Page 1

THE LEGEND PLUS BATCH

MODEL LGPB INSTRUCTION MANUAL

Page 2

INTRODUCTION

The Legend Plus Batch unit (LGPB) is another unit in our multi-purpose series

of industrial control products that are field-programmable for solving various

applications. This series of products is built around the concept that the end user

has the capability to program different indication and control requirements.

The Legend Plus which you have purchased, has the same high quality

workmanship and advanced technological capabilities that have made Red Lion

Controls the leader in today’s industrial market.

Red Lion Controls has a complete line of industrial indication and control

equipment, and we look forward to servicing you now and in the future.

CAUTION: Risk of Danger.

Read complete instructions prior to

installation and operation of the unit.

CAUTION: Risk of electric shock.

Page 3

Table of Contents

GENERAL DESCRIPTION ·······················································5

BlockDiagram ······························································ 5

SafetySummary ···························································· 6

BasicOperation ·····························································6

Messages ································································· 8

User Input Message Request Operation ········································8

Binary Message Request Operation ···········································8

Output Message Request ···················································8

MessageCancellation ······················································ 8

OverflowIndication ·························································· 9

Peak&Valley ······························································9

NormalOperatingMode ·······················································9

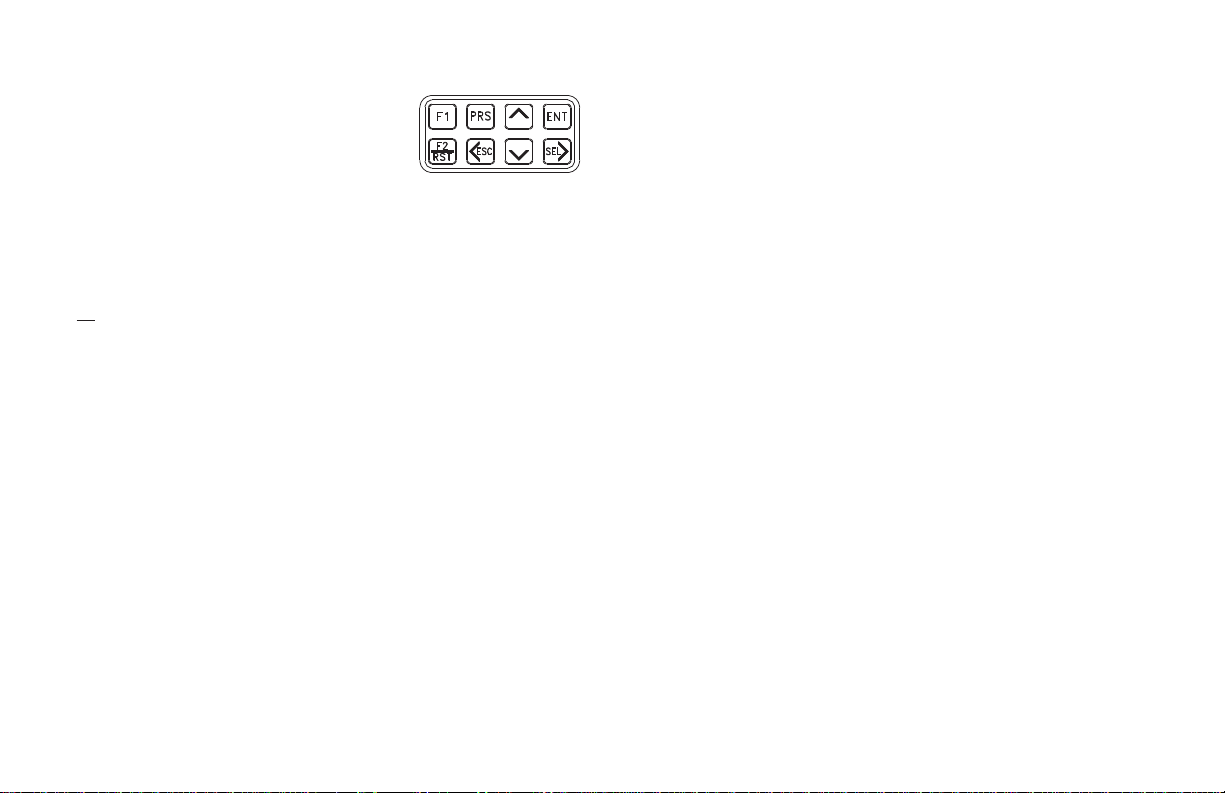

KeypadDescription ·························································10

KeypadFunctions ························································ 10

ProgramCodeNumber(PRO.CODE) ·········································11

Front Panel Accessible Functions With Program Disable ·····························11

PROGRAMMING GENERAL DESCRIPTION ·········································12

Program Presets & Counter Load Module ·········································13

