Page 1

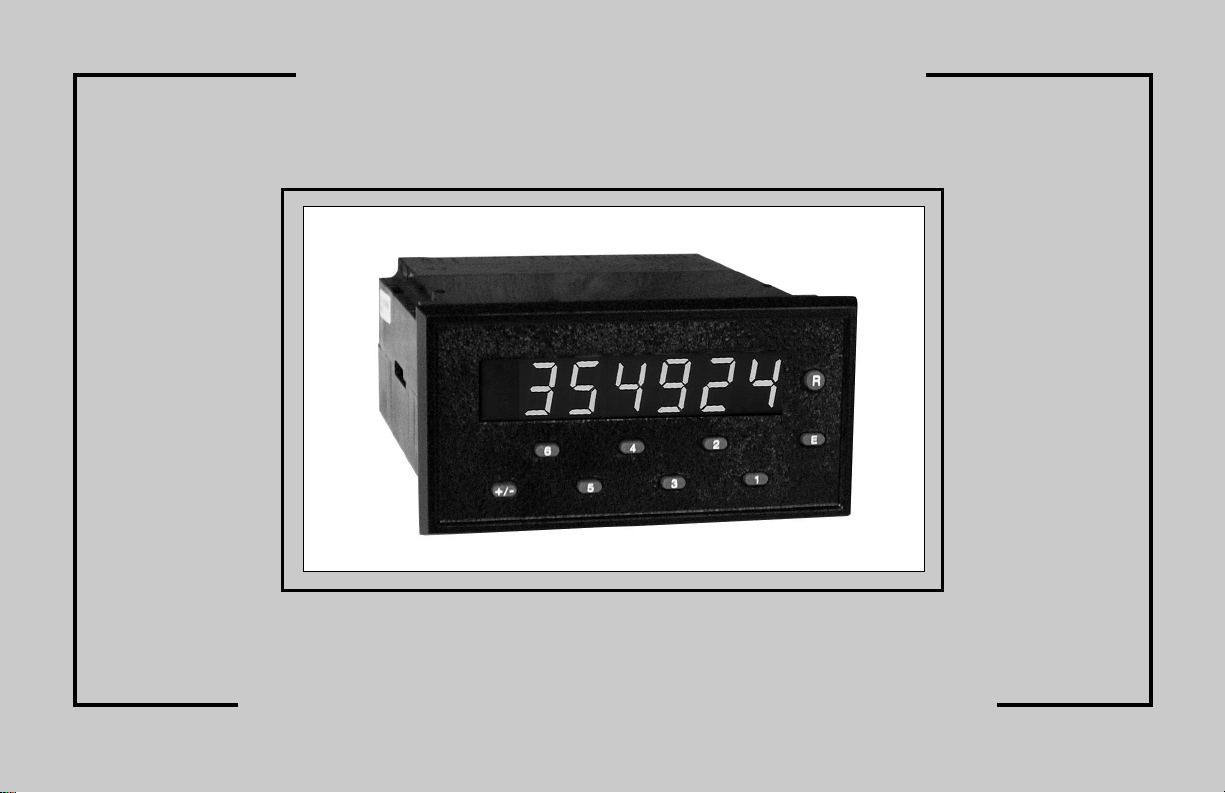

THE ASTRO LINE SERIES

GEMINI 1000/2000 INSTRUCTION MANUAL

Page 2

INTRODUCTION

The Gemini 1000 and 2000 are both units in a multi-purpose series of

industrial control units that are field-programmable to solve multiple

applications. This series, known as the Astro-Line family of products, is built

around the concept that the end user has the capability to program different

personalities and functions into the unit in order to adapt to different indication

and control requirements.

The Gemini, which you have purchased, has the same high quality

workmanship and advanced technological capabilities that have made Red Lion

Controls the leader in today's industrial market.

Red Lion Controls has a complete line of industrial indication and control

equipment, and we look forward to being of service to you now and in the future.

CAUTION: Read complete instructions prior

to installation and operation of the unit.

CAUTION: Risk of electric shock.

Page 3

TABLE OF CONTENTS

I. GENERAL DESCRIPTION

Safety Summary................................................... 2

Programming The Gemini 1000/2000 ........................................ 2-3

Programming The Personality............................................ 3

Programming The Presets, Scale Factor, & Output Time Delays.......................... 3-4

Factory Settings ................................................... 5

Operator Accessible Functions With Programming Disabled ............................ 6

Diagnostics, Self-Test, & “Watchdog” Timer .................................... 6-7

Input Circuitry & Set-up ............................................... 7

Overflow Indication ................................................. 7

II. PROGRAMMING INSTRUCTIONS FOR THE COUNTER VERSION OF THE GEMINI 1000/2000........ 8-13

Codes 41, 43, 44, 45, & 46 ............................................. 8-9

Codes 51, 52, 53, 54, & 55 ............................................. 9-12

Codes 61, 66, Preset Values, & Scale Factor ................................... 12-13

Dual Preset Counting & Programming Application Example ............................ 14-15

III. PROGRAMMING INSTRUCTIONS FOR THE RATE INDICATOR VERSION OF THE GEMINI 1000/2000 . . . 16-21

Codes 41, 44, 45, & 46 ............................................... 16

Codes 51, 52, 53, 54, & 55 ............................................. 16-18

Codes 61, 63, 66, Preset Values, & Scale Factor.................................. 8-19

Dual Preset Rate Programming Application Example................................ 20-21

IV. 20 mA CURRENT LOOP SERIAL COMMUNICATIONS (GEMINI 2000 ONLY) ................. 22-29

Communication Format ............................................... 22

Sending Commands & Data To The Gemini 2000 ................................. 22-23

Receiving Data From The Gemini 2000....................................... 24

Print Options .................................................... 24

Current Loop Installation .............................................. 25-26

Communications Application ............................................ 27

Troubleshooting Gemini Serial Communications .................................. 28

Serial Loop-Back Self-Test ............................................. 28

V. APPENDIX “A” - INSTALLATION & INPUT CONFIGURATION SWITCH SET-UP ............... 29-39

VI. APPENDIX “B” - SPECIFICATIONS & DIMENSIONS .............................. 40-41

VII. APPENDIX “C” - TROUBLESHOOTING GUIDE ................................ 42-44

VIII. APPENDIX “D” - FUNCTION COMMAND CODE SUMMARY ......................... 45-47

IX. APPENDIX “E” - SCALING FOR RATE INDICATION .............................. 48-49

X. APPENDIX “F” - GEMINI 1000/2000 PROGRAMMING CHARTS ........................ 50-53

XI. APPENDIX “G” - ORDERING INFORMATION .................................. 54

–1–

Page 4

GENERAL DESCRIPTION

The Geminiis a two input,microprocessor-based device whichoffersthe features

and performance of a single (GEM 1000)/dual (GEM 2000) level preset counter or

sample time, rate indicator. The 6-digit display features 0.56" LEDs with negative

sign and overflow indicators. The internalprecision is maintained to 9 digits. The 20

mA Current Loop Option (Gemini 2000 only) makes possible remote or

computerized monitoring or control of the count, Presets and Scale Factor.

Flexibility and usefulness are insured through user programmability. With

simple front panelkeystrokes and rear panelswitch settings, any oneof a number

of configurations can be selected. Once the selection is made, all or part of the

keyboard can be disabled to protect the settings and guarantee that no unwanted

changes can occur during the measurements. All set-up data is stored in

2

E

PROM, which will hold data for a minimum of 10 years without power.

Whenever the power comes on, the Gemini performs a series of internal

diagnostics to verify the integrity ofthe stored data. Thereis also a self-testmode

and an ever-present “watchdog” timer to prevent processor lockup.

The construction of the Gemini features a metal, die cast bezel for maximum

durability with high quality appearance. The sealed front panel meets NEMA

4/IP65 specifications forwashdownand/or dust. Electrical connectionsare made

with removable, plug-in terminal strips at the rear of the unit. Clamp type

pressure plate terminals accept stripped #14 AWG wire without lugs.

As a counter,the Gemini can monitor bi-directional, unidirectional(totalizer),

or quadrature signals. It can double or (with quadrature) even quadruple the

resolution of the incoming signal. Counting modes also provide for

anti-coincidence applications. Bothchannels of count information aremonitored

simultaneously, no counts are lost, and the final output can be chosen as the sum

or difference of the two input channels.

As a rate indicator, a variety of sampling times are available. Accurate to one

hundredth of a percent,the sampling time can be setas 1, 2, 5, 10, 20, or50 seconds.

The preset level(s) can be selected to control an open collector output(s). The

optional Gemini plug-in relay board makes it easy to field upgrade your Gemini

to provide 5amp,240 VAC relay output(s).Theoutput(s) are also programmable

and can be set for terminate at the “other” output start, “other” output end, at

reset or reset end, after time delay, or boundary.

Preset and reset behavior of the output(s) and display are completely

programmable. The preset(s) canhave a value ranging from -999999 to +999999.

Decimal placement will bethe sameas the decimal placement on the inputvalue.

Various resetmodes can be selected: manualreset to zero or preset; automatic

reset to zero or preset; or automatic reset after time delay. The manual reset will

always override automatic reset, if it has been enabled.

The scale factor, moveable decimal point, dummy right hand zeros, leading

zero blanking, and decade divider capabilities of the Gemini permit complete

control of the Gemini display. These features provide easy conversion of input

signals to desired measurement units (feet to meters, etc.). The input values can

be multiplied by any number from -5.9999 to +5.9999 with the scale factor. The

addition of up to 3 dummy right hand zeroes gives an effective display

multiplication of 10, 100, or 1000. Similarly, the decade divider provides 1, 2, or

3 decades of prescaling.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Do notuse this unit todirectly command motors,valves, or other actuators not

equipped with safeguards. To do so, can be potentially harmful to persons or

equipment in the event of a fault to the unit.

