red lion RL-SPBS Owner's Manual

ENGLISHEN

Sump Pump Battery

Backup System

Owner’s Manual

Table of Contents

Before Getting Started .................................................................2

Getting Started.............................................................................. 3

Specifications ................................................................................ 4

Pump Performance Curves ..........................................................4

www.RedLionProducts.com

Installation of Backup System on

Common Discharge (Model RL-SPBS) ......................................... 5

Charger/Controller Unit Installation ............................................ 8

Electrical Connections .........................................................10

Wiring Diagram ...................................................................10

Charger/Controller Unit Operation ..............................................11

Sump System Operation Testing ................................................12

System Maintenance....................................................................13

System Troubleshooting .............................................................14

Limited Warranty ......................................................................... 15

Before Getting Started

Read and follow safety instructions. Refer to product data plate(s) for additional operating instructions and specifications.

This is the safety alert symbol. When you see this symbol on your pump or in this manual, look for one of the following signal words and be

alert to the potential for personal injury or property damage if ignored:

!

s DANGER

warns about hazards that will cause serious personal injury, death or major property damage if ignored.

!

s WARNING

!

s CAUTION

!

s NOTICE

in this manual and on pump.

!

s WARNING

WARNING RISK OF ELECTRIC SHOCK - This product is supplied with a grounding conductor and grounding-type attachment plug. To reduce risk

of electric shock, be certain that it is connected only to a properly grounded, grounding-type receptacle. Disconnect power before working on or

around the sump pump or battery backup system.

This equipment should be installed by technically qualified personnel. Comply with national and local electrical and plumbing codes when

installing this unit. Failure to install it in compliance with national and local electrical and plumbing codes and within these recommendations

may result in electrical shock or fire hazard, unsatisfactory performance, or equipment failure. Installation information is available through pump

manufacturers and distributors, or directly from Red Lion® at our toll free number 1-888-956-0000.

warns about hazards that can cause serious personal injury, death or major property damage if ignored.

warns about hazards that will or can cause minor personal injury or major property damage if ignored.

indicates special instructions which are important but not related to hazards. Carefully read and follow all safety instructions

WARNING

DANGER

This equipment must not be used by children or persons with reduced physical, sensory or mental abilities, or lacking in experience and expertise,

unless supervised or instructed. Children may not use the equipment, nor may they play with the equipment or in the immediate vicinity.

!

s CAUTION

• Keep work area clean, well-lit, and uncluttered.

• Keep safety labels clean and in good condition.

• Wear safety glasses while installing or performing maintenance on pump.

• Do not run pump dry. Fill pump with water before starting or pump will be damaged.

• Make sure all ELECTRICAL POWER IS OFF before connecting any electrical wires. Wire sump pump system for correct voltages. Follow all pump

wiring instructions provided in the “System Wiring Diagram” and “Electrical Connections” sections of this manual.

2

Getting Started

This owner’s manual provides you with the information required to safely own and operate your Red Lion battery backup system. Retain these instructions

for future reference. The Red Lion battery backup system you have purchased is of the highest quality workmanship and material, and has been engineered

to give you long and reliable service. Red Lion products are carefully tested, inspected, and packaged to ensure safe delivery and operation. Please examine

your product carefully to ensure that no damage occurred during shipment. If damage has occurred, please contact the place of purchase. They will assist

you in replacement or repair, if required.

!

s WARNING

THE PRODUCT’S APPLICATION, LIMITATIONS, AND POTENTIAL HAZARDS. PROTECT YOURSELF AND OTHERS BY OBSERVING ALL SAFETY INFORMATION. FAILURE

TO COMPLY WITH THESE INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE!

NOT FOR SALE IN CALIFORNIA: The battery charger contained in this product does not meet the California Eciency Regulations codified at 20 CCR §1601-1608.

Description

The battery backup system is designed as a backup to work in conjunction with a primary sump pump providing operation during temporary power

outages or if the primary pump fails to function due to a blown fuse, tripped circuit breaker, defective switch, debris clogging the primary pump, or for

any other reason.

READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO INSTALL, OPERATE, OR SERVICE YOUR RED LION PRODUCT. KNOW

WARNING

!

s DANGER

Pump should only be used with liquids compatible with pump component materials. Do not handle pump or charger/controller unit or junction box with

wet hands or when standing on a wet or damp surface, or in water.

!

s WARNING

the 115 VAC pump and the charger/controller unit are connected to outlets protected by ground fault circuit interrupters (GFCI). Comply with all national and

local electrical and plumbing codes when installing this unit. Do not use the same 115 VAC outlet for the primary pump and the battery charger/controller

unit. Do not use an extension cord.

!

s WARNING

disconnections from the battery. Take care to prevent accidental shorting across battery terminals during handling. Do not leave battery uncovered. Attach

or strap cover securely on battery box when completing installation.

Do not use to pump flammable or explosive fluids such as gasoline, fuel oil, kerosene, etc. Do not use in explosive atmospheres.

To reduce risk of electric shock which can result in personal injury, death or major property damage if ignored, be certain that

A spark near the battery may cause an explosion. Always unplug the charger/controller unit prior to making connections to or

DANGER

WARNING

!

s CAUTION

manufacturer’s safety guidelines. Failure to use proper personal protective equipment or electrical caution can result in hazards that will or can cause

personal injury or major property damage if ignored.

!

s CAUTION

false alarms could result. CO detectors should be a minimum of 15 feet (4.6 m) from the systems. Refer to the manufacturer of CO detector for additional

instructions or information.

!

s NOTICE

audible high water alarm on the sump system is recommended in any installations where property damage and/or personal injury might result from an

inoperative sump system due to long term power outages, discharge line blockage, or any other reason.

The battery required to operate this unit contains acid and proper precautions must be taken when handling. Refer to battery

If a carbon monoxide (CO) sensor is installed near the battery backup system, battery, or charger/controller unit, nuisance or

The charger/controller unit emits an audible alarm when running the 12 VDC backup pump. An additional (not supplied in this kit)

3

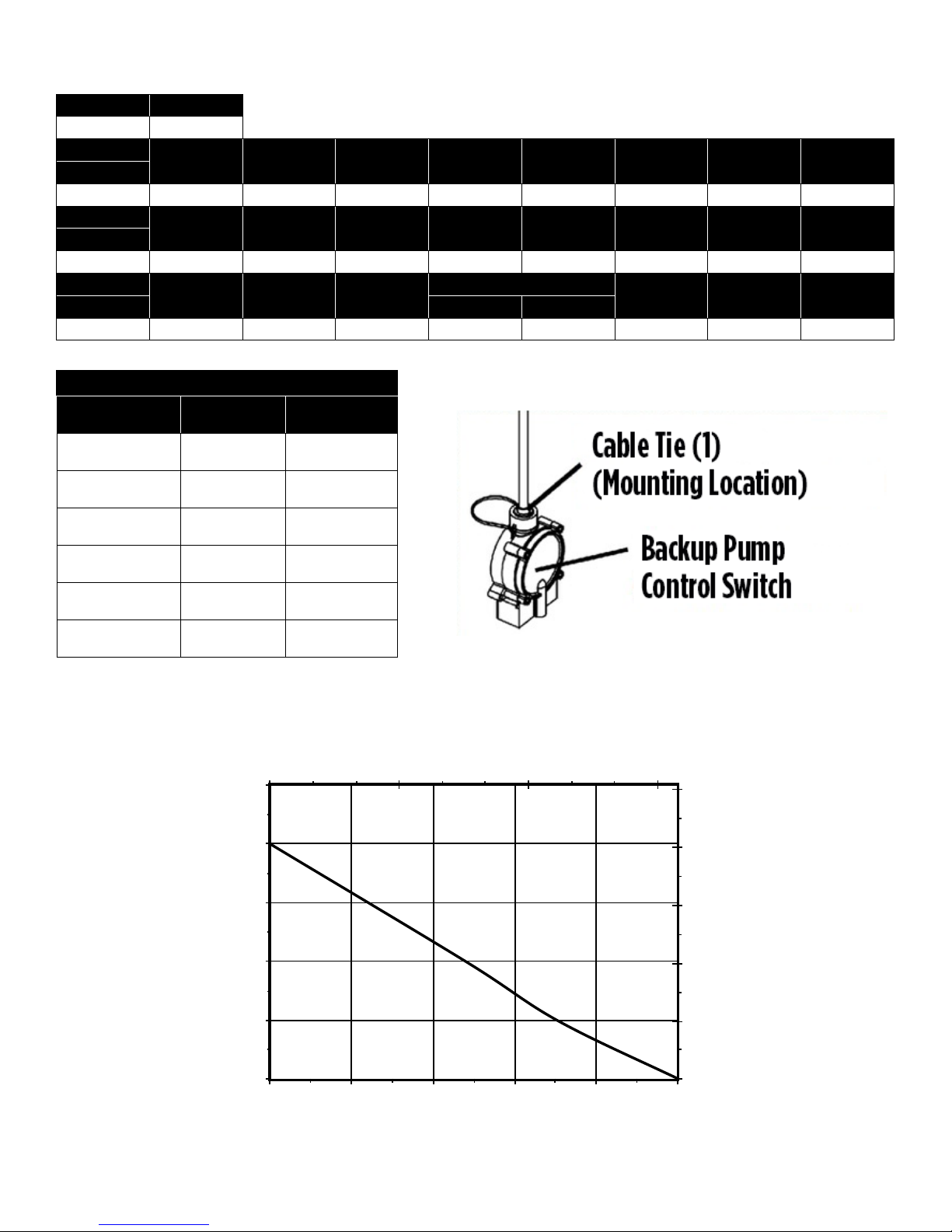

Specifications

HEAD - METERS

FLOW - GALLONS/HOUR

Item Number Model Number

14942792 RL-SPBS

Charging Unit

Item Number

106459 1HF 115 VAC 60 0.2 0.9 23 6' 2

Backup Pump Switch

Item Number

105601 RS-12 12 VDC - 13.5'' 9'' - 9' 0.5

Backup Pump

Item Number FLA Start

106960 2500 12 VDC - 14 32 168 6' 6

Mounting Location

(from bottom of sump pump)

