Page 1

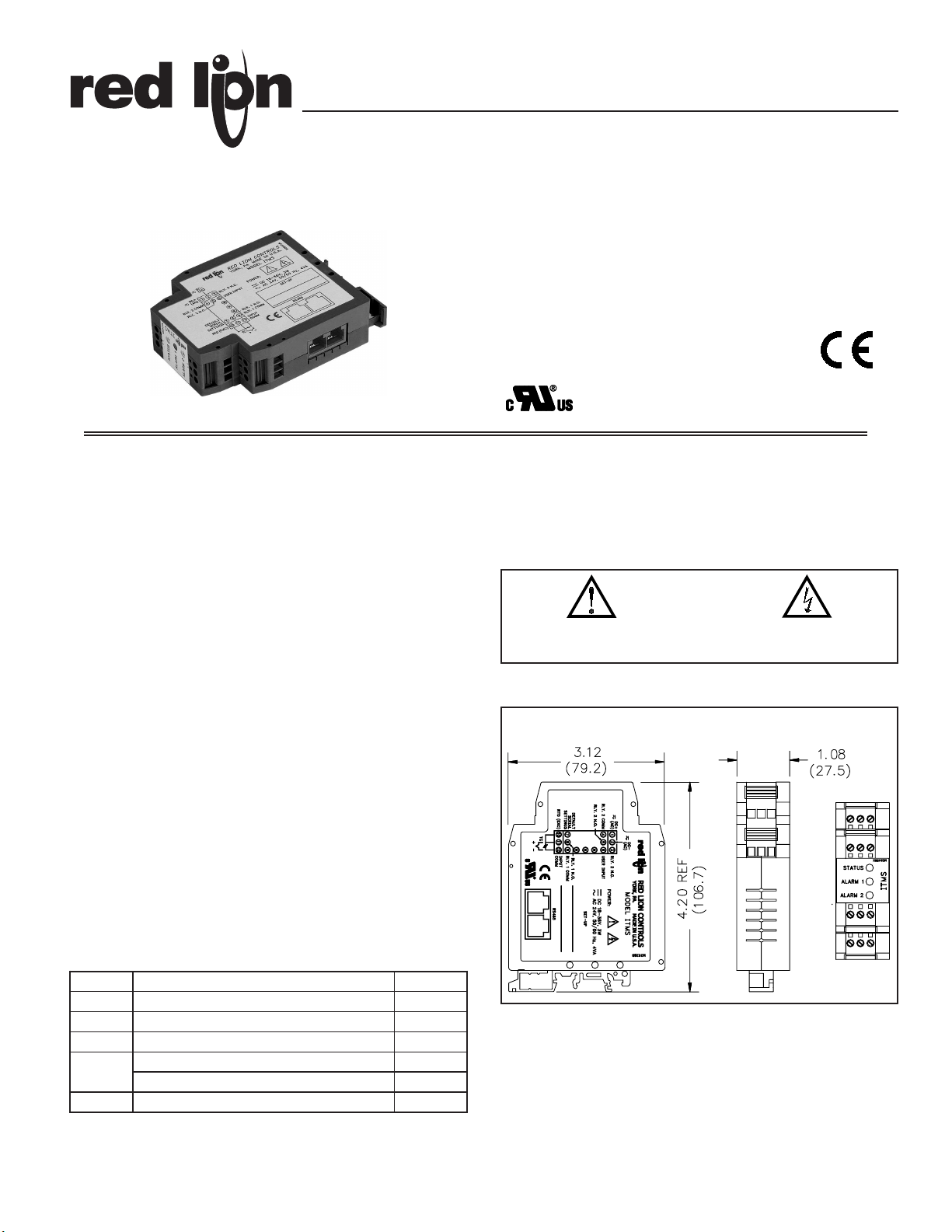

GENERAL DESCRIPTION

The ITMS4037 Intelligent Temperature to MODBUS™ Conditioner with

Alarms accepts a wide range of temperature sensors (thermocouple and RTD

elements), and converts the signal into a register format that can be read using

either ASCII or RTU MODBUS protocol.

The ITMS allows a choice of either Fahrenheit or Celsius readout with 0.1 or

1 degree of resolution. An offset value can be programmed to scale the input

signal to meet most process requirements. Additionally, two setpoint values can

be entered for dual relay process monitoring alarms.

The ITMS is programmed with Windows™ based SFIMS software. The

software allows configuration, calibration, and storage of ITMS program files.

Additionally, all setup parameters can be interrogated and modified through

MODBUS register and coil commands.

The RS485 port allows the ITMS to be multidropped, with Baud rates up to

38400. The CBPRO007 programming cable converts the RS232 port of a PC to

RS485, and is terminated with an RJ-11 connector. The bidirectional capability

of the CBPRO007 allows it to be used as a permanent interface cable as well as

a programming cable.

The ITMS’s two relay alarms can be configured independently for absolute

high or low acting with balanced or unbalanced hysteresis. Alarm 2 can also be

configured for deviation and band alarms. In these modes, Setpoint 2 tracks

Setpoint 1. Adjustable alarm trip delays can be used for delaying output

response. The alarms can be programmed for Automatic or Latching. Latched

alarms can be reset with a serial command or a user input. A standby feature

suppresses the alarm during power-up until the temperature stabilizes outside

the alarm region. Standby eliminates power-up tripping for low acting alarms.

A user input can be used to set and reset non-latching alarms. The output relays

can also be manually controlled with register commands.

The module’s high density packaging and DIN rail mounting saves time and

panel space. The module is equipped with a universal mounting foot for

attachment to standard DIN rails, including top hat (T) profile or G profile rail.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

1

O

TEMPERATURE TO MODBUS CONVERSION

O

ACCEPTS THERMOCOUPLE, RTD, mV OR RESISTANCE

SIGNALS

O

PROCESSOR BASED SCALING

O

PC CONFIGURATION SOFTWARE

O

DUAL SETPOINT RELAY ALARMS

O

FOUR WAY SIGNAL ISOLATION

MODEL ITMS - INTELLIGENT TEMPERATURE TO MODBUS CONDITIONER W/ ALARMS

MODEL

ITMS

DESCRIPTION

Temperature to MODBUS Conditioner w/Alarms

PART NUMBER

ITMS4037

CBPRO

SFIMS

Programming Interface Cable

PC Configuration Software for Windows

CBPRO007

SFIMS

CBJ

Cable RJ11 to Unterminated 7 foot length CBJ11A07

RJ Connector to Terminal Adapter

Cable RJ11 to RJ11 6 inch jumper

DRRJ11T6

CBJ11BD5

ORDERING INFORMATION

DIMENSIONS In inches (mm)

CAUTION: Read complete

instructions prior to installation

and operation of the unit.

CAUTION: Risk of electric shock.

Bulletin No. ITMS-B

Drawing No. LP0494

Released 1/07

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

UL Recognized Component,

File # E179259

Page 2

2

SPECIFICATIONS

1. POWER: 18-36 VDC, 3.0 W max. or 24 VAC, ±10%, 50/60 Hz, 4 VA max.

2. INPUT:

Sample Rate: 67 msec. (15 Hz)

Failed Sensor Response: Open or shorted (RTD only) sensor coils indication,

error code returned in Process Value

Common Mode Rejection: 50/60 Hz, 110 dB min.

Overvoltage: 30 VDC

Response Time: 150 msec. max.

3. THERMOCOUPLE INPUTS:

Types: T, E, J, K, R, S, B, N, C, linear mV

Input Impedance: 20 MΩ

Lead Resistance Effect: 0.22 µV/Ω

Resolution: 1° or 0.1° for all types

4. RTD INPUTS:

Type: 2 or 3 wire

Excitation: 150 µA

Lead Resistance: 10 Ω max.

Resolution: 1° or 0.1° for all types

5. INDICATION ACCURACY: ±(0.3% of span, +1°C), includes NIST

conformity, cold junction effect, A/D conversion errors, tempco and

linearization conformity at 23°C after 20 minute warm-up.

Span Drift (max) : 0.01% /°C

6. USER INPUT: Internally pulled up to +5 VDC. VIL= 0.78 V max.,

VIH= 1.8 V min. I

OFF

= 9 µA max. 30 V max. over voltage continuously.

7. ISOLATION LEVEL: 1.5 KV @ 50/60 Hz, 1 minute (150 V working)

between input, RS485 and power supply. 2300 Vrms, 1 minute (300 V

working) to relay contacts.

8. SERIAL COMMUNICATIONS:

Type: RS485; RTU and ASCII MODBUS modes

Baud: 300, 600, 1200, 2400, 4800, 9600, 19200, and 38400

Format: 7/8 bit, odd, even and no parity

Transmit Delay: Programmable. (See Transmit Delay explanation in Step 6)

Transmit Enable (TXEN): (primarily for 20 mA loop converter) open

collector V

OH

= 10 VDC max. VOL= 0.5 VDC @ 5 mA max. current limit

9. A/D CONVERTER: 16 bit resolution

10. RELAY OUTPUTS:

Type: 1 Form A N.O. contacts, 1 Form C DPDT

Rating: 5A @ 30 VDC or 250 VAC max. (resistive)

1/10 HP @ 120 VAC (inductive)

Response Time: 155 msec. max. to close including step response, 153 msec.

max. to open.

