Page 1

Bulletin No. GRAC1-A

C

US LISTED

U

L

R

IND. CONT

C

US

U

L

R

LISTED

IND.CONT. EQ.

Drawing No. LP0994

Effective 2017-01-27

MODELGRAC0001‐Graphit e®EdgeContr ollerWithPlug‐InI/OModule

andPr otocolConversionCapability

• RUGGED CONTROLLER WITH BUILT-IN CONTROL ENGINE

• PROTOCOL CONVERSION FEATURE CONVERTS 13

PROTOCOLS SIMULTANEOUSLY

• OVER 300 BUILT-IN DRIVERS ALLOWS EASY DATA MAPPING

TO PLCs, PCs, AND SCADA SYSTEMS

• BUILT-IN WEB SERVER ALLOWS REMOTE VIEW OR CONTROL

FROM ANY INTERNET-CONNECTED PC OR SMART PHONE

• SYNCS DATA LOGS TO FTP SERVERS AND MICROSOFT SQL

SERVER

• PROVIDES EMAIL AND SMS TEXT MESSAGE ALERTS

(SMS Requires GMHSPA00 module)

• CONFIGURED USING CRIMSON

CONTROL

• 3 FULLY ISOLATED SERIAL COMMUNICATION PORTS

(1 RS232 and 2 RS422/485)

• 2 10 BASE T/100 BASE-TX ETHERNET CONNECTIONS CAN

CONNECT TO AN UNLIMITED NUMBER OF DEVICES VIA TEN

PROTOCOLS SIMULTANEOUSLY

• INTEGRATED GRAPHITE RACK EXPANSION PORT. ADD UP TO

4 GEXRACK2 3 PORT EXPANSION RACKS.

• CAST ALUMINUM CASE CONSTRUCTION SUPPORTS DIN RAIL

AND PANEL MOUNT

®

®

3 SOFTWARE WITH CRIMSON

FOR USE IN HAZARDOUS LOCATIONS:

Class I, Division 2, Groups A, B, C, and D

3PWL

. EQ.

34AD

GENERALDESCRIPTION

The Graphite

monitor and control equipment in process applications. At the core of the

product is Crimson

engine, that can be configured via Ladder, Function Block, Structured

Text, and Instruction List. Additionally, the Graphite Edge Controller is

optimized for multi-vendor environments with powerful protocol

conversion, built-in data logging and a virtual operator interface for

remotely viewing equipment and processes. The Edge Controller can be

expanded to meet almost any application requirement through the use of

plug-in digital and analog I/O modules that leverage the Graphite

Expansion Racks. The integrated rack port supports 4 GEXRACK2

bases (12 modules). An additional 12 modules can be added using the

USB host port (GEXRACK1, 3 GEXRACK2).

Red Lion’s industry leading protocol library offers access to over 300

drivers including PLCs, drives, cameras, bar code readers and many

other devices providing easy data mapping to PLCs, PCs, and SCADA

Systems. In addition, the Edge Controller can convert over 13 protocols

simultaneously, seamlessly connecting and communicating with

disparate devices. Graphite Edge Controllers offer numerous

communication ports including high-speed RS-232/485 and 10/100BaseT(X) Ethernet ports. Additionally, the Edge Controller features built-in

USB host ports for fast downloads of configuration files and access to

trending and data logging information. Eliminate the need for external

protocol converters and use an Edge Controller to connect and control to

all your devices.

The Graphite Edge Controller can be programmed with Red Lion’s

Crimson 3.0 software using a simple drag and drop interface to configure

data tags, virtual displays, protocol conversion and data logging in

minutes. Embedded in Crimson 3.0 software platform is the IEC 61131

control engine, Crimson Control which can be written in 4 programming

languages including Ladder, Function Block, Structured Text, and

Instruction List. The controller comes with Crimson Control functionality

®

Edge Controller is designed to remotely connect,

®

3.0 featuring an embedded IEC61131 control

enabled, without the need for additional equipment or modules.

Red Lion’s Edge Controller is housed in an all-aluminum housing,

which provides reliable operation that can withstand even the most

demanding environments. The result is an industrially-hardened solution

that connects, monitors, and controls disparate equipment in multivendor applications.