7" (18 cm)

8" (20 cm)

9" (23 cm)

10" (25 cm)

11" (28 cm)

12" (30 cm)

Model Number Volts Hz

Model Number Volts Hz Switch On Level Switch O Level Watts Cord (ft) Weight (lb)

Model Number Volts Hz

Switch Levels

On Levels O Levels

9.75" - 11.25"

25 cm - 29 cm

10.75" - 12.25"

27 cm - 31 cm

11.75" - 13.25"

30 cm - 34 cm

12.75" - 14.25"

32 cm - 36 cm

13.75" - 15.25"

35 cm - 39 cm

14.75" - 16.25"

37 cm - 41 cm

4.5" - 6.5"

11 cm - 16 cm

5.5" - 7.5"

14 cm - 19 cm

6.5" - 8.5"

17 cm - 22 cm

7.5" - 9.5"

19 cm - 24 cm

8.5" - 10.5"

22 cm - 27 cm

9.5" - 11.5"

24 cm - 29 cm

Max Input Amps at

115 VAC

Max Output Amps at

Amps

12 VDC

Watts Cord (ft) Weight (lb)

Watts Cord (ft) Weight (lb)

Pump Performance Curves

0 3000 6000 9000

25

20

15

HEAD - FEET

10

5

0

0 500 1000 1500 2000 2500

FLOW - LITERS/HOUR

7,5

6

4,5

3

1,5

0

2500 12 VDC (106960)

4

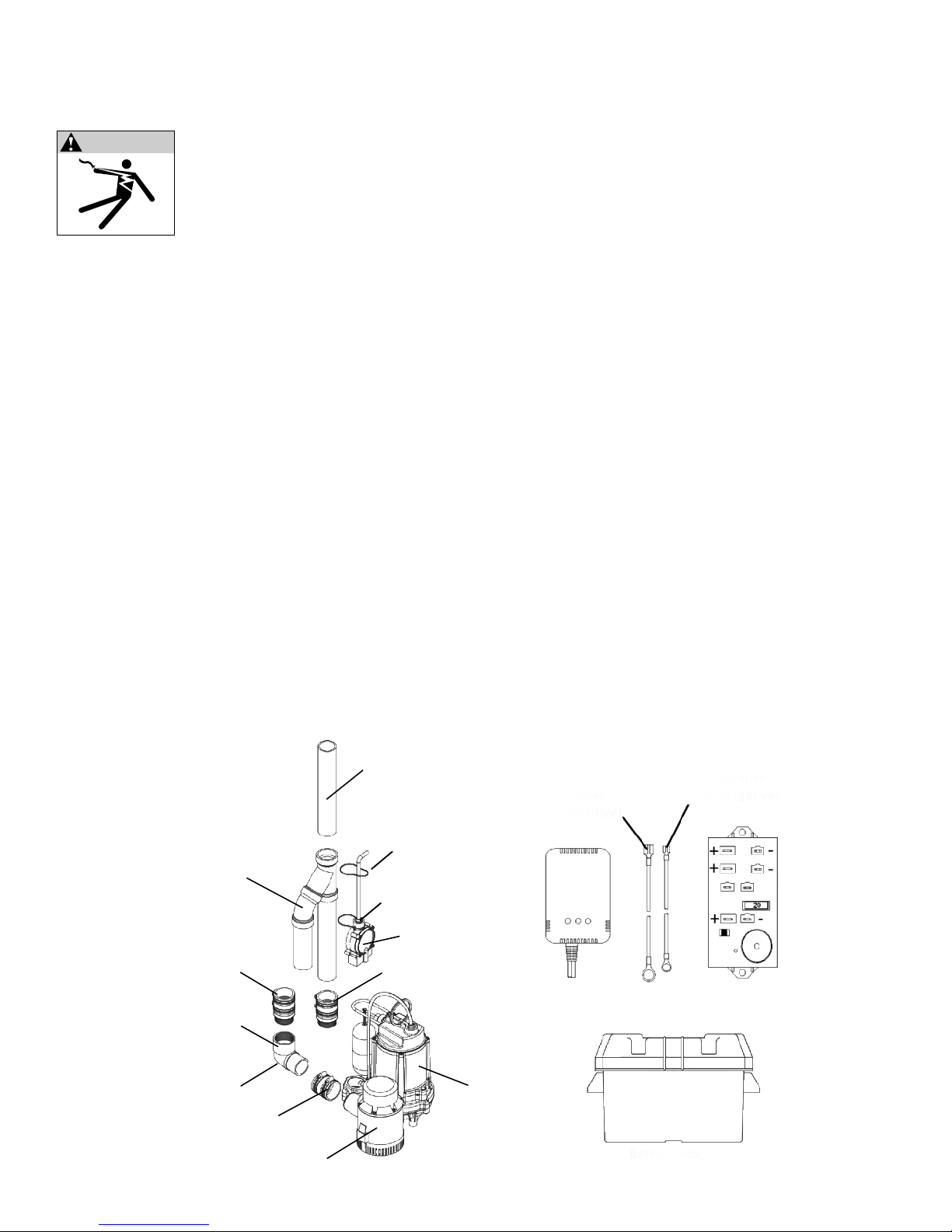

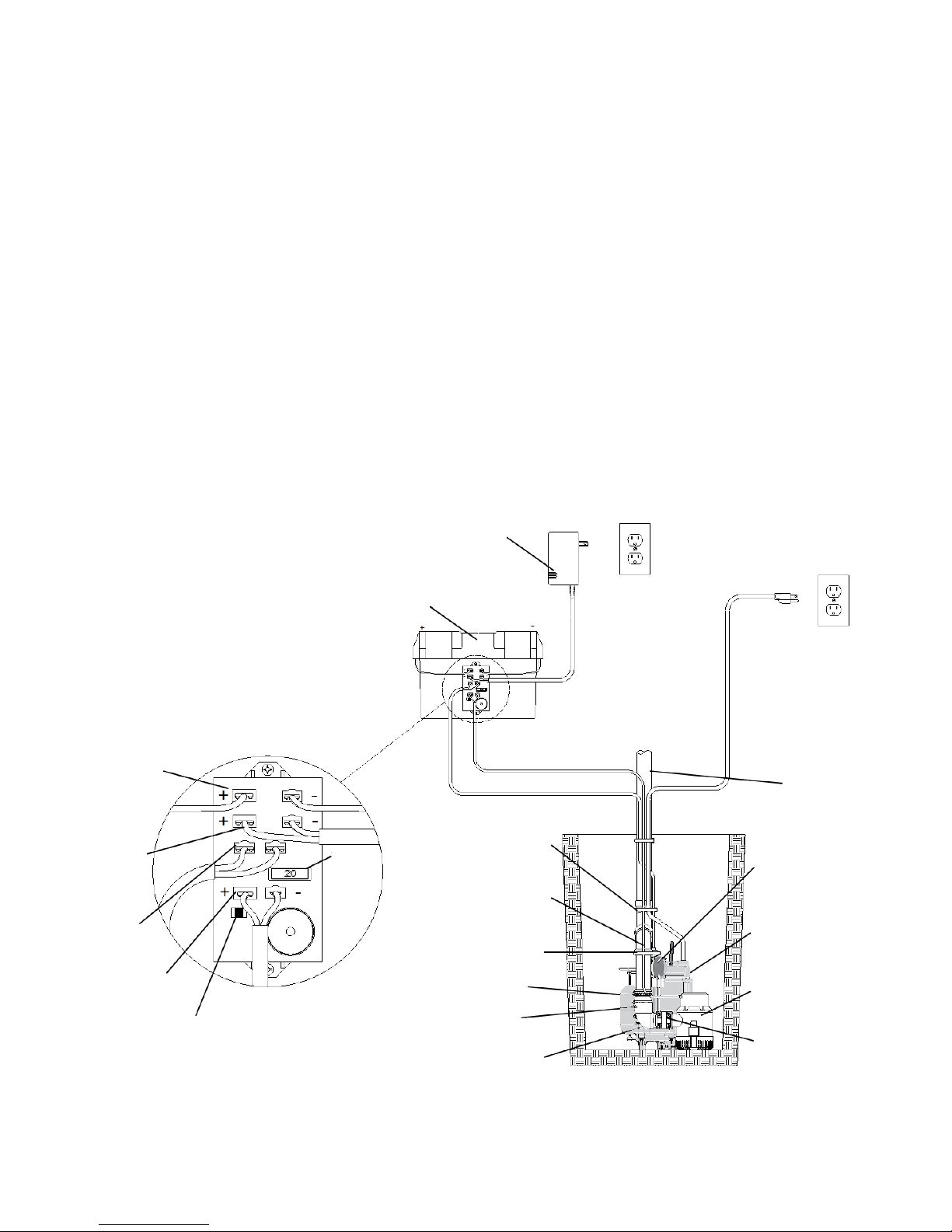

Installation of a Backup System on a Common Discharge

(For 12 VDC Backup System RL-SPBS which does not include a 115 V primary sump pump assembly)

!