Output On Delay Time: Programmable from 0 to 32000 sec ±0.01% - 1 sec. max.

11. MEMORY: Nonvolatile E

2

PROM retains all programmable parameters.

12. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range: -20 to +65 °C

Storage Temperature Range: -40 to +85 °C

Operating and Storage Humidity: 85% max. relative humidity (noncondensing) from -20 to +65 °C

Altitude: Up to 2000 meters

13. CERTIFICATIONS AND COMPLIANCE:

SAFETY

UL Recognized Component, File # E179259, UL3101-1, CSA 22.2 No. 1010-1

Recognized to U.S. and Canadian requirements under the Component

Recognition Program of Underwriters Laboratories, Inc.

IECEE CB Scheme Test Certificate # US/5141A/UL,

CB Scheme Test Report # 01ME11540-0702001

Issued by Underwriters Laboratories, Inc.

IEC 1010-1, EN 61010-1: Safety requirements for electrical equipment

for measurement, control, and laboratory use, Part 1.

ELECTROMAGNETIC COMPATIBILITY

Notes:

1. This device was designed for installation in an enclosure. To avoid

electrostatic discharge to the unit in environments with static levels above

6 KV, precautions should be taken when the device is mounted outside an

enclosure. When working in an enclosure (ex. making connections, etc.),

typical anti-static precautions should be observed before touching the module.

Refer to the EMC Installation Guidelines section of this bulletin for

additional information.

14. CONSTRUCTION: Case body is black high impact plastic. Installation

Category II, Pollution Degree 2.

15. CONNECTIONS: Wire clamping screw terminals.

16. MOUNTING: Universal mounting foot for attachment to standard DIN

style mounting rails, including top hat (T) profile rail according to EN50022

- 35 x 7.5 and -35 x 15, and G profile rail according to EN50035 - G32.

17. WEIGHT: 4.5 oz. (127.57 g)

Power mains class A

Enclosure class AEN 55011RF interference

Emissions to EN 55011

Level 3; 10 V/mENV 50204Simulation of cordless telephone

150 KHz - 80 MHz

Level 3; 10 V/rms EN 61000-4-6RF conducted interference

Level 3; 2 KV power

Level 4; 2 KV I/O EN 61000-4-4Fast transients (burst)

80 MHz - 1 GHz

Level3; 10 V/MEN 61000-4-3Electromagnetic RF fields

Level 3; 8 KV air

1

Level 2; 4 KV contact EN 61000-4-2Electrostatic discharge

200 Hz, 50% duty cycle

Immunity to EN 50082-2

900 MHz ± 5 MHz

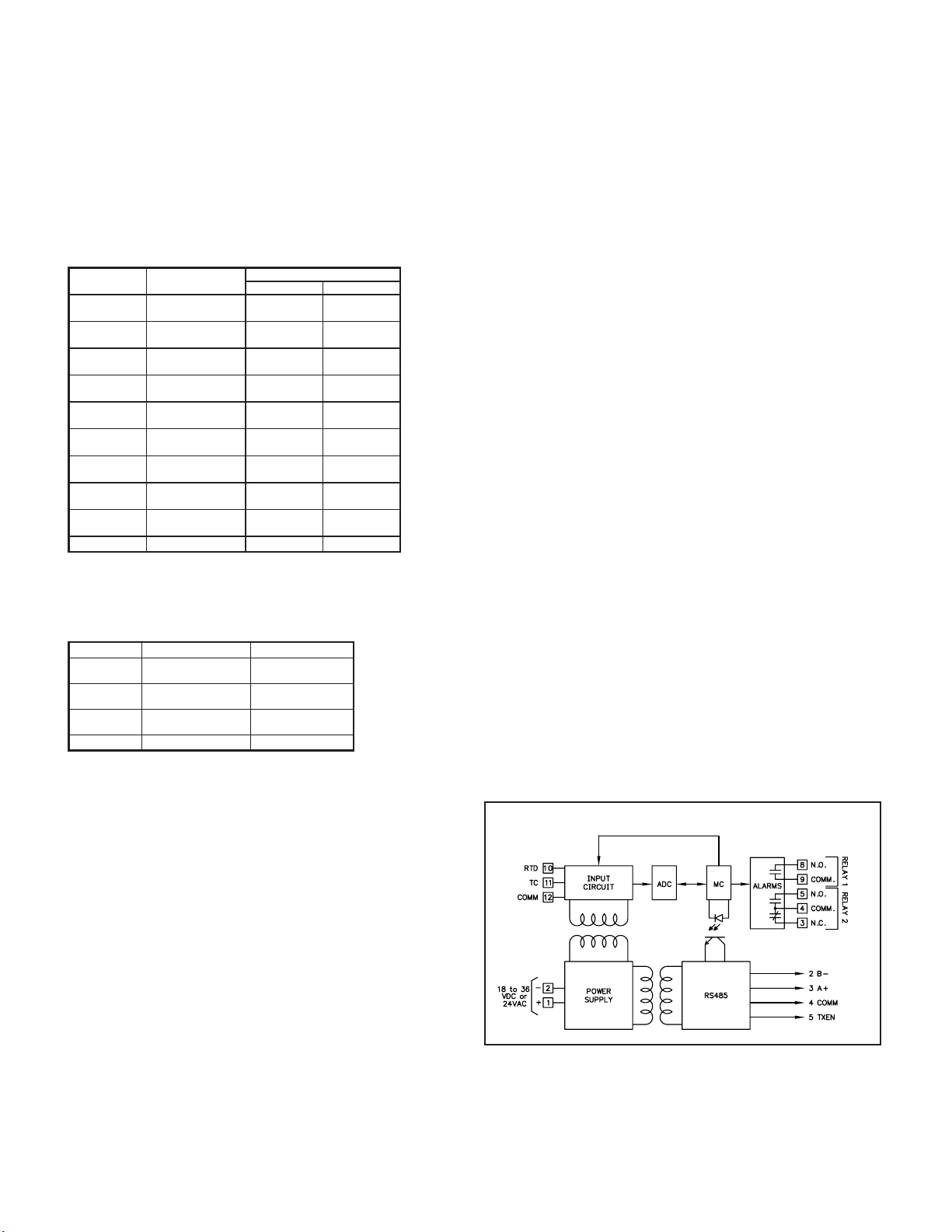

BLOCK DIAGRAM

RTD TYPE INPUT TYPE RANGE

385

100 Ω platinum,

Alpha=.00385

-200 to +800°C

-328 to +1472°F

392

100 Ω platinum,

Alpha=.003919

-200 to +800°C

-328 to +1472°F

672

120 Ω nickel,

Alpha=.00672

-80 to +260°C

-112 to +500°F

Ohms Linear Resistance

0 to 440 Ω

TC TYPE DISPLAY RANGE

WIRE COLOR

ANSI BS 1843

T

-200 to +400°C

-328 to +752°F

(+) blue

(-) red

(+) white

(-) blue

E

-200 to +750°C

-328 to +1382°F

(+) violet

(-) red

(+) brown

(-) blue

J

-200 to +760°C

-328 to +1400°F

(+) white

(-) red

(+) yellow

(-) blue

K

-200 to +1372°C

-328 to +2502°F

(+) yellow

(-) red

(+) brown

(-) blue

R

0 to +1768°C

+32 to +3214°F

No Standard

(+) white

(-) blue

S

0 to +1768°C

+32 to +3214°F

No Standard

(+) white

(-) blue

B

+200 to +1820°C

+392 to +3308°F

No Standard No Standard

N

-200 to +1300°C

-328 to +2372°F

(+) orange

(-) red

(+) orange

(-) blue

C

W5/W26

0 to +2315°C

+32 to +4199°F

No Standard No Standard

mV -10 mV to 65 mV NA NA

Page 3

3

MODULE ISOLATION

The ITMS features “4-way” signal isolation. The 4-way isolation is a

combination of optical, transformer and relay barriers, providing common mode

voltage (CMV) isolation to 1.5 KV for 1 minute between input, RS485, and

power supply. Isolation between relay contacts and all other inputs is 2300 Vrms

for 1 minute.

LED FUNCTIONALITY

CONDITION GREEN LED 2 RED LEDS

Power Applied On ———

Communication Received Flashing ———

Respective Alarm On On

Checksum error Flashing Flashing

Calibration Off On

EMC INSTALLATION GUIDELINES

Although this module is designed with a high degree of immunity to ElectroMagnetic Interference (EMI), proper installation and wiring methods must be

followed to ensure compatibility in each application. The type of the electrical

noise, source or coupling method into the unit may be different for various

installations. Cable length, routing, and shield termination are very important

and can mean the difference between a successful or troublesome installation.

