware Manual Page 28 of 35

four transceivers

Page 29

Verifying

After all Ethernet and/or fiber connections are made, check the LED’s corresponding to the

section on LEDs).

A standard cross-wired telephone patch cable should be used to connect to the phone line

Telephone

Connectivity

ports that each of the devices are connected to. Ensure that for each port that is in use, the

LED is on or blinking. If a port LED is off, go back and check for connectivity problems

between that port and the network device connected to that particular port. In addition, the

color of the LED should indicate the speed for which your device is connected at (see prior

Telephone

Port Wiring

(MDM models)

Ports on

Modem Models

provided by the phone company. Tip and Ring are the only two pins used on the Ethernet

Land-Line modem.

Slim Line Switch Hardware Manual Page 29 of 35

Page 30

An optional way to configure the switch is through the RJ45 console RS232 port. Use a

Switch

Adapter

RJ45F

Pin #

Signal

Name

Signal

Name

DB9F

Pin #

1

RI/DSR in

DTR out

4 2 DCD in

N/C

n/c 3 DTR out

DSR in

6 4 GND

GND 5 5

RXD in

TXD out

3 6 TXD out

RXD in

2 7 CTS in

RTS out

7

8

RTS out

CTS in

8

Newer models of these switches may also have an USB port instead of or in addition to the

on the bottom edge or front face of the swi tc h

RS232

RJ45F

Mini-USB

RS232

RJ45F

Mini-USB

Serial

Console Port

Wiring

USB Console

Port Wiring

DB9F to RJ45F adapter along with a RJ45 male to RJ45 male straight-thru-wired patch

cable to make a connection between a com port on your PC (DB9 male) and the RS232

port of the Managed Switch (RJ45 female). Contact Red Lion or your switch vendor to

purchase this adapter as an accessory.

A typical DB9F to RJ45F adapter should be wired as follows:

RS232 port. Use a standard USB cable with a mini-USB plug on one end and an A-typeUSB plug on the other end. The A-type plug goes into a standard USB port on a computer.

The mini-USB plug goes into the USB port on the switch.

Refer to the software user manual for how to use this USB port.

The RS232 and/or USB ports may located

Slim Line Switch Hardware Manual Page 30 of 35

Page 31

Section 6

Technical Specifications

Here are the hardware technical specifications for the industrial Ethernet switches covered

Note: These specifications are subject to change. Contact Red Lion for the latest details.

Ethernet switch type

Unmanaged or managed with up to 9 ports

Operating mode

Store and forward, wire-speed switching, non-blocking

Devices supported

All IEEE 802.3 compliant devices are supported

SNMPv1/v2/v3, RMON, DHCP, SNTP, TFTP, STP, RSTP,

HTTPS (SSL & TSL), Telnet, SSH and more

Industrial protocols

supported

Modbus/TCP, EtherNet/IP, PROFInet, Foundation Fieldbus HSE

and others

Standards (depends on

model)

IEEE 802.3, 802.3u, 802.3ab/z, 802.3x, 802.1D/w, 802.1p, 802.1Q

and others

Management interfaces

(managed models only)

Web (see online demo), text (Telnet & SSH), CLI (command line

interface) and SNMP (see software manual for supported MIBs)

Open source linux

(managed models only)

MAC addresses

1024 on unmanaged (ES) models;

8192 on Gigabit (MG) models

Memory bandwidth

3.2 Gbps on ES & MS models; 32 Gbps on MG models

Latency for 10 Mbps

16 us + frame time (typical)

Latency for 100/1000 Mbps

<5 us + frame time (typical)

Ethernet isolation

1500 VRMS 1 minute

Management serial port

(managed models only)

RS232 (TXD, RXD and GND), 9600, 8, N, 1 fixed

and/or mini-USB

Copper ports

Shielded RJ45

Speed

10/100 Mbps or 10/100/1000 Mbps (depending on model)