WARNING

s WARNING

Disconnect power from all electrical equipment housed within the sump system before working on or around the sump pump

or battery backup system beginning with 115 VAC powered pumps, level switches, and charger controllers, followed by DC

powered items. Includes all items such as pumps, level control switches, charger/controller unit, and battery systems.

Included in the RL-SPBS:

1. Battery charger unit and junction box

2. Battery case (battery not included)

3. (1) 1-½" street elbow near 12 VDC pump

4. Flexible coupling from 12 VDC pump discharge

5. Check valve for 12 VDC pump

6. Switch to control 12 VDC pump

7. 12 VDC backup pump

8. Red jumper wire (positive)

9. Black jumper wire (negative)

10. (4) Cable ties

Customer required to purchase separately:

1. 12 VDC deep cycle battery – BCI Group 27, rated 85 – 140Ah, lead-acid or AGM

2. 115 VAC primary pump. Red Lion’s RL-33SC or RL-50SC automatic pump is recommended

3. Check valve for 115 VAC pump

4. 1-½" pipe as needed

5. 1-½" DWV street elbow H-SPG 45 degree

6. 1-½" DWV Wye

7. Fittings – as required

Comply with all national and local electrical and plumbing codes when installing this unit.

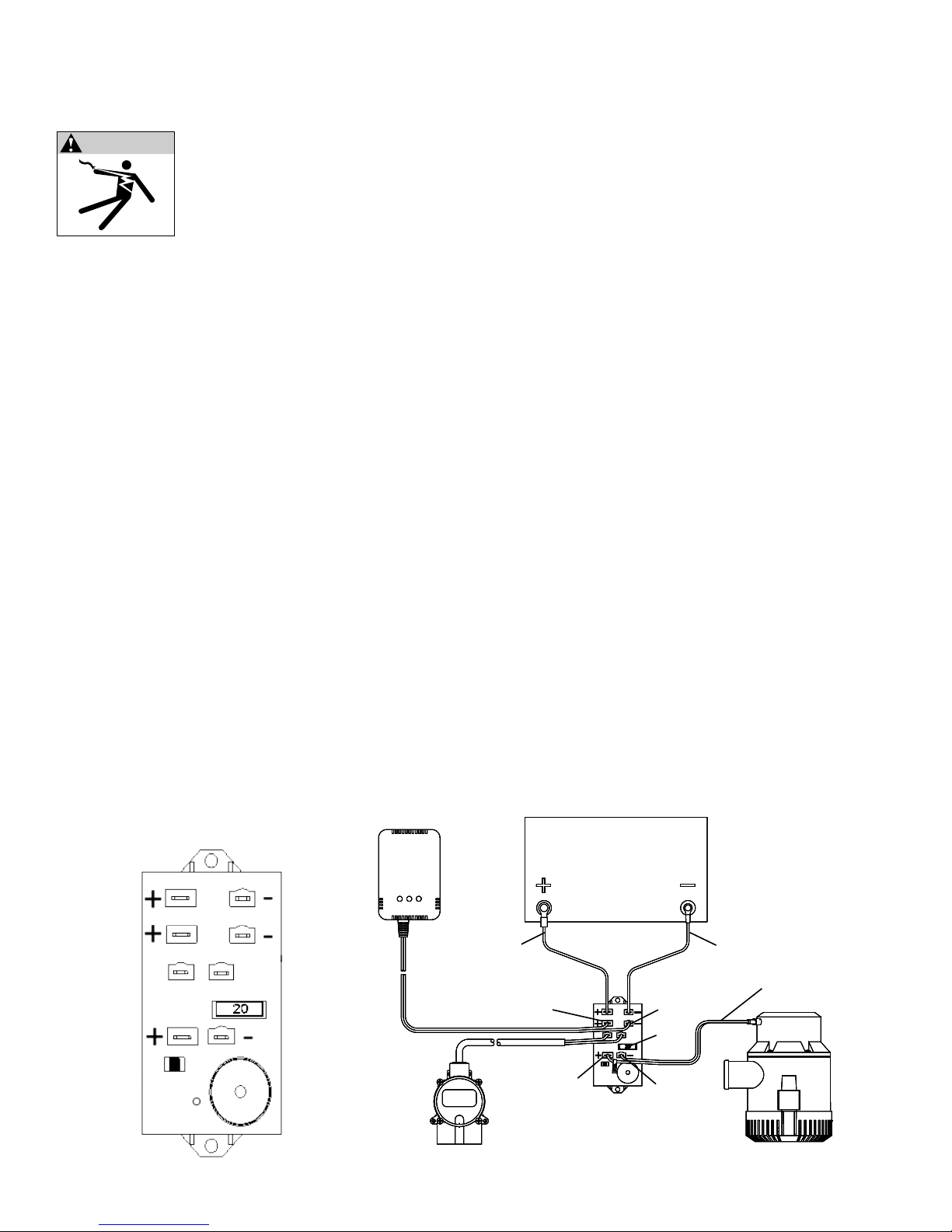

Backup System on a Common Discharge

Figure 1

Discharge Pipe

“Wye” Assembly

(not included)

Check Valve

90° Street Elbow

Air Bleed Hole

Flexible Coupling

Backup Pump

Common Drain Pipe From

Household Plumbing

(not included)

Cable Tie (1)

Cable Tie (2)

Backup Pump

Control Switch

Check Valve

(not included)

Primary Pump

(not included)

Red Jumper Wire

(Positive)

MICRO PROCESSOR

CONTROLLED

5 STAGE

BATTERY CHARGER/

MAINTAINER

CHARGED

CHARGING

A.C. POWER

WHEN YELLOW - GREEN FLASHING ALTERNATELY

REFER TO ERROR TABLE IN MANUAL

Charger Unit

Battery Box

Black Jumper Wire

(Negative)

BATTERY CONNECTION

CHARGER CONNECTION

FLOAT SWITCH CONNECTION

REPLACE FUSE WITH SAME 20 AMP 38V TYPE

AND RATING ONLY

PUMP FUSE &

CONNECTION

DISABLE

ENABLE

AUDIBLE ALARM

DISABLE WHEN LIT

Junction Box

5

!

s CAUTION

system underperformance. Discharge piping that is of insucient size can result in premature pump and/or system operation failure.

Reduction of plumbing sizes from what is used for the discharges of the primary 115 VAC pump and 12 VDC pump can result in

Figure2

Drill 3/16 Hole

Step 1 Step 2 Step3 Step4 Step5 Step6

!

s NOTICE

and routing wiring away from control floats will be much easier on a bench rather than working down inside a sump pit (Figure 2).

Do not glue any parts until the entire assembly, including primary pump, has been dry-assembled to verify fits. Fitting plumbing

Step 1

a. Install flexible coupling onto 12 VDC pump discharge.

b. Position two hose clamps in the grooved recesses of flexible coupling installed on the 12 VDC pump.

c. Tighten the flexible coupling’s first hose clamp connection to securely fasten it to the 12 VDC pump discharge.

d. Leave the hose clamp on the opposite end loose for the next plumbing piece.

Step 2

a. A 3/16" diameter air bleed hole has been drilled in the 90º street elbow that is provided with the kit. (NOTICE: Air bleed hole must be located between

the check valve and the 12 VDC pump to prevent the 12 VDC pump from air-locking.) The bleed hole is located so that the water flow through it will be at

a downward angle to prevent splashing from the basin/pit.

b. Slip 90º street elbow into the flexible coupling attached to the 12 VDC pump discharge, and tighten the hose clamp to secure elbow to the 12 VDC pump’s

discharge. (When properly installed the threaded elbow connection of the 90º street elbow should be facing straight up toward the top of the sump pit).