PresetValues ··························································· 13

Counter Load Value ······················································13

Program Scale Factors Module ················································14

Count Scale Factor ·······················································14

RateScaleFactor ························································14

TotalScaleFactor ·······················································14

PROGRAMMING MENUS ······················································· 15

Program Scaling Module ····················································· 16

Count Scale Factor (COUNT SF) ············································16

RateScaleFactor(RATESF) ··············································· 16

TotalScaleFactor(TOTSF) ················································16

Count Scale Multiplier (CNT.SCM) ···········································16

RateScaleMultiplier(RATESCM) ···········································16

RateConversionFactor(RATEPER) ·········································16

DecimalPoint(CNT.DP,RATEDP,TOTDP) ···································17

Change Count Value With Scale Factor (CHG CNT W/SF) ·························17

-1-

Page 4

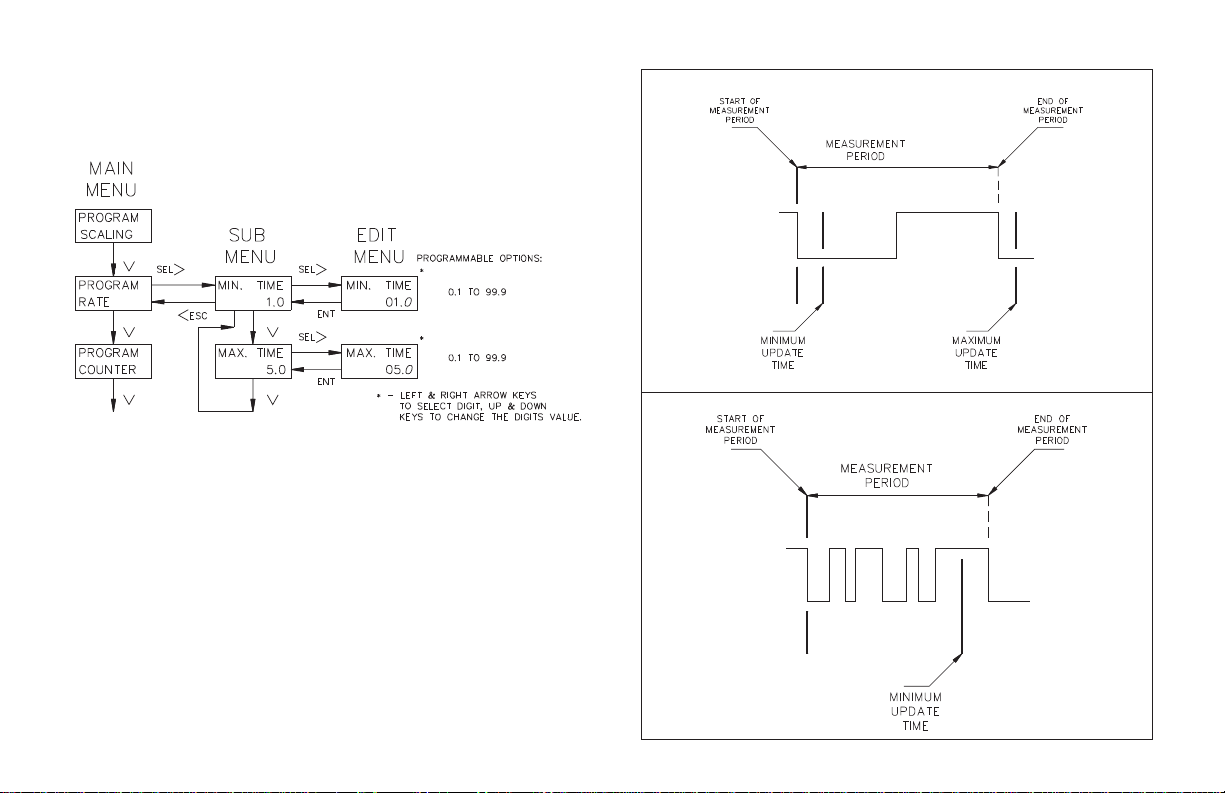

Program Rate Module ······················································· 18

Minimum And Maximum Update Time ·········································18

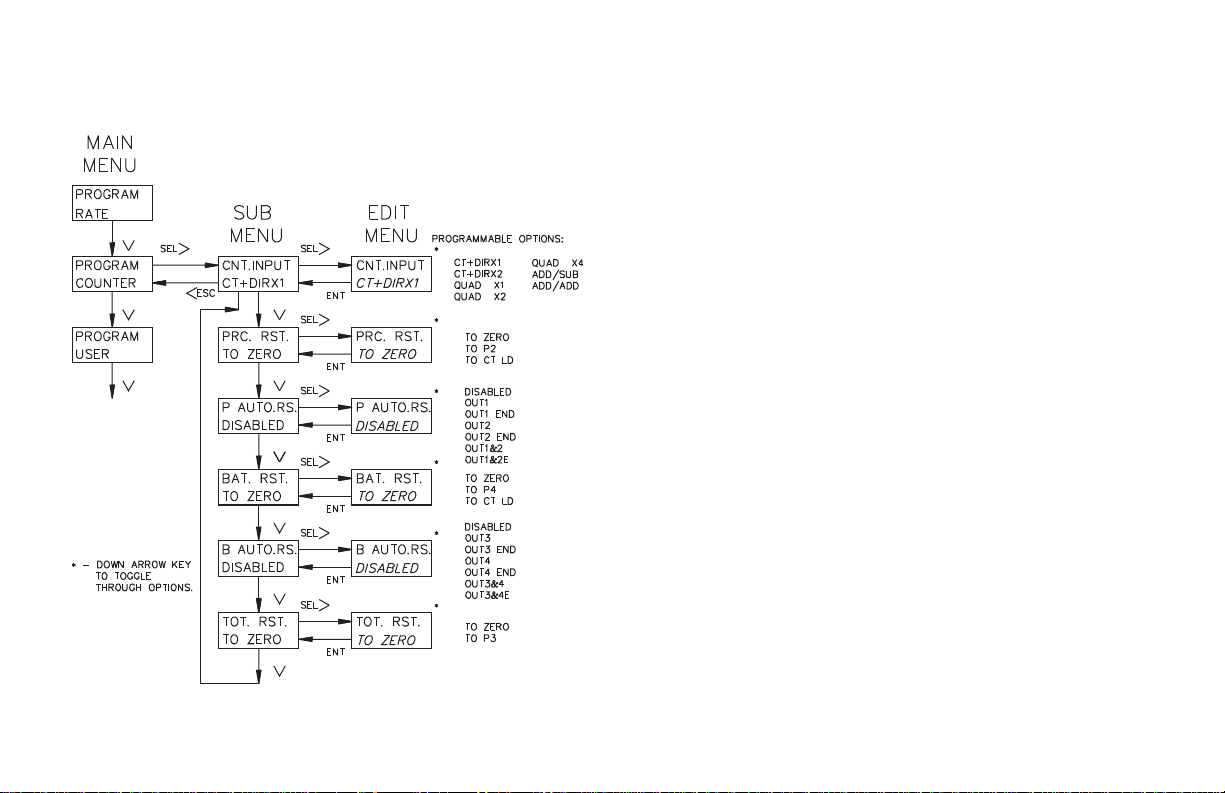

Program Counter Module ····················································· 19

Count Modes (CNT. INPUT) ················································19

ProcessResetAction(PRC.RST.) ··········································· 20

ProcessAutomaticReset(PAUTO.RS) ·······································20

BatchResetAction(BAT.RST) ·············································21

BatchAutomaticReset(BAUTO.RS) ········································· 21

TotalResetAction(TOT.RST.) ············································· 21

Program User Module ······················································· 22

Binary Message Request (BIN MSG REQ) ·····································22

NoMode······························································· 23

MaintainedReset(MNTRST) ··············································· 23

MomentaryReset(MOMRST) ··············································23

ResetOutput(RSTOUT) ··················································23

SetOutput(SETOUT) ····················································23

View/FreezeDisplay(VIEWDS1) ············································ 23

Change Display (CHG DSP) ················································ 24

Request Message (REQ MSG#) ·············································24

ClearMessage(CLRMSG)·················································24

SkipPreset(SKIPPRS) ··················································· 24

Counter Load (CNT LD) ··················································· 24

Print Request (PRINT RQ) ·················································24

ProgramDisable(PGM.DIS.) ··············································· 24

Inhibit Count ···························································· 24

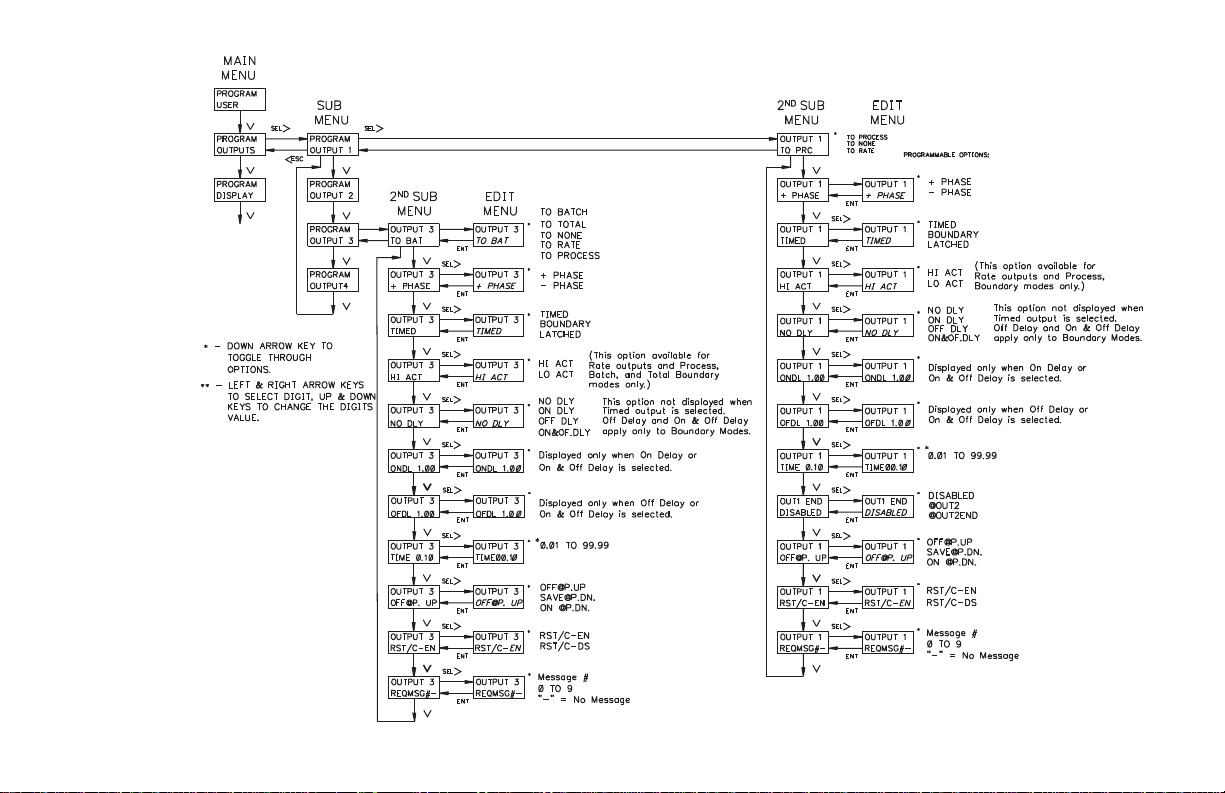

Program Outputs Module ·····················································25

Phase ································································· 25

Output Modes - Timed, Latched or Boundary ···································25

Rate Output On/Off Delay ·················································· 25

Output End (Reset) Modes - OUT1 END, OUT2 END ·····························27

Output Power Up State (OFF@P.UP, SAVE@P.DN OR ON @P.UP) ··················27

Reset Output With Count (RST/C-EN OR DS) ···································27

Request Message (REQMSG#—) ············································27

Program Display Module ····················································· 28

Displays1to4 ·························································· 28

Scroll Speed (SCRO.SPD) ·················································28

-2-

Page 5

Display Intensity (DSP.LEVEL) ··············································28

CustomDisplayLines(CUST.DSP.1/CUST.DSP.2)······························28

Mnemonic ······························································ 28

Program Message Module ····················································30

MessageType ··························································30

MessageText ··························································· 31

MessagePriority(PRIOR-1) ···············································33

Blinking Message (BLNK-YES/NO) ···········································33

Multiplex (MUX - YES/NO) ·················································33

Maintained/Momentary Message Request ······································33

MessageCancellation ····················································· 33

MessageTime ··························································33

MessageColor ·························································· 33

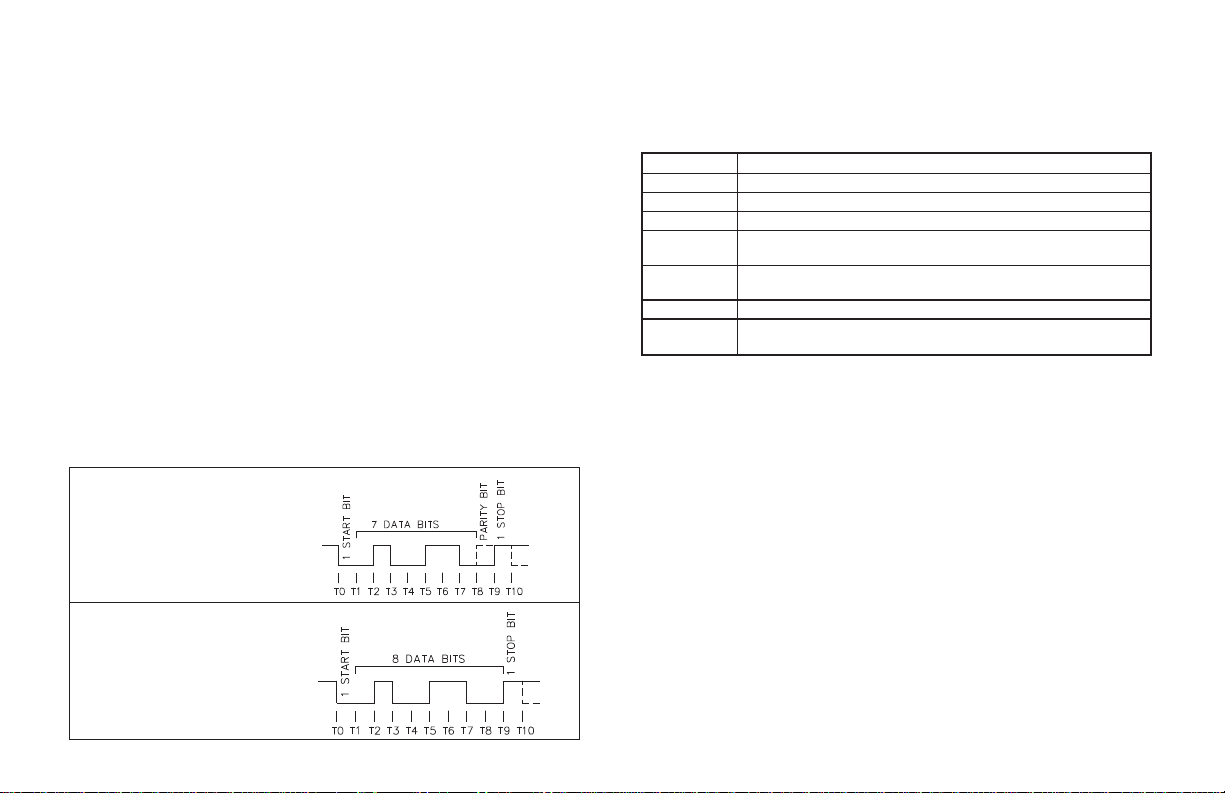

ProgramCommunicationPort··················································34

BaudRate ····························································· 34

Parity/NumberOfDataBits ················································ 34

UnitAddress ····························································34

SerialTransmitDelay ····················································· 34

Program Print Options Module ················································· 35

Mnemonics(MNEM-Yes/No) ················································35

TransmitandReset(TX&R-Yes/No) ··········································35

Message0(MSG0-Yes/No) ················································ 35

Program Options Module ····················································· 36

OperatorAccess ························································· 36

PresetTracking ························································· 36

ProgramCode(PRO.CODE) ···············································36

UserSettings ··························································· 37

LGPB Factory Settings Program Sheet ········································37

LGPB User Settings Program Sheet ··········································39

SERIALCOMMUNICATIONS ····················································42

ProgrammingSoftware ······················································· 42

Installing Software ······················································· 42

UsingSoftware ·························································· 42

CommunicationFormat ······················································ 43

Sending Commands and Data ·················································43

ReceivingData ···························································· 46

-3-

Page 6

Serial Connections ·························································· 47

Connecting to a Host Terminal ··············································48

Troubleshooting Serial Communications ··········································49

INSTALLATION&CONNECTIONS ················································ 50

EMCComplianceInstallation ·················································· 51

Additional EMC Installation Guidelines ··········································· 51

Wiring Connections ·························································52

A.C.PowerWiring ·······················································52

DCPowerWiring ························································ 52

SerialCommunications ····················································52

User Input Wiring ··························································52

OutputWiring ····························································· 52

Signal Wiring ······························································ 53

Inputs A & B ····························································53

Installation&RemovalofRelayBoard ··········································· 54

DIPSwitchSet-up ··························································54

Various Sensor Output Connections ············································· 55

SPECIFICATIONS & DIMENSIONS ···············································57

TROUBLESHOOTINGGUIDE ···················································· 59

APPENDIX“A”-SCALINGFORCOUNTANDTOTALINDICATION ······················62

Scaling For Count Indication ··················································62

Count Scale Multiplier ······················································· 63

ScalingForTotalIndication ···················································64

APPENDIX“B” -SCALINGFORRATEINDICATION ··································65

RateScaleMultiplier ························································66

APPENDIX“C” -APPLICATION··················································68

APPENDIX“D” -ORDERINGINFORMATION ·······································71

APPENDIX“E” -FLOWCHARTFOLD-OUT······································ (Insert)

-4-

Page 7

GENERAL DESCRIPTION

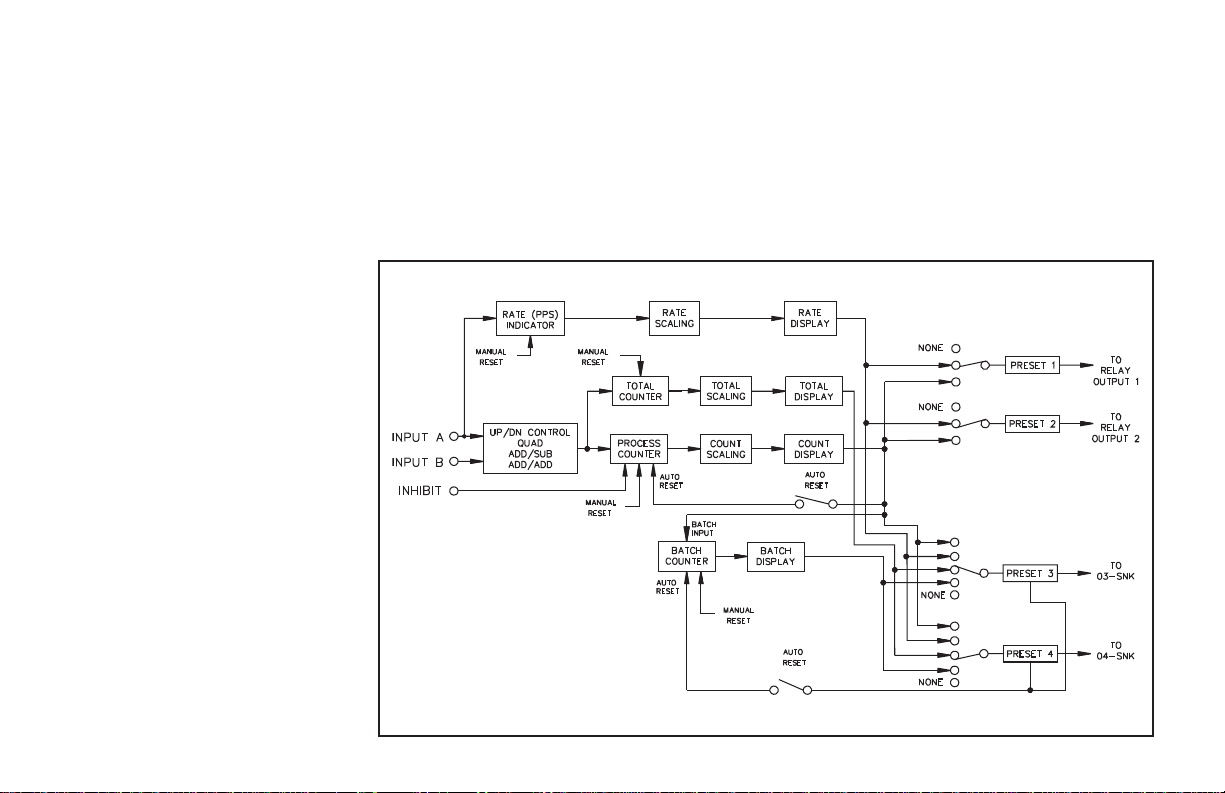

The Legend Plus Batch Counter (LGPB) is a

multi-input, counting panel instrument that

features process, batch, and total counting, as well

as a timeinterval rate indicator. All four available

presets can be assigned to the process counter or

the rate indicator. Outputs three and four can also

be assigned to the batch or total indicator.