Listed below are some EMC guidelines for successful installation in an

industrial environment.

1. Use shielded (screened) cables for all Signal and Control inputs. The shield

(screen) pigtail connection should be made as short as possible. The

connection point for the shield depends somewhat upon the application.

Listed below are the recommended methods of connecting the shield, in order

of their effectiveness.

a. Connect the shield only at the rail where the unit is mounted to earth

ground (protective earth).

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is above 1 MHz.

c. Connect the shield to common of the unit and leave the other end of the

shield unconnected and insulated from earth ground.

2. Never run Signal or Control cables in the same conduit or raceway with AC

power lines, conductors feeding motors, solenoids, SCR controls, and

heaters, etc. The cables should be run in metal conduit that is properly

grounded. This is especially useful in applications where cable runs are long

and portable two-way radios are used in close proximity or if the installation

is near a commercial radio transmitter.

3. Signal or Control cables within an enclosure should be routed as far away as

possible from contactors, control relays, transformers, and other noisy

components.

4. In extremely high EMI environments, the use of external EMI suppression

devices, such as ferrite suppression cores, is effective. Install them on Signal

and Control cables as close to the unit as possible. Loop the cable through the

core several times or use multiple cores on each cable for additional

protection. Install line filters on the power input cable to the unit to suppress

power line interference. Install them near the power entry point of the

enclosure. The following EMI suppression devices (or equivalent) are

recommended:

Ferrite Suppression Cores for signal and control cables:

Fair-Rite # 0443167251 (RLC # FCOR0000)

TDK # ZCAT3035-1330A

Steward # 28B209-0A0

Line Filters for input power cables:

Schaffner # FN610-1/07 (RLC # LFIL0000)

Schaffner # FN670-1.8/07

Corcom # 1 VR3

Note: Reference manufacturer’s instructions when installing a line filter.

5. Long cable runs are more susceptible to EMI pickup than short cable runs.

Therefore, keep cable runs as short as possible.

Page 4

4

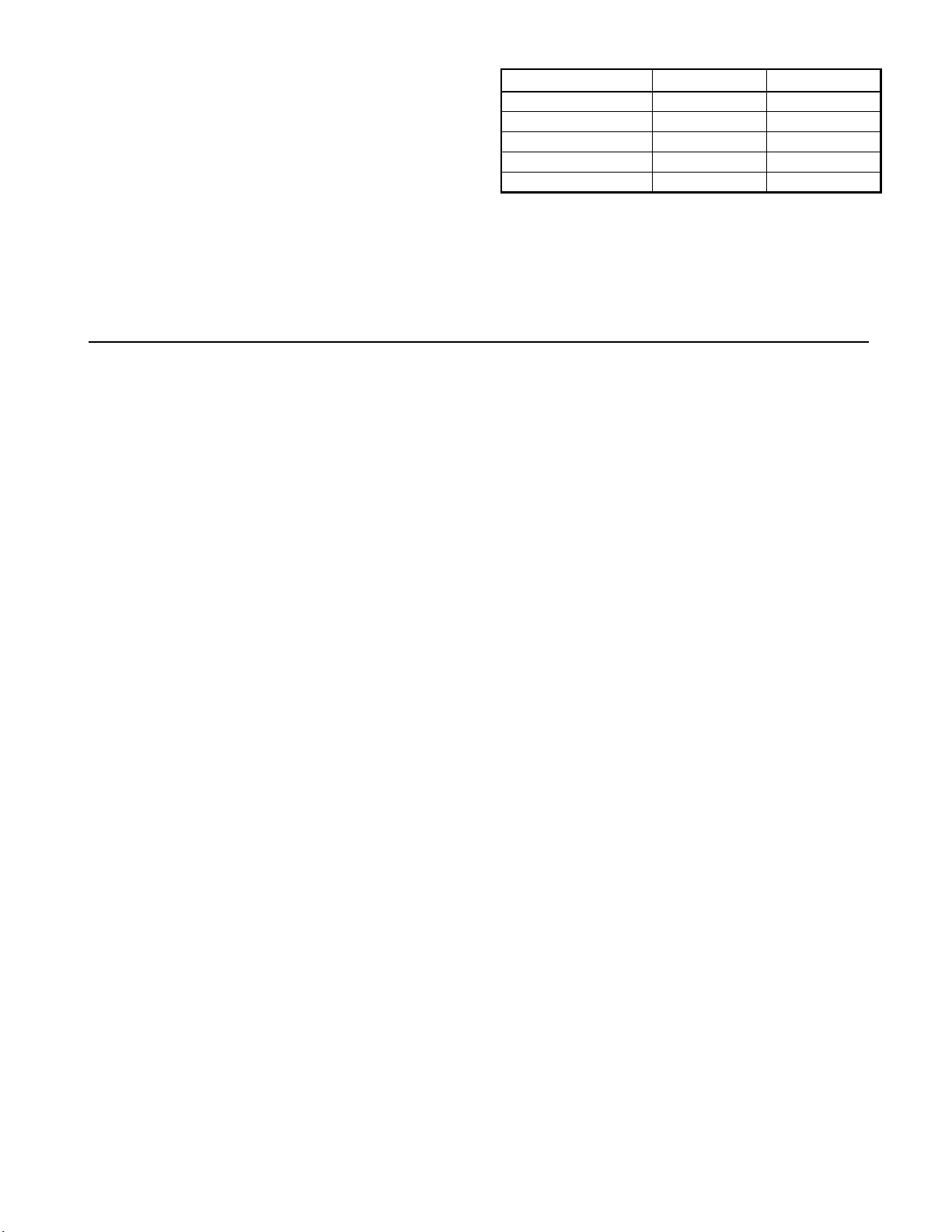

WIRING CONNECTIONS

All conductors should meet voltage and current ratings for each terminal.

Also, cabling should conform to appropriate standards of good installation, local

codes and regulations. When wiring the module, use the numbers on the label to

identify the position number with the proper function. Strip the wire, leaving

approximately 1/4" (6 mm) of bare wire exposed. Insert the wire into the

terminal, and tighten the screw until the wire is clamped tightly. (Pull wire to

verify tightness.) Each terminal can accept up to one #14 AWG (2.55 mm), two

#18 AWG (1.02 mm), or four #20 AWG (0.61 mm) wires.

MODULE POWER CONNECTIONS

AC module power is connected to terminals 1 and 2. DC module power is

connected with (+) to terminal 1 and (-) to terminal 2. For best results, the power

should be relatively “clean” and within the specified limits. Drawing power

from heavily loaded circuits or from circuits that also power loads that cycle on

and off should be avoided. It is recommended that power supplied to the module

be protected by a fuse or circuit breaker.

INPUT CONNECTIONS

Thermocouple Input

Thermocouple leads are connected to terminals 11 (+) and 12 (-).

RTD Input

For 3-wire RTD elements, connect the sense leads to terminals 11 and 12. The

excitation lead is connected to terminal 10 (EXC).

For 2-wire RTD elements, connect the sense leads to terminals 11 and 12.

Install a copper sense lead of the same gauge and length as the RTD leads.

Attach one end of the wire at the probe and the other end to terminal 10.

Complete lead wire compensation is obtained. This is the preferred method. If a

sense wire is not used, then Terminal 11 should be shorted to terminal 10. A

temperature offset error will exist. The error may be compensated by

programming a temperature offset.

RELAY OUTPUT CONNECTIONS

Relay 1

Relay 1 is a Form A output relay. Wiring is connected between terminal 9

(COMM.) common and terminal 8 (N.O.) the normally open contact.

Relay 2

Relay 2 is a Form C output relay. Wiring is connected between terminal 4

(COMM.) common and either terminal 5 (N.O.), the normally open contact, or

terminal 3 (N.C.), the normally closed contact.

To prolong contact life and suppress electrical noise interference due to the

switching of inductive loads, it is good installation practice to install a snubber

across the contacts. Follow the manufacturer’s instructions for installation.

Note: Snubber leakage current can cause some high impedance loads to be held ON.

DEFAULT SERIAL SETTING CONNECTION

If the ITMS settings are unknown, or forgotten, they can be reset to the

factory defaults by connecting the Serial Default terminal 7 to Input Comm.

terminal 12 with a jumper, and then cycling power.

Defaults:

USER INPUT CONNECTION

The user input is activated when terminal 6 is pulled low (connected to Input

Comm. terminal 12).

RS485 SERIAL CONNECTIONS

There are two RJ-11 connectors located on the bottom for paralleling

communications. For single device communications, either connector can be

used. When used in conjunction with Red Lion Control Paradigm HMI products,

reverse A+ and B- wiring.