Step 3

!

s NOTICE

plumbing between the backup pump and the Wye connection joining the backup pump’s discharge to that of the primary pump’s discharge.

a. Apply PTFE tape to male threads of provided check valve.

b. Thread PTFE-taped end of check valve into 90° elbow.

A check valve is supplied and required for the backup pump’s discharge plumbing. This check valve must be installed in the discharge

Step 4

a. Position two hose clamps in the grooved recesses of the flexible coupling on the check valve installed in the elbow.

b. Tighten the lower hose clamp to secure the flexible coupling to the check valve body.

c. Loosely tighten the upper hose clamp so it does not fall o. This clamp will be used to secure the check valve to the discharge pipe “Wye” assembly.

Step 5

a. Review the discharge plumbing of the 115 VAC primary pump.

!

s NOTICE

installed in the discharge plumbing between the primary pump and the Wye connection joining the backup pump’s discharge to that of the primary pump’s

discharge. A 3/16" diameter air bleed hole must be located between the check valve and the 115 VAC pump to prevent the 115 VAC pump from air-locking.

Locate the bleed hole so that the water flow through it will be at a downward angle to prevent splashing from the basin/pit.

b. The 1-1/2" PVC pipe used in making the discharge pipe “Wye” assembly must be cut so as to ensure that both the 115 VAC primary pump and the 12 VDC

backup pump rest flat on the floor of the sump basin when the plumbing is completely assembled and to align connection to the drain piping from the

home. Dry-fit the assembly to confirm prior to gluing (see Figure 2).

c. Once dry-fit confirms that both pumps rest flat on the sump basin floor and the Wye assembly piping aligns with drain piping from the home, secure

all connections by applying approved waterproof adhesive to all necessary joints and confirm that all flexible coupling hose clamps are fully engaged

with plumbing and fully tightened.

A customer-supplied check valve is required in the discharge plumbing of the 115 VAC primary sump pump. This check valve must be

6

Step 6

a. Cable ties (1) and (2) will be used to attach the 12 VDC pump control switch housing and power cord to the discharge pipe. Installing both cable ties

to the 12 VDC pump control switch is critical for proper operation of 12 VDC pump (see Figure 1).

b. Thread cable tie (1) through the eyelets on the 12 VDC pump control switch housing.

c. Position the 12 VDC pump control switch on the discharge pipe such that cable tie (1) is 4" to 6" above the “ON” water level of the 115 VAC primary pump.

d. Tighten cable tie (1) to secure the 12 VDC pump control switch to the discharge pipe.

e. Install cable tie (2) around both the power cord of the 12 VDC pump control switch and the discharge pipe such that the power cord is securely routed

away from any control floats.

f. Use electrical tape to further secure the power cord of the 12 VDC pump control switch to the discharge pipe.

!

s NOTICE

The RS-12 switch cord contains a breather tube. Be sure the switch cord is not pinched so that the breather tube is not obstructed.

Non-restrictive air flow in the breather tube is required for proper RS-12 operation.

!

s NOTICE

For proper pump operation, the exit point of all drain piping from the home must be lower, or sloping away, from the discharge

plumbing’s highest point. Improper water drainage can allow freezing within the line leading to system or component damage or failure.

!

s CAUTION

Ensure all hose clamp connections and threaded connections are tight, and that all plumbing slip-fit connections are properly

glued prior to starting the sump pump system. Failure to do so can result in damage to pump system and/or cause property damage due to flooding.

!

s CAUTION

Do not install or store the pump where it will be exposed to the weather or to temperatures below freezing

or damage to the pump will occur.

Figure 3

Battery Box

Charger Unit

Jumper Wire to

Battery Connection

Charger Connection

Float Switch

Connection

Pump Connection

Disable/Enable

Junction Box

20A FUSE

Cable Tie (2)

Discharge Pipe

“Wye” Assembly

(not included)

Cable Tie (1)

Check Valve

90° Street Elbow

Air Bleed Hole

Common Drain Pipe from

Household Plumbing

(not included)

Backup Pump Switch

Primary Pump and Primary

Pump Check Valve

(not included)

