red lion RJS-PREM Series, RJS-50-PREM, RJS-75-PREM, RJS-100-PREM Owner's Manual

THIS PUMP IS DUAL VOLTAGE AND FACTORY SET FOR 230 VOLTS.

SEE VOLTAGE SETTING INSTRUCTIONS TO SET FOR 115 VOLTS.

redlionproducts.com

ENGLISHEN

PREMIUM SHALLOW

WELL JET PUMP

RJS-PREM Series

Owner’s Manual

Table of Contents

Before Getting Started .................................................................2

Installation Checklist..................................................................... 3

Introduction ...................................................................................4

Voltage Setting Instructions ........................................................4

Materials and Tools Needed ......................................................... 5

Important Information ................................................................. 5

Quick Installation Guide ............................................................... 6

Plug Descriptions and Socket Sizes .............................................6

Detailed Installation Instructions ................................................ 7

Typical Installations ......................................................................9

Pump to Tank Installation ...........................................................10

Wiring Instructions .......................................................................11

Priming the Pump ....................................................................... 12

Maintenance .................................................................................13

Troubleshooting ...........................................................................14

Replacement Parts ......................................................................15

Limited Warranty .........................................................................16

BEFORE GETTING STARTED

Read and follow safety instructions. Refer to product data plate(s) for additional operating instructions and specifications.

This is the safety alert symbol. When you see this symbol on your pump or in this manual, look for one of the following signal words and be

alert to the potential for personal injury or property damage if ignored:

!

s DANGER

warns about hazards that will cause serious personal injury, death or major property damage if ignored.

!

s WARNING

!

s CAUTION

!

s NOTICE

in this manual and on pump.

BEFORE OPERATING OR INSTALLING THIS PUMP, READ THIS MANUAL AND FOLLOW ALL SAFETY RULES AND OPERATING INSTRUCTIONS.

!

s WARNING

!

s WARNING

National Electrical Code (NEC) and with any local codes and ordinances. Employ a licensed electrician.

warns about hazards that can cause serious personal injury, death or major property damage if ignored.

warns about hazards that will or can cause minor personal injury or major property damage if ignored.

indicates special instructions which are important but not related to hazards. Carefully read and follow all safety instructions

WARNING

READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

ELECTRICAL PRECAUTIONS - All wiring, electrical connections, and system grounding must comply with the

WARNING

!

s WARNING

!

s NOTICE

!

s WARNING

• Have an electrician provide electrical power to motor.

• We recommend that a separate circuit be lead from the home electrical distribution panel, properly protected with a fuse

or a circuit breaker.

• A ground fault interrupter (GFI) protected circuit is also recommended for use with any electrical device operating near water.

• For recommended cable size see Table 2.

• Motor must be grounded and terminal cover in place to reduce electrical shock hazard.

• Keep motor operating area as dry as possible.

• Always disconnect power before servicing.

• Not investigated for use in swimming pool areas.

!

s WARNING

This pump is capable of producing high pressure. Installing a 75 psi pressure relief valve is highly recommended.

FOR DUAL VOLTAGE MOTORS (115/230 V) - Voltage change instructions are located in this manual.

The motor voltage is factory set at 230 V.

RISK OF ELECTRIC SHOCK

75 PSI PRESSURE RELIEF VALVE RECOMMENDED

2

INSTALLATION CHECKLIST

This checklist has been provided for your convenience. If a step was missed, ensure power has been shut o at the breaker

and completely relieve pressure from the water system before continuing to work on the system.

!

s WARNING

This pump is capable of producing high pressure. Installing a 75 psi pressure relief valve is highly recommended.

Model #: ________________

Serial #: _________________

Date purchased: ____________

Location purchased: ________________________________________________

KEEP THIS MANUAL ACCESSIBLE FOR FUTURE REFERENCE.

75 PSI PRESSURE RELIEF VALVE RECOMMENDED

✓

Description

Voltage setting on pump verified and set to match voltage on the circuit breaker

Foot valve (for drilled wells) or check valve (for driven wells) installed

Wiring and electrical connected by licensed electrician

Pump intake connected to piping in well

Well seal in place

Pump discharge connected to tank and service line

Tank pressure checked and charged to 28 psi

All joints sealed with PVC cement, PTFE tape or heat and clamps

All connections checked for leaks

Pressure relief valve installed

All other accessories installed: drain cock, shut-o valve, pressure gauge (optional)

Breaker turned on

Pump primed

Model number and serial number recorded in this manual

Receipt stapled to manual

3

INTRODUCTION

L2

L1

115230

L2

L1

115 230

L2

L1

115230

The shallow well jet pump is ideal for the supply of fresh water to rural

homes, farms, and cabins. This pump is suitable for installations where the

vertical distance from the pump to the water level does not exceed 25 ft

(7.6 m), including drawdown (less at high altitudes). In oset installation,

friction losses in the suction pipe must be taken into consideration

(refer to Table 1, Friction Loss).

This instruction sheet provides you with the information required to

safely own and operate your product. Retain these instructions for

future reference.