RJ11 ITMS

1 Not used

2B-

3A+

4 COMM

5 TXEN

6

2345

Not used

ITMS CONNECTOR

STEP 1 WIRING THE MODULE

STEP 2 INSTALLING SFIMS (Software for Intelligent Modules)

Insert the SFIMS diskette into the A: or B: drive. Then Run A:\SETUP

(or B:\SETUP) to install RLCPro onto the hard drive. An icon labeled

RLCPro will be created under the group RLCPro.

Protocol: RTU 8Data Bits:

Address: 247 noneParity:

Baud Rate: 9600

Page 5

5

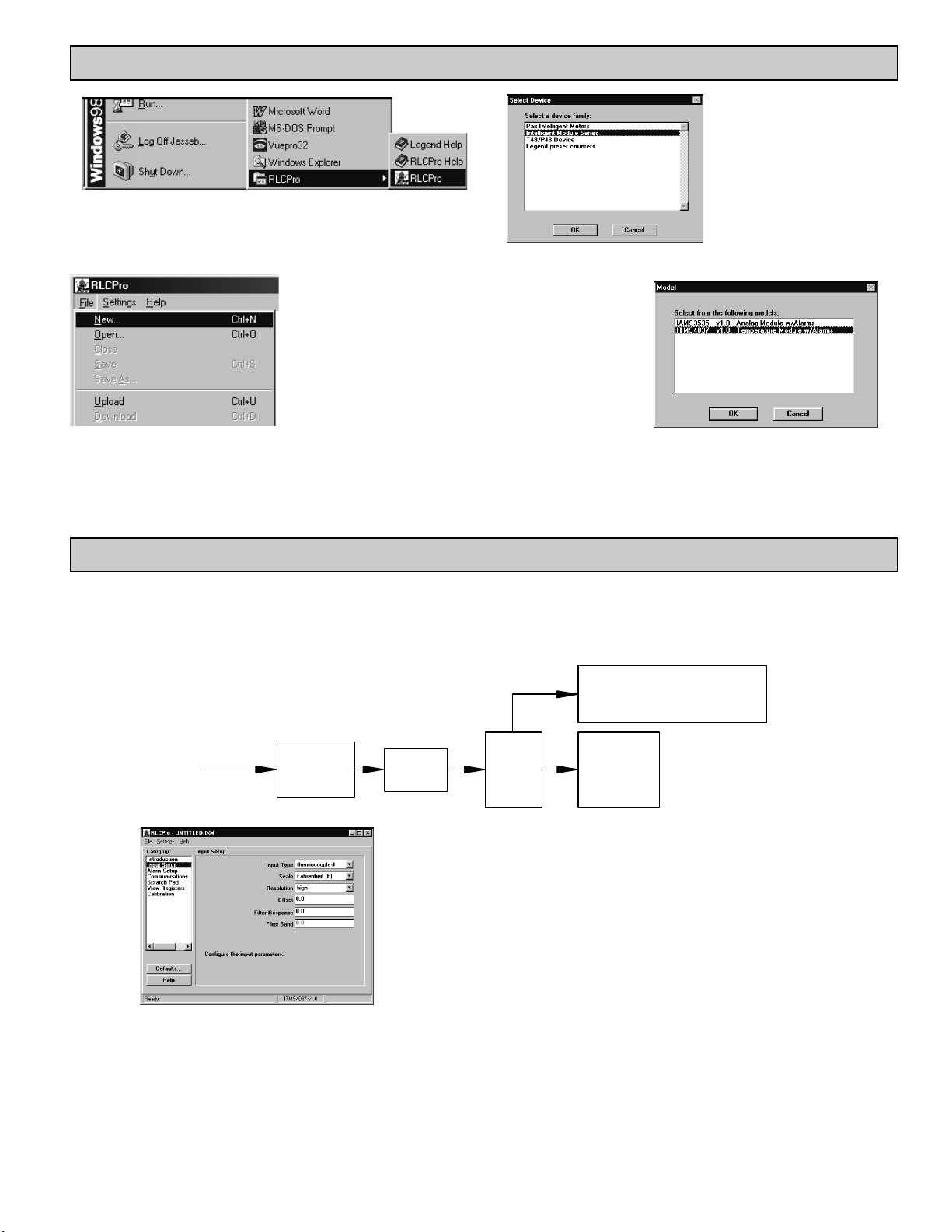

STEP 3 PROGRAMMING - Getting Started

Run RLCPro by double-clicking the icon, or use the start menu.

Use the FILE pull-down menu

to select a NEW file.

You will be prompted to

select the proper device,

and then the model.

STEP 4 PROGRAMMING THE INPUT

The ITMS receives a temperature sensor input, converts it to a raw digital value, and stores this number in the ADC Value (register 40001). This number

is scaled into degrees, and a programmable Offset Value (register 40012), that can be used for sensor correction, is applied. The result is stored as the

Temperature Value (register 40002). It is also stored in the IEEE 754 Standard 32-bit floating decimal format (register 40003 and 40004). The non-scaled

ADC, the scaled Process Temperature Value, or the Floating Point Value may be accessed for the purpose of monitoring the input level.

INPUT

SIGNAL

Register 40001

ADC READING

INTERNAL

MATH

OFFSET

PROCESS

TEMPERATURE

VALUE

LO Order Byte

HI Order Byte

IEEE STANDARD 754

FLOATING DECIMAL POINT

Register 40003

Register 40004

Register

40012

Register 40002

Input Type: Select the proper input type from the pull down menu.

Scale: Select Fahrenheit or Celsius. In linear millivolt or resistance modes, this has no

effect.

Resolution: For thermocouple, RTD, or linear resistance modes, low resolution selects

whole degrees or ohms. In these same modes, high resolution selects tenth of degrees

or ohms. In linear mV mode, low selects hundredths of mV, and high selects

thousandths of mV.

Offset: The Offset value can be used as a sensor correction value.

Filter Response: The Filter Response is a time constant, in tenth of second increments,

that is used to stabilize an erratic input. The Process Value stabilizes to 99% of the final

value within approximately 5 time constants. A value of ‘0’ disables digital filtering.

Filter Band: Filter Band is a value expressed in Temperature (degrees or tenths) units.

When a fluctuating signal remains within the band value, the Digital Filter is active,

and therefore stabilizes the Process Temperature Value. When a fluctuating signal

exceeds the Filter Band value, the Digital Filter is momentarily disabled to allow for

quick response to valid process changes. Once the signal variation is less than the Filter

Band value, the Digital Filter is reactivated.

Page 6

6

STEP 5 PROGRAMMING THE ALARMS

USER INPUT MODE OPERATION

INPUT

ACTION

INPUT

ACTIVATION

AUTOMATIC ALARM LATCHED ALARM

IN ALARM REGION OUTSIDE ALARM REGION IN ALARM REGION OUTSIDE ALARM REGION

Reset Edge No action

Resets and puts the alarm in

Standby mode; resets alarm if in

Hysteresis band

Resets alarm if on

Set Edge No action No action No action Sets alarm latched

Reset Level No action

Resets alarm while input is active,

resumes normal operation when

input is inactive; resets alarm if in

Hysteresis band

Resets alarm if on

Set Level No action No action Sets alarm latched

Resets and puts the alarm in

Standby mode; resets alarm if in

Hysteresis band

Action: Alarm 1 can be programmed for 5 modes of operation, Alarm 2 has 9 possible modes. See

Setpoint Alarm figures for illustration.

Manual: In Manual mode, the Alarms are forced on and off by writing ‘0’ or ‘1’ to the appropriate

MODBUS register (Alarm 1 state = 40027, Alarm 2 state = 40028). The alarms are

configured for this action from the factory. In this mode, the alarms will not respond to their

setpoint or hysteresis values.

Absolute HI: (with balanced or unbalanced hysteresis) The Alarm energizes when the Temperature

Value exceeds the Setpoint Limit Value.

Absolute LO: (with balanced or unbalanced hysteresis) The Alarm energizes when the Temperature

Value falls below the Setpoint Limit Value.

Deviation HI, Deviation LO, Band Inside or Outside: In these modes, Alarm 2 “tracks”

Alarm/Setpoint 1.

Setpoint: The alarm Setpoint value, entered in degrees. If the ITMS is programmed for mV or resistance modes, then the Setpoint is in mV or Ohms,

respectively.

Hysteresis: Hysteresis is used to eliminate output chatter. The Hysteresis Amount is the difference between the points where an Alarm will turn on

and turn off. In Unbalanced modes, the alarm turns on at the Setpoint, and turns off at Setpoint minus hysteresis for HI alarms, and Setpoint plus

hysteresis for LO alarms. In Balanced modes, the hysteresis is evenly divided above and below the Setpoint value. (See the Setpoint Alarm

Figures.)

Note: The Setpoint, along with the Hysteresis, MUST NOT produce a “trigger point” higher than 32,000, or less than -32,000. (See the Setpoint

Alarm Figures.)

