Page 1

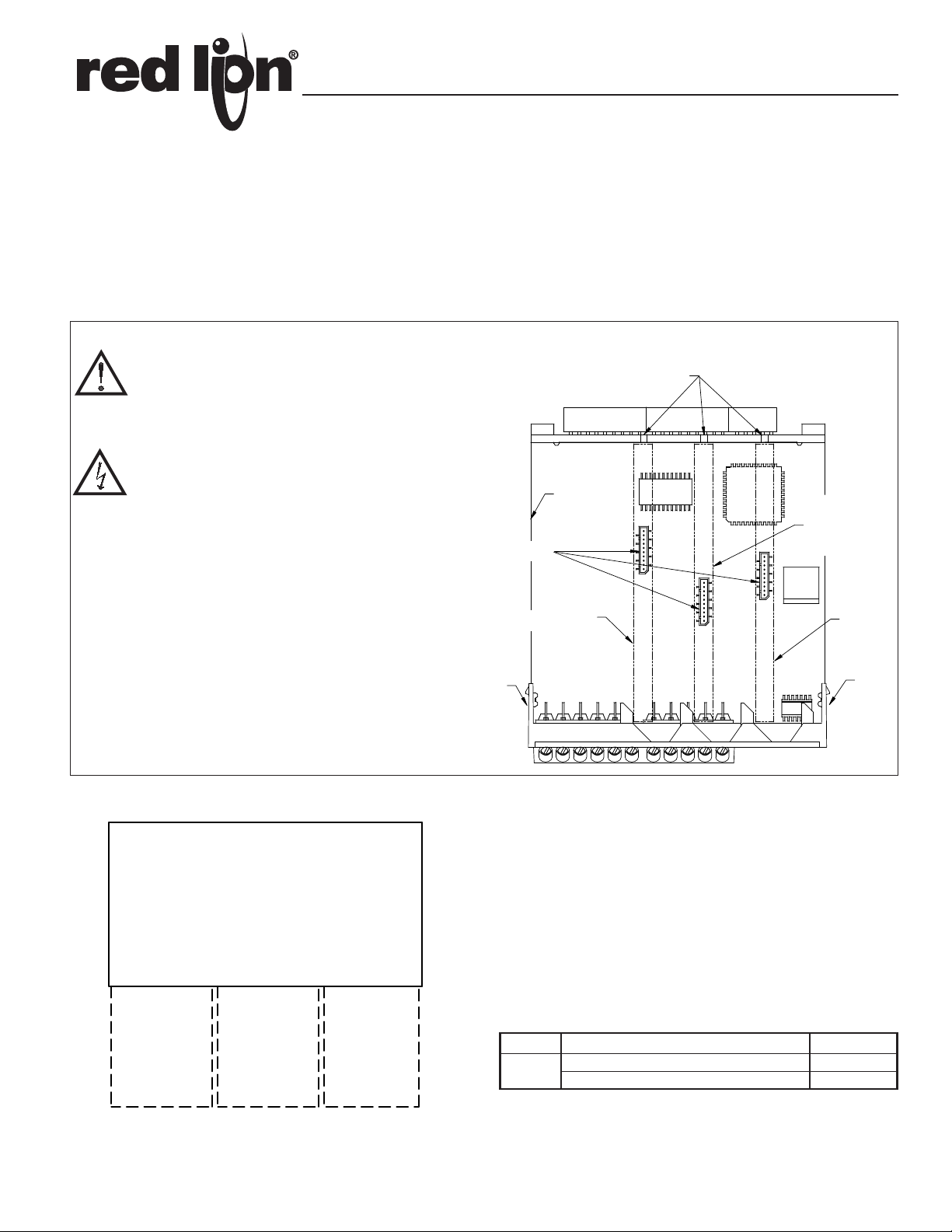

Finger

Hold

Finger

Hold

Serial

Communications

Card

Setpoint

Output

Card

Alignment

Slots

Connectors

Main

Circuit

Board

Analog Output

or

Real-Time

Clock Card

ANALOG

OUTPUT OR

REAL-TIME

CLOCK CARD

SETPOINT

OUTPUT

CARD

LABEL

SERIAL

OUTPUT

CARD

LABEL

MAIN

LABEL

LABEL

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

MODEL PAXCDC -MODBUS OUTPUT OPTION CARD

DESCRIPTION

This product bulletin covers the MODBUS Communication Card for the PAX

Meters. The card will allow the PAX Meter to transmit Display Values,

Setpoints and Reset Values via

and ASCII modes.