The product you have purchased is of the highest quality workmanship and

material, and has been engineered to give you long and reliable service.

This product has been carefully tested, inspected, and packaged to ensure

safe delivery and operation. Please examine your item(s) carefully to

ensure that no damage occurred during shipment. If damage has occurred,

please contact the place of purchase. They will assist you in replacement or

repair, if required.

Orange

L1

115 230

Brown

Voltage Change Device

L2

Terminal

Board

#1

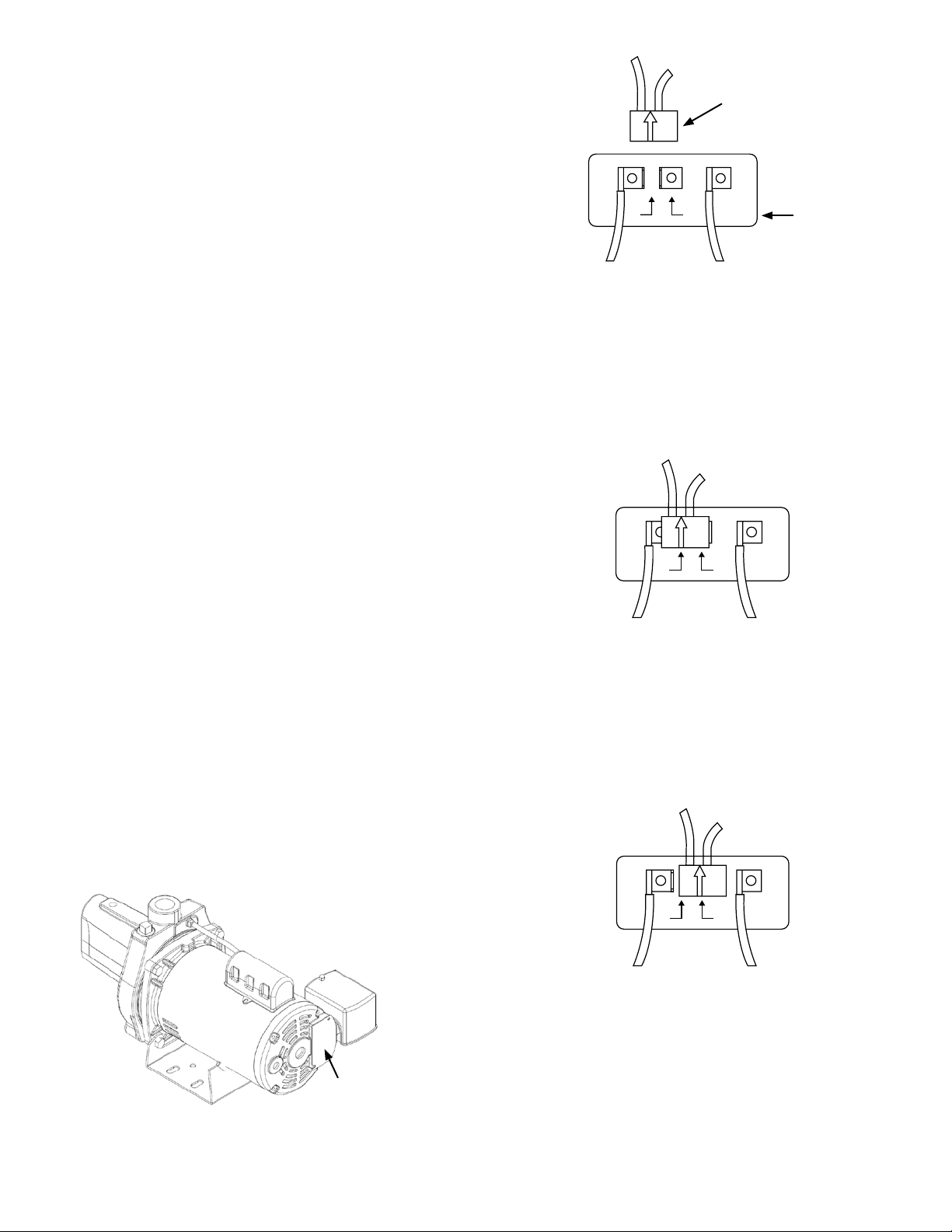

In #1, the motor's switch is shown before the black voltage change device is

pressed down onto the voltage terminals.

NOTE: DO NOT MOVE WHITE LEAD WIRES ON L1 & L2.

Orange Brown

READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO INSTALL,

OPERATE OR SERVICE YOUR PRODUCT. KNOW THE PRODUCT’S APPLICATION,

LIMITATIONS, AND POTENTIAL HAZARDS. PROTECT YOURSELF AND OTHERS

BY OBSERVING ALL SAFETY INFORMATION. FAILURE TO COMPLY WITH

THESE INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR

PROPERTY DAMAGE!

