WARNING - EXPLOSION HAZARD

EQUIPMENT UNLESS POWER HA

UL Recognized Component,

File # E179259

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT

EQUIPMENT UNLESS POWER HAS BEEN SWITCHED OFF

OR AREA IS KNOWN TO BE NON-HAZARDOUS.

CAUTION: Risk of Danger.

Read complete instructions prior to installation

and operation of the unit.

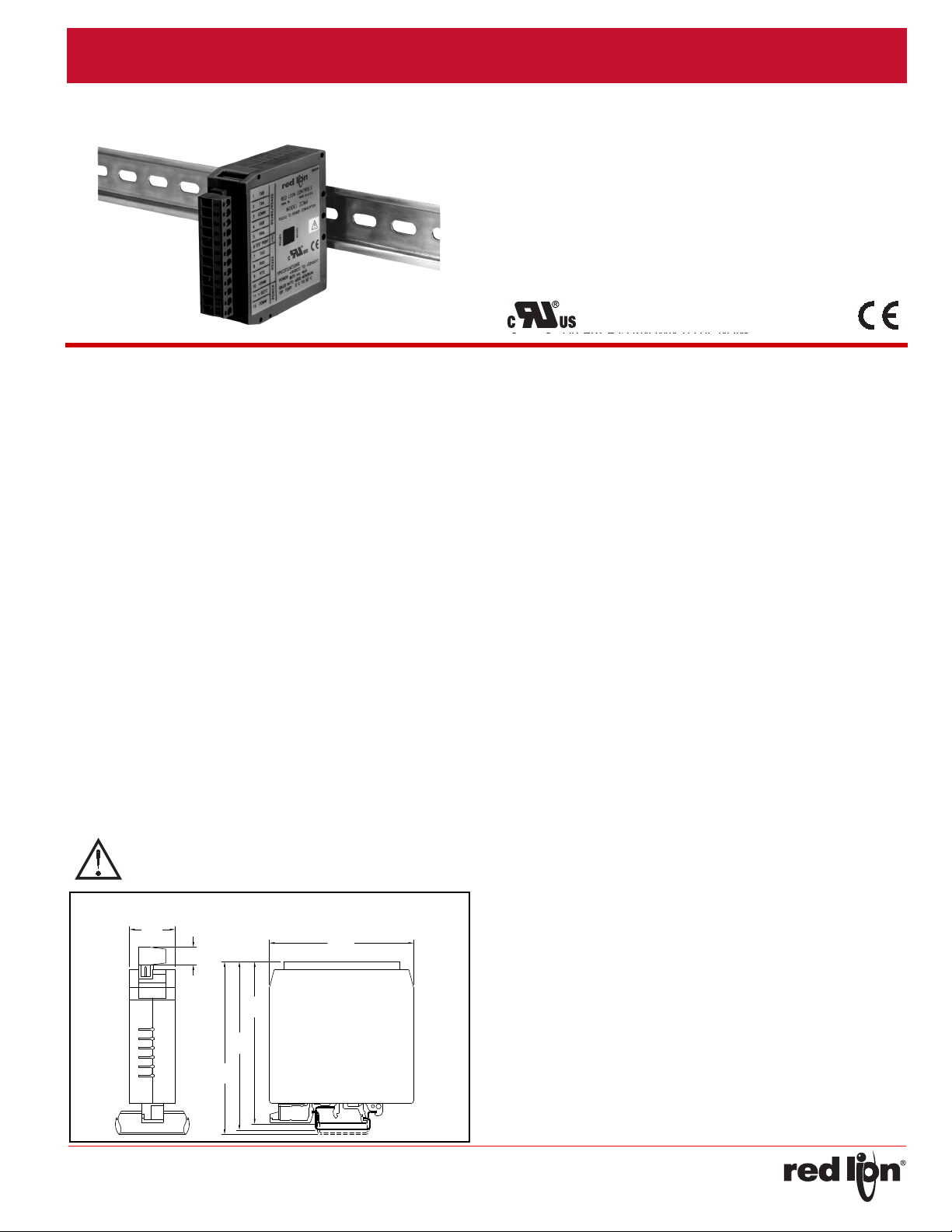

.98

(25)

.39

(10)

3.11

(79)

3.86

(98)

3.76

(95.5)

3.56

(90.5)

DIMENSIONSIninches(mm)

ModelICM4‐SerialCon verterModule(RS ‐232C/RS‐485)

