Page 1

(85.1)

3.35

(89)

3.5

.39

(10)

(25)

.98

COMM

COMM

PWR

TXD

RS485

M2869X

MADE IN U.S.A.

RED LION CONTROLS

57600 BAUD

115200 BAUD

38400 BAUD

OFF 4 WIRE/ ON 2 WIRE

OFF 422/ ON 485

120Ω TERMINATION

OFF 4 WIRE/ ON 2 WIRE

OFF DCE/ ON DTE

OFF DTE/ ON DCE

OFF DTE/ ON DCE

OFF DCE/ ON DTE

OFF 422/ ON 485

YORK, PA.

MODEL ICM5

MUST BE SET

IN GROUPS

SWITCHES

*

*

*

*

*

@ 125mA MAX.

9-26VDC CLASS 2

19200 BAUD

9600 BAUD

PULL UP

PULL DOWN

RS232

10

6

213

5

4

798

NC

1

34526

7

SPLY

PWR

ON

+ VDC

422

485/

LEDS

ON

RXA

RXB

TXB

TXA

2

1

4

3

5

6

7

Bulletin No. ICM5-D

Drawing No. LP0529

Released 09/09

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

MODEL ICM5 – THREE WAY ISOLATED SERIAL CONVERTER MODULE

(RS-232C/RS-485)

ALLOWS COMMUNICATIONS BETWEEN RS-232 CONTROL

EQUIPMENT AND PRODUCTS WITH RS-422/RS-485 SERIAL

COMMUNICATIONS

THREE WAY ISOLATION PROTECTS SERIAL EQUIPMENT FROM

GROUND LOOPS (1000 VDC)

AUTOMATIC RS-485 DRIVER CONTROL

DIP SWITCH SELECTABLE BAUD RATES 9600, 19200, 38400,

57600, 115200

WIDE DC INPUT POWER RANGE (+9 to 26 VDC)

HALF DUPLEX (RS-485) AND FULL DUPLEX (RS-422)

LED INDICATION FOR RXD, TXD, and POWER

9 PIN D-SUB CONNECTOR FOR RS-232 CONNECTION

SWITCHABLE TERMINATION AND BIASING RESISTORS

MODULAR RJ JACK OR SCREW TERMINAL FOR RS-485

CONNECTION

UNIVERSAL MOUNTING FOOT FOR DIN RAIL INSTALLATION

SELECTABLE DTE & DCE OPERATION WORKS WITH ANY

RS-232 CABLE

UL Recognized Component,

File # E179259

DESCRIPTION

The ICM5 Serial Converter Module provides the capability of interfacing

equipment with RS-485 serial communications to equipment with RS-232

communications while providing three way isolation. Data format of the

RS-232 and RS-485 equipment must be the same.

The unit can be configured for full duplex (RS-422), or half duplex (RS-485)

operation. In half duplex mode, the RS-485 driver is automatically enabled

using the leading edge of the first character that is received on the RS-232 side.

After the last character is received, the converter waits one character time (at the

selected baud rate) to disable the RS-485 driver.

An external DC power source (+9 to 26 VDC) is required to power the ICM5.

The external power source and RS-485 communications connections are made

via a 7-position removable terminal block located on the front of the module. A

modular RS-485 connector is also provided for fast and efficient connection to

other Red Lion devices that use a modular connector. The RS-232 connection is

provided via a standard D-SUB 9-pin male connector. The ICM5 can be

configured for DTE or DCE operation, allowing the use of modem or nullmodem cables.

There are 3 LEDs that can be viewed from the front of the converter module.

A green power LED indicates power is on, a red RS-232 TXD LED flashes

when the module is transmitting, and a green RS-232 RXD LED flashes when

the module is receiving.

