Page 1

MODEL IAMA - CONFIGURABLE 3-WAY ISOLATING AMPLIFIER

C

US

3-WAY ISOLATION OF ANALOG SIGNALS

UNIVERSAL CONVERSION MODULE - INPUTS AND OUTPUTS

SELECTED VIA DIP SWITCH SETTINGS

OVER 35 INPUT AND OUTPUT ANALOG CONVERSION

COMBINATIONS

ULTRA SLIM DESIGN – ONLY 0.244" WIDE

19 to 30 VDC POWER

PROCESS CONTROL

U

C

LISTED

R

L

EQUIPMENT FOR HAZARDOUS

US

LOCATIONS 31ZN

CLASS 1, DIV 2

GROUPS A, B, C, D T5

GENERAL DESCRIPTION

The IAMA can isolate and convert over 35 combinations of analog signal

ranges. The IAMA converts and transmits signals linearly proportional to the

input. DIP switch range selection eliminates the need to order and stock

different modules for each input and output signal range, and allows quick and

convenient setup for over 35 standard signal conversions. In addition to the

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

conversion capabilities, the IAMA modules feature optically isolated Input/

Output signal circuits and isolated Power to Input, Power to Output circuits. The

modules’ overall full scale accuracy typically exceed 0.04%. DIN rail mounting

saves time and panel space. The units are equipped with universal mounting feet

for attachment to standard top hat profile rail according to EN50022 - 35x7.5.

DIMENSIONS In inches (mm)

0.24

(6.2)

1

5

on

S2

off

6

6

1

1 2

7

8

1

2

on

off

2

S1

4.00

3

(101.6)

3

4

4

CAUTION: Read complete

instructions prior to installation

and operation of the unit.

SPECIFICATIONS

1. POWER: 19.2 to 30 V DC, 450 mW max.

2. INPUT / OUTPUT RANGES: See table 1

3. SPAN ADJUSTMENT: Potentiometer, located below transparent top cover.

4. MAX INPUT SIGNAL:

Current: 50 mA

Voltage: 30 V

5. INPUT RESISTANCE:

Current: Approx. 50

Voltage: Approx. 100 k

6. OUTPUT: Self-powered (Active)

7. MAX OUTPUT SIGNAL:

Current: 28 mA/12.5 V

CAUTION: Risk of electric shock.

Voltage: 12.5 V/22 mA

8. LOAD RESISTANCE:

Current: 500 max.

Voltage: 10 k min

9. OUTPUT COMPLIANCE:

Current: 12.5 V max (500 ). Ripple: < 20 mV

3.65 (92.7)

Voltage: 22 mA (10 k). Ripple: < 20 mV

10. TRANSMISSION ERROR:

The transmission error without adjustment is < 0.4%. Using the potentiometer,

the error can be adjusted to < 0.1%.

11. TEMPERATURE COEFFICIENT:

ORDERING INFORMATION

MODEL NO. DESCRIPTION PART NUMBER

IAMA IAMA0006Configurable 3-Way Isolating Amplifier

Max.: < 0.01%/K

Typ.: < 0.002%/K

12. CUT-OFF FREQUENCY: 100 Hz

13. STEP RESPONSE (FROM 10 to 90 %): 3.5 msec

14. TEST VOLTAGE (Input/Output/Supply): 1.5 kV, 50 Hz, 1 min.

15. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range: -20°C to 65°C (-4°F to 149°F)

Storage Temperature Range: -40°C to +85°C (-40°F to 185°F)

1

Page 2

16. TESTS/APPROVALS:

C

US

I,U

1

2

IN UI

GND1

5

6

OUT UI

GND2

U

U,I

DCDCDC

4

3

GND3

UB + UB +

8

7

GND3

PROCESS CONTROL EQUIPMENT FOR

U

R

C

US

L

HAZARDOUS LOCATIONS

LISTED

31ZN

Class I Div 2 Groups A, B, C, D T5

A) This equipment is suitable for use in Class I, Division 2, Groups A, B,

C and D or non- hazardous locations only.

B) Warning - explosion hazard - substitution of components may impair

suitability for Class 1, Division 2.

C) W arning - explosion hazard - do not disconnect equipment unless power

has been switched off or the area is known to be non-hazardous.

INPUTS

The IAMA accepts a full range of process signal inputs and isolates and

converts these signals to common industrial control signals. The input signal

combinations are configured by making specific DIP switch selections on the 6

and 2 position DIP switches.

OUTPUTS

As with the input choices, the process signal output of the modules is DIP

switch selectable. The maximum output current signal is 28 mA with =500

output resistance and the maximum output voltage signal is 12.5 V with =10 K

output resistance. The transmission error without adjustment is < 0.4%. Using

the potentiometer, the error can be adjusted to < 0.1%.

