Page 1

INDUCTIVE PROXIMITY SENSORS

METAL

TARGET

CIRCUIT

OSC.

SENSING FIELD

] PSA1B, or 2B OUTPUT

] PSA6B, 7B, or 8B OUTPUT

OUTPUT ON

<1mA

OSCILLATOR STALLED

A

MPLITUDE

ABSENT

TARGET

>2.2mA

OUTPUT OFF

SENSOR

TARGET APPROACHING

TARGET PRESENT

TARGET ABSENT

SENSE FERROUS & NON-FERROUS METAL OBJECTS TO

“ZERO SPEED”

2-WIRE CURRENT SOURCE (NAMUR) & 3-WIRE NPN TRUE

OPEN COLLECTOR OUTPUTS

5 SIZES & 3 SENSING DISTANCES FOR APPLICATION

VERSATILITY

L.E.D. TARGET INDICATOR (PSA 2B, 6B, 7B, & 8B)

Bulletin No. PSAB-D

Drawing No. LP0443

Released 05/13

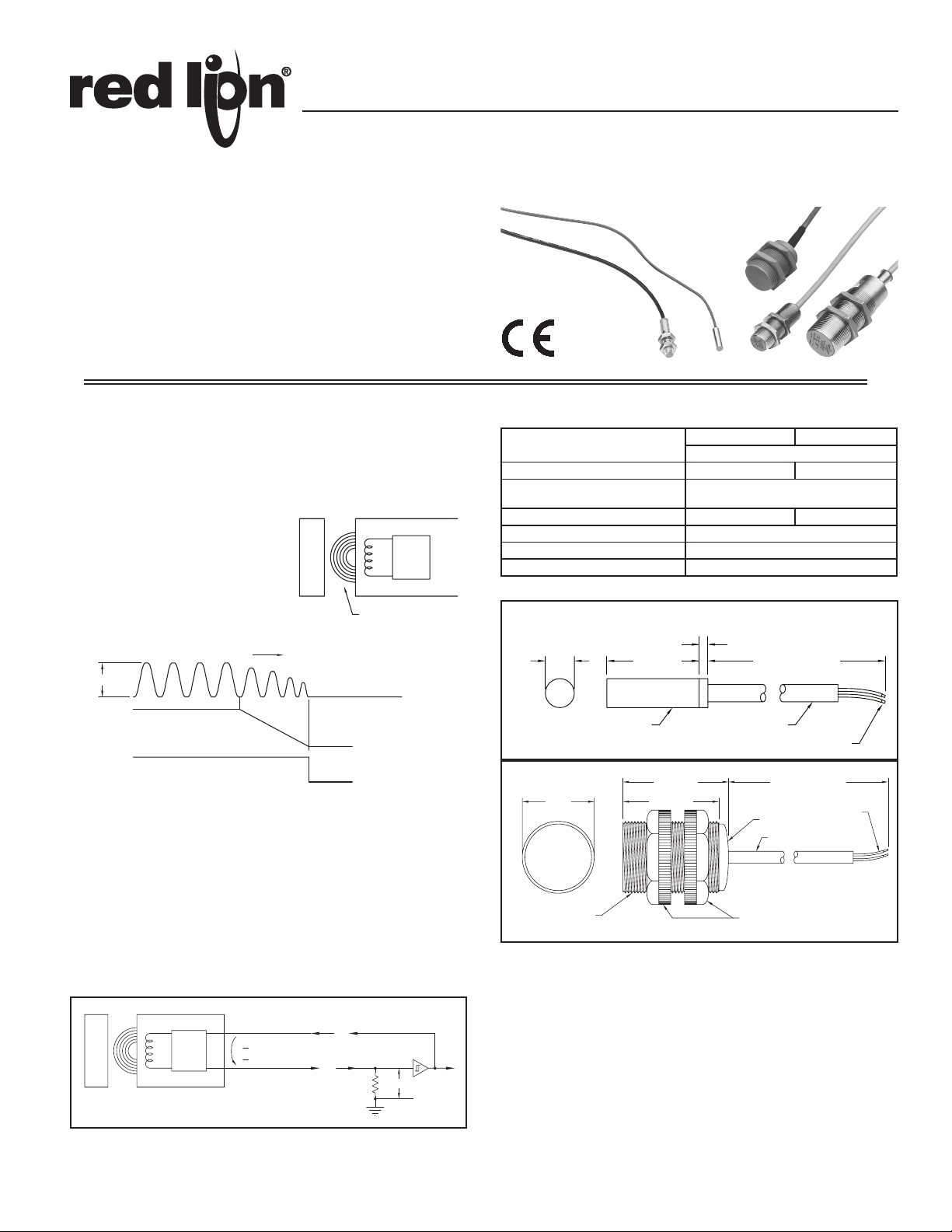

DESCRIPTION & OPERATION

Inductive Proximity Sensors detect the presence of metal objects which come

within range of their oscillating field and provide target detection to “zero

speed”. Internally, an oscillator creates a high frequency electromagnetic field

(RF) which is radiated from the coil and out from the sensor face (See Figure

1). When a metal object enters this field, eddy currents are induced into

the object.

As the metal moves closer to

the sensor, these eddy currents

increase and result in an absorption

of energy from the coil which

dampens the oscillator amplitude

until it finally stops.

Figure 1

MODELS PSA-1B & 2B

The 2-wire Models PSA-1B and 2B contain only the coil and oscillator

circuit (See Figure 2). With no metal object being sensed, the circuit oscillates

and draws greater than 2.2 mA of supply current. As a metal object of sufficient

size is brought into the sensing field, the oscillator amplitude dampens and

finally stops, resulting in less than 1 mA of circuit current being drawn. This

greater than 2.2 mA to less than 1 mA change in circuit current between

oscillating and non-oscillating conditions is converted into a usable voltage

signal (V

) by placing a resistor (RS) in series with the sensor leads.

S

PSA 1B, 2B

METAL

TARGET

OSC.

COIL

CIRCUIT

BRN

> 2.2mA-NO METAL

1mA-METAL SENSED

<

BLUE

Figure 2

+VDC