• ALLOWS COMMUNICATIONS BETWEEN RS-232 CONTROL

EQUIPMENT AND PRODUCTS WITH RS-485 SERIAL

COMMUNICATIONS

• WIDE DC INPUT POWER RANGE (+9 to 32 VDC)

• HALF DUPLEX (RS-485) AND FULL DUPLEX (RS-422)

• LED INDICATION FOR RXD, TXD, and POWER

• UNIVERSAL MOUNTING FOOT FOR DIN RAIL INSTALLATION

Bulletin No. ICM4-F

Drawing No. LP0416

Released 2016-08-26

DESCRIPTION

The ICM4 Serial Converter Module provides the capability of

interfacing equipment with RS-485 serial communications to equipment

with RS-232 communications. Data format of the RS-232 and RS-485

equipment must be the same.

For full duplex (RS-422), the DIP switch on the side of the module

must be in the RS-422 position. For half duplex (RS-485), the DIP switch

must be in the RS-485 position. In half duplex mode, the RS-485 driver is

enabled using the leading edge of the first character transmitted (RXD

input). After the last character transmits, the converter waits one

character time (at 9600 baud) to disable the RS-485 driver.

There are 3 LED’s that can be viewed from the front of the converter

module. A green power LED indicates power is on, a red RS-232 TXD

LED flashes when the module is transmitting, and a green RS-232 RXD

LED flashes when the module is receiving.

An external DC power source (+9 to 32 VDC) is required to power the

ICM4. The external power source and serial communications

connections are made via a 12 position removable terminal block located

on the front of the module.

The unit is equipped with a universal mounting foot for attachment to

standard DIN style mounting rails, including top hat profile rail according

to EN50022 - 35 x 7.5 and 35 x 15, and G profile rail according to

EN50035 - G32.

SAFETYSUMMARY

All safety related regulations, local codes and instructions that appear

in this literature or on equipment must be observed to ensure personal

safety and to prevent damage to either the instrument or equipment

connected to it. If equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

DIMENSIONSIninches(mm)

SPECIFICATIONS

1. POWER: +9 to 32 VDC @ 75 mA maximum. Above 26 VDC, derate

max. operating temperature to 40 °C. Power supply must be Class 2

or SELV rated.

2. RS232 VOLTAGES:

Receive Data Pin: ± 30 VDC max.

Mark Condition: ≤ 0.8 VDC

Space Condition: ≥ 2.4 VDC

Transmit Data Pin:

Mark Condition: -8 VDC (typ.)

Space Condition: +8 VDC (typ.)

3. RS485 VOLTAGES:

Differential Output Voltage: ± 5 VDC max. under no load

Differential Input Voltage: ± 5 VDC max.

Mark Condition: ≤ -0.2 VDC

Space Condition: ≥ +0.2 VDC

RS485 Drive Capability: Up to 32 RS-485 receivers connected in

parallel.

RS485 Drive Disable Time: 4 msec. max.

4. MAXIMUM CABLE LENGTH:

RS232: 50 feet

RS485: 4000 feet

5. BAUD RATE: 9600 min., 19200 max.

6. CERTIFICATIONS AND COMPLIANCES:

CE Approved

EN 61326-1 Immunity to Industrial Locations

Emission CISPR 11 Class B

Safety requirements for electrical equipment for measurement,

control, and laboratory use:

EN 61010-1: General Requirements

RoHS Compliant

UL Recognized Component: File #E179259

IP20 Enclosure rating (Rear of unit)

Refer to EMC Installation Guidelines section of the bulletin for additional

information.

7. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range: 0 to 50 °C. Derate max. operating

temperature to 40 °C above 26 VDC.

Storage Temperature: -40 to + 75 °C

Operating and Storage Humidity: 85% max.relative humidity

(non-condensing) from 0 to 50 °C

Vibration to IEC 68-2-6: Operational 5 to 150 Hz, 2 g.

Shock to IEC 68-2-27: Operational 30 g.

Altitude: Up to 2000 meters

8. CONSTRUCTION: Case body is black, high impact plastic. Installation

Category I, Pollution Degree 2.