VOLTAGE SETTING INSTRUCTIONS

To change the pump voltage from the factory setting of 230 volts, a

qualified electrician should:

1. Disconnect the power supply to the pump.

2. Remove the cover from the motor terminal box.

L1

115 230

L2

#2 (Set to 115 V)

In #2, the motor's switch is set for 115 V. The black voltage change device

is pressed down onto both terminals with the white arrow on the voltage

change device pointing directly to the 115 V arrow on the terminal board.

Orange Brown

L1

115230

L2

Motor Terminal Box Cover

#3 (Set to 230 V)

In #3, the motor's switch is set for 230 V. The black voltage change device is

pressed down onto only one terminal with the white arrow on the voltage

change device pointing directly to the 230 V arrow on the terminal board.

4

MATERIALS AND TOOLS NEEDED

IMPORTANT INFORMATION

MATERIALS NEEDED

Pipe Joints

• One roll of PTFE tape

• One can PVC primer

• One can PVC cement

• Steel clamps (optional)

Drilled Wells (driven well materials are listed separately)

• One 1-1/4" foot valve (not needed for driven wells)

• One 1-1/4" PVC pipe (to attach to foot valve; needed for shallow well only)

• Rigid 1-1/4" PVC pipe and couplings to reach from bottom of well to pump

• One 1-1/4" male PVC adapter (for discharge opening)

• Well seal with vent tube

• One 1-1/4" PVC 90° elbow (to join piping from well to pump)

• One 1-1/4" male galvanized adapter (for suction opening)

Driven Wells

• Well point (more than one may be needed)

• 1-1/4" galvanized pipe from bottom of well to top of well plus 1 ft (30 cm)

(if more than one well point is needed, additional piping and elbows will

be needed to join the well points together)

• One 1-1/4" galvanized 90° elbow

• One 1-1/4" galvanized nipple

• One 1-1/4" check valve

• One 1-1/4" male PVC adapter

• One 1-1/4" male galvanized adapter

• 1-1/4" PVC pipe measured from adapter connected to pump to check valve

• Restrictor valve (connected after the elbow on the pump discharge)

• Low pressure cut-o pressure switch (recommended)

JOINING PIPE FITTINGS

Follow the fitting guidelines below for all attachments unless

otherwise specified.

PVC PIPE FITTINGS

When joining two PVC joints together (such as joining an adapter to a

PVC pipe), always use PVC primer to clean both pieces. Apply the primer

to the inside of one joint and the outside of the other joint so the primed

areas meet. Select Method 1, 2 or 3 to ax the joints. When tightening PVC,

tighten securely, but do not overtighten or you could break the fitting.

Method 1 - PTFE tape: Wrap PTFE tape tightly around the male

threads. Start wrapping the threads at the end of the pipe, keeping

tension on the tape. Do not let the tape hang over the edge of the

adapter. Starting from the end, wrap in the direction of the threads

for the full length of the adapter. Overlap each wrap about 70%.

Method 2 - Using PVC cement: Apply PVC cement to the areas

that were just primed and join the two pieces together. Twist to

the right and back to the left to help embed the cement between

the pieces.

Method 3 - Using heat and clamps: Add two steel clamps to the

largest fitting before joining the fittings. Heat the largest fitting

with a heat gun (follow all safety instructions in the heat gun

manual). This will shrink the fitting, bonding it to the smaller

joint. Once the joint has cooled down, tighten the clamps with

a screwdriver.

Pump to Tank Installation

• One male PVC adapter (attached to tank) – the tank fitting size depends

on the system connect on the tank

• One tank tee – size should be the same as the adapter above

• One 1" PVC elbow

• PVC piping to fit from tank tee to the elbow on the pumps discharge

and to join the service line

• High pressure safety relief valve (attached to the tank tee)

• One 1/2" drain cock (attached to the tank tee)

TOOLS NEEDED

• Round file

• Pipe clamp

• Pipe wrench or crescent wrench

• Slotted screwdriver

• Cross-head screwdriver

• Hacksaw or reciprocating saw

• Heat gun (optional)

• 5/16" - 8 point socket and ratchet

• 9/16" - 8 point socket and ratchet

• Measuring tape

METAL PIPE FITTINGS

Use PTFE tape or thread compound to coat the threading.

CHECK TO ENSURE THE JOINTS ARE AIRTIGHT.

EVEN A PINHOLE CAN PREVENT PROPER OPERATION OF THE PUMP.

SUCTION AND PRESSURE PIPE

It is recommended that only new, clean 1-1/4" pipe or hose be used. If the

pump is installed any appreciable distance away from the source of water,

the suction pipe should be increased to 1-1/2". Horizontal lengths of pipe

must gradually slope upward from the source of water to the pump to

avoid air pockets in the line. Thread compound should be used on all pipe

joints and connections should be thoroughly tightened. A foot valve or

check valve must be installed and its operation should be checked, since

a leak will prevent proper operation of the system. Make sure the foot

valve is located so that it will be submerged at all times. If a sand point or

driven well is used, install a check valve next to the pump suction instead

of the foot valve (see Typical Installations, Figure 5). All installations must

have a foot valve or a check valve in the suction pipe.

5

Loading...

Loading...