Page 1

1

O

WIDE SELECTION OF INPUT MODULES

O

3.32 INCH (84.4 mm) HIGH DIGITS

O

115/230 VAC SWITCH SELECTABLE

O

RUGGED STEEL CONSTRUCTION

O

AVAILABLE IN 4 OR 6-DIGIT VERSIONS

O

AVAILABLE WITH RED OR GREEN LED DISPLAY

O

SEALED FRONT PANEL CONSTRUCTION (NEMA 4/IP65)

O

VERSATILE MOUNTING OPTIONS

O

TEMPLATE PROVIDED FOR EASY INSTALLATION

DESCRIPTION

The Large Digit Display, Model LDD, is a versatile display which can

increase your productivity by offering your plant floor or production area a

visual display of their current status, such as counting, rate indication, real time,

or any engineering unit required. The LDD is available in either a 4-digit or a

6-digit display version with Red or Green LED displays, that accepts a selection

of personality boards to meet your specific application needs (see Personality

Module Bulletins for more information).

There are four panel wiring knock-outs provided, two 7/8" (22.2 mm) knockouts and two 1/2"(12.7 mm) knock-outs. Also provided is a removeable cover

located on the rear panel which will expose one open ended cut-out for easy

wire installation.

The LDD has a sealed front panel which meets NEMA 4/IP65 requirements

for wash-down and dusty environments when properly installed. The 3.32"

(84.4 mm) digits are readable to 130 feet (40 M).

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

SPECIFICATIONS

1. DISPLAY: 3.32" (84.4 mm) High, Red or Green LED display.

2. POWER REQUIREMENTS: Switch selectable 115/230 VAC (±10%),

50/60 Hz, 17 VA 4-digit, 21 VA 6-digit (including module).

3. CONSTRUCTION: Steel construction textured with polyurethane paint for

scratch and corrosion resistance protection. Front panel meets NEMA 4/IP65

requirements for indoor use when properly installed. Installation Category II,

Pollution Degree 2. (Panel gasket included with unit.)

4. ENVIRONMENTAL CONDITIONS:

Operating Temperature: SEE MODULE LITERATURE

Storage Temperature: -40 to 70°C

Operating and Storage Humidity: 85% max. relative (non-condensing)

