red lion RL-SWJ Series Owner's Manual

www.RedLionProducts.com

ENGLISHEN

SHALLOW WELL JET PUMP

RL-SWJ Series

Owner’s Manual

THIS PUMP IS DUAL VOLTAGE AND FACTORY SET FOR 230 VOLTS.

SEE VOLTAGE SETTING INSTRUCTIONS TO SET FOR 115 VOLTS.

Table of Contents

Before Getting Started .................................................................2

Installation Checklist .................................................................... 3

Introduction ...................................................................................4

Voltage Setting Instructions ........................................................4

Materials and Tools Needed ......................................................... 5

Important Information ................................................................. 5

Quick Installation Guide ............................................................... 6

Detailed Installation Instructions .............................................7-8

Typical Installations ......................................................................9

Pump to Tank Installation ...........................................................10

Wiring Instructions .......................................................................11

Priming the Pump ....................................................................... 12

Maintenance ............................................................................ 13-14

Troubleshooting ...........................................................................14

Replacement Parts ......................................................................15

Limited Warranty ......................................................................... 16

BEFORE GETTING STARTED

Read and follow safety instructions. Refer to product data plate(s) for additional operating instructions and specifications.

This is the safety alert symbol. When you see this symbol on your pump or in this manual, look for one of the following signal words and be

alert to the potential for personal injury or property damage if ignored:

!

s DANGER

warns about hazards that will cause serious personal injury, death or major property damage if ignored.

!

s WARNING

!

s CAUTION

!

s NOTICE

in this manual and on pump.

BEFORE OPERATING OR INSTALLING THIS PUMP, READ THIS MANUAL AND FOLLOW ALL SAFETY RULES AND OPERATING INSTRUCTIONS.

!

s WARNING

!

s WARNING

National Electrical Code (NEC) and with any local codes and ordinances. Employ a licensed electrician.

warns about hazards that can cause serious personal injury, death or major property damage if ignored.

warns about hazards that will or can cause minor personal injury or major property damage if ignored.

indicates special instructions which are important but not related to hazards. Carefully read and follow all safety instructions

WARNING

READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

ELECTRICAL PRECAUTIONS - All wiring, electrical connections, and system grounding must comply with the

DANGER

!

s WARNING

!

s NOTICE

!

s WARNING

• Have an electrician provide electrical power to motor.

• We recommend that a separate circuit be lead from the home electrical distribution panel, properly protected with a fuse

or a circuit breaker.

• A ground fault interrupter (GFI) protected circuit is also recommended for use with any electrical device operating near water.

• For recommended cable size see Table 2.

• Motor must be grounded and terminal cover in place to reduce electrical shock hazard.

• Keep motor operating area as dry as possible.

• Always disconnect power before servicing.

• Not investigated for use in swimming pool areas.

!

s WARNING

This pump is capable of producing high pressure. Installing a 75 psi pressure relief valve is highly recommended.

FOR DUAL VOLTAGE MOTORS (115/230 V) - Voltage change instructions are located in this manual.

The motor voltage is factory set at 230 V.

RISK OF ELECTRIC SHOCK

75 PSI PRESSURE RELIEF VALVE RECOMMENDED

2

INSTALLATION CHECKLIST

This checklist has been provided for your convenience. If a step was missed, ensure power has been shut o at the breaker and completely relieve pressure

from the water system before continuing to work on the system.

!

s WARNING

This pump is capable of producing high pressure. Installing a 75 psi pressure relief valve is highly recommended.

Model #: ________________

Serial #: _________________

Date purchased: ____________

Location purchased: ________________________________________________

KEEP THIS MANUAL ACCESSIBLE FOR FUTURE REFERENCE.

75 PSI PRESSURE RELIEF VALVE RECOMMENDED

✓

Description

Voltage setting on pump verified and set to match voltage on the circuit breaker

Foot valve (for drilled wells) or check valve (for driven well) installed

Wiring and electrical connected by licensed electrician

Pump intake connected to piping in well

Well seal in place

Pump discharge connected to tank and service line

Tank pressure checked and charged to 28 psi

All joints sealed with PVC cement, PTFE tape or heat and clamps

All connections checked for leaks

Pressure relief valve installed

All other accessories installed: drain cock, shut-o valve, pressure gauge (optional)

Breaker turned on

Pump primed

Model number and serial number recorded in this manual

Receipt stapled to manual

3

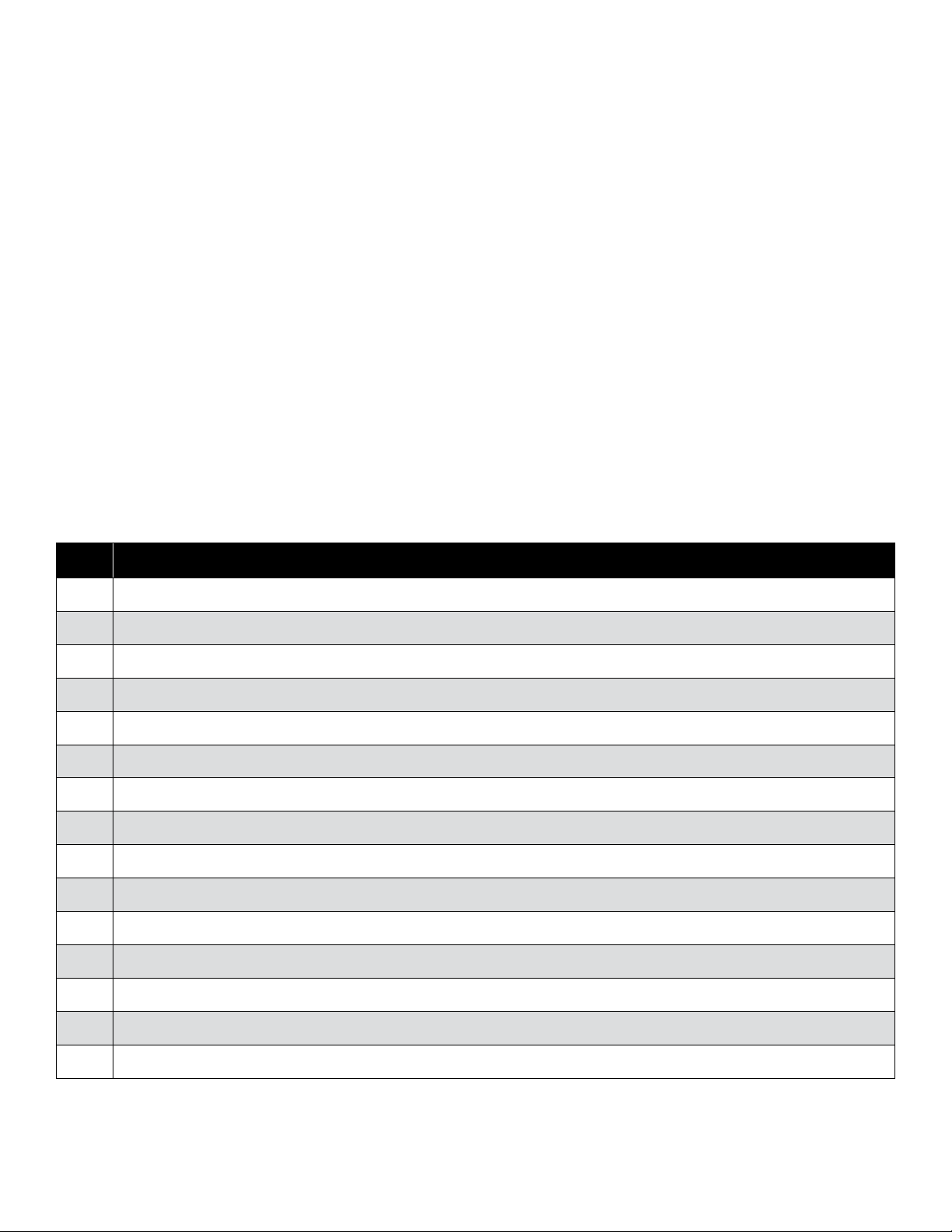

INTRODUCTION

VOLTAGE SETTING INSTRUCTIONS

The shallow well jet pump is ideal for the supply of fresh water to rural

homes, farms, and cabins. This pump is suitable for installations where the

vertical distance from the pump to the water level does not exceed 25 ft

(7.6 m), including drawdown (less at high altitudes). In oset installation,

friction losses in the suction pipe must be taken into consideration

(refer to Table 1, Friction Loss).