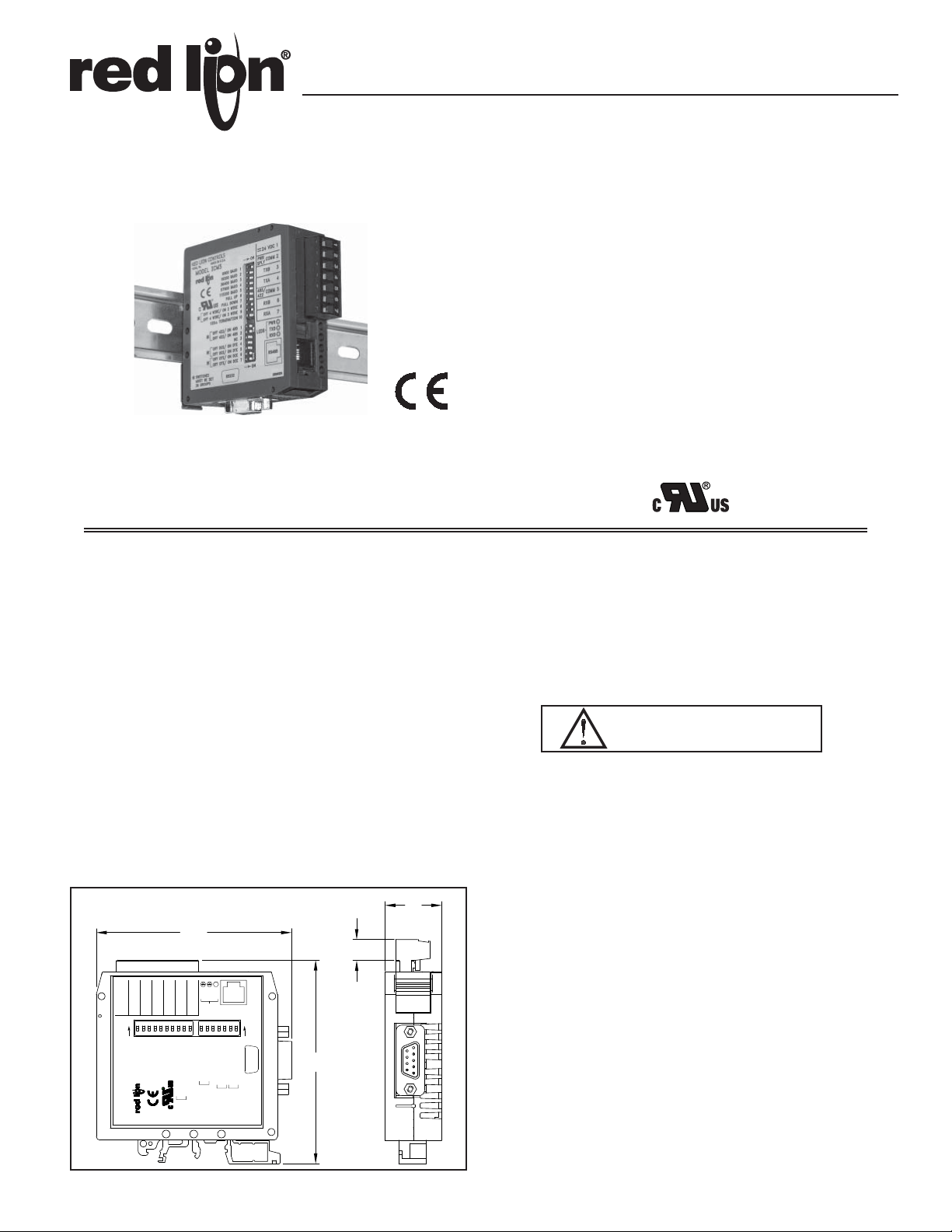

DIMENSIONS In inches (mm)

The unit is equipped with a universal mounting foot for attachment to

standard DIN style mounting rails, including top hat profile rail according to EN

50 022 - 35x7.5 and 35x15, and G profile rail according to EN 50 035 - G32.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Read complete instructions prior to

installation and operation of the unit.

CAUTION:

SPECIFICATIONS

1. POWER: +9 to 26 VDC @ 125 mA maximum. 85 mA typical

Power Supply must be Class 2 or SELV rated.

2. RS-232 VOLTAGES:

Receive Data Pin: 30 VDC max.

Mark Condition: 0.8 VDC

Space Condition: 2.4 VDC

Transmit Data Pin:

Mark Condition: -8 VDC (typ.)

Space Condition: 8 VDC (typ.)

3. RS-485 VOLTAGES:

Differential Output Voltage: 5VDC max. under no load

Differential Input Voltage: 5VDC max.