Bulletin No. PAXCDC4-F

Drawing No. LP0502

Released 09/09

MODBUS RS485 communication, in the RTU

INSTALLING AN OPTION CARD

Caution: The option and main circuit cards contain static

sensitive components. Before handling the cards, dischar ge static

charges from your body by touching a grounded bare metal

object. Ideally, handle the cards at a static controlled clean

workstation. Also, only handle the cards by the edges. Dirt, oil or

other contaminants that may contact the cards can adversely

affect circuit operation.

Warning: Exposed line voltage exists on the circuit boards.

Remove all power to the meter AND load circuits before

accessing the unit.

1. Remove the main assembly from the rear of the case. Squeeze the finger

holds on the rear cover, or use a small scewdriver to depress the side

latches to release it from the case. It is not necessary to separate the rear

cover from the main circuit card.

2. Locate the option card connector for the type of option card to be

installed. Hold the unit by the rear connector, not the display board, when

installing an option card.

3. Install the option card by aligning the option card connector with the slot

in the rear cover. The cards are keyed by position with different main

board connector locations. Be sure the connector is fully engaged and the

tab on the option card rests in the alignment slot on the display board.

4. Slide the assembly back into the case. Be sure the rear cover latches fully

into the case.

5. Apply the option card label to the bottom side of the meter. Do not cover

the vents on the top surface of the meter. The surface of the case must be

clean for the label to adhere properly. Apply the label to the area

designated by the large case label.

6. See manual for wiring connections and programming procedures.

TOP VIEW

MODBUS SPECIFICATIONS

1. Type: RS485; RTU and ASCII MODBUS modes

2. Isolation To Sensor & User Input Commons: 500 Vrms for 1 minute.

Working Voltage: 50 V. Not isolated from all other commons.

3. Baud Rates: 300 to 38400.

4. Data: 7/8 bits

5. Parity: No, Odd, or Even

6. Addresses: 1 to 247.

7. Transmit Delay: Programmable; See Transmit Delay explanation.

ORDERING INFORMATION

MODEL DESCRIPTION PART NUMBER

1

PAXCDC

PAX MODBUS Output Card

PAX MODBUS Output Card with RJ11 Connector

PAXCDC40

PAXCDC4C

Page 2

12

B(-)

33K

33K

+5V

Transmit

Enable

PAX METER

RECEIVING DEVICE

A

(+)

COMM. *

NC

*

OPTIONAL

13

14

15

RS485 COMMUNICATIONS

The RS485 communication standard allows the connection of up to 32

devices on a single pair of wires, distances up to 4,000 ft. and data rates as high

as 10M baud (the PAX is limited to 19.2k baud). The same pair of wires is used

to both transmit and receive data. RS485 is therefore always half-duplex, that

is, data cannot be received and transmitted simultaneously.

Transmit

Enable

Terminal Block Connection Figure

Not used

PAX CONNECTOR

Not used

COMM

B-

A+

3542

Extended Comms Connection Figure

PAX METER

+5V

33K

33K

Not used

RECEIVING DEVICE

12

(+)

13

COMM.

14

15

NC

OPTIONAL

SERIAL SET-UP DIP SWITCH OPERATION

Serial port configuration is accomplished through two banks of DIP switches

on the MODBUS card. The bank of 8 switches sets the Unit Address, the bank

of 7 switches sets the Serial port parameters (ASCII/RTU, 7/8 bits, Parity, and

Baud rate). Changes to the switch settings are only detected on power-up of the

unit. After changing a switch setting, power to the unit must be cycled for the

new switch setting to take effect.

BIT

(+128)

(+64)

(+32)

(+16)

(+8)

(+4)

(+2)

WEIGHTS

ON

12345678 1234567

Both unit address and serial set-up are set via DIP switches on the

option card. See the DIP switch setting table for more details on these

DIP switches.

