Bulletin No. CUB1/2-K

Drawing No. LP0001

Released 07/14

MODELS CUB 1 & CUB 2 - MINIATURE ELECTRONIC 6-DIGIT COUNTER

CUB 1 MINIATURE

ELECTRONIC COUNTER

CUB 2 GENERAL PURPOSE

INDUSTRIAL COUNTER

GENERAL DESCRIPTION

SELF POWERED

Self-Contained batteries eliminate the need for external power and prevent

loss of count if power fails. Also provides for remote or portable applications.

Battery operation also means elimination of shock hazard and allows the use of

2-conductor bell wire for count signals and micro-power input signals.

Batteries are easily replaceable (2 “N” Cells, alkaline) and average battery

life is four years.

FLEXIBILITY

Various count inputs allow use with switch contacts or high speed pulse

outputs from electronic sensors and circuits. The reset function can be disabled,

set up for front panel reset, remote reset, or both.

NO-WEAR, NO-NOISE

The CUB’s micro-circuits can accurately and silently accumulate enough

counts in one hour to completely wear out an ordinary E.M. counter. More over,

it can repeat this performance many times with just one set of batteries.

RELIABILITY

Internal “micro-assembly” construction withstands many times the “g” force

of shock and vibration compared to conventional construction.

CUB counters also feature elastomeric contacts. This eliminates long term

problems associated with contact corrosion.

Battery operation, a high degree of input filtering, plus an inherent common

mode rejection ratio of more than 120 dB @ 50/60 Hz, provides ultra-high

immunity from electrical noise interference.

ACCEPTS HIGH SPEED PULSES FROM TTL, CMOS, OR OTHER

ELECTRONIC SOURCES

PRICED LESS THAN EQUIVALENT

E.M.[ELECTRO-MECHANICAL] COUNTERS

RUGGED CONSTRUCTION

SPECIFICATIONS

1. DISPLAY: 6-digit LCD

CUB 1: 0.2" (5 mm) high

CUB 2: 0.35" (9 mm) high

2. POWER SOURCE: No external power required. Operates from 2 “N” type

alkaline batteries (supplied separately). Battery life up to 4 years. (See Note

below.)

3. COUNT & RESET INPUT SIGNALS: Adapts to Count-Switch Contact

Signals, Open-Collector Transistor Outputs, and Bi-Polar Drive Outputs as

shown in the diagrams on the following page. Counter increments and resets

on negative going (pull down) transition of count or reset signal.

4. ENVIRONMENTAL CONDITIONS:

Storage Temperature Range: -20° to 60°C (-4° to 140°F)

Operating Temperature Range: 0° to 50°C (32° to 122°F)

Vibration to IEC 68-2-6: Operational 5 to 500 Hz, 5 g.

Shock to IEC 68-2-27: Operational 30 g.

5. COUNT SPEED: Up to 50 Hz with switch contact input (counters have

internal de-bounce circuits) or up to 5 KHz with solid-state electronic input

(See diagrams on following page).

6. CONSTRUCTION: Rugged die-cast metal case with clear viewing window.

The sealed front panel meets NEMA 4X/IP65 requirements when properly

installed. Panel gasket and mounting clips included.

7. WEIGHT:

CUB 1: 4.0 oz (113.4 g)

CUB 2: 5.2 oz (147.4 g)

Note: When using switch contacts for count input or remote reset, normally

open contact circuits are recommended. Switch contacts that remain

normally-closed and are opened only briefly to signal a count, can reduce

battery life to somewhat less than 4 years.

USE CUB COUNTERS WITH:

VCM • VOLTAGE CONVERTER MODULES for isolated, A.C., control voltage count inputs to 270 VAC,

LCM • LOGIC CONVERTER MODULES for interface with standard logic voltages & outputs