CNT.

VsRs

PSA-1B & PSA-2B SPECIFICATIONS

1. Power Supply:

2. Maximum Switching Frequency: 5 KHz 500 Hz

3. Output:

4. Maximum Sensing Distance: 0.059" (1.5 mm) 0.394" (10 mm)

5. Wire Color Code: Brown = +VDC; Blue = Count

6. Operating Temperature: -25°C to +70°C (-13°F to +158°F)

7. Construction: NEMA 1, 3, 4, 6, 13, and IEC IP 67.

PSA-1B PSA-2B

+5 to +30 VDC

Less than 1 mA Target Sensed; Greater

than 2.2 mA No Target.

DIMENSIONS In inches (mm)

PSA-1B

.256

(6.5)

DIA.

PSA-2B

(ISO 68 METRIC

TRAIGHT THREADING)

1

1.18

(30)

M30 X 1.5

1.181 (30)

CHROMED

BRASS CASE

1.74 (44)

1.57 (40)

PLASTIC CASE & JAM NUTS

.118 (3.0)

6.56′ (2 METERS)

PVC JACKET

2-CONDUCTORS

6.56' (2 METERS)

2 CONDUCTORS

LED

PVC JACKET

1.42 (32) ACROSS FLATS

.39 (10) THICKNESS

#24 AWG

#20 AWG

Page 2

In addition to the coil and oscillator circuit, the 3-wire Models PSA-6B, 7B,

and 8B each contain a Detector Circuit and NPN Transistor Output (See Figure

3). In these units, the Detector Circuit senses when the oscillator stops, and

turns on the Output Transistor which controls the load. The Detector Circuit

also turns on an integrally case mounted L.E.D., visually indicating when a

metal object is sensed.

METAL

TARGET

PSA 6B, 7B, or 8B

COIL

CIRCUIT

OSC.

LED

OUTPUT TRANSISTOR OUTPUTDETECTOR

Figure 3

+VDC

COMMON

PSA-6B, 7B, & 8B

These Inductive Proximity Sensors have a maximum sensing distance of

0.059" (1.5 mm), 0.197" (5 mm) and 0.394" (10 mm) respectively, and operate

over a wide power supply range (See Specifications Below). They are each

housed in threaded metal cases and are supplied with 2 metal jam nuts for

mounting. The NPN transistor outputs are true open collector and are

compatible with most RLC counter and rate input circuits. Maximum sensing

frequencies are ≤ 3 KHz, 1 KHz, and 500 Hz respectively. In addition, the

outputs are overload and short circuit protected. These sensors are shielded for

flush mounting in metal applications.