Trigger Points: Trigger Points are the Process Values where the alarm state changes. Their values cannot be entered directly, but are shown as a

reference in the SFIMS software. The Setpoint Value, Hysteresis Value, and Setpoint Alarm Type determine the trigger points. With Deviation or

Band modes, Setpoint 1 and Setpoint 2 are combined to determine the trigger points. Trigger Points cannot be greater than +32000 or less than -

32000. If these limits are exceeded, the alarm is disabled and an alarm threshold over range error is set. The Trigger Points can be outside the

Temperature Value range for a given sensor type without receiving an error, but the alarm will not change state for that trigger point.

Reset: The alarms can be programmed for Automatic or Latched. In Automatic mode, an energized alarm turns off by itself once the Process Value

leaves the alarm region. In Latched mode, an energized alarm requires a reset from the User input, or a serial reset command. This is done by

writing a ‘0’ to the appropriate MODBUS register. (Alarm 1 state = 40027, Alarm 2 state = 40028)

On Delay: The time, in whole second increments, that the alarm will take to energize when the Process Value enters into an alarm region.

Enable Standby Delay: Standby prevents nuisance (typically low level) alarms after a power up. After powering up the unit, the temperature must

leave the alarm region. Once this has occurred, the standby is disabled, and the alarm responds normally until the next module power up.

User Input Action: The User Input can be programmed to Reset, or Set, either Alarm 1, Alarm 2, or both. The User Input is activated when terminal

6 is pulled low. (Connected to the Common terminal 12.)

User Input Activation: The User Input can be programmed to respond as a Level (maintained) or Edge (momentary) input. See the User Input Mode

Operation Table below.

Sensor Failure Action: This setting allows different alarm responses when the temperature sensor fails. The ITMS can be programmed to turn one

or both alarms on or off.

Sets alarm while input active,

resumes normal operation when

input is inactive

Resets alarm while input is active,

resumes normal operation when

input is inactive; resets alarm if in

Hysteresis band

Page 7

7

SETPOINT ALARM FIGURES

STEP 6 PROGRAMMING THE ITMS COMMS PORT

MODBUS Protocol: RTU or ASCII

Unit Address: 1-247

Baud Rate: 300, 600, 1200, 2400, 4800, 9600, 19200, or 38400

Data Bits: 7 or 8

Parity: odd, even, or none

Transmit Delay: Programmable from 1-255 milliseconds. The Transmit

Delay is the time the ITMS waits to respond to a serial command,

UNLESS the values in the table are larger.

Note: If the communication settings are changed and then a download is

performed, the module will now respond to the new settings. Any further attempts to communicate to the module

must target the new address, with the new settings. If you do not know or cannot recall the ITMS settings, they

can be reset to factory defaults. Connect the Serial Default terminal to Common, and cycle power. The Defaults

button in the SFIMS software will update the category display to these settings.

Communications Diagnostics: The Communications Diagnostics function can be used to troubleshoot systems that are

experiencing communication errors. Press the Read button to retrieve the diagnostics information. The Commands

Received and the Commands Processed values are automatically reset when the values are read, and at each unit power-up.

Commands Received: The number of messages received that started with the units own address.

Commands Processed: The number of “good” messages received. A “good” message is considered one that contained the

correct unit address, parity, and checksum (CRC or LRC).

BAUD RTU ASCII

38400 2 msec. 2 msec.

19200 3 msec. 2 msec.

9600 5 msec. 2.3 msec.

4800 9 msec. 4.6 msec.

2400 17 msec. 9.2 msec.

1200 33 msec. 18.4 msec.

600 65 msec. 36.7 msec.

300 129 msec. 73.4 msec.

Page 8

8

STEP 7 PC PORT CONFIGURATION

STEP 8 DOWNLOADING

Go to the SETTINGS pull-down menu, and select PC PORT SETTINGS.

The Communications Settings window allows you to set up the software properly to perform a download.

Connection: Select the computer port (COMM 1-4) that the ITMS is connected to.

Note: The following settings must match the ITMS. If you do not know or cannot recall the ITMS settings, they can

be reset back to factory defaults. Simply jumper the Serial Default terminal to Common, and cycle power. The

serial settings will default to RTU mode, 9600 baud, 8 data bits, No parity, with an address of 247.

Protocol: RTU or ASCII

Unit Address: 1-247

Baud Rate: 300, 600, 1200, 2400, 4800, 9600, 19200, 38400

Data Bits: 7 or 8

Parity: odd, even, or none

Note: The CBPRO007 download cable DOES NOT

typically require power. In most cases it will derive

its power from the PC. If communications can not be

established, follow the troubleshooting guide. If it is

determined that the converter requires power, attach

a 12 VDC power supply to the VDC and common

terminals of the cable.

Go to the FILE pull-down menu, and select DOWNLOAD.

The following screen prompts you to

ensure that the proper file is downloaded

to the correct module. Click “OK” to

continue.

Connect the ITMS to the computer with the CBPRO007 interface cable (or any suitable RS232/RS485 converter).

Apply 18-36 VDC to the supply terminals of the ITMS.

Page 9

9

STEP 9 SCRATCH PAD MEMORY

STEP 10 VIEW REGISTERS

STEP 11 CALIBRATION

The ITMS is fully calibrated from the factory. Recalibration is recommended every two years. Each

range has its own internal references that are recalled when the range is selected. This allows

independent calibration for each range. All calibration settings are stored in the E2PROM. Calibration

may be performed by using SFIMS software or MODBUS commands.

RTD and CJ calibrations are dependent on the millivolt calibration and, therefore, must be performed

after a millivolt calibration has been completed. RTD or CJ calibration may be performed independently

of the millivolt calibration.

Calibration Type: This specifies the type of calibration to be performed.

Cold Junction Calibration:

TC Type: This selects the type of TC that is being used to calibrate the cold junction.

Scale: This selects the scale in which the Thermometer temperature is entered and the Module

temperature is displayed.

Thermometer: Enter the reference thermometer temperature here.

Module: This displays the ITMS process temperature value after a cold junction calibration is

completed to verify the accuracy.

Calibrate: The Calibrate button initiates the calibration process after the appropriate settings are

selected.

Note: Millivolt calibration requires a precision voltage source with an accuracy of 0.025% or better.

Allow the ITMS to warm up for 30 minutes minimum and follow the manufacturer’s warm-up

recommendations for the calibration source. RTD calibration requires a 0.1% precision 300 ohm

resistor. CJ calibration should be performed with a TC of known accuracy of types T, E, J, K, C or N

only. When using SFIMS for calibration, select the type of calibration to be performed, and press the

Calibrate button. Follow the calibration procedures in the software.

The Scratch Pad category can be used to read or write to the Scratch Pad memory locations (41101-

41116). The Scratch Pad locations can be used to store user information.

Data Format: Allows registers to be viewed in decimal or hexadecimal format.

Upload: The Upload button causes SFIMS software to read the Scratch Pad registers from the module.

Download: The Download button causes SFIMS software to write to the Scratch Pad registers in the

module.

Note: Downloading new values to the module Scratch Pad locations overwrites the information that is

currently stored in those registers.

The View Registers category can be used as a method of diagnostics. Use the ITMS Register Table

as a reference of register assignments and data.

First Register: This specifies the first, or only, register to be read in a block.

# of Registers: This is the length of the block to be read. The module supports block read and write

commands up to 16 registers in length.

Data Format: Allows registers to be viewed in decimal or hexadecimal format.

Read: Clicking the Read button causes SFIMS software to read the selected register from the module.

Write: Clicking the Write button causes SFIMS software to write the selected registers to the module.

Note: The Write button overwrites the existing register values, and may change the module setup and

operation.

Page 10

10

INSTALLATION

The unit is equipped with a universal mounting foot for attachment to standard DIN style mounting rails, including G profile rail

according to EN50035 - G32 , and top hat (T) profile rail according to EN50022 - 35 x 7.5 and 35 x 15. The unit should be installed in a

location that does not exceed the maximum operating temperature and provides good air circulation. Placing the unit near devices that

generate excessive heat should be avoided.

G Rail Installation

To install the ITMS on a “G”

style DIN rail, angle the module

so that the upper groove of the

“foot” catches under the lip of the

top rail. Push the module toward

the rail until it snaps into place.

To remove a module from the

rail, push up on the bottom of the

module while pulling out and

away from the rail.

T Rail Installation

To install the ITMS on a “T”

style rail, angle the module so

that the top groove of the “foot”

is located over the lip of the top

rail. Push the module toward the

rail until it snaps into place. To

remove a module from the rail,

insert a screwdriver into the slot

on the bottom of the “foot”, and

pry upwards on the module until

it releases from the rail.

APPLICATION

A chemical company wanted to remotely monitor the

temperature of several holding tanks. Using the ITMS, the

customer was able to receive, interpret, and store the

temperature readings via standard thermocouples. To provide a

remote display, the customer chose a Red Lion Paradigm HMI

(Human Machine Interface). The HMI communicates with the

ITMS modules and displays the information graphically,

providing an intuitive interface. As an added benefit, the ITMS

alarm setpoints can be adjusted from the HMI, while providing

reliable local alarm outputs.