Mark Condition: -0.2 VDC

Space Condition: 0.2 VDC

RS-485 Drive Capability: Up to 32 RS-485 receivers connected in parallel

RS-485 Drive Disable Time: one character time (at the set baud rate)

4. MAXIMUM CABLE LENGTH:

RS-232: 50 feet (15.24 m)

RS-485: 4000 feet (1219.2 m)

5. BAUD RATE: 9600 min., 115200 max.

6. ISOLATION: 1000 VDC

7. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range: 0 to 50C.

Storage Temperature: -40 to + 75C

Operating and Storage Humidity: 85% max. relative humidity

(non-condensing) from 0 to 50C

1

Page 2

Vibration according to IEC 68-2-6: Operational 5 to 150 Hz in X, Y, Z

8

5

4.7K

RXB

COMMON

6

5

2

4

6

7

3

2

9 PIN "D"

CONNECTOR

1

POWER IN

RS232

SWITCHES

BAUD RATE

RD

DTE/DCE

SWITCHES

TD

RS485

CONTROL

TX

RX

4 WIRE

2 WIRE/

4.7K

+5V

TXA

4

RXA

TXB

TERMINATION

120

Ω

7

3

+VDC

COMM

TX/RX

TX/RX

DTR

DSR

RTS

CTS

COMM

direction for 1.5 hours, 2 g’s.

Shock according to IEC 68-2-27: Operational 30 g’s, 11 msec in 3 directions.

Altitude: Up to 2000 meters

8. CERTIFICA TIONS AND COMPLIANCES:

SAFETY

UL Recognized Component, File #E179259, UL3101-1, CSA 22.2 No. 1010-1

Recognized to U.S. and Canadian requirements under the Component

Recognition Program of Underwriters Laboratories, Inc.

IECEE CB Scheme Test Report #01ME11540-0702001

Issued by Underwriters Laboratories, Inc.

IEC 61010-1, EN 61010-1: Safety requirements for electrical equipment

for measurement, control, and laboratory use, Part 1.