For the Unit Address bank, the high order bit is switch 1, and the ON

position is a ‘1’, the OFF position is a ‘0’. Legal unit addresses are 1 to 247.

When a Unit Address of 0 is selected, the card responds to Unit Address 1.

When a Unit Address of 248 through 255 is selected, the card responds to Unit

Address 247.

(+1)

SERIAL SET-UPUNIT ADDRESS

MODBUS

For the serial bank, the following settings apply:

SWITCH SETTINGS AVAILABLE

5 Baud Rate

6 Baud Rate

7 Baud Rate

(See Baud Rate

Switch Selections)

BAUD RATE SWITCH SELECTIONS

5 6 7

38400:

19200:

9600:

4800:

2400:

1200:

ON ON ON

ON ON OFF

ON OFF ON

ON OFF OFF

OFF ON ON

OFF ON OFF

OFF OFF ON

600:

OFF OFF OFF

300:

FACTORY

SETTINGS

RTU1 OFF: ASCII ON: RTU

8 Bits2 OFF: 7 Bits ON: 8 Bits

No Parity3 OFF: None ON: Parity

OFF4 OFF: Even ON: Odd

9600

2

Page 3

MODBUS SUPPORTED FUNCTION CODES

COIL FUNCTIONS

FC01: Read Coils

FC05: Force Single Coil, FC15: Force Multiple Coils.

1. Valid coil addresses are 1-49.

2. Block starting point can not exceed coil 49.

HOLD REGISTER FUNCTIONS

FC03: Read Holding Registers.

FC06: Preset Single Register, FC16: Preset Multiple Registers.

1. Valid register address are 40001 – 40039, 40041, 40042, 41001 – 41010.

2. Up to 16 registers can be requested at one time.

3. Block starting point can not exceed the register boundaries.

4. Holding registers are a mirror of Input registers (FC04).

5. Unused registers will return a value of HEX <8000>.

6. If a register is implemented, but does not exist for a particular unit

configuration (such as SP3, SP4) a value of HEX <0000> will be returned.

7. Registers 41001 – 41010 contain the slave ID. See FC17.

8. Broadcast write is supported for FC06 & FC16. Register writes using address

“0” will be recognized by the MODBUS card, regardless of address DIP

switch setting.

PAX MANUAL MODE DESCRIPTION

(CSR) Control Status Register [40021]

The Control Status Register is used to directly control the meter’s outputs

(setpoints and analog output), or view the state of the setpoint outputs and the

status of the temperature sensor (PAXT only). The register is bit mapped with

each bit position within the register assigned to a particular control function. The

control functions are invoked by writing to each bit position. The bit position

definitions are:

bit 1: SP2 Output

bit 2: SP3 Output

bit 3: SP4 Output

bit 4: Manual Mode

0 = automatic mode

1 = manual mode

In Manual Mode, the setpoint outputs are defined by the values written to bits

b0, b1, b2, b3; and the analog output is defined by the value written to the AOR.

Internal control of these outputs is then overridden. In automatic mode, the

setpoint outputs can only be reset off.

0 = output off

1 = output on

bit 5: Always stays 0, even if 1 is sent.bit 0: SP1 Output

bit 6: Sensor Status (PAXT only)

0 = sensor normal

1 = sensor fail

bit 7: Always stays 0, even if 1 is sent.

OTHER SUPPORTED FUNCTIONS

FC04:

Returns the same values as FC03, except the register number starts with “3”

(Ex: Pax Input Hi is 30001)

FC08 – Fetch Comm. Event Counter.

The MODBUS response breaks down as follows:

“:010804”<TOT HI><TOT LO><GOOD HI><GOOD LO>XX<CR><LF>

The “TOT HI” and “TOT LO” values are the total number of messages that

were received, that started with the card’s address. The “GOOD HI” and

“GOOD LO” are “good” messages (correct address, parity, and checksum). The

values are reset on power up and every time the FC08 function is requested.

FC17 - Report Slave ID.

The following is sent upon FC17 request:

Unit Address, 17 (FC code), RLC-PAX(I or ?) 00?0, 0100 (for code version

1.00), 16 (number of read supported registers), 16 (number of write supported

registers), 00 (number of registers available for GUID/Scratch pad memory),

checksum of the string.