Backup Pump

Flexible Coupling

A-N614

7

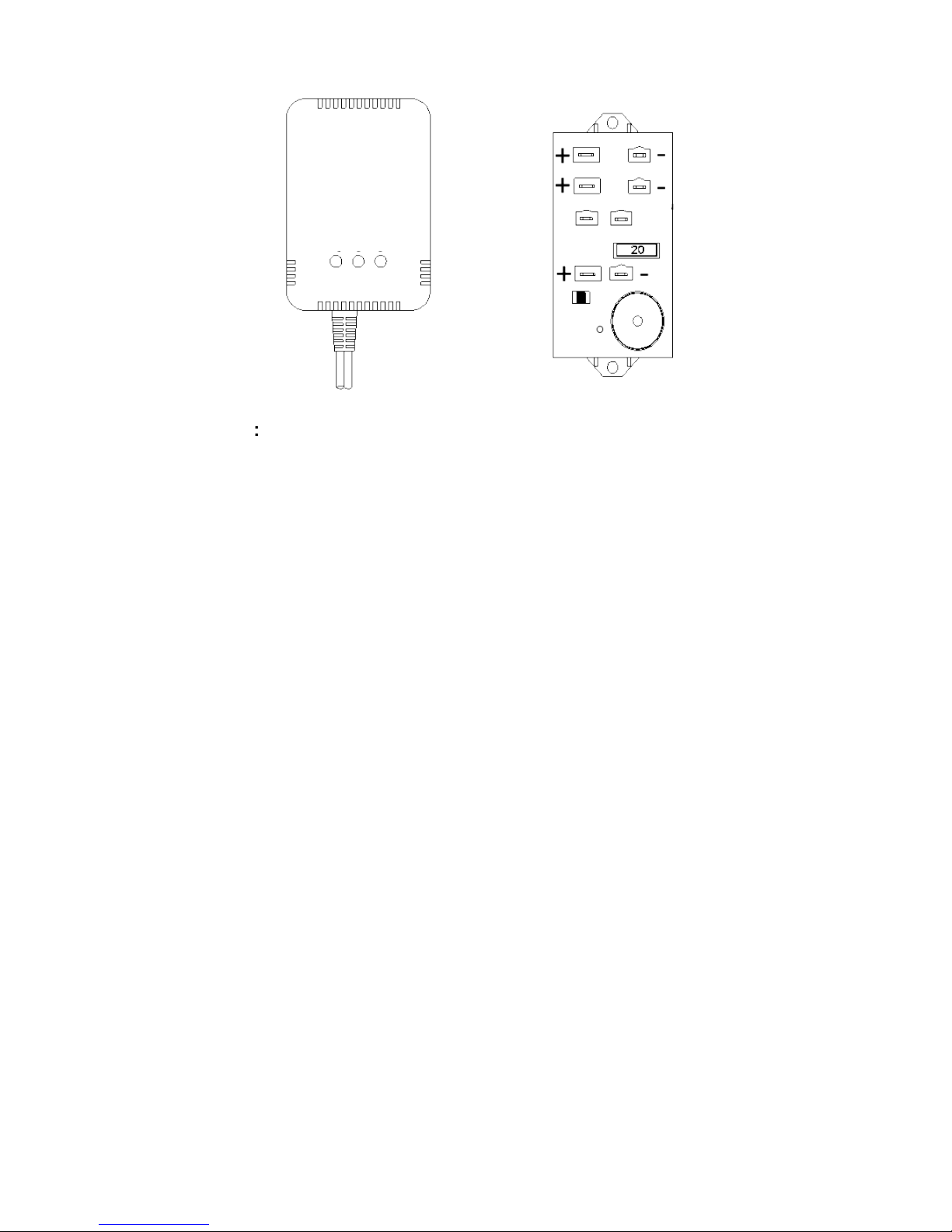

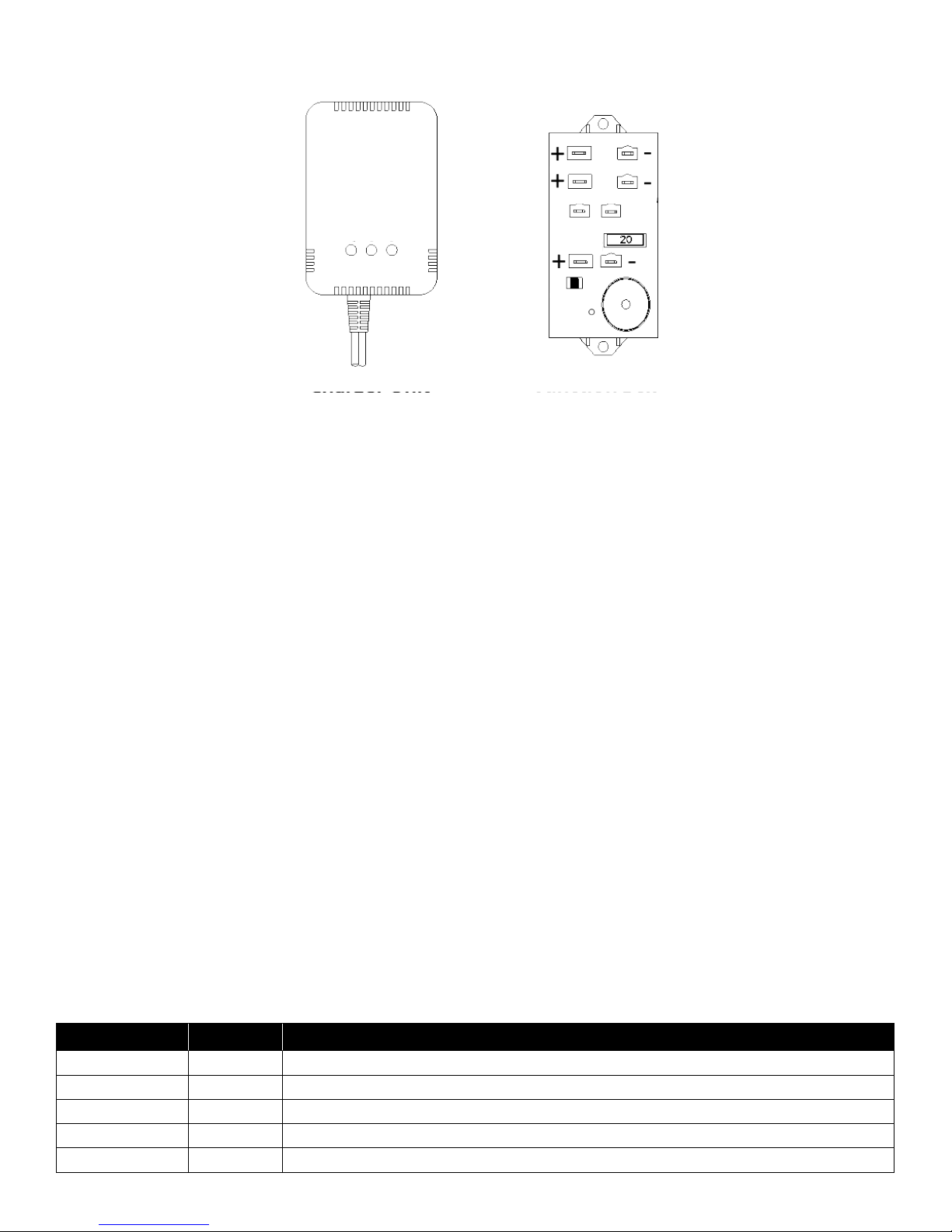

Charger/Controller Unit Installation

Charger/Controller Electrical Ratings:

Input: 120 VAC, 0.2 Amp

Output (Maximum Charging Current):

• Model 1HF: 12 VDC, 900 Milliamps

Use only with 12 VDC deep cycle battery rated 85 – 140Ah, lead-acid or AGM

MICRO PROCESSOR

CONTROLLED

5 STAGE

BATTERY CHARGER/

MAINTAINER

CHARGED

CHARGING

A.C. POWER

WHEN YELLOW - GREEN FLASHING ALTERNATELY

REFER TO ERROR TABLE IN MANUAL

Charger Unit Junction Box

BATTERY CONNECTION

CHARGER CONNECTION

FLOAT SWITCH CONNECTION

REPLACE FUSE WITH SAME 20 AMP 38V TYPE

AND RATING ONLY

PUMP FUSE &

CONNECTION

DISABLE

ENABLE

AUDIBLE ALARM

DISABLE WHEN LIT

!

s WARNING

Do not use in explosive atmospheres. Do not handle charger/controller unit with wet hands or when standing on a wet or

damp surface, or in water.

!

s WARNING

To reduce risk of electric shock that can result in personal injury, death or major property damage if ignored, be certain that the

115 VAC pump and the charger/controller unit are connected to outlets protected by ground fault circuit interrupters (GFCI). Comply with all national and local

electrical and plumbing codes when installing this unit. Do not use the same 115 VAC outlet for the primary pump and the battery charger/controller unit.

Do not use an extension cord.

!

s WARNING

A spark near the battery may cause an explosion. Always unplug the charger/controller unit prior to making connections to or

disconnections from the battery. Take care to prevent accidental shorting across battery terminals during handling. Do not leave battery uncovered. Attach or

strap cover securely on battery box when completing installation.

!

s CAUTION

The battery required to operate this unit contains acid and proper precautions must be taken when handling. Refer to battery

manufacturer’s safety guidelines. Failure to use proper personal protective equipment or electrical caution can result in hazards that will or can cause

personal injury or major property damage if ignored.

!

s CAUTION

If a carbon monoxide (CO) sensor is installed near the battery backup system, battery, or charger/controller unit, nuisance or false

alarms could result. CO detectors should be a minimum of 15 feet from the systems. Refer to the manufacturer of CO detector for additional instructions or

information.

!

s CAUTION

The backup pump relies on a suciently charged battery to operate the pump. The charger is designed to charge the battery and

maintain charge level when the backup pump is not in use. If battery voltage drops below 10 Volts, the backup pump must be disconnected from the circuit

for the charger to recharge the battery.

!

s NOTICE

The charger/controller unit emits an audible alarm when running the 12 VDC backup pump. An additional (not supplied in this kit)

audible high water alarm on the sump system is recommended in any installations where property damage and/or personal injury might result from an

inoperative sump system due to long term power outages, discharge line blockage, or any other reason.

8

Charger/Controller Unit Installation (continued)

Step 1 – Mounting the Charger/Controller Unit

!

s NOTICE

a. Complete all plumbing, pump installation, and pump control switch installation before installing the charger/controller unit and before beginning

work on the electrical connections to the charger/controller junction box or the battery.

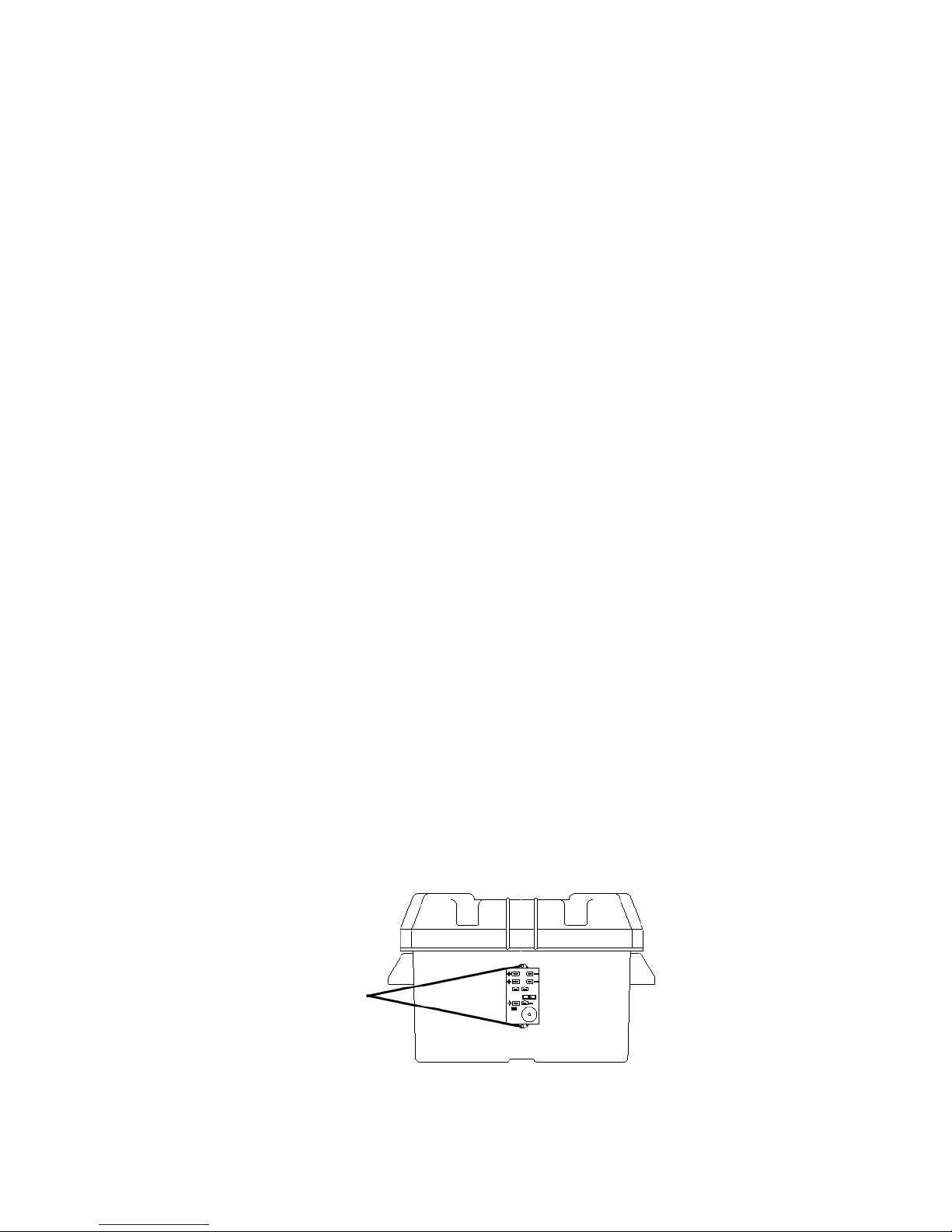

b. JUNCTION BOX INSTALLATION: Complete this step prior to installing battery. Install the junction box onto the battery case using two screws, lock

washers, and nuts, provided.

c. The charger/control unit is NOT to be plugged in until after all other electrical connections have been made as outlined in Step 2 “Electrical Connections”.

d. The charger/controller unit is designed to be plugged directly into a 115 VAC wall electrical receptacle outlet in a visible location. The LED lights on the

front of the charger/controller unit as well as the switch on the face of the charger/controller junction box should be accessible and clearly visible.

e. Select a location for the charger/controller unit and the battery relative to the sump basin such that all the provided wiring will reach their respective

connections with some slack remaining in the wiring. Locate the charger/controller unit as far away from battery as the provided wiring permits.