ELECTROMAGNETIC COMPATIBILITY

Immunity to EN 50082-2

Electrostatic discharge EN 61000-4-2 Level 2; 4 Kv contact

Level 3; 8 Kv air

1

Electromagnetic RF fields EN 61000-4-3 Level 3; 10 V/m

80 MHz - 1 GHz

Fast transients (burst) EN 61000-4-4 Level 4; 2 Kv I/O

Level 3; 2 Kv power

RF conducted interference EN 61000-4-6 Level 3; 10 V/rms

150 KHz - 80 MHz

Emissions to EN 50081-1

RF interference EN 55022

Enclosure class B

Power mains class B

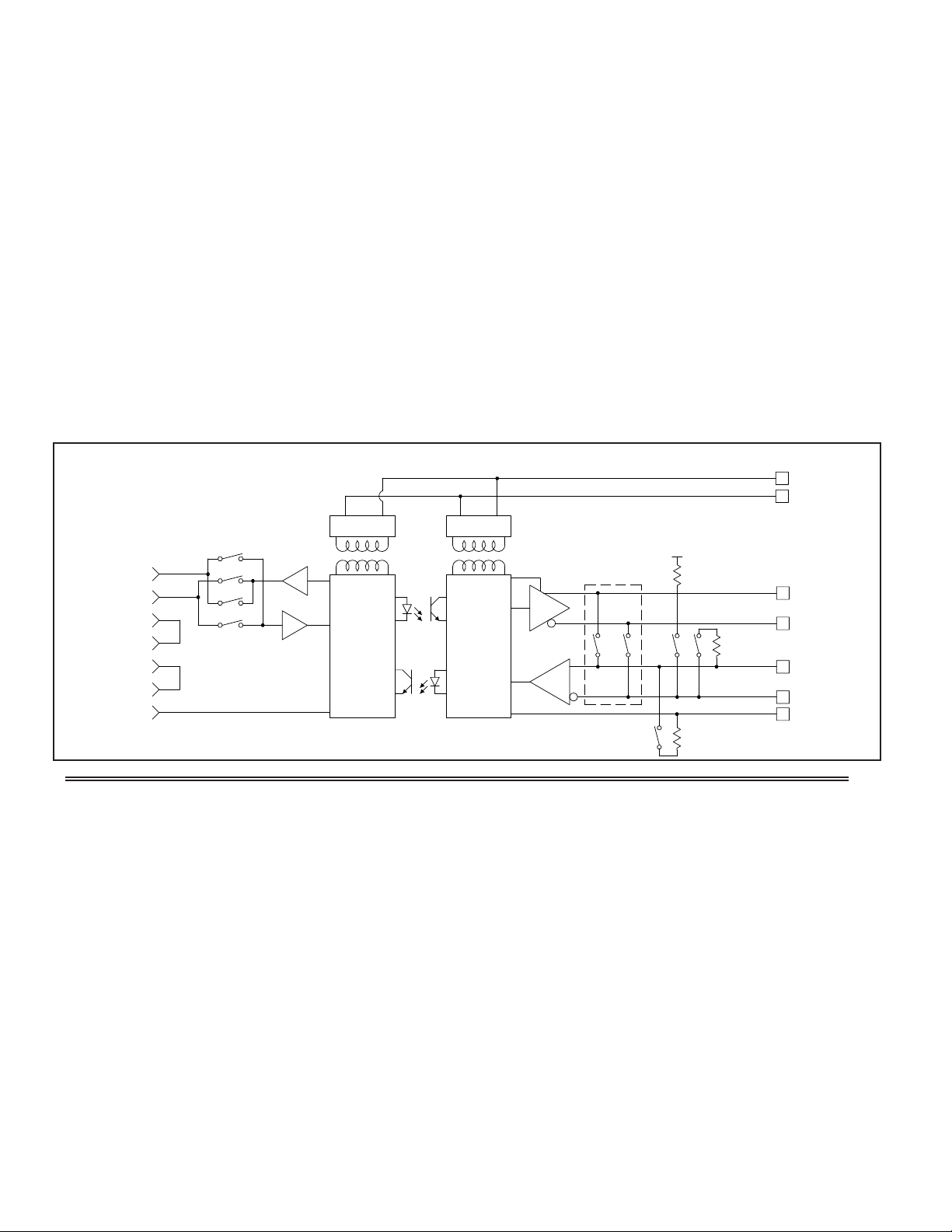

BLOCK DIAGRAM

Note:

1. This device was designed for installation in an enclosure. To avoid

electrostatic discharge to the unit in environments with static levels above

4 Kv, precautions should be taken when the device is mounted outside an

enclosure. When working in an enclosure, (ex. making adjustments, setting

switches etc.) typical anti-static precautions should be observed before

touching the unit.

Refer to EMC Installation Guidelines for additional information.

9. CONSTRUCTION: Case body is black, high impact plastic. Installation

Category I, Pollution Degree 2.

10. MOUNTING: Standard DIN rail top hat (T) profile rail according to

EN50022- 35 X 7.5 and 35 X 15

11. WEIGHT: 3.3 oz. (93.6 g)

1

EMC INSTALLATION GUIDELINES

Although this unit is designed with a high degree of immunity to

ElectroMagnetic Interference (EMI), proper installation and wiring methods

must be followed to ensure compatibility in each application. The type of

electrical noise, source or coupling method into the unit may be different for

various installations. In extremely high EMI environments, additional measures

may be needed. Cable length, routing and shield termination are very important

and can mean the difference between a successful or a troublesome installation.

Listed below are some EMC guidelines for successful installation in an

industrial environment.

1. DC power to the unit should be relatively clean and within the specified

limits. Connecting power to the unit from circuits that power inductive loads

that cycle on and off, such as contactors, relays, motors, etc., should be

avoided. This will reduce the chance of noise spikes entering the DC power

2. The shield (screen) pigtail connection should be made as short as possible.

connection and affecting the unit.

The connection point for the shield depends somewhat upon the application.

Listed below are the recommended methods of connecting the shield, in

order of their effectiveness.

a. Connect the shield only at the unit to earth ground (protective earth).

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is above 1 MHz.

c. Connect the shield to common of the unit and leave the other end of the

shield unconnected and insulated from earth ground.

3. Never run Signal cables in the same conduit or raceway with AC power lines,

conductors feeding motors, solenoids, SCR controls, and heaters, etc. The

cables should be run in metal conduit that is properly grounded. This is

especially useful in applications where cable runs are long and portable twoway radios are used in close proximity or if the installation is near a

commercial radio transmitter.