17. CERTIFICA TIONS AND COMPLIANCES:

Conformance With EMC Guideline 2004/108/EC And Low Voltage Directive 2006/95/EC

Immunity to Interference According to EN 61000-6-2

Discharge of static electricity (ESD) EN 61000-4-2 Criterion B

Electromagnetic HF field EN 61000-4-3 Criterion A

Fast transients (Burst) EN 61000-4-4 Criterion B

Surge voltage capacities (Surge) EN 61000-4-5 Criterion B

Conducted disturbance EN 61000-4-6 Criterion A

Noise Emission According to EN 50081-2

Noise emission of housing EN 55011

1

EN 61000 corresponds to IEC 1000

2

Criterion B: T emporary impairment to operational behavior that is corrected

by the device itself.

3

Criterion A: Normal operating behavior within the defined limits.

4

EN 55011 corresponds to CISPR11

5

Class A: Area of application industry.

1

2

3

2

2

3

4

Class A

5

18. CONNECTIONS: 12 AWG max., Stripping length: 0.47" (12 mm)

19. CONSTRUCTION: Polybutylenterephthalate PBT, black

20. MOUNTING: Standard DIN top hat (T) profile rail according to EN50022

- 35x7.5

21. WEIGHT: 2 oz. (54 g)

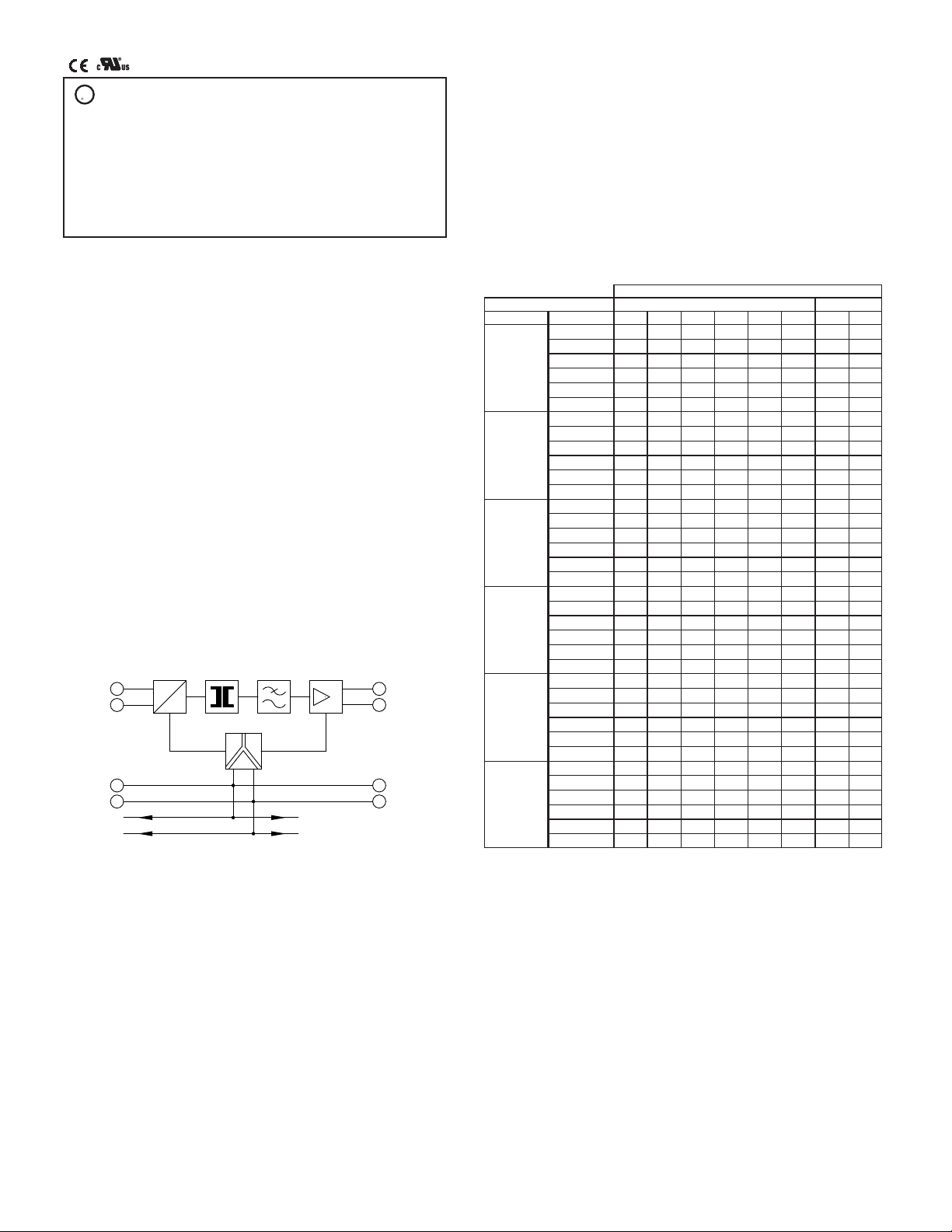

BLOCK DIAGRAM

TABLE 1 - CONFIGURATION

RANGES

IN

0 –10 V

2 – 10 V

0 – 5 V

1 – 5 V

0 – 20 mA

4 - 20 mA

OUT 1

0 – 20 mA off off off off off off off off

4 - 20 mA off off off off off ON off off

0 – 10 V ON off ON off off off off off

2 – 10 V ON off ON off off ON off off

0 – 5 V ON ON off off off off off off

1 – 5 V ON ON off off off ON off off

0 – 20 mA off off off ON ON off off off

4 - 20 mA off off off off off off off off

0 – 10 V ON off ON ON ON off off off

2 – 10 V ON off ON off off off off off

0 – 5 V ON ON off ON ON off off off

1 – 5 V ON ON off off off off off off

0 – 20 mA off off off off off off ON off

4 - 20 mA off off off off off ON ON off

0 – 10 V ON off ON off off off ON off

2 – 10 V ON off ON off off ON ON off

0 – 5 V ON ON off off off off ON off

1 – 5 V ON ON off off off ON ON off

0 – 20 mA off off off ON ON off ON off

4 - 20 mA off off off off off off ON off

0 – 10 V ON off ON ON ON off ON off

2 – 10 V ON off ON off off off ON off

0 – 5 V ON ON off ON ON off ON off

1 – 5 V ON ON off off off off ON off

0 – 20 mA off off off off off off off ON

4 - 20 mA off off off off off ON off ON

0 – 10 V ON off ON off off off off ON

2 – 10 V ON off ON off off ON off ON

0 – 5 V ON ON off off off off off ON

1 – 5 V ON ON off off off ON off ON

0 – 20 mA off off off ON ON off off ON

4 - 20 mA off off off off off off off ON

0 – 10 V ON off ON ON ON off off ON

2 – 10 V ON off ON off off off off ON