The charger/controller unit should not be installed directly over the battery. Gases from the battery will corrode and damage the charger/controller

unit. The battery should be positioned away from the wall to allow adequate ventilation of any fumes that are given o during charging.

!

s CAUTION

unit should be well away from other sources of heat such as space heaters, radiators, boilers, furnace, etc.

!

s CAUTION

the junction box to the battery. If any of the cords are damaged, or the charger/controller unit itself becomes damaged, immediately unplug the

charger/controller unit and remove it from service. Always disconnect the 115 VAC power supply cord before doing any service of the product and allow

the charger/controller unit to cool. Disconnect the 115 VAC power supply cord before disconnecting battery leads.

Do not expose the charger to excessive moisture. Install charger in a dry location. Indoor use only.

All combustible materials should be kept away from the hot surfaces of the charger/controller unit, and the charger/controller

The charger/controller unit has a cord for connecting to the junction box and black and red jumper wires for connecting from

!

s CAUTION

!

s CAUTION

charger/controller unit body. Hazardous voltage exists inside the enclosure.

!

s CAUTION

!

s NOTICE

Do not disconnect the pump cable while power is going to the 12 VDC backup pump.

There are no serviceable parts inside the charger/controller unit body. Do not open or attempt any repairs inside the

Do not try to charge non-rechargeable batteries.

The 12 VDC backup pump fuse is located on the junction box. Replacement fuse should be automotive type 32 V, 20A type ATC.

Figure 4

Junction Box

Mounting Location

9

Charger/Controller Unit Installation (continued)

Step 2 – Electrical Connections

WARNING

!

s WARNING

Comply with all national and local electrical and plumbing codes when installing this unit.

Disconnect power from all electrical equipment housed within the sump system before working on or around the sump pump

or battery backup system beginning with the 115 VAC powered pump, level switches, and charger controllers; followed by DC

powered items. Includes all items such as pumps, level control switches, charger/controller unit, and battery system.

!

s NOTICE

Installation of the 115 VAC electrical supply circuit to the battery charger is to be done by a certified licensed electrician in accordance

with national and local codes.

a. Verify that charger/controller unit is NOT connected to the power supply source.

b. Verify that all plumbing is complete per instructions.

c. Connect the terminals from the control switch cord to the (2) male tab terminals on the junction box marked “FLOAT SWITCH CONNECTION”.

d. Connect the terminals from the backup pump cord to the (2) male tab terminals on the junction box marked “PUMP FUSE & CONNECTION”, being

careful to match the correct polarity. Correct polarity is marked on the pump cord (“POS” is positive) as well as the junction box (“+” is positive;

“-” is negative).

e. Connect charger/controller unit to the (2) male tab terminals on the junction box marked “CHARGER CONNECTION” being careful to match the correct

polarity. Correct polarity is marked on the cord (red terminal is positive; black terminal is negative) as well as the junction box (“+” is positive;

“-” is negative).

f. Check polarity of battery posts. Positive (POS, P, +) battery post usually has a larger diameter than the negative (NEG, N, -) battery post. Some

batteries are equipped with wing-nut terminals allowing for easy attachment of the jumper wires to these posts.

g. Attach the ring terminal of the black jumper wire to the negative battery post. Attach the quick connect terminal of the black jumper wire to the

negative (“-”) male tab on the junction box marked “BATTERY CONNECTION”.

h. Attach the ring terminal of the red jumper wire to the positive battery post. Attach the quick connect terminal of the red jumper wire to the positive

(“+”) male tab on the junction box marked “BATTERY CONNECTION”.

i. Do not connect this charger/controller unit to the same circuit as is used for the primary pump. The AC outlet used for the charger/controller unit

requires separate 0.2A, 115 VAC circuit.

j. Verify that all wiring is per instructions. Once all plumbing and electrical connections are complete and verified, plug the charger/controller unit into

a 115 VAC electrical outlet.

k. Review Charger/Controller Operation section.

l. Perform testing per the Sump System Operation Testing section.

Wiring Diagram

BATTERY CONNECTION

CHARGER CONNECTION

FLOAT SWITCH CONNECTION

REPLACE FUSE WITH SAME 20 AMP 38V TYPE

AND RATING ONLY

PUMP FUSE &

CONNECTION

DISABLE

ENABLE

AUDIBLE ALARM

DISABLE WHEN LIT

10

MICRO PROCESSOR

CONTROLLED

5 STAGE

BATTERY CHARGER/

MAINTAINER

Charger Unit

CHARGED

CHARGING

A.C. POWER

WHEN YELLOW - GREEN FLASHING ALTERNATELY

REFER TO ERROR TABLE IN MANUAL

Red Jumper Wire

(Positive)

Charger Positive Lead

Pump Positive Lead

Backup Pump Control Switch 12 VDC Backup Pump

12 VDC Deep

Cycle Battery

Charger Negative Lead

Pump Fuse

Pump Negative Lead

Black Jumper Wire

(Negative)

Pump Cord

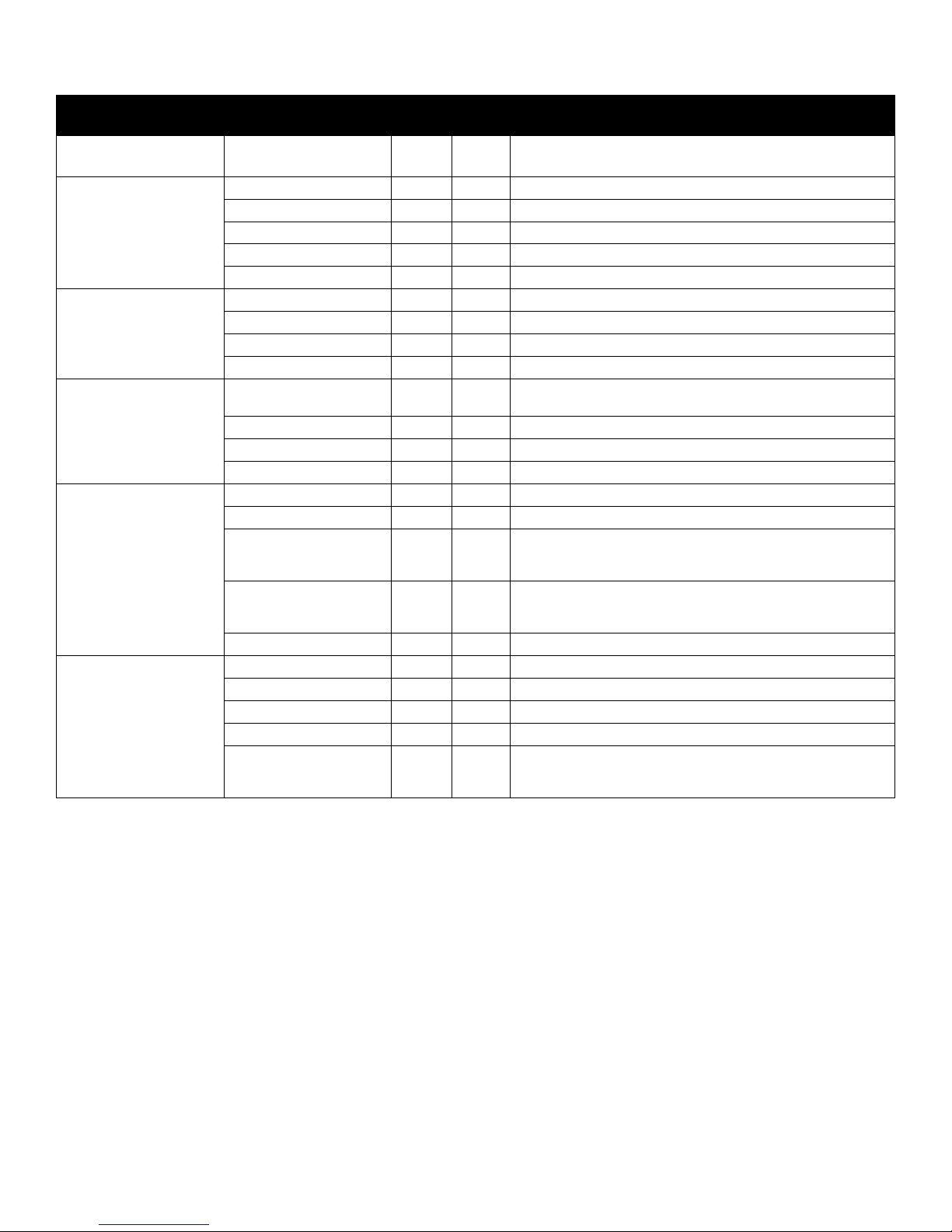

Charger/Controller Unit Operation

Charger Unit Junction Box

Figure 7

!

