Page 1

Bulletin No. CS8-K

C

US LISTED

C

US

Drawing No. LP0556

Released 06/12

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

MODELS CSTC, CSRTD, CSINI, CSINV MODULAR CONTROLLER SERIES ANALOG INPUT MODULES

DEDICATED HIGH DENSITY INPUT MODULES FOR THE

U

R

C

L

U

R

C

L

LISTED

IND.CONT. EQ.

3PWL

US LISTED

IND. CONT. EQ.

34AD

FOR USE IN HAZARDOUS LOCATIONS:

US

Class I, Division 2, Groups A, B, C, and D

MODULAR CONTROLLER SERIES

MODELS AVAILABLE TO ACCEPT ±10 V, 0/4-20 mA,

THERMOCOUPLE AND RTD INPUTS

±10 V AND 0/4-20 mA INPUT VERSIONS FULLY SCALABLE

±10 V AND 0/4-20 mA INPUT VERSIONS AVAILABLE WITH 100

POINT LINEARIZATION

UNUSED INPUTS CAN BE DISABLED TO INCREASE OVERALL

READING RATE

IDEAL FOR DATA-ACQUISITION APPLICATIONS

AUTO ADDRESSING MINIMIZES CONFIGURATION TIME

CAN BE USED IN CONJUNCTION WITH ANY CS

SERIES MODULES

GENERAL DESCRIPTION

The Model CSTC, CSRTD, CSINI, and CSINV are 16-bit analog input

modules designed for use with the Modular Controller Series. These modules

provide a means of high-density signal measurement for data-acquisition

applications. The CSTC module accepts a wide range of thermocouple types,

while the CSRTD accepts various RTD inputs. The CSINI and CSINV accept

0/4-20 mA and ±10 V process signals, respectively.

The modules connect and communicate via a backplane connection to the

CSMSTR Modular Controller Series Master. The CSMSTR, equipped with serial

ports as well as an Ethernet port, allows the system to share data with PCs, PLCs,

and SCADA systems. The Master supports any combination of up to 16 CS series

modules, allowing a total of 128 signals to be monitored via a single Master.

Internal power management circuits allow the modules to be replaced while

power is applied, which reduces downtime. All configuration information is

stored locally within the module, as well as in the Master, so replacement

modules do not need to be configured.

The Modular Controller Series’ high density packaging and DIN rail

mounting saves time and panel space. The backplane connection provides power

and communication to the module and snaps easily onto standard top hat (T)

profile DIN rail.

DIMENSIONS In inches (mm)

1.24

(31.5)

4.98

(126.5)

13

4.17 (105.9)

CONFIGURATION

The Modular Controller Series is configured with Windows® compatible

Crimson® software. The software is an easy to use, graphical interface which

provides a means of configuration and commissioning of new systems, as well

as routine module re-calibration.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Do not use the module to directly command motors, valves, or other actuators

not equipped with safeguards. To do so can be potentially harmful to persons or

equipment in the event of a fault to the module. An independent and redundant

temperature limit indicator with alarm outputs is strongly recommended.

CAUTION: Risk of Danger.

Read complete instructions prior to

installation and operation of the unit.

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF

COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS I,

DIVISION 2

THIS EQUIPMENT IS SUITABLE FOR USE IN CLASS I,

DIVISION 2, GROUPS A, B, C, D, OR NON-HAZARDOUS

LOCATIONS ONLY

CAUTION: Risk of electric shock.

7

1

1

Page 2

GENERAL SPECIFICATIONS

1. POWER: Derived from system backplane. (75 mA load on power input of

MASTER). Module may be hot-swapped (replaced while powered up).

2. LEDs:

STS - Status LED shows module condition.

ALM - Alarm LED is lit during any internal alarm condition.

3. MEMORY: Non-volatile memory retains all programmable parameters.

MASTER also stores the parameters in order to reprogram modules that are

replaced.

4. ISOLATION LEVEL: 500 Vrms @ 50/60 Hz for 1 minute between the

Signal Inputs and the CS Master Power Supply Input.

5. COMMUNICATIONS: Provided by the CS Master

6. CERTIFICA TIONS AND COMPLIANCES:

SAFETY

Check each module’s specifications to determine system compliance.

