Page 1

OWNER'S

SUBMERSIBLE

MANUAL

SAFETY WARNINGS

BEFORE OPERATING OR

INSTALLING THIS PUMP,

READ THIS MANUAL AND

FOLLOW ALL SAFETY

RULES AND OPERATING

INSTRUCTIONS.

SAFETY

CAUTION

• Review instructions before operating.

CAREFULLY READ THESE SAFETY

MESSAGES IN THIS MANUAL AND ON

PUMP.

UTILITY PUMP

RL160U

WARNING - ELECTRICAL PRECAUTIONS

All wiring, electrical connections, and system grounding must comply with the National Electrical Code

(NEC) and with any local codes and ordinances. Employ a licensed electrician.

WARNING - RISK OF ELECTRICAL SHOCK

• Have an electrician provide electrical power to the

motor plug receptacle.

• Always disconnect plug from power source before

handling.

• This product is furnished with a three prong plug for

grounding, connect only to properly grounded receptacle.

APPLICATION

This pump is suitable for portable applications where

the total head requirement (including pipe friction

losses) does not exceed the pump's maximum capability. Also, the maximum solids size must not be greater

RL160U

• Do not under any circumstances remove ground plug.

• Keep electric plug dry.

• Do not lift pump using cord.

• Not investigated for use in swimming pool area.

• A ground fault interrupter (GFI) protected circuit is

recommended for use with any electrical appliance

operating in or near water.

than the pump capability. This pump is for use with

water only, NOT FOR USE IN EFFLUENT OR SEWAGE APPLICATIONS!

200567e 0902

PRINTED IN

TAIWAN

Page 2

INSTALLATION

Before installation, check your local electrical and

plumbing codes. These regulations are for your safety.

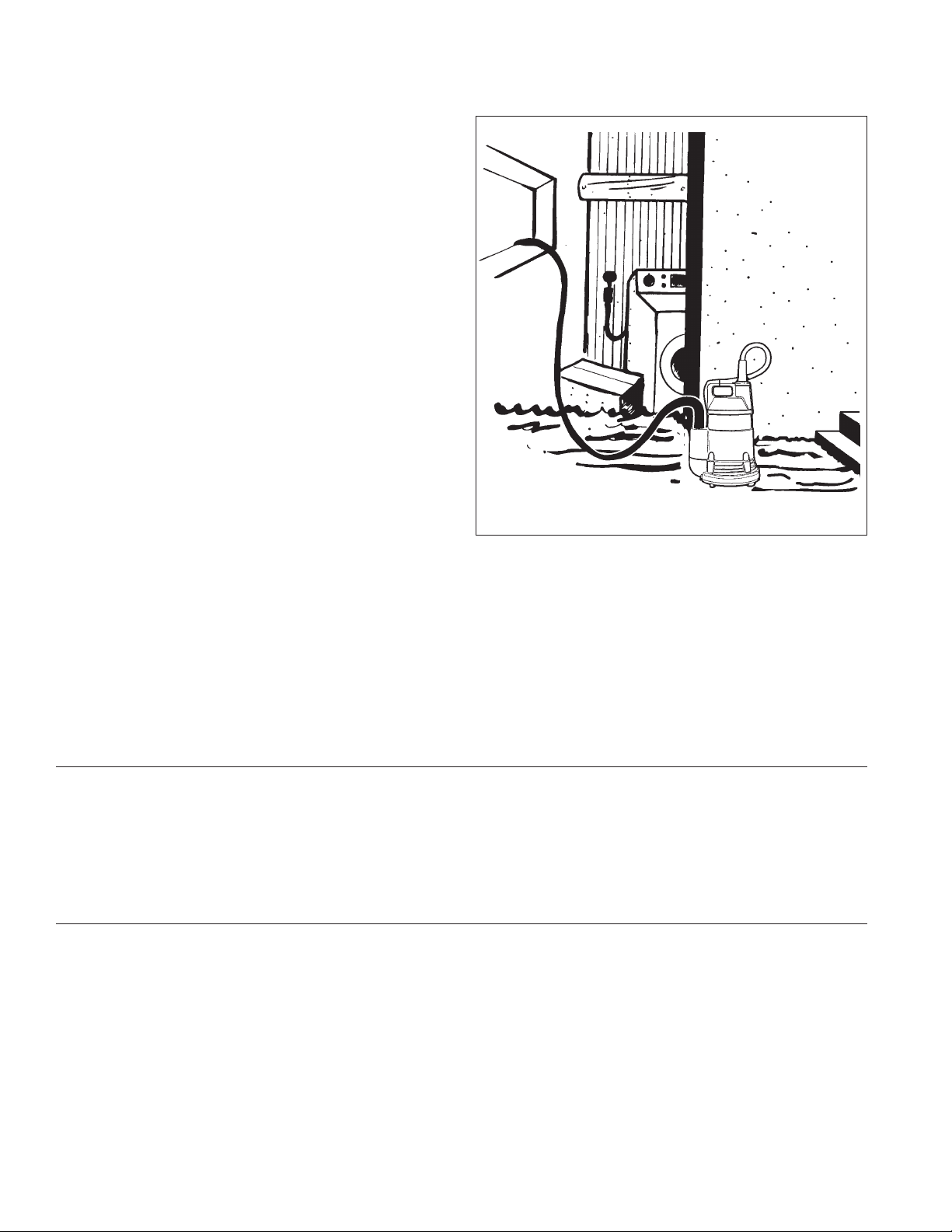

1) Location:

The pump should be located on a solid level foundation.

a) Do not suspend pump from electrical cord.

b) Do not suspend pump from discharge pipe.

c) Keep pump inlet screen clear.

2)

WARNING

- RISK OF ELECTRICAL SHOCK

All connections must be made into a grounded outlet.

A ground fault interrupter (GFI) protected circuit is

recommended for use with any electrical appliance

operating in or near water.

The electrical power outlet required for this pump is a

separate 15 amp circuit of 115 volts, AC 60HZ, with a

proper fused switch in the line. This must be located

within 8 feet of the pump. The ground terminal on the

plug is provided for your protection. Do not remove.

Plug the pump cord into the 115 volt grounded service

and connect the discharge piping, your pump is then

ready for operation.

3) Discharge Piping - Rigid Pipe:

a) The pump has a threaded discharge opening.

b) PVC or ABS adapters may be used to adapt to

other sizes of pipe.

c) We recommend that you not reduce the discharge

pipe size, use as large as possible.

d) Keep piping length to a minimum (extra length

increases friction losses).

FIG.1 TYPICAL INSTALLATION

4) Discharge Piping - Garden Hose:

a) Thread garden hose adapter into pump. Note: Fine

threads go into pump, coarse threads are for garden hose.

b) Attach garden hose, shorter hose lengths will allow

better flow from the pump.

AIR LOCKING

If the pump is placed into the water while running, it will

air lock. This means that air is trapped in the pump,

preventing it from pumping water. To avoid this, always

MAINTENANCE

Your pump has been built to give many years of

satisfactory service. No regular maintenance is required since the pump is completely self lubricating.

The following routine checking procedure is recommended to be carried out once a year and is especially

important for occasional use applications.

place the pump in the water when it is off, and then plug

it in. If the pump does air lock, simply unplug it and then

plug it back in.

a) Check the power cords and electrical outlet for

damage or corrosion.

2

Page 3

TROUBLE SHOOTING GUIDE

Trouble Probable Cause Corrective Action

Motor does not run Blown fuse Replace fuse

Tripped circuit Reset

Disconnected plug Reinstall

Corroded plug Clean prongs

Tripped overload Allow pump to cool, investigate cause (jammed

impeller)

Defective switch Replace switch

Defective motor Replace pump/repair

Float-improper position Check for freedom of movement

Motor hums but flow Impeller jammed Remove bottom plate and clean.

reduced or none at all Plugged check valve Remove valve, clean or replace

Partially blocked inlet Clean inlet

Line leak Repair

Worn impeller Replace pump/repair

Defective motor Replace pump/repair

SAFETY TIPS (ELECTRICAL)

1) Never make adjustments with the power connected.

Always disconnect your pump from the electrical outlet

before beginning any service procedures.

2) Do not stand on wet floor when servicing.

Red Lion

P.O. Box 429

Winnipeg, MB

R3C 3E4

Pump Hotline (1-800-667-1457)

www.redlionproducts.com

3) Do not put your finger into the fuse socket - it could be

fatal.

4) Never remove the round pin from your plug; this is the

ground and is there for your safety.

Canada

LIMITED RED LION WARRANTY

For 1 year from date of purchase, Red Lion will replace or repair for the original purchaser, free of charge, any part or parts,

found upon examination by any Red Lion Authorized Service Depot or by the Red Lion factory, to be defective in material or

workmanship or both. Equipment and accessories not manufactured by Red Lion are warranted only to the extent of the

original manufacturer's warranty. All transportation charges on parts submitted for replacement or repair under this warranty

must be borne by the purchaser. For warranty service see your nearest Red Lion Authorized Service Depot. THERE IS NO

OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE ARE LIMITED TO 1 YEAR FROM PURCHASE AND TO THE EXTENT PERMITTED BY LAW.

LIABILITY FOR CONSEQUENTIAL DAMAGES UNDER ANY AND ALL WARRANTIES ARE EXCLUDED TO THE EXTENT

EXCLUSION IS PERMITTED BY LAW.

This warranty is an addition to any statutory warranty.

3

Loading...

Loading...