This instruction sheet provides you with the information required to

safely own and operate your product. Retain these instructions for

future reference.

The product you have purchased is of the highest quality workmanship and

material, and has been engineered to give you long and reliable service.

This product has been carefully tested, inspected, and packaged to ensure

safe delivery and operation. Please examine your item(s) carefully to

ensure that no damage occurred during shipment. If damage has occurred,

please contact the place of purchase. They will assist you in replacement or

repair, if required.

READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO INSTALL,

OPERATE OR SERVICE YOUR PRODUCT. KNOW THE PRODUCT’S APPLICATION,

LIMITATIONS, AND POTENTIAL HAZARDS. PROTECT YOURSELF AND OTHERS

BY OBSERVING ALL SAFETY INFORMATION. FAILURE TO COMPLY WITH

THESE INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR

PROPERTY DAMAGE!

To change the pump voltage from the factory setting of 230 Volts,

a qualified electrician should:

1. Disconnect power supply to pump

2. Remove the cover from the motor terminal box

3. Slide the voltage switch from 230 V to 115 V, as shown in Figure 2

4. Reassemble the terminal box cover

Motor Terminal Box Cover

Figure 1

The motor's switch

is set for 230 V:

Place screwdriver where indicated and slide left or right.

Figure 2 - VOLTAGE SWITCH

The motor's switch

is set for 115 V:

4

MATERIALS AND TOOLS NEEDED

IMPORTANT INFORMATION

MATERIALS NEEDED

Pipe Joints

• One roll of PTFE tape

• One can PVC primer

• One can PVC cement

• Steel clamps (optional)

Drilled Wells (driven well materials are listed separately)

• One 1-1/4" foot valve (not needed for driven wells)

• One 1-1/4" PVC pipe (to attach to foot valve – needed for

shallow well only)

• Rigid 1-1/4" PVC pipe and couplings to reach from bottom of well to pump

• One 1-1/4" male PVC adapter (for discharge opening)

• Well seal with vent tube

• One 1-1/4" PVC 90° elbow (to join piping from well to pump)

• One 1-1/4" male galvanized adapter (for suction opening)

Driven Wells

• Well point (more than one may be needed)

• 1-1/4" galvanized pipe from bottom of well to the top of well plus 1 ft

(30 cm) (if more than one well point is needed, additional piping

and elbows will be needed to join the well points together)

• One 1-1/4" galvanized 90° elbow

• One 1-1/4" galvanized nipple

• One 1-1/4" check valve

• One 1-1/4" male PVC adapter

• One 1-1/4" male galvanized adapter

• 1-1/4" PVC pipe measured from adapter connected to pump to check valve

• Restrictor valve (connected after the elbow on the pump discharge)

• Low pressure cut-o pressure switch (recommended)

Pump to Tank Installation

• One male PVC adapter (attached to tank) – the tank fitting size depends

on the system connect on the tank

• One tank tee – size should be the same as the adapter above

• One 1" PVC elbow

• PVC piping to fit from tank tee to the elbow on the pumps discharge

and to join the service line

• High pressure safety relief valve (attached to the tank tee)

• One 1/2" drain cock (attached to the tank tee)

TOOLS NEEDED

• Round file

• Pipe clamp

• Pipe wrench or crescent wrench

• Slotted screwdriver

• Cross-head screwdriver

• Hacksaw or reciprocating saw

• Heat gun (optional)

JOINING PIPE FITTINGS

Follow the fitting guidelines below for all attachments unless

otherwise specified.

PVC PIPE FITTINGS

When joining two PVC joints together (such as joining an adapter to a PVC

pipe) always use PVC primer to clean both pieces– applying the primer

to the inside of one joint and the outside of the other joint so the primed

areas meet. Select Method 1, 2 or 3 to ax the joints. When tightening PVC,

tighten securely but do not over-tighten or you could break the fitting.

Method 1 – PTFE tape: Wrap PTFE tape tightly around the male

threads. Start wrapping the threads at the end of the pipe, keeping

tension on the tape. Do not let the tape hang over the edge of the

adapter. Wrap in the direction of the threads starting from the end

for the full length of the adapter. Overlap each wrap about 70%.

Method 2 – Using PVC cement: Apply PVC cement to the areas

that were just primed and join the two pieces together. Twist to

the right and back to the left to help imbed the cement between

the pieces.

Method 3 – Using heat and clamps: Add two steel clamps to the

largest fitting before joining the fittings. Heat the largest fitting

with a heat gun (follow all safety instructions in the heat gun

manual). This will shrink the fitting, bonding it to the smaller

joint. Once the joint has cooled down, tighten the clamps with

a screwdriver.

METAL PIPE FITTINGS

Use PTFE tape or thread compound to coat the threadings.

CHECK TO ENSURE THE JOINTS ARE AIRTIGHT.

EVEN A PINHOLE CAN PREVENT PROPER OPERATION OF THE PUMP.

SUCTION AND PRESSURE PIPE

It is recommended that only new, clean 1-1/4" pipe or hose be used. If the

pump is installed any appreciable distance away from the source of water,

the suction pipe should be increased to 1-1/2". Horizontal lengths of pipe

must gradually slope upward from the source of water to the pump to

avoid air pockets in the line. Thread compound should be used on all pipe

joints and connections should be thoroughly tightened. A foot valve or

check valve must be installed and its operation should be checked since

a leak will prevent proper operation of the system. Make sure the foot

valve is located so that it will be submerged at all times. If a sandpoint or

driven well is used, install a check valve next to the pump suction instead

of the foot valve (see Typical Installations Figure 5). All installations must

have a foot valve or a check valve in the suction pipe.

5

QUICK INSTALLATION GUIDE (Replacing an Existing Pump)

This quick installation guide assumes you will be cutting the existing pump free from the plumbing.

More detailed instructions are provided in the Detailed Installation Instructions.

!

s WARNING

DO NOT RUN THE PUMP BEFORE PRIMING IT; THE SEAL AND IMPELLER COULD BE PERMANENTLY DAMAGED

1. Ensure power has been shut o at the breaker

before proceeding.

2. This pump is dual voltage (115/230 V)! Inspect the voltage

wiring on the pump and ensure it matches the voltage on

the breaker before continuing with the installation

(see Voltage Setting Instructions).

3. Completely relieve pressure from the water system before

working on the water system. Open the faucet nearest the

tank and allow the water to drain until the tank is empty.

4. Disconnect wiring from the pressure switch to the

electrical source.

5. Using a hacksaw or reciprocating saw, cut all PVC piping as close

to the old pump as possible at both the suction and discharge

openings. Ensure the pipe from the well and the pipe from the

tank are clean and free of any pipe shavings or pieces as these

could get into the pump and damage the impeller.

6. Set the new pump in place.

7. Seal the threads on the suction opening on the pump with PTFE

tape or thread compound and insert the 1-1/4" male galvanized

adapter into the suction opening. Tighten securely but do not

over-tighten as this could crack the fitting.

