Page 1

IDEAL FOR PORTABLE, MOBILE, OR STATIONARY INDUSTRIAL

APPLICATIONS

AVAILABLE IN TWO VERSIONS:

FRONT PANEL RESET OR REMOTE RESET

LOW COST/HIGH PERFORMANCE

OPERATES FROM SWITCH CONTACT OR NPN OPEN

COLLECTOR INPUTS

PROVIDES YEARS OF SILENT OPERATION WITHOUT

MECHANICAL WEAR

SELF POWERED, 2-WIRE CONNECTION, ELIMINATES

POWER WIRING

EASY SNAP-IN MOUNTING IN 1" X 2" (25 mm x 50 mm)

PANEL OPENING

MODEL CUB 3 & CUB3R - GENERAL PURPOSE, MINIATURE ELECTRONIC COUNTERS

ECONOMICAL REPLACEMENT FOR ELECTRO-MECHANICAL COUNTERS

DESCRIPTION

The CUB3s are miniature electronic counters. The CUB3 has front panel

reset, while the CUB3R has remote reset. These units fill a wide variety of

applications.

The CUB3s feature a rugged reinforced nylon case that snap-fits into a

standard rectangular opening without screws or other hardware. Hook-up is

simply a matter of connecting two wires, and since the operating voltage is only

3 V and with currents in microamps, almost any kind of wire can be used. No

external power is required since the internal batteries provide years of

uninterruptible service. In addition to these advantages, the CUB 3’s offer the

inherent ruggedness, reliability, and permanence of completely integrated

circuitry, embedded in a single monolithic, silicon, micro-chip.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

SPECIFICATIONS

1. DISPLAY: 6-Digit, LCD, 0.2" (5.1 mm) High.

2. POWER: 3 Volts supplied by 2 replaceable Alkaline “N” Cells. Nominal

battery life 4 years. Battery life is dependent upon usage. Count and reset

contacts that remain closed for long periods of time reduce battery life.

3. RESET:

CUB 3 - Via front panel reset button only.

CUB 3R - (Remote Reset Only) Switch Contact or Solid State Transistor

Switch (See Connections). Contact burden 14 µA; Max. OFF-State

leakage current must be less than 2 µA. Counter resets with negative pulse

with a min. pulse width of 5 msec.

4. COUNT INPUT: Switch Contact or Solid-State Transistor Switch (See

Connections). Contact burden 14 µA; Max. OFF-State leakage current must

be less than 2 µA. Counter increments on negative going edge of input.

5. COUNT SPEED: 100 counts/sec (6000 counts/min). Min. input pulse width

5 msec, with 5 msec spacing between count pulses.

6. ENVIRONMENTALCONDITIONS:

Operating Temperature: -30° to +75°C

Storage Temperature: -40° to +80°C

Vibration According to IEC 68-2-6: Operational 5 to 500 Hz, in X, Y, Z

direction for 1.5 hours, 5g’s.

Shock According to IEC 68-2-27: Operational 30 g, 11 msec in 3 directions.

Operating and Storage Humidity: 85% max. relative humidity (non-

condensing) from 0°C to 50°C.

Altitude: Up to 2000 meters

7. CERTIFICA TIONS AND COMPLIANCES:

SAFETY

IEC 1010-1, EN 61010-1: Safety requirements for electrical equipment for

measurement, control, and laboratory use, Part 1.

ELECTROMAGNETIC COMPATIBILITY

Note:

Refer to the EMC Installation Guidelines section of this bulletin for additional

information.

8. CONSTRUCTION: Installation Category I, Pollution Degree 2

9. WEIGHT: 3 oz. (85 g) [Less Batteries]

Level 3; 10 V/mENV 50204

200 Hz, 50% duty cycle

900 MHz, ±5 MHz

Immunity to EN 50082-2

Electrostatic discharge EN 61000-4-2 Level 2; 4 Kv contact

Emissions to EN 50081-2

Level 3; 8 Kv air

Electromagnetic RF fields EN 61000-4-3 Level 3; 10 V/m

80 MHz - 1 GHz

Fast transients (burst) EN 61000-4-4 Level 4; 2 Kv I/O

Level 3; 2 Kv power

RF conducted interference EN 61000-4-6 Level 3; 10 V/rms

150 KHz - 80 MHz

Power frequency magnetic fields EN 61000-4-8 Level 4; 30 A/m

RF interference EN 55011 Enclosure class A

Power mains class A

CAUTION: Read complete instructions prior to

installation and operation of the unit.