The Legend Plus has advanced features that

allow the unit to be more closely coupled to the

application. The unit features a 2 line by 8

character alphanumeric display, allowing the

value mnemonics and programming menus to be

easily read. The unit is available in single or dual

color display models. The four scroll-through

indication displays can be programmed to show

various parameters and to automatically scroll.

On dual color models, each indicationdisplay can

be programmed for either color. The mnemonics

corresponding to the maindisplay values (RATE,

PROCESS, BATCH, TOTAL), can be

individually programmed and modified as

desired. For example, the RATE mnemonic can

be reprogrammed to display the word SPEED, so

that when the rate mnemonic is to be displayed,

the mnemonic SPEED is displayed instead.

Two custom display lines allow the user to

specify the number of digits of a value to be

displayed on a line, along with any

alphanumeric prefix or suffix. This capability

allows displays such as; ‘1000 RPM’, ‘99999

Ft’, or ‘PRC 9999’, etc.

The Legend Plus also features messaging

capabilities that can inform the user of output

actions or other events that occur in a system.

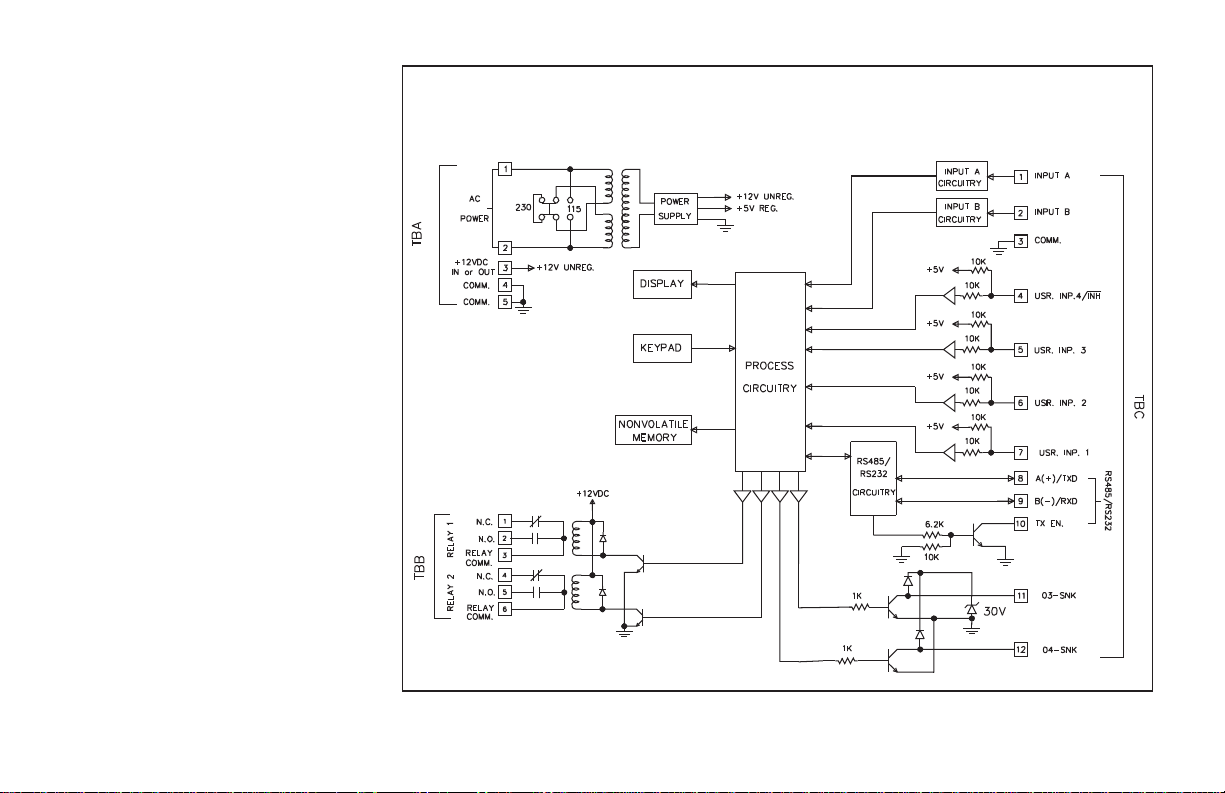

BLOCK DIAGRAM

-5-

Page 8

GENERAL DESCRIPTION (Cont’d)

Up to ten messages can be programmed. Messages can be requested by an

output status change, User Input(s), or through serial communications. The

messages can be programmed for block or character scroll, to blink, time out, and

to alternately flash between message and indication display. On dual color models

the message can be programmed to be displayed in either color. This capability is

very useful in drawing the operator’s attention to particular messages.

The program disable DIP switch, a code value, and an external User Input

selected for Program Disable can be utilized to provide multi-level protection

against unwanted changes to data values and unit configuration.

The Legend Plus features enhanced serial communications. The Serial port

can be configured for connectiontoRS-485 or RS-232 devices. It canbeused for

data retrieval and for programming various data values.

Optional Legend Plus Programming software (SFLGP) for IBM

PCs is availableto program all of the Legend Configuration parameters, such as,

messages, count modes, etc. The software allows unit configurations to be

created, uploaded, downloaded,and saved to a file for rapid programming of the

Legend unit.

The six Programmable User Inputs can be configured to provide a variety of

functions. Four User Inputs are located on the upper rear terminal block. The

other two inputs are front panel function keys.

The LGPB offers a choice of seven programmable counting modes for use in

applications requiring bidirectional, Anti-coincidence, and Quadrature

counting. The count inhibit function can be utilized with all of these input

response modes by programming User Input 4 for the Inhibit Count function.

Input A accepts a signal for the Process, Total and Rate displays. Input B

accepts a signal f or the Process display or direction control. In the

Anti-coincidence mode, both inputs are monitored simultaneously, so that no

counts are missed, and the final count can be chosen as the sum or difference of

the two inputs.

Rate, Process & Total displays have separate scaling and decimal point

placement, for readouts in different units. The Counter Load feature enables the

operator to modify thecount value. This is useful when flawed materialhas been

counted and it is necessary to adjust the count value accordingly.

®

compatible

The rate operates in the timeintervalmethod(1/tau)to calculate the rate value.

This method insures high resolution at all input rates. Averaging can be

accomplishedby programmingtheMinimumand MaximumUpdate Time for the

desired response. Extensive scaling capabilities allow practically any reading at

very slow input rates.

The construction of the LGPB unit is a lightweight, high impact plastic case

with a clear viewing window. The sealed front panel with the silicone rubber

keypad meets NEMA 4X/IP65 specifications for wash-down and/or dusty

environments, when properly installed. Plug-in style terminal blocks simplify

installation and wiring changes.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Do not use thisunit to directly command motors, valves, or other actuators not

equipped with safeguards. To do so, can be potentially harmful to persons or

equipment in the event of a fault to the unit.

BASIC OPERATION

The unit contains three counters that keep track of the Process Count, Batch

Count, and Total Count. Theunit takes the actual number of pulses counted (internal

count value) and multiplies them by the Count Scale Factor and Count Scale

Multiplier. This results in the desired reading value for the Process Count display.

The Total Count is scaled by the same Count Scale Factor and Count Scale

Multiplier as the Process, and is additionally scaled by a Total Scale Factor. A Total

Scale factor of 1.0000 provides a total count that is scaled identically to the process

count. A Total Scale Factor of 0.0010 provides 1 total count for every 1000 process

counts. The Batch Count registers 1 count each time a process is completed.

During operation of the Legend Plus, after internal scaling is complete, any

digits remaining to the right of the least significant digit (LSD) of the display is

examined by the unit. If this digit is equal to or greater than 0.5, the LSD of the

display is rounded to the next higher digit. Any number less than 0.5 is ignored.

-6-

Page 9

During Reset to Preset modes of operation, any remainder greater than 0.5 will

cause the display to be rounded up. Due to this rounding action, the output

activation may appear to be delayed. In actuality the display may haverounded up

or down, but the internal count had not yet reached the preset value or zero.

The Process and Batch Counters have three Reset Action modes associated

with their displays; Reset to Zero(up-countmodes),Reset to Preset (down-count

modes), or Reset to the Counter Loadvalue. Both counters can be independently

programmed to operate in one of these reset modes. A Reset can be a manual

reset, using a programmable User Input, o r it can be one of the seven

programmableAutomaticReset modes. Both the reset action andautomaticreset

modes are programmed in the Program Counter Module.

The Process Counter displays the scaled

number of pulses in the currentBatchcycle.

The Batch counter displays the number of

processes that have been completed. When

the process count equals either preset 1 or 2

depending on the selection of the automatic

reset mode, the Batch count increments by

one. If the automaticresetmodeis disabled,

the batch counter will increment at the

preset 2 value (if Output 2 is assigned to

Process). The Batch count can also be

programmed to automatically reset.

The Total Count is the scaled total number

of counts that have been received since the

Total was last reset. It can be used to keep a

running total of process units on a desired per

shift, per day, per week, etc. basis. The Total

counter can also be used to convert the

Process Counter value to different units of

measure (i.e feet to meters, etc.). The

direction of count for the Total is dependent

on the process count direction and the Total

reset mode. The Total count can be

programmed to reset to zero, or reset topreset

3 and requiresa manual reset by a User Input.

The reset can be independent of the process

and batch count.

The signal at Input A is used for the Rate indicator. The rate indicator uses a

time interval method (1/tau) to calculate the rate value. The unit counts on the

negative edge of the input pulses. After the programmed minimum update time

elapses and the next negative edge occurs,theunitsaves the number of edges that

occurred during the elapsed time. The number of edges is multiplied by the Rate

Scale Factor, Rate Scale Multiplier, and the Rate Conversion Factor to calculate

the rate value. Averaging can be accomplished by programming the Rate

Minimum Update Time for the desired response. Extensive scaling capabilities

allow practically any desired reading at very slow count rates.

The following is a Block Diagram overview of the basic operation.

-7-

Page 10

MESSAGES

The Legend Plus features messaging capabilities that can inform the user of

output actions or other events that occur in a system. Up to ten messages can be

programmed. Messages can be requested by an output status change, User

Input(s), or through serial communications.

When a message is requested, the unit checks if there is a message already on the

display. If there are no messages on the display, the requested message is displayed.

A message on the display is replaced, if the requested messagehasthesameorhigher

priority. If the unit is not at the main display, the unit stores one message request. If

subsequent messages are requested while not at the main display, the unit stores the

last message requested, or the highest priority message requested. 2.5 seconds after

the user returns to the main display the stored message is displayed.

If a message is displayed and the user presses the appropriate key to get to the

Preset, Scaling or Programmingmenudisplay, the displayed messageis temporarily

suspended. While the message is suspended the message timer, if used, is also halted.

2.5 seconds after the user returns to the main displays, the message is redisplayed and

the message timer resumes. If the Up orDownarrow key is pressed while inthe main

display loop, the message is also suspended, and the appropriate programmed

display is shown. The message is redisplayed 2.5 seconds after the last key press.

USER INPUT MESSAGE REQUEST OPERATION

Individual User Inputs can be programmed to activate any of the tenmessages.

The messages can be maintained or momentary. Messages can be assigned a

priority from 1 to 8 (1 is highest). This assures that very important messages are

displayed first.

BINARY MESSAGE REQUEST OPERATION

Two, three or all four of the User Inputs can be configured to request messages in a

binary fashion. Messages 1 through 9 can be requested in this manner. The binary

state 0 (all binary inputs inactive), is used to indicate no message requested. During

the scanning of thebinary message request inputs, if theInput state is the sameas the

last requested binary message no change will occur. When an input change occurs,

the unit requests the message number corresponding to the state of the inputs. The

inputs must be stable for 100 msec (debounce time) for the message to be requested

(See Program User Module for more details). Changing the individual binary

message request input linesslowly will cause unwanted message requests, if several

bits need to be changed. This would be noticeable on the display, if a user was

utilizing a thumbwheel switch to change between messages.

OUTPUT MESSAGE REQUEST

Each output can be individually programmedto request a specific message when

activated. The appropriate message will be requested regardless of the method used

to activate the output, i.e. User Input, Count/preset processing, serial command,etc.

Note: The Output must be active for a minimum of 50 msec. for the request to be seen.

MESSAGE CANCELLATION

Messages can be cancelled automatically, or manually. When cancelled,

messages programmed for maintained request, willbe re-requested if thedisplay

is available and the request source is still active. A request for a message of the

same or higher priority will cancel the current message on the display. Messages

can also becancelled by a User Input programmed for Cancel Message or via the

serial port. The three programmable cancellation options are Latched, Timed,

and Til End. (See Program User Message Cancellation for details).