9. Seal the threads of the discharge opening on the pump with

PTFE tape or thread compound and insert the 1" male PVC

adapter into the discharge opening. Tighten securely but

do not over-tighten as this could crack the fitting.

10. Attach the 1" PVC pipe from the tank to the 1" male PVC adapter

(additional fitting may need to be added). Check to ensure the

joints are airtight. Even a pinhole can prevent proper operation

of the pump.

11. A pressure gauge is not supplied with the pump. It should be

installed into the 1/8" NPT hole on the front of the casing on the

opposite side of the pressure switch (see Typical Installations

Figures 3, 4, 5, or 6).

12. An electrician should be employed to do the wiring and connect

the electrical service to the pump (see Wiring Instructions).

13. Prime the pump (see Priming Instructions).

14. Verify everything has been completed using the Installation

Checklist provided in this manual.

8. Attach the 1-1/4" PVC pipe from the well to the male adapter

(additional fittings may need to be added). Check to ensure the

joints are airtight. Even a pinhole can prevent proper operation

of the pump.

6

DETAILED INSTALLATION INSTRUCTIONS

!

s WARNING

Before proceeding, ensure power has been shut o at the breaker. If this is replacing an existing pump, completely relieve pressure from the water system

before working on the water system. Open the faucet nearest the tank and allow the water to drain until the tank is empty.

DO NOT RUN THE PUMP BEFORE PRIMING IT; THE SEAL AND IMPELLER COULD BE PERMANENTLY DAMAGED

SHALLOW WELL APPLICATION

(for pumping depths down to 25 ft [7.6 m])

Shallow well installations use only a single pipe connecting the pump to

the water supply. This pump can be used for drilled wells (see Figures 3,

4 or 6) or driven wells (see Figure 5). Drilled wells are holes drilled into

the ground by professional well drillers using a large rig. Driven wells

use well points (also known as sand points), which is a long pointed tube

with a screen that allows water to enter the pipe but keeps out sand and

sediment. The water level in a driven well is fairly high or near ground

level (maximum 30 ft [9.1 m]). Continue with the appropriate shallow

well installation.

DRILLED WELLS (with foot valve)

1. Measure from the bottom of the well to the top of the well and

subtract 5 ft (1.5 m). This is the length of 1-1/4" rigid PVC pipe

and couplings you will need from the bottom of the well to the

first elbow. Cut the pipe and use a round file to smooth the pipe

cutting. Ensure the pipe is clean and free of any pipe shavings or

pieces as these could get into the pump and damage the impeller.

The remainder of the pipe will be used to connect the pump to

the well.

2. Attach the 1-1/4" male PVC adapter to one end of the rigid PVC

pipe and attach the adapter to the foot valve. Check to ensure the

joints are airtight. Even a pinhole can prevent proper operation

of the pump.

5. Attach the end of the pipe securely to a 1-1/4" PVC 90° elbow.

6. Install the pump in a clean, dry, and ventilated location which

provides adequate room for services and protection from

freezing temperatures. It should be bolted to a good foundation,

preferably concrete, and provided with adequate drainage.

Locating the pump as close as possible to the water source

reduces the friction in the suction pipe and will provide

maximum performance.

7. A pressure gauge is not supplied with the pump. It should be

installed into the 1/8" NPT hole on the front of the casing on the

opposite side of the pressure switch (see Typical Installations

Figures 3, 4 or 6).

8. Attach a 1-1/4" male galvanized adapter into the suction inlet.

Do not over-tighten as this could crack the fitting.

9. Use the remainder of the PVC pipe from Step 4. Smooth the pipe

cutting using a round file. Ensure the pipe is clean and free of

any pipe shavings or pieces as these could get into the pump and

damage the impeller; connect one end of the pipe to the adapter

attached to the suction inlet. Check thoroughly for any leaks.

All connections and joints must be airtight. A small pinhole leak

can prevent the pump from operating properly.

10. Follow the Pump to Tank Installation procedures.

11. Verify everything has been completed using the Installation

Checklist provided in this manual.

3. Firmly clamp the unfinished end of the pipe with a pipe clamp 1 ft

(30 cm) from the top of the pipe. This will prevent the pipe from

dropping to the bottom of the well. Lower this section into the

well foot valve first.

4. On the end protruding from the well, which is held in place with

the pipe clamp, insert the well seal and have the pipe protrude

1 ft (30 cm) outside of the well seal. If you have measured

correctly, the foot valve will be suspended 4 ft (1.2 m) from the

bottom of the well. This will ensure sand and sediment doesn’t

get drawn into the system. Install a well vent tube in the well cap.

7

DETAILED INSTALLATION INSTRUCTIONS

DRIVEN WELL (with check valve and well point)

1. Drive the well point into the ground according to the instructions

that come with the well point. It must be deep enough to bore

through the water bearing formation below the water table but

should not exceed 25 ft (7.6 m) in depth. An individual well point

may not supply the amount of water needed. Sometimes it is

necessary to use more than one well point to increase the water

supply. The two separate well points can be jointed together

using additional piping and a cross joint (see Figure 5).

2. Plan to have at least 1 ft (30 cm) of pipe protruding from

the ground. The rise pipe should be galvanized pipe in

approximately 5 ft (1.5 m) sections. This makes it easier to hand

drive. Use as much pipe and as many drive couplings as it takes

to both reach the water and account for the 1 ft (30 cm) of pipe

protruding from the ground.

3. Attach a 1-1/4" galvanized elbow onto the pipe protruding

from the ground.

4. Attach a 1-1/4" galvanized nipple to the 1-1/4" galvanized elbow.

5. Attach a 1-1/4" check valve to the 1-1/4" galvanized nipple.

6. Attach a 1-1/4" male PVC adapter to the 1-1/4" check valve.

7. Install the pump in a clean, dry, and ventilated location

which provides adequate room for services and protection

from freezing temperatures. It should be bolted to a good

foundation, preferably concrete, and provided with adequate

drainage. Locating the pump as close as possible to the water

source reduces the friction in the suction pipe and will provide

maximum performance.

8. A pressure gauge is not supplied with the pump. It should be

installed into the 1/8" NPT hole on the front of the casing on the

opposite side of the pressure switch (see Typical Installations

Figure 5).

9. Attach a 1-1/4" male galvanized adapter into the pump suction

inlet. Do not over-tighten as this could crack the fitting. Measure

from this adapter to the check valve that was installed in Step

6. Cut 1-1/4" PVC pipe to this measurement. Using a round file,

smooth the pipe cutting. Ensure the pipe is clean and free of

any pipe shavings or pieces as these could get into the pump

and may damage the impeller. Attach the 1-1/4" PVC pipe to the

adapter and then to the check valve. Check thoroughly for any

leaks. All connections and joints must be airtight. A pinhole

leak can prevent proper operation of the pump.

10. Driven wells water levels may, at times, be too low to pump up.

To prevent damage to the pump, have an electrician replace the

pressure switch with a low pressure cut-o switch.

11. Follow the Pump to Tank Installation procedures.

12. Verify everything has been completed using the Installation

Checklist provided in this manual.