The following is the HEX of a PAXI (with unit address of 247):

:<F7><11><14><52><4C><43><2D><50><41><58><49><30><30><3F>

<30><01><00><00><10><00><10><00><00><XX><CR><LF>

XX is the LRC Checksum

(SOR) Setpoint Output Register [40038] (PAXI/DR/CK/TM)

This register is used to view or change the states of the setpoint outputs.

Reading from this register will show the present state of all the setpoint outputs.

A “0” in the setpoint location means the output is inactive and a “1” means the

output is active.

In Automatic Mode (See MMR Description), the meter controls the setpoint

output state. In Manual Mode, writing to this register will change the output

state. The bit position definitions are:

bit 0: SP1

bit 1: SP2

bit 2: SP3

bit 3: SP4

Examples:

1. Turn all outputs on:

Value to write to holding register 40038: 000Fh.

2. Turn outputs 1, 3 on:

Value to write to holding register 40038: 0005h.

3. Turn all outputs off:

Value to write to holding register 40038: 0000h.

0 = Output off

1 = Output on

(MMR) Auto/Manual Mode Register [40036] (PAXI/DR/CK/TM)

This register sets the controlling mode for the outputs. In Auto Mode (0) the

meter controls the setpoint output. In Manual Mode (1) the outputs are defined

by the registers SOR. When transferring from auto mode to manual mode, the

meter holds the last output value (until the register is changed by a write). Each

output may be independently changed to auto or manual. Select values to place

in manual mode by writing appropriate value to holding register 40036. The bit

position definitions are:

PAXI/PAXDR

bit 0: Analog Output

bit 1: SP4

bit 2: SP3

bit 3: SP2

bit 4: SP1

Examples:

1. Select manual mode for all outputs (PAX):

Value to write to holding register 40021: 0010h

2. Select manual mode for all outputs and AOR (PAXI, PAXDR):

Value to write to holding register 40036: 001Fh

0 = Auto Mode

1 = Manual Mode

PAXCK/PAXTM

bit 0: SP4

bit 1: SP3

bit 2: SP2

bit 3: SP1

0 = Auto Mode

1 = Manual Mode

(AOR) Analog Output Register (Not Applicable to P AXCK/TM)

The Analog Output Register controls the analog output of the meter. The

manual mode must first be engaged by setting bit 4 of the CSR (PAX) or bit 0

of the MMR (P AXI/DR). The range of values of this register is 0 to 4095, which

corresponds to 0 mA, 0 V and 20 mA, 10 V; respectively. If a value larger than

4095 is written to the AOR register, 4095 will be loaded. The table lists

correspondence of the output signal with the register value.

Register Value

0 0.0000.000

1 0.00250.005

2047 5.00010.000

4094 9.997519.995

4095 10.00020.000

Writing to this register while the meter is in the manual mode causes the output

signal to update immediately. While in the automatic mode, this register may be

written to, but the output will not update until the meter is placed in manual mode.

Examples:

1. Set output to full scale:

Value to write to holding register 40020 (PAX) or 40037 (PAXI/DR): 0FFFh

(4095).

2. Set output to zero scale:

Value to write to holding register 40020 (PAX) or 40037 (P AXI/DR): 0000h (0).

3

Output Signal*

I (mA)

V (V)

*Due to the absolute accuracy rating and

resolution of the output card, the actual

output signal may differ 0.15% FS from

the table values. The output signal

corresponds to the range selected (20 mA

or 10 V).

Page 4

HOLDING REGISTERS

Values less than 65,535 will be in (LO word). Values greater than 65,535 will continue into (HI word). Negative values are represented by two’s complement of the

combined (HI word) and (LO word).