-8-

Page 11

OVERFLOW INDICATION

The unit flashes the word “OVERFLOW” (or assigned mnemonic) in the

appropriate display when an overflow condition occurs. An overflow occurs if the

capacity of the display (6-digits Process& Batch, 8-digits Total) is exceeded orif the

internal count capacity (9-digits Process, 7-digits Batch, 11-digits Total) is

exceeded. The use of anextremelysmallScale Multiplier and Scale Factor valuecan

cause the internal count capacity to overflow before the displayed value overflows.

For example, if a Scale Factor of 0.0001 and a Scale Multiplier of 0.001 is

used, for every 10,000,000 count edges received, the display increments by 1.

Before the display reaches 215, the internal counter overflows. When the

capacity of the display is exceeded, the count value is maintained and is valid. If

the internal count capacity is exceeded, the count value is no longer valid.

Use of a Scale Factor larger than “1” can cause the displayed Process or Total

value to overflow before 999,999 counts are accumulated. The use of a Rate

Scale Factor, Scale Multiplier, and Rate Conversion Factor larger than “1” can

cause the rate display to be in an overflow condition.

The counters should not be allowed to operate in an overflow condition. As

soon as, or beforethe counters overflow, the informationshould be recorded and

the counters reset.

PEAK & VALLEY

The Peak and Valley registers record the lowest (Valley) and the highest

(Peak) readings of the rateinputsignal. These values are viewed inthe indication

display loop and are updated automatically. A User Input can be programmed to

reset the values to the current rate value individually or by sending the proper

command via the serial communication port. The Peak and Valley values are

NOT retained when power to the unit is removed.

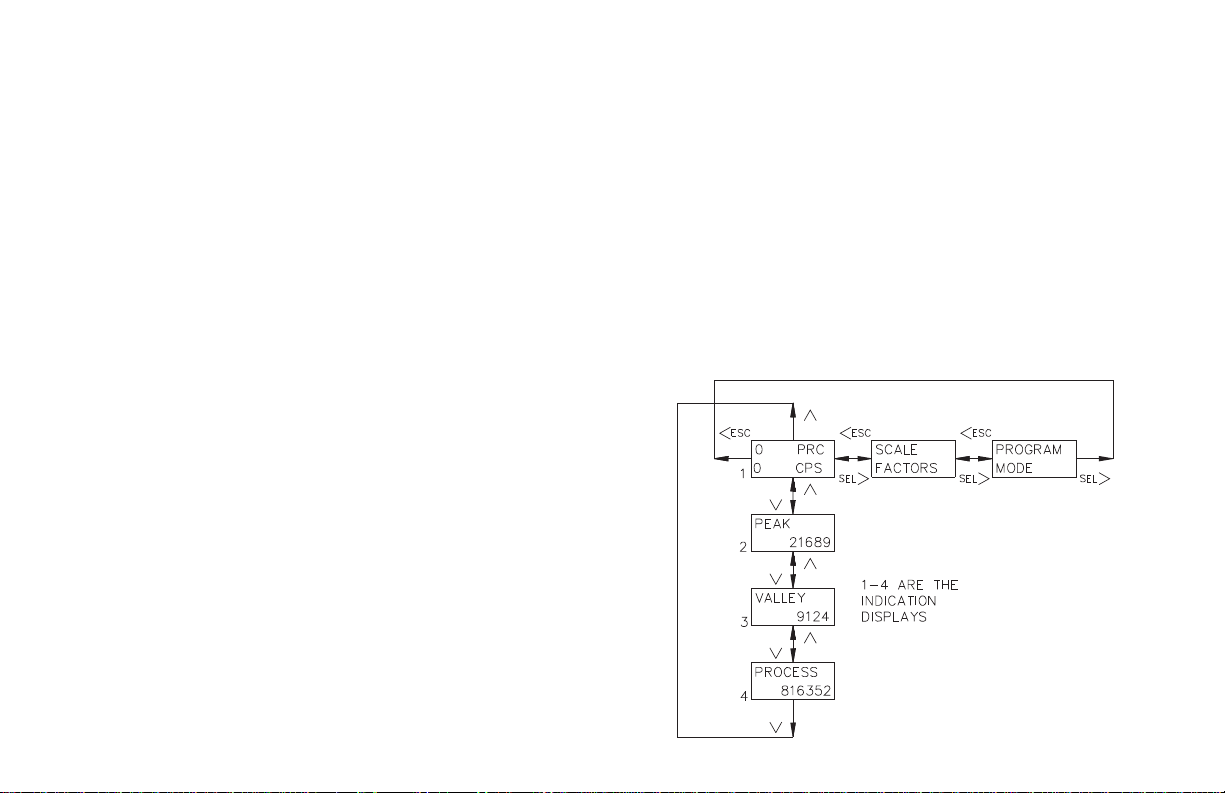

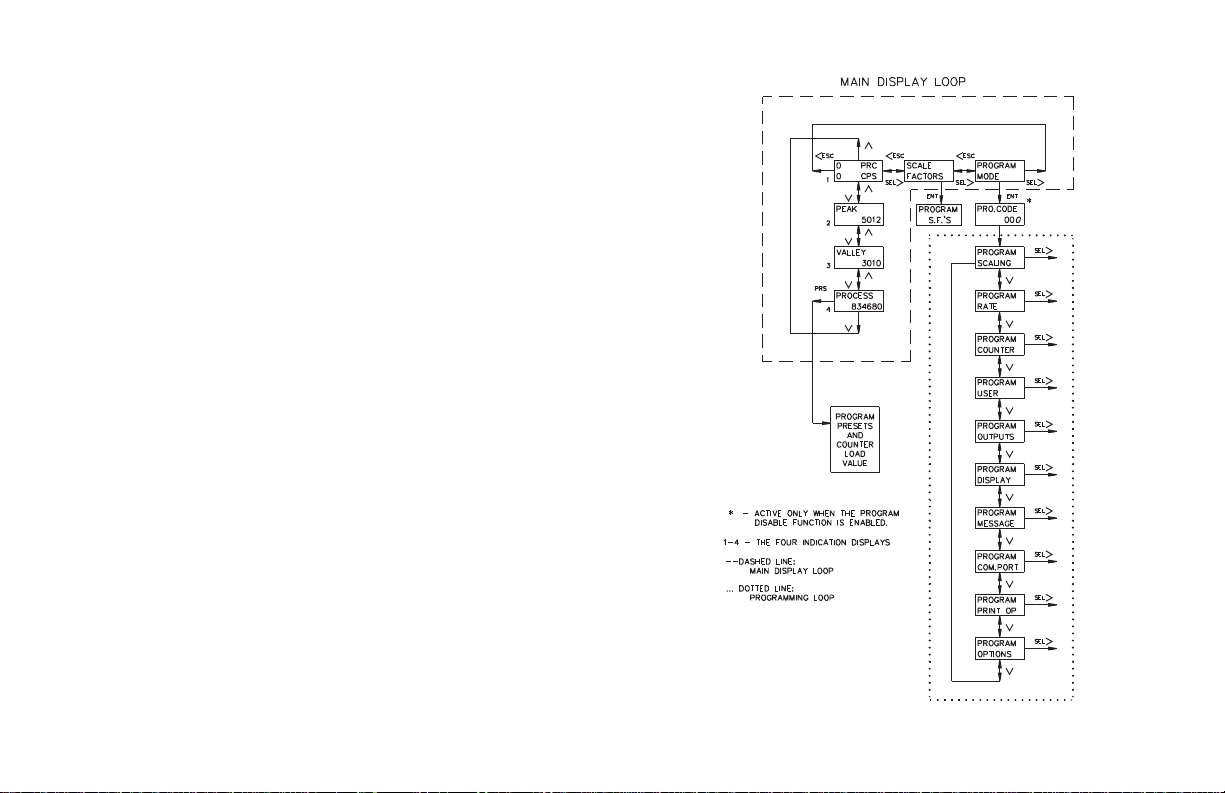

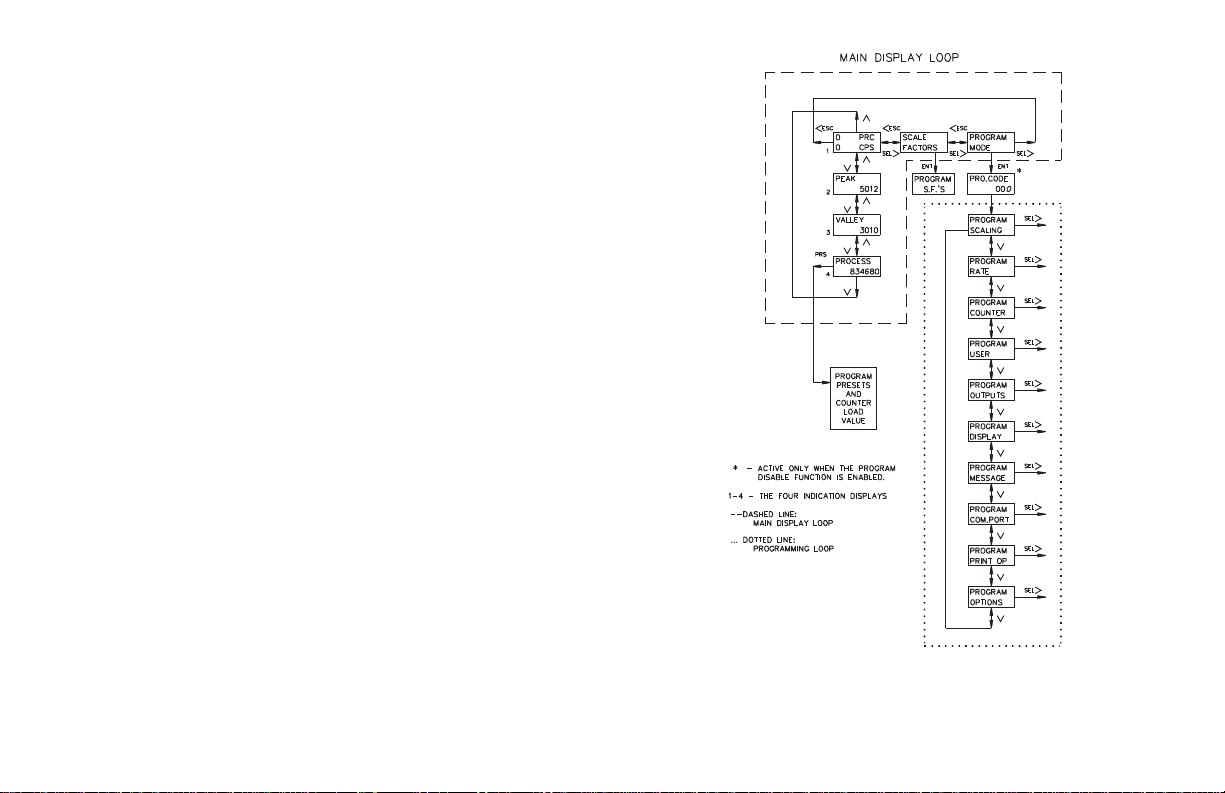

NORMAL OPERATING MODE

In the normal operating mode, the up, down, left, and right arrow keys are used

to scroll through the main display loop. In the main display loop, the four

indication displays, scale factors, and program mode modules are viewed, as

shown at right. In the indication display loop, the up and down arrow keysare used

to scroll to each display. The indication displays are referenced as 1 (0 PRC/0

CPS), 2 (PEAK), 3 (VALLEY), and 4 (PROCESS), which are the factory default

settings. The indication displays canbe programmedto show other parameters and

automatically scroll (See Program Displays Module). The last indication display

that was viewed at power down, is the one viewed on power up.

The Presets and Counter Load values are accessed from any of the indication

displays or from the programmingloop.The Count, Rate, and Total scale factors

are accessed from the Scale Factors display or when in the programming loop

from the Program Scaling module. In the Program Mode display, the operator

enters the programming loop to access all parameters to configure the unit.

Shown below is the Main Display Loop.

-9-

Page 12

KEYPAD DESCRIPTION

The keypad has a key array of two rows by four

columns. Some keys have a dual function. For a

description of key functions during text and

mnemonics editing, see Text Editing in the

Program Message Module. The following is a

description of each key and its function during

programming and normal operation:

KEYPAD FUNCTIONS

F1

- Function key F1 is aUserProgrammable Input. Whenthekeyis pressed,

the unit performs the appropriate function as programmed in the

“Program User Module”.

- Function key F2/RST is a User Programmable Input. When the key is

F2

RST

PRS

<ESC

^

pressed, the unit performs the appropriate function, as programmed in

the “Program User Module”. The “RST” printing on this key is used as

a quick reference for the operator if the function key is selected for a

reset function.

- The PRS key accesses the Preset and Counter Load Module provided

these values are not programmed for ‘loc’k. If all values are ‘loc’ked,

pressing the PRS key does nothing. Preset values that are accessible

(changeable), can be changed immediately. Pressing the SEL> key is

no longer necessary to edit preset values. Within the preset menu,

pressing this key saves the value and advances the display to the next

available preset. Pressing the PRS key attheend of the module exits the

module and returns the user to the main display loop.

- The Left arrow/escape key scrolls to the left in the main display loop.