over operating range

Altitude: Up to 2000 meters

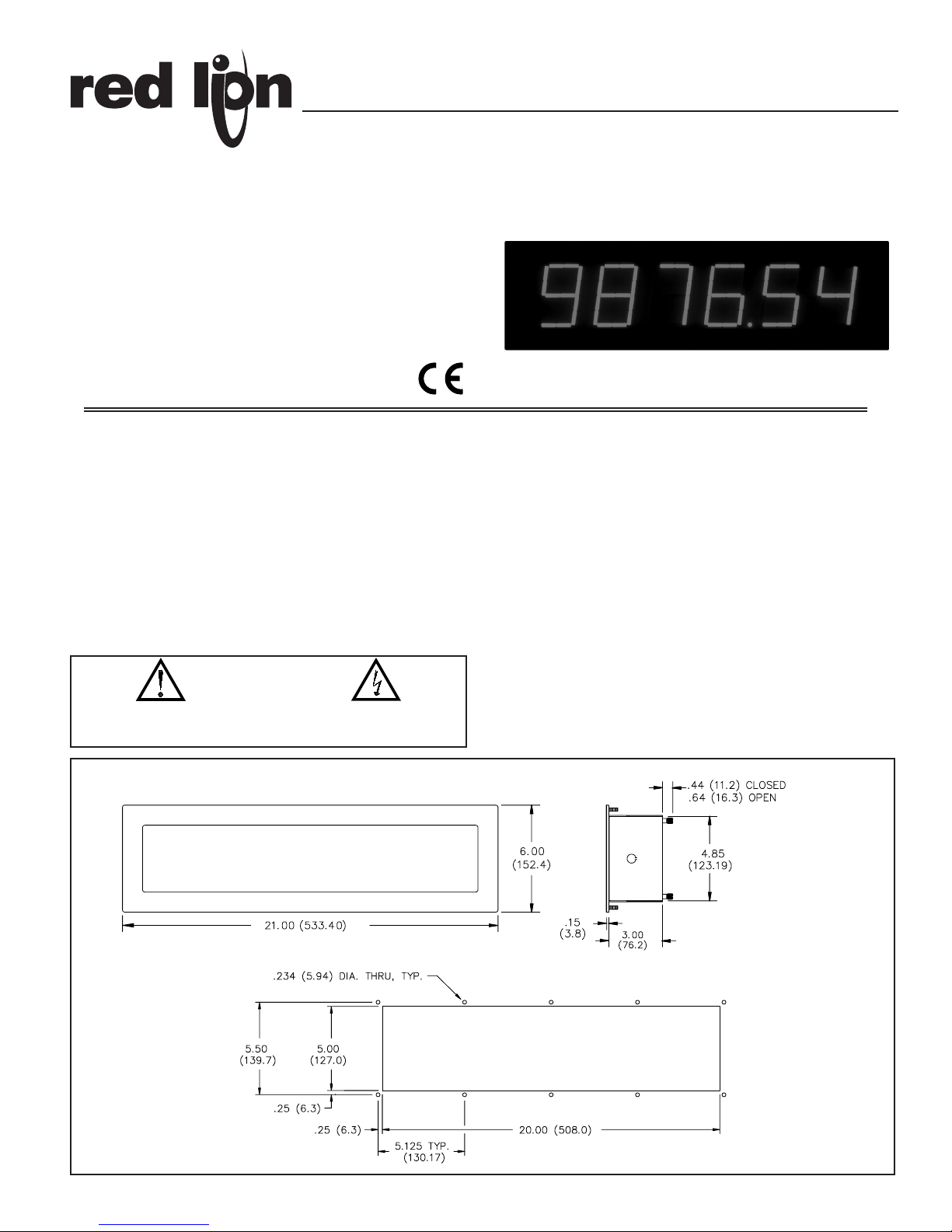

MODEL LDD - LARGE DIGIT DISPLAY

DIMENSIONS In inches [mm]

PANEL CUT-OUT

Bulletin No. LDD-N

Drawing No. LP0205

Released 1/06

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

CAUTION: Risk of Danger.

Read complete instructions prior to

installation and operation of the unit.

CAUTION: Risk of electric shock.

Page 2

2

SPECIFICATIONS (Cont’d)

5. CERTIFICATIONS AND COMPLIANCES:

SAFETY

IEC 61010-1, EN 61010-1: Safety requirements for electrical equipment

for measurement, control, and laboratory use, Part 1.

IP65 Enclosure rating (Face only), IEC 529

Type 4 Enclosure rating (Face only), UL50

EMC EMISSIONS: Meets EN 50081-2: Industrial Environment.

EMC IMMUNITY: Meets EN 50082-2: Industrial Environment.

Refer to individual personality module specifications for aditional

information.

6. MOUNTING REQUIREMENTS:

Max. panel thickness is 0.375" (9.5 mm).

Min. panel thickness for NEMA 4/IP65 sealing is 0.125" (3.2 mm).

7. WEIGHT: 8 lbs (3.6 kg) (less module).

Warning: Disconnect all power before installing or removing module.