UL Listed, File #E302106, UL508, CSA 22.2 No. 14-M05 and File #E179259,

UL61010-1, CAN/CSA-C22.2 No. 61010-1; and File #E317425, ANSI/ISA

12.12.01-2007, CSA 22.2 No. 213-M1987

LISTED by Und. Lab. Inc. to U.S. and Canadian safety standards

IEC 61010-1, EN 61010-1: Safety requirements for electrical equipment

for measurement, control, and laboratory use, Part 1.

ELECTROMAGNETIC COMPATIBILITY

Emissions and Immunity to EN 61326: 2006: Electrical Equipment for

Measurement, Control and Laboratory use.

Immunity to Industrial Locations:

Electrostatic discharge EN 61000-4-2 Criterion B

Electromagnetic RF fields EN 61000-4-3 Criterion B

Fast transients (burst) EN 61000-4-4 Criterion B

I/O signal 1kV

Surge EN 61000-4-5 Criterion B

4kV contact discharge

8kV air discharge

3

10V/m (80 MHz to 1 GHz)

3 V/m (1.4 GHz to 2 GHz)

1 V/m (2 GHz to 2.7 GHz)

power 2kV

power 1 kV L to L, 2 kV L to G

signal 1 kV

RF conducted interference EN 61000-4-6 Criterion A

3 Vrms

Emissions:

Emissions EN55011 Class A

Notes:

1. Criterion A: Normal operation within specified limits.

2. Criterion B: Temporary loss of performance from which the unit selfrecovers.

3. The module’s analog input and/or output signals may deviate during

disturbance, but self-recover when disturbance is removed.

4. Power supplied from backplane via Master Module.

7. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range: 0 to +50 °C

Storage Temperature Range: -40 to +85 °C

Operating and Storage Humidity: 85% max relative humidity, non-

condensing, from 0 to +50 °C

Vibration According to IEC 68-2-6: Operational 10 to 150 Hz, 0.075 mm

amplitude in X, Y, Z direction 1 g.

Shock According to IEC 68-2-27: Operational 25 g, 11 msec in 3 directions.

Altitude: Up to 2000 meters

8. CONSTRUCTION: Case body is burgundy high impact plastic. For indoor

use only. Installation Category II, Pollution Degree 2.

9. CONNECTIONS: Removable wire clamp screw terminal blocks

Wire Gage: 28-16 AWG terminal gage wire

Torque: 1.96-2.23 inch/lbs (0.22-0.25 N-m)

10. MOUNTING: Snaps on to standard DIN style top hat (T) profile mounting

rails according to EN50022 -35 x 7.5 and -35 x 15.

11. WEIGHT: 6 oz (170.1 g)

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT

EQUIPMENT UNLESS POWER HAS BEEN SWITCHED OFF OR

AREA IS KNOWN TO BE NON-HAZARDOUS.