ORDERING INFORMATION

Bulletin No. CUB3/R-F

Drawing No. LP0126

Released 02/09

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

Simulation of cordless telephones

BNA00001

Note: Batteries not supplied with counter, order separately.

1.5 V Alkaline “N” Cells (2 Req’d)BNA

CUB3R000CUB3 (Remote Reset Only)CUB3R

CUB30000CUB3 (Front Panel Reset Only)CUB3

PART NUMBERSDESCRIPTIONMODEL NO.

Page 2

Installation Environment

The unit should be installed in a location that does not exceed the maximum

operating temperature and provides good air circulation. Placing the unit near

devices that generate excessive heat should be avoided.

The bezel should be cleaned only with a soft cloth and neutral soap product.

Do NOT use solvents. Continuous exposure to direct sunlight may accelerate

the aging process of the bezel.

Do not use tools of any kind (screwdrivers, pens, pencils, etc.) to operate the

keypad of the unit.

EMC INSTALLATION GUIDELINES

Although this unit is designed with a high degree of immunity to

ElectroMagnetic Interference (EMI), proper installation and wiring methods

must be followed to ensure compatibility in each application. The type of the

electrical noise, source or coupling method into the unit may be different for

various installations. Listed below are some additional EMC guidelines for

successful installation in an industrial environment.

1. Use shielded (screened) cables for all Signal and Control inputs. The shield

(screen) pigtail connection should be made as short as possible. The

connection point for the shield depends somewhat upon the application.

Listed below are the recommended methods of connecting the shield, in

order of their effectiveness.

a. Connect the shield only at the panel where the unit is mounted to earth

ground (protective earth).

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is above 1 MHz.

c. Connect the shield to common of the unit and leave the other end of the

shield unconnected and insulated from earth ground.

2. Never run Signal or Control cables in the same conduit or raceway with AC

power lines, conductors feeding motors, solenoids, SCR controls, and

heaters, etc. The cables should be run in metal conduit that is properly

grounded. This is especially useful in applications where cable runs are long

and portable two-way radios are used in close proximity or if the installation

is near a commercial radio transmitter.

3. Signal or Control cables within an enclosure should be routed as far away as

possible from contactors, control relays, transformers, and other noisy

components.

4. In extremely high EMI environments, the use of external EMI suppression

devices, such as ferrite suppression cores, is effective. Install them on Signal

and Control cables as close to the unit as possible. Loop the cable through the

core several times or use multiple cores on each cable for additional protection.

The following EMI suppression devices (or equivalent) are recommended:

Ferrite Suppression Cores for signal and control cables:

Fair-Rite # 0443167251 (RLC #FCOR0000)

TDK # ZCAT3035-1330A

Steward #28B2029-0A0

5. Long cable runs are more susceptible to EMI pickup than short cable runs.

Therefore, keep cable runs as short as possible.

ELECTRICAL CONNECTIONS & COUNT INPUTS

The CUB 3s can be supplied with count input signals from mechanical

switch contacts or solid-state switches (NPN or PNP transistors) as shown in

the diagrams below. Reed switches, mercury-wetted contacts, snap-action limit

switches, and silver alloy contacts with wiping action are usually satisfactory

choices for mechanical switch input. Heavy “clapper-type” contacts such as

used in contactors or large machine tool relays, tungsten contacts, or brush type

contacts are not recommended as count input devices.