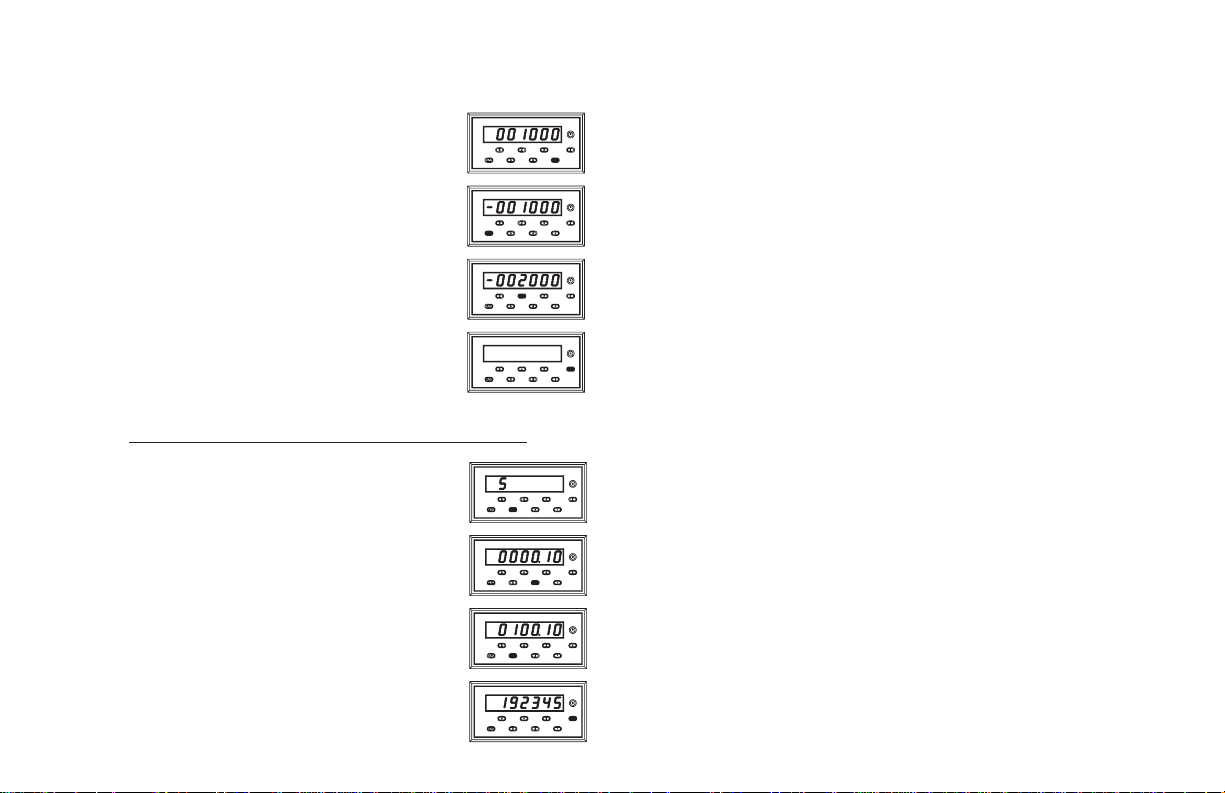

PROGRAMMING THE GEMINI

When your Gemini arrives from the factory, it has already been programmed

to function as a preset counter.

The personality,functions, and modes are thenset by pressing the appropriate

keys. A function is defined by a two-digit code which appears on the left side of

the display. The mode of that function is shown as a one-digit code on the right

side of the display. At times there will be a (-) sign modifier.

–2–

Page 5

Data forthe presets, scalefactor, and time delays are entered differently. Each

digit key controls the digit on the display directly above it. Changing the digits

can bedone by repeatedly pressing the key beneath thedigit position you wish to

change orby merely holding it down. As youhold it down or press it, thevalue of

that digit will change cyclically, counting up to 9, then to 0, and then up again.

The 6 numbered keys correspond to the six digits, and the “+/-” key

correspond to polarity.

PROGRAMMING THE PERSONALITY

Entering function and mode is easily accomplished by

pressing the appropriate digit key. For the personality

function, enter 41 by pressing the front panel key 4.

Then press the front panel key 1. The leftmost LEDs

show the function; the rightmost is the present mode.

A new mode selection is made by entering a new

number. On some of the entries, you have the option of a

plus (+) or minus (-) sign. In the cases where a “+” sign is

required, no sign will be displayed. If you do enter a “-”

sign (using the “+/-” key), a minus sign will be displayed

in front of the appropriate digit.

Pressing the “E” key finalizes the change. The display

will now show the count or rate value immediately.

If you do not press the “E” key the change will not be

recorded. The display will remain for 15 seconds, and then

return to normaloperating mode using theold function and

mode settings. (Note: The reset button “R”, if enabled, is

always active. Pressing reset will immediately abort the

function selection, and reset the instrument.)

The major personality is function code 41. If it is

changed from rate to counter or vice-versa, it may effect

settings like count mode, reset mode, and output

termination modes.

PROGRAMMING THE PRESETS, SCALE FACTOR, &

OUTPUT TIME DELAYS

The scale factor and preset values are commonly reprogrammed on a daily

basis. As such, single keystroke access has been provided on the front panel.

To change the scale factor, pressthe “3” key. Thedisplay

will then show you’re the present scale factor value. The

scale factor can be set from -5.9999 to +5.9999.

Changing the digits can be done by repeatedly pressing

the key beneath the digit position you wish to change or by

merely holding it down.

The newvalue will be entered when the “E”key is pressed.

This key mustbeheld down until the displayhas blanked after

which the unit will return to the normal display mode.

The internal count value is multipliedby the scale factor value, which changes

the displayed value accordingly. This is true for all response modes, Count with

Inhibit, Count with UP/DN Control, Two Input Anti-Coincidence and for all

Quadrature Counting Modes.

–3–

Page 6

PROGRAMMING THE PRESETS, SCALE FACTOR, &

OUTPUT TIME DELAYS (Cont’d)

The preset level is changed in the same way as the scale

factor. Pressingthe “1” key willdisplay the presentvalue of

preset 1.

To change the value, merely cycle the digits through as

you have done before. The presets can be selected from

-999999 to +999999.

The new value will be entered when the “E” key is

pressed. (The display will blank for a short duration of time

and then re-display the count value.)

The Scale Factor value will have a direct effect on the

preset being entered. For scale factors greater than one, the

preset shouldbe an integer multiple of the scale factor. If it is

not, the Gemini will automatically adjust the preset value up

or down to force it to be evenly divisible by the scale factor.

A time delay is changed by entering a two-digit function

code. The display will then immediately show the present

time delay in seconds with a two decimal place accuracy.

The time delay valuescan beset from .01 to 599.99 seconds.

To change output1 time delay, enter functioncode 53 and

enter the new value by holding down or repeatedly pressing

the key below the digit position you wish to change.

Note: A time delay value of zero cannot be programmed into the Gemini. If a

value of 0 is entered into the display and the “E” key is pressed, the unit will

continue to use the previous time delay value.

As with the other functions, you must press“E” to record the changes. For the

data entry modes, if you do not press the “E” key, a time out of 5 seconds occurs,

then the display returns to operating mode without any change to the value. The

only time any change will occur is when the “E” key is pressed. As in all other

modes, the reset button is always active if enabled. Pressing “R” will abort the

data entry and reset the instrument.

The new value willbe entered when the “E” key is pressed

and the display will immediately return to the count value.

–4–

Page 7

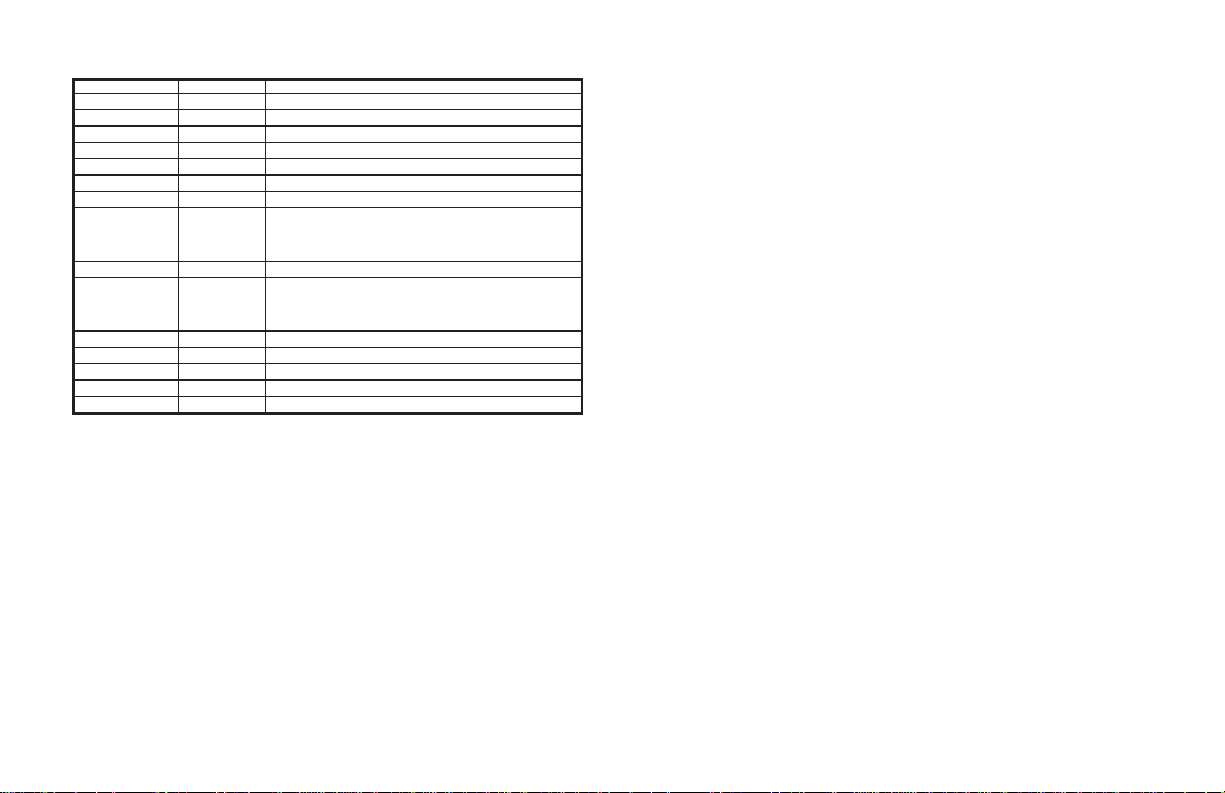

FACTORY SETTINGS

Keys Struck Display Description

4,1 41 1

4,3 43 1

4,4 44 1

4,5 45 1

4,6 46 1

5,1 51 1

5,2 52 3

5,3 0000.10

*5,4 54 3

*5,5 0000.10

6,1 61 4

6,6 66 4

3 01.0000

1 000500

*2 001000

When the unit is shipped from the factory, the functions and modes are

programmed as shown above.

