Page 1

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

MODEL GMSG1 – GRAPHITE SERIES STRAIN GAGE MODULE

STRAIN GAGE MODULE FOR THE GRAPHITE SERIES

PID CONTROL WITH REDUCED OVERSHOOT

LOAD CELL, PRESSURE AND TORQUE BRIDGE INPUTS

SELECTABLE LOW LEVEL INPUTS (20 mV, 33 mV or 200 mV

FULL SCALE)

SOFTWARE SELECTABLE 5 VDC or 10 VDC BRIDGE

EXCITATION

DIGITAL TARE (re-zero), BATCH TOTALIZER, AND PEAK/VALLEY

(max/min) RECORDING

ON DEMAND AUTO-TUNING OF PID SETTINGS

DC ANALOG OUTPUT

WINDOWS® CONFIGURATION SOFTWARE

Bulletin No. GMSG1-A

Drawing No. LP0952

Effective 02/14

GENERAL DESCRIPTION

The Model GMSG is a full featured single loop PID controller designed for

use with the Graphite Series. The module accepts low level signals from a

variety of bridge-type transducers, such as load cells, pressure transducers,

torque transducers, etc. An optional second signal input is available, providing

math capabilities between the two input channels (average, differential, etc.).

Each input channel provides a software selectable 5 V or 10 V stable bridge

excitation voltage, capable of driving up to four 350 Ω bridges (combined total

per module). The inputs are selectable for ±20 mV, ±33 mV, or ±200 mV full

scale. With solid state or relay outputs, plus an analog output, the GMSG

module can perform virtually any combination of time-proportioning or linear

control. The discrete outputs may also be assigned to one of seven internal soft

alarms; and the linear output can be assigned to transmit virtually any internal

variable. In addition, digital tare (re-zero), batch totalizer, and peak/valley (max/

min) are provided.

The modules connect and communicate via proprietary USB connection to

the various Graphite host devices. Those devices, equipped with serial ports as

well as Ethernet port(s), allows the system to share data with PCs, PLCs, and

SCADA systems.

Caution should be used when adding modules to Graphite. Some modules,

depending on usage, may consume high levels of power. This may limit the total

number of modules that can be installed on a single Graphite host. Check the

Graphite module and Graphite host data sheets for specific usage and power

requirements.

The GMSG modules are available with relays, or open drain MOSFET

outputs. For applications requiring large loads to be controlled, several DIN rail

mount relays are available.

The modules can operate in On/Off, P, PI, or PID control mode, and use an

on-demand Auto-Tune that establishes the tuning constants. The PID constants

may be fine-tuned through the serial or Ethernet interface. The modules employ

a unique overshoot suppression feature, which allows the quickest response

without excessive overshoot. The modules can also be operated in manual mode,

providing the operator with direct control of the output.

CONFIGURATION

The Graphite Series is configured with Windows® compatible Crimson®

software. The software is an easy to use, graphical interface which provides a

means of configuration and commissioning of new systems, as well as routine

module re-calibration.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Do not use the controller to directly command motors, valves, or other

actuators not equipped with safeguards. To do so can be potentially harmful to

persons or equipment in the event of a fault to the controller.

CAUTION: Risk of Danger.

Read complete instructions prior to

installationand operation of the unit.

CAUTION: Risk of electric shock.