s NOTICE

The battery required for operation of this kit is not included. This kit requires a good quality 12 VDC deep cycle battery rated 85 –

140Ah, Lead-Acid or AGM to gain maximum pumping time during a power outage. A battery of this size will provide up to 7 hours of operation of the 12

VDC pump included with this kit in an installation with 8' of head pressure. How long the pump will operate on a fully charged battery will depend upon

the battery’s capacity, age, and state of charge. An older battery will provide less time. Maximum battery size that can fit in the supplied battery case is 8"

height X 7-1/2" width X 12-1/2" length (BCI Group 27).

MICRO PROCESSOR

CONTROLLED

5 STAGE

BATTERY CHARGER/

MAINTAINER

CHARGED

CHARGING

A.C. POWER

WHEN YELLOW - GREEN FLASHING ALTERNATELY

REFER TO ERROR TABLE IN MANUAL

BATTERY CONNECTION

CHARGER CONNECTION

FLOAT SWITCH CONNECTION

REPLACE FUSE WITH SAME 20 AMP 38V TYPE

AND RATING ONLY

PUMP FUSE &

CONNECTION

DISABLE

ENABLE

AUDIBLE ALARM

DISABLE WHEN LIT

CHARGING A 12 VDC BATTERY

The charger/controller unit is equipped with a 900 mA amp automatic charger for maintaining the battery in a ready state. After connection to the battery

and AC power, the charger starts its 5-Stage charging process.

STAGE ONE: PRE-QUALIFICATION TEST (Battery Testing)

a. Yellow LED flashes for normally 45 seconds. If reverse battery connections, wrong battery connected (24 V battery etc.), or battery with shorted cells is

found, further testing stops and the red LED will flash.

STAGE TWO: BULK-CHARGE CHARGING

a. Yellow LED illuminates continuously, indicating that the charger is charging the battery at the full rated amps output. This stage ends when the

battery voltage reaches 14.4 VDC.

STAGE THREE: EQUALIZATION-CHARGE CHARGING

a. Yellow LED illuminates continuously and regulates battery voltage to approximately 14.4 VDC until battery reaches full charge.

STAGE FOUR: FLOAT / MAINTENANCE

a. Green LED illuminates continuously. Charging is complete. The charger maintains the battery at full charge by regulating the battery’s voltage to

approximately 13.2 VDC. Recharging time depends upon the power drain during the AC power interruption. A completely drained battery may require

up to 150 hours for full recharge.

STAGE FIVE: RECYCLED CHARGE

a. If a load is applied to the battery, or if a minimum of 28 days elapses, the charger resets itself automatically and begins a new charge cycle, starting

from Stage One.

ITEM FUNCTION DESCRIPTION/OPERATIONS

AC POWER LED Indicator Indicates AC power is present. If no power is available then the light does not light and the charger will not charge the battery.

CHARGING LED Indicator Indicates battery is receiving current from the charger.

CHARGED LED Indicator Indicates battery is between 75% and fully charged. Charger is in maintenance mode to maintain highest battery capacity possible.

AUDIBLE ALARM LED Indicator Indicates the backup pump’s control switch is in the ON position.

DISABLE-ENABLE Switch This switch turns o the buzzer.

11

Sump System Operation Testing

!

s WARNING

Failure to do so can result in hazardous electrical shock.

!

s CAUTION

glued prior to starting the sump pump system. Failure to do so can result in damage to pump system and/or cause property damage due to flooding.

!

s CAUTION

Step 1

a. Verify that all wiring is per instructions and that primary pump and controller are connected to power.

i. The red “AC POWER” indicator light should be lit on the charger/controller unit.

Step 2

a. Run water into the sump basin until the primary pump is activated.

i. Do not attempt to run the pump without water; this could result in permanent damage to the pump.

ii. Confirm that primary pump and its control switch are functioning as intended.

iii. Confirm that ON-OFF levels are within specification and confirm that no potential obstructions exist that could inhibit switch operation.

iv. Confirm that there are no leaks in the primary pump discharge plumbing and main home drain pipe plumbing

a) It is normal for a stream of water to spray from the air bleed hole in the primary pump’s plumbing. Confirm that this spray is captured within

the sump basin.

Always disconnect the electrical power before touching the pump or discharge when water is present in the area of the pump.

Ensure all hose clamp connections and threaded connections are tight and that all plumbing slip-fit connections are properly

Do not allow the pump to run dry or damage to the pump will occur. Do not allow the sump basin to overflow during this testing.

Step 3

a. After primary pump function has been confirmed, disconnect power to primary pump.

i. This is typically done at an electrical connection box or a plug receptacle.

Step 4

a. Run water into the sump basin until the backup pump is activated.

i. Do not attempt to run the pump without water; this could result in permanent damage to the pump.

ii. Confirm that backup pump and its control switch are functioning as intended.

iii. Confirm that the charger/controller unit emits an audible alarm when running the backup pump.

a) Slide the DISABLE-ENABLE switch on the junction box to DISABLE to silence the audible alarm.

iv. Confirm that ON-OFF levels are within specification and confirm that no potential obstructions exist that could inhibit switch operation.

a) The RS-12 switch will activate the 12 VDC backup pump when water is approximately 6" above the bottom of the RS-12 switch.

v. Confirm that there are no leaks in the backup pump discharge plumbing and main home drain pipe plumbing.

a) It is normal for a stream of water to spray from the air bleed hole in the backup pump’s plumbing. Confirm that this spray is captured within

the sump basin.

Step 5

a. After backup pump function has been confirmed, slide the DISABLE-ENABLE switch on the charger/controller junction box back to ENABLE to restore

functionality of the audible alarm.

b. Disconnect power to the charger/controller unit to confirm proper battery function.

i. This is typically done at an electrical connection box or a plug receptacle.

Step 6

a. Run water into the sump basin until the backup pump is activated.

i. Confirm that backup pump and its control switch are functioning as intended.

ii. Confirm that the charger/controller unit emits an audible alarm when running the backup pump.

a) Slide the DISABLE-ENABLE switch on the junction box to DISABLE to silence the audible alarm.

12

Sump System Operation Testing (continued)

Step 7

a. After primary pump, backup pump, and charger/controller unit function has been confirmed, reconnect power to the charger/controller unit and the

primary pump.

i. Confirm that primary pump activates and evacuate the remaining water from the sump basin down to the normal OFF level of the primary pump.

Primary pump should deactivate when the OFF level is reached.

ii. Slide the DISABLE-ENABLE switch on the charger/controller junction box back to ENABLE to restore functionality of the audible alarm once operation

testing is completed.

Step 8

a. Charger/controller unit LED indicators should provide status of battery’s charge.

i. See Charger/Controller Unit Operation section for details.

Step 9

a. Confirm that battery is in working condition according to the battery manufacturer’s instructions and is fully charged.

Step 10

a. The primary and backup pumps are now ready for operation.

System Maintenance:

WARNING

!

s CAUTION

sewage or any other debris (gravel, sand, floating debris, etc.) is present.

!

s CAUTION

!

s NOTICE

Step 1

a. = Refer to battery manufacturer’s instructions to confirm that battery is in working condition and is fully charged.

i. Clean any corrosion from the battery posts or pump terminals.

Step 2

a. Remove all debris (gravel, sand, floating debris, etc.) from the sump basin.

b. Review sump system components for any build-up (minerals, etc.) that would inhibit functionality of the components.

i. If significant, remove build-up or replace aected components.

!

s WARNING

on or around the sump pump or battery backup system beginning with 115 VAC powered pumps, level switches, and charger

controllers; followed by DC powered items. Includes all items such as pumps, level control switches, charger/controller unit,

and battery systems.

The backup pump is designed for pumping clear water only. Do not use the pump in applications where euent (gray water),

Do not allow the sump basin to overflow during this maintenance.

Inspect and test the sump system condition and operation every 3 months (more frequently in heavy-use applications).

Disconnect power from all electrical equipment housed within the sump system before working

Step 3

a. Confirm that all flexible coupling hose clamps are fully engaged with plumbing and fully tightened.

