Page 1

HMI Operator Interfaces

Rugged Graphite® & G3 HMIs

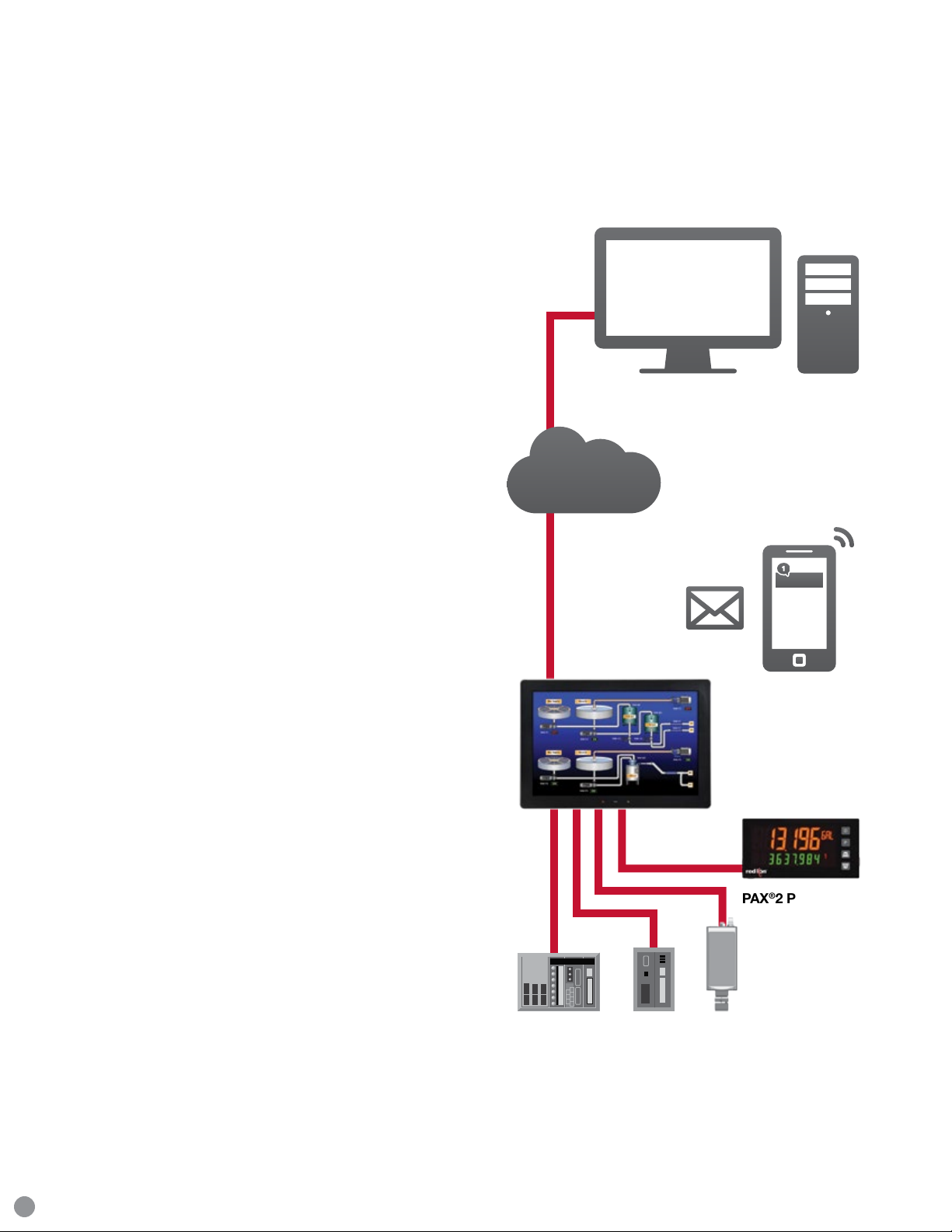

Protocol conversion | Multi-vendor support | Web server

Data logging | Email notification | SMS message alerts

Page 2

Sleek. Rugged. Flexible. Red Lion is the Best Choice for HMI Panels.