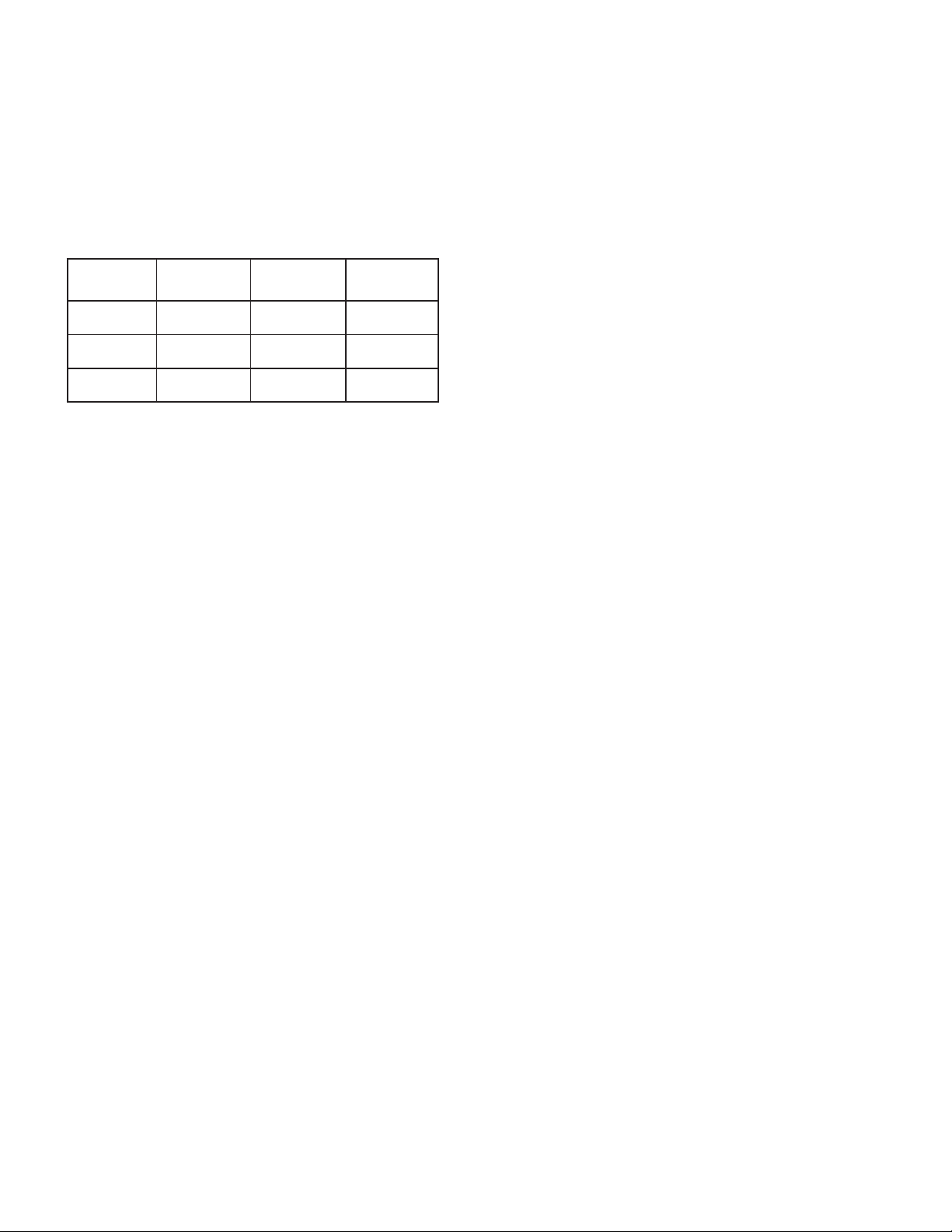

DIMENSIONS In inches (mm)

2.97 (76)

1.25 (32)

4.65

(118)

1

Page 2

SPECIFICATIONS

1. POWER: Power will be supplied by the Graphite host device. Some

modules, depending on usage may consume high levels of power. This may

limit the total number of modules that can be installed on a single Graphite

host. Check the Graphite module and Graphite host data sheets for specific

usage and power requirements.

GMSG1 Max Power: 5.6 W

2. LEDs*:

STS - Status LED shows module condition.

OP1, OP2, OP3 - Indicate status of outputs 1, 2, and 3

ALM - Alarm LED is lit during any internal alarm condition.

* Default configuration.

3. MEMORY: Non-volatile memory retains all programmable parameters.

4. INPUTS:

SELECTABLE

INPUT RANGE

±20.000 mVDC

±33.000 mVDC

±200.00 mVDC

ACCURACY *

18 TO 28°C

10 TO 75% RH

0.02% of reading

+3 µV

0.02% of reading

+5 µV

0.02% of reading

+30 µV

* After 20 minute warm-up. Accuracy includes the temperature coefficient.