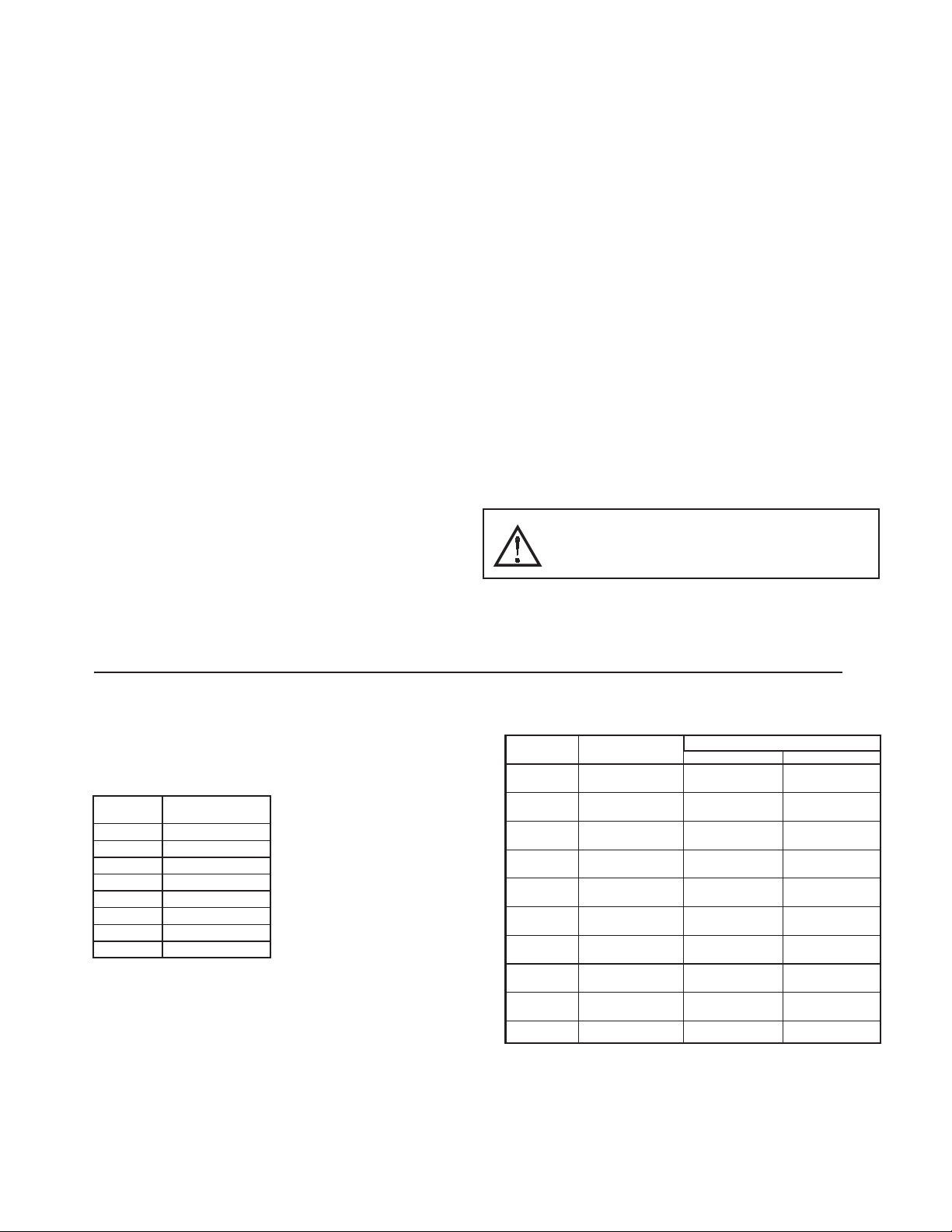

CSTC8 SPECIFICATIONS

12. INPUTS:

Channels: 8 single-ended

Effective Resolution: Full 16-bit

Sample Time: 50 msec - 400 msec, depending on number of enabled inputs.

ENABLED

INPUTS

1 50 msec (20 Hz)

2 100 msec (10 Hz)

3 150 msec (6.7 Hz)

4 200 msec (5 Hz)

5 250 msec (4 Hz)

6 300 msec (3.3 Hz)

7 350 msec (2.9 Hz)

8 400 msec (2.5 Hz)

Common Mode Rejection: >110 dB, 50/60 Hz

Normal Mode Rejection: >90 dB, 50/60 Hz

Temperature Coefficient: 0.01%/°C

Step Response Time: One scan time (to within 99% of final value)

Types: T, E, J, K, R, S, B, N, C

Slope & Offset: Provides sensor error correction

Input Impedance: 20 M

Lead Resistance Effect: 0.25 μV/

Cold Junction Compensation: Less than ±1 °C typical (±1.5 °C max) over 0

to 50 °C ambient temperature

SCAN TIME

(READING RATE)