CONTENTSOFPACKAGE

- Graphite Edge Controller

- Terminal block for connecting power.

- (1) Module port cover

- Downstream port cover

- User Bulletin

ORDERINGINFORMATION

DESCRIPTION PART NUMBER

Graphite Edge Controller GRAC0001

SAFETYSUMMARY

All safety related regulations, local codes and instructions that appear

in the manual or on equipment must be observed to ensure personal

safety and to prevent damage to either the instrument or equipment

connected to it. If equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

Do not use the controller to directly command motors, valves, or other

actuators not equipped with safeguards. To do so can be potentially

harmful to persons or equipment in the event of a fault to the unit.

-1-

Page 2

Effective 2017-01-27 Bulletin No. GRAC1-A

WARNING - DO NOT CONNECT OR DISCONNECT CABLES

WHILE POWER IS APPLIED UNLESS AREA IS KNOWN TO BE

NON-HAZARDOUS.

Module sold

separately

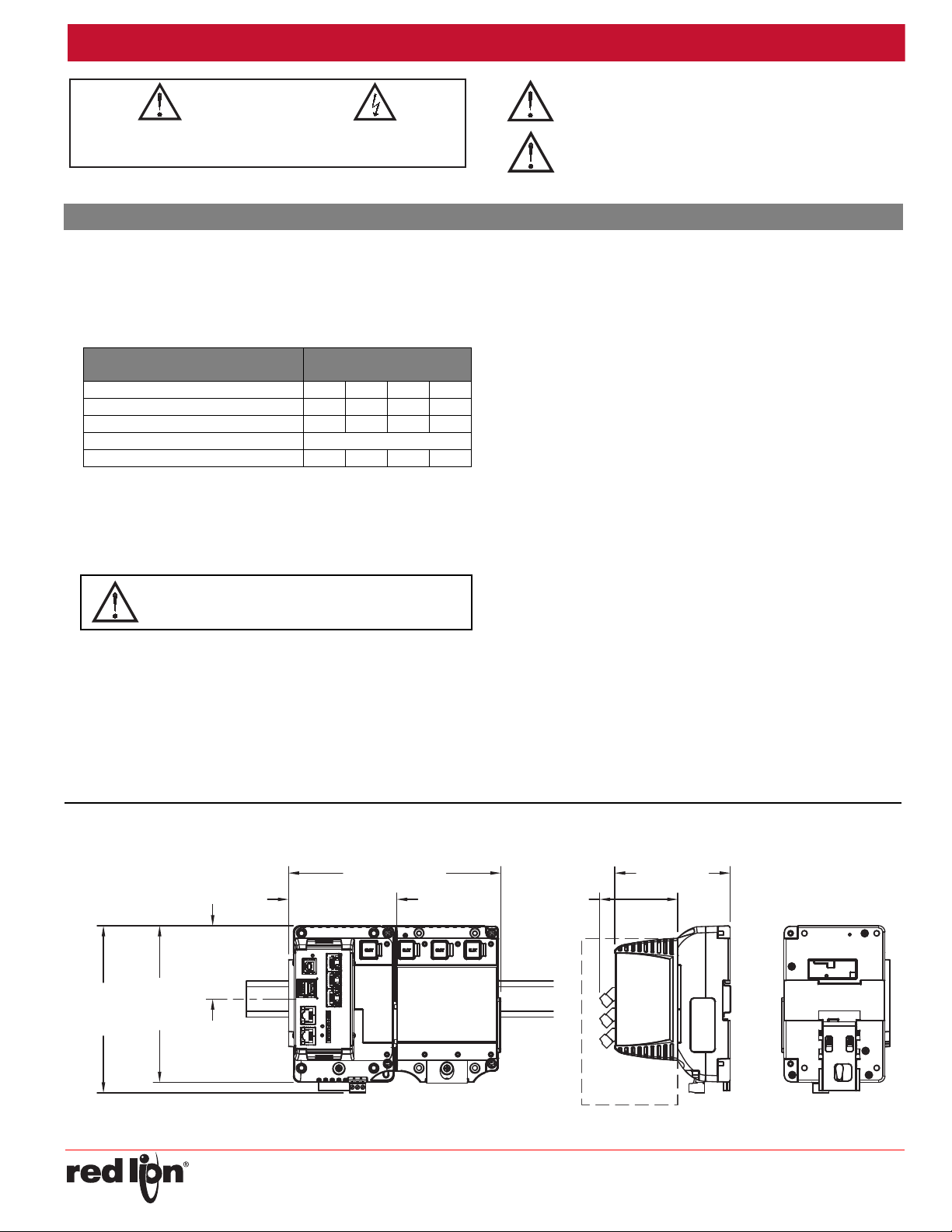

2.97 (76)