9. MOUNTING: Standard DIN rail top hat (T) profile rail according to

EN50022- 35 X 7.5 and 35 X 15

10.WEIGHT: 3.2 oz. (90.7 g)

-1-

Released 2016-08-26 Bulletin No. ICM4-F

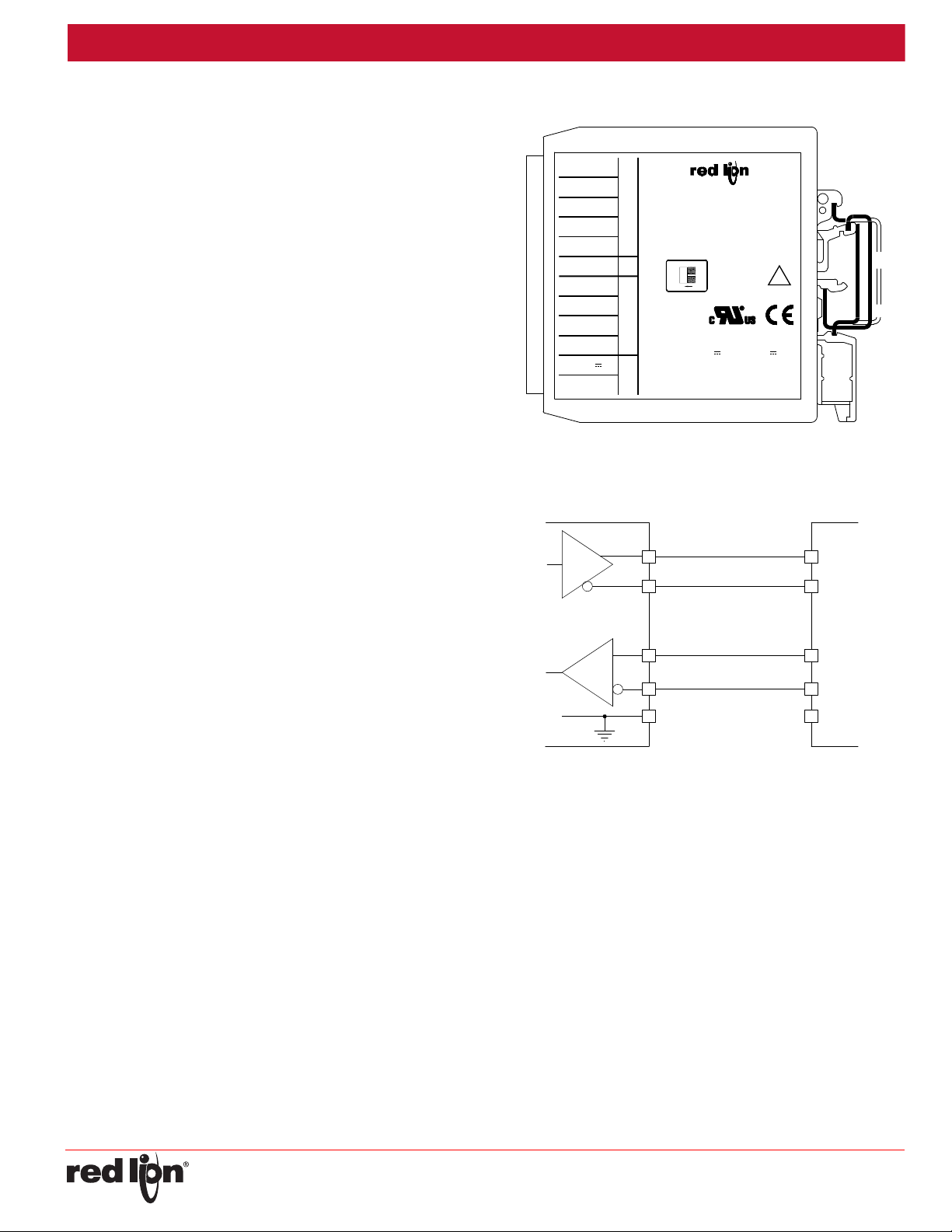

RS422

RS485

ON

RS485/RS422

SPECIFICATIONS

BAUD RATE: 9600 MINIMUM

OP. TEMP: 0° C TO 50° C

RED LION CONTROLS

MODEL ICM4

RS232 TO RS485 CONVERTER

YORK, PA.

COMM

COMM

+ DC

11

12

10

98RTS

RXD

POWER RS232

POWER:

COMM

TEST POINT

7 TXD

6

5 RXA

3

4 RXB

2 TXA

+5V

+9VDC TO +32VDC

@75 ma. MAX.

MADE IN U.S.A.

!