When programminganumericalvalue,itselectsthedigitto the left. In a

sub-menu, it exits to the next higher level menu in the loop. It is also

used to exit the programming loop. When exiting the programming

loop, the unit stores all parameters in non-volatile memoryand returns

to the last viewed indication display.

- The Up arrow key scrolls through the indication displays. In the

programming loop, this key can be used to scroll through the main

menus. When programming a numerical value, it increments

(decrements, i.e., goes more positive, for negative values) at the

selected digit position.

KEYPAD FUNCTIONS (Cont’d)

If the key is pushed and held, the value will scroll (count up)

automatically. After 5 counts, the unit enters fast scroll mode. If the

key remains pushed, a digit shift occurs every one hundred counts

until the maximum value or zero (for negative presets) is reached.

When the digit shift occurs, the previously scrolling digit goes to

zero. When zero is reached (for negative values), the display holds at

zero. To go positive, the key must be released and pushed again.

- The Down arrow key scrolls through the indication displays. In the

v

ENT

SEL>

programming loop, it scrollsthrough the mainmenus and sub menus.

When programming a numerical value, it decrements (increments or

goes more negative, for negative values)at the selected digit position.

If the key is pushed and held, the value will auto scroll (count down

automatically). After 5 counts, the unit enters fast scroll mode. If the

key remains pushed, a digit shift occurs every one hundred counts

until zero is reached. When the digit shift occurs, the previously

scrolling digit goes tozero. When zero is reached,the display holds at

zero. To go negative, the key must be released and pushed again.

- The Enter key enters the programming loop, when “Program Mode” is

displayed from the main display loop. When “Scale Factors” is

displayed, pressing Enter allows access to the scale factors. This keyis

also used to save changes to data values. If the data value is a preset or

counter load value, the value is entered and the preset menu is exited.

For all other numeric data values (i.e., Output time, Rate update times,

etc.), the value isentered and the value edit mode is exited. The value is

still viewed in the display, but with no digits flashing.

- The Select/Right arrow key scrolls right in the main d isplay loop.

When programming a numericalvalue, it selects the digit to the right.

In a sub-menu loop, it is used to go to the next lower level and

eventually into an edit menu.

-10-

Page 13

PROGRAM CODE NUMBER (PRO.CODE)

In two of the Program Disable states, it is necessary to enter the PRO.CODE

number before gaining access to the programming menus. The default value for

the code is “00”, but should b e programmed differently (See Program Options

Module). This helps prevent inadvertententry into the unit programmingmenus.

The PRO.CODE prompt is viewed when PROGRAM MODE is displayed and

the enter key ispressed. At this time,the Code Number must be entered using the

arrow keys. If the wrong code number is entered, the operator will NOT be able to

enter the programming loop and the unit returns to the main display loop.

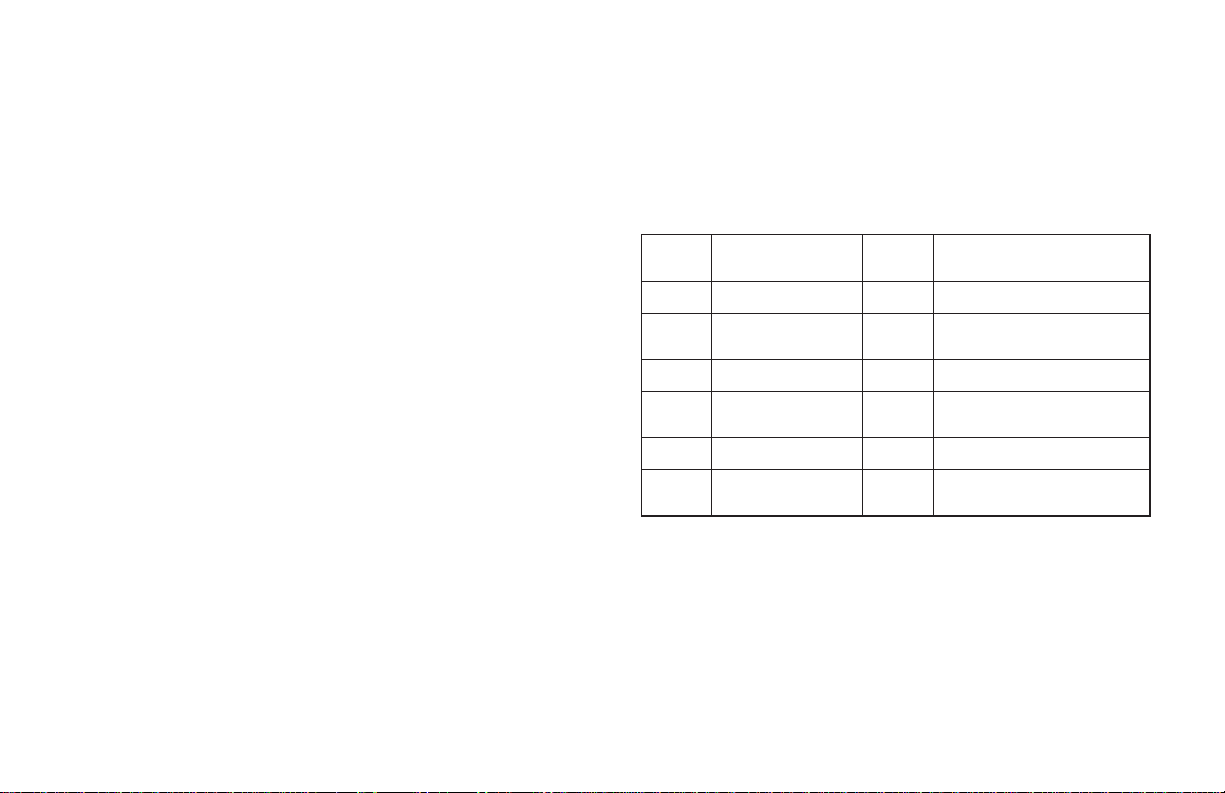

FRONT PANEL ACCESSIBLE FUNCTIONS WITH PROGRAM

DISABLE

The Legend Plus has several ways to limit the programming of parametersfrom

the front panel keypad. The Operator Access section of the Program Options

Module is used with the Program Disable (PGM.DIS.) DIP switch and aUserInput

selected for PGM.DIS to limit programming. To enter the programming loop, a

code number may need to be entered, depending on the Program Disable setting.

Only an external User Input can be selected for Program Disable. The following

list describes the possible program disabling settings.

PGM.DIS.

SWITCH

OFF INACTIVE or Not

OFF ACTIVE 0 to 98 Operator Accessible Functions

OFF ACTIVE 99 Operator Accessible Functions

ON INACTIVE or Not

ON INACTIVE or Not

ON ACTIVE ALL Operator Accessible Functions

Note: If the User Input, set for PGM.DIS., is changed to another function, make

sure the User Input is not low (active). If the input is low when the function is

changed, the program disable function is still active for the User Input.

USER INPUT

TERMINAL

Programmed for PGM.DIS

Programmed for PGM.DIS

Programmed for PGM.DIS

PROGRAM

CODE

NUMBER

ALL All programming enabled.

Enabled, Programming Loop

Accessible via code number.

Enabled, ProgrammingLoop Disabled.

0 to 98 Operator Accessible Functions

Enabled, Programming Loop

Accessible via Code number.

99 Operator Accessible Functions

Enabled, ProgrammingLoop Disabled.

Disabled, Programming Loop

Disabled.

ACTION

-11-

Page 14

PROGRAMMING GENERAL DESCRIPTION

Programming of the Legend Plus is done through the front panel keypad, which

allows the user to enter into Main Menus, Sub-Menus, and Edit Menus. English

language prompts, flashing parameter values, and the front panel keypad aid the

operator during programming.

Although the unit has been programmed at the factory, the parameters generally

have to be changed to suit the desired application. The Main Menus are entered by

pressing the enter (ENT) key when Program Mode is displayed. From Main Menus,

the u ser can enter a Sub-Menu where parameter values can be viewed. From the

Sub-Menu, the operator can advance into an Edit Menu, where a parameter value is

changed and entered. There are three types of Edit Menus:

1. A Choice Edit Menu allows the operator to scroll through options by repeatedly

pressing the down arrow key until the desired option is viewed. The option is

selected by pressing the ENT (enter) key, which returnstheoperatortothe previous

sub-menu. The operator can exit the Edit Menu WITHOUT making a selection by

pressing the <ESC key, which returns the operator to the previous sub-menu.

2. In a Numerical Value Edit Menu, the operator uses the left or right arrow key to

select a digit. The up and down arrow keys change the digit’s value. The PRS key

toggles the left-most digit between a minus (-) and a zero for plus (+), for that

numeric value. When the appropriate numerical value is selected, it is entered by

pressing the ENT key, which returns the operator to the previous sub-menu.

3. A Text Edit Menu is where messages are programmed, and changes are made to

mnemonics and custom display lines. The up and down arrow keys are used to

scroll through characters. The function keys are used with the up and down arrow

keys to toggle between upper and lower case letters and to togglebetween standard

and extended character sets. A complete listing of key functions in a Text Edit

menu can be found in the Program Message Module.

All parameter values changed in the Programming Loop are saved when exiting the

loop. The operator can exit the programming loop from any of the main menus by

pressing the <ESCkey. When the <ESC key is pressed, the display momentarily shows

“Please Wait...”, while theparametervalues are saved in non-volatile memory.The unit

returns to the indication displaythat was last viewed. Shown arethe Main Display Loop

and the Main ProgrammingmenusoftheFourPresetBatchLegendPlus(LGPB)unit.

All following flow charts have slanted characters to show parameters that are

flashing in the unit’s display and have programmable options.

-12-

Page 15

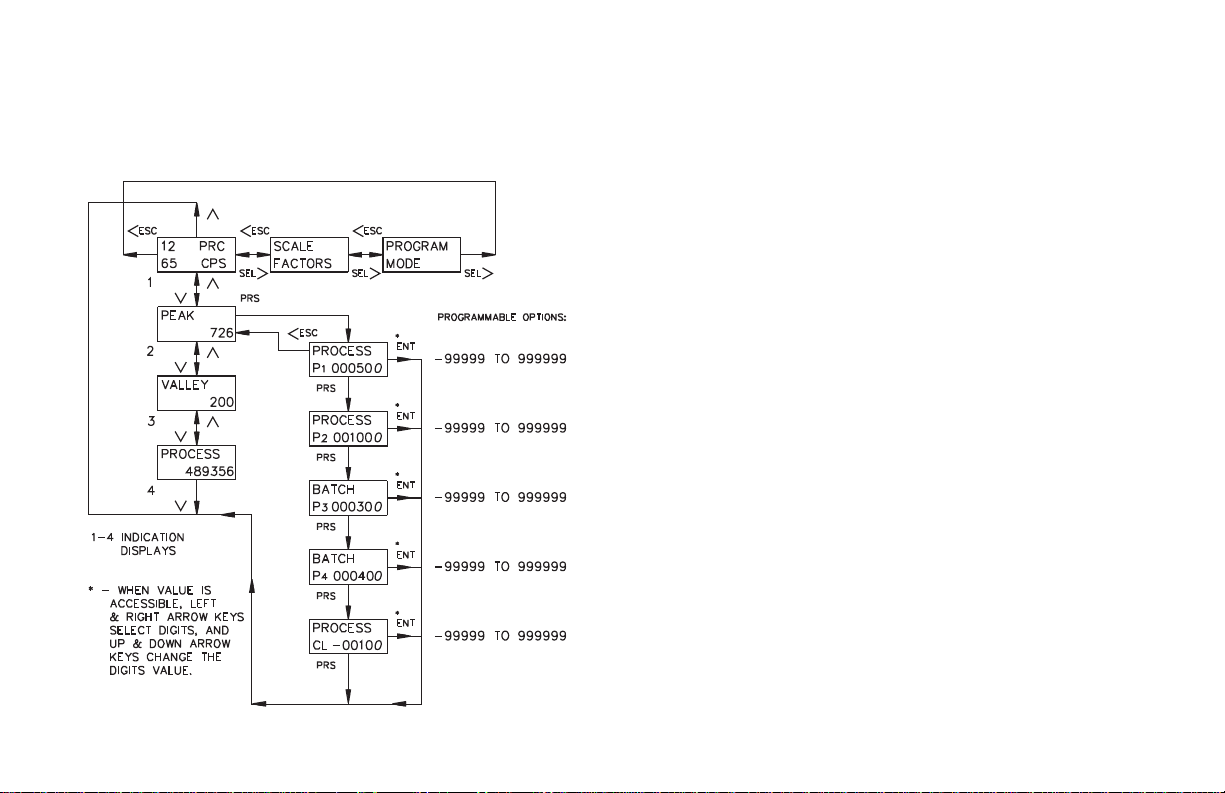

PROGRAM PRESETS & COUNTER LOAD MODULE

The Preset and Counter Load values are accessed from any of the indication

displays, or fromanyof the main menusin the programmingloop,bypressingthe

PRS key. The top line indicates which display the preset is assigned to. The

bottom line indicates which preset is viewed and the programmed value. The

following flowchart shows only the Preset and Counter Load portion:

PRESET VALUES

Preset values P1 and P2 can activate relay outputs one and two respectively,

when the display value equals the preset value. All outputs (presets) can be

assigned to the process count, rate indication display, or none. Presets P3 and P4

can activate solid state outputs O3-SNK & O4-SNK respectively, when the

assigned display equals the preset value. Only outputs three and four can be

assigned to the Batch Counter, or Total Counter. The output action (timed,

latched, or boundary) is programmed in the Program Outputs Module. The preset

values may range from -99,999 to 999,999.