*Applies to the Gemini 2000 only.

Personality selected as Counter

Count with Inhibit

Count on one edge of input (no doubling)

Scale Multiplier of 1.0

Leading zero blanking and no decimal point

Manual reset-to-zero, as longasbutton remains PUSHED

Output 1 terminates at Reset, Normal Output Phase

0.10 second Output 1 time delay. Note that this function

will display the actual amount of time delay, and not a

mode command. In this case, it displays a 0.10 indicating

0.10 seconds.

Output 2 terminates at Reset, Normal Output Phase.

0.10 second Output 2 time delay. Note that this function

will display the actual amount of time delay, and not a

mode command. In this case, it displays a 0.10 indicating

0.10 seconds.

No right-hand dummy zeros

Reset enabled along with scale factor and presets.

Scale Factor set to unity

Preset 1 value equals 500

Preset 2 value equals 1000

–5–

Page 8

OPERATOR ACCESSIBLE FUNCTIONS WITH

PROGRAMMING DISABLED

(For details on keyboard entry, see preceding section)

One of the important features of the Gemini is the ability to disable

programming. With this ability, accidental bumping of the keys or tampering by

unauthorized personnel can be prevented. However,it may be necessary to allow

reset and certain programming functions, such as, preset and scale factor values

to be changed in daily operation. The Gemini, through the use of the “Operator

Accessible Functions”Modes, can enablethese functions evenwhen the “PGM.

DIS.” terminal is connected to “COMMON”.

The “Operator Accessible Functions” Modes are programmed by a two-digit

function code (66), like the other function modes. But in this case, the modes do

not take effect until the “PGM. DIS.” terminal is connected to “COMMON”.

(Bear in mind that all function modes of the Gemini are accessible until “PGM.

DIS.” is connected to “COMMON”.)

There are four basic “Operator Accessible Functions” Modes available.

These modes enable the following functions.

1. NO FUNCTIONS EXCEPT RESET ENABLED - In this mode, manual

reset is enabled, but none of the programming functions can be changed.

However, the functions can be interrogated.

2. PRESET PROGRAMMING ANDRESET ENABLED - The entirefront

panel is disabled with the exceptions of preset programmability and

manual reset. All functions can be interrogated.

3. SCALE FACTOR PROGRAMMING AND RESET ENABLED - The

entire front panel is disabled with the exceptions of scale factor

programmability and manual reset. All functions can be interrogated.

4. SCALE FACTOR AND PRESET PROGRAMMING, AND RESET

ENABLED - Theentire front panel is disabledwith the exceptions of scale

factor and preset programmability, and manual reset. All functions can be

interrogated.

All of these four basic modes can be modified with the addition of a minus

sign. The minus sign disables the manual reset, at the front panel and the remote

reset terminal, at the rear of the unit.

There is also a rear panel DIP switch which permits disabling of the front panel

manual resetbutton. This isindependent of the rearterminal remote reset,and can be

used in conjunction with any front panel disable mode. The combination of manual

and remote inputs provides a high level of security without sacrificing flexibility.

DIAGNOSTICS, SELF TEST, & “WATCHDOG” TIMER

The security and integrity of the Gemini is further enhanced by its self-test,

diagnostic and “watchdog” timer capabilities.

The diagnostics are concerned with the special, no power memory of the

Gemini. Whenever the poweris turned off, on purposeor by accident, all pertinent

function settings and measurementsare automatically saved. Then, when power is

restored, the function and data are re-instated. This allows you to program a

Gemini once and nothave to re-program it until youwish to use it in another mode.

When the function codes and data are saved, computations are made with

these values.The result of these computations is stored in the memory to serve as

a check against possible error. Then on power up, the same computations are

repeated on the stored data. Ifthe results donot agree with thestored results, then

a “P” will appear on the left side of the display. If this occurs, refer to the

troubleshooting guide for directions.

Another error indicator is the “watchdog” timer. In order to insure proper

software functioning, the program constantly monitors itself. If the proper sequence

and timingofinternal events doesnotoccur, an “E”will appear onthe left side ofthe

display. If this occurs, refer to the troubleshooting guide for instructions.

The final type of built-in error checking is the front panel initiated self test. It

can be performed at any time, even when the Gemini is running. It will not

interfere with theaccumulation of counts or controlfunctions. A function code of

“6” “+/-” starts thetest. At this time, whatever was displayedwill be replaced by

a string of decimal points andthe overflow indicator. Then,the display will show

a string of 9’s, then 8’s then 7’s, etc., until a string of 0’s is shown. The self test

will then turn offthe overflow indicator and activate the minus(-) sign. After this,

the unit showsan interlace pattern of-0, 1, 0, 1,0,1, then -2, 1,2, 1, 2, 1,followed

by -2, 3, 2, 3, 2, 3, etc., until -8, 9, 8, 9, 8, 9, is reached. At this time, the outputs

can be tested by pressing the “1” and “2” keys.

(The program disablepin must be high inorder to allow activation ofthe output.)

Note: During selftest caution should be usedwhen testing the outputs soas not to

cause any undesirable or hazardous conditions in the system.

–6–

Page 9

An automatic exit will take place after six seconds or immediately if the

Program Disable terminal is connected to common. Normal length of display

time for each of the patterns is approximately 0.5 seconds. Rapidly pressing the

“+/-” key during self test can speed up the process.

INPUT CIRCUITRY & SET-UP

There are two independent input channels on the Gemini. Various types of

sensor outputs can be accommodated by appropriate DIP switch set-up; such as

TTL or CMOS logic, current sinking, current sourcing, or dry contact.

Channel A consists of a logic input and a separate low level magnetic pickup

input.

Channel B is a completely independent count or control input channel. Like

Channel A, it can be programmed with DIP switches for a wide variety of logic

inputs and is identical to Channel A in this regard.

For a complete detailed description of set-up, see Appendix “A”.

OVERFLOW INDICATION

The Gemini features an overflow indicator (LED) which is located to the left

of the sixth digitand above the polarity annunciator. This LED will turn on if the

capacity of the display (6-digits) is exceeded or if the internal count capacity

(9-digits) is exceeded. Use of extremely small scale multiplier and scale factor

values can cause the internal count capacity to overflow before the displayed

value wouldoverflow. It should also be noted thatthe use of Right Hand Dummy

Zeros or Scale Factors larger than one could cause the Displayed value to

overflow before a value of 999,999 (6-digits) is accumulated.

When the capacity of the display is exceeded, the count value will be

maintained and willbe valid. Butif the internal countvalue is exceeded, thenthis

value may no longer be valid.

–7–

Page 10

PROGRAMMING INSTRUCTIONS FOR THE COUNTER VERSION OF THE GEMINI

The first part of this section provides detailed description of the function

command codes for countingmodes, reset modes, output terminations, etc. Then,

using an actual application example, the programming instructions for a counter

version will be “walked through”, to give the user a full understanding of the

Gemini programming procedure. The descriptions below give the function

command code first, followed by the individual mode identifier. The Function

Command Code Summary in the appendix lists all codes. (Only commands and

modes pertaining to the counter will be discussed in this section.)

CODE 41 - UNIT PERSONALITY

Two basic personalities are available for the Gemini. They are the counter

mode and the rate indicator mode.

[41 1] COUNTER- Setting this mode selectstheunit to function as acounter.

This is the basic personality mode and must be programmed before any

other modes areset. (This command forces default mode valuesin certain

command codes.)

CODE 43 - INPUTSA&BRESPONSE MODES

The Gemini has six different input response modes. They are: Count with

Inhibit; Count with Up/Down Control; Two-Input Anti-Coincidence Add;

Two-Input Anti-Coincidence Add/Subtract; Quadrature; and Quadrature X4.

[43 1] COUNT WITH INHIBIT - Input A in this case, serves as the count

input. Input B serves as the inhibit terminal. When Input B is low, count

signals appearing at A will be ignored. When Input B is at a high level,

negative going (falling) signals appearing at A will be counted.

[43 2] COUNT WITH UP/DOWN CONTROL - When in this mode, count

direction can be controlled by a second input. Input A serves as the count

input, and Input B serves as the direction control signal. When B is at a

high level, negative going transitions at A will cause the unit to count in

the positive direction. When Input B is at a low level, negative going

transitions at A will cause thecounter tocountin the negative direction.

[43 3] TWO(2)INPUT ANTI-COINCIDENCE ADD/SUBTRACT - This mode

effectively separates count pulses which may simultaneously appear at the

two inputs. The Gemini unit then processes the count pulses into a string of

time-separated pulses, so the internal counter will not lose any counts. Input

A serves as the add input, and Input B serves as the subtract input.

[43 4] TWO (2) INPUT ANTI-COINCIDENCE ADD - This mode functions

in the same manner as the Two Input Add/Subtract mode except both

Input A and Input B serve as “ADD” inputs.

