Page 1

MODEL IRMA DC - INTELLIGENT RTD MODULE WITH ANALOG OUTPUT

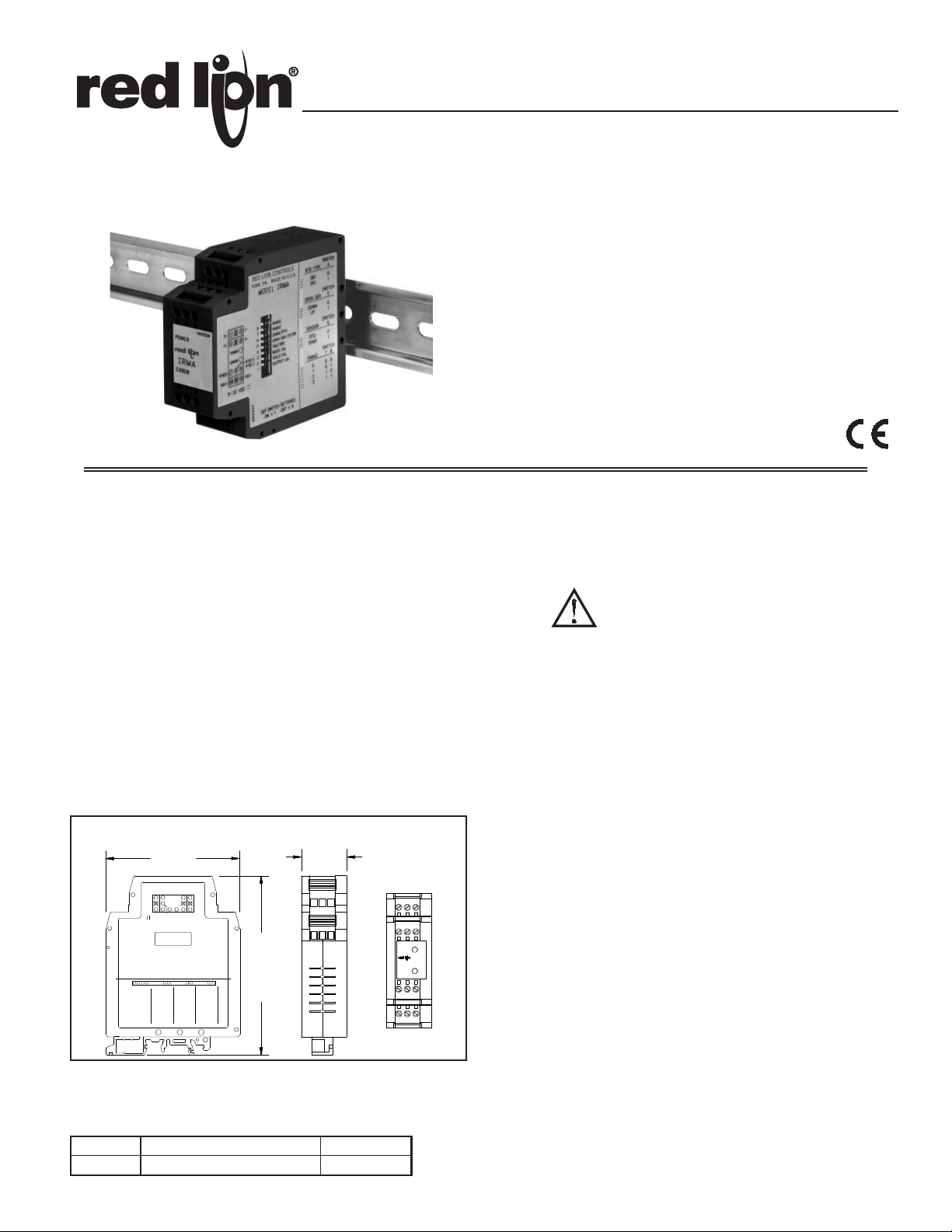

4.20 REF

1.08

3.12

(27.5)

(106.7)

(79.2)

ERROR

POWER

IRMA

DIP SWITCH SETTINGS:

ON = 1 OFF = 0

MC2234X

9-32 VDC

ERROR

POWER

VDC+ 10

RTD(S)

7

V+ 4

I+ 1

VDC-

RTD(-)

1211

98

65V-

32I-

78RANGE

RTD

OHMS

RTD TYPE

385

392

OPEN SEN

DOWN

SENSOR

UP

0

1

SWITCH

4

0

SWITCH

5

SWITCH

1

6

SWITCH

1

0

012

3

0

0

1

010

11

392/385

5 OPEN SEN UP/DN

OHMS/RTD

RANGE

1

4

3

2

OUTPUT CAL

FIELD CAL

BASIC CAL

876

RTD(+)

RANGE

MADE IN U.S.A.