4

HOLDING

REGISTER

PAX

ACCESS ACCESS ACCESS

40001: Input (HI) Read Only CTA (HI) Timer (HI) Read/Write Rate A (HI) Read Only

40002: Input (LO) Read Only CTA (LO) Timer (LO) Read/Write Rate A (LO) Read Only

40003: Total (HI) Read Only CTB (HI) Counter (HI) Read/Write Rate B (HI) Read Only

40004: Total (LO) Read Only CTB (LO) Counter (LO) Read/Write Rate B (LO) Read Only

40005: Min (HI) Read Only CTC (HI) RTC Time (HI) Read/Write Rate C (HI) Read Only

40006: Min (LO) Read Only CTC (LO) RTC Time (LO) Read/Write Rate C (LO) Read Only

40007: Max (HI) Read Only RTE (HI) RTC Date (HI) Read/Write Total A (HI) Read/Write

40008: Max (LO) Read Only RTE (LO) RTC Date (LO) Read/Write Total A (LO) Read/Write

40009: SP1 (HI) Read/Write Min (HI) SP1 (HI) Read/Write Total B (HI) Read/Write

40010: SP1 (LO) Read/Write Min (LO) SP1 (LO) Read/Write Total B (LO) Read/Write

40011: SP2 (HI) Read/Write Max (HI) SP2 (HI) Read/Write Total C (HI) Read/Reset

40012: SP2 (LO) Read/Write Max (LO) SP2 (LO) Read/Write Total C (LO) Read/Reset

40013: SP3 (HI) Read/Write SFA (HI) SP3 (HI) Read/Write SFA (HI) Read/Write

40014: SP3 (LO) Read/Write SFA (LO) SP3 (LO) Read/Write SFA (LO) Read/Write

40015: SP4 (HI) Read/Write SFB (HI) SP4 (HI) Read/Write SFB (HI) Read/Write

40016: SP4 (LO) Read/Write SFB (LO) SP4 (LO) Read/Write SFB (LO) Read/Write

40017: Polling1 * Read/Write SFC (HI) SP1 Off (HI) Read/Write SFC (HI) Read/Write

40018: Reset * Read/Write SFC (LO) SP1 Off (LO) Read/Write SFC (LO) Read/Write

40019: TRX Delay

40020: AOR

2

3

Read/Write LDA (HI) SP2 Off (HI) Read/Write LDA (HI) Read/Write

Read/Write LDA (LO) SP2 Off (LO) Read/Write LDA (LO) Read/Write

40021: CSR Read/Write LDB (HI) SP3 Off (HI) Read/Write LDB (HI) Read/Write

40022: Terminate1 Read/Write LDB (LO) SP3 Off (LO) Read/Write LDB (LO) Read/Write

40023: LDC (HI) SP4 Off (HI) Read/Write

40024: LDC (LO) SP4 Off (LO) Read/Write

40025: SP1 (HI) Timer Start (HI) Read/Write SP1 (HI) Read/Write

40026: SP1 (LO) Timer Start (LO) Read/Write SP1 (LO) Read/Write

40027: SP2 (HI) Counter Start (HI) Read/Write SP2 (HI) Read/Write

40028: SP2 (LO) Counter Start (LO) Read/Write SP2 (LO) Read/Write

40029: SP3 (HI) Timer Stop (HI) Read/Write SP3 (HI) Read/Write

40030: SP3 (LO) Timer Stop (LO) Read/Write SP3 (LO) Read/Write

40031: SP4 (HI) Counter Stop (HI) Read/Write SP4 (HI) Read/Write

40032: SP4 (LO) Counter Stop (LO) Read/Write SP4 (LO) Read/Write

40033: Polling1 * Polling1 * Read/Write Polling1 * Read/Write

40034: Polling2 * Polling2 * Read/Write Polling2 * Read/Write

40035: TRX Delay

40036: MMR MMR Read/Write MMR Read/Write

40037: AOR

40038: SOR SOR Read/Write SOR Read/Write

40039: Reset * Reset * Read/Write Reset * Read/Write

40040:

40041: Terminate1 Terminate1 Read/Write Terminate1 Read/Write

40042: Terminate2 Terminate2 Read/Write Terminate2 Read/Write

PAXI

5

2

3

PAXCK/PAXTM

TRX Delay

RTC Day Read/Write AOR

5

3

Read/Write TRX Delay

2

PAXDR

3

5

Read/Write

Read/Write

* See Coil Table for register mapping and Coil Descriptions for functionality.