From factories to extreme remote locations, Red Lion's HMI solutions enable customers to easily connect, monitor and

control processes across a diverse range of industries that include manufacturing, oil and gas and water/wastewater.

2

Page 3

Connect Every Device.

Anywhere. Anytime.

Optimizing the performance of industrial assets can only occur when both

those in the field and in management can see the right data at the right time

and act on it. This is a truth that remains consistent even as the details of

various industrial installations and applications change. From factory floors to

hazardous remote locations, whether simple systems or complex multi-vendor

environments, the ability to connect devices, monitor performance and control

operations is critical to operational success.

This is why Red Lion Controls offers a comprehensive array of HMI operator

panels to address the varying requirements found within the industrial

automation space. With a full spectrum of indoor and outdoor models ranging

in size from 3” through 15” touchscreens, our HMIs give organizations the

ability to select exactly the functionality they need to connect, monitor and

control operations.

By combining powerful features such as web serving and data logging with

built-in protocol conversion, our award-winning HMIs work with over 300

leading industrial protocols to connect disparate systems and devices across

industries that include manufacturing, packaging, oil and gas, water/wastewater

and more.

Whether installing new best-in-class equipment from multiple vendors or

extending the lifespan of existing equipment, Red Lion’s protocol conversion

capabilities provide the path toward seamless equipment integration.

Supporting up to 20 simultaneous protocol conversions, our database of

over 300 industrial drivers offers the most powerful cross-communication

platform available today.

3

Page 4

More than Machine Access.

With features ranging from protocol conversion to SMS message alerting, Red Lion HMIs are powerful tools

that provide real-time information access—anywhere, anytime.

Unify disparate equipment.

By easily integrating into single or multi-vendor environments,

our HMIs provide the ability to network-enable and web-serve

different devices through a variety of built-in connection methods

that include serial, USB and 10/100Base-T(X) Ethernet ports.

These features allow you to choose best-in-class equipment

from virtually any vendor to create machines, systems and

processes and control them all from a single point. From PLCs

to drives, cameras, PID controllers and more, Red Lion HMIs

unify disparate equipment to help ensure everything

communicates seamlessly.

• Communicate with over 300 major industrial protocols

• Support up to 20 simultaneous protocol conversions

• Convert between serial, USB and Ethernet devices

• Manage multi-vendor environments with ease

Monitor and control remotely.

Web-enabled remote monitoring allows organizations to monitor

and control operations in real time, regardless of where process

operations are occurring. With a built-in web server, our HMIs

provide you with real-time access to remote locations or factory

floor data, even when that data is derived from legacy serialconnected equipment. Virtual HMI capabilities give operators full

control over a remote HMI or simply provide view-only access for

process monitoring.

•

Synchronize logged data between HMIs and remote

FTP sites automatically

• Download, upload and remotely access data and

configuration files from SD card or use a USB drive

to load database and configuration updates

• Use pass-through programming for connected devices

that don't typically allow remote programming

• Provide remote virtual HMI display and/or full control

from any web browser

Graphite HMI

PAX®2 Panel Meter

Camera

DrivePLC

4

Page 5

Stay informed in real time.

A rapid response to issues as they occur can be the difference

between a major crisis and a small hiccup. Red Lion HMIs feature

powerful messaging capabilities that automatically send email or

SMS text messages to notify operators or management should a

process issue occur or if a value moves out of a specified range.

Given the stakes, being proactively notified of issues as they

happen can help you stay on top of operations and give you

the competitive advantage needed today.

• Send email or SMS text messages based on alarms

and system values

• Alert operators or management in real time on

critical processes

Improve performance.

Communicating between devices is an important step in the drive

toward efficiency, but it is only the beginning of overall process

improvement efforts. To be able to truly improve performance

requires review and analysis of cumulative data and results.