Connection Type:

4-wire bridge (differential)

2-wire (single-ended)

Sample Time: 50 msec (20 readings per second)

Common Mode Range (with respect to input common): 0 to +5 VDC

Common Mode Rejection: > 100 dB, DC to 120 Hz

Temperature Coefficient (ratio metric): 20 ppm/°C max.

Step Response Time: 200 msec max. to within 99% of final process value

Input Impedance: 100 MΩ

Max Continuous Overload: 30 V

PV Range: -30,000 to 30,000

Effective Resolution: 16-bit

5. BRIDGE EXCITATIONS:

Software selectable:

5 VDC, ±2%, 65 mA max.

10 VDC, ±2%, 125 mA max. combined (excitation 1 plus excitation 2).

Temperature coefficient (ratio metric): 20 ppm/°C max.

Max. four 350Ω bridges per module.

6. ISOLATION LEVEL: 500 Vrms @ 50/60 Hz for 1 minute between the

following:

OP1 * OP2 * OP3 *

Linear Output

Signal Inputs (the 2 input channels are not isolated from each other)

Power Supply Input

* Outputs OP1, OP2 and OP3 of SSR model are not isolated from each other

7. COMMUNICATIONS: Provided by the Graphite host device.

8. DISCRETE OUTPUTS:

Available as (3) Solid State NFET, or (3) Form A relay.

Solid State Output:

Type: Switched DC, N Channel open drain MOSFET

Current Rating: 1 A max

VDS ON: 0.3 V @ 1 A

VDS MAX: 30 VDC

Offstate Leakage Current: 0.5 mA max

Form A Relay Output:

Type: N.O.

Current Rating: 3 Amps @ 125 VAC

1/10 HP @ 125 VAC

Life Expectancy: 200,000 cycles at maximum load rating. (Decreasing

load, increasing cycle time, and use of surge suppression such as RC

snubbers increases life expectancy.)

9. CONTROL MODES:

Control: On/Off, P, PI, or PID

Output: Time proportioning or linear

Cycle Time: Programmable from 0.0 to 60.0 sec

Auto-Tune: When selected, sets proportional band, integral time, derivative

time values, and output dampening time

Input Fault Response: Upscale

ACCURACY *

0 TO 50°C

0 TO 85% RH

0.07% of reading

+4 µV

0.07% of reading

+7 µV

0.07% of reading

+40 µV

ACCURACY *

-40 TO 70°C

0 TO 85% RH

0.09% of reading

+5 µV

0.09% of reading

+9 µV

0.09% of reading

+50 µV

10. ALARMS:

Modes: Manual

Absolute High Acting Absolute Low Acting

Deviation High Acting Deviation Low Acting

Inside Band Acting Outside Band Acting

Reset Action: Programmable; automatic or latched

Standby Mode: Programmable; enable or disable

Hysteresis: Programmable

Input Fault Response: Upscale

11. ANALOG DC OUTPUT:

Software programmable for 0-10 VDC, 0-20 mA, or 4-20 mA

Resolution:

Voltage: 500 µV

Current: 1 µA

Accuracy:

0.1% of full scale (18 to 28°C)

0.2% of full scale (-40 to 70°C)

Update Time: 0.0 to 60.0 sec

Compliance (for current output only): 500 Ω max.

Minimum load (voltage output only): 10 KΩ min.

Output is software selectable for either 10 V or 20 mA. The output range may

be field calibrated to yield approximate 10% overrange and a small

underrange (negative) signal.

12. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range: -40 to +70°C

Storage Temperature Range: -40 to +85°C

Operating and Storage Humidity: 85% max relative humidity, non-condensing,

from 0 to +50°C

Altitude: Up to 2000 meters

13. CERTIFICATIONS AND COMPLIANCES:

CE Approved

EN 61326-1 to Industrial Locations

IEC/EN 61010-1

RoHS Compliant

14. CONSTRUCTION: Case body is all metal construction. For indoor use

only. Installation Category II, Pollution Degree 2.