RED LION CONTROLS

MODEL IRMA

YORK, PA.

USER PROGRAMMABLE INPUT

(RTD alpha = 0.00385 (DIN 43760), alpha = 0.00392, or resistance)

MICROPROCESSOR CONTROLLED

SIMPLE ADJUSTABLE RANGE SETTING (Using Input Signal)

RTD BREAK DETECTION

MOUNTS ON “T” AND “G” STYLE DIN RAILS

3-WAY ELECTRICAL ISOLATION (POWER/INPUT/OUTPUT)

MULTIPLE ANALOG OUTPUTS (0 to 20 mA, 4 to 20 mA, and 0 to

10 VDC)

WIDE OPERATING TEMPERATURE RANGE (-25°C to 75°C)

LED INDICATION (POWER & MEMORY ERROR)

9 to 32 VDC POWERED

DESCRIPTION

The IRMA accepts an RTD or resistance input and converts it into a voltage

or current output. The output is linearly proportional to the temperature or

resistance input. This output is ideal for interfacing to indicators, chart

recorders, controllers, or other instrumentation equipment.

The IRMA is DC powered. The DC power input is isolated from the signal

input and analog output. The unit scales the analog output proportionally to the

RTD or resistance input signal. The analog output may be configured for one of

the following: 0 to 20 mA, 4 to 20 mA, or 0 to 10 VDC. Making the signal

conversion with the IRMA to a current output signal, makes the signal less

susceptible to noise interference and allows accurate transmission over long

distances. The 3-Way isolation allows the use of grounded RTD’s which can

provide additional noise reduction benefits.

The IRMA uses an eight position DIP switch to accomplish the input sensor

configuration, range selection, and unit calibration. A simple range setting

technique (Field Calibration) is used so the actual input signal adjusts the output

for scaling. This technique eliminates the need for potentiometers which are

vulnerable to changes due to vibration.

The unit is equipped with a universal mounting foot for attachment to

standard DIN style mounting rails, including top hat rail (T) according to EN 50

7.5 and 35 15, and (G) profile according to EN 50 035 - G 32.

022 - 35

DIMENSIONS In inches (mm)

ORDERING INFORMATION

MODEL NO. DESCRIPTION PART NUMBER

IRMA Intelligent RTD Module IRMA3035

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

CAUTION: Read complete instructions prior

to installation and operation of the unit.

SPECIFICATIONS

1. POWER: 9 to 32 VDC; 1.75 W. 200 mA max. current. The power supply

must have 400 mA for 200 msec. surge capacity.

2. INPUT: RTD 2, 3, or 4 wire, 100 ohm platinum, alpha = 0.00385

(DIN 43760), alpha = 0.00392, or resistance [selectable via DIP switches].

Excitation: 0.170 mA nominal

Lead resistance: Less than 0.5°C with 15 ohms max. per lead

Note: There is no lead compensation for 2 wire input. Field calibration

should be performed with equivalent series resistance.

3. OUTPUT: All output signals scaled linearly using temperature or resistance

input. Unit is shipped set for the 4 to 20 mA output. 4 to 20 mA or 0 to 20

mA selected via internal jumper.

Voltage Output Compliance:

0 to 10 VDC across min. 1 K load (10 mA)

20 mV peak to peak max. ripple (for frequencies up to 120 Hz)

Current Output Compliance:

0 to 20 mA through max. 600 load (12 VDC)

4 to 20 mA through max. 600 load (12 VDC)

15 mV peak to peak max. ripple across 600 load (for frequencies up to

120 Hz)

4. RTD BREAK DETECTION: Nominal values shown in the following order:

(0 to 20 mA, 4 to 20 mA, and 0 to 10 VDC).