4. Signal cables within an enclosure should be routed as far away as possible

from contactors, control relays, transformers, and other noisy components.

5. In extremely high EMI environments, the use of external EMI suppression

devices, such as ferrite suppression cores, is effective. Install them on Signal

cables as close to the unit as possible. Loop the cable through the core several

times or use multiple cores on each cable for additional protection.

Install line filters on the power input cable to the unit to suppress power line

interference. Install them near the power entry point of the enclosure. The

following EMI suppression devices (or equivalent) are recommended:

Ferrite Suppression Cores for signal cables:

Fair-Rite # 0443167251 (RLC #FCOR0000)

TDK # ZCAT3035-1330A

Steward #28B2029-0A0

Line Filters for input power cables:

Schaffner # FN610-1/07 (RLC #LFIL0000)

Schaffner # FN670-1.8/07

Corcom #1VR3

Note: Reference manufacturer’s instructions when installing a line filter.

6. Long cable runs are more susceptible to EMI pickup than short cable runs.

Therefore, keep cable runs as short as possible.

2

Page 3

LEDS

*

SWITCHES

IN GROUPS

MUST BE SET

*

*

OFF DCE/ ON DTE

RS232

OFF DTE/ ON DCE

OFF DTE/ ON DCE

OFF DCE/ ON DTE

*

6

5

7

ON

PULL UP

PULL DOWN

OFF 4 WIRE/ ON 2 WIRE

OFF 4 WIRE/ ON 2 WIRE

120Ω TERMINATION

38400 BAUD

115200 BAUD

57600 BAUD

OFF 422/ ON 485

OFF 422/ ON 485

*

9

1

NC23

4

10

6

7

8

3

4

5

RED LION CONTROLS

MODEL ICM5

YORK, PA.

9600 BAUD

19200 BAUD

MADE IN U.S.A.

9-26VDC CLASS 2

@ 125mA MAX.

1

2

ON

M2869X

RS485

TXD

RXD

PWR

RXA 7

COMM

485/

RXB

422

TXA

5

6

4

COMM

TXB

PWR

SPLY

+ VDC

2

3

1

SIDE VIEW OF ICM5

ON

115200 BAUD

57600 BAUD

38400 BAUD

PULL DOWN

9600 BAUD

19200 BAUD

*****

PULL UP

6

543

7

*

1

2

*

OFF DTE/ ON DCE

OFF DTE/ ON DCE

OFF DCE/ ON DTE

OFF DCE/ ON DTE

OFF 422/ ON 485

OFF 422/ ON 485

120Ω TERMINATION

OFF 4 WIRE/ ON 2 WIRE

OFF 4 WIRE/ ON 2 WIRE

4

*

*

NC 3

2

1

***

9

8

10

567

JUMPERED

INTERNALLY

TX2

SIG COM

3

5

RX

TYPICAL RS-232 CONNECTIONS

ON

DCE

RXTXSIG COM

2

3

5

INTERNALLY

JUMPERED

1

9600 BAUD

Note:

Connect shield (drain wire) to earth ground.

235

4

57600 BAUD

38400 BAUD

19200 BAUD

*******

*

6

7PULL UP

8

PULL DOWN

115200 BAUD

OFF 4 WIRE/ ON 2 WIRE

DTE

Note:

Connect shield (drain wire) to earth ground.

***

*

1

9

2

4

10

NC 3

OFF 422/ ON 485

OFF 422/ ON 485

OFF DCE/ ON DTE

OFF DCE/ ON DTE

120Ω TERMINATION

OFF 4 WIRE/ ON 2 WIRE

- Application Dependent

*

- Application Dependent

*

ON

765

OFF DTE/ ON DCE

OFF DTE/ ON DCE

DIP SWITCH SETTINGS

Top Bank of 10 Switches

Switches 1-5 - BAUD

Select the appropriate baud rate. This

adjusts the time delay for the automatic

RS-485 driver controller. Only one of the

DEFAULT SETTINGS

BAUD RATE 9600

DCE

2 WIRE \ RS-485

NO TERMINATION

NO PULL-UP OR PULL DOWN

baud switches should be in the ON position.