SET-UP

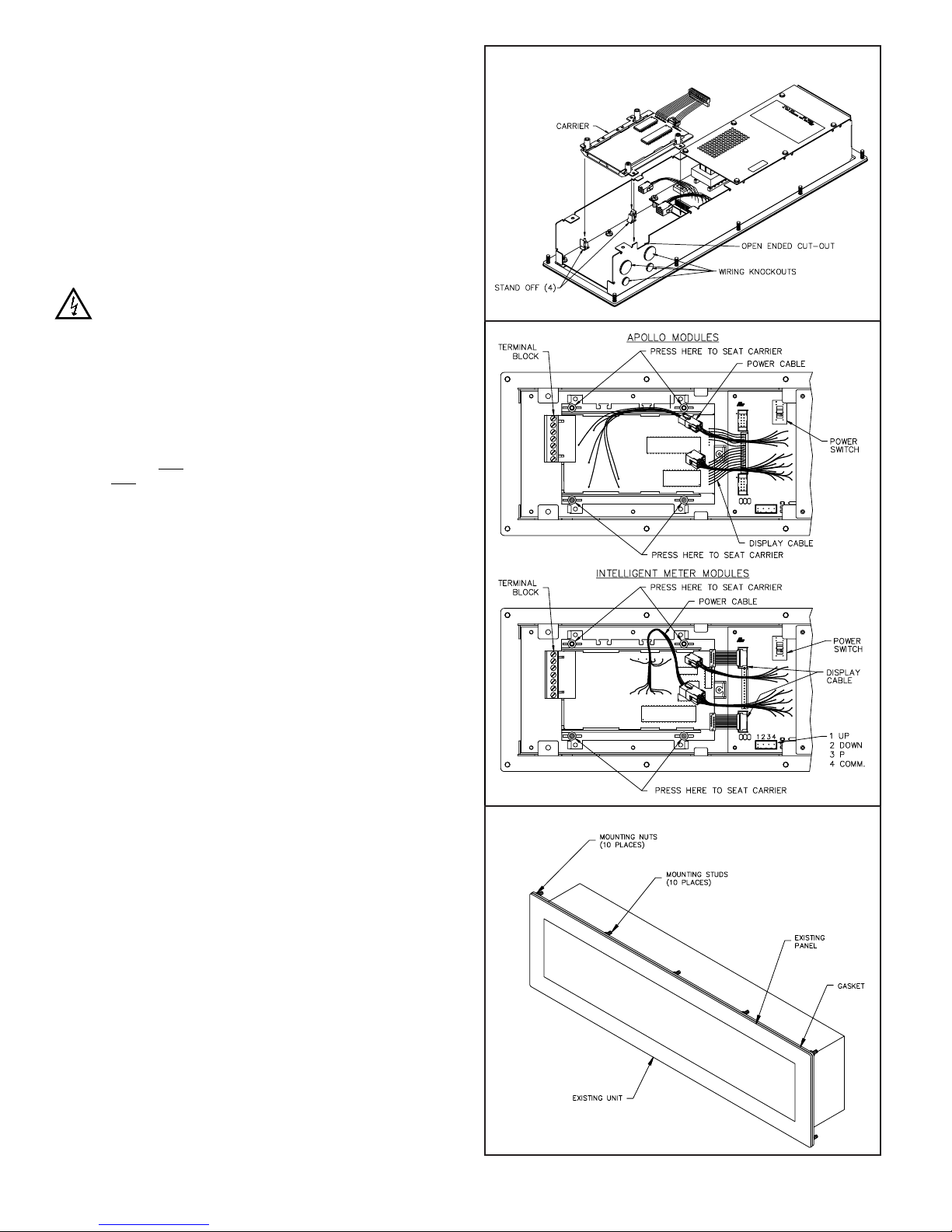

To place the personality module into the LDD, first remove the rear cover

by unscrewing the two captive fasteners. Then, before installing the module

into the LDD, configure the module for the specific application by SETTING

ALL APPLICABLE DIP SWITCHES AND JUMPERS AT THIS TIME (see

accompanying module data sheet). Place the module on the plastic standoffs

(see figure 1). Push on the four posts as shown in figure 2 until the carrier snaps

into place.

Note: Power should NOT be applied until the terminal block is plugged into the

module AND

the module is properly installed into the Large Digit Display.

Select the proper voltage by setting the switch to either 115 or 230 volts.

Connect the display and power cables on the module to the appropriate

connectors on the power supply board (see figure 2).

To program the Intelligent Meter, three normally open momentary

pushbuttons are connected to “P”, “UP”, “DOWN”, and common of the LDD

(not included with the Intelligent Meter). The Model PGM is a small plastic

case with three normally open momentary pushbuttons and 10 feet (3 M) of

shielded cable, and is well suited for programming the Intelligent Meter

module. Although, any normally open, momentary pushbutton switches can be

used. (SEE APPROPRIATE MODULE LITERATURE FOR SET-UP AND

OTHER CONNECTIONS.)

To remove module from the LDD, disconnect the display and power cables,

then remove the carrier from the standoffs by disengaging the tabs and

simultaneously lifting the carrier. Repeat this until the module has cleared all 4

standoffs.