Resolution: 0.1°

TYPE

T

E

J

K

R

S

B

N

C

W5/W6

Millivolt

MEASUREMENT

RANGE

-200 to +400 °C

-328 to +752 °F

-200 to +730 °C

-328 to +1346 °F

-200 to +760 °C

-328 to +1400 °F

-200 to +1350 °C

-328 to +2462 °F

0 to +1768 °C

+32 to +3214 °F

0 to +1768 °C

+32 to +3214 °F

+149 to +1820 °C

+300 to +3308 °F

-200 to +1300 °C

-328 to +2372 °F

0 to +2315 °C

+32 to +4199 °F

-10.00 to +56.00 mV

No Standard

No Standard

No Standard

No Standard

ANSI

(+) Blue

(-) Red

(+) Violet

(-) Red

(+) White

(-) Red

(+) Yellow

(-) Red

(+) Orange

(-) Red

WIRE COLOR

BS 1843

(+) White

(-) Blue

(+) Brown

(-) Blue

(+) Yellow

(-) Blue

(+) Brown

(-) Blue

(+) White

(-) Blue

(+) White

(-) Blue

No StandardNo Standard

(+) Orange

(-) Blue

No Standard

No Standard

13. TEMPERATURE INDICATION ACCURACY: ± (0.3% of span, +1 °C).

Includes NIST conformity, cold junction effect, A/D conversion errors,

temperature coefficient and linearization conformity at 23 °C after 20 minute

warm up.

14. PROBE BREAK RESPONSE: Upscale drive, Input Fault Alarm bit set high,

ALM LED illuminates.

2

Page 3

CSRTD6 SPECIFICATIONS

15. RTD INPUTS:

Channels: 6 single-ended

Effective Resolution: Full 16-bit

Sample Time: 67 msec - 400 msec, depending on enabled inputs.

ENABLED

INPUTS

1 67 msec (14.9 Hz)

2 133 msec (7.5 Hz)

3 200 msec (5 Hz)

4 267 msec (3.8 Hz)

5 333 msec (3 Hz)

6 400 msec (2.5 Hz)

SCAN TIME

(READING RATE)

Common Mode Rejection: >110 dB, 50/60 Hz

Normal Mode Rejection: >90 dB, 50/60 Hz

Temperature Coefficient: 0.01%/°C

Step Response Time: One scan time (to within 99% of final value)