The powerful data-logging capabilities found in Red Lion HMIs

allow you to compile data from all connected devices in a

single CSV file, even in the most complex multi-vendor, multiprotocol, multi-device environments. With the ability to store,

view and analyze data locally or transfer it via email, FTP or

posting to custom web pages, our HMIs provide options that

make data logging easy and intuitive.

Save time.

Changing equipment parameters and configurations is

unavoidable, but the time and resources required to program

equipment and protocol converters equates to process and

equipment downtime and reduced productivity. This makes

minimizing the duration of these interruptions critically important.

This is why Red Lion HMIs are programmed using our flagship

Crimson® software, an intuitive, easy-to-use Windows-based

program that combines drag-and-drop simplicity with

unprecedented configuration power. The best part is that

Crimson software is included with every HMI and comes

with free updates and ongoing support.

• Acquire data from connected devices into a single file

• Create batch logs or record data from each batch

run separately

• Store security logs to capture user IDs when performing

tasks as well as note alarm event data

• Create password-protected data screens to segment

data by user

• Automatically push stored data to SQL server for

reporting and analysis

• Configure HMIs with drag-and-drop interface and

programming tools

• Use built-in gateway and protocol converter to quickly

Ethernet-enable connected devices

5

Page 6

A Red Lion HMI for Every

Application and Environment.

While connected equipment may vary from application to application, our industry-leading protocol conversion

capabilities let you integrate virtually any device with ease. With a wide range of features in a variety of sizes,

Red Lion lets you choose the best HMI to address your specific needs.

Rugged Graphite HMIs

• Convert up to 20 protocols simultaneously from over 300

supported drivers

• Offer unparalleled expansion capabilities via plug-in modules

• Feature wide -20° to 60°C operating temperature range

• Include sunlight readable outdoor-rated models

Outdoor applications?

No problem, we have Graphite HMI models

for you. Our rugged 7" and 10" touchscreens

are available with sunlight-readable displays

and UV protective overlays to support

outdoor environments. Add a wide operating

temperature range coupled with high shock/

vibration tolerances and Graphite HMIs offer

the perfect outdoor solution.

• Provide built-in data logging (SD card), web server

and FTP for remote access

• Send email and/or SMS notifications on alarm conditions

• UL Class 1, Division 2 Listed for hazardous locations,

ABS and ATEX/IECEx zone 2/22 approved

6

Page 7

Powerful G3 HMIs

G3 Kadet HMIs

• Convert up to 13 protocols simultaneously from over 300

supported drivers

Provide built-in data logging (CF card), web server and FTP

•

• Convert up to seven protocols simultaneously from over 300

supported drivers

• Offer several connectivity ports including serial and Ethernet

for remote access

• Send email and/or SMS notifications on alarm conditions

Offer multiple connectivity ports including serial,

•

Ethernet and USB

• UL Class 1, Division 2 Listed for hazardous locations

HMI Operator Panel Feature Comparison

FEATURES GRAPHITE HMIs G3 HMIs G3 KADET HMIs

Serial Ports 4* 4* 3*

Ethernet 2* 1 1

USB Host 2 1*

Crimson 3.0 Programmed • •* •

C-Type User Programming • •

Protocol Converter • • •

Simultaneous Conversions 20 13 7

Web Server, FTP, Data Logging • •

Expansion Card Slots 8* 1

Temperature Range -20˚ to 60˚C 0˚ to 50˚C 0˚ to 45˚C

On-Display Keypad •

* Model specific

7

Page 8

Rugged Graphite HMIs

GRAPHITE HMIs G15 G12

Display Type 15" XGA, 16M Color 12" WXGA, 16M Color (Widescreen)

Resolution 1024 x 768 1280 x 800

Sunlight Readable

Dimensions

Module Slots 8 8

Serial Ports Up to 4 Up to 4

14.03" x 11.10" x 2.14"

(356.3 x 281.8 x 54.3 mm)

12.10" x 8.20" x 2.06"

(307.3 x 208.3 x 52.4 mm)

Sleek design. Versatile plug-in modules.

