red lion RL-SP25T, RL-SP33T, RL-SP50V, RL-SP50T, RL-SP33V Owner's Manual

THERMOPLASTIC SUMP PUMPS

Owner’s Manual

Table of Contents

SAFETY INSTRUCTIONS - - - - - - - 2

Product Description - - - - - - - - - 4

Models - - - - - - - - - - - - - - - 4

Flow Rates - - - - - - - - - - - - - 4

Specifications - - - - - - - - - - - 4

Installation - - - - - - - - - - - - - - 5

Physical Installation - - - - - - - - 5

Electrical Connections - - - - - - - 7

Operation Testing - - - - - - - - - - 8

Maintenance - - - - - - - - - - - - - 9

Periodic Service - - - - - - - - - - 9

Troubleshooting - - - - - - - - - - 10

Replacement Parts - - - - - - - - - 11

Limited Warranty - - - - - - - - - - 12

redlionproducts.com

SAFETY INSTRUCTIONS

Hazard Messages

SAFETY INSTRUCTIONS

Hazard Messages

This manual includes safety precautions and other important

information in the following formats:

Indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in minor or

moderate personal injury.

Indicates a potentially hazardous situation

which, if not avoided could result in damage to

equipment or other property.

IMPORTANT: Identifies information that controls correct assem-

bly and operation of the product.

NOTE: Identifies helpful or clarifying information.

This symbol alerts the user to the presence of dangerous

voltage inside the product that might cause harm or electrical shock.

Before Getting Started

This equipment should be installed and serviced by technically

qualified personnel who are familiar with the correct selection

and use of appropriate tools, equipment, and procedures. Failure

to comply with national and local electrical and plumbing codes

and within Red Lion recommendations may result in electrical

shock or fire hazard, unsatisfactory performance, or equipment

failure.

Know the product’s application, limitations, and potential hazards. Read and follow instructions carefully to avoid injury and

operty damage. Do not disassemble or repair unit unless

pr

described in this manual.

Refer to product data plate(s) for additional precautions, operating instructions, and specifications.

Failure to follow installation or operation procedures and all

applicable codes may result in the following hazards:

Risk of death, personal injury, or

property damage due to explosion, fire,

or electric shock.

• Do not use to pump flammable or explosive fluids such as

gasoline, fuel oil, kerosene, etc.

• Do not use in explosive atmospheres or hazardous locations as classified by the NEC, ANSI/NFPA70.

• Do not handle a pump or pump motor with wet hands or

when standing on a wet or damp surface, or in water.

• When a pump is in its application, do not touch the motor,

pipes, or water until the unit is unplugged or electrically

disconnected.

2

This symbol alerts the user to the presence of hot surfaces that might cause fire or personal injury.

SAFETY INSTRUCTIONS

Before Getting Started

High voltages capable of causing severe

injury or death by electrical shock are

present in this unit.

• To reduce risk of electrical shock, disconnect power before

working on or around the system. More than one disconnect switch may be required to de-energize the equipment

before servicing.

• Be certain that this pump is connected to a circuit

equipped with a ground fault circuit interrupter (GFCI)

device if required by code.

• Wire pump system for correct voltages.

• The pump has been evaluated for use with water only.

Pump should only be used with liquids compatible with

pump component materials. If the pump is used with liquids incompatible with the pump components, the liquid

can cause failure to the electrical insulation system resulting in electrical shock.

Risk of damage to pump or other equipment.

• Do not use this pump for pumping sea water, beverages,

acids, chemical solutions, or any other liquid that promotes corrosion as this can result in damage to the pump.

• Do not run pump dry. For optimal cooling and to prolong

the motor life, the liquid level being pumped should normally be above the top of the pump housing.

• This pump is not suitable for pond applications.

Risk of bodily injury, electric shock,

or property damage.

• This equipment must not be used by children or persons

with reduced physical, sensory, or mental abilities, or lacking in experience and expertise, unless supervised or

instructed. Children may not use the equipment, nor may

they play with the unit or in the immediate vicinity.

• Do not use this pump for pumping any liquid intended for

human consumption.

• Equipment can start automatically. Always unplug the

pump power cord and disconnect the electrical power

before servicing the pump or switch. Lockout-Tagout

before servicing equipment.

• An inoperative or malfunctioning pump could lead to

flooding, resulting in personal injury or property damage.

• In applications where property damage and/or personal

injury might result from an inoperative or leaking pump

due to power outages, discharge line blockage, or any

other reason, an automatic back-up system and/or an

alarm should be installed.

• Do not run the pump dry. If run dry, the surface temperature of the pump will rise to a high temperature that could

cause skin burns if touched, and will cause serious damage to the pump.

• Do not oil the motor. The pump’s motor housing is sealed,

and contains a high-grade dielectric oil for heat transfer

and lifetime lubrication. Use of other oils could cause serious electric shock and/or permanent damage to the

pump.

• Operation of this equipment requires detailed installation

and operation instructions provided in this manual for use

with this product.

