Page 1

z UNIVERSAL OUTPUT

z SELF-POWERED

z EASILY ADJUSTABLE SETPOINT

z FIXED OR SPLIT-CORE CASE

GENERAL DESCRIPTION

CTS Series Transducers are self-powered, solid-state current-operated

switches that trigger when the current level sensed through the aperature

exceeds the adjusted setpoint. The solid state output contacts can switch AC or

DC; this “universal” output makes them well suited for application in

automation systems.

CTS Series Current Operated Switches combine a current transformer, signal

conditioner and limit alarm into a single package for use in status monitoring or

proof of operation applications. Offering an extended setpoint range of 1-150 A

and universal, solid-state outputs, the self-powered CTS can be tailored to

provide accurate and dependable digital indication of over-current conditions

across a broad range of applications. Available in solid-core enclosure styles or

in a split-core case to maximize ease of installation.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

literature or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Do not use this unit to directly command motors, valves, or other actuators

not equipped with safeguards. To do so, can be potentially harmful to persons or

equipment in the event of a fault to the unit.

SPECIFICATIONS

1. POWER SUPPLY: None - self powered

2. OUTPUT: Magnetically isolated normally open solid-state switch

3. OUTPUT RATING: 0.15A, 240 VAC/VDC

4. OFF STATE LEAKAGE: <10 μA

5. RESPONSE TIME: 120 msec

6. HYSTERESIS: Approx 5% of Setpoint

7. SETPOINT RANGES AND MAXIMUM AMPS:

8. SETPOINT ADJUST: 4 Turn potentiometer (CTSS)

15 Turn Potentiometer (CTSF)

9. FREQUENCY RANGE: 6-100 Hz

10. ISOLATION VOLTAGE: UL Listed to 1,270 VAC. Tested to 5,000 VAC

11. CASE: UL 94V-0 Flammability rated thermoplastic

12. ENVIRONMENTAL: -58 to 149 °F (-50 to 65 °C)

0-95% RH, non-condensing

13. TORQUE RATINGS: 5 in-lbs

14. LISTING: UL 508 Industrial Control Equipment, CSA C22.2 No. 14-M95,

and CE Certified.

MODEL CTS - AC CURRENT OPERATED SWITCH

Bulletin No. CTS- A

Drawing No. LP0651

Released 4/08

C

US LISTED

U

L

R

IND. CONT. EQ.