Red Lion Graphite advanced operator panels are the industry’s

first rugged HMI touchscreens to combine a wide range of

versatile plug-in modules with protocol conversion, data logging

and web-based monitoring and control. With all cast-aluminum

construction and UL Class 1, Division 2, ABS, ATEX and IECEx

zone 2/22 approvals, Graphite HMIs support wide operating

temperatures and high shock/vibration tolerances to enable

you to connect, monitor and control processes regardless

of environment. For outdoor applications, sunlight-readable

models are available in both 7" and 10" sizes.

• Rugged cast-aluminum housing for outdoor and indoor display

• Powerful protocol conversion with support for up to 20

simultaneous conversions across 300+ industrial protocols

• Real-time data logging provides historic visibility to support

process improvements

• Web and FTP servers enable remote monitoring and control

• Variety of plug-in modules expand capabilities

• USB synchronization of database and log files

• Crimson 3.0 software for easy drag-and-drop programming

8

Page 9

G10 G09 G07

10" G10R SVGA,

16M Color (High Res)

800 x 600 640 x 480 800 x 480 800 x 480

10.84" x 8.57" x 2.06"

(275.2 x 217.7 x 52.4 mm)

10” G10C & G10S VGA,

16M Color

G10S Models G07S Model

7 6 5

3 3 3

9" WVGA, 16M Color (Widescreen) 7" WVGA, 16M Color (Widescreen)

10.06" x 6.47" x 2.06"

(255.6 x 154.4 x 52.4 mm)

Specification Highlights

1

Power

2

USB Device

3

10/100 Ethernet

• SD memory card slot for data log storage

• Extreme -20˚ to 60˚C operating temperature range

• +24 VDC +/-20% power input

• ATEX and IECEx zone 2/22 approvals

• UL Class 1, Division 2 Listed; NEMA 4x/IP66 rated

4

USB Host

5

RS-232

6

RS-422/485

1 2 3 4 3 5 6 5

Graphite HMIs come standard with one 10/100Base-T(X)

Ethernet port, two RS-232 and one RS-422/485 serial ports,

one USB Device and two USB Host ports. Additional Ethernet

and/or RS-422/485 ports are available on specific models.

7.70" x 5.51" x 2.00"

(195.5 x 139.9 x 50.8 mm)

9

Page 10

Graphite Plug-In Modules

Build the perfect HMI solution.

With up to eight available plug-and-play module slots, Graphite HMIs can integrate complex multi-vendor environments.

Employing modules to address PID control, data acquisition and communication, Graphite HMIs allow you to

connect a wide array of equipment to meet your specific needs.

Data Acquisition

Advanced data acquisition and management is easy with our

powerful Graphite plug-in modules. For instance, a fullypopulated 7” Graphite HMI can monitor and control up to 40

onboard I/O points while our 15” Graphite HMIs can support up

to 64 I/O points using data acquisition modules with integrated

I/O. Even better, this high-density data acquisition tool also lets

you log data and access files remotely through any Internet

browser and enables remote alerts that you can receive via

email or SMS text messages.

MODEL NUMBER INPUT(S) INPUT TYPE CONTROL OUTPUT(S) ANALOG OUTPUT

GMDIOR00 8 - Digital DC Inputs or Switch Closures 6 - Relays -

GMDIOS00 8 - Digital DC Inputs or Switch Closures 6 - SSR -

GMINI800 8 - DC Current 0/4 to 20mA Inputs - -

GMINV800 8 - DC Volt +/-10 V Inputs - -

GMOUT400 - - 4 - Analog +/-10 V or 0/4 to 20 mA

GMTC8000 8 - Thermocouple T, E, J, K, R, S, B, N, C and Millivolt - -

GMRTD600 6 - RTD 385, 392, 428, 672 and Ohms - -

GMSG10R0 1 - Strain Gage ±20 mV, ±33 mV, or ±200 mV 3 - Relays +/- 10 V or 0/4 to 20 mA