Switches 6-7 - PULL UP / PULL DOWN

These switches connect 4.7 K biasing resistors to the A and B lines of the

485 receiver. To minimize loading of the network, these should only be used if

no other device in the system provides biasing.

Switches 8-9 - OFF 4 WIRE / ON 2 WIRE

These switches can be used to internally jumper the A and B lines of the

RS-485 driver and receiver together. This allows 2-wire operation without the

use of external jumper wires. To use the RJ-11 connector, the ICM5 must be in

2-wire mode. Both switches should be in the same position.

Switch 10 - 120 TERMINATION

This switch connects a 120 resistor across the A and B lines of the RS-485

receiver. The use of the resistor prevents signal reflection, or echoing, at high

baud rates, over long distances. This should only be turned on if the ICM5 is

the first, or last, device in a multi-drop network that is experiencing reflection

due to long cable distances.

Bottom Bank of 7 Switches

Switches 1-2 - OFF 422 / ON 485

These switches enable and disable the automatic RS-485 driver control. In

the 422 position, the driver is always enabled, allowing 4-wire full duplex

operation. In the 485 position, the driver is enabled as soon as characters are

received on the RS-232 side. When the RS-485 driver has transmitted the last

character, it waits one character time (at the selected baud rate), and then enters

a high-impedance state. The receiver is also enabled and disabled in a similar

fashion to prevent transmitted characters from being echoed back. This allows

2-wire, half-duplex operation, without the use of handshake lines. Both

switches should be in the same position.

Switch 3 - N/C

No Connection

Switches 4-7 - OFF DCE / ON DTE

These switches configure the RS-232 port to act as a DCE or DTE device.

With all of the switches in the DCE position, pin 2 of the DB-9 connector is the

RS-232 receiver, and pin 3 is the RS-232 transmitter. DTE configures pin 2 as

the transmitter, and pin 3 as the receiver. These switches allow the use of

modem or null-modem cables. All of these switches should be in the DCE or

DTE position. No other combinations are valid.

TYPICAL RS-422 CONNECTIONS

A

TX

RX

ON

4.7K

4.7K

*

*

1

3

2

9600 BAUD

19200 BAUD

38400 BAUD

B

+5V

*

*

4

57600 BAUD

115200 BAUD

6

PULL DOWN

***

9

785

PULL UP

OFF 4 WIRE/ ON 2 WIRE

OFF 4 WIRE/ ON 2 WIRE

Notes:

1. Connect shield (drain wire) to earth ground.

2. RS-422 polarity: Terminal “A” is negative with respect to Terminal “B” in the

mark (logic 1) condition.

120Ω

*

1

10

OFF 422/ ON 485

120Ω TERMINATION

4

TRANSMIT DATA

TRANSMIT DATA

3

A

7

RECEIVE DATA

B

6

RECEIVE DATA

5

SIGNAL COMMON

***

NC

OFF 422/ ON 485

OFF DCE/ ON DTE

OFF DCE/ ON DTE

ON

*

6

74523

OFF DTE/ ON DCE

OFF DTE/ ON DCE

- Application Dependent

*

TYPICAL RS-485 CONNECTIONS

+5V

Note:

Connect shield (drain wire)

to earth ground.

3

TX/RX

ON

***

213

9600 BAUD

19200 BAUD

38400 BAUD

4.7K

***

6

5

4

57600 BAUD

PULL DOWN

115200 BAUD

7

PULL UP

4.7K

*

9

8

10

120Ω TERMINATION

OFF 4 WIRE/ ON 2 WIRE

OFF 4 WIRE/ ON 2 WIRE

*

1

OFF 422/ ON 485

OFF 422/ ON 485

120Ω

***

6

3NC25

4

OFF DTE/ ON DCE

OFF DCE/ ON DTE

OFF DCE/ ON DTE

A

7

B

6

SIGNAL COMMON

5

ON

*

7

OFF DTE/ ON DCE

- Application Dependent

*

Page 4

TYPICAL CONNECTION FOR RS-485 DEVICES

RS485

+VDC

PWR

SPLY

485/

422

TXB

TXA

RXB

RXA

COMM

COMM

COMM.

1+ VDC

2

3

4

5

6

7

TC

COMM

RTD

AC~~AC

312

31 2

LEGEND

- B(-)

12

- A(+)

13

- COMMON

14

- N/C

15

USER INPUTS

COMM132N/C

N/C

TX/RX (+)

TX/RX (-)

TX EN.