4.40 (112)

Optional

GEXRACK2

unit

4.11 (104.5)

8.07 (205) *

* +3.96 for each additional base

6.35

(161.4)

2.79

(70.8)

5.95

(151.1)

CAUTION: Risk Of Danger.

Read complete instructions prior to

installation and operation of the unit.

CAUTION: Risk of electric shock.

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT

EQUIPMENT UNLESS POWER HAS BEEN SWITCHED OFF

OR AREA IS KNOWN TO BE NON-HAZARDOUS.

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT

EQUIPMENT UNLESS POWER HAS BEEN SWITCHED OFF

OR AREA IS KNOWN TO BE NON-HAZARDOUS.

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF

COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS I,

DIVISION 2.

Drawing No. LP0994

SPECIFICATIONS

1. POWER REQUIREMENTS:

Must use a Class 2 circuit according to National Electrical Code (NEC),

NFPA-70 or Canadian Electrical Code (CEC), Part I, C22.1 or a

Limited Power Supply (LPS) according to IEC 60950-1 or Limitedenergy circuit according to IEC 61010-1.

Power connection via removable three position terminal block.

Supply Voltage: 10-30 VDC

GRAC0001 POWER RATINGS

(WATTS)

Input Voltage 10 V 12 V 24 V 30 V

Typical Power GRAC0001 only: 4 W4 W5 W5 W

Maximum Power GRAC0001 only: 9 W 9 W 10 W 10 W

Available Power for Modules: 55 W

Max Power GRAC0001 With Module(s): 64 W 64 W 65 W 65 W

2. BATTERY: Lithium coin cell. Typical lifetime of 6 years, nominal.

3. MEMORY:

On Board User Memory: 256 Mbyte of non-volatile Flash memory.

Memory Card: SD slot accepts standard capacity cards up to 2 Gbyte.

4. COMMUNICATION CAPABILITIES:

USB Port: Adheres to USB specification 2.0 (high speed, full speed)

only using Type B connection.

USB Host Ports: Comply with Universal Serial Bus Specification Rev

2.0. Support data transfers at (high speed, full speed). Hardware

over current protected (0.5 A max per port).

Serial Ports: Ports are individually isolated. Format and Baud Rates for

each port are individually software programmable up to 115,200

baud.

PGM Port: RS232 port via RJ12.

COMMS Ports: RS422/485 ports via RJ45

DH485 TXEN: Transmit enable; open collector, V

= 0.5 V @ 25 mA max.

V

OL

Port to Port Isolation: 500 Vrms for 1 minute. Signal Isolation: 50 V.

Ethernet Ports: 10 BASE-T / 100 BASE-TX

RJ45 jack is wired as a NIC (Network Interface Card).

Isolation from Ethernet network to GRAC0001: 1500 Vrms

5. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range: -40 to 70 °C, or lowest range among

equipment used in your Graphite system. Consult the user manual

Storage Tempe

Panel Mount Vibration to IEC 68-2-6: Operational 5-500 Hz, 4 g

Panel Mount Shock to IEC 68-2-27: Operational 40 g (10 g, modules w/

relays)

DIN Rail Mount Vibration to IEC 68-2-6: Operational 5-500 Hz, 2 g

DIN Rail Mount Shock to IEC 68-2-27: Operational 15 g (10 g, modules

w/relays)

Requires DIN Rail type: DIN 1010, DIN 1065, or DIN 3065.