GMSG10S0 1 - Strain Gage ±20 mV, ±33 mV, or ±200 mV 3 - SSR +/- 10 V or 0/4 to 20 mA

GMSG11R0 2 - Strain Gage ±20 mV, ±33 mV, or ±200 mV 3 - Relays +/- 10 V or 0/4 to 20 mA

GMSG11S0 2 - Strain Gage ±20 mV, ±33 mV, or ±200 mV 3 - SSR +/- 10 V or 0/4 to 20 mA

GMUIN400 4 - Universal 0/4 to 20 mA, 0 to 10 V, Thermocouple or RTD - -

Full PID Control

Lifting the burden of temperature control from the PLC is a wise

choice. But integrating real-time PID controllers previously meant

hours and hours of custom PLC protocol development with

costly and complex standalone controllers. Now, with Graphite

MODEL NUMBER INPUT(S) CONTROL OUTPUT(S) ANALOG OUTPUT OPTION

PID module drag-and-drop configuration and built-in drivers,

you can easily configure and integrate high-density multi-zone

systems in only minutes.

10

GMP1RA00 Single PID Loop 3 - Relays +/- 10 V or 0/4 to 20 mA -

GMP1RM00 Single PID Loop 3 - Relays - Heater Current Monitor

GMP1SA00 Single PID Loop 4 - SSR +/- 10 V or 0/4 to 20 mA -

GMP1SM00 Single PID Loop 4 - SSR - Heater Current Monitor

GMP2R000 Dual PID Loops 4 - Relays - -

GMP2RM00 Dual PID Loops 4 - Relays - Heater Current Monitor

GMP2S000 Dual PID Loops 4 - SSR - -

GMP2SM00 Dual PID Loops 4 - SSR - Heater Current Monitor

Page 11

Communication

Programmed using our award-winning Crimson 3.0 software,

Graphite HMI communication modules provide a space-saving

solution that simplifies installation and reduces external hardware.

MODEL NUMBER FUNCTION

GMCAN000 CAN Communication

GMJ19390 J1939 Communication

GMDN0000 DeviceNet Communication

GMPBDP00 PROFIBUS DP Communication

GMHSPA00 HSPA+ Cellular modem Communication

See manual for model-specific certifications

From high-speed cellular to protocol specific modules,

Graphite HMIs offer a comprehensive communication platform.

Crimson 3.0 Software

Seamless configuration,

unprecedented control.

Red Lion’s Crimson 3.0 software is an easy-to-use programming

tool that is included with our HMIs to give you unprecedented control.

Unlike competitive HMIs that charge extra for cumbersome proprietary

software, our award-winning Crimson software simplifies the setup of

even the most sophisticated applications. Configuring communications

protocols, defining data tags and creating intuitive user interfaces are

easier and virtually self-explanatory with Crimson software. Best of all,

Crimson software updates, support, cabling instructions and

communication drivers come with every Red Lion HMI.

Crimson software benefits include:

• Easily establish communication between HMIs and connected devices using extensive library of over 300 industrial protocols

• Quickly enable data logging, protocol conversion, web serving and remote access

• Rapidly build graphic interfaces with comprehensive image library of over 5,000 industrial graphics

• Extend HMI capabilities using full-featured C-type syntax programming environment to support advanced math, local variables,

pass parameters, calls, return values and more

Need more I/O?

Easily expand your Graphite HMI’s I/O capabilities with

Red Lion’s rugged E3 I/O

configurations—including discrete, analog and temperature—

E3 I/O modules add powerful I/O monitoring to any industrial

application. Configured with Red Lion’s Crimson software,

E3 I/O modules can be quickly set up and deployed.