15. CONNECTIONS: Removable wire clamp screw terminal blocks.

Wire Gage: 28-16 AWG terminal gage wire

Torque: 6.0 lbf-inch (96 oz-inch)

16. MOUNTING: Screws to host.

17. WEIGHT: 8 oz (224 g)

2

Page 3

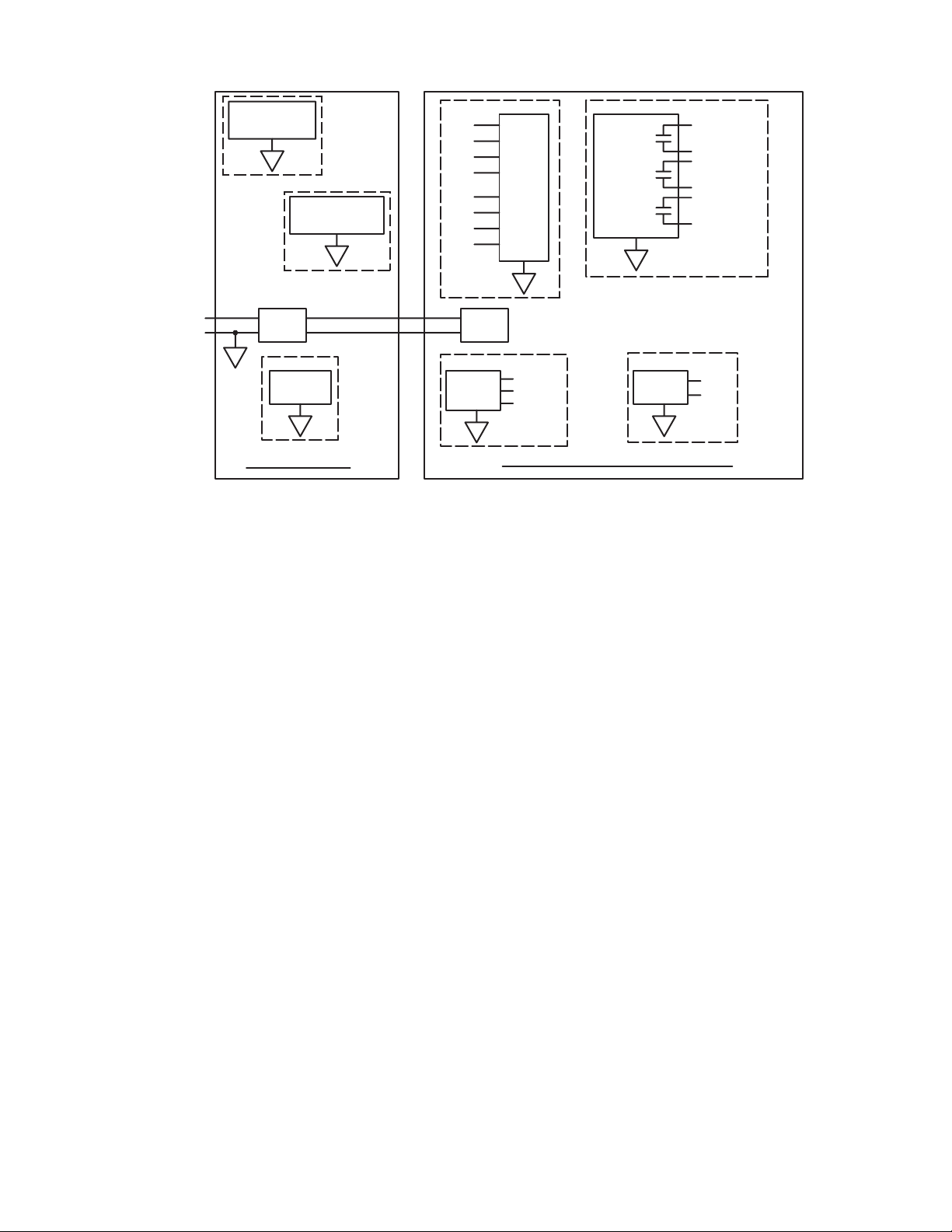

BLOCK DIAGRAM

VDC

RELAY

D

LINEAR

OUTPUT

ISOLATED

OP1-RELAY

OP2-RELAY

OP3-RELAY

ISOLATED

0-10V

0-20mA

F

PORT 1

PROGRAMMING

A

PORT 2

COMMUNICATIONS

A

+

-

POWER

SUPPLY

A

ISOLATED

PORT 3

ETHERNET

B

GRAPHITE HOST

+EXC

+SIG

-SIG

COM

+EXC

+SIG

-SIG

COM

SSR

OUTPUTS

ISOLATED

INPUT1

OUTPUTS

INPUT2

C

POWER

SUPPLY

ISOLATED

OP1-SSR1

OP2-SSR2

OP3-SSR3

E

GMSG1 - STRAIN GAGE MODULE

EMC INSTALLATION GUIDELINES

Although Red Lion Controls Products are designed with a high degree of

immunity to Electromagnetic Interference (EMI), proper installation and wiring

methods must be followed to ensure compatibility in each application. The type

of the electrical noise, source or coupling method into a unit may be different

for various installations. Cable length, routing, and shield termination are very

important and can mean the difference between a successful or troublesome

installation. Listed are some EMI guidelines for a successful installation in an

industrial environment.

1. A unit should be mounted in a metal enclosure, which is properly connected

to protective earth.

2. Use shielded cables for all Signal and Control inputs. The shield connection

should be made as short as possible. The connection point for the shield

depends somewhat upon the application. Listed below are the recommended

methods of connecting the shield, in order of their effectiveness.

a. Connect the shield to earth ground (protective earth) at one end where the

unit is mounted.

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is over 1 MHz.

3. Never run Signal or Control cables in the same conduit or raceway with AC

power lines, conductors, feeding motors, solenoids, SCR controls, and

heaters, etc. The cables should be run through metal conduit that is properly

grounded. This is especially useful in applications where cable runs are long

and portable two-way radios are used in close proximity or if the installation

is near a commercial radio transmitter. Also, Signal or Control cables within