8

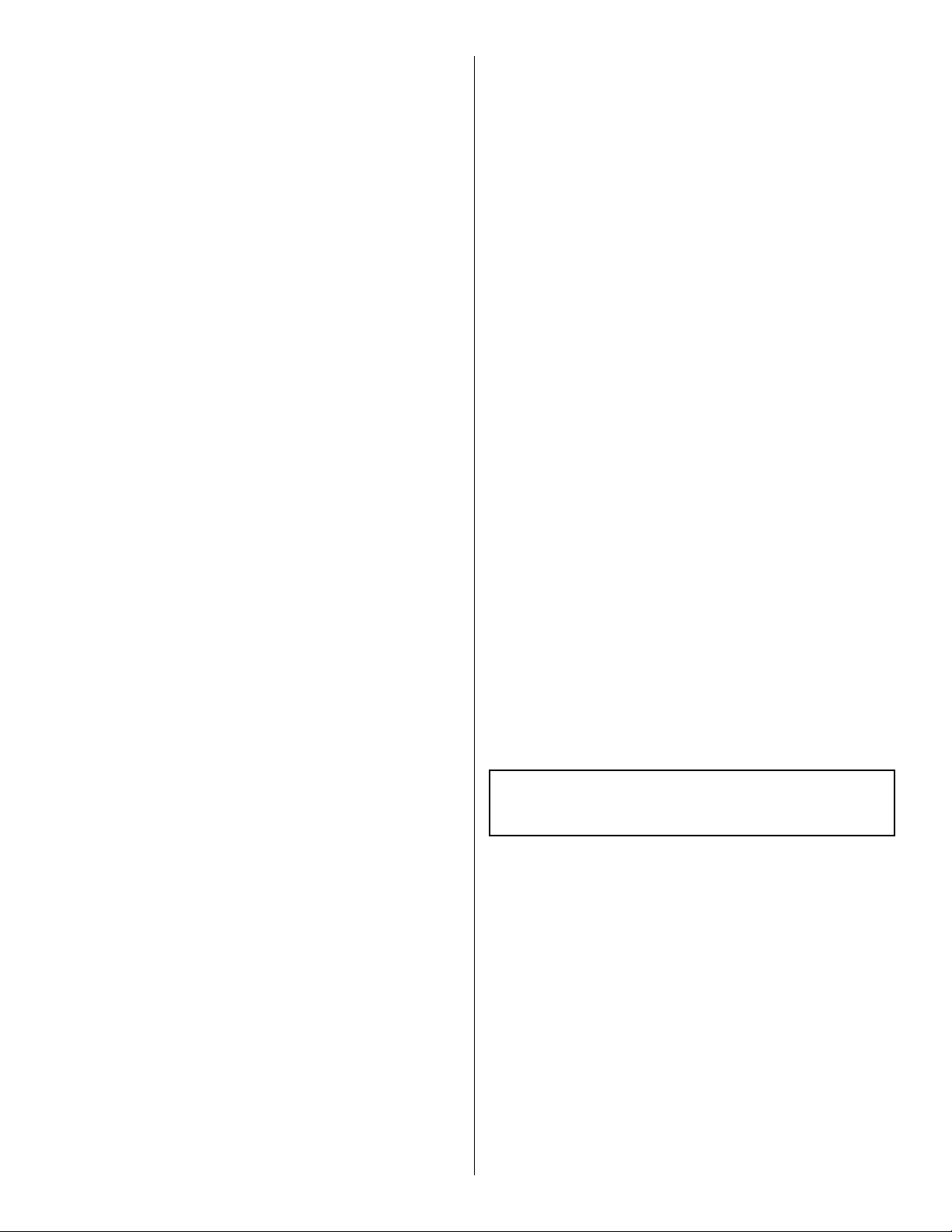

TYPICAL INSTALLATIONS

Tank

Relief Valve

Service Line

Drain

Suction Pipe

Vent Pipe

Well Seal

Well

Foot Valve

Figure 3 - SHALLOW WELL

(with foot valve)

Relief valve

Priming Plug

Pressure gauge port (1/8" NPT)

Tank

Drain Plug

Service Line

Suction Pipe

Vent Pipe

Well Seal

Well

Foot Valve

Tank

Priming Plug

Pressure Gauge Port (1/8" NPT)

Figure 4 - SHALLOW WELL, INLINE TANK

(with foot valve)

Service Line

Relief Valve

Drain Plug

Service line

Drain

Suction Pipe

Vent Pipe

Well Seal

Well

Figure 5 - SHALLOW WELL

(with inline check valve)

Inline check valve

1-1/4"

Galvanized Pipe

Well Point

Priming plug

Drain plug

Pressure gauge port (1/8" NPT)

1-1/4" PVC Elbow

Shuto Valve

Priming Plug

Suction Pipe

Vent Pipe

Well Seal

Well

Foot Valve

Pressure

Gauge Port

(1/8" NPT)

Relief Valve

Drain

Figure 6 - SHALLOW WELL, TANK MOUNTED SYSTEM

(with foot valve)

Union Coupling (2 required)

Drain Plug

Tank

9

PUMP TO TANK INSTALLATION

Red Lion® recommends using pre-charged diaphragm tanks. Instructions

for connecting the pump to a diaphragm tank have been provided for

your convenience.

If a non-diaphragm tank is used in the pressure system, an air volume

control must be used to maintain an air cushion in the pressure tank. If

not, air in the tank will gradually be absorbed by water, causing the tank

to water log and the pump to short cycle (turn o and on frequently). This

greatly shortens the life of the motor. An air volume control will provide

the right air/water ratio and prevent water logging. Refer to the pressure

tank owner’s manual for instructions.

NOTE: A check valve should never be installed between the pump

and the tank.

9. Check the tank pre-charge with a tire gauge. It should be equal to

2 psi below the pressure switch cut-in setting (the pressure at which

the pump will start). For this pump that is 30 psi, therefore the

pre-charge pressure should be adjusted to 28 psi. Use a tire pump

or air compressor to charge the tank, if necessary.

10. Replace and tighten the PVC cap on the air valve.

11. See Typical Installations for examples of dierent

pump/tank configurations.

12. Verify everything has been completed using the Installation

Checklist provided in this manual.