Upscale: 22.9 mA, 22.5 mA, and 11.5 VDC

Downscale: -0.5 mA, 3.5 mA, and -0.4 VDC

5. RESPONSE TIME: 400 msec. (to within 99% of final value w/step input;

typically, response is limited to response time of probe.)

6. TEMPERATURE EFFECTS:

Temperature Coefficient: 0.025% of input range per C

7. DIELECTRIC WITHSTAND VOLTAGE: 1500 VAC for 1 minute

Working Voltage: 50 VAC

Power input to Signal input, Power input to Signal output, & Signal input to

Signal output.

1

Page 2

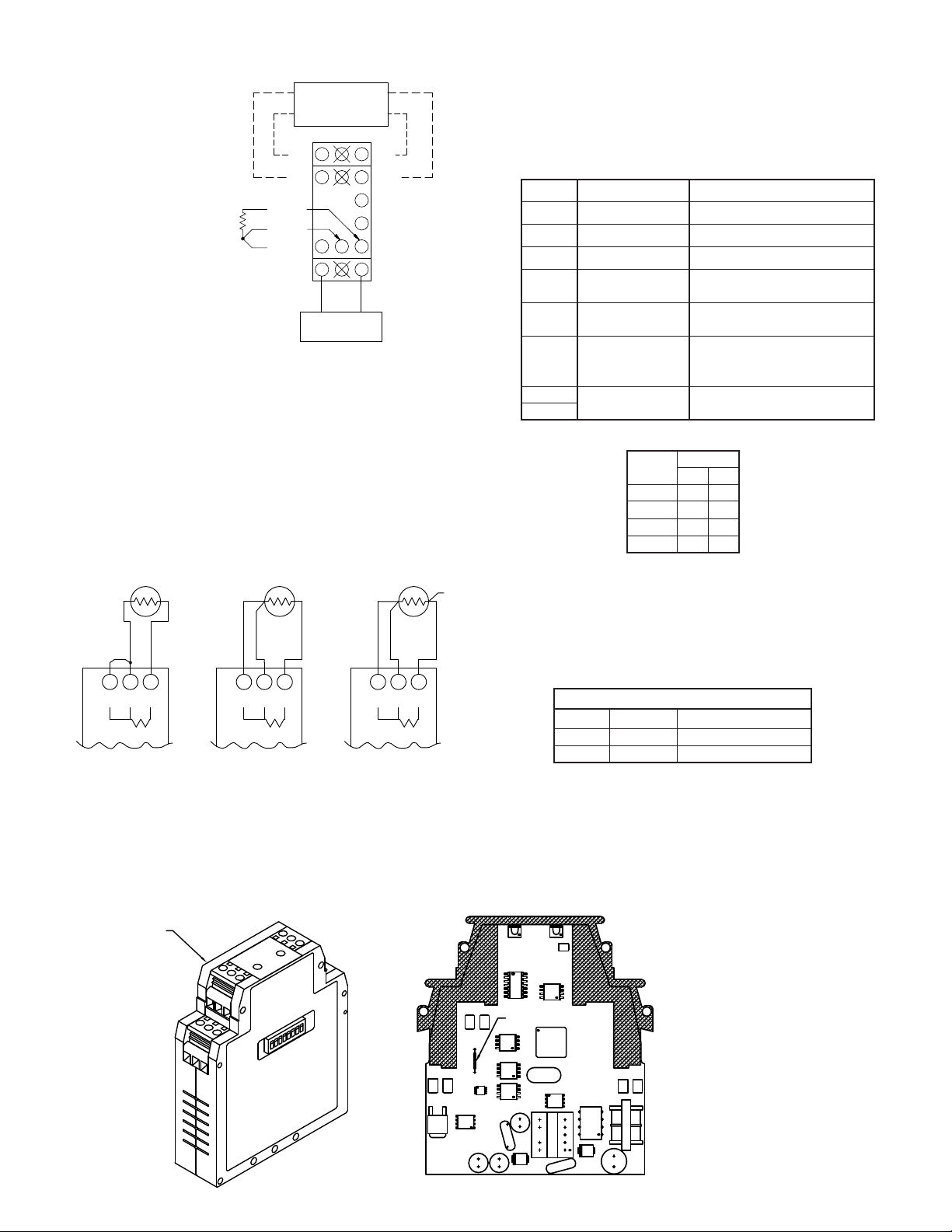

ANALOG

OUTPUT

CIRCUITRY

1

3

CIRCUITRY

CONTROL

PWM

POWER

SUPPLY

22V

3V

CIRCUITRY

PROCESS

CONVERTER

A/D

CURRENT

OUTPUT

12

10

4V

POWER

DC

6

4

+

+

-

-

VOLTAGE

OUTPUT

3V

9

8

7

0.170mA

8. RANGE & ACCURACY: (12 Bit resolution)

Accuracy: ( 0.075% Range + 0.1°C [Conformity]) at 23°C after 45 min.

warm-up, conforming to ITS-90.