5T44

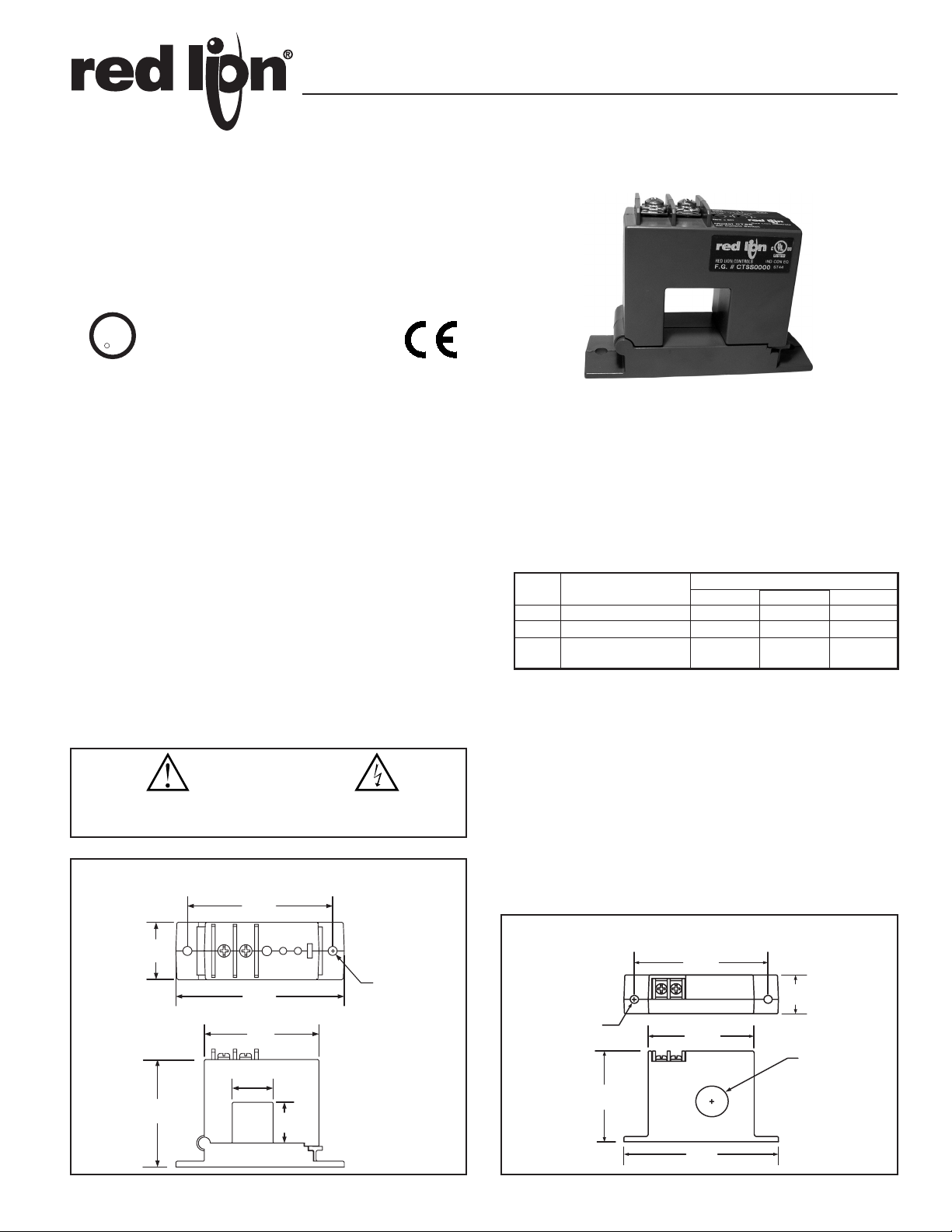

DIMENSIONS In inches (mm)

SPLIT-CORE

DIMENSIONS In inches (mm)

FIXED-CORE

1000 A250 A 400 A

1000 A150 A 400 ASplit-Core: 1.75 - 150 A

1000 A150 A 400 AFixed-Core: 1 - 150 ACTSF

CTSS

CTSG

1 secContinuous

6 sec

MAXIMUM INPUT AMPS

SETPOINT RANGEMODEL

CAUTION: Risk of Danger.

Read complete instructions prior to

installation and operation of the unit.

CAUTION: Risk of electric shock.

Fixed-Core Go/No Go:

0.75 A max

3.04

(77.2)

1.19

(30.2)

3.53

(89.7)

2.40

(61)

0.85

(21.6)

2.25

(57.2)

0.85

(21.6)

Ø 0.19

(4.8)

3.03

(77.0)

Ø 0.19

(4.8)

2.18

(55.4)

2.40

(61.0)

3.50

(88.9)

0.93

(23.6)

Ø 0.74

(19)