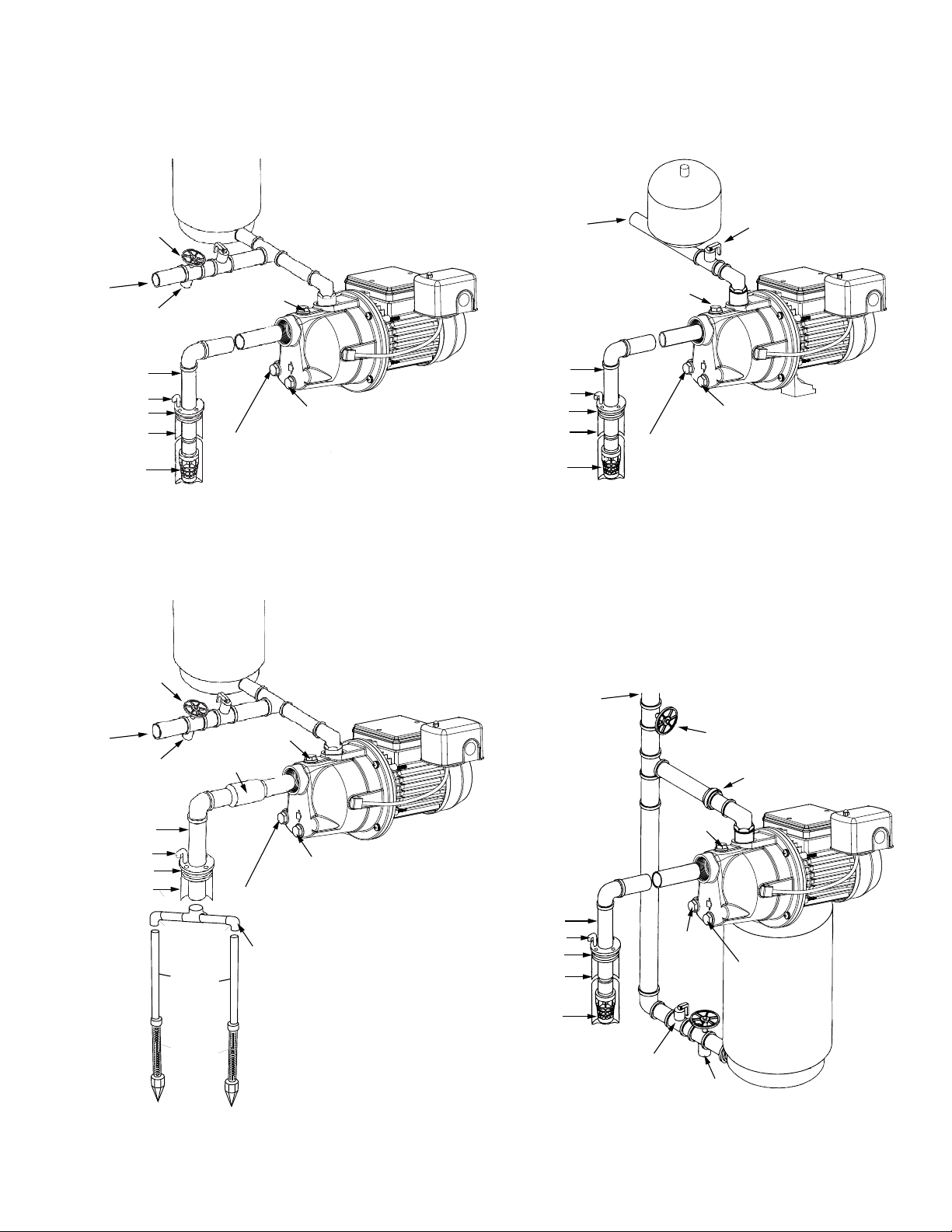

Table 1 - FRICTION LOSS FOR PLASTIC PIPE*

Before proceeding, ensure power has been shut o at the breaker. If this

is replacing an existing pump, completely relieve pressure from the water

system before working on the water system. Open the faucet nearest the

tank and allow the water to drain until the tank is empty.

!

s WARNING

75 PSI PRESSURE RELIEF VALVE RECOMMENDED

This pump is capable of producing high pressure. Installing a 75 psi

pressure relief valve is highly recommended.

1. The discharge pipe from the pump to the tank should be as short and

direct as possible and should be the same size as the discharge outlet.

You should have already attached a 1" PVC adapter to the discharge

opening of the pump.

2. Attach a PVC 90° elbow to the adapter.

3. Attach a male PVC adapter to the tank. The tank fitting size depends

on the system connect on the tank.

4. Install a 1" brass tank tee to the tank adapter.

5. Measure the distance from the tank tee to the elbow (or restrictor

valve) on the pump’s discharge and attach 1" PVC piping to fit.

6. Attach accessories to the brass tee such as restrictor valve

(recommended for well point installations), high pressure safety relief

valve (recommended for all installations), and drain cock. Ensure the

high pressure safety relief valve’s location is near the discharge of the

pump, in an area with adequate drainage. Be sure to direct the valve

so that any water flow will not spray toward the pump or any other

electrical devices.

7. Add piping and coupling to join up the service line. The size of the

service line required is governed entirely by the amount of water

needed and the length of the pipe. The pipe selected should be large

enough so that the friction loss (determined from Table 1, Friction

Loss for Plastic Pipe) will never exceed 20 ft (6 m) of head.

8. Remove the PVC cap on the air valve on the tank.

Loss of head in feet due to friction per 100 feet of pipe.

Nominal

Pipe Size

U.S. GPM 3/4" 1" 1-1/4'' 1-1/2'' 2''

4 3.75 1.15 0.30 0.14 –

5 5.66 1.75 0.46 0.22 –

6 7.9 5 2.45 0.65 0.31 –

7 10.60 3.25 0.86 0.41 –

8 13.50 4.1 6 1.10 0.52 –

9 16.80 5.17 1.35 0.65 –

10 20.40 6.31 1.67 0.79 0.23

11 24.40 7.58 1.98 0.95 0.27

12 28.60 8.85 2.33 1.10 0.32

14 38.00 11.80 3.10 1.46 0.43

16 48.60 15.10 3.96 1.87 0.55

18 60.50 18.70 4 .93 2.33 0.69

20 73.50 22.80 6.00 2.83 0.84

Loss of head in meters, due to friction per 100 meters of pipe.

Nominal

Pipe Size

L/Min. 20mm 25mm 32mm 40mm 50mm

15 3.7 1.15 0.30 0 .13 –

20 5.3 1.64 0.4 3 0.1 9 –

25 7.1 2.18 0.56 0.27 –

30 13.5 4.1 3 1.08 0.49 –

35 16.3 5.00 1.31 0.61 –

40 23.5 7. 30 1.90 0.88 0.25

45 28.3 8.74 2.31 1.07 0.29

50 34.2 10.60 2.79 1.32 0.38

55 40.7 12.60 3.32 1.56 0.46

60 48.1 14.90 3 .92 1.85 0.54

65 55.7 17.30 4.45 2.15 0.63

70 63.8 19.70 5.20 2.46 0.73

75 72.2 22.40 5.89 2.78 0.83

*For galvanized pipe, double the figures.

10

WIRING INSTRUCTIONS

!

s WARNING

All wiring, electrical connections, and system grounding must comply with the National Electrical Code (NEC) and with any local codes and ordinances.

Employ a licensed electrician.

!

s WARNING

Before servicing motor-operated equipment, shut o the power at the main electrical panel and disconnect the power supply from motor and accessories.

Use safe working practices during servicing of equipment.