Note: RTD Conformity does not apply to resistance input. For best accuracy,

calibration should be performed under operating conditions.

Relative Humidity: Less than 85% RH (non-condensing)

Span: The input span can be set to a min. of 1/8 of the full scale range,

anywhere within that range.

Range Accuracy

DIP SWITCH

INPUT RANGE

RTD alpha = 0.00385

RTD alpha = 0.00392

OHMS

Note: DIP switch settings ON = 1 OFF = 0

Accuracy Example:

RTD 385 Range “0”

-160°C to 654°C

TYPE RANGE

4 6 7 8

0 0 0 0 0 -160 to 654°C 0.61°C

1 0 0 0 1 -108 to 207°C 0.24°C

2 0 0 1 0 -5 to 414°C 0.31°C

3 0 0 1 1 194 to 608°C 0.31°C

0 1 0 0 0 -157 to 640°C 0.60°C

1 1 0 0 1 -106 to 203°C 0.23°C

2 1 0 1 0 -5 to 406°C 0.31°C

3 1 0 1 1 190 to 596°C 0.30°C

0 0 1 0 0 35.5 to 331.0 0.222

1 0 1 0 1 57.0 to 178.5 0.091

2 0 1 1 0 98.0 to 252.0 0.116

3 0 1 1 1 173.5 to 316.5 0.107

( ±0.61°C + ±0.1°C) = ±0.71°C

TEMPERATURE

& OHMS RANGE

ConformityRange

RANGE

ACCURACY

Total Error

9. CERTIFICATIONS AND COMPLIANCES:

SAFETY

IEC 61010-1, EN 61010-1: Safety requirements for electrical equipment

for measurement, control, and laboratory use, Part 1.

ELECTROMAGNETIC COMPATIBILITY

Immunity to EN 50082-2

Electrostatic discharge

EN 61000-4-2

Level 2; 4 kV contact

Level 3; 8 kV air

EN 61000-4-3Electromagnetic RF fields

Level 3; 10 V/m

80 MHz - 1 GHz

Fast transients (burst)

EN 61000-4-4

Level 4; 2 kV I/O

Level 3; 2 kV power

RF conducted interference

EN 61000-4-6

Level 3; 10 V/rms

150 KHz 80 MHz

Power frequency magnetic fields

EN 61000-4-8

Level 4; 30 A/m

Emission to EN 50081-2

RF interference

EN 55011

Enclosure class B

Notes:

1. This device was designed for installation in an enclosure. To avoid

electrostatic discharge, precautions should be taken when the device is

mounted outside an enclosure. When working in an enclosure (ex. making

adjustments, setting switches etc.) typical anti-static precautions should be

observed before touching the unit.

2. Self-recoverable loss of performance during EMI disturbance at 10 V/m:

Analog output signal may deviate during EMI disturbance.

For operation without loss of performance:

Unit is mounted in a metal enclosure (Buckeye SM7013-0 or equivalent)

I/O and power cables are routed in metal conduit connected to earth gr ound.

Refer to the EMC Installation Guidelines section of this bulletin for additional

information.

10. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range: -25°C to 75°C (-13°F to 167°F)

Storage Temperature Range: -40 to 85°C (-40°F to 185°F)

Operating and Storage Humidity: 85% max. relative humidity (non-

condensing) from -25°C to 75°C.

Vibration According to IEC 68-2-6: Operational 5 to 150 Hz, in X, Y, Z

direction for 1.5 hours, 2 g’s.

Shock According to IEC 68-2-27: Operational 30 g’s, 11 msec in 3 directions.