The Count Scale Factor, has a direct effect on the preset value entered, when

the output (preset) is assigned to a counter display. For a Scale Factor Value

greater than “1”, the preset value should be a whole number multipleof the Scale

Factor value. If it is not, the unit automatically adjusts the preset value up or down

to force it to be evenly divisible by the Scale Factor.

COUNTER LOAD VALUE

The Counter Load (CL) value allows the user to start the process or batch

count value from a value other than zero or a preset. The Process and Batch

display reset mode is set in the Program Counter Module. The Counter Load

value can be programmed from -99,999 to 999,999. The Counter Load value is

assigned to the process Counter unless otherwise programmed.

-13-

Page 16

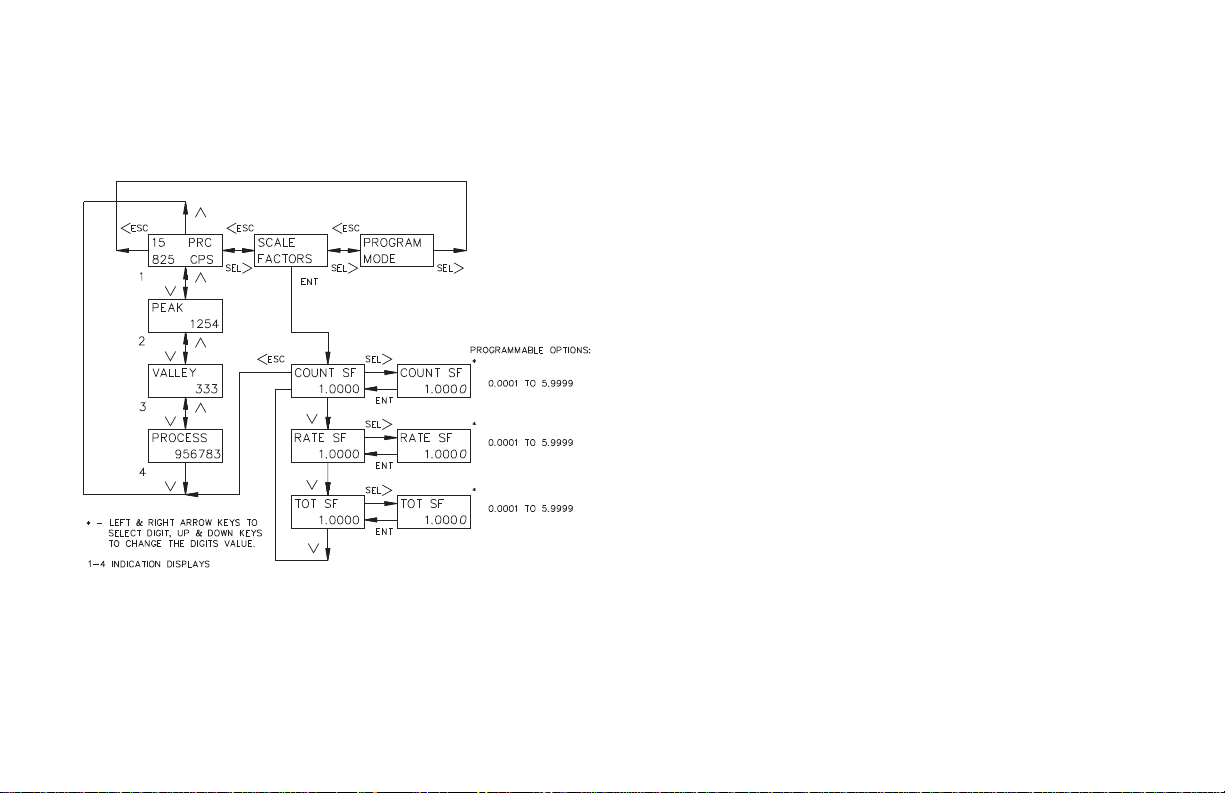

PROGRAM SCALE FACTORS MODULE

The Scale Factors are accessed from the Scale Factors Module in the main

display loop or from the Scaling Module in the programming loop. Since the

Scale Factors may need to be changed periodically, this module allows the

operator to change a Scale Factor value WITHOUT entering the programming

loop. The following flowchart shows only the Scale Factor portion:

COUNT SCALE FACTOR

The number of pulses counted (internal count value) is multiplied by the

Count Scale Factor value and the Scale Multiplier to obtain the desired Process

Count display value. A Count Scale Factor value of 1.0000 and a Scale

Multiplier of “1” results in the display of theactual number of input pulses that

were counted. The Count Scale Factor value is used for converting the number

of pulses counted tothe required units of measure for thedisplay. This includes

conversion from different units of measure (i.e feet to meters,etc.). The Count

Scale Factor value can range from0.0001 to 5.9999. It is importantto note that

the precision of a counter application cannot be improved by using a Scale

Factor greater than “ 1”. To accomplish greater precision, more pulse

information must be generated per measuring unit. For details, refer to Scaling

for Count and Total Indication in the Appendix.

RATE SCALE FACTOR

The internal rate value (pulses per second) is multiplied by the Rate Scale

Factor, Rate Scale Multiplier, and Rate Conversion Factor values, to obtain the

desired rate display value. The Rate Scale Factor value is usedfor converting the

internal rate to the required units of measure for the d isplay. This includes

conversion from different units of measure (i.e feet to meters, etc.). The Rate

Scale Factor Values range from 0.0001 to 5.9999. Due to the way the rate is

calculated, high resolution and accuracy are achieved at all input rates. For

details, refer to Scaling for Rate Indication in the Appendix.

TOTAL SCALE FACTOR

The number of pulses counted (internal total count value) is multiplied by the

Count Scale Factor, the Scale Multiplier, and the Total Scale Factor to obtain the

desired Total display value. A value of 1.0000 results in the same scaling as the

Process Count display. The Total Scale Factor value is used for converting the

number of pulses counted to the required units of measure for the Total display.

This includes conversion from different units of measure (i.e feet to meters, etc.).

The Total Scale Factor value can range from0.0001 to 5.9999. Fordetails, refer

to Scaling for Count and Total Indication in the Appendix.

-14-

Page 17

PROGRAMMING MENUS

The programming menus are accessed when “Program Mode” is displayed in

the main display loop. All parameter values can be accessed from the Main

Programming Menus. Accessibility to the programming menus depends on the

Program Disable Function setting (See Front Panel Accessible Functions with

Program Disable) and could require a Program Code number to enter the

programming menus.

In the programming menus, pressing the up ordown arrow key scrolls through

the main menus. From the Main Menu, a sub-menu is accessed by pressing the

SEL> key. In a sub-menu, the operator can view the parameter values that are

currently selected. To change a parameter value, the edit menu is accessed by

pressing the SEL> key (See Programming General Description section).

The Preset and Counter Load module can be accessed from any Main

ProgrammingMenu by pressing thePRS key. When exiting thepreset and counter

load module, the unit returns to the last main menu that was viewed.

When all parameter changes have been made, the operator can exit the

programming loop, from any main menu, by pressing the <ESC key. Exiting

saves all parameter values and returns the unit to the last indication display that

was viewed. Shown are all of the main programming menus:

-15-

Page 18

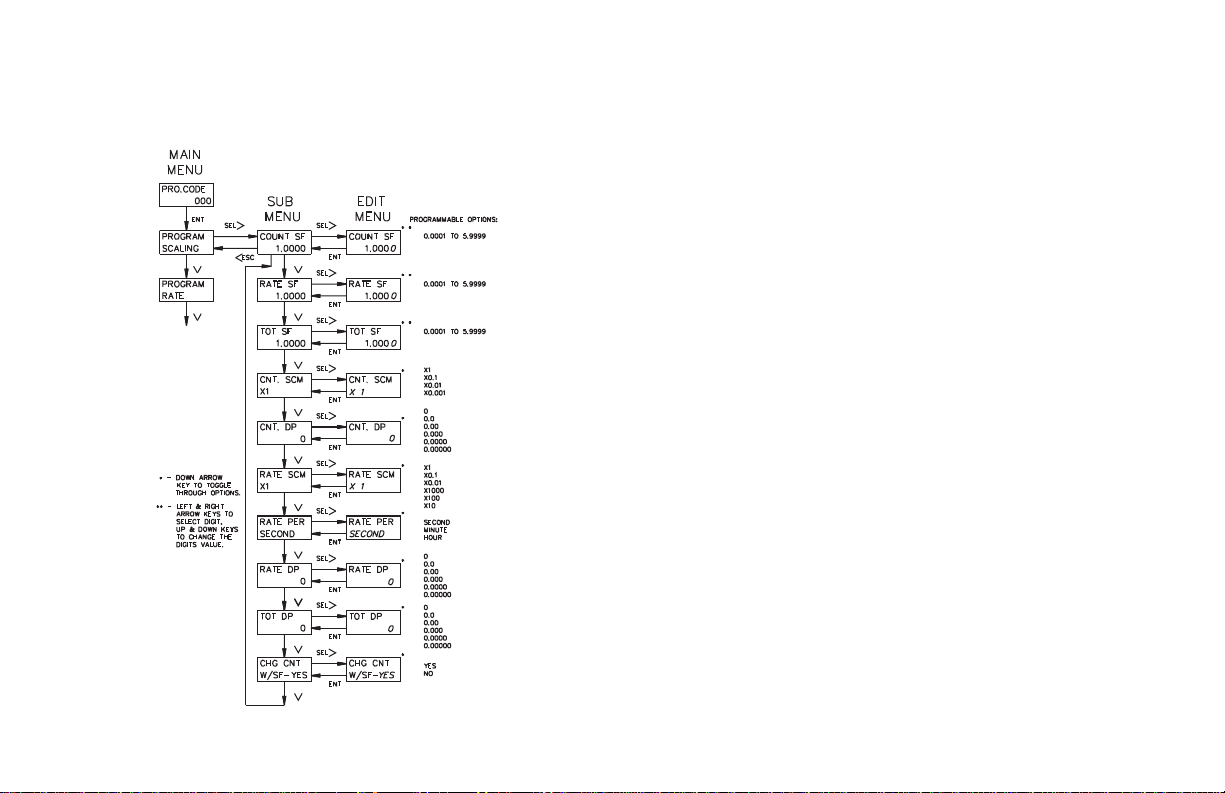

PROGRAM SCALING MODULE

In the scaling module, the Count, Rate, and Total Scale Factors, scale

multipliers, rate conversion factor, and decimal points are accessed. The

following flowchart shows only the Scaling portion:

COUNT SCALE FACTOR (COUNT SF)

The Count Scale Factor Value can range from 0.0001 to 5.9999. See Program

Scale Factors Module for detailed description.

RATE SCALE FACTOR (RATE SF)

The Rate Scale Factor Value can range from 0.0001 to 5.9999. See Program

Scale Factors Module for detailed description.

TOTAL SCALE FACTOR (TOT SF)

The Total Scale Factor value can range from 0.0001 to 5.9999. See Program

Scale Factors Module for detailed description.

Note: Since the Process, Total and Rate Scale Factors, may need to be changed

periodically, they can also be accessed from the Scale Factors Module in the

main display loop.

COUNT SCALE MULTIPLIER (CNT.SCM)

There are four Count Scale Multipliers available; X 1, X 0.1, X 0.01, or X

0.001 that change the Process count display value accordingly. The number of

pulses counted (internal countvalue) is multiplied by thescale multiplier and the

scale factor values to obtain the desired Process Count display.

Note: Use of a small scale multiplier with a small scale factor could cause the

internal count value to be exceeded before the 6-digit display value is exceeded.

RATE SCALE MULTIPLIER (RATE SCM)

The Rate Scale Multiplier isused with the rate scale factorand rate conversion

factor to scale the rate display value for the proper units of measure. The scale

multipliers available are; X 1, X 0.1, X 0.01, X 1000, X 100, or X 10.

RATE CONVERSION FACTOR (RATE PER)

The Rate Conversion Factor is used to display the rate value in the proper

time units of measure, per second (X1), per minute(X60), or per hour (X3600)

for the Rate display.

-16-

Page 19

DECIMAL POINT (CNT. DP, RATE DP, TOT DP)

There are six Decimal Point locations available fortheRate, Total and Process

displays. The decimal point position is programmed individually for each

display. The decimalpoint location programmed f or the Rate display is the same

for the Peak and Valley displays.

CHANGE COUNT VALUE WITH SCALE FACTOR (CHG CNT W/SF)

Any changes to the count or total scale factorsadjustthecurrentlydisplayedcount

and total values to reflect the new scale factor. If this option is set to no, the internal

count value is modified so that the count and total display values are not affected.