ELECTRICAL PRECAUTIONS

RISK OF ELECTRICAL SHOCK

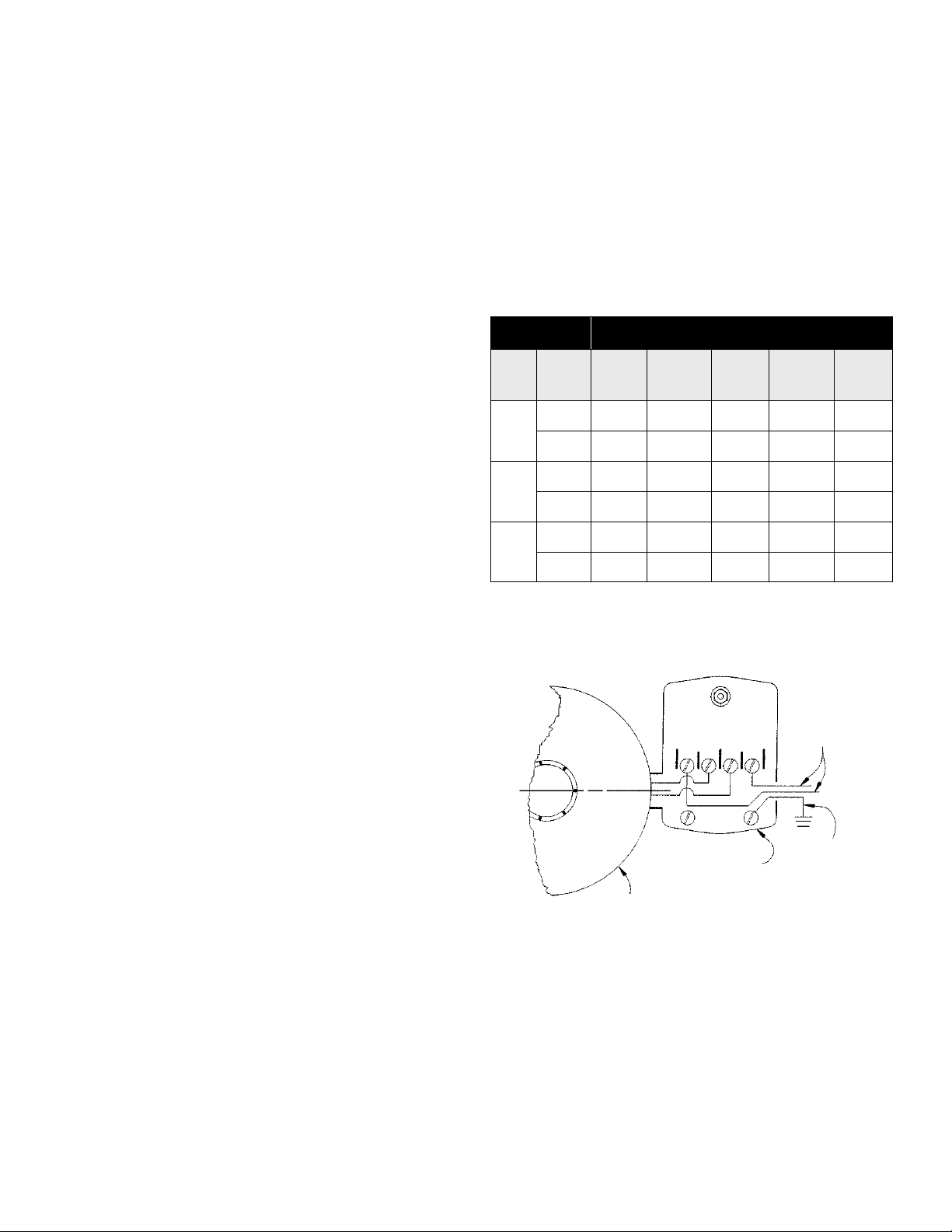

WIRING

An electrician should be employed to do the wiring and connect the

electrical service to the pump. The pressure switch is wired to the motor

at the factory and the voltage for which the motor is wired is indicated by

the voltage change device which is found under the wiring access cover

located on the back of the pump. Make sure the motor is wired for the

same voltage as the power supply. Refer to the inside of the wiring access

cover or this manual for voltage changing instructions. The power lines

should be connected to the pressure switch terminals marked "line"

(Figure 7). It is recommended that a separate circuit be led from the

distribution panel to the pump unit. A ground fault interrupter (GFI)

protected circuit should be used for all electrical devices operating near

water. Install a properly fused disconnect switch in the line and make

certain the wiring is adequately sized and well insulated. Undersized wire

between the motor and the power source will adversely limit the starting

and load carrying abilities of the motor. Minimum wire sizes for motor

branch circuits are recommended (see Table 2). For added safety, the pump

and motor should be grounded to the well casing, if metal, or the ground

in the distribution panel.

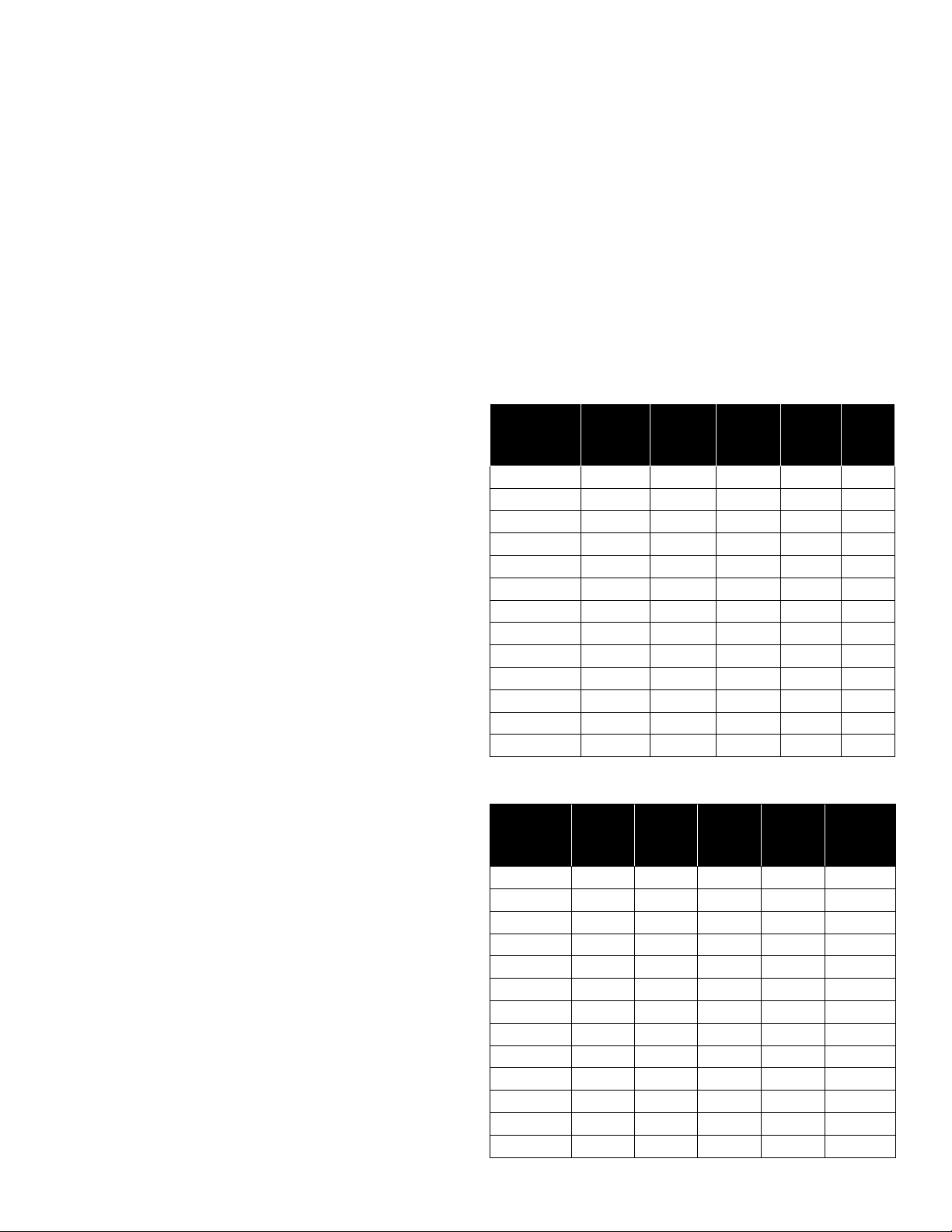

Table 2 - MAXIMUM WIRE LENGTH

MOTOR WIRE GAUGE (AWG)

HP Volts

115 14 14 12 10 8

1/2

230 14 14 14 14 14

115 14 14 10 8 8

3/4

230 14 14 14 14 12

115 14 12 10 8 6

1

230 14 14 14 14 12

Based on an approximate 3% voltage drop.

Figure 7 - ELECTRICAL CONNECTIONS

25 ft

(8 m)

50 ft

(15 m)

L 1 L 2

100 ft

(30 m)

150 ft

(46 m)

Power Supply (Line)

200 ft

(61 m)

Ground

Pressure Switch

Motor (Load)

11

PRIMING THE PUMP

!

s WARNING

NOTE: You will need enough water to fill the suction line(s) and casing. Priming time depends on the distance from the water source

to the pump (5-15 minutes).

DO NOT RUN THE PUMP BEFORE PRIMING IT; THE SEAL AND IMPELLER COULD BE PERMANENTLY DAMAGED.

USING AN INLINE CHECK VALVE

1. Open the discharge valve on service line and nearby tap to

monitor water flow.

2. With a wrench, remove the priming plug.

3. Pour clean water through the priming plug opening.

4. Continue filling the pump until water flows out of the

priming hole.

5. Reinstall the priming plug, hand tighten.

6. Start the pump. If a tap is visible, you may see a short discharge

of water that will last 5-10 seconds.