Altitude: Up to 2000 meters

11. MOUNTING: Universal mounting foot for attachment to standard DIN

style mounting rails, including top hat (T) profile rail according to EN50022

7.5 and 35 15, and G profile rail according to EN50035 - G32.

- 35

12. CONNECTION: Compression type terminal block

13. CONSTRUCTION: High impact black plastic case, Installation Category I,

Pollution Degree 2.

14. WEIGHT: 4.02 oz. (114.0 g)

BLOCK DIAGRAM

FUNCTION DESCRIPTIONS

Open Sensor Detection

The output can be set to go Upscale or Downscale for the detection of an open

sensor. The nominal values for each output range are listed under RTD Break

Detection in the Specifications section. This setting is always active, so changes

to the setting are effective immediately.

Unit Malfunction

If the unit has scaling problems (output remains at -0.5 mA, 3.5 mA, or -0.5

VDC nominal), check the ERROR LED on the front of the unit. An E2PROM

problem is indicated when the ERROR LED is on. If the ERROR LED is on,

perform a Basic Calibration followed by a Field Calibration. Turn the power off

for 5 seconds. Turn power on and check if the ERROR LED is on. If the LED is

on, contact the factory.

EMC INSTALLATION GUIDELINES

Although this unit is designed with a high degree of immunity to

ElectroMagnetic Interference (EMI), proper installation and wiring methods

must be followed to ensure compatibility in each application. The type of the

electrical noise, source or coupling method into the unit may be different for

various installations. Cable length, routing and shield termination are very

1

important and can mean the difference between a successful or a troublesome

2

installation. Listed below are some EMC guidelines for successful installation in

an industrial environment.

1. Use shielded (screened) cables for all Signal and Control inputs. The shield

(screen) pigtail connection should be made as short as possible. The

connection point for the shield depends somewhat upon the application.

Listed below are the recommended methods of connecting the shield, in order

of their effectiveness.

a. Connect the shield only at the rail where the unit is mounted to earth ground

(protective earth).

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is above 1 MHz.

c. Connect the shield to common of the unit and leave the other end of the

shield unconnected and insulated from earth ground.

2. Never run Signal or Control cables in the same conduit or raceway with AC

power lines, conductors feeding motors, solenoids, SCR controls, and heaters,

etc. The cables should be run in metal conduit that is properly grounded. This

is especially useful in applications where cable runs are long and portable

two-way radios are used in close proximity or if the installation is near a

commercial radio transmitter.

3. Signal or Control cables within an enclosure should be routed as far away as

possible from contactors, control relays, transformers, and other noisy

components.

4. In extremely high EMI environments, the use of external EMI suppression

devices, such as ferrite suppression cores, is effective. Install them on Signal

and Control cables as close to the unit as possible. Loop the cable through the

core several times or use multiple cores on each cable for additional protection.

Install line filters on the power input cable to the unit to suppress power line

interference. Install them near the power entry point of the enclosure. The

following EMI suppression devices (or equivalent) are recommended:

Ferrite Suppression Cores for signal and control cables:

Fair-Rite # 0443167251 (RLC #FCOR0000)

TDK # ZCAT3035-1330A

Steward #28B2029-0A0

Line Filters for input power cables:

Schaffner # FN610-1/07 (RLC #LFIL0000)

Schaffner # FN670-1.8/07

Corcom #1VR3

Note: Reference manufacturer’s instructions when installing a line filter.

5. Long cable runs are more susceptible to EMI pickup than short cable runs.

Therefore, keep cable runs as short as possible.

2

Page 3

WIRING CONNECTIONS

ERROR

POWER

VDC+

10

RTD(S)

7

V+

4

I+

1

VDC-

RTD(+)

1211

98

65

V-

32

I-

POWER SUPPLY

9 to 32 VDC

VOLTAGE METER

OR

CURRENT METER

MONITORING INSTRUMENT

RTD(-)

87 9

RTD

S

-

+

-

RTD

+

7S8 9

RTD

7S8+9

-

3-WIRE RTD 4-WIRE RTD

N.C.

2-WIRE RTD

All conductors should meet

voltage and current ratings for

each terminal. Also, cabling

should conform to appropriate

standards of good installation,

local codes and regulations. It

is recommended that power

supplied to the unit be

protected by a fuse or circuit

breaker. When wiring the unit,

use the numbers on the label

to identify the position

number with the proper

function. Strip the wire,

leaving approximately 1/4" (6

mm) of bare wire exposed

(stranded wire should be

tinned with solder). Insert the

wire into the terminal, and

tighten the screw until the

wire is clamped tightly.