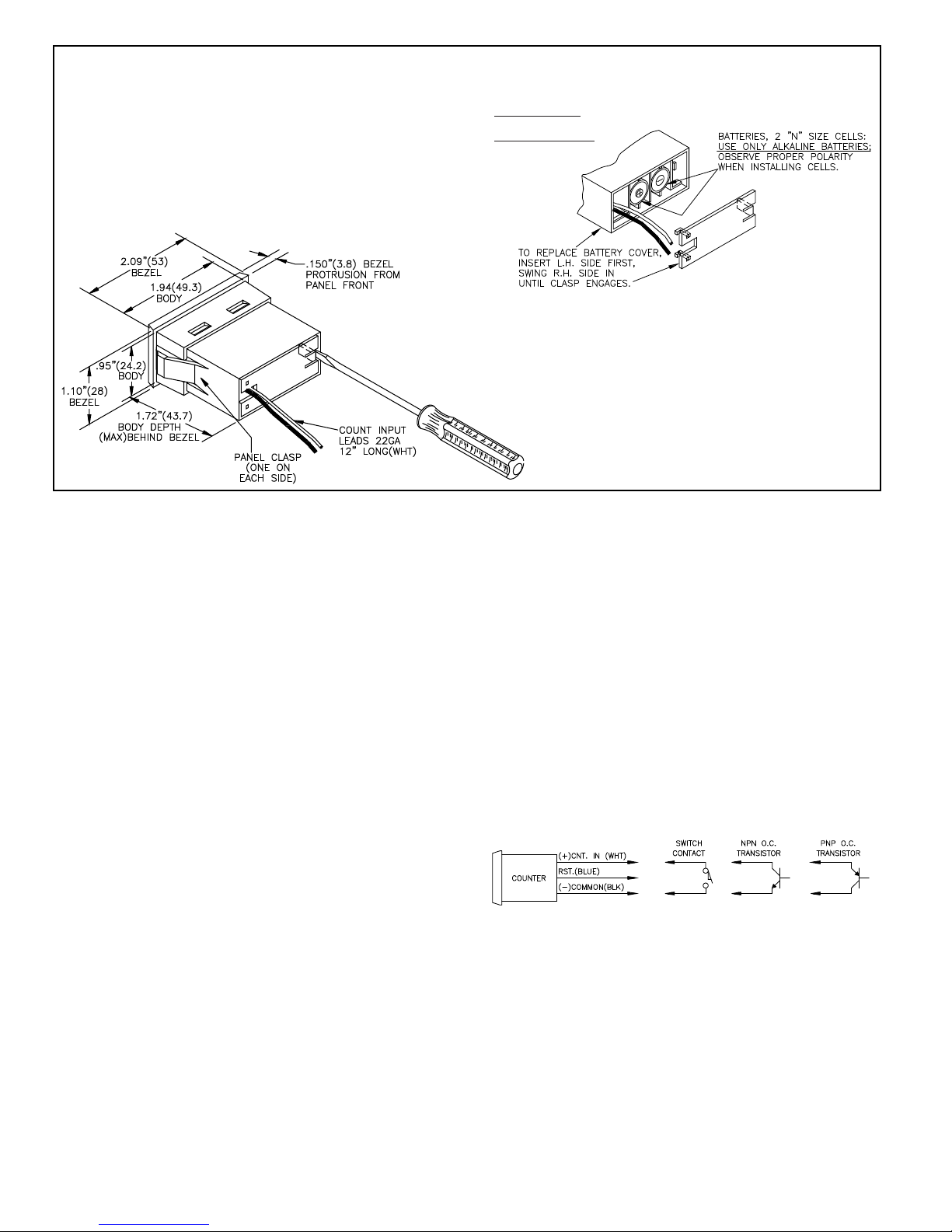

DIMENSIONS In inches (mm), INSTALLATION & BATTERY INSERTION

TO REMOVE REAR BATTERY COVER

INSERT BLADE OF SMALLSCREWDRIVER

IN R.H. OPENING AND SWING HANDLE

SLIGHTLYTO THE RIGHT TO DEFLECT

INTERNAL CLASP. RIGHT HAND SIDE OF

COVER WILL NOW SWING OUT.

P

ANEL

CUT

-OUT

1" x 2" or 25 MM x 50 MM

P

ANEL THICKNESS

0.05" to 0.125"

TROUBLESHOOTING

For further technical assistance, contact technical support at the appropriate company

numbers listed.

Red Lion Controls

Headquarters

20 Willow Springs Circle

York PA 17406

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

Red Lion Controls

China

Unit 101, XinAn Plaza

Building 13, No.99 Tianzhou Road

ShangHai, P.R. China 200223

Tel +86 21 6113-3688

Fax +86 21 6113-3683

Red Lion Controls

Europe

Printerweg 10

NL - 3821 AD Amersfoort

Tel +31 (0) 334 723 225

Fax +31 (0) 334 893 793

Red Lion Controls

India

54, Vishvas Tenement

GST Road, New Ranip,

Ahmedabad-382480 Gujarat, India

Tel +91 987 954 0503

Fax +91 79 275 31 350

Loading...

Loading...