Operating and Storage Humidity: 0 to 85% max. RH non-condensing

Altitude: Up to 2000 meters

6. CERTIFICATIONS AND COMPLIANCES:

CE Approved

EN 61326-1 Immunity to Industrial Locations

Emission CISPR 11 Class A

IEC/EN 61010-1

RoHS Compliant

UL Listed: File #E302106

UL Hazardous: File #E317425

7. CONNECTIONS: High compression cage-clamp terminal block

Wire Strip Length: 0.3" (7.5 mm)

Wire Gauge Capacity: One 14 AWG (1.63 mm) solid,

two 18 AWG (1.02 mm) or four 20 AWG (0.81 mm)

8. CONSTRUCTION: Cast aluminum. Installation Category II, Pollution

Degree 2 as defined in IEC 60664-1.

9. WEIGHT: 2 lb 4.2 oz. (1.03 Kg)

rature Range: -40 to 85 °C

= 15 VDC,

OH

DIMENSIONSIninches(mm)

-2-

Page 3

Effective 2017-01-27 Bulletin No. GRAC1-A

2.13 (54)1.72 (43.6)

2.75

(69.8)

5.12

(130)

Captive Screws to fasten

the bases together

1.83 (46.6)

2.13 (54)

Optional GEXRACK2 units

UNLOCK

LOCK

For hazardous location installation, this device is

open type and must be mounted in a suitable ATEX/

IECEx certified tool accessible end-enclosure with a

minimum ingress protection rating of at least IP54 as

defined in EN/IEC 60529 and used in an environment of not

more than Pollution Degree 2 per EN 60664-1. Must be wired

using Division 2 wiring methods as specified in article 501-4

(b), 502-4 (b), and 503-3 (b) of the National Electrical Code,

NFPA 70 for installation within the United States, or as

specified in section 19-152 of Canadian Electrical Code for

installation in Canada.

The protective conductor terminal is bonded to conductive

parts of the equipment for safety purposes and must be

connected to an external protective earthing system.

Drawing No. LP0994

GRAPHITEEDGECONTROLLERINSTALLATION

PANELMOUNTINGINSTRUCTIONS

The Controller can be mounted on a DIN rail for normal environments,

or bolted to a panel for high vibration environments. Refer to the diagram

for the panel mount hole spacing.

DINRAILMOUNTANDCAMOPERATION

It is recommended that the controller be DIN rail mounted only in low

vibration environments. Refer to the Specifications section for details.

1. Using a screwdriver, push in and fully rotate the Cam counter-

clockwise to push the DIN clip downward against spring pressure

locking it open

2. Place the controller on the DIN rail

3. Using a screwdriver, push in and rotate the Cam 90 degrees clockwise

to release the DIN clip to engage the DIN rail

4. Rotate the Cam an additional 90 degrees clockwise to lock the DIN clip

in the closed position.

CONNECTING TO EARTH GROUND

The third pin of the power connector of the Edge Controller is chassis

ground for the unit. Your unit should be connected to earth ground

(protective earth).

The chassis ground is not connected to signal common of the unit.

Maintaining isolation between earth ground and signal common is not

required to operate your unit. But, other equipment connected to this unit

may require isolation between signal common and earth ground. To

maintain isolation between signal common and earth ground care must

be taken when connections are made to the unit. For example, a power

supply with isolation between its signal common and earth ground must

be used. Also, plugging in a USB cable may connect signal common and

earth ground.

1

USB’s shield may be connected to earth ground at the host. USB’s

shield in turn may also be connected to signal common.

1

POWER SUPPLY REQUIREMENTS

The Graphite Edge Controller requires a 10-30 VDC power supply.

Your unit may draw considerably less than the maximum rated power

depending upon the features being used, and the applied voltage. As

additional features are used your unit will draw increasing amounts of

power. Items that could cause increases in current are modules,

additional on-board communications, SD card, and other features

programmed through Crimson software.

Note: Modules connected via a GEXRACK1 to the Edge Controller, are

powered by the GEXRACK1 and not the Edge Controller

To ensure you do not exceed the capacity of your Graphite host power

supply, calculate the total power consumption required for all of your

planned modules. Each module’s maximum power consumption is listed

in the Specifications of their Product Bulletin. The total power available for

modules is listed in the specifications of the Graphite host.

In any case, it is very important that the power supply is mounted

correctly if the unit is to operate reliably. Please take care to observe the

following points:

– Voltage range stated is at the power connector, not at the power source.