TROUBLESHOOTING

* Can be monitored by accessing coils 9-16, or register 40025.

For further technical assistance, contact technical support.

PROBLEM CAUSE REMEDIES

Green LED will not light Module power Check module power connections and voltage level

Process Value not changing Input signal Check input signal connections and signal level

Incorrect scaling Check input setup, scaling values, and re-download

Alarms disabled Alarm threshold over range*; checksum

error; Input over/under range; open or

shorted probe*; calculated results over

+32000 or -32000; in Calibration Mode

Adjust alarm Setpoint and Hysteresis to ensure trigger

point is within -32000 to +32000 (See Alarm setup). For

other possible causes, see the remaining remedies

Process Value stays at 32001 or -32001 Input over or under range* due to:

Wrong TC, or RTD

Incorrect input type

Check input level

Check input type, and re-download

Process Value stays at -32002

NOTE: The ITMS’ serial settings must match the device that it is communicating with. If you do not know or

cannot recall the ITMS settings, they can be reset back to factory defaults. Simply jumper the Serial Default

terminal to Common, and cycle power. The serial settings will default to RTU mode, 9600 baud, 8 data bits, no

parity, with an address of 247.

Shorted RTD:*

Process Value stays at 32002 Open TC or RTD:* Check input signal connections and probe

Process Value stays at 32100, Flashing

LEDs, alarms disabled

Parameter checksum*, loss of

parameter settings

Calibration checksum*

Re-download SFIMS file (reconfigures each parameter)

Perform calibration procedure

Will not communicate

(Green LED not flashing)

Incorrect serial settings (ITMS port)

Incorrect serial settings (computer port)

Incorrect wiring

Verify ITMS communications setup

Go to pull down menu SETTINGS, PC PORT SETTINGS

Try switching A+ and B- lines

Provide a common connection

Check input signal connections and probe

Process Value stays at +32003 or -32003 Calculated Temp. value over +32000 or

-32000

Check offset value, Register 40012

Process Value not changing or incorrect

Page 11

11

MODBUS INFORMATION

The remaining sections of this bulletin list ITMS Register Format information and MODBUS conformity.

MODBUS SUPPORTED FUNCTION CODES

FC01: Read Coils

1. Valid coil addresses are 1-16.

2. Only 16 coils can be requested at one time.

3. Block starting point can not exceed coil 16.

FC05: Force Single Coil

1. Valid write (force) coil addresses are 1-10.

2. <8001>HEX is echoed back that the coil did not change during the request to

write to a read only coil.

FC15: Force Multiple Coils

1. Valid write (force) coil addresses are 1-10.

2. Block starting point can not exceed coil 10.

3. If a multiple write includes read only coils, then only the write coils will change.

FC03: Read Holding Registers

1. Valid addresses are 40001-40029, 41001-41010, 41101-41116.

2. Only 16 registers can be requested at one time.

3. Block starting point can not exceed the register boundaries.

4. <8000>HEX is returned in registers beyond the boundaries.

5. Holding registers are a mirror of Input registers.

FC06: Preset Single Register

1. Valid write (preset) addresses are 40006-40029, 41101-41116.

2. <8001>HEX is echoed back that the register did not change during the

request to write to a read only register.

3. If the write value exceeds the register limit (see Register Table), then that

register value changes to its exceeded high or low limit. It is also returned in

the response.

FC16: Preset Multiple Registers

1. Valid write (force) register addresses are 40006-40029, 41101-41116.

2. No response is given with an attempt to write to more than 16 registers at a time.

3. Block starting point can not exceed the read and write boundaries.

4. If a multiple write includes read only registers, then only the write registers

will change.

5. If the write value exceeds the register limit (see Register Table), then that

register value changes to its exceeded high or low limit.

FC04: Read Input Registers

1. Valid addresses are 30001-30029, 31001-31010, 31101-31116.

2. Only 16 registers can be requested at one time.

3. Block starting point can not exceed register boundaries.

4. <8000>HEX is returned in registers beyond the boundaries.

5. Input registers are a mirror of Holding registers.

FC08: Diagnostics

The following is sent upon FC08 request:

Unit Address, 08 (FC code), 04 (byte count), “Total Comms”

2 byte count,

“Total Good Comms” 2 byte count, checksum of the string.

“Total Comms” is the total number of messages received that were addressed to

the ITMS. “Total Good Comms” is the total messages received by the ITMS

with good address, parity and checksum. Both counters are reset to 0 upon

response to FC08.

FC17: Report Slave ID

The following is sent upon FC17 request:

Unit Address, 17 (FC code), RLC-ITMS4037, 0100 (for code version 1.00), 16

(number of read supported registers), 16 (number of writes supported

registers), 16 (number of registers available for GUID/ Scratch pad memory),

checksum of the string.

The following is the HEX of the above (with unit address of 247):

<F7><11><14><52><4C><43><2D><49><54><4D><53><34><30><33>

<37><01><00><00><10><00><10><00><10><8D><9F>

SUPPORTED EXCEPTION CODES

01: Illegal Function

Issued whenever the requested function is not implemented in the unit.

02: Illegal Data Address

Issued whenever an attempt is made to access a single register or coil that

does not exist (outside the implemented space) or to access a block of registers

or coils that falls completely outside the implemented space.

03: Illegal Data Value

Issued when an attempt is made to read or write more registers or coils than

the unit can handle in one request.

07: Negative Acknowledge

Issued when a write to coil or register is attempted with an invalid string

length.

CHECKSUM ERRORS

1. Calibration checksum covers the E2PROM that contains calibration values

for all ranges. When a calibration checksum error occurs, coil 10 becomes a

1. (See Coils Table)

2. Parameter checksum covers the E2PROM that contains the stored Holding

register settings. When a parameter checksum error occurs, coil 9 becomes a

1. (See Coils Table)

3. All of the LEDs will flash as long as either error occurs.

4. The alarms are disabled as long as either error occurs.

5. Either error can be cleared or activated manually by writing to the appropriate

coil. (This does not correct the reason for the error. It may be necessary to

reconfigure or calibrate.)

6. Both checksums are verified at power up.

CALIBRATION

Calibration may be performed by using SFIMS software, or MODBUS

commands. Review Calibration explanation in Step 11, before performing these

steps.

mV Calibration

1. Connect the signal source to proper ITMS terminals.

2. To set Input Type, enter 9 into register 40008.

3. To start calibration, enter <7777> HEX into register 40029.

4. To start ADC calibration, enter <0001> HEX into register 40029.

5. Apply the appropriate voltage and enter the corresponding <>HEX value into

register 40029 for each range to be calibrated.

0 mV <0002>, 14 mV <0003>, 28 mV <0004>, 42 mV <0005>, 56 mV<0006>

6. To save the values and end calibration, enter <0000> HEX into register 40029.

CJ Calibration

Note: In this procedure, write functions are performed in HEX and a write to a

register is monitored by a read in a different register.

1. Connect the thermocouple probe source to the proper ITMS terminals. (Types

T, E, J, K, N and C only).

2. To set Input Type, enter connected TC type into register 40008.

3. To set Scale, enter 1 for °C or 0 for °F into register 40006.

4. To set High Resolution, enter 1 into register 40009.

5. Place an external reference thermometer probe at the end of the ITMS probe.

The two probes should be shielded from air movement and allow sufficient

time to equalize in temperature. (As an alternative, the ITMS probe may be

placed in a calibration bath of known temperature.)

6. To start calibration, enter <7777> HEX into register 40029.

7. To start CJ calibration, enter <0010> HEX into register 40029.

8. Read the Process Temperature Value register 40002 (Read as an Integer).

9. Subtract the external reference reading from the Process Temperature Value

register 40002 reading. Adjust the results to hundredths position, drop

decimal point, and maintain the results sign. (If the difference is -2.0 degrees,

then adjust to -2.00 and remove decimal point yielding a value of -200.)

10. Enter <0011> HEX into register 40029.

11. Add the value from step 9 (maintain the sign) to the value existing in register

40007 (Read as an Integer).

12. If necessary, continue to adjust register 40007 value until the Process

Temperature Value register 40002 matches the external reference reading.

13. To save the values and end calibration, enter <0000> HEX into register

40029.

RTD Calibration

1. Connect precision 300 ohm resistor to terminals 11 & 12. Short terminals 10 & 11.

2. To set Input Type, enter 13 (Integer) or <000D> HEX into register 40008.

3. To start calibration, enter <7777> HEX into register 40029.

4. To start 0 ohm RTD calibration, enter <0015> HEX into register 40029.

5. Apply 0 ohms by shorting terminals 11 & 12 for 10 seconds.

6. To start 300 ohm RTD calibration, enter <0016> HEX into register 40029.

7. Apply 300 ohms by removing short from terminal 11 for 10 seconds.

8. To save the values and end calibration, enter <0000> HEX into register 40029.

Page 12

12

“1” = Open RTD or TC, causes Process Temp. Value to be 32002, disables alarms, causes no LED indication.