1

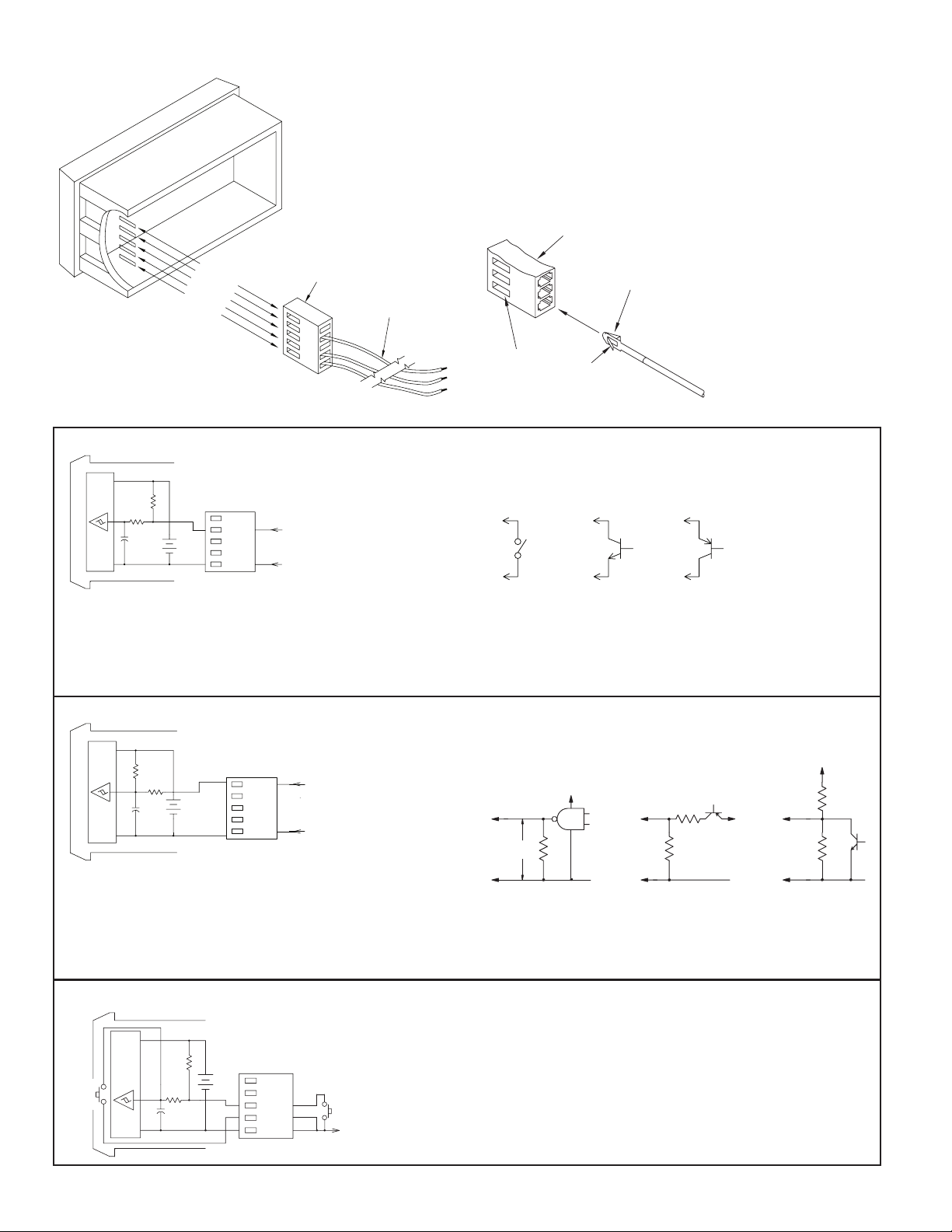

APPLICATION FLEXIBILITY VIA RECONNECT OPTIONS

COMMON

COMMON

COMMON

SWITCH

NPN

PNP

Selection of desired operating modes is easily done by adding or moving

terminal leads in the Input Connector Body. The connector body is polarized to

prevent incorrect insertion, and locked in place by the battery cover to avoid

accidental disengagement. Connectors are supplied with the 3 leads installed as

shown below. A spare blue lead is supplied in the hardware pack.

TO REMOVE TERMINAL, insert blade of a small screwdriver into slot of

connector body, and gently push in to disengage lock pawl. Pull terminal out.

WHEN INSERTING TERMINAL into connector body, make sure the lock

pawl is toward the slot in the body. Push terminal in until lock pawl snaps

into slot.

CONNECTOR

BODY

H.S. CNT.

L.S. CNT.

REM. RST.

RST. EN.

COMMON

CONNECTOR

BODY

WHT

YELL

BLK

22GA STANDARD

WIRE 10" LONG

LOCK PAWL

ENGAGES IN SLOT

CONNECTOR

TERMINAL

LOW SPEED COUNT INPUT, 50 Hz MAX. [For 250 Hz see note in text]

+3V

µ

CHIP

COMM.

CONTACT

INPUT

300K

1M

C

4700pf

BATT.

3.0V

H.S. CNT.

L.S. CNT.

REM. RST.