Example; a count scale factor of 1.000 with a count value of 36 and a total

value of 4 is changed toacount scale factor of 0.500. If the optionisset to yes, the

new count value would be 18 and the newtotalvalue,2.If the option was selected

as no, the count and total display values would remain at 36 and 4.

-17-

Page 20

PROGRAM RATE MODULE

MINIMUM AND MAXIMUM UPDATE TIME

The Minimum and Maximum Update Times are programmed in the Rate

module. The update times can range from 0.1 to 99.9 seconds. The following

flowchart shows only the Rate portion:

The Rate value is calculatedusing the time measured between thefirst and last

pulse as the measurement period. The measurement period ends when the

minimum update time has expired, and the next negative edge occurs. The

number of pulses that occurred during the measurement period are counted and

multiplied by the rate scale factor, scale multiplier, and rate conversion factor.

The result is divided by the actual measurement period to obtain the rate display

value. If the unit does not receive a negative edge within the period between the

minimum update time and the maximum update time from the start of the

measurement period, the time period ends and the rate display goes to zero. At

very slow count rates the measurement period is the actual period of one count

cycle, as long as the input rate frequency is not longer than the maximumupdate

time. The rate indicator only uses the falling edge of the Input A signal.

Note: The minimum update time must be equal to or less than 65536 divide by the

maximum operating frequency (in Hz) or the internal rate counter will

overflow. For example: If the maximum operating frequency is 10 KHz, the

minimum update time must be less than 6.5 sec (65,535 ¸ 10,000 = 6.5).

BASIC TIMING DIAGRAMS FOR RATE OPERATION

ONE COUNT CYCLE MEASUREMENT

AVERAGE CYCLE MEASUREMENT

-18-

Page 21

PROGRAM COUNTER MODULE

In the Counter Module, the count mode, reset action, and automatic reset

capability are selected. The following flowchart shows only the Counter portion:

COUNT MODES (CNT. INPUT)

There are seven available count modes. User Input 4 programmed for the

count Inhibit function can be used with any count mode. Input A signal is used for

the count and rate input. Input B is used in combination with Input A for Count

Control Direction, Quadrature counting, Anti-coincidence Add/Subtract or

Anti-coincidence Add/Add counting applications.

CT+DIRX1 (X1 COUNTING WITH DIRECTION)

The unit counts one count on every negative edge of theinput signal at Input

A. The direction of the count isdetermined by the logic state of Input B.A high

level at Input B causes the unit to count in a positive direction. A low level

causes the unit to count in a negative direction. The rate display is NOT affected

by the logic state of Input B.

CT+DIRX2 (X2 COUNTING WITH DIRECTION)

The unit counts one count on every negative edge of the input signal and one

count on every positive edge ofthe input signal at Input A. Inthis mode,the input

signal is effectively doubled. The direction of the count is determined by the

logic state of Input B.A high level at InputB causes the unit to countin a positive

direction. A low level causes the unit to count in a negative direction. The rate

display is NOT affected by the state of Input B.

QUAD X1 (QUADRATURE X1)

Quadrature counting modes are primarily used in positioning and anti-jitter

applications. This mode works due to the manner in which the two incoming

pulses are positioned relativeto each other. The pulsesignal on Input B isshifted

90º away from the pulsesignal at Input A. These twosignals are processed by the

Legend Plus as follows:

Input A serves as the count and rate input, while Input B serves as the quadrature

input. For quadrature with single edge counting, the counter counts in a positive

direction when Input A is a negative going edge and Input B is at a low level. The

counter counts in a negative direction when Input A is a positive going edge and

Input B is at a low level. All transitions on Input A are ignored when Input B is at a

high level. These logic rules provide the basis foranti-jitteroperationwhich prevents

false counts from occurring due to back-lash, vibration, chatter, etc.

-19-

Page 22

COUNT MODES (CNT.INPUT) (Cont’d)

QUAD X2 (QUADRATURE X2)

When two edge counting is used, the quadrature mode works the same as with

single edge counting when Input B is low. But when Input B is a high level,

counts at Input A are no longer ignored. Instead, the logic rules for Input A are

complemented, allowing both edges of Input A to be counted. This doubles the

effective resolution of the encoded input.

QUAD X4 (QUADRATURE X4)

This mode takes the quadrature mode, with two edge counting, one step

further. In quadrature times 4, both Input A and Input B serve as the count or

quadrature input, depending on their state. In one instance, Input A serves as the

count input and Input B serves as thequadrature input. In another instance, Input

A is the quadrature input and Input B is the count input. This enables each edge,

positive and negative going, of both inputs, A and B, to be counted. This results

in a resolution four times greater than in the basic quadrature X1 mode.As in the

other modes, Input A is also used for the rate input.

ADD/SUB (TWO INPUT ANTI/COINCIDENCE ADD/SUBTRACT)

This mode effectively separates count pulses that may simultaneously appear

at the two inputs. The Legend Plus processes the count pulses into a string of

time-separated pulses, so the internal counter does not miss any count pulses.

Input A serves as the add input (count increments) and Input B serves as the

subtract input (count decrements).

ADD/ADD (TWO INPUT ANTI/COINCIDENCE ADD/ADD)

This mode effectively sums count pulses that may simultaneously appear at

the two inputs. The Legend Plus processes the count pulses into a string of

time-separated pulses so the internal counter does not miss any count pulses.

Input A serves as an add input (count increments) and Input B serves as an

additional add input (count increments).

PROCESS RESET ACTION (PRC. RST.)

The Process count display can be reset to Zero, Preset 2, or to the Counter Load

value. The display can be reset automatically or by aUserInput.AUser Input can

be programmedfor a Maintained or Momentary reset (See Program User Module

for details). Automatic reset is covered in the next section.

RESET TO ZERO

The Process Counter Display value returns to Zero.

TO P2 (PRESET 2)

The Process Counter Display value returns to the Preset 2 value. Output 2

triggers when the count reaches zero.

TO CT LD (COUNTER LOAD)

The Process Counter Display value returns to the Counter Load value.

Note: The Counter Load reset action should be programmed for only one count

display, either the process count or the batch count.

PROCESS AUTOMATIC RESET (P AUTO.RS)

The Automatic reset mode can be enabled or disabled. The Process Counter

display automatically resets to the programmed reset action, when one of the

automatic reset modes is selected. A manualresetby a User Input causes thecount to

reset regardless of the automatic reset mode. The following choices are available:

OUT1 (Reset at Beginning Of Output 1)

The counter resets when the count equals the preset 1 value. Output 1 can be

timed or latched.

OUT1END (Reset at End Of Timed Output 1)

The counter resets after output 1 has timed out.

OUT2 (Reset at Beginning Of Output 2)

The counter resets when the count equals the preset 2 value or zero (Reset to

P2). Output 2 can be timed or latched.

OUT2END (Reset at End Of Timed Output 2)

The counter resets after output 2 has timed out.

OUT1&2 (Reset at Beginning Of Output 1 or Output 2)

The counter resets when the count equals preset 1, preset 2,or zero (reset to

P2). Outputs 1 and 2 can be Timed or Latched.

OUT1&2E (Reset at End Of Timed Output 1 or Output 2)

The counter resets after output 1 or output 2 has timed out.

Notes:

1. For Auto Reset modes, when operating between approximately

count rate, all other presets should not occur within1 to 6 counts following the

count value at which Auto Reset occurs. In Reset to Zero modes with positive

preset values, this would apply to count values between 0 and 6. For Reset to

-20-

1

to maximum

2

Page 23

Preset or Counter Load modes, it would apply to preset value between 0 to 6

less than the Preset 2 value (when positive).

2. For Auto Reset modes, no other count presets should be set to the same count

value at which Auto Reset occurs (Preset 2 or Zero for Reset to Preset or

Counter Load mode). If they are, only the auto reset output will activate. If the

process counter is set to Auto Reset at OUT1 & 2, and other Presets are the same

as Preset 2 (or Zero for Reset to Preset mode), only Output 2 will activate. If the

unit is set to Auto Reset at OUT1, only Outputs 1 and 2 will activate.

BATCH RESET ACTION (BAT. RST)

The Batch count display can be reset to Zero, Preset 4, or to the Counter Load

value. The display can be reset automatically or by a User Input. Reset by User

Input can be a Maintained or Momentary reset (See Program User Module for

details). Automatic reset is covered in the next section.

TO ZERO

The Batch Counter Display value returns to zero.

TO P4 (PRESET 4)

The Batch Counter Display value returns to the Preset 4 value. Output 4

triggers when the count reaches zero.

TO CT LD (COUNTER LOAD)

The Batch Counter Display value returns to the Counter Load value.

Note: The Counter Load reset action should be programmed for only one count

display, either the process count or the batch count.

BATCH AUTOMATIC RESET (B AUTO. RS)

The Automatic reset mode can be enabledor disabled. The Batch Counterdisplay

automatically resets to the programmedresetaction, when one of theautomatic reset

modes is selected. A manual reset by a User Inputcausesthe count to reset regardless

of the automatic reset mode. The following choices are available:

OUT3 (Reset at Beginning Of Output 3)

The batch counter resets when the count equals the preset 3 value. Output 3

can be timed or latched.

OUT3END (Reset at End Of Timed Output 3)

The batch counter resets after output 3 has timed out.

OUT4 (Reset at Beginning Of Output 4)

The batch counterresets when the count equals preset 4, or zero (Reset to P4).

Output 4 can be timed or latched.

OUT4END (Reset at End Of Timed Output 4)

The batch counter resets after output 4 has timed out.

OUT3&4 (Reset at Beginning Of Output 3 or Output 4)

The batch counter resets when the count equals preset 3, preset 4, or zero

(Reset to P4). Outputs 3 and 4 can be Timed or Latched.

OUT3&4E (Reset at End Of Timed Output 3 or Output 4)

The batch counter resets after output 3 or output 4 has timed out.

TOTAL RESET ACTION (TOT. RST.)

The Total count display can bereset to Zero, or to Preset3.Output 3 must be set to

Total for P3 to be selected.The method of reset is by UserInput. The User Input can

be set for a Momentaryor Maintained reset (See ProgramUserModulefordetails).

TO ZERO

The Total Count Display value returns to Zero. In this mode, the Total count

direction is up.

TO P3 (PRESET 3)

The Total Count Display value returns to the Preset 3 value. Output 3 triggers

when the count reaches zero. In this mode, the Total count direction is down.

-21-

Page 24

PROGRAM USER MODULE

There are six User Input; four external User

Inputs, and two front panel Function keys, which

have various programmable capabilities. An

external User Input is active when tied to common.

A front panel function key is active when pressed.

The options for each User Input are the same,

except as noted below:

1. The two Function keys (F1 & F2/RST) DO NOT

have the Program Disable (PGM.DIS.) option.

2. Only User Input 4 has the Inhibit Function.

The operator can select only one option for each User

Input. The operator mayhave to entera second sub-menu

for some options before entering the edit menu. The

following flowchart shows only the user portion:

BINARY MESSAGE REQUEST (BIN MSG REQ)

Two, three, or all four of the external User Inputs can be

configured as binary message request inputs. When

configured as binary message request inputs, the individual

user input options are not displayed or available. The inputs

are active when pulled low (to common). In order for a

message to be requested, the inputs must remain stable for

100 msec minimum. The number of messages that can be

requested varies with the mode (# ofbits) selected; for 2bit 3 messages, 3bit - 7 messages, 4bit - 9 messages. Message

#0 cannot be requested, since binary state 0 is used to

indicate no request.

Example: If the Legend Plus is set up for 2 bit Binary

Requests, User Inputs 1 and 2 do not appear in the

Program User loop for programming. Activating User

Input 1 displays Message 1, and activating User Input 2

displays Message 2. Activating both together displays

Message 3. Changing the individual binary message

request inputs slowly may cause unwanted message

requests, if several bits need to be changed.

-22-

Page 25

USER INPUT NUMBER (0=INACTIVE, 1=ACTIVE) MESSAGE

43 2 1

0 0 0 0 NONE

0 0 0 1 MESSAGE #1

0 0 1 0 MESSAGE #2

0 0 1 1 MESSAGE #3

0 1 0 0 MESSAGE #4

0 1 0 1 MESSAGE #5

0 1 1 0 MESSAGE #6

0 1 1 1 MESSAGE #7

1 0 0 0 MESSAGE #8

1 0 0 1 MESSAGE #9

REQUESTED

USR.IN 1-4

NO MODE

If a User Input terminal or a Function key is activated, it is ignored.

MAINTAINED RESET (MNT RST)

Maintained reset has six selectable options. Any or all can be selected in the

edit menu by selecting YES or NO using the UP and DOWN arrow keys.

RATE: Resets the measurement period. The Rate display value is the last

reading obtained before the reset. The next reading occurs after the

release of thereset and the expiration of the measurementperiod. The

Rate display does not reset to zero.

PEAK: Resets the Peak value to the current rate value.

VALLEY: Resets the Valley value to the current rate value.