Notes:

1. Any registers marked with “——” are unused and will return a value of HEX <8000>.

2. If a value larger than 4095 is written to the AOR register, 4095 will be loaded.

3. TRX delay is the minimum time from the reception of the last character in the

2 character times (2 msec min.). The user can increase the delay time by writing to the TRX Delay register. Any value written to the TRX Delay register that is

less than the value calculated at power up will be ignored. The TRX Delay value is stored in E

the value read back from the E

2

PROM. The greater of the 2 values will be used as the TRX Delay value and will be written to the TRX Delay register.

MODBUS Query until the response is started. The minimum delay value is equal to

2

PROM memory. On power-up, the calculated value is compared to

4. Numeric data is limited to value -19999 to 99999.

5. Numeric data is limited to the value listed for that parameter according to the meter’s literature.

4

Page 5

COIL TABLE

COIL

ADDRESS

COIL

NUMBER

COIL NAME

PAX PAXI PAXCK PAXDR

MIRROR

REGISTER

COIL NAME

MIRROR

REGISTER

COIL NAME

MIRROR

REGISTER

COIL NAME

MIRROR

REGISTER

01 0 SP1 Output 40021 (bit 0) SP1 Output 40038 (bit 0) SP1 Output 40038 (bit 0) SP1 Output 40038 (bit 0)

02 1 SP2 Output 40021 (bit 1) SP2 Output 40038 (bit 1) SP2 Output 40038 (bit 1) SP2 Output 40038 (bit 1)

03 2 SP3 Output 40021 (bit 2) SP3 Output 40038 (bit 2) SP3 Output 40038 (bit 2) SP3 Output 40038 (bit 2)

04 3 SP4 Output 40021 (bit 3) SP4 Output 40038 (bit 3) SP4 Output 40038 (bit 3) SP4 Output 40038 (bit 3)

05 4 Reset Max 40018 (bit 2) Reset Max 40039 (bit 2) ——— ——— Reset Total C 40039 (bit 2)

06 5 Reset Min 40018 (bit 3) Reset Min 40039 (bit 3) ——— ——— Reset Total B 40039 (bit 3)

07 6 ——— ——— Reset CNT A 40039 (bit 7) Reset Timer 40039 (bit 7) ——— ———

08 7 ——— ——— Reset CNT B 40039 (bit 6) Reset Counter 40039 (bit 6) ——— ———

09 8 ——— ——— Reset CNT C 40039 (bit 5) ——— ——— ——— ———

10 9 Reset Total 40018 (bit 4) ——— ——— ——— ——— ——— ———

11 10 Poll Input 40017 (bit 0) Poll CNT A 40033 (bit 0) Poll Timer 40033 (bit 0) Poll Rate A 40033 (bit 0)

12 11 Poll Total 40017 (bit 1) Poll CNT B 40033 (bit 1) Poll Counter 40033 (bit 1) Poll Rate B 40033 (bit 1)

13 12 Poll Max 40017 (bit 2) Poll MAX 40033 (bit 2) Poll SP2 40033 (bit 2) Poll Total C 40033 (bit 2)

14 13 Poll Min 40017 (bit 3) Poll MIN 40033 (bit 3) Poll SP1 40033 (bit 3) Poll Total B 40033 (bit 3)

15 14 Poll SP1 40017 (bit 4) Poll SP1 40033 (bit 4) Poll Timer Start 40033 (bit 4) Poll SP1 40033 (bit 4)

16 15 Poll SP2 40017 (bit 5) Poll SP2 40033 (bit 5) Poll Counter Start 40033 (bit 5) Poll SP2 40033 (bit 5)

17 16 Poll SP3 40017 (bit 6) Poll SP3 40033 (bit 6) Poll Timer Stop 40033 (bit 6) Poll SP3 40033 (bit 6)

18 17 Poll SP4 40017 (bit 7) Poll SP4 40033 (bit 7) Poll Counter Stop 40033 (bit 7) Poll SP4 40033 (bit 7)

19 18 Poll AOR 40017 (bit 8) Poll AOR 40033 (bit 8) Poll Day 40033 (bit 8) Poll AOR 40033 (bit 8)

20 19 Poll CSR 40017 (bit 9) Poll SOR 40033 (bit 9) Poll SOR 40033 (bit 9) Poll SOR 40033 (bit 9)