Protocols supported

All standard IEEE 802.3

Auto-crossover

Yes, allows you to use straight or cross wired cables

Auto-sensing operation

Yes, Full and half duplex

Auto-negotiating

Yes, 10BaseT and 100BaseT

Auto-polarity

Yes, on the TD and RD pair

Flow control

Automatic

Ethernet isolation

1500 VRMS 1 minute

Plug and play

Yes

Cable requirements

Twisted pair (Cat. 5 or better) (shielded recommended)

Max. cable distance

100 meters

PoE models

Power input with reverse

10-44 VDC with no PoE output

45-52 VDC for PoE output

Switch power consumption

1000 Mbps)

4.3 W (SLX-5EG-1) + PoE

PoE power consumption

Up to 15.4 W per port

RJ45 pin assignments for PoE

TX/V- (3, 6); RX/V+ (1, 2)

Technical

Specs

General Specifications:

Protocols

(managed models only)

by this manual. For the managed models, refer to the software user manual or datasheet

for complete software specifications.

QoS/CoS/ToS/DS, IGMPv1/v2, VLAN (tag and port based), HTTP,

The Linux Advantage – Contact Red Lion for more information

2048 on managed (MS)models;

Varies on load and settings

Copper RJ45 Ports: (10/100 Mbps or 10/100/1000 Mbps)

polarity protection

(typical all ports active at

Slim Line Switch Hardware Manual Page 31 of 35

6.2 W (SLX-5EG-2SFP) + PoE

Page 32

Power input transient

protection

15,000 watts peak

Power input spike Protection

5,000 watts (10 times for 10 uS)

PoE operation

Auto power management

PoE disconnect mode

DC disconnect

PoE auto-detection

Per IEEE 802.2af

PoE protection

Over-temperature, over-current, over/under-voltage and transient

100BaseF ports

Up to 4

Fiber port mode

Multimode (mm) or Singlemode (sm)

Fiber port connector

Duplex SC or ST

Half and full duplex

Full duplex on unmanaged models;

Software configurable on managed models

Ethernet compliance

100BaseF

Eye safety

IEC 60825-1, Class 1; FDA 21 CFR 1040.10 and 1040.11

Fiber Mode

MM

SM

SM

Fiber Length

2 km

30 km

60 km

TX Power Min

-23.5 dBm

-15 dBm

-5 dBm

RX Sensitivity Max

-32 dBm

-34 dBm

-35 dBm

Wavelength

1310 nm

1310 nm

1310 nm

Note: On the Gigabit (MG) models these ports are pluggable and accept many different types of pluggable

SFP (Mini-Gbic) transceiver modules for Gigabit fiber connections.

Gigabit SFP ports

Up to 4

Port types supported

Gigabit fiber multimode, fiber singlemode, fiber long-haul singlemode, fiber

single-strand and more

Fiber port connector

LC typically for fiber (depends on module)

Half and full duplex

Software Configurable(managed models only)

Ethernet compliance

1000BaseT and 1000BaseF (SX/LX/LH)

Eye safety

IEC 60825-1, Class 1; FDA 21 CFR 1040.10 and 1040.11

Part Number

FMFIBER-SFP-2K

FMFIBER-SFP-4K

FMFIBER-SFP-30K

FMFIBER-SFP-60K

FMFIBER-SFP-60K

Fiber Mode

MM

MM

SM

SM

SM

Fiber Length

2 km

4 km

30 km

60 km

100 km

RX Sensitivity

Max

Wavelength

1310 nm

1310 nm

1310 nm

1310 nm

1550 nm

Laser Type

FP

FP

FP

FP

DFB

* The nominal distance is for referenc e on ly. Use t he p ower budget method for m ore a c c urat ely es t im at ing di s t anc e.