• Read entire manual before starting installation and operation.

• End User should receive and retain manual for future use.

• Keep safety labels clean and in good condition.

• Keep work area clean, well-lit, and uncluttered.

• Wear safety glasses while installing or performing maintenance on the pump.

• Do not wear loose clothing, jewelry, or anything that may

be caught in the rotating parts. Tie up long hair and

remove jewelry.

3

PRODUCT DESCRIPTION

Models

PRODUCT DESCRIPTION

This submersible pump is for use in basins or lift stations and is suitable for pumping clear water and other

non-explosive, non-corrosive liquids. Do not use the pump in applications where sewage or any other debris

(gravel, sand, floating debris, etc.), abrasives, or corrosives are present.

These products have been carefully tested, inspected, and packaged to ensure safe delivery and operation.

Please examine your pump carefully to ensure that no damage occurred during shipment. If damage has

occurred, please contact the place of purchase. They will assist you in replacement or repair, if required.

The pump motor is equipped with an automatic resetting thermal protector, and may restart unexpectedly.

Thermal Protector tripping is an indication of motor overloading or overheating, which can be caused by

application issues such as an obstructed pump impeller, float stuck in the ON position, pump running dry,

pump air-locked, pump short cycling, excessively high or low voltage supply, or possibly a pump, motor,

bearings, or seal that have reached the end of their useful life.

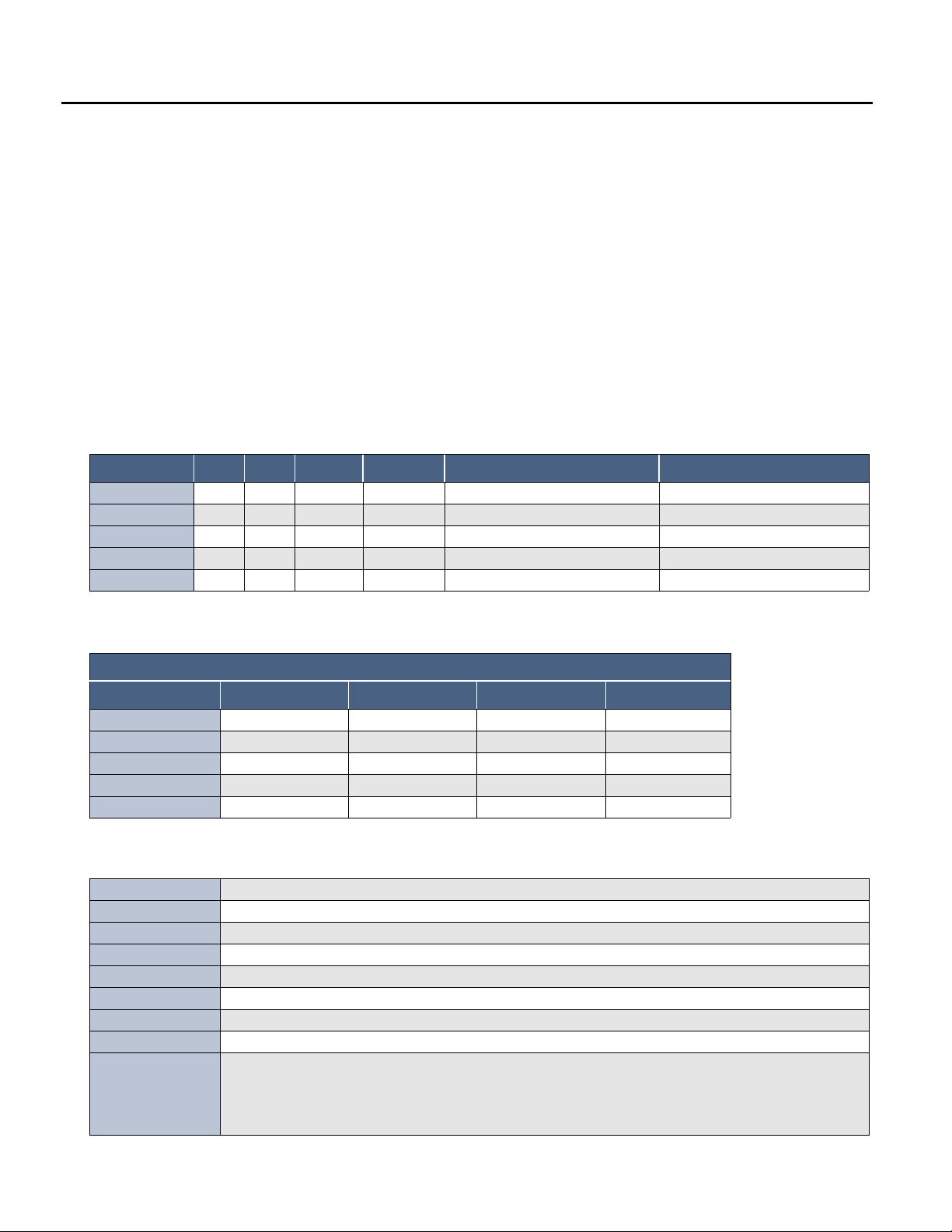

Models

Model HP Amps Voltage Float Type On/Off Levels Minimum Basin Diameter

RL-SP25T 1/4 6 115 Tethered 14.5” (368 mm)/5.5” (140 mm) 14” (356 mm)