[43 5] QUADRATURE COUNTING - Quadrature counting modes are

primarily used in positioning and anti-jitter applications. The reason this

mode is used is due to the manner in which two pickups are positioned

relative to each other.Input B is a pulsetrain signal shifted 90° awayfrom

Input A. These two signals are processed by the Gemini as follows:

Input A serves as the count input, while Input B serves as the quadrature

input (B is theinput shifted 90° away from A). Forquadrature with single edge

counting, the counter will count in a positive direction when Input A is a

negative going edge and Input B is at a low level. The counter will count in a

negative direction when Input A is a positive going edge and Input B is at a

low level. All transitions on Input A are ignored when B is at a high level.

These logic rulesprovide the basis for anti-jitteroperationwhich will prevent

false counts from occurring due to back-lash, vibration, chatter, etc.

When two edge counting is used, the quadrature mode works the same as

with single edge counting when Input B is low. But when Input B is at a high

level, counts atInput A are no longerignored. Instead the logic rulesfor A are

complemented, allowing both edges of A to be counted. This doubles the

effective resolution of the encoded input.

[43 6] QUADRATURETIMES 4 -This mode takes the quadrature mode, with

two edge counting, onestep further. In quadrature times 4, both InputAand

Input B serve as count or quadrature input, depending on their state. In one

instance, Input A will serve as the count input and Input B will serve as the

quadrature input. In another instance, Input A will be the quadrature input

and Input B will be the count input. This enables each edge, positive and

negative going, of each input, A and B, to be counted. This results in a

resolution four times greater than in the ordinary quadrature mode.

–8–

Page 11

CODE 44 - NUMBER OF COUNT EDGES

The Gemini can be programmed for either single edge or two edge (doubling)

counting. The number of count edges cannot be set when the count mode is

programmed for quadrature X4 operation (the Gemini will ignore any attempt to

enter function command code 44 when set for quadrature X4).

[44 1] SINGLE EDGE COUNTING - The unit counts on the negative going

(falling) edge of the count input signal. The count mode descriptions

describe how each mode uses this method of edge counting.

[44 2] TWO EDGE COUNTING - This mode is used when doubling of the

count signal input is required. The unit counts on the positive going

(rising) edge of the count input signal, as well as, the negative going

(falling) edge.

CODE 45 - SCALE MULTIPLIER

There arefour scale multiplier values that are available.They are: 1;0.1; 0.01;

and 0.001. They effectively divide the internal count value by 1, 10, 100, and

1000 respectively, to yield the displayed count value. Note: Use of a small scale

multiplier inconjunction with asmall scale factorcould cause theinternal count

value to be exceeded before the 6-digit display valueis exceeded. See “Overflow

Indication” section for more details.

[45 1] SCALE MULTIPLIER VALUE OF 1 - This value multiplies the

internal count by 1.

[45 2] SCALE MULTIPLIER VALUE OF 0.1 - This value multiplies the

internal count by 0.1. (Effectively divides by 10.)

[45 3] SCALE MULTIPLIER VALUE OF 0.01 - This value multiplies the

internal count by 0.01. (Effectively divides by 100.)

[45 4] SCALE MULTIPLIER VALUE OF 0.001 - This value multiplies the

internal count by 0.001. (Effectively divides by 1000.)

CODE 46 - DECIMAL POINT & LEADING ZERO BLANKING

There are six basic modes of decimal point placement on the Gemini. The

decimal point is placed to the right of the display digit that corresponds to the

mode identifier.(The right most decimalpoint, digit 1,is never turned on.) A “-”

sign in front of the mode identifier will inhibit leading zero blanking. The

absence of the “-” sign will enable leading zero blanking.

[46 1] 0

[46 2] 0.0

[46 3] 0.0 0

[46 4] 0.000

[46 5] 0.0000

[46 6] 0.00000

[46 -1] 000000

[46 -2] 00000.0

[46 -3] 0000.00

[46 -4] 000.000

[46 -5] 00.0000

[46 -6] 0.00000

LEADING ZERO

BLANKING

LEADING ZERO

BLANKING INHIBITED

CODE 51 - RESET MODES

The Gemini has six different reset modes. They are: Manual Reset to Zero;

Manual Reset to Preset; Automatic Reset to Zero After Output Time Delay;

Automatic Reset to Preset after Output Time Delay; Automatic Reset to Zero at

the Beginning of the Output Time Delay; and Automatic Reset to Preset at the

Beginning of theOutput Time Delay. (Note:For the Gemini 2000,reset to preset

modes reset to preset 2 and Output refers to Output 2.) There are also two

methods by which manual reset can act on the unit (reset must be enabled). The

first is a “maintained” reset action where the unit is held at reset as long as the

reset terminal is heldlow or the front panel resetbutton is pressed. The second is a

“momentary” reset in which the unit resets when reset is activated and

immediately starts countingeventhough the terminal maystill be low or thereset

button may still be pressed. (Note: In momentary reset, the display will not

update until reset is released, but internal counting and all other functions are

operative.) A “-” sign in front of the code identifier will provide for

“momentary” reset, and theabsence ofa “-” sign will give “maintained” reset.

[51 1] MANUAL RESET TO ZERO (RTZ) - Manual reset to zero is

accomplished by pullingremote reset to ground, or if thefront panel reset

is enabled, by pressing the frontpanel resetbutton.Reset is “maintained”.

[51 2] MANUAL RESET TO PRESET (RTP) - Manual reset to preset is

accomplished by pulling reset to ground, or if the front panel reset is

enabled, by pressing the front panelreset button.Resetis“maintained”.

–9–

Page 12

CODE 51 - RESET MODES (Cont’d)

[51 3] AUTOMATIC RESET TO ZERO AFTER OUTPUT TIME DELAY -

The counter resets to zero when the output time delay ends. Manual reset

is “maintained” and will override automatic reset.

[51 4]AUTOMATIC RESET TOPRESET AFTER OUTPUT TIME DELAY -

The counter resets to the preset value when the output time delay ends.

Manual reset is “maintained” and will override automatic reset.

[51 5] AUTOMATIC RESET TO ZERO AT THE BEGINNING OF THE

OUTPUT TIME DELAY - When in this reset mode, the unit will

automatically reset to zero atthe beginningof the output time delay (when

the preset point is reached).For the Gemini 2000, the output1 and output 2

time delays must be shorter than the time required for the counter to count

to the preset 2 value. Otherwise, the output(s) will appear to be latched on.

Manual reset is “maintained” and will override automatic reset.

[51 6] AUTOMATIC RESET TO PRESET AT THE BEGINNING OF THE

OUTPUT TIME DELAY - In this reset mode, the unit will automatically

reset to preset at the beginning of the output time delay (when zero is

reached). For the Gemini 2000, the output 1 and output 2 time delay must

be shorter than the time required for the counter to count to zero.

Otherwise, the outputs will appear to be latched on. Manual reset is

“maintained” and will override automatic reset.

[51 -1]

[51 -2]

[51 -3] These modes are the same as above with the exception

[51 -4] that Reset is set for “momentary” operation.

[51 -5]

[51 -6]

CODE 52 - OUTPUT 1 TERMINATION MODES

The Gemini has six Output Termination Modes. They are: Terminate at

Output 2 Start; Terminate at Output 2 End; Terminate at Manual Reset;

Terminate at Manual Reset End; Terminate After Time Delay; and Boundary.

A Reverse Phase Option is available on the Gemini. This refers to

complementing the logic state of the output. With normal phase operation, when

the count reaches preset 1 the output will turn on. The reset condition of the

output is output off. In reverse phase operation, the output turns off when the

preset is reached. The reset condition of the output is output on. (Note: The state

of the relay, if used, is also reversed.) A “-” sign in front of the mode identifier

will provide for reverse phase operation. The absence of a “-” sign will give

normal phase operation.

In all modes except boundary, when the unit is powered up, the relays or

outputs will beturned off. This isdone to help preventa hazardous situation from

occurring. If other than boundary or time delay operation is selected, the unit

should be reset upon power up.

[52 1] TERMINATE AT OUTPUT 2 START - Output 1 will terminate when

Output 2 starts. (Gemini 2000 only)

[52 2] TERMINATE AT OUTPUT 2 END - Output 1 will terminate when

Output 2 terminates. (Gemini 2000 only)

[52 3] TERMINATE AT MANUAL RESET - In this mode, output 1, once

activated, does notdeactivate until the momenta reset occurs. The resetcan be

from the front panel button or from the remote reset terminal at the rear of the

unit. The output is set for normal phase operation.

[52 4] TERMINATE AT MANUAL RESET END - This mode is like the

preceding output mode, except output 1 deactivates when the reset ends. The

output is set for normal phase operation.

[52 5] TERMINATE AFTER OUTPUT 1 TIME DELAY - Once output 1 has

been activated, it will deactivate after the predetermined length of output 1

time delay has expired. Manual reset, by either the front panel button or the

reset terminal, will override the output 1 time delay and reset the output. The

output is set for normal phase operation.

[52 6] BOUNDARY MODE - This mode can be used when the unit is

functioning as a counter, but is more applicable to the rate indicator mode.

When in boundary mode, the preset 1 value serves as the boundary point.

When the count is less than the preset, the output is not activated (normal

phase). When the count is greater than or equal to the preset, the output is

activated. Ifthe count value were to drop belowpreset, the outputwould again

deactivate. For negative preset points, the output is not activated when the

count value is more positive than the preset value. When the count is more

negative than or equal to the preset, the output is activated. If the count

becomes more positive than the preset, the output again deactivates. Upon

power up, the output will “remember” its power down boundary condition

and go to that state. The output is set for normal phase operation.

–10–

Page 13

[52 -1]

[52 -2]

[52 -3] These modes are the same as above with the exception

[52 -4] that the output is set for reverse phase operation.

[52 -5]

[52 -6]

CODE 53 - OUTPUT 1 TIME DELAY

The Gemini hasthe capability of varying theoutput time delay from 0.01second

to 599.99 seconds. When the code is entered, instead of a single mode identifier

digit beingdisplayed, six digits will beshown. Refer tothe “Programming Preset,

Scale Factor, and Output Time Delay” section for more details about entering.

Output time delay will be terminated if the unit is manually reset.