Part Number

GMFIBER-SFP-500

GMFIBER-SFP-2K*

GSFIBER-SFP-10K

GSFIBER-SFP-30K

GSFIBER-SFP-50K

GSFIBER-SFP-80K

Fiber Mode

MM

MM

SM

SM

SM

SM

Fiber Length

500 m

2 km

10 km

30 km

50 km

80 km

TX Power Min

-9.5 dBm

-9 dBm

-9.5 dBm

-2 dBm

-2 dBm

0 dBm

Max

Wavelength

850 nm

1310 nm

1310 nm

1310 nm

1550 nm

1550 nm

Laser Type

VCSEL

FP

FP

DFB

DFB

DFB

transceiver is used on both end s of t he c able f o r bes t perf ormance. Do not use this transc eiver with singlemode fiber cable.

SC or ST Fiber Ports: (100BaseF multimode or singlemode)

SFP Mini-Gbic SFP (pluggable) Ports: (many types available)

Note: 100 Mbps fiber transceiver modules are also supported on these ports.

Fast Ethernet Transceivers

TX Power Min

-9 dBm -9 dBm -15 dBm -5 dBm -5 dBm

-19 dBm -30 dBm -34 dBm -35 dBm -35 dBm

Gigabit Transceivers

RX Sensitivity

-17 dBm -19 dBm -20 dBm -23 dBm -23 dBm -24 dBm

*Use this special singlemode trans c ei ver with multimode fiber cable for a nominal maximum link dis tance of 2km. This transceiver offsets the

transmitted light (so no mode c ondit ioni ng pat c h c ord i s required) and is s pec i f ic ally fo r us e with multimode f i ber c able. I t is recommended that this

Slim Line Switch Hardware Manual Page 32 of 35

Page 33

Maximum data rates

56 Kbps

Compatibility

V.90, V.34, V.32, V.32 bis, V.22, V.22 bis, V.21

Data compression

V.42 bis

Error correction

V.42 MNP or LAP

Ringer

0.3

Jacks

2 RJ11 (phone and line)

Command sets

Standard AT and S register

Country compatibility

World-wide (100+ countries)

Telecom ratings

FCC Part 68; Industry Canada CS03-8; CTR21 (98/482/EC); ACA TS

001 and ACA TS 002

PLC / Alarm output voltage

Same as switch input power voltage

Maximum current output

0.5 Amp

PLC / Trigger input voltage

10-30 VDC

Typically current input

6.5 mA @ 24 VDC

“OK” Output

ON if P1 and P2 have power and switch software is running

Voltage

Same as switch input voltage

Maximum current output

0.5 Amp

Power input

Redundant Input Terminals

Input power (typical with all

2.0 W (2-port converter with 1 fiber),

3.6 W (5-port managed w/o fiber),

10 W (18-port man. gigabit w/ 2 fiber)

Input voltage (all models)

12-48 VDC @ 1.3A , Amb: T4 @ 85C

Reverse power protection

Yes

Transient protection

15,000 watts peak

Spike protection

5,000 watts (10x for 10 uS)

Industrial Telephone Modem (SL-5MS-MDM Only)

“PLC” Input and Output (SL-5MS-MDM Only)

“OK” Alarm Output (managed models only)

Power Input:

ports active at 100 Mbps)

2.0 W (5-port unmanaged w/ 0 fiber),

3.0 W (5-port unmanaged w/ 1 fiber),

5.0 W (6-port unmanaged w/ 2 fiber),

4.0 W (8-port unmanaged w/ 0 fiber),

5.0 W (9-port unmanaged w/ 1 fiber),

8.0 W (8-port unmanaged w/ 3 fiber)

4.8 W (5-port with phone modem),

5.6 W (5-port managed w/ 2 fiber),

4.3 W (8-port managed w/ 0 fiber),

6.3 W (8-port managed w/ 2 fiber),

9.0 W (8-port managed w/ 4 fiber),

12 W (8-port man. gigabit w/ 0 fiber)

15 W (8-port man. gigabit w/ 4 fiber),

5.0 W (10-port man. gigabit w/ 0 fiber),

7.0 W (10-port man. gigabit w/ 2 fiber),

7.0 W (16-port man. gigabit w/ 0 fiber),

8.0 W (18-port man. gigabit w/ 0 fiber),

Slim Line Switch Hardware Manual Page 33 of 35

Page 34

Operating temperature

SL-2/5/6/8/9ES models: -10 to +60°C (cold startup at -10°C)

Contact Red Lion if wider ranges are needed.