Type: 2 or 3 wire

Excitation: 150 μA

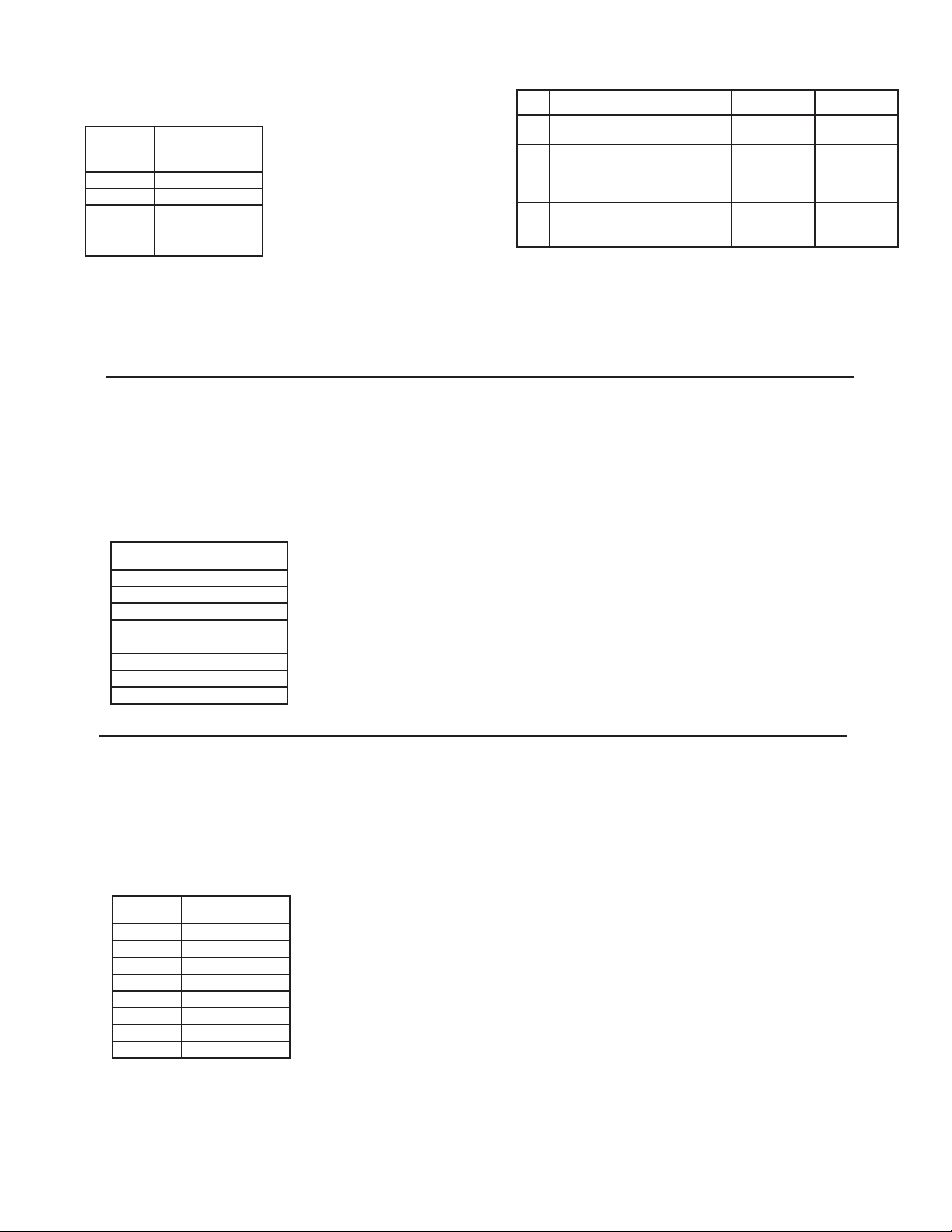

CSINI8 SPECIFICATIONS

18. INPUTS:

Channels: 8 single-ended

Ranges: 0-20 mA or 4-20 mA

Effective Resolution: Full 16-bit

Programmable Scaling: ±30,000

Linearizer: 100 Points (CSINI8L0 only)

Sample Time: 50 msec - 400 msec, depending on number of enabled inputs.

ENABLED

INPUTS

1 50 msec (20 Hz)

2 100 msec (10 Hz)

3 150 msec (6.7 Hz)

4 200 msec (5 Hz)

5 250 msec (4 Hz)

6 300 msec (3.3 Hz)

7 350 msec (2.9 Hz)

8 400 msec (2.5 Hz)

SCAN TIME

(READING RATE)

Lead Resistance: 15 Max

Resolution: 0.1°

Slope & Offset: Provides sensor error correction

TYPE INPUT TYPE RANGE

100 platinum,

385 ± (0.2% of span)± (0.1% of span)

Alpha = .00385

100 platinum,

392 ± (0.2% of span)± (0.1% of span)

Alpha = .003919

120 nickel,

672

Alpha = .00672

Ohms Linear resistance

50 copper,

428

Alpha = .00428

-200 to +600 °C

-328 to +1100 °F

-200 to +600 °C

-328 to +1100 °F

-80 to +215 °C

-112 to +419 °F

0 to 300

-50 to +200 °C

-58 to +392 °F

ACCURACY

18 TO 28°C

ACCURACY

0 TO 50°C

± (0.2% of span)± (0.1% of span)

± (0.2% of span)± (0.1% of span)

± (1.2% of span)± (0.6% of span)

16. TEMPERA TURE INDICATION ACCURACY: Includes NIST conformity,

A/D conversion errors, temperature coefficient and linearization conformity at

23 °C after 20 minute warm up.

17. PROBE BREAK RESPONSE: If channel is enabled: upscale drive, Input

Fault Alarm bit set high, ALM LED illuminates.

Common Mode Rejection: >110 dB, 50/60 Hz

Normal Mode Rejection: >90 dB, 50/60 Hz

Step Response Time: One scan time (to within 99% of final value)

Input Impedance: 10

Max. Continuous Overload: 100 mA

19. ACCURACY: ±0.1% of span

20. INPUT FAULT RESPONSE: Upscale Drive, Input Fault Alarm bit set

high, ALM LED illuminates below -3 mA, and above 23 mA for 0-20 mA

range; below +3 mA and above 23 mA for 4-20 mA signals.

CSINV8 SPECIFICATIONS

21. INPUTS:

Channels: 8 single-ended

Ranges: 0-10 VDC or ±10 VDC

Effective Resolution: Full 16-bit

Programmable Scaling: ±30,000

Linearizer: 100 Points (CSINV8L0 only)

Sample Time: 50 msec - 400 msec, depending on number of enabled inputs.