Note: A time delay value of zero cannot be programmed into the Gemini. If a

value of 0 is entered into the display and the “E” key is pressed, the unit will not

enter the 0, but will revert back to displaying the previous time delay.

CODE 54 - OUTPUT 2 TERMINATION MODES (GEMINI 2000

Only)

The Gemini 2000 hassixOutput 2 Termination Modes. They are:Terminateat

Output 1 Start; Terminate at Output 1 End; Terminate at Manual Reset;

Terminate at Manual Reset End; Terminate After Time Delay; and Boundary.

A Reverse Phase Option is available on the Gemini 2000. This refers to

complementing the logic state of the output. With normal phase operation,when the

count reaches preset 2, output 2 will turn on. The reset condition of the output is

output off.In reverse phaseoperation,the output turnsoff when thepresetis reached.

The reset condition of the outputis outputon. (Note: The state of the relay, if used, is

also reversed.) A “-” sign in front of the mode identifier will provide for reverse

phase operation. The absence of a “-” sign will give normal phase operation.

In all modes except boundary, when the unit is powered up, the relays or

outputs will beturned off. This isdone to help preventa hazardous situation from

occurring. If other than boundary or time delay operation is selected, the unit

should be reset upon power up.

[54 1] TERMINATE AT OUTPUT 1 START - Output 2 will terminate when

Output 1 starts.

[54 2] TERMINATE AT OUTPUT 1 END - Output 2 will terminate when

Output 1 terminates.

[54 3] TERMINATE AT MANUAL RESET - In this mode, output 2, once

activated, does notdeactivate until the momenta reset occurs. The resetcan be

from the front panelbutton or from the remote reset terminal,at the rear of the

unit. The output is set for normal phase operation.

[54 4] TERMINATE AT MANUAL RESET END - This mode is like the

preceding output mode, except output 2 deactivates when the reset ends. The

output is set for normal phase operation.

[54 5] TERMINATE AFTER OUTPUT 2 TIME DELAY - Once output 2 has

been activated, it will deactivate after the predetermined length of output 2

time delay has expired. Manual reset, by either the front panel button or the

reset terminal, will override the output 2 time delay and reset the output. The

output is set for normal phase operation.

[54 6] BOUNDARY MODE - This mode can be used when the unit is

functioning as a counter, but is more applicable to the rate indicator mode.

When in boundary mode, the preset 2 value serves as the boundary point.

When the count is less than the preset, the output is not activated (normal

phase). When the count is greater than or equal to the preset, the output is

activated. Ifthe count value were to drop belowpreset, the outputwould again

deactivate. For negative preset points, the output is not activated when the

count value is more positive than the preset value. When the count is more

negative than or equal to the preset, the output is activated. If the count

becomes more positive than the preset, the output again deactivates. Upon

power up, the output will “remember” its power down boundary condition

and go to that state. The output is set for normal phase operation.

[54 -1]

[54 -2]

[54 -3] These modes are the same as above with the exception

[54 -4] that the output is set for reverse phase operation.

[54 -5]

[54 -6]

–11–

Page 14

CODE 55 - OUTPUT 2 TIME DELAY (GEMINI 2000 Only)

The Gemini 2000 has the capability of varying the output time delay from 0.01

second to 599.99 seconds. When the code is entered, instead of a single mode

identifier digitbeing displayed, sixdigits will beshown. Refer to the “Programming

Preset, Scale Factor, and Output Time Delay” section for more details about

entering. Output time delay will be terminated if the unit is manually reset.

Note: A time delayvalue of zero cannot be programmed into theGemini 2000.If a

value of 0 is entered into the display and the “E” key is pressed, the unit will

not enter the 0, but will revert back to displaying the previous time delay.

CODE 61 - RIGHT HAND DUMMY ZEROS

These zerosare used toeffectively move significantdigits to theleft. Up tothree

non-functional zeros canbe used. Therefore, a normalcountof 1 could be shownas

a 10, 100, or1000 without setting or changing anyother parameter of the system.

Note: Use ofdummy zeros or scale factorvaluesgreater than one could causethe

displayed value to overflow before a value of 999,999 (6-digits) is

accumulated. See “Overflow Indication” section for more details.

[61 1] 1 RIGHT HAND DUMMY ZERO - One is displayed.

[61 2] 2 RIGHT HAND DUMMY ZEROS - Two are displayed.

[61 3] 3 RIGHT HAND DUMMY ZEROS - Three are displayed.

[61 4] NO RIGHT HAND DUMMY ZEROS - None are displayed.

CODE 66 - “OPERATOR ACCESSIBLE FUNCTIONS” MODES

(PGM. DIS. Connected to “COMMON”)

The Gemini has four basic levels of “Operator Accessible Functions”.

However, each of these levels canbe modified to enable or disable manual reset.

When the “PGM. DIS.” (program disable) terminal is connected to

“COMMON”, access to all functions is disabled except for those listed below

which will remain enabled. All of the function codes and parameters can be

interrogated regardless of the“Operator AccessibleFunctions” mode selected.

A “-”sign in front of themode identifier will disable resetand the absence of a

“-” sign will enable the reset terminal and front panel reset button.

(Note: Front panel reset can be independently “Disabled” by using the disable

reset DIP switch.)

[66 1] NO FUNCTIONSENABLED EXCEPT RESET - In this mode, manual

reset is enabled, but none of the programming functions can be changed.

[66 2] PRESET PROGRAMMING AND RESET ENABLED - In this mode,

manual reset and the programming of the Preset Values are enabled.

[66 3] SCALE FACTOR PROGRAMMING ANDRESET ENABLED - In this

mode, manual reset and the programming of the Preset values are enabled.

[66 4] SCALE FACTOR, PRESET PROGRAMMING AND RESET

ENABLED - In this mode, manual reset and the programming of the Scale

Factor and Preset Values are enabled.

[66 -1]

[66 -2] These Modes are the same as above with the

[66 -3] exception that manual reset is disabled.

[66 -4]

PRESET VALUES

Whenever the count value equals the preset value, an output action will occur.

(This action depends on the previously programmed modes). The Preset Value may

vary from -999,999 to999,999. Refer to “Programming ThePresets, Scale Factors,

And Timed Output Values” section for instructions on entering the Preset Value.

The Scale Factor valuewillhave a direct effect on thepreset being entered. For

Scale Factors greater than one, the preset value should be an integer multiple of

the scale factor. If it is not, the Gemini will automatically adjust the preset value

up or down to force it to be evenly divisible by the scale factor.

“1” - PRESET 1 VALUE

“2” - PRESET 2 VALUE (GEMINI 2000 ONLY)

SCALE FACTOR

“3” SCALE FACTOR - The internal count value is multiplied by the scale

factor value, which changes the displayed value accordingly. This is true for all

response modes, Count with Inhibit, Count with UP/DN Control, Two Input

Anti-Coincidence and for all Quadrature Counting Modes. Scale factor is used

primarily for conversion from existing pulses per unit of measure to the required

displayed units. This includes conversion from different units of measure (i.e.

feet to meters, etc.). The scale factor value may range from -5.9999 to 5.9999.

(Refer to “Programming The Presets, Scale Factor & Output Time Delays”

section for entering instructions.)

–12–

Page 15

It is important to note that the precision of an application cannot be improved

by using a scale factor greater than one. To accomplish greater precision, more

pulse information must be generated permeasuring unit. For example,if 5 pulses

are being received per foot of material, the precision of 10th of feet cannot be

attained by simply programming a 2.000 scale factor, even though the display is

reading in tenths. In this case, the display will increment by two for each count

input. Thus, if an odd preset value was entered, such as 6.7 ft., the Gemini will

alter the preset to read in even tenths of feet.

Note: Use of a small scale factor in conjunction with a small scale multiplier

could cause the internal count value to be exceeded before the 6-digit display

value is exceeded. See “Overflow Indication” section for more details.

–13–

Page 16

DUAL PRESET COUNTING & PROGRAMMING APPLICATION EXAMPLE

A typical industrialapplicationfor Gemini 2000 will requirebotha slow down

output and a finalstop output. The Gemini can easily beprogrammed to solve this

requirement. For instance, let’s look at a textile web process that requires a dual

output asthe web progresses to the proper length. A typical lengthof material for

this application is 10,000 feet for total length, and a slow down output 500 feet

prior to the end of the 10,000 foot length. In this case, it would be best to set the

unit up as Manual Reset to Preset 2. Preset 2 would be set at 10,000, and Preset 1

would be set for 500. The counter would count down to 500, and output 1 would

activate and cause the process to slow down until 0 is reached at which point

Output 2 would activate and latch for final stop. The advantage of using manual

Reset to Preset 2 is that when changing the total length it is only necessary to

change Preset2 (length). Preset 1 (slow down) would remain the same, assuming

the same amount of slow down is required.