RST. EN.

COMMON

WHT

BLK

L.S. CNT.

O.C. TRANSISTOR

OR (N) FET

INPUT

L.S. CNT.

O.C. TRANSISTOR

OR (P) FET

INPUT

L.S. CNT.

Pulling the L.S. CNT. Input to Common with a mechanical or solid-state

switch increments the counter. The low pass filter (1meg resistor and 4700

pf cap) used with a Schmidt trigger circuit debounces mechanical switch

signals. The switch load is 14 µA (max. voltage drop 0.5 V) when ON. OFF-

state leakage current must be less than 2 µA.

HIGH SPEED COUNT INPUT, 5 KHz MAX.

+3V

µ

CHIP

COMM.

1.3M

10K

C

4700pf

BATT.

3.0V

H.S. CNT.

L.S. CNT.

REM. RST.

RST. EN.

COMMON

WHT

BLK

Moving the white wire to the H.S. CNT. Input allows the CUB Counter to

operate at speeds up to 5 KHz when driven by bi-polar outputs or external

circuits having an output impedance of 3.3 KΩ or less. Input drive voltage

must be limited to 3.0 V maximum to avoid a charging current into the

batteries which can cause premature battery failure or leakage. CMOS and

TTL Logic outputs can be loaded with a resistor (Rl) to limit drive voltage,

or a voltage divider can be used as shown for the PNP O.C. Transistor output.

RESET OPTIONS

+3V

FRONT

PANEL

RESET

COMM.

CHIP

µ

220K

BATT.

H.S. CNT.

3.0V

1M

R

4700pf

L.S. CNT.

REM. RST.

RST. EN.

COMMON

BLUE

YEL

BLK

REMOTE

RESET

TO COUNT

SIGNAL

COMMON

Reed switches, mercury wetted contacts, snap action limit switches, and

silver alloy relay contacts with wiping action are usually satisfactory for

generating count input signals. Motor starter contacts, tungsten contacts, and

brush-type contacts should NOT be used.

Note: By parallel connecting both H.S. CNT. and L.S. CNT. inputs, count

speed can be increased to 250 Hz if de-bounce is not needed.

TTL OR CMOS PNP O.C. TRANSISTOR NPN

OUTPUT OR BI-POLAR OUTPUT O.C. TRANSISTOR

+V

H.S. CNT

COM

3.0 V

MAX.

R

SEE

TEXT

+5 VDC

L

H.S. CNT

COM

3.3 K

R

H.S. CNT

+V

COM

R

3.3 K

INPUT PULSE EXCURSION LIMITS

Vin (High) = +2.7 V min. +3.3 V max.

Vil (Low) = +0.5 V max.

Connecting the RST. EN. (Reset Enable) Input to Common activates the

front panel Reset button. When the front panel Reset button is to be

de-activated, remove the yellow wire from the RST. EN. Input.

When Remote Reset is required, the blue wire in the hardware pack is

inserted in the REM. RST. Input. Pulling this input low causes the counter to

reset. The REM. RST. can be pulled low by either a mechanical switch or

solid-state transistor switch. Switch load and leakage are the same as for L.S.

CNT. Input above.

Note: The RC protection circuit on the REM. RST. Input causes a delay of

approximately 6 msec in Reset response.

2

DIMENSIONS, INSTALLATION, & BATTERY INSERTION

.26"

MOUNTING

1.415"

After cutting opening in panel, slide the panel gasket over the rear of the

counter body to the back of the bezel. Then slide counter through the panel cutout. Install mounting clips on each side of counter body with mounting screws.

the counter body so that the “Tang Ends” or “Tabs” wedge between the panel

opening and body as the screws are tightened.

Make sure the side rails or tabs of the clips fit into the recesses in the side of

CUB 1

(6.6)

EXISTING PANEL

.05" TO .20" THICK

(1.3 TO 5.1 mm THICK)

PANEL CUT OUT

.87"X 1.77"

(22.2 X 45mm)

MOUNTING

CLIPS

TAB

SCREWS

(36)

.945"

(24)

1.89"

(48)

UPPER

CLASP

LOWER

CLASP

1.81"

(46)

GASKET

.032"(0.8)

THICK

BATTERY

COVER

TAB

DIMENSIONS In inches (mm)

BATTERY COVER REMOVAL & BATTERY INSERTION

CUB 1

The battery cover is held in place by upper and lower clasps that capture

mating lock ramps on the cover. To remove, insert thumbnail and index finger

nail in the gaps between the upper and lower clasps and the battery cover, and

deflect the clasps slightly to clear the edges of the ramps while pulling out on

the cover. To replace cover, simply push into place until both clasps snap into

engagement with lock ramps.