POWER

Connect DC power to terminals #10 and #12 observing proper polarity. Be

certain DC power is within the 9 to 32 VDC specifications.

POWER LED

The IRMA has a green LED located on the front to indicate that power is

applied to the unit.

DIP SWITCH SETTING DESCRIPTIONS

SWITCH

1 OUTPUT CAL Output Calibration

2 FIELD CAL Field Calibration

3 BASIC CAL Basic Calibration

4 385/392 RTD Type

5 OPEN SEN UP/DN

6 RTD/OHMS

LABEL

DESCRIPTION

Open Sensor Detection Upscale (ON) / Downscale (OFF)

Select Input Type Ohms (ON) / RTD (OFF)

INPUT AND POWER/OUTPUT CONNECTIONS

INPUT

When connecting the RTD or resistance device, be certain that the

connections are clean and tight. Attach the device to terminals #8 and #9. Install

a copper sense lead of the same gauge as those used to connect the device.

Attach one end of the wire at the probe where the lead connected to terminal #8

is attached and the other end to terminal #7. This configuration will provide

complete lead wire compensation. If a sense wire is not utilized, then Terminal

#7 should be shorted to terminal #8. T o avoid errors due to lead wire resistance,

field calibration should be performed with a series resistance equal to the total

lead resistance in the system. Always refer to the probe manufacturer’s

recommendations for mounting, temperature range, shielding, etc.

OUTPUT

Connect the output signal wires to the desired output terminals. For voltage

output, use terminals #4 and #6; for current output, use terminals #1 and #3

observing proper polarity. Only one output may be used at a time. The unit is

factory set for a 4 to 20 mA output. The voltage output will track the current

output linearly within ±2.5% deviation of range endpoints.

To select 0 to 20 mA, output you must open the case and cut the wire jumper.

The jumper is located to the left side of the board as shown in the drawing.

Remove this

side of the

unit case.

7

8

RANGE

Sensor Range - 2 switch

combination setting

Range switch settings (ON = 1 OFF = 0)

DIP SWITCH

RANGE

7 8

0 0 0

1 0 1

2 1 0

3 1 1

FACTORY SETTINGS

The unit is shipped from the factory calibrated for a 4 to 20 mA output using

a type 385 RTD in range 0. The IRMA should be Field calibrated by the

operator for the application environment it will be used in. If the unit is not

recalibrated by the operator, the following table lists the temperature ranges for

each RTD type.

NOMINAL FACTORY FIELD CALIBRATION

TYPE

385

392 0 150°C to 595°C

RANGE

0

TEMPERATURE RANGE

150°C to 606°C

TROUBLESHOOTING

For further technical assistance, contact technical support at the appropriate

company numbers listed.

WIRE JUMPER

3

Page 4

DIP SWITCH SETTINGS:

ON = 1 OFF = 0

9-32 VDC

V+

I+

VDC+

RTD(S)

POWER

RTD(-)

RTD(+)

VDC-

9

ERROR

78

1210 11

634152V-

I-

5

1

4

3

2

8

76RANGE

RANGE

OHMS/RTD

FIELD CAL

BASIC CAL

OUTPUT CAL

392

SEN UP/DN

MODEL IRMA

ERROR

POWER

VDC+

10

RTD(S)

7

V+

4

I+

1

VDC-

RTD(+)

1211

98

65

V-

32

I-

POWER SUPPLY

9 to 32 VDC

VOLTAGE METER

OR

CURRENT METER

MONITORING INSTRUMENT

RTD(-)

ADJUSTABLE

RESISTANCE

SOURCE

-

+

S

1.0 Field Calibration

CALIBRATION PROCEDURES

Field Calibration scales the selected output to a temperature or resistance

input. This procedure assigns an input value to the low end and an input value

to the high end. The microprocessor handles configuring the output so it is

linear to the temperature or resistance input. The Field Calibration procedure is

described below.