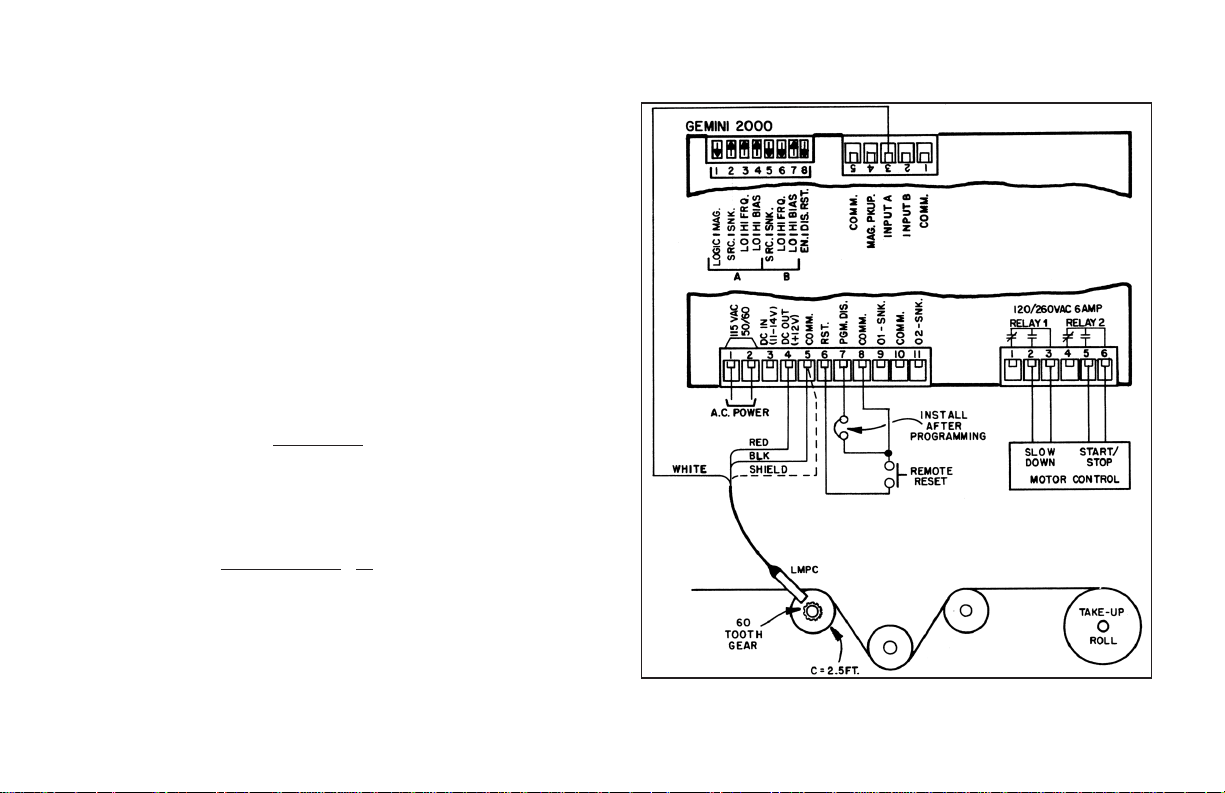

The accompanying drawing shows an LMPC sensing a 60 tooth gear which is

attached to a 2.5 ft. circumference drum. Since the unit of measure is a foot, the

first step is to find the number of pulses per foot that will be used. The following

formula is used.

Pulses/ft. = 60 pulses/rev.

2.5 ft./rev.

Since the desired readout is in feet, and there are 24 pulses per foot, it is

necessary to scale the count. To determine the multiplier that is needed, the

formula below is used.

“desired reading”=1=0.0416667

K=

“# of pulses” 24

To get the maximum amount of decimal point accuracy a scale multiplier of

0.01 (divide by 100) is used which would give us a scale factor (rounded off) of

4.1667. If we used the multiplieras the scale factor,and used ascale multiplier of

1, the scale factor would round off to 0.0417, in which case 2 decimal places of

accuracy would be lost.

= 24 pulses/ft.

–14–

Page 17

HARDWARE SET-UP

The application drawing shows how the hardware for this system is to be

connected. The Red, Black, and White wires of the LMPC are connected to the

DC OUT, COMM., and INPUT A terminals respectively. The shield of the

LMPC cable is also connected to COMM. A Remote reset button is connected

between the RST.and COMM. terminals. After theprogramming is completed, a

jumper is connected between PGM. DIS. and COMM. terminals of the Gemini

2000. This terminal, in conjunction with the “Operator Accessible Functions”

mode, will prevent accidental changes in the units operating modes. The

Normally Open contact of Relay 1 is connected to the slow down actuator, and

the Normally Open contact of Relay 2 is connected to the motor control.

DIP switch1 is set tothe LOGIC position.This allows Input Ato function asthe

count input. Switch position 2 is set to SNK. (current sinking), which provides an

internal pull-upresistor to 12 VDC.Position 3 is setto HI FRQ. becauseof the high

count speeds involved. Position 4 is set to HI BIAS for higher noise immunity.

Since theGemini 2000 willbe counting down, Input B will beused as thedirection

input which will be fixed. To count down, Input B must be held low. To do this,

switch position5 can beset in theSRC. position whichconnects a 3.9K pull-down

resistor at InputB to COMM. The positionsofswitches 6 and 7 areset, as shown, to

provide highest noise immunity. Switch position 8 is set to RST. EN. to allow the

front panel reset of the Gemini 2000 to operate.

STEP BY STEP PROGRAMMING OF THE GEMINI 2000

Refer to the programming section for instructions on programming function

codes and entering Scale factor and Presets.

STEP 1 - Select function code 41 (Unit Personality). Select and enter an

identifier of 1 if it isn’t already. This sets unit personality to a counter.

STEP 2 - Enter function code 43 (InputA&BResponse Modes), and enter a

mode identifier of 2 (A = CNT, B = UP/DN).

STEP 3 - Enter function code 44 (Number of Count Edges), and enter a 1 for

single edge counting.

STEP 4 - Enter function code 45 (Scale Multiplier Values), and enter a mode

identifier of 3 for a scale multiplier of 0.01.

STEP 5- Enter function code 46 (Decimal Point & Leading Zero Blanking), and

enter a mode identifierof 1for no decimal points with Leading ZeroBlanking.

STEP 6 - Enter function code 51 (Reset Modes), and enter a mode identifier of 2

for Manual reset to Preset 2. This mode was chosen to allow set-up time for a

new roll or take-up spool.

STEP 7- Enter function code 52(Output 1 Termination Modes), and enter a mode

identifier of 3 (Terminate at Start of Manual Reset). Output 1 is the slow down

output which once activatedshould remain so until the unitis reset for start up.

STEP 8 -Enter function code 54(Output 2 Termination Mode),and enter a mode

identifier of-3 (Terminate at start ofManual Reset, reverse phase operation).

This mode was selected so that when the system is powered up, the relay

would be in the open condition which is motor drive off. To start the process,

the Reset button is pushed which would close the Output 2 Relay (turn on

motor drive) and would stay closed until 0 is reached, at which time it would

open (turn motor drive off).

STEP 9 - Enter function code 61 (Right Hand Dummy Zeros), and enter a mode

identifier of 4 for no Right Hand Dummy zeros.

STEP 10- Press 1and then enterthe desired slowdown value (500is used inthis

application).

STEP 11 -Press 2 and enter the totallength of material to beprocessed (10,000 feet).

STEP 12 - Press 3 and enter a scale factor value of 4.1667.

STEP 13 - Enter code 66 (Operator Accessible Functions Modes) and enter a

mode identifier of 2 (Presets and Reset Enabled). When the “PGM. DIS.”

terminal is connected to “COMM.”, the only changes that will bepossible are

resetting the unit and changing the presets.

–15–

Page 18

PROGRAMMING INSTRUCTIONS FOR THE RATE INDICATOR VERSION OF THE GEMINI

The first part of this section provides detailed descriptions of the function

command codes for scale multiplier, leading zero blanking, output terminations,

etc. Then,using an actual applicationexample, the programminginstructions for

a rate indicator will be “walked through” togive the user a full understanding of

the Gemini programming procedure. The descriptions below give the Function

Command Code first, followed by the individual mode identifier. The Function

Command Code Summary in Appendix “D”, lists all codes. (Only commands

and modes pertaining to the rate indicator will be discussed in this section).

CODE 41 - UNIT PERSONALITY

Two basic personalities are available for the Gemini. They are the counter

mode and the rate indicator mode.

[41 2] RATE INDICATOR - Setting this mode selects the unit to function as a

rate indicator. This is the basic personality mode and must be programmed

before any other modes are set. (This command forces default mode values in

certain command codes.)

CODE 44 - NUMBER OF COUNT EDGES

The Gemini can be programmed for either single edge or two edge (doubling)

counting.

[44 1] SINGLE EDGE COUNTING - The unit counts on the negative going

(falling) edge of the count input signal.

[44 2] TWOEDGECOUNTING - This mode is usedwhen doubling of the count

signal input is required. The unit counts on the positive going (rising) edge of

the count input signal, as well as, the negative going (falling) edge. This

effectively doubles the resolution

of the input signal.

CODE 45 - SCALE MULTIPLIER

There arefour scale multiplier values that are available.They are: 1;0.1; 0.01;

and 0.001. They effectively divide the internal count value by 1, 10, 100, and

1000 respectively, to yield the displayed rate value.

[45 1] SCALEMULTIPLIER VALUE OF 1 -This value multiplies theinternal

rate by 1.

[45 2] SCALE MULTIPLIER VALUE OF 0.1 - This value multiplies the

internal rate by 0.1. (Effectively divides by 10.)

[45 3] SCALE MULTIPLIER VALUE OF 0.01 - This value multiplies the

internal rate by 0.01. (Effectively divides by 100.)

[45 4] SCALE MULTIPLIER VALUE OF 0.001 - This value multiplies the

internal rate by 0.001. (Effectively divides by 1000.)

CODE 46 - DECIMAL POINT & LEADING ZERO BLANKING

There are six basic modes of decimal point placement on the Gemini. The

decimal point is placed to the right of the display digit that corresponds to the

mode identifier.(The right most decimalpoint, digit 1,is never turned on.) A “-”

sign in front of the mode identifier will inhibit leading zero blanking. The

absence of the “-” sign will enable leading zero blanking.

[46 1] 0

[46 2] 0.0

[46 3] 0.0 0 LEADING ZERO

[46 4] 0.0 0 0 BLANKING

[46 5] 0.0000

[46 6] 0.00000

[46 -1] 000000

[46 -2] 00000.0

[46 -3] 0 0 0 0.0 0 LEADING ZERO

[46 -4] 0 0 0.0 0 0 BLANKING INHIBITED

[46 -5] 00.0000

[46 -6] 0.00000

CODE 51 - RESET MODES (Manual Reset to Zero)

In the majority of rate indicator applications, the settingof function code 51 is

not relevant to the desired operation of the unit, and thus need not be

programmed. TheGemini is designed to automatically update atthe end ofevery

sample time cycle, which will provide a continuous rate indication reading, as is

–16–

Page 19

the case withall standard rate indicators.In order toensure this type ofoperation,

it is important that the reset Disable/Enable switch be disabled to preclude any

unwanted re-start of the sample time cycle.