0 – 5 V ON ON off ON ON off off ON

1 – 5 V ON ON off off off off off ON

DIP SWITCHES

OUTPUT (S2)

2 3 4 5 6 1

INPUT (S1)

2

2

Page 3

WIRING CONNECTIONS

5

6

7

8

-

+

RECORDER

CHART

FLOW

SENSOR

0-5 VDC

IAMA6

Primary power is connected to terminals 7 or 3 (19.2 – 30 VDC) and 8 or 4

(GND 3). For best results, the power should be relatively “clean” and within the

specified variation limits. Drawing power from heavily loaded circuits or from

circuits that also power loads that cycle on and off, should be avoided.

The input signal is connected to pins 1 (In U,I) and 2 (GND 1). Connections

for the output signal are made on pins 5 (Out U,I) and 6 (GND 2).

OUT UI 5

GND2 6

19.2...30VDC 7

GND3 8

on

S2

off

6

1

1 2

DIN rail release latch

1 IN UI

2 GND1

on

S1

off

3 19.2...30VDC

4 GND3

INSTALLATION

The unit is equipped with a universal mounting foot for attachment to

standard DIN style top hat (T) profile rail according to EN50022 - 35 x 7.5 and

35 x 15. The unit should be installed in a location that does not exceed the

maximum operating temperature and provides good air circulation. Placing the

unit near devices that generate excessive heat should be avoided.

T Rail Installation

To install the IAMA on a “T”

style rail, angle the module so that

the top groove of the “foot” is

located over the lip of the top rail.

Push the module toward the rail

until it snaps into place. To

remove a module from the rail,

insert a screwdriver into the slot

on the bottom of the “foot”, and

pry upwards on the module until it

releases from the rail.

APPLICATION

Cost efficiency measurements of a printing company included the reduction

of bulk stock of the various inks used in their printing processes. The

company currently had various ink flow and level devices with different

current and voltage outputs and wanted to record these measurements into a

control room PC. Several IAMA Universal Signal Conditioning Modules

were the answer. The IAMA’s universal input allowed for easy signal

conditioning of the various output signals to the required PC’s Bus Board

0 to 10 VDC input signal. In this case, the IAMA’s re-transmitted 0 to 10

VDC output was field calibrated, negating the expense and time

required to rewrite the PC’s software parameters. In addition to

accepting multiple signal types, the IAMA also provides the

necessary electrical isolation between the control room PC

and the hazards of the printing floor electrical noise.

3

Loading...

Loading...