– The power supply must be mounted close to the unit, with usually not

more than 6 feet (1.8 m) of cable between the supply and the operator

interface. Ideally, the shortest length possible should be used.

– The wire used to connect the operator interface’s power supply

should be at least 22-gage wire suitably rated for the temperatures

of the environment to which it is being installed. If a longer cable run

is used, a heavier gage wire should be used. The routing of the

cable should be kept away from large contactors, inverters, and

other devices which may generate significant electrical noise.

– A power supply with an NEC Class 2 or Limited Power Source (LPS)

and SELV rating is to be used. This type of power supply provides

isolation to accessible circuits from hazardous voltage levels generated

by a mains power supply due to single faults. SELV is an acronym for

“safety extra-low voltage.” Safety extra-low voltage circuits shall exhibit

voltages safe to touch both under normal operating conditions and after

a single fault, such as a breakdown of a layer of basic insulation or after

the failure of a single component has occurred. A suitable disconnect

device shall be provided by the end user.

– Peak efficiency (GRAC0001) occurs at the low side of the voltage

range (approx. 12 V), recommended for high temperature applications.

EMCINSTALLATIONGUIDELINES

Although Red Lion Controls products are designed with a high degree

of immunity to Electromagnetic Interference (EMI), proper installation and

wiring methods must be followed to ensure compatibility in each

application. The type of the electrical noise, source or coupling method

into a unit may be different for various installations. Cable length, routing,

and shield termination are very important and can mean the difference

between a successful or troublesome installation. Listed are some EMI

-3-

Page 4

Effective 2017-01-27 Bulletin No. GRAC1-A

REMOVE RUBBER

MODULE PLUG

WARNING: Disconnect all power

to the unit before installing or

removing modules.

WARNING - DO NOT CONNECT OR DISCONNECT CABLES

WHILE POWER IS APPLIED UNLESS AREA IS KNOWN TO BE

NON-HAZARDOUS.

Drawing No. LP0994

guidelines for a successful installation in an industrial environment.

1. A unit should be mounted in a metal enclosure, which is properly

connected to protective earth.

2. Use shielded cables for all Signal and Control inputs. The shield

connection should be made as short as possible. The connection point

for the shield depends somewhat upon the application. Listed below

are the recommended methods of connecting the shield, in order of

their effectiveness.

a. Connect the shield to earth ground (protective earth) at one end

where the unit is mounted.

b. Connect the shield to earth ground at both ends of the cable, usually

when the noise source frequency is over 1 MHz.

3. Never run Signal or Control cables in the same conduit or raceway with

AC power lines, conductors, feeding motors, solenoids, SCR controls,

and heaters, etc. The cables should be run through metal conduit that

is properly grounded. This is especially useful in applications where

cable runs are long and portable two-way radios are used in close

proximity or if the installation is near a commercial radio transmitter.

Also, Signal or Control cables within an enclosure should be routed as

far away as possible from contactors, control relays, transformers, and

other noisy components.

4. Long cable runs are more susceptible to EMI pickup than short cable runs.

5. In extremely high EMI environments, the use of external EMI

suppression devices such as Ferrite Suppression Cores for signal and

control cables is effective. The following EMI suppression devices (or

equivalent) are recommended:

Fair-Rite part number 0443167251 (Red Lion Controls #FCOR0000)

Line Filters for input power cables:

Schaffner # FN2010-1/07 (Red Lion Controls #LFIL0000)

6. To protect relay contacts that control inductive loads and to minimize

radiated and conducted noise (EMI), some type of contact protection

network is normally installed across the load, the contacts or both. The

most effective location is across the load.

a. Using a snubber, which is a resistor-capacitor (RC) network or metal

oxide varistor (MOV) across an AC inductive load is very effective at

reducing EMI and increasing relay contact life.

b. If a DC inductive load (such as a DC relay coil) is controlled by a

transistor switch, care must be taken not to exceed the breakdown

voltage of the transistor when the load is switched. One of the most

effective ways is to place a diode across the inductive load. Most

Red Lion products with solid state outputs have internal zener diode

protection. However external diode protection at the load is always a

good design practice to limit EMI. Although the use of a snubber or

varistor could be used.