21 20 Term Total 40022 (bit 0) Poll CNT C 40033 (bit 10) Poll RTC Time 40033 (bit 10) Poll Rate C 40033 (bit 10)

22 21 Term Max 40022 (bit 1) Poll RATE 40033 (bit 11) Poll RTC Date 40033 (bit 11) Poll Total A 40033 (bit 11)

23 22 Term Min 40022 (bit 2) Poll SFA 40033 (bit 12) Poll SP3 40033 (bit 12) Poll SFA 40033 (bit 12)

24 23 Term SP1 40022 (bit 3) Poll SFB 40033 (bit 13) Poll SP4 40033 (bit 13) Poll SFB 40033 (bit 13)

25 24 Term SP2 40022 (bit 4) Poll SFC 40033 (bit 14) Poll SP1 Off 40033 (bit 14) Poll SFC 40033 (bit 14)

26 25 Term SP3 40022 (bit 5) Poll LDA 40033 (bit 15) Poll SP2 Off 40033 (bit 15) Poll LDA 40033 (bit 15)

27 26 Term SP4 40022 (bit 6) Poll LDB 40034 (bit 0) Poll SP3 Off 40034 (bit 0) Poll LDB 40034 (bit 0)

28 27 Term AOR 40022 (bit 7) Poll LDC 40034 (bit 1) Poll SP4 Off 40034 (bit 1) ——— ———

29 28 Term CSR 40022 (bit 8) Poll MMR 40034 (bit 2) Poll MMR 40034 (bit 2) Poll MMR 40034 (bit 2)

30 29 Response Delay 40017 (bit 10) Response Delay 40034 (bit 3) Response Delay 40034 (bit 3) Response Delay 40034 (bit 3)

31 30 ——— ——— Term CNT A 40041 (bit 0) Term Timer 40041 (bit 0) Term CNT A 40041 (bit 0)

32 31 ——— ——— Term CNT B 40041 (bit 1) Term Count 40041 (bit 1) Term CNT B 40041 (bit 1)

33 32 ——— ——— Term CNT C 40041 (bit 2) Term RTC Time 40041 (bit 2) Term CNT C 40041 (bit 2)

34 33 ——— ——— Term Rate 40041 (bit 3) Term RTC Date 40041 (bit 3) Term Total A 40041 (bit 3)

35 34 ——— ——— Term Min 40041 (bit 4) Term SP1 40041 (bit 4) Term Total B 40041 (bit 4)

36 35 ——— ——— Term Max 40041 (bit 5) Term SP2 40041 (bit 5) Term Total C 40041 (bit 5)

37 36 ——— ——— Term SFA 40041 (bit 6) Term SP3 40041 (bit 6) Term SFA 40041 (bit 6)

38 37 ——— ——— Term SFB 40041 (bit 7) Term SP4 40041 (bit 7) Term SFB 40041 (bit 7)

39 38 ——— ——— Term SFC 40041 (bit 8) Term SP1 Off 40041 (bit 8) Term SFC 40041 (bit 8)

40 39 ——— ——— Term LDA 40041 (bit 9) Term SP2 Off 40041 (bit 9) Term LDA 40041 (bit 9)

41 40 ——— ——— Term LDB 40041 (bit 10) Term SP3 Off 40041 (bit 10) Term LDB 40041 (bit 10)

42 41 ——— ——— Term LDC 40041 (bit 11) Term SP4 Off 40041 (bit 11) ——— ———

43 42 ——— ——— Term SP1 40041 (bit 12) Term Time Start 40041 (bit 12) Term SP1 40041 (bit 12)

44 43 ——— ——— Term SP2 40041 (bit 13) Term Count Start 40041 (bit 13) Term SP2 40041 (bit 13)

45 44 ——— ——— Term SP3 40041 (bit 14) Term Time Stop 40041 (bit 14) Term SP3 40041 (bit 14)

46 45 ——— ——— Term SP4 40041 (bit 15) Term Count Stop 40041 (bit 15) Term SP4 40041 (bit 15)

47 46 ——— ——— Term AOR 40042 (bit 0) Term MMR 40042 (bit 0) Term AOR 40042 (bit 0)

48 47 ——— ——— Term MMR 40042 (bit 1) Term Day 40042 (bit 1) Term MMR 40042 (bit 1)

49 48 ——— ——— Term SOR 40042 (bit 2) Term SOR 40042 (bit 2) Term SOR 40042 (bit 2)

5

Page 6

COIL DESCRIPTIONS

Coils 1-4: Output Coils

These coils are used to read or change the states of the Setpoint Outputs.