1 TXB

M2293C

TX

RX

2

TRANSMIT DATA

TRANSMIT DATA RETURN

RECEIVE DATA

RECEIVE DATA RETURN

SIGNAL COMMON

1

5

4

3

*

*

*

*

*

RX+

RX-

TX+

TX-

ICM4

CONNECTING

DEVICE

B"

"

A"

"

B"

"

A"

"

Drawing No. LP0416

EMCINSTALLATIONGUIDELINES

Although Red Lion Controls products are designed with a high degree

of immunity to Electromagnetic Interference (EMI), proper installation and

wiring methods must be followed to ensure compatibility in each

application. The type of the electrical noise, source or coupling method

into a unit may be different for various installations. Cable length, routing,

and shield termination are very important and can mean the difference

between a successful or troublesome installation. Listed are some EMI

guidelines for a successful installation in an industrial environment.

1. A unit should be mounted in a metal enclosure, which is properly

connected to protective earth.

2. Use shielded cables for all Signal and Control inputs. The shield

connection should be made as short as possible. The connection point

for the shield depends somewhat upon the application. Listed below

are the recommended methods of connecting the shield, in order of

their effectiveness.

a. Connect the shield to earth ground (protective earth) at one end

where the unit is mounted.

b. Connect the shield to earth ground at both ends of the cable, usually

when the noise source frequency is over 1 MHz.

3. Never run Signal or Control cables in the same conduit or raceway with

AC power lines, conductors, feeding motors, solenoids, SCR controls,

and heaters, etc. The cables should be run through metal conduit that

is properly grounded. This is especially useful in applications where

cable runs are long and portable two-way radios are used in close

proximity or if the installation is near a commercial radio transmitter.

Also, Signal or Control cables within an enclosure should be routed as

far away as possible from contactors, control relays, transformers, and

other noisy components.

4. Long cable runs are more susceptible to EMI pickup than short cable

runs.

5. In extremely high EMI environments, the use of external EMI

suppression devices such as Ferrite Suppression Cores for signal and

control cables is effective. The following EMI suppression devices (or

equivalent) are recommended:

Fair-Rite part number 0443167251 (Red Lion Controls # FCOR0000)

Line Filters for input power cables:

Schaffner # FN2010-1/07 (Red Lion Controls # LFIL0000)

6. To protect relay contacts that control inductive loads and to minimize

radiated and conducted noise (EMI), some type of contact protection

network is normally installed across the load, the contacts or both. The

most effective location is across the load.

a. Using a snubber, which is a resistor-capacitor (RC) network or metal

oxide varistor (MOV) across an AC inductive load is very effective at

reducing EMI and increasing relay contact life.

b. If a DC inductive load (such as a DC relay coil) is controlled by a

transistor switch, care must be taken not to exceed the breakdown

voltage of the transistor when the load is switched. One of the most

effective ways is to place a diode across the inductive load. Most

Red Lion products with solid state outputs have internal zener diode

protection. However external diode protection at the load is always a

good design practice to limit EMI. Although the use of a snubber or

varistor could be used.

Red Lion part numbers: Snubber: SNUB0000

7. Care should be taken when connecting input and output devices to the

instrument. When a separate input and output common is provided,

they should not be mixed. Therefore a sensor common should NOT be

connected to an output common. This would cause EMI on the

sensitive input common, which could affect the instrument’s operation.

Visit www.redlion.net/emi for more information on EMI guidelines,

Safety and CE issues as they relate to Red Lion products.

Varistor: ILS11500 or ILS23000

SIDE VIEW OF ICM4

TYPICAL RS-422 CONNECTIONS

Notes:

1. Connect shield drain wire to earth ground.

2. Place DIP switch on the side of the ICM4 in the 422 position.

3. RS-422 polarity: Terminal “A” is negative with respect to Terminal “B” in

the mark (logic 1) condition.