Note: The unit needs to have the Field Calibration completed by the operator

before normal operation. To abort this calibration and reset to the previous

settings, set the FIELD CAL switch OFF prior to the final OFF setting of the

OUTPUT CAL switch (Step 1.1 1) and turn off power. Wait 5 seconds and then

turn on power and the previous settings will be loaded.

1 6543287

ON

Step 1.2

1 6543287

Field Calibration Wiring

Step 1.3

1 6543287

Step 1.5

ON

ON

RTD temperature to resistance conversion table

Temperature

°C

alpha

0.00385

alpha

0.00392

34.3835.53-160

38.6439.71 -150

59.5560.25-100

79.9680.30-50

100.00100.000

119.75119.4050

139.20138.5100

158.36157.33150

173.48172.17190

177.23175.85200

195.80194.09250

Temperature

°C

alpha

0.00385

alpha

0.00392

214.08212.03300

232.07229.69350

249.77247.05400

253.28250.49410

267.18264.13450

284.30280.92500

301.13297.42550

314.38310.41590

317.66313.63600

330.68326.38640

333.90329.54650

Field Calibration with an Accurate Adjustable Resistance Source

Note: The nominal output value for the various output ranges are designated in the

following order: (0 to 20 mA, 4 to 20 mA, 0 to 10 VDC)

1.1 Connect resistance source to the RTD input terminals using a third sense wire.

(For 2 wire sensors, short terminal #7 to terminal #8.)

1.2 Set the type and Range for the RTD or resistance used in your application. (DIP

switches #4, #6, #7 & #8). (RTD alpha = 0.00385, Range 0 shown). APPLY

OPERATING VOLTAGE and allow 45 minute warm-up period.

1.3 Set the FIELD CAL switch (#2) ON. [Output goes to -0.8 mA, 3.5 mA, or -0.4 V

nominal]

1.4 Set the input resistance to the value intended to generate the analog low endpoint

(For 2 wire sensors, add the system lead resistance to the desired value.)

1.5 Set the OUTPUT CAL switch (#1) ON. [Output stays at -0.8 mA, 3.5 mA, or -0.4

V nominal]

1 6543287

Step 1.7

1 6543287

Step 1.9

1 6543287

Step 1.11

1 6543287

Step 1.12

1.6 Adjust the input signal up until the analog output equals desired low value.[0 mA,

4 mA, or 0 V]

ON

1.7 Set the OUTPUT CAL switch (#1) OFF. [Output increases to 22.9 mA, 22.5 mA,

or 11.5 V nominal]

1.8 Set the input resistance to the value intended to generate the analog high endpoint.

(For 2 wire sensors, add the system lead resistance to the desired value.)

ON

1.9 Set the OUTPUT CAL switch (#1) ON. [Output decreases to 21.1 mA, 20.7 mA,

or 10.6 V nominal]

1.10 Adjust the input signal down until the output equals desired high value. [20 mA,

20 mA, or 10 V]

ON

1.11 Set the OUTPUT CAL switch (#1) OFF.

1.12 Set the FIELD CAL switch (#2) OFF.

ON

1.13 Disconnect the resistance source from the IRMA and connect the actual sensor to

be used in the application.

4

Page 5

ERROR

POWER

VDC+

10

RTD(S)

7

V+

4

I+

1

VDC-

RTD(+)

1211

98

65

V-

32

I-

POWER SUPPLY

9 to 32 VDC

VOLTAGE METER

OR

CURRENT METER

MONITORING INSTRUMENT

RTD(-)

ADJUSTABLE

RESISTANCE

SOURCE

-

+

S

2.0 Basic Calibration

DIP SWITCH SETTINGS:

ON = 1 OFF = 0

9-32 VDC

V+

I+

VDC+

RTD(S)

POWER

RTD(-)

RTD(+)

VDC-

9

ERROR

78

1210 11

634152V-

I-

5

1

4

3

2

8

76RANGE

RANGE

OHMS/RTD

FIELD CAL

BASIC CAL

OUTPUT CAL

392

SEN UP/DN

MODEL IRMA

The Basic Calibration should only be performed with an ambient temperature between

21°C and 29°C. The Basic Calibration was performed on the unit at the factory and

generally does not need to be done again. This procedure initializes the unit by calibrating

the input. The Basic Calibration should be performed only if a condition exists as

described in the “Unit Malfunction” section. After completion of this calibration, the unit

needs to be scaled in Field Calibration. The Basic Calibration procedure is described

below.