™

modules. Featuring mixed I/O

11

Page 12

Powerful G3 HMIs

G3 SERIES G315C2 G310C2, G310R2, G310S2

Display Type 32K Color XGA LCD Display

Resolution 1024 X 768

Dimensions

Sunlight Readable G310S Only

Keypad Programmable 10-Key Membrane Programmable 8-Key Membrane

USB Device & USB Host Yes Yes

Serial Ports 4 3

13.0" x 16.0" x 2.8"

(330.2 x 406.4 x 71.5 mm)

800 x 600

10.4" TFT 32K-Color

G310C/G310S: VGA G310R: SVGA

G310R:

9.50" x 12.83" x 2.45"

(241.3 x 325.8 x 62 mm)

G310C & G310S:

Feature-rich functionality. Reliable performance.

With a proven track record of reliable performance in

industrial environments, Red Lion G3 HMIs provide durability

and functionality beyond the industry standard with an intuitive,

easy-to-use programming interface. Our G3 HMIs feature

built-in, powerful protocol conversion with support for over

300 industrial drivers to connect disparate devices and

simplify communication across multi-vendor environments.

• Convert up to 13 protocols simultaneously from over 300

supported drivers

• Real-time data logging provides historic visibility to support

process improvements

• Web and FTP servers enable remote monitoring and control

• Communication cards extend connectivity options

• USB synchronization of database and log files

• Crimson software for easy drag-and-drop programming

640 x 480

12

Page 13

G308A2, G308C1 G306A, G306M*, G306MS G303M, G303S*

G308A: 8.4" TFT 32K-Color

G308C: 7.5" TFT 32K-Color

640 x 480 320 x 240 128 x 64

5.7" TFT Active Matrix, 256-Color QVGA Display

Monochrome Models Available

3.2" Graphical Monochrome LCD

with Yellow Backlight

8.18" x 10.32" (207.8 x 262 mm)

G308A Depth: 2.9" (73 mm)

Programmable 7-Key Membrane Programmable 5-Key Membrane Programmable 32-Key Membrane

G308A: Yes G308C: USB Device Only USB Device Only USB Device Only

3 3 3

7.08" x 8.83" x 2.3"

(179.8 x 224.3 x 58 mm)

G306MS Only G303S Only

5.85" x 7.45" x 2.1"

(148.6 x 189.2 x 52 mm)

Specification highlights

1

Power

2

USB Type B

3

10/100 Ethernet

• CompactFlash® slot for storage and collection

of logged data

• Wide 0˚ to 50˚C operating temperature range

• +24 VDC +/-20% power input

• UL Class 1, Division 2 Listed

• NEMA 4x/IP66 rated

4

USB Host

5

RS-232

6

RS-422/485

1 2 4 43 35 56

G3 HMIs come standard with one 10/100Base-T(X) Ethernet port,

two RS-232 and one RS-422/485 serial ports, and one USB

Device port. Additional Ethernet and/or RS-422/485 ports are

available on specific models.

* Crimson 2.0

13

Page 14

G3 Kadet HMIs

G3 KADET HMIs G307K2 G304K2

Display Type 7" TFT 32K-Color 4.3" TFT 32K-Color

Resolution 800 x 480 480 x 272

Dimensions 5.76" x 7.88" x 1.67" (146 x 200 x 43 mm) 4.016" x 5.039" x 1.50" (102 x 128 x 38 mm)

Serial Ports (1) RS-232, (2) RS-232/422/485 (1) RS-232, (1) RS-232/422/485

Essential features. Exceptional value.

Red Lion G3 Kadet HMIs are the perfect choice when what

you need is the core functionality and consistent performance of

a top-quality HMI to support the ongoing operation of equipment

in less complex industrial environments. Available in two sizes,

our G3 Kadet HMIs cost-effectively deliver the power of

best-in-class communications alongside industry-leading

protocol conversion capabilities, allowing you to seamlessly

integrate with PLCs, drives, motion controllers and other

automation devices.