Red Lion part numbers: Snubber: SNUB0000

Varistor: ILS11500 or ILS23000

7. Care should be taken when connecting input and output devices to the

instrument. When a separate input and output common is provided,

they should not be mixed. Therefore a sensor common should NOT be

connected to an output common. This would cause EMI on the

sensitive input common, which could affect the instrument’s operation.

8. For GEXRACK1 connection, recommend Tripp Lite Model: U023-006 6

ft cable.

I/OMODULEINSTALLATION

The physical order of all installed modules must match the modules

order as set in Crimson database. Torque screws to 6.0 pound-force inch

[96 ounce-force inch] (0.68 Nm).

COMMUNICATINGWITHTHECONTROLLER

CONFIGURINGANEDGECONTROLLER

The Controller is configured using Crimson® software. Crimson

software is available as a no charge download from Red Lion’s website.

Crimson updates for new features and drivers are posted on the website

as they become available. By configuring the Edge Controller using the

latest Crimson version, you are assured that your unit has the most up to

date feature set. Crimson software can configure the controller through

the RS232 PGM port, USB port, ethernet port or SD card.

The USB port is connected using a standard USB cable with a Type B

connector. The driver needed to use the USB port will be installed as part

of Crimson configuration.

The RS232 PGM port uses a programming cable made by Red Lion to

connect to the DB9 COM port of your computer. If you choose to make

your own cable, use the “Graphite Edge Controller Port Pin Out Diagram”

for wiring information.

The SD card can be used to program a controller by placing a

configuration file and firmware on the SD card. The card is then inserted

into the target controller and powered. Refer to the Crimson literature for

more information on the proper names and locations of the files.

SYSTEM LEDs

COLOR STATUS

GREEN (STS) Bootloader/Power

GREEN (SD) File system SD Card

USB HOST LEDs

COLOR STATUS

OFF Not operational

RED Error

GREEN Normal operation

USB,DA TATRANSFERSFROMTHESDCARD

In order to transfer data from the SD card via the USB port, a driver

must be installed on your computer. This driver is installed with Crimson

software and is located in the folder C:\Program Files\Red Lion

Controls\Crimson 3.0\Device\ after installation. This may have already

been accomplished if your controller was configured using the USB port.

Once the driver is installed, connect the controller to your PC with a

USB cable, and follow “Mounting the SD” instructions in the Crimson 3.0

user manual.

-4-

Page 5

Effective 2017-01-27 Bulletin No. GRAC1-A

TX

5V

8

1

7

2

TxB

TxA

130K

130K

5

RX

130K

5V

130K

RxB

4

RxA

3

COMM

6

RS422/485 4-WIRE

CONNECTIONS

RS485 2-WIRE

CONNECTIONS

TX/RX

130K

5

TxA

2

8

130K

5V

7

1

TxB

6 COMM

Drawing No. LP0994

INSERTION/REMOVALOFTHESDCARD

Insert the SD card into the slot provided with the card oriented as shown.

The card is inserted properly when the end of the card is flush with the

Edge Controller case. To remove the SD card, push in slightly on the card.

Warning: Do not remove the SD card while power is applied.

CABLESANDDRIVERS

Red Lion has a wide range of cables and drivers for use with many

different communication types. A list of these drivers and cables along

with pin outs is available from Red Lion’s website. New cables and

drivers are added on a regular basis. If making your own cable, refer to

the “Port Pin Outs” that corresponds to your specific model for wiring

information.

ETHERNETCOMMUNICATIONS

Ethernet communications can be established at either 10 BASE-T or

100 BASE-TX. The Graphite unit’s RJ45 jack is wired as a NIC (Network

Interface Card). Ports support Auto MDI-X (which automatically detects

and configures the cable connection).

The Ethernet connector contains two LEDs. A yellow LED in the upper

right, and a green LED in the upper left. The LEDs represent the following

statuses:

LED COLOR DESCRIPTION

YELLOW solid Link established.

YELLOW flashing Data being transferred.

GREEN (OFF) 10 BASE-T Communications

GREEN (ON) 100 BASE-TX Communications

A 12-digit MAC address label is provided for each Ethernet port. Refer

to the Crimson manual and Red Lion’s website for additional information

on Ethernet communications.