7. Run the pump for 2 minutes and then shut it o.

Remove the priming plug.

8. You have completed the first priming cycle, consisting of Steps

3 to 7. This process will have to be repeated from 2 to 6 times,

depending on the length of your suction line. (Approximately

one priming cycle for every 5 ft [1.5 m] of suction line.) You

will know when to stop because the pump will begin to

pump water continuously.

USING A FOOT VALVE

1. Open the discharge valve on the service line and nearby tap

to monitor water flow.

2. With a wrench, remove the priming plug.

3. Pour clean water through the priming plug opening. You will

need approximately 1 quart (1 liter) of water for every 3 ft

(1 m) of suction line.

NOTE: If you are unable to fill the suction line, please follow

the directions for an inline check valve.

4. Continue filling the pump until water flows out of the

priming hole.

5. Reinstall the priming plug, hand tighten.

6. Start the pump. If the pump is primed correctly it should start

pumping water immediately.

7. If within 2 minutes water is not being pumped continuously, stop

the pump. Remove the priming plug. Repeat Steps 3 through 7.

If this does not work, stop the pump and check the suction line

for leaks.

9. Once the pump begins pumping water continuously,

firmly tighten the priming plug with a wrench.

10. If the pump does not draw water within 8 tries, shut it o

and check the suction line for leaks.

8. Once the pump begins pumping water continuously, firmly

tighten the priming plug with a wrench.

12

MAINTENANCE

!

s WARNING

Before servicing motor-operated equipment, shut o the power at the main electrical panel and disconnect the power supply from motor and accessories.

Use safe working practices during servicing of equipment.

RISK OF ELECTRICAL SHOCK

PERFORM INSPECTIONS MONTHLY

1. Ensure pump is still securely bolted to the foundation.

2. To avoid any fire hazards, ensure that there is adequate clearance

from any combustible materials, shelving or cabinets. Ensure

there are no leaves or debris near the pump.

3. Ensure that the motor is securely wired into a proper GFCIprotected circuit. Test the GFCI periodically by pressing the test

switch when the pump is operating. This should shut o the

pump. If the GFCI does not shut the pump o, have an electrician

replace the GFCI as soon as possible. Remember to reset the GFCI

by pressing the reset switch.

4. Look for any signs of leaks in pipes. Replace or repair, if necessary.

5. Clean the exterior of the pump, if needed, with a solution of

vinegar and water.

DRAINING

Should the unit be subject to freezing, it will be necessary to drain the

pump and tank. To do this, shut o the power to the pump at the main

electrical panel. Open a tap in the water system to release the pressure.

Remove the drain and priming plugs from the pump casing. Remove the

pressure tank drain plug (if so equipped). Allow ample time for the system

to drain before reinstalling the plugs.

LUBRICATION

The pump requires none.

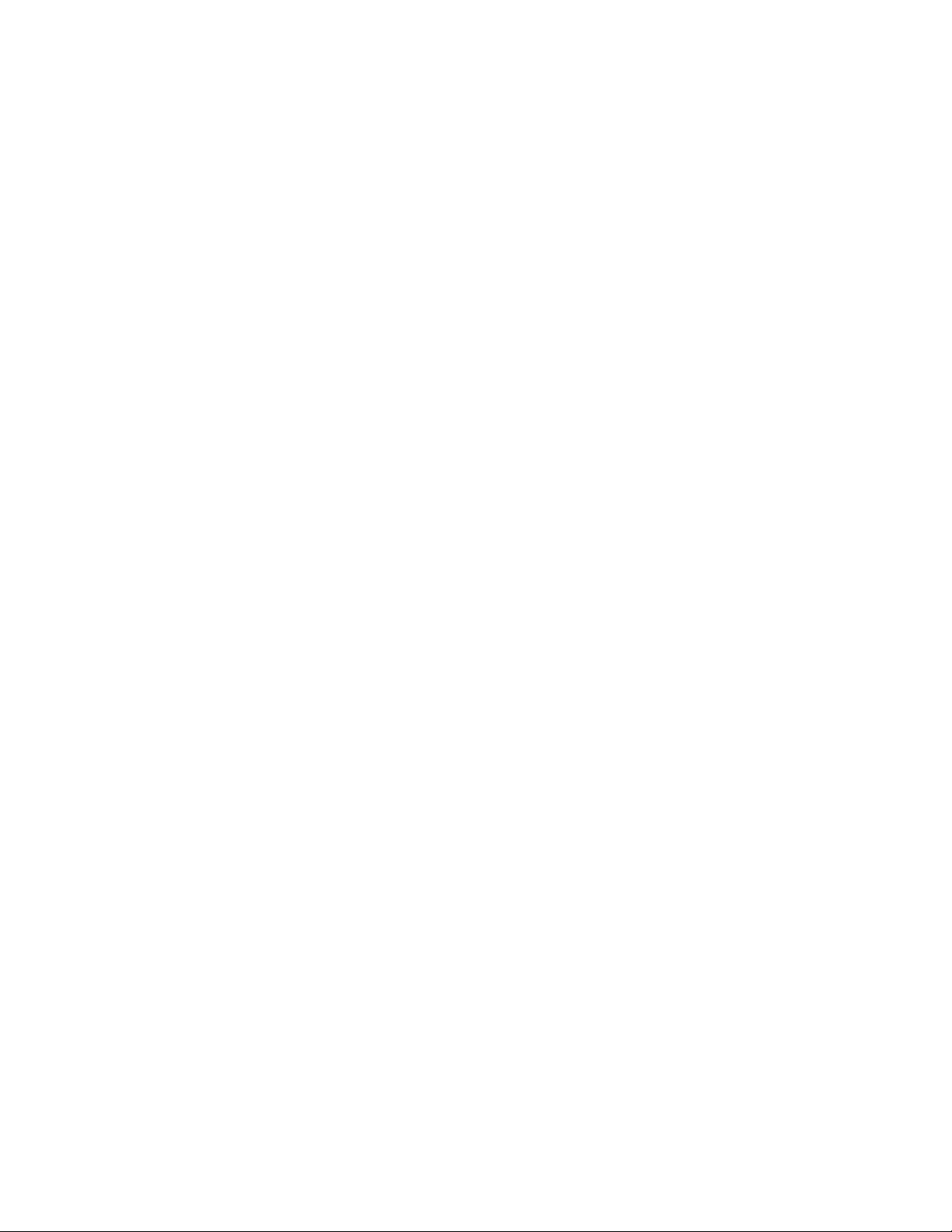

REPLACING MECHANICAL SEAL (See Figure 8)

!

s CAUTION

MAINTENANCE ON ELECTRICAL AND/OR MECHANICAL DEVICES.

Disassembly:

1. Shut o the power to the pump at the main service panel and

disconnect the power supply from motor.

2. Open a tap in the water system to release the pressure.

3. Remove the drain and fill plugs to allow the pump to drain.

4. Remove the bolts (1) and remove casing (2).

5. Remove fan shroud fasteners from the motor and remove the

fan shroud (3).

!

s CAUTION

the motor fan or shroud.

6. Remove the impeller (4) by firmly holding on to the motor fan

(5) and turn the impeller in a clockwise direction.

7. Slip rotating seal (9) o the shaft.

8. Remove motor tie bolts and remove motor (6) from adapter (7)

by slightly tapping end of motor shaft with a mallet.

9. Remove the adapter plate and the O-ring.

Reassembly:

1. Clean all parts thoroughly before assembling.

ONLY DULY QUALIFIED PERSONS SHOULD PERFORM

Care must be taken not to damage

13

2. Lightly lubricate (soapy water) the rubber cap on the ceramic

seal (8) and push it into the adapter (7) using thumbs only. Make

sure the smooth surface of the ceramic seat faces outward.