PSA-6B, 7B, & 8B SPECIFICATIONS

PSA-6B PSA-7B

+10 to +30 VDC

1. Power Supply:

+10 to +30 VDC

@ 10 mA max.

@ 10 mA max.

REVERSE POLARITY PROTECTION

2. Maximum Switching Frequency:

3. Output:

≤ 3 KHz 1 KHz 500 Hz

NPN Open Collector Output,

Overload and Short Circuit protected.

V

= 1.8 V @

SAT

150 mA max. load

V

200 mA max. load

4. Maximum Sensing Distance: 0.059" (1.5 mm) 0.197" (5 mm) 0.394" (10 mm)

5. Wire Color Code: Brown = +VDC; Blue = Common; Black = Output

6. Operating Temperature: -25°C to +70°C (-13°F to +158°F)

7. Construction: NEMA 1, 3, 4, 6, 13 and IEC IP 67

DIMENSIONS In inches (mm)

PSA-6B

.315

(8)

1.64 (41.6) 6.56' (2 METERS)

1.57 (40)

LED

= 1.8 V @

SAT

3-CONDUCTORS

PSA-8B

#24 AWG

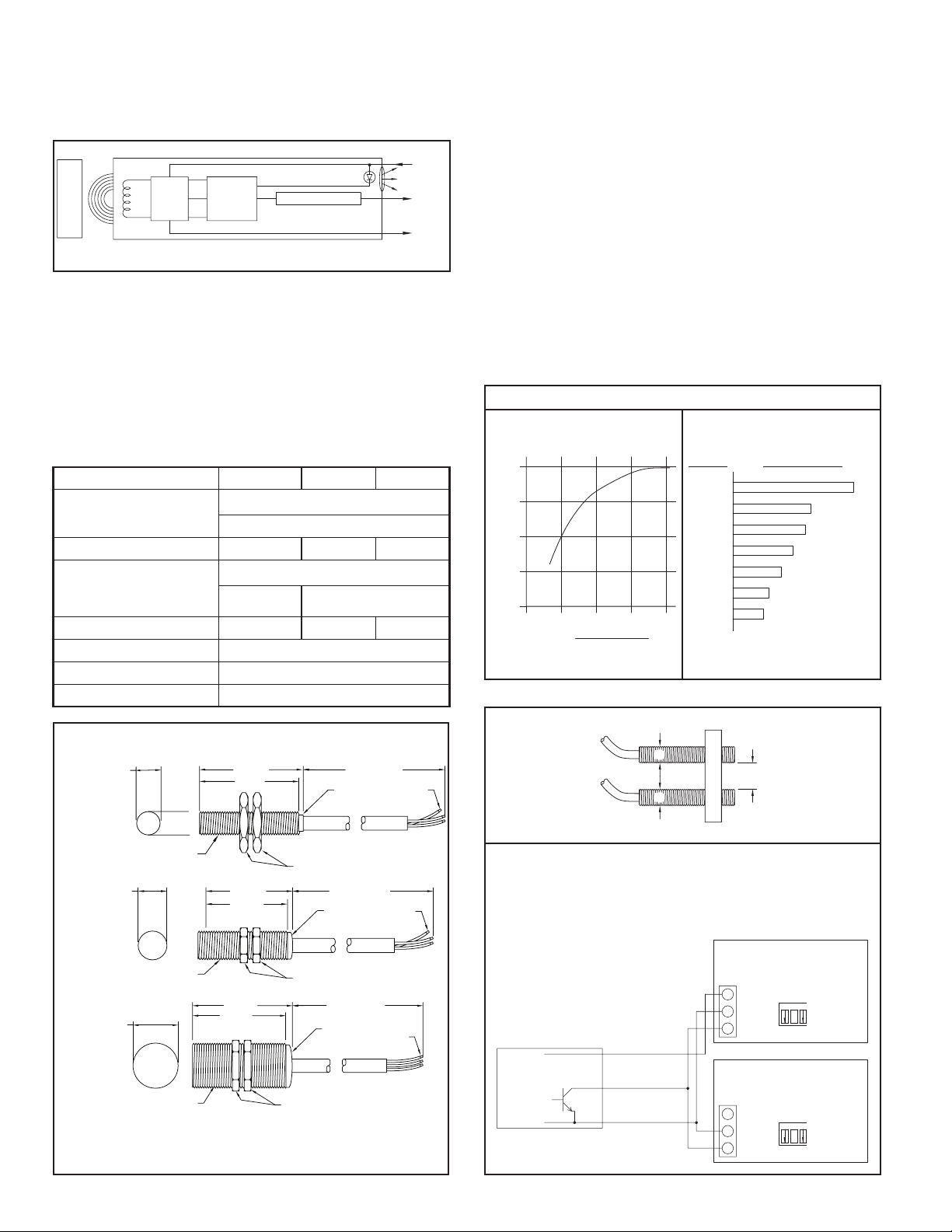

SELECTION & APPLICATION OF PROXIMITY

SENSORS

Selection of the proper proximity sensor depends on the size, material, and

spacing of the target being sensed and the sensing distance that can be

maintained. The maximum sensing distance is defined as the distance in which

the sensor is just close enough to detect a ferrous target whose diameter is equal

to or greater than the sensor diameter. In actual application, the sensing distance

should be between 50 to 80% of the maximum sensing range to assure reliable

detection. For target sizes smaller than the sensor diameter, the maximum

sensing distance can be estimated from the curve (See Figure 4). A further

reduction factor must also be applied if the target material is non-ferrous metal

(See Figure 5). Ideally, spacing between adjacent targets should be at least one

sensor diameter so that the first target completely leaves the sensors field before

the next target appears. Individual targets can still be resolved as separate

objects if this spacing is reduced to 70 or 75% of the sensor diameter, however,

this can introduce a minimum limit on sensing distance that makes adjustment