Certain special application requirements may exist for the sample time cycle to

commence at a specific time. In these applications, the remote reset terminal or the

front panel reset button (if the Disable/Enable switch is set to the enable position),

may be usedto activate the following tworeset modes, thus starting thesample time.

[51 1] MANUAL RESET TO ZERO (RTZ) - Manual reset to zero is

accomplished by pulling remote reset to ground or by pressing the front panel

reset button. In this mode the sample time is initiated immediately upon

release of the reset button.

[51 -1] MANUAL RESET TO ZERO (RTZ) - Same as [51 1] except that the

sample time is initiated immediately upon pressing the reset button.

CODE 52 - OUTPUT 1 TERMINATION MODES

The Geminihas two standard Output 1 Termination Modes whenoperating as

a rate indicator. They are: Terminate After Time Delay and Boundary.

A reverse phase option is available on the Gemini. This refers to

complementing the logicstate of the output.For normal phase operationthe reset

condition of the output is output off. For reverse phase operation the reset

condition of the output is output on. (Note: The state of the relay, if used, is also

reversed.) A “-” sign in front of the mode identifier will provide for reverse

phase operation. The absence of a “-” sign will give normal phase operation.

[52 5] TERMINATE AFTER OUTPUT 1 TIMEDELAY - In this mode, output 1

activates at the end of eachsample time in which the rate is lower than Preset 1

Once the output has been activated, it will deactivate after the predetermined

length of output 1 time delay has expired. If the output 1 time delay is longer

than thesample time, the output time delay will continually be restarted without

timing out until the rate exceeds the Preset 1 value. Manual reset, by either the

front panel button or the reset terminal, will override the output time delay and

reset the output. The output is set for normal phase operation.

[52 6] BOUNDARY MODE - When in the boundary mode, the preset 1 value

serves as the boundary point. When the rate value is more negative than the

preset, theoutput is not activated. When the rate value is more positivethan or

equal to the preset, the output activates. If the rate value were to drop below

preset, the outputwould again deactivate. For negative presetpoints(Negative

Scale Factor), the output is not activated when the rate value is more positive

than thepreset value. When the rate value is more negative thanor equal tothe

preset, theoutput is activated.If the ratevalue becomes more positive than the

preset, the output again deactivates. The output is set for normal phase.

In addition,when functioning as a rate indicator, the Geminialso has two special

use function modes, Terminate at Manual Reset and Terminate at Manual

Reset End. These modes are infrequently used. However, they may be useful

when a requirement exists to latch and manually release the output.

[52 3] TERMINATE AT MANUAL RESET - In this mode, Output 1 activates

when the rate exceeds the Preset 1 value. Once activated, the output does not

deactivate until the moment a reset occurs. The reset can be from the front

panel button or from the remote reset terminal, at the rear of the unit. The

output is set for normal phase operation.

[52 4] TERMINATE AT MANUAL RESET END - This mode is like the

preceding output mode,except the output deactivates whenthereset ends. The

output is set for normal phase operation.

[52 -3]

[52 -4] These modes are the same as above with the exception

[52 -5] that the output is set for reverse phase operation.

[52 -6]

CODE 53 - OUTPUT 1 TIME DELAY

The Gemini hasthe capability of varying theoutput time delay from 0.01second

to 599.99 seconds. When the code is entered, instead of a single mode identifier

.

digit beingdisplayed, six digits will beshown. Refer tothe “Programming Preset,

Scale Factor, and Output Time Delay” section for more details about entering.

Output time delay will be terminated if the unit is manually reset.

Note: A time delay value of zero cannot be programmed into the Gemini. If a

value of 0 is entered into the display and the “E” key is pressed, the unit will

not enter the 0, but will revert back to displaying the previous time delay.

–17–

Page 20

CODE 54 - OUTPUT 2 TERMINATION MODES (Gemini 2000 Only)

The Gemini 2000 has two standard Output 2 Termination Modes when

operating as a rateindicator. Theyare terminate After Time Delay and Boundary.

A Reverse Phase Option is available on the Gemini 2000. This refers to

complementing the logic state of the output. For normal phase operation, the

reset condition of the output is output off. For reverse phase operation, the reset

condition of the output is output on. (Note: The state of the relay, if used, is also

reversed.) A “-” sign in front of the mode identifier will provide for reverse

phase operation. The absence of a “-” sign will give normal phase operation.

[54 5] TERMINATEAFTEROUTPUT 2 TIME DELAY -In this mode, output 2

activates atthe end of eachsample time in whichthe rate is higherthan Preset 2

Once outputhas been activated,it will deactivateafter the predeterminedlength

of output 2 time delay has expired. If the output 2 time delay is longer than the

sample time, the output time delay will continually be restarted without timing

out until the rate is lower than Preset 2 value. Manual reset, by either the front

panel button or the reset terminal, will override the output time delay and reset

the output. The output is set for normal phase operation.

[54 6] BOUNDARY MODE - When in the boundary mode, the preset 2 value

serves asthe boundary point.Whenthe rate value ismorenegative than the preset,

the output is not activated. When the rate value is more positive than or equal to

the preset, the output is activated. If the rate value were to drop below preset, the

output would again deactivate. For negative preset points (Negative Scale

Factor), the output is not activated when the rate value is more positive than the

preset value. When the rate value is more negative than or equal to the preset, the

output is activated. If the rate value becomes more positive than the preset, the

output again deactivates. The output is set for normal phase operation.

In addition, when functioning as a rate indicator, the Gemini 2000 also has two

special use function modes, Terminate at Manual Reset and Terminate at

Manual Reset End. These modes areinfrequently used. However, theymay be

useful when a requirement exists to latch and manually release the output.

[54 3] TERMINATE AT MANUAL RESET - In this mode, Output 2 activates

when the rate exceeds the Preset 2 value. Once activated the output does not

deactivate until the moment a reset occurs. The reset can be from the front

panel button or from the remote reset terminal, at the rear of the unit. The

output is set for normal phase operation.

.

[54 4] TERMINATE AT MANUAL RESET END - This mode is like the

preceding output mode,except the output deactivates whenthereset ends. The

output is set for normal phase operation.

[54 -3]

[54 -4] These modes are the same as above with the exception

[54 -5] that the output is set for reverse phase operation.

[54 -6]

CODE 55 - OUTPUT 2 TIME DELAY (Gemini 2000 Only)

The Gemini 2000 has the capability of varying the output time delay from 0.01

second to 599.99 seconds. When the code is entered, instead of a single mode

identifier digitbeing displayed, sixdigits will beshown. Refer to the “Programming

Preset, Scale Factor, and Output Time Delay” section for more details about

entering. Output time delay will be terminated if the unit is manually reset.

Note: A time delayvalue of zero cannot be programmed into theGemini 2000.If a

value of 0 is entered into the display and the “E” key is pressed, the unit will

not enter the 0, but will revert back to displaying the previous time delay.

CODE 61 - RIGHT HAND DUMMY ZEROS

These zerosare used toeffectively move significantdigits to theleft. Up tothree

non-functional zeros canbe used. Therefore, a normalcountof 1 could be shownas

a 10, 100, or1000 without setting or changing anyother parameter of the system.

Note: Use ofdummy zeros or scale factorvaluesgreater than one could causethe

displayed value to overflow before a value of 999,999 (6-digits) is

accumulated. See “Overflow Indication” section for more details.

[61 1] 1 RIGHT HAND DUMMY ZERO - One is displayed.

[61 2] 2 RIGHT HAND DUMMY ZEROS - Two are displayed.

[61 3] 3 RIGHT HAND DUMMY ZEROS - Three are displayed.

[61 4] NO RIGHT HAND DUMMY ZEROS - None are displayed.

–18–

Page 21

CODE 63 - SAMPLE TIME

The Gemini offers six different lengths of sample times. They are 1 second; 2

seconds; 5seconds; 10 seconds; 20seconds; and 50 seconds.Sample Time is defined

as the time period allowed for input pulses to accumulate. At the conclusion of this

time period, the number of pulses which occur during the sample time, is multiplied

by the programmed scale factor value and then displayed. (For an explanation of

how to determine the proper sample time, refer to Appendix “E”).

[63 1] SAMPLE TIME OF 1 SECOND

[63 2] SAMPLE TIME OF 2 SECONDS

[63 3] SAMPLE TIME OF 5 SECONDS

[63 4] SAMPLE TIME OF 10 SECONDS

[63 5] SAMPLE TIME OF 20 SECONDS

[63 6] SAMPLE TIME OF 50 SECONDS

CODE 66 - “OPERATOR ACCESSIBLE FUNCTIONS”

MODES

(PGM. DIS. Connected to “COMMON”)

The Gemini has four basic levels of “Operator Accessible Functions”.

However each of these levels can be modified to enable or disable manual reset.

When the “PGM. DIS.” (program disable) terminal is connected to

“COMMON”, access to all functions is disabled except for those listed below

which will remain enabled. All of the function codes and parameters can be

interrogated, regardless of the“Operator AccessibleFunctions” mode selected.

A “-”sign in front of themode identifier will disable resetand the absence of a

“-” sign will enable the reset terminal and front panel reset button.

(Note: Front panel reset can be independently “Disabled”

reset DIP switch.)

[66 1] NO FUNCTIONS ENABLEDEXCEPT RESET-In this mode, manual

reset is enabled, but none ofthe programmingfunctionscan be changed.

[66 2] PRESET PROGRAMMING AND RESET ENABLED - In this mode,

manual reset and the programming of the Preset Values are enabled.

[66 3] SCALE FACTOR PROGRAMMING AND RESET ENABLED - In this

mode, manual reset and the programming of the Preset values are enabled.