RL-SP33T 1/3 4.4 115 Tethered 14.5” (368 mm)/5.5” (140 mm) 14” (356 mm)

RL-SP33V 1/3 4.4 115 Vertical 7.25” (184 mm)/2.75” (70 mm) 11” (279 mm)

RL-SP50T 1/2 5 115 Tethered 14” (356 mm)/6” (152 mm) 14” (356 mm)

RL-SP50V 1/2 5 115 Vertical 7.25” (184 mm)/2.75” (70 mm) 11” (279 mm)

Flow Rates

Gallons/Liters per Hour

At Height: (Head) 5 ft (1.5 m) 10 ft (3 m) 15 ft (4.5 m) Shut Off

RL-SP25T 2640 / 9993 2100 / 7949 1560 / 5905 23 ft (7 m)

RL-SP33T 2880 / 10,902 2340 / 8858 1680 / 6359 25 ft (7.6 m)

RL-SP33V 2880 / 10,902 2340 / 8858 1680 / 6359 25 ft (7.6 m)

RL-SP50T 3060 / 11,583 2520 / 9539 1920 / 7268 28 ft (8.5 m)

RL-SP50V 3060 / 11,583 2520 /9539 1920 / 7268 28 ft (8.5 m)

Specifications

Discharge Size 1-1/2" FNPT

Intake Size 1/8" (3.2 mm) screened opening

Pump Housing Thermoplastic (including volute and screen)

Impeller Vortex design

Motor Single phase PSC with automatic reset thermal overload protection

Hardware 300 series stainless steel

Bearings Ball bearings

Pump Shaft Seal Mechanical, spring-loaded, stationary carbon with Nitrile boot and rotating ceramic seat

The motor housing contains oil to cool the motor and to lubricate the bearings and seals. These pumps can

Cooling

be operated with the motor housing partially exposed for extended periods of time. However, for the best

cooling and longest motor life, the liquid level being pumped should normally be above the top of the

pump housing.

4

INSTALLATION

Physical Installation

Risk of severe injury or death by electrical shock.

• Always disconnect the electrical power before touching the pump or discharge.

• Check local electrical and building codes before installation. The installation must be in accordance

with their regulations as well as the most recent National Electrical Code (NEC).

1. Pump must be installed in a suitable basin that is at least 18” (457 mm) deep, and in accordance with

local plumbing codes. Refer to

2. Clean any debris from the basin and set the pump in the center of the basin (refer to “Typical Installa-

tion” on page 6).

3. The pump must be placed on a hard, level surface. Never place the pump directly on clay, earth or

gravel surfaces. These surfaces contain small stones, gravel, sand etc. that may clog or damage the

pump and cause pump failure.

4. Do not attempt to restrict the intake side of these pumps. Restricting the intake may cause damage to

the seal and may starve the pump. If you require reduced flow rates, place a valve on the discharge side

of the pump. Or, if flexible vinyl tubing is used, a clamp can be used on the tubing to restrict the flow.

5. Connect discharge piping. Use pipe joint compound at all connections. Sump pumps can be piped to

discharge into the house drainage system, to a dry well, splash block, or to a storm drain, depending on

local plumbing codes. The discharge pipe should be as short as possible and contain as few elbows as

possible. The discharge pipe should be the same diameter, or larger than, the pump discharge size. A

smaller pipe will restrict capacity and reduce pump performance. The pump comes with a 1-1/2" FNPT

discharge and a 1-1/4” FNPT reducing bushing.

• Support the pump and piping while assembling and when installed. Failure to do so may cause the

piping to break, the pump to fail, motor bearing failures, etc.

• Always install a union in the discharge line just above the basin cover to allow for easy removal of

the pump for cleaning or repair.

6. A full flow check valve must be used in the discharge line to prevent back-flow of liquid into the basin.

A missing, improperly installed, or malfunctioning check valve can cause a pump to short-cycle due to

back-flow of the pumped fluid from the discharge plumbing back into the basin, significantly shorten

ing the life of the pump.

“Models” on page 4 for minimum basin diameters.

INSTALLATION

Physical Installation

-

Risk of property damage due to flooding.

• When a check valve is used, drill a relief hole 1/8 – 3/16" (3.2 – 4.8 mm) in diameter in the discharge

pipe. This hole should be located below the floor line between the pump discharge and the check

valve. Unless such a relief hole is provided, the pump could “air lock” and will not pump water even

though it will run.

7. Tape the pump and switch cords to the discharge pipe with electrical tape to keep the power cords

securely routed away from the pump inlet and any control floats.

8. Connect the pump to an appropriate power supply following the instructions in “Electrical Connec-

tions” on page 7.

5

Loading...

Loading...