Note: To abort this calibration and reset to the previous settings, set the BASIC CAL

switch(#3) OFF prior to the final setting of the OUTPUT CAL switch (#1) (Step 4.17)

and turn off power for 5 seconds. Then turn on power and the previous settings will be

loaded.

Note: The nominal output value for the various output ranges are designated in the

following order: (0 to 20 mA, 4 to 20 mA, 0 to 10 VDC)

Basic Calibration Wiring

12345678

Step 2.1

1 2345678

12345678

Steps 2.3 to 2.15

312 54 678

Step 2.16

2.1 Connect an adjustable resistance source with an accuracy of 0.03% to the RTD input

ON

terminals using a third sense wire. Set the RANGE (#7& #8), TYPE (#4), OUTPUT

CAL (#1), and FIELD CAL (#2) switches OFF. Set the BASIC CAL switch (#3) ON.

2.2 Apply operating power and allow a 45 minute warm-up period. [Current goes to -0.9

mA, 3.4 mA, or -0.5 V(nominal)]

2.3 Set the OUTPUT CAL switch (#1) ON and then OFF.

2.4 Set the resistance source to 40 ohms and wait 5 seconds.

2.5 Set the OUTPUT CAL switch (#1) ON and then OFF.

2.6 Set the resistance source to 60 ohms and wait 5 seconds.

2.7 Set the OUTPUT CAL switch (#1) ON and then OFF.

ON

2.8 Set the resistance source to 100 ohms wait 5 seconds.

2.9 Set the OUTPUT CAL switch (#1) ON and then OFF.

2.10 Set the resistance source to 175 ohms and wait 5 seconds.

ON

2.11 Set the OUTPUT CAL switch (#1) ON and then OFF.

2.12 Set the resistance source to 250 ohms and wait 5 seconds.

2.13 Set the OUTPUT CAL switch (#1) ON and then OFF.

2.14 Set the resistance source to 315 ohms and wait 5 seconds.

2.15 Set the OUTPUT CAL switch (#1) ON and then OFF.

2.16 Set the BASIC CAL switch (#3) OFF. [Current increases to 3.6 mA (nominal) or

more]

ON

2.17 Perform a Field Calibration. (See Section 1.0)

5

Page 6

ERROR

POWER

VDC+

10

7

V+

4

I+

1

VDC-

1211

98

65

V-

32

I-

MELT FLOW

MONITORED

MACHINE'S

POWER SUPPLY

24VDC

COMM

MASTER

CONTROL

ROOM

+

-

RTD(+)

RTD(S)

RTD(-)

INSTALLATION

The unit is equipped with a universal mounting foot for attachment to standard DIN style mounting rails,

including G profile rail according to EN50035 - G32 , and top hat (T) profile rail according to EN50022 - 35 x 7.5

and 35 x 15. The unit should be installed in a location that does not exceed the maximum operating temperature and

provides good air circulation. Placing the unit near devices that generate excessive heat should be avoided.

To install the

IRMA on a “G”

style DIN rail, angle

the module so that

the upper groove of

the “foot” catches

under the lip of the

top rail. Push the

module toward the

rail until it snaps

into place. To

remove a module

from the rail, push

up on the bottom of

the module while

pulling out away

from the rail.

G Rail Installation

To install the IRMA

T Rail Installation

on a “T” style rail,

angle the module so

that the top groove of

the “foot” is located

over the lip of the top

rail. Push the module

toward the rail until it

snaps into place. To

remove a module from

the rail, insert a

screwdriver into the

slot on the bottom of

the “foot”, and pry

upwards on the module

until it releases from

the rail.

APPLICATION

injection molding process. Different plastic grades and the complexity of the

mold determine required temperatures for efficient material flow. The master

control room monitors the temperature of the melt flow of each injection mold

machine. They will determine whether the operator may start the process on his

machine or override the injection molding process. The injection molding

machines are located throughout the plant, posing an RTD signal loss problem

from long cable runs. The IRMA DC powered unit is mounted at the machine

and uses the local 24 VDC for power. The signal loss problem is solved using

the 4 to 20 mA analog output for the long cable run to the master control room.

The temperature of certain industrial plastics is critical for melt flow of an

6

Loading...

Loading...