RS232PORTS

The Edge Controller has a

single RS232 port. The port can

be used for either master or

slave protocols with any

Graphite configuration.

GRAPHITE RS232 TO A PC

Gxx:

RJ12

Name

4 COMM 1 DCD

5Tx2Rx

2Rx3Tx

N/C 4 DTR

3COMM5GND

N/C 6 DSR

1CTS7RTS

6RTS8CTS

N/C 9 RI

PC:

DB9

Name

RS422/485COMMSPORT

The controller has two RS422/485 ports. These ports can be

configured to act as either RS422 or RS485.

TxEN (OC)

Note: All Red Lion devices connect A to A and B to B.

ExamplesofRS4852‐WireConnections

GRAPHITE TO RED LION RJ11

Gxx:RJ45 Name RLC:RJ11 Name

5TxEN2 TxEN

6COMM3COMM

1TxB5 B-

2TxA4 A+

DH485COMMUNICATIONS

The Graphite Edge Controller’s RS422/485 COMMS port can also be

used for Allen Bradley DH485 communications.

GRAPHITE TO AB SLC 500

RJ45: RLC Name RJ45: A-B Name

1TxB1 A

2TxA2 B

3, 8 RxA - 24V

4, 7 RxB - COMM

5TxEN5TxEN

6COMM4SHIELD

4, 7 TxB - COMM

3, 8 TxA - 24V

-5-

TxEN (OC)

Page 6

Effective 2017-01-27 Bulletin No. GRAC1-A

USB

TYPE B

PORT B

USB HOST

PORT A

ETHERNET 1

(NIC)

ETHERNET 2

(NIC)

STATUS

STATUS

STATUS LED

RS232

PGM PORT

RTS (PIN 6)

COMM

COMM

CTS (PIN 1)

Tx

Rx

RS485 - A

COMMS PORT

TxA (PIN 8)

TxB (PIN 1)

COMM

RxB

TxB

TxEN

TxA

RxA

TxA (PIN 8)

COMMS PORT

RS485 - B

RxB

TxB (PIN 1)

TxA

RxA

COMM

TxB

TxEN

SD STATUS LED

FACTORY RESET BUTTON

POWER

CONNECTOR

+DC VOLTAGE

COMMON1CHASSIS

2

3

GRAPHITE EDGE CONTROLLER PORT PIN OUTS

WARNING - EXPLOSION HAZARD - DISCONNECT POWER AND

ENSURE THE AREAS IS KNOWN TO BE NON-HAZARDOUS

BEFORE SERVICING/REPLACING THE UNIT AND BEFORE

INSTALLING OR REMOVING I/O WIRING AND BATTERY.

Remove 4 Torx

T10 screws

Drawing No. LP0994

SOFTWARE/UNITOPERATION

CRIMSON

Crimson software is available as a no charge download from Red

Lion’s website. The latest version of the software is always available from

the website, and updating your copy is free.

FACTORYRESETBUTTON

The factory reset button is located on the front of the unit.

GRAPHITETROUBLESHOOTING

If for any reason you have trouble operating, connecting, or simply

have questions concerning your new Graphite unit, contact Red Lion’s

technical support.

BATTERY&TIMEKEEPING

A battery is used to keep time when the unit is without power. Typical

accuracy (at 25°C) of the time keeping is less than one minute per month

drift. This battery does not affect the unit’s memory, all configurations and

data is stored in non-volatile memory.

®

SOFTWARE

ChangingtheBattery

To change the battery, first remove power to the unit. Remove all

cables from the unit and any external module if installed. Remove the four

TORX screws holding the metal cover to the unit, two per side. Slide the

metal cover forward to gain access to the battery. Remove the old

battery* from the holder and replace with the new battery. Replace metal

cover with the four TORX screws. Reinstall external module if equipped,

reconnect cables and re-apply power. Using Crimson software, enter the

correct time and date.

* Please note that the old battery must be disposed of in a manner that

complies with your local waste regulations. The battery must not be

disposed of in fire, or in a manner whereby it may be damaged and its

contents could come into contact with human skin.

The battery used by the Graphite Edge Controller is an industrial

temperature grade (-40°C, 85°C) lithium type BR2032.

-6-

Loading...

Loading...