CAUTION: Do not deflect clasps more than necessary to clear lock ramps.

Excessive deflection can cause clasps to break off.

CUB 2

2.835"

(72)

BATTERY

COVER

GASKET

.032"(0.8)THICK

.325"

(8.3)

SLIDE

TO OPEN

0.95"

(24.1)

TANG

ENDS

EXISTING PANEL

.05" TO .20" THICK

(1.3 TO 5.1mm THICK)

PANEL CUT-OUT

1.3"X 2.65"

(33X 67.3mm)

MOUNTING

CLIPS

MOUNTING

SCREWS

CUB 2

Slide battery cover to the left until the right hand lip disengages and pops

out. To reinstall cover, insert left hand lips into case first, push cover to the left

until right hand lip drops down and cover snaps back into place. Install

batteries as shown below observing proper polarity.

Note: Push battery spring clips to the left (toward connector) to completely

free the batteries when removing or installing batteries. Conductive

rubber battery contacts can be torn from their retaining pins if batteries

are forced in.

BATTERIES SHOWN IN

+

INPUT CONNECTOR

-

PLACE: CENTER (+)

OUT, RIGHT (-) OUT.

ELECTRICAL CONNECTIONS

There are certain considerations that shoud be observed when running the

count and control signal wires. A length of wire can act like an antenna and the

closer it is to a source of electrical noise, the more it becomes susceptible to

that noise.

There are a few rules that should be followed when running these wires.

1. Never run count or control signal wires in the same conduit or raceway with

AC power lines, conductors that feed motors, solenoids, SCR controls,

heaters, etc.

ORDERING INFORMATION

MODEL NO. PART NUMBERS

CUB 1 CUB 1 Miniature Electronic Counter CUB10000

CUB 2 CUB20000

BNA BNA00001

HWK 1 CUB 1 Spare Hardware Kit (Note 2) HWK10000

HWK 2 CUB 2 Spare Hardware Kit (Note 2) HWK20000

For more information on Pricing, Enclosures & Panel Mount Kits refer to the RLC

Catalog or contact your local RLC distributor.

DESCRIPTION

CUB 2 Gen. Purpose Industrial Electronic Counter

“N” Type Alkaline Batteries (Note 1)

ICA ICA00000

Spare Input Connector & Terminal Wires (Note 3)

PUSH CONTACT SPRINGS

-

BATTERY

+

BATTERY

+

-

TOWARD CONNECTOR TO ALLOW

BATTERIES TO DROP IN FREELY.

DO NOT PUSH OR FORCE

BATTERIES INTO PLACE.

2. Signal wires within enclosures should be routed as far away as possible from

contactors, control relays, transformers, and other noisy components.

3. When shielded wire is used, connect the shield to the common of the CUB

unit, and leave the other end of the shield disconnected and insulated from

machine ground.

4. Mount the CUB in a panel that is grounded to the machine frame.

5. When using accessory devices such as LCMs or PSMs into the H.S. CNT.

Input, the accessory devices should be mounted near the CUB Counter.

NOTES

1. Batteries NOT supplied with counters, order separately.

2 required per unit.

2. Counters supplied with required hardware. Includes 2 mounting

clips & screws, panel gasket, 2-wire nuts & blue terminal wire.

3. Counters supplied with connector body & white, yellow, & black

wires. Kit ICA includes connector body & one each of black,

white, blue, & yellow terminal wires.

3

The Company warrants the products it manufactures against defects in materials and workmanship

LIMITED WARRANTY

for a period limited to two years from the date of shipment, provided the products have been stored,

handled, installed, and used under proper conditions. The Company’s liability under this limited

warranty shall extend only to the repair or replacement of a defective product, at The Company’s

option. The Company disclaims all liability for any affirmation, promise or representation with

respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against

damages, claims, and expenses arising out of subsequent sales of RLC products or products

containing components manufactured by RLC and based upon personal injuries, deaths, property

damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be

to any extent liable, including without limitation penalties imposed by the Consumer Product Safety

Act (P.L. 92-573) and liability imposed upon any person pursuant to the Magnuson-Moss Warranty

Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except

those expressly contained herein. The Customer acknowledges the disclaimers and limitations

contained herein and relies on no other warranties or affirmations.

Loading...

Loading...