Page 2

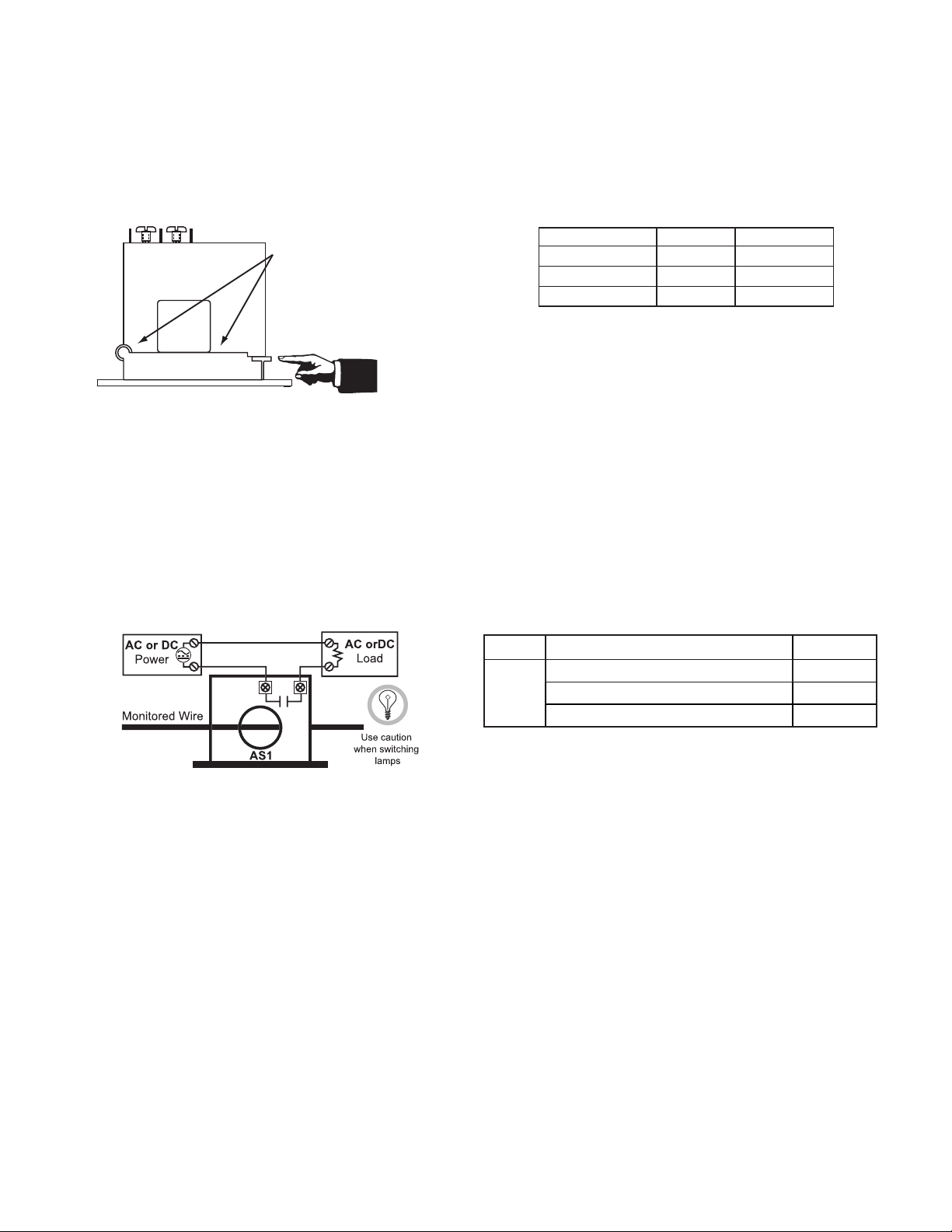

INSTALLATION

Run wire to be monitored through opening in the sensor. The CTS Series

transducers work in the same environment as motors, contactors, heaters, pullboxes, and other electrical enclosures. They can be mounted in any position or

hung directly on wires with a wire tie. Just leave at least one inch (25.4 mm)

distance between sensor and other magnetic devices.

Split-Core Versions

Press the tab in the direction as shown to open the sensor. After placing the

wire in the opening, press the hinged portion firmly downward until a definite

click is heard and the tab pops out fully.

KEEP SPLIT-CORE SENSORS CLEAN.

Silicone grease is factory applied on the mating surfaces to prevent rust and

improve performance. Be careful not to allow grit or dirt onto the grease in the

contact area. Operation can be impaired if the mating surfaces do not have good

contact. Check visually before closing.

OUTPUT WIRING

Connect control or monitoring wires to the sensor. Use up to 14 AWG copper

wire and tighten terminals to 5 inch-pounds torque. Be sure the output load does

not exceed the switch rating.

CAUTION: Incandescent lamps can have “Cold Filament Inrush” current of up

to 10 times their rated amperage. Use caution when switching lamps.

SETPOINT ADJUSTMENT

CTS Series SETPOINT is adjusted with a 4-turn potentiometer (CTSS) or a

15-turn potentiometer (CTSF). The pot is shipped factory set to the lowest

setpoint, fully clockwise (CW). Turning the pot counter-clockwise (CCW) will

increase the setpoint. The pot has a slip-clutch to prevent damage at either end

of its rotation. To determine where the adjustment is, turn the pot all the way

CW. This will return it to the minimum setpoint.

Adjustment Notes:

1. Output contacts are solid-state. Check output status by applying voltage to the

contacts and reading the voltage drop across the contacts. An Ohmmeter set

on “Continuity” will give misleading results.

2. It is recommended that the setpoint be adjusted to allow for voltage variations

of 10-15%.

Typical Adjustment

1. Turn the pot to minimum setpoint (4 or 15 turns CW).

2. Have normal operating current running through the sensor. The output

should be tripped since the pot is at its minimum setpoint. For units with

LED, it should be flashing fast (2 to 3 times per second).

3. Turn the pot CCW until the unit un-trips. This is indicated by the slow

flashing of the LED (once every 2 to 3 seconds), or by the changing of

the output switch status.

4. Now turn the pot CW slowly until the unit trips again.

It is now set at the current level being monitored.

A. To Set UNDERLOAD - Turn the pot about 1/8 turn further CW.

B. To Set OVERLOAD - Turn the pot about 1/8 turn further CCW.

TROUBLE SHOOTING

1. Sensor Is Always Tripped

A. The setpoint may be too low. Turn pot CCW to increase setpoint.

B. Switch has been overloaded and contacts are burned out. Check the output

load, remembering to include inrush on inductive loads (coils, motors,

ballasts).

2. Sensor Will Not Trip

A. The setpoint may be too high. Turn pot CW to decrease setpoint.

B. Split Core models: The core contact area may be dirty. Open the sensor and

clean the contact area.

C. Monitored current is below minimum required. Loop the monitored wire

several times through the aperture until the “sensed” current rises above

minimum. Sensed Amps = (Actual Amps) x (Number of Loops). Count

loops on the inside of the aperture.

D. Switch has been overloaded and contacts are burned out. Check the output

load, remembering to include inrush on inductive loads (coils, motors,

ballasts).

DESCRIPTION

PART NUMBERS

CTS

.75 A Fixed-Core Current Switch, Go-No Go

1-150 A Fixed-Core Current Switch, Adjustable

CTSG0000

CTSF0000

CTSS0000

ORDERING INFORMATION

MODEL NO.

MONITORED AMPS OUTPUT SMART-LED

None or <Min. OPEN OFF

Below Trip Level OPEN SLOW (2 sec)

Above Trip Level CLOSED FAST (0.5 sec)

1.75-150 A Split-Core Current Switch, Adjustable

Important!

Keep Contact

Area CLEAN!

To O pen

Press Tab

Toward Hinge.

Loading...

Loading...