ENABLED

INPUTS

1 50 msec (20 Hz)

2 100 msec (10 Hz)

3 150 msec (6.7 Hz)

4 200 msec (5 Hz)

5 250 msec (4 Hz)

6 300 msec (3.3 Hz)

7 350 msec (2.9 Hz)

8 400 msec (2.5 Hz)

SCAN TIME

(READING RATE)

Common Mode Rejection: >110 dB, 50/60 Hz

Normal Mode Rejection: >90 dB, 50/60 Hz

Step Response Time: One scan time (to within 99% of final value)

Input Impedance: 10 M

Max. Continuous Overload: 50 V

22. ACCURACY: ±0.1% of span

23. INPUT FAULT RESPONSE: Upscale Drive, Input Fault Alarm bit set

high, ALM LED illuminates below -10.4 VDC and above +10.4 VDC.

3

Page 4

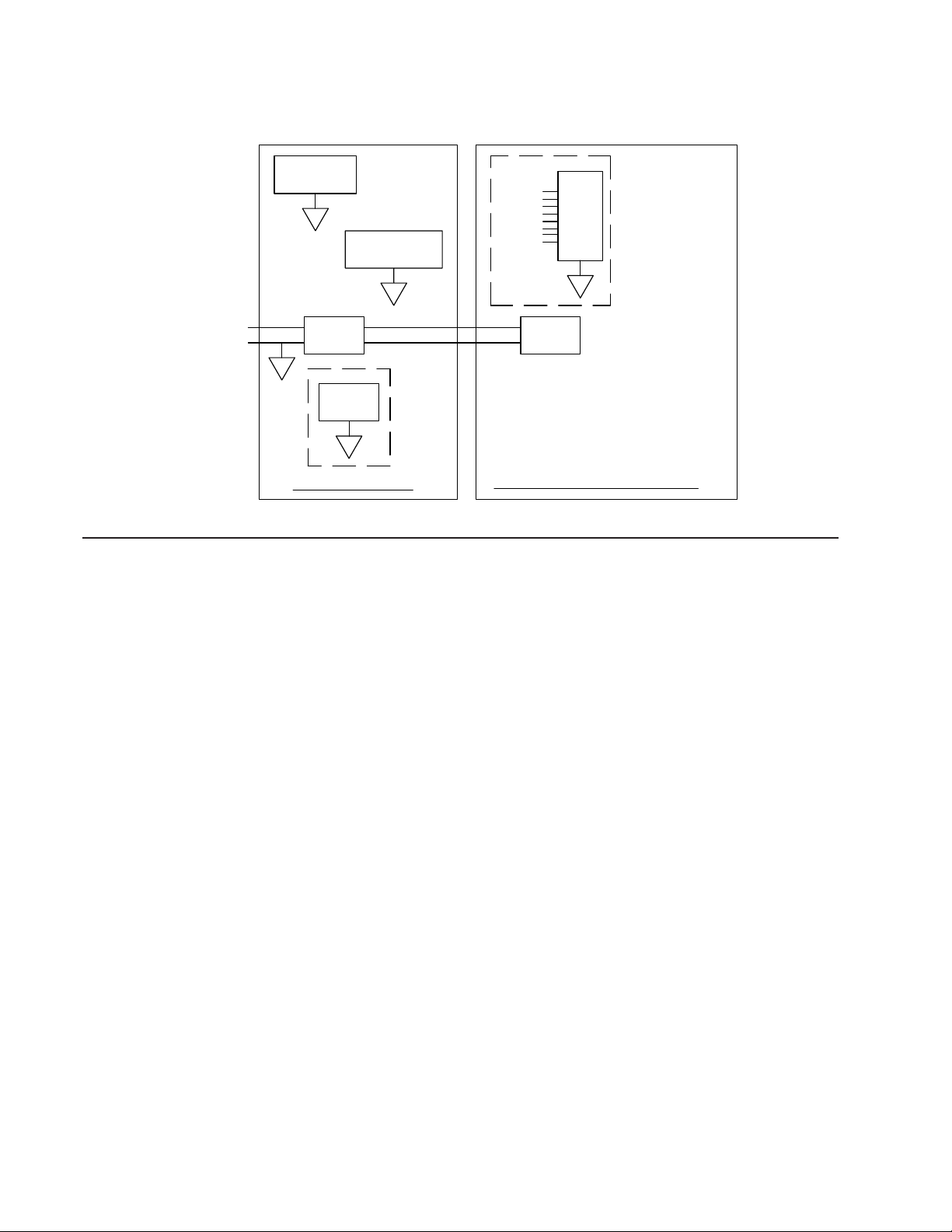

BLOCK DIAGRAM FOR

CSTC8, CSRTD6, CSINI8 & CSINV8

PORT 1

PROGRAMMING

A

PORT 2

COMMUNICATIONS

A

24VDC

+

-

POWER

SUPPLY

A

ISOLATED

PORT 3

ETHERNET

B

CSMSTR - MASTER

EMC INSTALLATION GUIDELINES

Although Red Lion Controls Products are designed with a high degree of

immunity to Electromagnetic Interference (EMI), proper installation and wiring

methods must be followed to ensure compatibility in each application. The type

of the electrical noise, source or coupling method into a unit may be different

for various installations. Cable length, routing, and shield termination are very

important and can mean the difference between a successful or troublesome

installation. Listed are some EMI guidelines for a successful installation in an

industrial environment.

1. A unit should be mounted in a metal enclosure, which is properly connected

to protective earth.

a. The mounting clip that connects to the DIN rail should have the DIN rail

connected to protective earth.

2. Use shielded (screened) cables for all Signal and Control inputs. The shield

(screen) pigtail connection should be made as short as possible. The

connection point for the shield depends somewhat upon the application.

Listed below are the recommended methods of connecting the shield, in order

of their effectiveness.

a. Connect the shield to earth ground (protective earth) at one end where the

unit is mounted.

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is over 1 MHz.

c. Connect the shield to common of the module and leave the other end of the

shield unconnected and insulated from earth ground.

3. Never run Signal or Control cables in the same conduit or raceway with AC

power lines, conductors, feeding motors, solenoids, SCR controls, and

heaters, etc. The cables should be run through metal conduit that is properly