PROCESS: Resets the process count value according to the programmed

reset action.

BATCH: Resets the batch count value according to the programmed reset

action.

TOTAL: Resets the total count value according to the programmed reset

action.

With Maintained reset, the value continuously resets as long asthe User Input

or Function Key is active. Maintained reset is level sensitive and overrides an

automatic reset mode.

MOMENTARY RESET (MOM RST)

Momentary reset has the same six selectable options as Maintained Reset.

With Momentary reset, the value resets when the User Input or Function Key is

activated. The value starts updating (counting), even if the User Input or

Function Key is still active. Momentary reset is negative edge sensitive and

overrides an automatic reset mode.

RESET OUTPUT (RST OUT)

The operator can select to have any or all of the Outputs, 1 through 4, reset. If

the output is active, it resets to its inactive state when the User Input or Function

Key is activated. This is a momentary reset.

Note: The Inactive State of an output can be ON or OFF depending on the Phase

programmed in the Program Outputs Module.

SET OUTPUT (SET OUT)

The operator can select to have any or all of the Outputs, 1 through 4, set. If the

output is inactive, it goes (sets) to its active state when the User Input or Function

Key is activated. If an output is programmed for a timedelay, the output does NOT

latch, but times out after the time delay value expires. This is a momentaryreset.

Note: The Active state of an output can be ON or OFF depending on the Phase

programmed in the Program Outputs Module.

VIEW/FREEZE DISPLAY (VIEW DS1)

When View Display is activated, the programmed indication display is viewed

and the numeric value for that display is held. This is a maintained action. If the

operator is in the main display loop, the unit advances to the indication display to

be viewed. If more than one User Input is programmed for this option, the input

with the highest priority is the only one that holds (freezes) the display and

advances from the main display loop. Any other User Input programmed only

advances in the indication display loop. The priority order is USR INP4, USR

INP3, USR INP2, USR INP1, F2, and F1 withUSR INP4 the highest priority.DS1

selects display 1, DS2 display 2, etc. The values that are viewed/frozen on the

display are determined by what is selected in the Program Displays Module.

Activation of a User Input programmed for View Display will suspend any

displayed message for 2.5 seconds. The User Input has a higher priority in this

instance.

-23-

Page 26

PROGRAM USER MODULE (Cont’d)

CHANGE DISPLAY (CHG DSP)

In the indication display loop, when a User Input is activated, the indication

display toggles to the next indication display. The change of display is a

momentary action.

Activation of a User Input programmed for Change Display will suspend any

displayed message for 2.5 seconds.

REQUEST MESSAGE (REQ MSG#)

The selected message is requested when theUser Input is activated. This may be

a maintainedor momentaryrequest,asselectedintheProgramMessageModule.

CLEAR MESSAGE (CLR MSG)

When the User Inputis activated, the displayed messageis cancelled. This is a

maintained action. While this input is held active, it prevents messages from

being requested. Only one User Input should be programmed for the Clear

Message function.

SKIP PRESET (SKIP PRS)

Up to 4 Presets can be set to be skipped using one User Input. When the User

Input is activated, the output does not activate/deactivate when the count/rate

output conditions are met. This includes an Automatic Reset at Preset. The

counter continues to count through the preset.

Note: An individual preset may be programmed to be skipped on only one User

Input. Other User Inputs may be programmed for skipping presets only if the

presets selected are not programmed to be skipped elsewhere.

COUNTER LOAD (CNT LD)

The process count value is set to the counter load value, regardless of the

process reset action programmed in the Program Counter Module. If the batch

reset mode is programmed for counter load, the batch value is set to the counter

load value, and the process count is ignored.

Note: The counter load reset action should be programmed for only one count

display, either the process count or the batch count. The counter load is a

maintained action.

PRINT REQUEST (PRINT RQ)

When a User Input is activated, the unit transmits all the information selected in

the Print Options Module via the serial port. The print request is a maintained action.

PROGRAM DISABLE (PGM.DIS.)

This option used with the Program Disable DIP switch can limit operator

access to programmable parameters (Refer to Operator Accessible Functions

With Program Disable section). Only one externalUserInput can be used forthis

option. The program disable is maintained.

INHIBIT COUNT

When active, the Input Count function prevents pulses from being counted

on Inputs A & B. The rate input is not affected by the Inhibit function, and

continues to indicate the rate of the signal at Input A. This function is only

available on User Input 4.

-24-

Page 27

PROGRAM OUTPUTS MODULE

Presets 1 and 2 can activate relay Outputs 1 and 2 respectively. They can be

assigned to the Process Count, Rate Indication display, or None. Output 2 has

the same programmable options as Output 1. Presets 3 and 4 can activate solid

state Outputs 3 and 4 respectively. Outputs 3 & 4 can be assigned to the Batch

Count, Total Count, Process Count, Rate indication display, or None. The

preset values are automatically assigned to the appropriate display. Outputs 3

and 4 have the same programmableoptions as Output 1, except they do not have

the Out End Mode option. Boundary mode is not available when the output is

assigned to the Batch counter. A manual reset, which requires the use of a User

Input, overrides a timed output. If boundaryor latched is selected for theoutput

mode the time value does not appear as an option. The flowchart on the

following page shows only the Outputs portion:

PHASE

The positive (+) phase of an output indicates that when the display value

equals the preset value, the output turns on. When the output is reset it is turned

off. The negative (-) phase of an output indicates that when the display value

equals the preset value, the output turns off. The reset condition of the output is

the on state. When an output phase is changed, it does not take effect until a

manual reset or power down is performed.

Note: The state of the relay, if used, is the same as the solid state output.

OUTPUT MODES - TIMED, LATCHED OR BOUNDARY

TIMED

For timed output operation, when the display value equalsthepreset value, the

output activates for the time selected. After the time value expires, the output

returns to its inactive state. The output time can be programmed from 0.01 to

99.99 seconds. An output may appear to be latched if thetimedelayislongerthan

the time required for the counter to reach the preset value. When an output is

assigned to the rate display, the output appears to be latched, if the output time

delay is greater than the minimum update time. The output deactivates when the

rate drops below the preset value and the output time expires.

LATCHED

An output selected for the Latched Mode activates when the display value

equals the preset value. The output stays active until it is manually reset by a User

Input selected for that function. When the unit is reset, the output returns to its

inactive state.

BOUNDARY

An output selected for the Boundary mode (Hi Acting) is active when the

display value is greater than or equal to the positive preset value. If the display

value is less than the positive preset value, the output will be inactive. For

negative preset values, the output will be active when the count value is less

(more negative) than the negative preset value. The output will be inactive when

the display value is greater (more positive) or equal to the negative preset value.

If outputs 1 or 2 are programmedfor boundary,the Output End (Reset) Modes are

not applicable and therefore do not appear in the display.

HI/LO ACTING

This mode is used inconjunction with all Rate modes, and also with Boundary

count modes. A Lo acting output would perform the Output action when the

count/rate is lower than the preset. A Hi acting output would perform the Output

action when the count/rate is higher than or equal to the preset.

RATE OUTPUT ON/OFF DELAY

This option is available for the rate indicator and is used to prevent output

chatter. The output condition mustbe satisfied for a period of time longer than the

delay period for the output state to change. The minimum on or off delay time

allowed is 0.10 seconds.ON/OFF Delay is not available if output is set for TIMED

operation. If LATCHED mode is selected, the OFF DLY options are not available.

NO DLY - No delay

ON DLY. - On Delay:

Prevents activation of output(s) for the amount of time

programmed.

OFF DLY. -OffDelay:

Prevents deactivation of output(s) for the amount of time

programmed.

OF&ON.DLY - On & Off Delay:

This mode prevents output state change for specified delay period

when turning on or off.

-25-

Page 28

-26-

Page 29

OUTPUT END (RESET) MODES - OUT1 END, OUT2 END

The Output End modes operate with a timed or latched output mode. If either

output is selected asboundary, the Output End modes areNOT available. Output

End Modes apply only to outputs 1 and2when assigned to the Process counter. If

the output is set for TIMED, the output mayde-activate from timing out or when

the output end mode is reached, whichever occurs first.

OUT1 END (OUTPUT 1)

@OUT2 (Output 1 End at Output 2 Start)

Output 1 resets to its inactive state when output 2 becomes active. This

action occurs when the count equals the presetvalue or zero (Reset to

Preset Modes). This mode does not apply if the output is activatedbya

User Input programmed for Set Output.

@OUT2END (Output 1 End at Timed Output 2 End)

Output 1 resets to its inactive state when output 2’s time delay expires.

OUT2 END (OUTPUT 2)

@ OUT1 (Output 2 End at Output 1 Start)

Output 2 resets to its inactive state when output 1 becomes active. This

action occurs when the count equals the presetvalue or zero (Reset to

Preset Modes). This mode does not apply if the output is activatedbya

User Input programmed for Set Output.

@OUT1END (Output 2 End at Timed Output 1 End)

Output 2 resets to its inactive state when output 1’s time delay expires.

OUTPUT POWER UP STATE (OFF@P.UP, SAVE@P.DN OR ON

@P.UP)

Each output can be programmed individually to have the state of the output

OFF at power up (OFF@P.UP), saved at power down (SAVE@P.DN) or ON at

power up (ON @P.UP). The save at power down option restores the state of the

output to what it was at power down when power is restored. The save at power

down option DOES NOT restore a timed output to the active state if the output

was active at power down. The OFF@P.UP and ON @P.UP option refers to the

active state of the output, which is determined by the Output Phase.

RESET OUTPUT WITH COUNT (RST/C-EN OR DS)

If Reset with Count is enabled, the output resets with a manual reset of the

Process, Batch, Total orRate display. If Resetwith Count is Disabled,the output

does NOT reset when a manual reset is performed on the value to which the

output is assigned.

REQUEST MESSAGE (REQMSG#—)

The selected messageis requested when the output is activated. This may be a

maintained or momentary request, as selected in the Program Message Module.

A dash ‘-’ indicatesthat no message is to be requested. The outputmust be active

for a minimum of 5 0 msec for the request to be seen.

-27-

Page 30

PROGRAM DISPLAY MODULE

DISPLAYS 1 TO 4

The four indication displays are programmed individually. Each line of each

display can be configured to show avaluemnemonic,anumericvalue,the output

status, a preset value, the counter load value, or a custom display line. Each

display can be programmed to be Green or Red on Dual Color models. The full

value mnemonics are factory set to:

RATE

PEAK

VALLEY

PROCESS

BATCH

TOTAL

The first character of the full mnem onicis displayed to the left of the appropriate

numeric value if the other line is not programme dto display the full mnemonic. The

mnemonic for the Total is not shown in the display, since the total count requires

eight digits. For rate peak and rate valley displays, the abbreviated mnemonic is the

first character of the full rate mnemonic, followed by the first character of the full

peak or valley mnemonic. The following is a list of the single or dual character

mnemonics that are displayed for the factory set full mnemonics:

R - Indicates the Rate Value.

Rp - Indicates the Rate Peak Value.

Rv - Indicates the Rate Valley Value.

P - Indicates the Process Counter Value.

B - Indicates the Batch Counter Value.

O -1234 - Indicates output status:

P1 - Indicates Preset 1 Value.

P2 - Indicates Preset 2 Value.

P3 - Indicates Preset 3 Value.

P4 - Indicates Preset 4 Value.

CL - Indicates Counter Load Value.

The numeric digits show which outputs are on.

When the output is off, the digit is replaced by a small box (

n).

SCROLL SPEED (SCRO.SPD)

The indication displays can be set to scroll automatically at a 2.5 or 5 second

rate. The displays can be selected not to scroll, in which case the up and down

arrow keys are used to scroll through the disp lays.

DISPLAY INTENSITY (DSP.LEVEL)

The brightness of the backlighting can be adjusted from 1 to 5, with 5 as the

brightest. On dual color models, there is a separate adjustment for each color.

CUSTOM DISPLAY LINES (CUST.DSP.1 / CUST.DSP.2)

The Legend Plus has two Custom Display Lines which allow the user to specify

the number of digits of a value to be displayed on the line, along with any

alpha-numeric prefix or suffix. This feature has the same available characters as

messages and program mnemonics. The numeric digit positions are indicated by

pressing F1 and ENT atthe desired display position. For acompletelist of characters

and text editing key functions, see Program Messages Text Editing section.

MNEMONIC

Allows the user to modify main display values (RATE, PROCESS, BATCH,

etc.) to display the value of their choice. For example, the value “ RATE” can be

changed to read “SPEED”. See Program Messages Text Editing section for a

complete listing of available characters and text editing commands.

-28-

Page 31

The following flowchart shows only the Display portion:

-29-

Page 32

PROGRAM MESSAGE MODULE

Up to 10 messages can beprogrammed in the LegendPlus.Messages

can be requested by an output status change, User Input(s), or through

serial communications. The messages can be programmed for block or

character scrolling, to blink, time out, and to alternately flash between

message and indication display. On dual color models the message can

be programmed to be displayed in the other color. This would by useful

in drawing the operator’s attention to the message. The following