• Convert up to seven protocols simultaneously from over 300

supported drivers

• Crimson 3.0 software for easy drag-and-drop programming

Serial Ports 3* 4*

Ethernet 1 1

USB Host 1*

Crimson 3.0 Programmed • •

C-Type User Programming •

Protocol Converter • •

Simultaneous Conversions 7 13

Web Server, FTP, Data Logging •

Expansion Card Slots 1

On-Display Keypad •

G3 KADET G3 HMI

14

Page 15

HMI Ordering Guide

Rugged Graphite HMIs

INDOOR/

MODEL NUMBER

G07C0000 Indoor 7" 800 x 480 3 iso. 1 2 5 Module Slots SD Card

G07S0000 Outdoor 7" 800 x 480 3 iso. 1 2 5 Module Slots SD Card

G09C0000 Indoor 9" 800 x 480 3 iso. 1 2 6 Module Slots SD Card

G09C1000 Indoor 9" 800 x 480 3 iso. 2 2 6 Module Slots SD Card

G10C0000 Indoor 10" 640 x 480 3 iso. 1 2 7 Module Slots SD Card

G10C1000 Indoor 10" 640 x 480 3 iso. 2 2 7 Module Slots SD Card

G10R0000 Indoor 10" 800 x 600 3 iso. 1 2 7 Module Slots SD Card

G10R1000 Indoor 10" 800 x 600 3 iso. 2 2 7 Module Slots SD Card

G10S0000 Outdoor 10" 640 x 480 3 iso. 1 2 7 Module Slots SD Card

G10S1000 Outdoor 10" 640 x 480 3 iso. 2 2 7 Module Slots SD Card

G12C0000 Indoor 12" 1280 x 800 3 iso. 1 2 8 Module Slots SD Card

G12C1100 Indoor 12" 1280 x 800 4 iso. 2 2 8 Module Slots SD Card

G15C0000 Indoor 15" 1024 x 768 3 iso. 1 2 8 Module Slots SD Card

G15C1100 Indoor 15" 1024 x 768 4 iso. 2 2 8 Module Slots SD Card

OUTDOOR

DISPLAY

SIZE DISPLAY

SERIAL

PORTS

ETHERNET

PORTS USB HOST EXPANSION

CARD

SUPPORT

Powerful G3 HMIs

INDOOR/

MODEL NUMBER

G303M000 Indoor 3" 128 x 64 3 1 - 1 Card Slot CF Card

G303S000 Outdoor 3" 128 x 64 3 1 - 1 Card Slot CF Card

G306M000 Indoor 6" 320 x 240 3 1 - 1 Card Slot CF Card

G306A000 Indoor 6" 320 x 240 3 1 Expansion Card 1 Card Slot CF Card

G306MS00 Outdoor 6" 320 x 240 3 1 - 1 Card Slot CF Card

G308C100 Indoor 8" 640 x 480 3 1 - 1 Card Slot CF Card

G308A210 Indoor 8" 640 x 480 3 iso. 1 1 1 Card Slot CF Card

G310C210 Indoor 10" 640 x 480 3 iso. 1 1 1 Card Slot CF Card

G310R210 Indoor 10" 800 x 600 3 iso. 1 1 1 Card Slot CF Card

G310R230 Indoor 10" 800 x 600 3 iso. 2 1 1 Card Slot CF Card

G310S210 Outdoor 10" 640 x 480 3 iso. 1 1 1 Card Slot CF Card

G310S230 Outdoor 10" 640 x 480 3 iso. 2 1 1 Card Slot CF Card

G315C210 Indoor 15" 1024 x 768 3 iso. 1 1 1 Card Slot CF Card

G315C230 Indoor 15" 1024 x 768 3 iso. 2 1 1 Card Slot CF Card

OUTDOOR

DISPLAY

SIZE DISPLAY

SERIAL

PORTS

ETHERNET

PORTS USB HOST EXPANSION

CARD

SUPPORT

G3 Kadet HMIs

INDOOR/

MODEL NUMBER

G304K200 Indoor 4" 480 x 272 2 1 - - G307K200 Indoor 7" 800 x 480 3 1 - - SD Card

OUTDOOR

DISPLAY

SIZE DISPLAY

SERIAL

PORTS

ETHERNET

PORTS USB HOST EXPANSION

CARD

SUPPORT

15

Loading...

Loading...