more critical. All Proximity sensors are internally shielded which allows the

sensor face to be flush mounted in metal applications without reducing sensing

distance. In applications where proximity sensors must be placed next to each

other, a distance of at least 1 sensor diameter should separate sensors to

eliminate any frequency interference (See Figure 6).

MAXIMUM SENSING DISTANCE REDUCTION FACTORS

Reduction in the max. sensing distance

due to decrease in diameter of ferrous

targets.

100

50

% OF MAX. SENSING DISTANCE

0

0 .25 .5 .75 1

RATIO,

TARGET DIAMETER

SENSOR DIAMETER

Figure 4

MINIMUM SENSOR SPACING

Typical reduction factors for various nonferrous targets with diameters equal to or

greater than sensor diameter.

MATERIAL

MILD STEEL

STAINLESS

STEEL

MERCURY

LEAD

BRASS

ALUMINUM

COPPER

Nominal sensing range x % sensing

distance = actual sensing range

% SENSING DISTANCE

APPROX. 40%

APPROX. 30%

APPROX. 25%

Figure 5

D

1 x D

D

100%

APPROX. 65%

APPROX. 60%

APPROX. 50%

M8 X 1

PSA-7B

PSA-8B

NOTES:

(ISO 68 METRIC

STRAIGHT THREADING)

.708

(18)

(ISO 68 METRIC

STRAIGHT THREADING)

1.181

(30)

(ISO 68 METRIC

STRAIGHT THREADING)

M18 X 1

M30 X 1.5

2.13 (54) 6.56' (2 METERS)

1.97 (50)

2.52 (64) 6.56' (2 METERS)

2.37 (60)

.51 (13) ACROSS FLATS

.16 (4) THICKNESS

.94 (24) ACROSS FLATS

.16 (4) THICKNESS

1.42 (36) ACROSS FLATS

.19 (5) THICKNESS

1. PSA 6B case material = #303 stainless steel.

2. PSA 7B & 8B case = chromed brass.

3. PVC Cable Jacket.

LED

LED

#20 AWG

3-CONDUCTORS

#20 AWG

3-CONDUCTORS

Figure 6

Note: PSA-6B, 7B, and 8B outputs are NPN open collector outputs. A

PSA-6B, 7B, or 8B may be used as an input to more than 1 indicator or

control only if the respective power supplies of each unit are

“unregulated” and can load share. It is recommended to use only one

power supply for sensor power. An indicator or control with a regulated

power supply may not be paralleled.