-2-

Released 2016-08-26 Bulletin No. ICM4-F

TX

RX

TWO WIRE

RS-485 BUS

REFERENCE GROUND

A"

B"

A"

B"

ȍ

"

"

"

"

1

5

4

3

2 *

*

*

TX/RX+

TX/RX-

ICM4 CONNECTING DEVICE

TX

RX

TWO WIRE

RS-485 BUS

REFERENCE GROUND

A"

B"

A"

B"

ȍ

"

"

"

"

1

5

4

3

2

*

*

*

TX/RX+

TX/RX-

ICM4

CONNECTING DEVICE

TWO WIRE

RS-485 BUS

*

*

TX/RX+

TX/RX-

CONNECTING DEVICE

8

7

10

7

3

2

RECEIVE DATA

TRANSMIT DATA

SIGNAL COMMON SIGNAL COMMON

TRANSMIT DATA

RECEIVE DATA

ICM4 RS232 DEVICE (25 pin)

ICM4 connector pin #'s

ICM4 connector pin #'s

RS232 DEVICE (9 pin)ICM4

RECEIVE DATA

TRANSMIT DATA

SIGNAL COMMONSIGNAL COMMON

TRANSMIT DATA

RECEIVE DATA

2

3

5

10

7

8

Drawing No. LP0416

TYPICAL RS-485 CONNECTIONS

TYPICAL MULTIPLE RS-485 CONNECTIONS

TYPICAL RS-232 CONNECTIONS

Notes:

1. Connect shield drain wire to earth ground.

2. Place DIP switch on the side of the ICM4 in the 485 position.

3. The transmit and receive data lines of the ICM4 should be wired

together.

-3-

Released 2016-08-26 Bulletin No. ICM4-F

LIMITED WARRANTY

(a) Red Lion Controls Inc., Sixnet Inc., N-Tron Corporation, or Blue Tree Wireless Data, Inc. (the “Company”)

warrants that all Products shall be free from defects in material and workmanship under normal use for the period of

time provided in “Statement of Warranty Periods” (available at www.redlion.net) current at the time of shipment of the

Products (the “Warranty Period”). EXCEPT FOR THE ABOVE-STATED WARRANTY, COMPANY MAKES NO

WARRANTY WHATSOEVER WITH RESPECT TO THE PRODUCTS, INCLUDING ANY (A) WARRANTY OF

MERCHANTABILITY; (B) WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE; OR (C) WARRANTY

AGAINST INFRINGEMENT OF INTELLECTUAL PROPERTY RIGHTS OF A THIRD PARTY; WHETHER EXPRESS

OR IMPLIED BY LAW, COURSE OF DEALING, COURSE OF PERFORMANCE, USAGE OF TRADE OR

OTHERWISE. Customer shall be responsible for determining that a Product is suitable for Customer’s use and that

such use complies with any applicable local, state or federal law.

(b) The Company shall not be liable for a breach of the warranty set forth in paragraph (a) if (i) the defect is a result

of Customer’s failure to store, install, commission or maintain the Product according to specifications; (ii) Customer

alters or repairs such Product without the prior written consent of Company.

(c) Subject to paragraph (b), with respect to any such Product during the Warranty Period, Company shall, in its

sole discretion, either (i) repair or replace the Product; or (ii) credit or refund the price of Product provided that, if

Company so requests, Customer shall, at Company’s expense, return such Product to Company.

(d) THE REMEDIES SET FORTH IN PARAGRAPH (c) SHALL BE THE CUSTOMER’S SOLE AND EXCLUSIVE

REMEDY AND COMPANY’S ENTIRE LIABILITY FOR ANY BREACH OF THE LIMITED WARRANTY SET FORTH

IN PARAGRAPH (a).

Drawing No. LP0416

INSTALLATION

The unit is equipped with a universal mounting foot for attachment to standard DIN style mounting rails, including G profile rail according to EN50035

- G32 , and top hat (T) profile rail according to EN50022 - 35 x 7.5 and 35 x 15. The unit should be installed in a location that does not exceed the

maximum operating temperature and provides good air circulation. Placing the unit near devices that generate excessive heat should be avoided.

G Rail Installation

To install the ICM4 on a “G” style DIN rail, angle the module so that

the upper groove of the “foot” catches under the lip of the top rail. Push

the module toward the rail until it snaps into place. To remove a module

from the rail, push up on the bottom of the module while pulling out away

from the rail.

To install the ICM4 on a “T” style rail, angle the module so that the top

groove of the “foot” is located over the lip of the top rail. Push the module

toward the rail until it snaps into place. To remove a module from the rail,

insert a screwdriver into the slot on the bottom of the “foot”, and pry

upwards on the module until it releases from the rail.

T Rail Installation

ORDERINGINFORMATION

MODEL NO. DESCRIPTION PART NUMBER

ICM4 RS-232/RS-485 Converter Module ICM40030

-4-

Loading...

Loading...