an enclosure should be routed as far away as possible from contactors, control

relays, transformers, and other noisy components.

4. Long cable runs are more susceptible to EMI pickup than short cable runs.

5. In extremely high EMI environments, the use of external EMI suppression

devices such as Ferrite Suppression Cores for signal and control cables is

effective. The following EMI suppression devices (or equivalent) are

recommended:

Fair-Rite part number 0443167251 (RLC part number FCOR0000)

Line Filters for input power cables:

Schaffner # FN2010-1/07 (Red Lion Controls # LFIL0000)

6. To protect relay contacts that control inductive loads and to minimize radiated

and conducted noise (EMI), some type of contact protection network is

normally installed across the load, the contacts or both. The most effective

location is across the load.

a. Using a snubber, which is a resistor-capacitor (RC) network or metal oxide

varistor (MOV) across an AC inductive load is very effective at reducing

EMI and increasing relay contact life.

b. If a DC inductive load (such as a DC relay coil) is controlled by a transistor

switch, care must be taken not to exceed the breakdown voltage of the

transistor when the load is switched. One of the most effective ways is to

place a diode across the inductive load. Most RLC products with solid state

outputs have internal zener diode protection. However external diode

protection at the load is always a good design practice to limit EMI.

Although the use of a snubber or varistor could be used.

RLC part numbers: Snubber: SNUB0000

Varistor: ILS11500 or ILS23000

7. Care should be taken when connecting input and output devices to the

instrument. When a separate input and output common is provided, they

should not be mixed. Therefore a sensor common should NOT be connected

to an output common. This would cause EMI on the sensitive input common,

which could affect the instrument’s operation.

Visit RLC’s web site at http://www.redlion.net/Support/InstallationConsiderations.

html for more information on EMI guidelines, Safety and CE issues as they

relate to Red Lion Controls products.

3

Page 4

HARDWARE

INPUT RANGE SELECTION

Select either ±20 mV or the ±33 mV | ±200 mV range by placing the input jumper

in the appropriate location. The input jumpers are located on the side of the GMSG1

module.