INSTALLATION ENVIRONMENT

The unit should be installed in a location that does not exceed the maximum

operating temperature and provides good air circulation. Placing the unit near

devices that generate excessive heat should be avoided.

The LDD may be cleaned using alcohol compounds such as Isopropanol or

methanol. Also, liquid glass cleaners may be used if they do NOT contain

ammonia.

NOTE: MINIMAL EXPOSURE OF KETONE SOLVENTS TO THE LDD IS

GOING TO CAUSE A WHITENING OF THE DISPLAY OVERLAY.

Continuous exposure to direct sunlight may accelerate the aging process of

the bezel.

The LDD is intended to be mounted into an enclosed panel with a gasket to

provide a water-tight seal. A gasket and ten 10 to 32 kep nuts are provided for

easy installation. The recommended minimum panel thickness for NEMA

4/IP65 applications is 0.125" (3.2 mm). Thinner panels may be used but may

distort and not provide a water-tight seal.

For ease of installation, the cardboard template (supplied with the LDD) may

be used to mark the holes and cut-out locations on the panel. After the panel

cut-out has been completed and deburred, insert the unit with the panel gasket,

into the panel as depicted in the drawing (see figure 3). Install the ten kep nuts

and tighten evenly for uniform gasket compression.

By using additional hardware, the LDD can be surface-wall mounted,

suspended, or bottom mounted. To surface-wall mount the unit, two sets of

MB6 brackets are required. To suspend or bottom mount the unit, one set of

MB6 brackets is required.

FIGURE 1 (shown with cover removed)

FIGURE 2

FIGURE 3

Page 3

3

MODEL NO. DESCRIPTION PART NUMBER

PBLCK

Apollo Real Time Clock Module for use with

PBLCK000

the 6-digit Large Digit Display

(1)

Apollo 4-digit Process Time Module for use

PBLPT400

PBLPT

with the 4-digit Large Digit Display

Apollo 5-digit Process Time Module for use

PBLPT500

with the 6-digit Large Digit Display

(2)

PBLR

Apollo Time Base Rate Module for use

PBLR0600

with the 4 or 6-digit Large Digit Display

(3)

PBLRI

Apollo Time Interval Rate Module for use

PBLRI600

with the 4 or 6-digit Large Digit Display

(4)

PBLT

Apollo 6-digit Totalizer Module for use

PBLT0600

with the 4 or 6-digit Large Digit Display

(5)

(1) See APLCK Bulletin for operating specifications.

(2) See APLPT Bulletin for operating specifications.

(3) See APLR Bulletin for operating specifications.

(4) See APLRI Bulletin for operating specifications.

(5) See APLT Bulletin for operating specifications.