!

s CAUTION

cleaners or lubricants.

!

s CAUTION

contaminate the ceramic seal face.

NOTE: If the pump will remain out of service for longer

than one week, the seal components must be installed dry

(no lubrication).

3. Reassemble the motor (6) to the adapter. Align the tabs of the

adapter plate with the slot at the bottom of the motor housing.

Do not use petroleum-based

Care must be taken not to

4. Lubricate the rubber components of the rotating seal (9) (soapy

water) and slip it on to the shaft with the ‘carbon’ ring towards

the ceramic seat.Replace the impeller (6) and the diuser (4).

!

s CAUTION

Care must be taken not to

contaminate the ceramic seal face.

5. Replace the impeller (4) and the shroud with fasteners.

Lubricate and replace the O-ring.

6. Replace the casing (2), making sure that O-ring is not damaged

and is in place.

4 8

9

5

7. Replace drain and fill plugs.

8. Reconnect power.

9. Prime the pump.

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE

No power to pressure switch due to blown fuses,

Motor will not start

Pump fails to

deliver water

open switches or loose connections.

Pump pressure switch not closed.

Pump not completely primed.

Suction lift is too great.

Foot valve is either not submerged, buried in

the mud or plugged.

Restrictor valve is fully closed.

Air leaks in suction line.

4

1

Figure 8

7

PROBLEM POSSIBLE CAUSE

Leaks in suction or discharge line.

Foot valve, suction line, impeller or nozzle are

partially plugged.

Suction lift is greater than recommended.

Pump delivers

water but not at

rated capacity

Improper impeller rotation or low speed.

Venturi or diuser is plugged.

Motor is wired for improper voltage.

Low line voltage at motor.

36

Pump loses prime

For well point

installations where

pump is losing

pressure or unable

to prime

Well draws down too far.

Faulty foot valve.

Have an electrician install a low pressure cut-o switch

to shut down the pump prior to critical failure.

Install or adjust a restrictor valve to oset

available capacity.

Add a larger tank (20 gallon or larger) for

additional capacity.

Pump starts and

stops too often

14

Filtration cartridge (if used) needs changing or is not

installed properly.

Faulty air volume control.

Air leaks in tank above the water level.

Incorrect setting on pressure switch.

Tank is water logged or incorrectly charged.

Foot valve leaks or is stuck open.

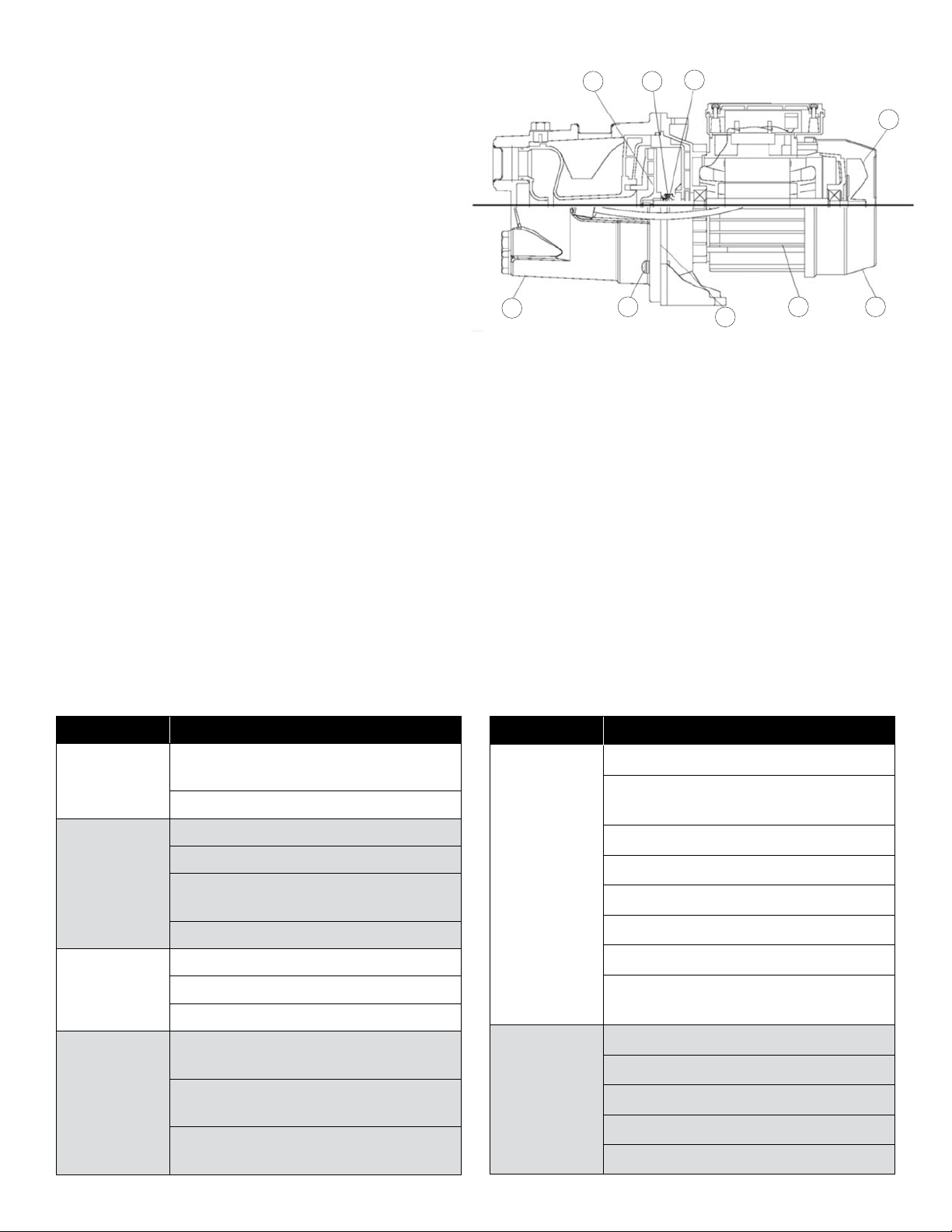

REPLACEMENT PARTS

A12

A13

A11

A10

A9

A8

A7

A5

A3

A6

A14

A4

A3

C3

C4

B1

A1

A2

B10

B7B6

B9

B2

B1

B1

B5

B8

B4

B3

A15

B11

B14

B13

Contents Item Replacement Parts Where Used

A5 & A10 305585001 Case/Seal Plate RL-SWJ50 & RL-SWJ75

B12

A2, A3, A4 & A9 305585002 Hardware Kit RL-SWJ50 & RL-SWJ75

A6, A7 & A8 305585005 Overhaul Kit RL-SWJ50

A6, A7 & A8 305585006 Overhaul Kit RL-SWJ75

A7 305585008 Impeller Kit RL-SWJ50

A7 305585009 Impeller Kit RL-SWJ75

A8 305585011 Shaft Seal Kit RL-SWJ50 & RL-SWJ75

A1, A14 & A15 305585012 Pressure Switch Kit RL-SWJ50 & RL-SWJ75

B2 & B9 305585003 Case/Seal Plate RL-SWJ100

B1, B3 & B8 305585004 Hardware Kit RL-SWJ100

B5, B6 & B7 305585007 Overhaul Kit RL-SWJ100

B6 305585010 Impeller Kit RL-SWJ100

B7 305585011 Shaft Seal Kit RL-SWJ100

B4, B12 & B13 305585012 Pressure Switch Kit RL-SWJ100

C3, C4 305592001 Pump/Tank Hardware Kit RL-SWJ50/RL6H

15

Loading...

Loading...