± 20 mV

Range

± 33 mV

or

± 200 mV

Range

HARDWARE INSTALLATION

Modules must be installed beginning with slot 1 (left-most slot), with no

empty slots between the modules, and the order must match the modules order

in Crimson. Torque screws to 6.0 pound-force inch (96 ounce-force inch)

CAUTION: Some modules, depending on usage, may consume high

levels of power. This may limit the total number of modules that can

be installed on a single Graphite host. Check the Graphite module and

Graphite host data sheets for specific usage and power requirements.

WARNING: Disconnect all power

to the unit before installing or

removing modules.

REMOVE RUBBER

MODULE PLUG

WIRING

WIRING CONNECTIONS

All conductors should meet voltage and current ratings for each terminal. Also, cabling should conform

to appropriate standards of good installation, local codes and regulations. When wiring the module, use the

numbers on the label to identify the position number with the proper function. Strip the wire, leaving

approximately 1/4" (6 mm) of bare wire exposed. Insert the wire into the terminal, and tighten.

Terminals 13 to 18

Terminals 7 to 12

Terminals 1 to 6

4

OP3 COM.

OP3 +

13

OP1 COM.

OP1 +

879

COM.

-SIG.

N/C

N/C

1514

16 17 18

(OPT.)

OP2 +

OP2 COM.

10 11

(OPT.)

+SIG.

+EXC

4312 5

ANALOG-

ANALOG+

2

+SIG.

+EXC

12

21

-SIG.

COM.

6

Page 5

INPUT CONNECTIONS

Load

Load

VDC+

VDC-

+SIG

-SIG

COM

-SIG

+EXC

-EXC

4-Wire Bridge Input2-Wire Single Ended Input

+SIG

+EXC

+SIG

COM

-SIG

-SIG

+EXC

+SEN

+SIG

-SEN

-EXC

6-Wire Bridge Input

BRIDGE COMPLETION RESISTORS

For single strain gage applications, bridge completion resistors must be employed externally to the module. Only use metal film

resistors with a low temperature coefficient of resistance.

Load cells and pressure transducers are normally implemented as full resistance bridges and do not require bridge completion resistors.

OUTPUT CONNECTIONS (3 Form A relays or 3 SSR; Each model has analog output)

Power

Power

Load

OP1 COM

OP1 +

OP2 COM

10 11 12987

OP2 +

+SIG2 (OPT)

+EXC2 (OPT)

Power

Load

16 17 18151413

OP3 COM

OP3 +

N/C

N/C

ANALOG+

ANALOG-

+EXC

+SIG

COM

-SIG

Outputs 1 and 2 - Relay Version

Power

Power

+

+

-

+

-

+

OP1 COM

OP1 +

OP2 COM

10 1211789

OP2 +

+SIG2 (OPT)

+EXC2 (OPT)

Outputs 1 and 2 - Solid State Version

16 181713 14 15

Recorder,

Controller,

Valve, etc

+

-

Analog Output

OP3 COM

OP3 +

N/C

N/C

ANALOG+

ANALOG-

Power

Output 3 - Relay Version

+

-

+

OP3 COM

OP3 +

N/C

16 17 18151413

N/C

ANALOG+

ANALOG-

Outputs 3 - Solid State Version

5

Page 6

LEDS

STS – STATUS LED

The Status LED is a green LED that provides information regarding the state

of the module. This includes indication of the various stages of the start-up

routine (power-up), as well as any errors that may occur.

Startup Routine

Off

Flashing Green Module switching to configuration.

Green Module performing normally.

Error States

Flashing Green

OP1, OP2, OP3, – OUTPUT STATUS LED

The OP1, OP2, andOP3 LEDs are factory configured to indicate the status of

the outputs. The LEDs turn on when the output is active.

These LEDs may be remapped to various other module properties.

Module is currently running the boot loader and/or

being flash upgraded by Crimson.

Module is controlling properly, but has lost

communication with the Host.

ALM – ALARM LED

The Alarm LED is factory configured to indicate the presence of an alarm.

Whenever one of the seven alarms is active, the LED turns on.

This LED may be remapped to various other module properties.