COIL ADDRESS COIL NAME ACCESS COMMENTS

1 Baud B0 Read/Write See Communication Register and Coils Table.

2 Baud B1 Read/Write See Communication Register and Coils Table.

3 Baud B2 Read/Write See Communication Register and Coils Table.

4 Parity B3 Read/Write See Communication Register and Coils Table.

5 Parity B4 Read/Write See Communication Register and Coils Table.

6 Data Bits B5 Read/Write See Communication Register and Coils Table.

7 Mode B6 Read/Write See Communication Register and Coils Table.

8 Change B7 Read/Write “1” = Change ITMS communications to above settings.

9 P. Checksum Error Read/Write “1” = Parameter checksum error, disables alarms, causes flashing LEDs.

10 C. Checksum Error Read/Write “1” = Calibration checksum error, disables alarms, causes flashing LEDs.

11 AL 1 Over Range Read Only “1” = Alarm 1 Threshold over range, disables alarms, causes no LED indication.

12 AL 2 Over Range Read Only

13 Open Input

14 Over Range

“1” = Alarm 2 Threshold over range, disables alarms, causes no LED indication.

Read Only “1” = Over Range, causes Process Temp. Value to be 32001, disables alarms, causes no LED indication.

Read Only

15 Under Range Read Only “1” = Under Range, causes Process Temp. Value to be -32001, disables alarms, causes no LED indication.

16 Shorted RTD Read Only “1” = Shorted RTD, causes Process Temp. Value to be -32002, disables alarms, causes no LED indication.

REGISTER TABLE

The below limits are shown as Integers or HEX < > values. Read and write functions can be performed in either Integers or HEX as long as the conversion was

done correctly. Negative numbers are represented by two’s complement.

COILS TABLE (COMMUNICATION AND ERRORS)

* For Input Registers, replace the 4xxxx with a 3xxxx in the above register address. The 3xxxx are a mirror of the 4xxxx Holding Registers.

† An attempt to exceed a limit will set the register to its high or low limit value.

Coils 1-7 mirror register 40026 and Coils 9-16 mirror register 40025.

REGISTER

ADDRESS *

REGISTER NAME

LOW LIMIT† HIGH LIMIT†

ACCESS COMMENTS

40007 CJ Temp -32000 32000

40001 ADC reading N/A N/A Read Only ADC (Analog to Digital Converter) reading of present input level.

Read/Write Cold Junction calibration temp (1 = 0.01°C).

40009 High Resolution

40002 Process Temperature Value N/A N/A Read Only Process Value (with scale and offset) of present input level.

0 1 Read/Write 0 = 1 degree, 1 = 0.1 degree.

40003 Floating Point LO N/A N/A Read Only

IEEE Standard 754 Floating Decimal Point, low order of Temperature Value.

(Allows 32 bit accuracy for external monitoring.)

40013 User Input Action <0000> <0015>

40004 Floating Point HI N/A N/A Read Only

IEEE Standard 754 Floating Decimal Point, high order of Temperature Value.

(Allows 32 bit accuracy for external monitoring.)

Read/Write See User Input Action Register Table.

40022 Sensor Failure Action

40005 User Input Pin State N/A N/A Read Only 0 = Active, 1 = Inactive.

0 3 Read/Write See Sensor Failure Action For Alarm State Table.

40006 Temperature Scale 0 1 Read/Write 0 = °F, 1= °C.

40008 Input Type 0 13 Read/Write See Input Type Register Table.

40010 Filter Band 0 32000 Read/Write See Filter Band explanation.

40011 Filter Response Time 0 1000 Read/Write See Filter Response Time explanation (1 = 0.1 second).

40012 Offset Value -32000 32000 Read/Write See Offset explanation.

40014 Alarm 2 Action <0000> <0038> Read/Write See Alarm 1 & 2 Action Register Table.

40015 Setpoint 2 Value -32000 32000 Read/Write Alarm 2 setpoint value based on Process Value.

40016 Alarm 2 Hysteresis 1 32000 Read/Write Alarm 2 hysteresis value based on Process Value.

40017 Alarm 2 Delay 0 32000 Read/Write Alarm 2 delay trip on time (1 = 1 second).

40018 Alarm 1 Action <0000> <0034> Read/Write See Alarm 1 & 2 Action Register Table.

40019 Setpoint 1 Value -32000 32000 Read/Write Alarm 1 setpoint value based on Process Value.

40020 Alarm 1 Hysteresis 1 32000 Read/Write Alarm 1 hysteresis value based on Process Value.

40021 Alarm 1 Delay 0 32000 Read/Write Alarm 1 delay trip on time (1 = 1 second).

40023 Transmit Delay 1 255 Read/Write Delay before serial transmission (1 = 1 msec). See Transmit Delay Explanation.

40024 Node (Unit) Address 1 247 Read/Write Node serial ITMS address.

40025 Error Coils <0000> <0003> Read/Write Mirror of Coils 9-16. See Coil Table.

40026 Comm. Coils <0020> <00FF> Read/Write Mirror of Coils 1-8. See Coil Table and Communications Table.

40027 Alarm 1 State 0 1 Read/Write Alarm 1 state (1 = on).

40028 Alarm 2 State 0 1 Read/Write Alarm 2 state (1 = on).

40029 Factory Calibration <0000> <7777> Read/Write See MODBUS Calibration explanation.

41001- 41010 Slave ID See FC17. See FC17. Read Only

ITMS-4037, 0100 (ver. 1.00), 16 reads, 16 writes, 16 scratch. The version value

could be higher.

41101- 41116 GUID/Scratch <0000> <FFFF> Read/Write

This area is for the user to store any related information.

This register area does not affect ITMS operations.

Page 13

13

ALARM 1 (40018) & 2 (40014) ACTION REGISTER TABLE

INPUT TYPE REGISTER (40008) TABLE

SENSOR FAILURE ACTION REGISTER (40022) TABLE

FOR ALARM STATE CONDITION

USER INPUT ACTION REGISTER (40013) TABLE

Examples:

Alarm 1 (40018):

Stand-by off, Latch on = 0 0 0 1 <1 >

Absolute Lo, Balanced = 0 0 1 0 < 2>

<1 2>

Alarm 2 (40014):

Stand-by on, Latch off = 0 0 1 0 <2 >

Band Outside = 0 1 1 1 < 7>

<27>

COMMUNICATIONS REGISTER (40026) AND COILS 1-8 TABLE

* When reading register 40026, B7 will be a 0. When writing (changing ITMS communications to the new setting), change B7 to a 1.

Mode Parity Baud

Coil 8

B7*

Coil 7

B6

Coil 6

B5

Coil 5

B4

Coil 4

B3

Coil 3

B2

Coil 2

B1

Coil 1B0Coil 8 =0

HEX

Coil 8 =1

HEX

RTU 8N1,2 300 0 / 1 0 1 0 0 0 0 0 <20> <A0>

RTU 8N1,2 600 0 / 1 0 1 0 0 0 0 1 <21> <A1>

RTU 8N1,2 1200 0 / 1 0 1 0 0 0 1 0 <22> <A2>

RTU 8N1,2 2400 0 / 1 0 1 0 0 0 1 1 <23> <A3>

RTU 8N1,2 4800 0 / 1 0 1 0 0 1 0 0 <24> <A4>

RTU 8N1,2 9600 0 / 1 0 1 0 0 1 0 1 <25> <A5>

RTU 8N1,2 19200 0 / 1 0 1 0 0 1 1 0 <26> <A6>

RTU 8N1,2 38400 0 / 1 0 1 0 0 1 1 1 <27> <A7>

RTU 8E1 300 0 / 1 0 1 0 1 0 0 0 <28> <A8>

RTU 8E1 600 0 / 1 0 1 0 1 0 0 1 <29> <A9>

RTU 8E1 1200 0 / 1 0 1 0 1 0 1 0 <2A> <AA>

RTU 8E1 2400 0 / 1 0 1 0 1 0 1 1 <2B> <AB>

RTU 8E1 4800 0 / 1 0 1 0 1 1 0 0 <2C> <AC>

RTU 8E1 9600 0 / 1 0 1 0 1 1 0 1 <2D> <AD>

RTU 8E1 19200 0 / 1 0 1 0 1 1 1 0 <2E> <AE>

RTU 8E1 38400 0 / 1 0 1 0 1 1 1 1 <2F> <AF>

RTU 8O1 300 0 / 1 0 1 1 1 0 0 0 <38> <B8>

RTU 8O1 600 0 / 1 0 1 1 1 0 0 1 <39> <B9>

RTU 8O1 1200 0 / 1 0 1 1 1 0 1 0 <3A> <BA>

RTU 8O1 2400 0 / 1 0 1 1 1 0 1 1 <3B> <BB>

RTU 8O1 4800 0 / 1 0 1 1 1 1 0 0 <3C> <BC>

RTU 8O1 9600 0 / 1 0 1 1 1 1 0 1 <3D> <BD>

RTU 8O1 19200 0 / 1 0 1 1 1 1 1 0 <3E> <BE>

RTU 8O1 38400 0 / 1 0 1 1 1 1 1 1 <3F> <BF>

Latched

Off=Auto

2nd Nibble

HEX

Stand By B7 B6 B5

off off 0 0 0 0 <0 >

off on 0 0 0 1 <1 >

on off 0 0 1 0 <2 >

on on 0 0 1 1 <3 >

B4

< 8>

< 7>

0

1

0

1

0

1

1

0

2

2

8

7

Band Inside

Band Outside

< 6>011026Deviation Lo

< 5>101025Deviation Hi

< 4>0010214Absolute Lo, unbalanced

< 3>1100213Absolute Hi, unbalanced

< 2>0100212Absolute Lo, balanced

< 1>1000211Absolute Hi, balanced

< 0>0000210Manual

1st Nibble

HEX

B0B1B2B3ALARMSMODEACTION

See Setpoint Alarm Figures, Page 5, for illustrations of alarm operation.