1067894 5

+

12

-

13

+

14

-

15

1187456 910

11

20

RLY1

10V

OUT

COMM

21

RLY2

COMM

22

23

RLY3

24

RLY4

25

20mA

OUT

PAX

*****

1

253

9600 BAUD

38400 BAUD

19200 BAUD

6

4

57600 BAUD

PULL DOWN

115200 BAUD

1

9

8ON7

10

PULL UP

OFF 422/ ON 485

120Ω TERMINATION

OFF 4 WIRE/ ON 2 WIRE

OFF 4 WIRE/ ON 2 WIRE

2

OFF 422/ ON 485

*

*

*

6

5

3

4

NC

OFF DCE/ ON DTE

OFF DCE/ ON DTE

OFF DTE/ ON DCE

ON

*

NOTE: FOR CONNECTIONS TO RS485

7

PORT ON PARADIGM PRODUCTS, A &

B ARE REVERSED.

OFF DTE/ ON DCE

*

- Application Dependent

TYPICAL RS-485 CONNECTIONS USING RJ-11

RED LION

PRODUCT

W/RJ11

ICM5

1

23

4

65

7

8 9

10

11 12

The unit is equipped with a universal mounting foot for attachment to

INSTALLATION

standard DIN style mounting rails, including G profile rail according to

EN50035 - G32 , and top hat (T) profile rail according to EN50022 - 35 x 7.5

and 35 x 15. The unit should be installed in a location that does not exceed the

maximum operating temperature and provides good air circulation. Placing the

unit near devices that generate excessive heat should be avoided.

G Rail Installation

To install the ICM5 on a "G" style DIN rail, angle the module so that the

upper groove of the "foot" catches under the lip of the top rail. Push the

module toward the rail until it snaps into place. To remove a module from the

rail, push up on the bottom of the module while pulling out away from the rail.

T Rail Installation

To install the ICM5 on a "T" style rail, angle the module so that the top

groove of the "foot" is located over the lip of the top rail. Push the module

toward the rail until it snaps into place. To remove a module from the rail,

insert a screwdriver into the slot on the bottom of the "foot", and pry upwards

on the module until it releases from the rail.

RS232

CABLE

ON

***

213

9600 BAUD

38400 BAUD

19200 BAUD

*

*

6

5

4

57600 BAUD

PULL DOWN

115200 BAUD

CBJ11BD5

RJ-11 JUMPER

1

9

8

7PULL UP

10

OFF 422/ ON 485

OFF 422/ ON 485

120Ω TERMINATION

OFF 4 WIRE/ ON 2 WIRE

OFF 4 WIRE/ ON 2 WIRE

***

6

7

3NC25

4

OFF DTE/ ON DCE

OFF DTE/ ON DCE

OFF DCE/ ON DTE

OFF DCE/ ON DTE

*

*

ON

- Application Dependent

CONNECTING TO PARADIGM INTERFACE

PARADIGM INTERFACE

MENU

MUTE

ALARMS

EXIT

ON

***

1

3

2

9600 BAUD

19200 BAUD

38400 BAUD

LOWER

RAISE

*

*

6

5

4

57600 BAUD

PULL DOWN

115200 BAUD

PREV

NEXT

*

***

1

9

2

8

7

10

PULL UP

OFF 422/ ON 485

OFF 422/ ON 485

120Ω TERMINATION

OFF 4 WIRE/ ON 2 WIRE

OFF 4 WIRE/ ON 2 WIRE

TO PROGRAMMING

PORT

*

6

7

3

5

4

NC

OFF DTE/ ON DCE

OFF DTE/ ON DCE

OFF DCE/ ON DTE

OFF DCE/ ON DTE

ON

ICM5

P890301Z PARADIGM

PROGRAMMING CABLE

- Application Dependent

*

ORDERING INFORMATION

MODEL NO. DESCRIPTION PART NUMBER

ICM5

RS-232/RS-485 Converter Module

CBJ

6" RJ-11 Jumper Cable

ICM50000

CBJ11BD5

TROUBLESHOOTING

For further technical assistance, contact technical support at the

appropriate company numbers listed.

Loading...

Loading...