FIRMWARE UPGRADE

The module’s firmware is stored in flash memory so that software/hardware

conflicts are avoided, and so features can be added in the future.

During a download, Crimson compares its own library of firmware files with

those stored in the module. If they do not match, Crimson will download the

necessary firmware.

CONFIGURATION

Programming is done via Crimson® software, a Windows® compatible

configuration interface. Please see the Crimson manual for more information.

ORDERING INFORMATION

TYPE DESCRIPTION PART NUMBER

Graphite 7" Color Touch Screen, Indoor, 24 VDC Powered G07C0000

Graphite 7" Color Touch Screen, Indoor/Outdoor, 24 VDC Powered G07S0000

Graphite 9" Color Touch Screen, Indoor, 24 VDC Powered G09C0000

Graphite 9" Color Touch Screen, Indoor, 24 VDC Powered, Additional Ethernet Port G09C1000

Graphite 10" Color Touch Screen, Indoor, 24 VDC Powered G10C0000

Graphite 10" Color Touch Screen, Indoor, 24 VDC Powered, Additional Ethernet Port G10C1000

Operator

Interface Panels

Input Modules

Graphite 10" High Resolution Display, Color Touch Screen, Indoor, 24 VDC Powered G10R0000

Graphite 10" High Resolution Display, Color Touch Screen, Indoor, 24 VDC Powered, Additional Ethernet Port G10R1000

Graphite 10" Color Touch Screen, Indoor/Outdoor, 24 VDC Powered G10S0000

Graphite 10" Color Touch Screen, Indoor/Outdoor, 24 VDC Powered, Additional Ethernet Port G10S1000

Graphite 12" Color Touch Screen, Indoor, 24 VDC Powered G12C0000

Graphite 12" Color Touch Screen, Indoor, 24 VDC Powered, Additional Ethernet and Serial Port G12C1100

Graphite 15" Color Touch Screen, Indoor, 24 VDC Powered G15C0000

Graphite 15" Color Touch Screen, Indoor, 24 VDC Powered, Additional Ethernet and Serial Port G15C1100

Graphite Module, Single Loop, One Strain Gage Input, Relay Outputs, and Analog Output GMSG10R0

Graphite Module, Single Loop, One Strain Gage Input, Solid State Outputs, and Analog Output GMSG10S0

Graphite Module, Single Loop, Two Strain Gage Inputs, Relay Outputs, and Analog Output GMSG11R0

Graphite Module, Single Loop, Two Strain Gage Inputs, Solid State Outputs, and Analog Output GMSG11S0

6

Page 7

This page intentionally left blank

7

Page 8

Red Lion Controls

Headquarters

20 Willow Springs Circle

York PA 17406

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

The Company warrants the products it manufactures against defects in materials and workmanship

LIMITED WARRANTY

for a period limited to two years from the date of shipment, provided the products have been stored,

handled, installed, and used under proper conditions. The Company’s liability under this limited

warranty shall extend only to the repair or replacement of a defective product, at The Company’s

option. The Company disclaims all liability for any affirmation, promise or representation with

respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against

damages, claims, and expenses arising out of subsequent sales of RLC products or products

containing components manufactured by RLC and based upon personal injuries, deaths, property

damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be

to any extent liable, including without limitation penalties imposed by the Consumer Product Safety

Act (P.L. 92-573) and liability imposed upon any person pursuant to the Magnuson-Moss Warranty

Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except

those expressly contained herein. The Customer acknowledges the disclaimers and limitations

contained herein and relies on no other warranties or affirmations.

Red Lion Controls

Europe

Softwareweg 9

NL - 3821 BN Amersfoort

Tel +31 (0) 334 723 225

Fax +31 (0) 334 893 793

Red Lion Controls

India

201-B, 2nd Floor, Park Centra

Opp 32 Mile Stone, Sector-30

Gurgaon-122002 Haryana, India

Tel +91 984 487 0503

Red Lion Controls

China

Unit 302, XinAn Plaza

Building 13, No.99 Tianzhou Road

ShangHai, P.R. China 200223

Tel +86 21 6113 3688

Fax +86 21 6113 3683

Loading...

Loading...