MODE TYPE MODE TYPE MODE TYPE

0 Tc - T 5 Tc - S 10 RTD - 385

1 Tc - E 6 Tc - B 11 RTD - 392

2 Tc - J 7 Tc - N 12 RTD - 672

3 Tc - K 8 Tc - C 13 LIN Ohms

4 Tc - R 9 LIN mV

MODE ACTION ALARM INPUT ACTIVATION

<0000> Reset 1 Level (Maintained)

<0001> Reset 2 Level (Maintained)

<0002> Reset 1 & 2 Level (Maintained)

<0003> Set 1 Level (Maintained)

<0004> Set 2 Level (Maintained)

<0005 Set 1 & 2 Level (Maintained)

<0010> Reset 1 Edge (Momentary)

<0011> Reset 2 Edge (Momentary)

<0012> Reset 1 & 2 Edge (Momentary)

<0013> Set 1 Edge (Momentary)

<0014> Set 2 Edge (Momentary)

<0015> Set 1 & 2 Edge (Momentary)

MODE ALARM 1 ALARM 2

0 Off Off

1 On On

2 Off On

3 On Off

Page 14

14

COMMUNICATIONS REGISTER (40026) AND COILS 1-8 TABLE (continued)

Mode Parity Baud

Coil 8

B7 *

Coil 7B6Coil 6B5Coil 5B4Coil 4B3Coil 3B2Coil 2B1Coil 1B0Coil 8 =0

HEX

Coil 8 =1

HEX

ASCII 7N2 300 0 / 1 1 0 0 0 0 0 0 <40> <C0>

ASCII 7N2 600 0 / 1 1 0 0 0 0 0 1 <41> <C1>

ASCII 7N2 1200 0 / 1 1 0 0 0 0 1 0 <42> <C2>

ASCII 7N2 2400 0 / 1 1 0 0 0 0 1 1 <43> <C3>

ASCII 7N2 4800 0 / 1 1 0 0 0 1 0 0 <44> <C4>

ASCII 7N2 9600 0 / 1 1 0 0 0 1 0 1 <45> <C5>

ASCII 7N2 19200 0 / 1 1 0 0 0 1 1 0 <46> <C6>

ASCII 7N2 38400 0 / 1 1 0 0 0 1 1 1 <47> <C7>

ASCII 7E1 300 0 / 1 1 0 0 1 0 0 0 <48> <C8>

ASCII 7E1 600 0 / 1 1 0 0 1 0 0 1 <49> <C9>

ASCII 7E1 1200 0 / 1 1 0 0 1 0 1 0 <4A> <CA>

ASCII 7E1 2400 0 / 1 1 0 0 1 0 1 1 <4B> <CB>

ASCII 7E1 4800 0 / 1 1 0 0 1 1 0 0 <4C> <CC>

ASCII 7E1 9600 0 / 1 1 0 0 1 1 0 1 <4D> <CD>

ASCII 7E1 19200 0 / 1 1 0 0 1 1 1 0 <4E> <CE>

ASCII 7E1 38400 0 / 1 1 0 0 1 1 1 1 <4F> <CF>

ASCII 7O1 300 0 / 1 1 0 1 1 0 0 0 <58> <D8>

ASCII 7O1 600 0 / 1 1 0 1 1 0 0 1 <59> <D9>

ASCII 7O1 1200 0 / 1 1 0 1 1 0 1 0 <5A> <DA>

ASCII 7O1 2400 0 / 1 1 0 1 1 0 1 1 <5B> <DB>

ASCII 7O1 4800 0 / 1 1 0 1 1 1 0 0 <5C> <DC>

ASCII 7O1 9600 0 / 1 1 0 1 1 1 0 1 <5D> <DD>

ASCII 7O1 19200 0 / 1 1 0 1 1 1 1 0 <5E> <DE>

ASCII 7O1 38400 0 / 1 1 0 1 1 1 1 1 <5F> <DF>

ASCII 8N1 300 0 / 1 1 1 0 0 0 0 0 <60> <E0>

ASCII 8N1 600 0 / 1 1 1 0 0 0 0 1 <61> <E1>

ASCII 8N1 1200 0 / 1 1 1 0 0 0 1 0 <62> <E2>

ASCII 8N1 2400 0 / 1 1 1 0 0 0 1 1 <63> <E3>

ASCII 8N1 4800 0 / 1 1 1 0 0 1 0 0 <64> <E4>

ASCII 8N1 9600 0 / 1 1 1 0 0 1 0 1 <65> <E5>

ASCII 8N1 19200 0 / 1 1 1 0 0 1 1 0 <66> <E6>

ASCII 8N1 38400 0 / 1 1 1 0 0 1 1 1 <67> <E7>

ASCII 8E1 300 0 / 1 1 1 0 1 0 0 0 <68> <E8>

ASCII 8E1 600 0 / 1 1 1 0 1 0 0 1 <69> <E9>

ASCII 8E1 1200 0 / 1 1 1 0 1 0 1 0 <6A> <EA>

ASCII 8E1 2400 0 / 1 1 1 0 1 0 1 1 <6B> <EB>

ASCII 8E1 4800 0 / 1 1 1 0 1 1 0 0 <6C> <EC>

ASCII 8E1 9600 0 / 1 1 1 0 1 1 0 1 <6D> <ED>

ASCII 8E1 19200 0 / 1 1 1 0 1 1 1 0 <6E> <EE>

ASCII 8E1 38400 0 / 1 1 1 0 1 1 1 1 <6F> <EF>

ASCII 8O1 300 0 / 1 1 1 1 1 0 0 0 <78> <F8>

ASCII 8O1 600 0 / 1 1 1 1 1 0 0 1 <79> <F9>

ASCII 8O1 1200 0 / 1 1 1 1 1 0 1 0 <7A> <FA>

ASCII 8O1 2400 0 / 1 1 1 1 1 0 1 1 <7B> <FB>

ASCII 8O1 4800 0 / 1 1 1 1 1 1 0 0 <7C> <FC>

ASCII 8O1 9600 0 / 1 1 1 1 1 1 0 1 <7D> <FD>

ASCII 8O1 19200 0 / 1 1 1 1 1 1 1 0 <7E> <FE>

ASCII 8O1 38400 0 / 1 1 1 1 1 1 1 1 <7F> <FF>

* When reading register 40026, B7 will be a 0. When writing (changing ITMS communications to the new setting), change B7 to a 1.

Page 15

15

This page intentionally left blank

Page 16

LIMITED WARRANTY

The Company warrants the products it manufactures against defects in materials and workmanship

for a period limited to two years from the date of shipment, provided the products have been stored,

handled, installed, and used under proper conditions. The Company’s liability under this limited

warranty shall extend only to the repair or replacement of a defective product, at The Company’s

option. The Company disclaims all liability for any affirmation, promise or representation with

respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against

damages, claims, and expenses arising out of subsequent sales of RLC products or products

containing components manufactured by RLC and based upon personal injuries, deaths, property

damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be

to any extent liable, including without limitation penalties imposed by the Consumer Product Safety

Act (P.L. 92-573) and liability imposed upon any person pursuant to the Magnuson-Moss Warranty

Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except those

expressly contained herein. The Customer acknowledges the disclaimers and limitations contained

herein and relies on no other warranties or affirmations.

Red Lion Controls

20 Willow Springs Circle

York PA 17406

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

Red Lion Controls AP

31, Kaki Bukit Road 3,

#06-04/05 TechLink

Singapore 417818

Tel +65 6744-6613

Fax +65 6743-3360

Red Lion Controls BV

Basicweg 11b

NL - 3821 BR Amersfoort

Tel +31 (0) 334 723 225

Fax +31 (0) 334 893 793

Loading...

Loading...