Storage temperature range

-40 to +85 °C

PoE Models

10-44 VDC with no PoE output

45-52 VDC for PoE output

4.3 W (5EG-1, all copper) typical

53W (5EG-2SFP) with 3 fully loaded PoE ports

PoE power consumption

Up to 15.4 W per port

protection

Power input spike Protection

5,000 watts (10 times for 10 uS)

PoE operation

Auto power management

PoE disconnect mode

DC disconnect

PoE auto-detection

Per IEEE 802.2af

PoE protection

Over-temperature, over-current, over/under-voltage and transient

Ingress protection

IP40 (all models)

Packaging and protection

UL94V0 Lexan plastic for all plastic cased units.

Aluminum w/ protective finish for all metal cased units.

Dimensions (L x W x H)

See mechanical diagrams for details

Weights (typical)

SL-2ES-2/3 and SL-5ES-1/2/3 in Lexan case – 4 oz (0.11 kg)

Environmental and Compliances:

range

SL-5/8MS models: -10 to +60°C (cold startup at -10°C)

SLX-3/5EG: -40 to +85°C (cold startup at -40°C)

SL/SLX-5MS-MDM: -40 to +75°C (cold startup at -40°C)

SL/SLX-8MG: -40 to +75°C (cold startup at -40°C)

SLX-5/6/8/9ES-1/2/3/4/5 models: -40 to +85°C (cold startup at -40°C)

SLX-8ES-6/7 models: -40 to 75° C (cold startup at -40°C)

SLX-5/8MS models: -40 to +75°C (cold startup at -40°C)

SLX-10/18MG-1 model -40 to +75°C (cold startup at -40°C)

SLX-16MS-1 model -40 to +75°C (cold startup at -40°C)

Power input with reverse

polarity protection

Switch power consumption

(typical all ports active at 1000

Mbps)

RJ45 pin assignments for PoE TX/V- (3, 6); RX/V+ (1, 2)

Power input transient

6.2 W (5EG-2SFP with 2 fiber) typical

66W (5EG-1) with 4 fully loaded PoE ports

15,000 watts peak

Mechanical:

SLX-3EG in metal case – 6 oz (0.17 kg)

SLX-5ES-1/2/3 in metal case – 6 oz (0.17 kg)

SLX-5EG-1/2SFP in metal case – 15.2 oz (0.43 kg)

SL/SLX-5MS-1/4/5 in metal case – 8 oz (0.23 kg)

SL-5MS-MDM managed – 11 oz (0.31 kg)

SL-6/8/9ES-1/2/3/4/5 in Lexan case – 6 oz (0.17 kg)

SLX-6/8/9ES-1/2/3/4/5 in metal case – 8 oz (0.23 kg)

SL/SLX-8MS-1/4/5 in metal case – 10 oz (0.28 kg)

SL/SLX-8xS-6/7/8/9 in metal case – 11 oz (0.31 kg)

SL-8MG-1 without fiber transceivers – 16 oz (0.45 kg)

SL-8MG with 4 fiber transceivers – 18 oz (0.50 kg)

SLX-10MG-1 in metal case – 12 oz (0.34 kg)

SLX-16MS-1 in metal case – 16 oz (0.45 kg)

SLX-18MG-1 in metal case – 16 oz (0.46 kg)

Slim Line Switch Hardware Manual Page 34 of 35

Loading...

Loading...