1. TOTALIZER

2. LINEARIZER

4-20 mA

MODEL NO. DESCRIPTION

+18 VDC 3. PEAK/VALLEY DUAL SERIAL

ANALOG PART NUMBER

EXCITATION 4. TARE ALARM OUTPUT

OUTPUT

5. E2-CON

6. EFFICIENCY

Intelligent Meter Modules NO NO NO NO NO PBD10000

For Decade Voltage Inputs* YES NO NO NO NO PBD10100

PBD1 YES NO YES NO NO PBD10102

(See IMD1 Bulletin for operating YES 1, 2, 3, 4, 5 NO NO NO PBD13100

Specifications.) YES 1, 2, 3, 4, 5 YES YES YES PBD13107

Intelligent Meter Modules NO NO NO NO NO PBD20000

For Decade Current Input* YES NO NO NO NO PBD20100

PBD2 YES NO YES NO NO PBD20102

(See IMD2 Bulletin for operating YES 1, 2, 3, 4, 5 NO NO NO PBD23100

Specifications.) YES 1, 2, 3, 4, 5 YES YES YES PBD23107

Intelligent Serial Slave Display Module* 20 mA SRC 3, 5 NO YES NO PBA04101

PBA (See IMA Bulletin for operating 20 mA SRC 3, 5 YES YES NO PBA04104

Specifications.) 20 mA SRC 3, 5 YES YES YES PBA04107

+12 VDC 1, 2, 3, 5, 6 NO NO NO PBI04100

Intelligent Digital Rate Meter* +12 VDC 1, 2, 3, 5, 6 NO YES NO PBI04101

PBI (See IMI Bulletin for operating +12 VDC 1, 2, 3, 5, 6 YES NO NO PBI04102

Specifications.) +12 VDC 1, 2, 3, 5, 6 NO NO YES PBI04103

+12 VDC 1, 2, 3, 5, 6 YES YES YES PBI04107

PGM Programming Box PGM00000

* Note: All the above Intelligent Meter modules require a 6-digit Large Digit Display, Model LDD00600 or LDD0G600.

ORDERING INFORMATION FOR APOLLO INTELLIGENT METER MODULES

ORDERING INFORMATION

FOR APOLLO PERSONALITY MODULES

ORDERING INFORMATION FOR LARGE DIGIT DISPLAY

MODEL NO. DESCRIPTION PART NUMBER

4-digit, Red Large Digit Display LDD00400

LDD

4-digit, Green Large Digit Display LDD0G400

6-digit, Red Large Digit Display LDD00600

6-digit, Green Large Digit Display LDD0G600

MB6 Mounting Brackets MB600000

ENC7 LDD NEMA 4/IP65 Enclosure ENC70000

SHR Shroud For LDD SHR10000

ORDERING INFORMATION

FOR APOLLO BCD SLAVE MODULE

MODEL NO. DESCRIPTION PART NUMBER

Apollo BCD Slave Display Module for use

PBLSP

with 4 or 6-digit Large Digit Display

PBLSP600

(See APLSP Bulletin for operating

specifications.)

PERSONALITY MODULES

The following Apollo and IM capabilities are available as modules for the

Large Digit Display (LDD). These modules are ordered separately from the

LDD (see ordering information), and can quickly be installed by the user (see

“Set-up” for further details).

Application

Model Digit Display

Number Required

Counting (Totalization) PBLT0600 4/6-digit

Tachometer/Rate (Time Base) PBLR0600 4/6-digit

Tachometer/Rate (Time Interval) PBLRI600 4/6-digit

Process Time (Decimal Point) PBLPT400 4-digit

Process Time (Chronometer) PBLPT500 6-digit

Real Time Clock/Elapsed Time PBLCK000 6-digit

Intelligent Decade Voltmeter (IMD1) PBD1xxxx 6-digit

Intelligent Decade Current Meter (IMD2) PBD2xxxx 6-digit

Intelligent Rate Meter (IMI) PBIxxxxx 6-digit

Intelligent Slave Display (IMA) PBAxxxxx 6-digit

Apollo Slave Display (APLSP) PBLSP600 4/6-digit

TROUBLESHOOTING

For further technical assistance, contact technical support at the appropriate

company numbers listed.

Page 4

LIMITED WARRANTY

The Company warrants the products it manufactures against defects in materials and workmanship

for a period limited to two years from the date of shipment, provided the products have been stored,

handled, installed, and used under proper conditions. The Company’s liability under this limited

warranty shall extend only to the repair or replacement of a defective product, at The Company’s

option. The Company disclaims all liability for any affirmation, promise or representation with

respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against

damages, claims, and expenses arising out of subsequent sales of RLC products or products

containing components manufactured by RLC and based upon personal injuries, deaths, property

damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be

to any extent liable, including without limitation penalties imposed by the Consumer Product Safety

Act (P.L. 92-573) and liability imposed upon any person pursuant to the Magnuson-Moss Warranty

Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except those

expressly contained herein. The Customer acknowledges the disclaimers and limitations contained

herein and relies on no other warranties or affirmations.

Red Lion Controls

20 Willow Springs Circle

York PA 17402

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

Red Lion Controls AP

31, Kaki Bukit Road 3,

#06-04/05 TechLink

Singapore 417818

Tel +65 6744-6613

Fax +65 6743-3360

Red Lion Controls BV

Basicweg 11b

NL - 3821 BR Amersfoort

Tel +31 (0) 334 723 225

Fax +31 (0) 334 893 793

Loading...

Loading...