[66 4] SCALE FACTOR, PRESET PROGRAMMING AND RESET

ENABLED - In this mode, manual reset and the programming of the Scale

Factor and Preset Values are enabled.

by using the disable

[66 -1]

[66 -2] These Modes are the same as above with the

[66 -3] exception that manual reset is disabled.

[66 -4]

PRESET VALUES

Whenever the count value equals the preset value, an output action will occur.

(This action depends on the previously programmed modes). The Preset Value may

vary from -999,999 to999,999. Refer to “Programming ThePresets, Scale Factors,

And Timed Output Values” section for instructions on entering the Preset Value.

The Scale Factor valuewillhave a direct effect on thepreset being entered. For

Scale Factors greater than one, the preset value should be an integer multiple of

the scale factor. If it is not, the Gemini will automatically adjust the preset value

up or down to force it to be evenly divisible by the scale factor.

“1” - PRESET 1 VALUE

“2” - PRESET 2 VALUE (GEMINI 2000 ONLY)

SCALE FACTOR

“3” SCALE FACTOR - The internal count value is multiplied by the scale

factor value,which changes the displayed value accordingly. Scale factor is used

primarily for conversion from existing pulses per unit of measure to the required

displayed units. This includes conversion from different units of measure (i.e.

feet to meters, etc.). The scale factor value may range from -5.9999 to 5.9999.

(Refer to “Programming The Presets, Scale Factor & Output Time Delays”

section for entering instructions.)

It is important to note that the precision of an application cannot be improved

by using a scale factor greater than one. To accomplish greater precision, more

pulse information must be generated permeasuring unit. For example,if 5 pulses

are being received per foot of material, the precision of 10th of feet cannot be

attained by simply programming a 2.000 scale factor, even though the display is

reading in tenths. In this case, the display will increment by two for each count

input. Thus, if an odd preset value was entered, such as 6.7 ft., the Gemini will

alter the preset to read in even tenths of feet.

–19–

Page 22

DUAL PRESET RATE PROGRAMMING APPLICATION EXAMPLE

A typical industrial Dual preset rate indicator application would be the

speed control of a web press operation in a newspaper plant. The Gemini

2000 as pictured, is programmed to read out in feet/min. every two seconds.

The input is from the rotary pulse generator thatis attached on the drive roll.

In this case, the RPG is delivering 120 pulses/rev. and the circumference of

the rollis 6.35 ft. By substituting in our formulas as shown in Appendix “E”,

the correct parameters are determined.

FORMULA [A]

FORMULA [B]

SCALE FACTOR

By programming a 1.5875 Scale Factor and a 2-second sample time, the

Gemini 2000 will display the FPM of the roll every 2 seconds. If added

resolution is desired, the number of count edges could be changed to 2, and

the scale factor would become 0.7938.

The drive mechanism of the roll will react to a contact closure to increase

or decrease speed at a set rate for the duration of the closure. The 2-second

sample time with a 0.5 second closure (Time delay) at the beginning of each

sample time, will allow the web process to remain within the lower and

upper tolerances. In this application, the lower speed limit is 500 FPM and

the upper limit is 700 FPM. When time delay output termination modes are

used in the Gemini 2000, Output 1 activates when the rate is lower than

Preset 1 and Output 2 activates when the rate is higher than Preset 2. With

this in mind, Output 1 is connected to the speed increase drive and set to the

lower limit andOutput 2 is set tothe upper limit of thespeed range. When the

rate drops below 500 FPM for the 2-second sample time, Output 1 will

activate for0.5 seconds. Conversely, when the rate exceeds700 FPM forthe

2-second sample time, Output 2 will activate for 0.5 seconds.

PPS

RPM x PPR=1 x 120=2 PPS

=

60 sec. 60

DESIRED READING=6.35=1.5875

=

PPS x SAMPLE TIME 2x2

–20–

Page 23

HARDWARE SET-UP

The application drawing shows how the hardware for this system is to be

connected. The Red (supply), Black (Common), and White (signal) leads of the

RPG Cable are connected to the “DC OUT”, “COMM.”, and “INPUT A”

terminals respectively. The shield of the cable is connected to “COMM.”. The

normally open contact of Relay 1 is connected to the “Speed Increase Control”

and the normally open contact of Relay 2 is connected to the “Speed Reduction

Control”.A“Start” button isused to start upthe system and getit “up to speed”,

at which point the Gemini 2000 can take over and control the speed. After

programming is completed, a jumper is placed between the “COMM.” and

“PGM. DIS.” terminals of the unit. This terminal, working in conjunction with

the “Operator Accessible Functions” mode, will prevent accidental changes in

the unit’s operating modes.

The Input DIP Switch position 1 is set to the LOGIC position since an RPG is

being utilized. Position 2 is set to “SNK.”, which provides an internal pull-up

resistor to +12 VDC. (The RPGB has an open collector sinking output.) Position

3 is set to“HI FRQ.” since the input rate will be over 100 cps. Position 4 is set to

“HI BIAS” to provide higher noise immunity. Because Input B is not used, the

settings of Positions 5-7 are all selected as shown to provide maximum noise

immunity. Position 8 is set to “DIS.RST.” to disable the frontpanel reset button.

For more detailed descriptions of the Input switch set-up, see Appendix “A”.

STEP BY STEP PROGRAMMING OF THE GEMINI 2000

The steps for programming the Gemini should be followed in this order each

time a change is made ina basic parameter ofthe system. (The preset value, scale

factor value and output time delay value can be changed at any time or in any

sequence, provided the unit is already operating in a valid mode, and an

“Operator Accessible Functions” mode is not preventing this change.)

Refer to the programming section, for instructions in programming function

codes and entering Scale Factor and Preset Values.

STEP 1 - Enter code 41 (Unit Personality), and a mode identifier of 2 for a rate

indicator unit personality.

STEP 2 - Enter code 44 (Number of Count Edges), and enter 1 for single edge

counting.

STEP 3 - Enter code 45(Scale Multiplier Values), and enter a mode identifier of

1 for a scale multiplier of 1.

STEP 4 - Enter code 46 (Decimal Point and Leading Zero Blanking) and enter 1

for no decimal points and lead zero blanking.

STEP 5 - Enter code 52(Output 1 Termination Modes) and enter 5for time delay

operation.

STEP 6 - Enter code 53 (Output 1 Time Delay) and enter a time delay value of

0000.50.

STEP 7 - Enter code 54 (Output 2 Termination Modes) and enter a mode

identifier of 5 for time delay operation.

STEP 8 - Enter code 55 (Output 2 Time Delay) and enter a time delay value of

0000.50.

STEP 9 - Enter code 61 (Right-Hand Dummy Zeros) and enter an identifier of 4

for no right-hand dummy zeros.

STEP 10 - Enter code 63 (Sample Time) and enter a mode identifier of 2 for a 2

second sample time.

STEP 11 -Press “1”. Enter the lowerspeed limit for Preset 1which is 000500 for

this application.

STEP 12 - Press “2”. Enter the upper speed limit for Preset 2, which is 000700

for this application.

STEP 13 - Press“3”. Enterthe Scale factor for this application whichis 1.5875.

STEP 14 -Enter code 66 (“Operator AccessibleFunctions”mode) and enter a -1

for all Operator Functions disabled. For this application the Scale Factor and

speed limits are fixed and do not require changing. Also there is no need to

reset the Sample time so Reset is locked out. (Note: After this code is

programmed, the “PGM. DIS.” terminal is connected to “COMM.” to

prevent any accidental changes.)

–21–

Page 24

GEMINI 2000 20 mA CURRENT LOOP COMMUNICATIONS

The Gemini 2000 20 mA Current Loop Communications Option allows a

“two-way” serial communications link to be established in order to monitor or

change the count value, Presets and Scale Factor from a remote location. Some

typical devicesthat can be connectedwith the Gemini 2000are: a printer,terminal,

programmable controller, or host computer. For devices that use RS232, a

GCM232 SerialConverter Module is available to convert the20 mA CurrentLoop

signals to RS232 and vice-versa.

There are two loops that must be established. One for sending commands to the

Gemini 2000 and one for receiving the data values from the Gemini 2000. Up to

sixteen Geminis or other RLC units with 20 mA serial communication capability,

can be connectedtogether in the “loop” ifa24 V external current sourceis utilized.

A maximum of seven units can be installed in the loop if the Gemini’s 20 mA

current source is used. The units are assigned addresses by setting the Serial DIP

Switches on each unit. The applications can be as simple as attaching a printer to

obtain hardcopy of the displayinformation or as involvedas using a hostcomputer

to automatically set up Presets and Scale Factors on a number of Geminis.

With the Communications Option,the followingfunctions can be performed:

1. Interrogation of the Count Value, Presets, and Scale Factor.

2. Changing of the Presets and Scale Factor.

3. Resetting of the Count Value and Outputs.

4. Automatic print-out whenusing aprinter and the “Print Request” Terminal.

COMMUNICATION FORMAT

Data is sentby switching off and on thecurrentin the 20 mA currentloop.Data

is receivedby monitoring theswitching action andinterpreting the codesthat are

transmitted. In order for data to be interpreted correctly, there must be identical

formats and Baud Rates.

The format that the Gemini 2000 will acceptis: 1 start bit, 7 data bits, 1 odd parity

bit, and 1stop bit. The Baud Ratesthat are available are: 300,600, 1200 and 2400.

The selection of the Baud Rate is done by setting DIP switches. Refer to the

“Current Loop Installation” section, for set-up instructions.

FIG. 1: DATA FORMAT-10 BIT FRAME [300, 600, 1200, 2400 Baud]

SENDING COMMANDS & DATA TO THE GEMINI 2000

When sending commands to the Gemini 2000, a command string must be

constructed. The command string may consist of command codes, value

identifiers, and numerical data. Following is a list of commands and value

identifiers that are used when communicating with the Gemini 2000.

COMMAND DESCRIPTION

N (4EH) Address command; followed by a one or 2 digit unit address

P (50H) Transmit per Print Options command.

R (52H) Reset command

T (54H) Transmit Value command; followed by a value identifier