To change the state of the output(s), the output(s) must be in manual mode.

Refer to the CSR or MMR/SOR registers in the Manual Mode Description

section.

Coils 5-10: Reset Coils

These coils are used to perform the Reset command for the values listed.

Forcing the coil “on” causes the appropriate value in the unit to be reset.

The coil is cleared after the command is executed, therefore, the coil value

read will always be 0 (zero).

Coils 11-29: Polling Coils

The MODBUS card is continually requesting values from the PAX unit. The

polling bit coils determine what values are requested during each loop.

Setting the coils to “1” enables the card to poll that particular value. A “0”

value disables it. Turning polling coils off allows the user to request fewer

values and therefore decreases the internal loop time, which allows the

values that are polled to be updated more often.

If a MODBUS read is issued for any value, that value is automatically

updated to the latest value, regardless of whether the polling bit is on or

off. On power up, all values are updated regardless of Polling bit settings.

Polling coil values are saved in E2PROM memory. Factory settings is “on”

for all Polling coils.

TYPICAL UPDATE TIMES**

PAX PAXI/DR/CK/TM

All values (10) - 1.15 sec All values (19) - 900 msec

5 values - 500 msec 10 values - 480 msec

1 value - 100 msec 5 values - 230 msec

1 value - 52 msec

Coils 21-29 (P AX), Coils 31-49 (P AXI/DR/CK/TM): T erminating

Coils

This set of coils determines what terminating character is sent to the

PAX meter when a write command is executed. If the flag is 0, a $ is used

as the terminating character and the value is not saved to E

memory in the PAX. If the flag is 1, an * is used as the terminating

character and the value is saved to E

2

PROM memory in the PAX.

2

PROM

Coil 30: Response Delay

When a write command is issued, the new value is written to the PAX. If

the coil is off, the MODBUS write response is not issued until the value is

read back from the PAX. For

response is not issued until the latest value is read back from the PAX. If

the coil is set “on” the MODBUS response is issued as soon the received

command is complete. The write coil is saved in E2PROM memory.

Factory setting is on.

MODBUS reads, if a polling coil is off, the

**Update time is the typical time to update the internal memory provided no

MODBUS requests are incoming.

6

Page 7

This page intentionally left blank

7

Page 8

The Company warrants the products it manufactures against defects in materials and workmanship

LIMITED WARRANTY

for a period limited to two years from the date of shipment, provided the products have been stored,

handled, installed, and used under proper conditions. The Company’s liability under this limited

warranty shall extend only to the repair or replacement of a defective product, at The Company’s

option. The Company disclaims all liability for any affirmation, promise or representation with

respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against

damages, claims, and expenses arising out of subsequent sales of RLC products or products

containing components manufactured by RLC and based upon personal injuries, deaths, property

damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be

to any extent liable, including without limitation penalties imposed by the Consumer Product Safety

Act (P.L. 92-573) and liability imposed upon any person pursuant to the Magnuson-Moss Warranty

Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except those

expressly contained herein. The Customer acknowledges the disclaimers and limitations contained

herein and relies on no other warranties or affirmations.

Red Lion Controls

Headquarters

20 Willow Springs Circle

York PA 17406

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

Red Lion Controls

Europe

Printerweg 10

NL - 3821 AD Amersfoort

Tel +31 (0) 334 723 225

Fax +31 (0) 334 893 793

Red Lion Controls

India

54, Vishvas Tenement

GST Road, New Ranip,

Ahmedabad-382480 Gujarat, India

Tel +91 987 954 0503

Fax +91 79 275 31 350

Red Lion Controls

China

Unit 101, XinAn Plaza

Building 13, No.99 Tianzhou Road

ShangHai, P.R. China 200223

Tel +86 21 6113-3688

Fax +86 21 6113-3683

Loading...

Loading...