Step 4

a. Test operation of the sump system following the instructions outlined in the Sump System Operation Testing section of this manual.

13

Troubleshooting

PROBLEM PROBABLE CAUSES 115 V 12 V CORRECTIVE ACTION

Pump does not turn on or o.

Pump does not deliver rated capacity.

Pump cycles continually.

Pump will not shut o.

NOTE: Before troubleshooting automatic

control, check to see that pump operates

on manual control. To do this create slight

vacuum on breather tube (near plug),

then close o tube with thumb, plug into

wall outlet. If pump works, proceed to

check switch; if not, fault is in pump or

power supply.

Pump runs but does not discharge liquid.

TROUBLESHOOTING INFORMATION

Bad connection. x x Plug in pump.

Blown fuse. x Turn on circuit breaker or replace fuse.

Bad battery. x Replace battery.

Pump impeller obstructed. x x Pull pump and clean.

Pump control switch. x x Replace switch.

Low battery. x When power is restored, the charger will charge the battery.

Check valve installed backwards. x x Check flow indication arrow on check valve body to ensure it is installed properly.

Low voltage, speed to slow. x x Check for proper supply voltage to make certain it corresponds to name plate voltage.

Impeller or discharge pipe is clogged. x x Pull pump and clean. Check pipe for scale or corrosion.

No check valve in long discharge pipe

allowing liquid to drain back into sump.

Check valve leaking. x x Inspect check valve for correct operation.

Sump pit too small for inflow. x x Install larger sump pit.

Defective battery. x Replace battery.

Pump control switch. x x Replace switch.

Plugged vent tube. x Clear vent tube of any obstruction.

Dirt or sediment lodged between retainer

ring and rubber diaphragm causing

contacts to remain closed.

Pump is air locked. x x

Liquid inflow matches pump capacity. x x Larger pump required.

Check valve installed backwards. x x Check flow indicating arrow on check valve body to ensure it is installed properly.

Check valve stuck or plugged x x Remove check valve and inspect for proper operation.

Lift too high for pump. x x Check pump performance as compared to the vertical distance needed to evacuate the sump water.

Inlet to impeller plugged. x x Pull pump and clean.

Pump is air locked. x x

x x Install a check valve in discharge line.

x Clean area around rubber diaphragm.

Shut power o for approximately 1 minute, then restart. Repeat several times to clear air from pump. If

system includes a check valve, a 3/16" hole should be drilled in the discharge pipe between the pump

discharge and the check valve.

Shut power o for approximately 1 minute, then restart. Repeat several times to clear air from pump. If

system includes a check valve, a 3/16" hole should be drilled in the discharge pipe between the pump

discharge and the check valve.

14

LIMITED WARRANTY

THIS WARRANTY SETS FORTH THE COMPANY’S SOLE OBLIGATION AND PURCHASER’S EXCLUSIVE REMEDY FOR DEFECTIVE PRODUCT.

The Red Lion brand (hereafter “the Brand”) warrants that the products accompanied by this warranty are free from defects in materials or workmanship of the Brand that exist at the time of sale by

the Brand and which occur or exist within the applicable warranty period. Any distributor, sub-distributor, recipient, end-user and/or consumer agrees that by accepting the receipt of the products,

the distributor, sub-distributor, recipient, end user and/or consumer expressly agree to be bound by the terms of the warranty set forth herein.

I. Applicable Warranty Period

The products accompanied by this warranty shall be covered by this Limited Warranty for a period of 24 months from the date of original purchase by the consumer. In the absence of suitable

proof of purchase date, the warranty period of this product will begin to run on the product’s date of manufacture.

II. Instructions Applicable to this Limited Warranty

1. Consumers wishing to submit a warranty claim must return the products accompanied by this warranty to the point of purchase for warranty consideration.

2. Upon discovery of a defect, any personal injury, property damage or any other type of resulting damage, if applicable, shall be reasonably mitigated to the extent possible.

3. At its discretion, the Brand may inspect products either at its facilities or in the field, and after determination of a warranty claim, will, at its option, repair or replace defective parts.

Repaired or replaced parts will be returned freight prepaid by the Brand.

4. This warranty policy does not cover any labor or shipping charges. The Brand shall not be liable for any costs or charges attributable to any product testing, maintenance, installation, repair or

removal, or for any tools, supplies, or equipment needed to install, repair, or remove any product.

III. Limitations Applicable to this Limited Warranty

THIS WARRANTY DOES NOT APPLY TO ANY OF THE FOLLOWING:

1. Any product that is not installed, applied, maintained, and used in accordance with the Brand’s published instructions, applicable codes, applicable ordinances and/or with generally

accepted industry standards.

2. Any product that has been subject to misuse, misapplication, neglect, alteration, accident, abuse, tampering, acts of God (including lightning), acts of terrorism, acts of war, fire, improper

storage or installation, improper use, improper maintenance or repair, damage or casualty, or to an excess of the recommended maximums as set forth in the product instructions.

3. Any product that is operated with any accessory, equipment, component, or part not specifically approved by the Brand.

4. Use of replacement parts not sold by the Brand, the unauthorized addition of non-Brand products to other Brand products, and the unauthorized alteration of Brand products.

5. Products damaged by normal wear and tear, normal maintenance services and the parts used in connection with such service, or any other conditions beyond the control of the Brand.

6. Any product that has been used for purposes other than those for which it was designed and manufactured.

7. Any use of the product where installation instructions and/or instructions for use were not followed.

The Brand reserves the right at any time, and from time to time, to make changes in the design and/or improvements upon its product without thereby imposing any obligation upon itself to make

corresponding changes or improvements in or upon its products already manufactured and/or previously sold. The Brand further reserves the right to substitute parts or components of substantially

equal quality in any warranty service required by operation of this Limited Warranty.

This written Limited Warranty is the entire warranty authorized and oered by the Brand. There are no warranties or representations beyond those expressed in this document.

THIS WARRANTY AND REMEDY IS IN LIEU OF ALL OTHER WARRANTIES AND REMEDIES INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE,

WHICH ARE HEREBY SPECIFICALLY DISCLAIMED AND EXPRESSLY EXCLUDED. CORRECTION OF NON-CONFORMITIES, IN THE MANNER AND FOR THE PERIOD OF TIME AS SET FORTH ABOVE, SHALL CONSTITUTE

FULFILLMENT OF ALL LIABILITY OF THE BRAND TO THE PURCHASER WHETHER BASED ON CONTRACT, NEGLIGENCE, OR OTHERWISE.

THE BRAND SHALL NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES SUCH AS, BUT NOT LIMITED TO:

DAMAGE TO OR LOSS OF OTHER PROPERTY OR EQUIPMENT, LOSS OF USE OF EQUIPMENT, FACILITIES OR SERVICE, LOSS OF PROFIT OR SALES, COST OF PURCHASES OR REPLACEMENT GOODS, CLAIMS OF

CUSTOMERS OF THE PURCHASER, FAILURE TO WARN AND/OR INSTRUCT, LOSS OF OTHER PRODUCTS, OR COSTS OF ENVIRONMENTAL REMEDIATION, OR DIMINUTION IN PROPERTY VALUE. THE REMEDIES OF

THE PURCHASER SET FORTH HEREIN ARE EXCLUSIVE, AND THE LIABILITY OF THE BRAND SHALL NOT, EXCEPT AS EXPRESSLY PROVIDED HEREIN, EXCEED THE PRICE OF THE PRODUCTS UPON WHICH SUCH

LIABILITY IS BASED. DAMAGES AS SET FORTH IN THIS PARAGRAPH SHALL BE REASONABLY MITIGATED TO THE EXTENT POSSIBLE. THIS PARAGRAPH SHALL ALSO APPLY TO ALL DAMAGES RESULTING FROM

CONDITIONS SET FORTH IN SECTION III ABOVE AND (1) DEFECTS IN PRODUCT PROTOTYPES OR REPLACEMENT PART PROTOTYPES THAT HAVE NOT BEEN PUT INTO PRODUCTION, CIRCULATED AND SOLD BY

THE BRAND, AND/OR (2) DEFECTS THAT WERE NOT FOUND AT THE TIME OF SALE DUE TO SCIENTIFIC AND TECHNOLOGICAL REASONS.

This Limited Warranty gives you specific legal rights. You may have other rights, which vary according to the applicable laws and regulations. Where any term of this warranty is prohibited by such

laws, it shall be null and void, but the remainder of this warranty shall remain in full force and eect.

DISCLAIMER: Any oral statements about the product made by the seller, the Brand, the representatives or any other parties, do not constitute warranties, shall not be relied upon by the user,

and are not part of the contract for sale. Seller’s and the Brand’s only obligation, and buyer’s only remedy, shall be the replacement and/or repair by the Brand of the product as described above.

Before using, the user shall determine the suitability of the product for his intended use, and user assumes all risk and liability whatsoever in connection therewith.

15

Loading...

Loading...