Counter #1 and #2 both contain

unregulated +12 VDC Power

Supplies.

PSA 6B, 7B, or 8B

NPN OPEN

COLLECTOR

+VDC

OUTPUT

COMMON

COUNTER #1

+12V

COMM.

CNT.

COUNTER #2

+12V

COMM.

CNT.

TYPICAL COUNTER

INPUT SWITCH SET-UP

SRC

1 2

*

SNK

TYPICAL COUNTER

INPUT SWITCH SET-UP

SRC

123

*

SNK

2

LO FRQ

LO BIAS

3

HI

HI

LO FRQ

LO BIAS

HI

HI

* APPLICATION

DEPENDENT

* APPLICATION

DEPENDENT

Page 3

TYPICAL HOOK-UPS

PSA 1B or 2B

< 1mA > 2.2mA

CURRENT SOURCE

BRN

BLUE

TYPICAL COUNTER

INPUT SWITCH SET-UP

+12V

COMM.

CNT.

SRC

123

*

SNK

LO FRQ

HI

LO BIAS

* APPLICATION

DEPENDENT

HI

PSA 6B, 7B, or 8B

NPN OPEN

COLLECTOR

APPLICATION SELECTION CHART

PSA-1B PSA-2B PSA-6B PSA-7B PSA-8B

MAX. SENSING DISTANCE 0.059" (1.5 mm) 0.394" (10 mm) 0.059" (1.5 mm) 0.197" (5 mm) 0.394" (10 mm)

MAX. SWITCHING FREQ. 5 KHz 500 Hz ≤ 3 KHz 1 KHz 500 Hz

POWER SUPPLY 5-30 VDC 5-30 VDC 10-30 VDC 10-30 VDC 10-30 VDC

OUTPUT <1 mA> 2.2 mA <1 mA> 2.2 mA NPN Open Collector Transistor

L.E.D. TARGET INDICATOR No Yes Yes Yes Yes

MODELS MB4B & 5B MOUNTING BRACKETS

PSA 6B, 7B, or 8B = BRN

PSA 6B, 7B, or 8B = BLK

PSA 6B, 7B, or 8B = BLU

TYPICAL COUNTER

INPUT SWITCH SET-UP

+12V

COMM.

CNT.

SRC

123

*

SNK

LO FRQ

LO BIAS

HI

HI

* APPLICATION

DEPENDENT

The Models MB4B and 5B are stainless steel right angle

mounting brackets, designed to provide easy mounting and

adjustment of PSA-7B and 8B respectively, using the 2 hex jam

nuts provided with each sensor.

DIMENSIONS In inches (mm)

BRACKET

MODEL NO.

MB4B PSA7B

SENSOR

MODEL

A B C D E F G H J SLOT

1.63

(41.5)

1.00

(25.4)

2.5

(63.5)

1.25

(31.8)

DIMENSIONS

0.62

(15.7)

DIMENSIONS

30°

J

F

0.31

(7.9)

1.88

(47.8)

0.75

(19.1)

H

A

B

C

G

E

D

0.06

(1.5)

0.22 X 0.75

(5.6 X 19.1)

MB5B PSA8B

2.62

(66.5)

1.75

(44.5)

4.25

(108.0)

1.75

(44.5)

0.88

(22.4)

0.37

(9.5)

3.50

(88.9)

ORDERING INFORMATION

MODEL NO. DESCRIPTION PART NUMBER

PSA1B 2-Wire Cylindrical Proximity Sensor PSA1B000

PSA2B 2-Wire, 30 mm Threaded Proximity Sensor PSA2B000

PSA6B 8mm Threaded Proximity Sensor PSA6B000

PSA7B 18mm Threaded Proximity Sensor PSA7B000

PSA8B 30mm Threaded Proximity Sensor PSA8B000

MB4B Mounting Bracket for PSA7B MB4B0000

MB5B Mounting Bracket for PSA8B MB5B0000

Do not dispose of unit in trash - Recycle

3

1.19

(30.2)

0.07

(1.8)

0.28 X 1.25

(7.1 X 31.8)

Page 4

Loading...

Loading...