grounded. This is especially useful in applications where cable runs are long

and portable two-way radios are used in close proximity or if the installation

is near a commercial radio transmitter. Also, Signal or Control cables within

an enclosure should be routed as far away as possible from contactors, control

relays, transformers, and other noisy components.

4. Long cable runs are more susceptible to EMI pickup than short cable runs.

Therefore, keep cable runs as short as possible.

ISOLATED

INPUTS

C

POWER

SUPPLY

CSTC8, CSRTD6, CSINI8, CSINV8

5. In extremely high EMI environments, the use of external EMI suppression

devices such as Ferrite Suppression Cores for signal and control cables is

effective. The following EMI suppression devices (or equivalent) are

recommended:

Fair-Rite part number 0443167251 (RLC part number FCOR0000)

TDK part number ZCAT3035-1330A

Steward part number 28B2029-0A0

6. To protect relay contacts that control inductive loads and to minimize radiated

and conducted noise (EMI), some type of contact protection network is

normally installed across the load, the contacts or both. The most effective

location is across the load.

a. Using a snubber, which is a resistor-capacitor (RC) network or metal oxide

varistor (MOV) across an AC inductive load is very effective at reducing

EMI and increasing relay contact life.

b. If a DC inductive load (such as a DC relay coil) is controlled by a transistor

switch, care must be taken not to exceed the breakdown voltage of the

transistor when the load is switched. One of the most effective ways is to

place a diode across the inductive load. Most RLC products with solid state

outputs have internal zener diode protection. However external diode

protection at the load is always a good design practice to limit EMI.

Although the use of a snubber or varistor could be used.

RLC part numbers: Snubber SNUB0000

Varistor ILS11500 or ILS23000

Note: Reference manufacturer’s instructions when installing any EMI

suppression device.

7. Also care should be taken when connecting input and output devices to the

instrument. When a separate input and output common is provided, they

should not be mixed. Therefore a sensor common should NOT be connected

to an output common. This would cause EMI on the sensitive input common,

which could effect the instrument’s operation.

Visit RLC’s web site at www.redlion.net for more information on EMI

guidelines, Safety and CE issues as they relate to Red Lion Controls products.

4

Page 5

HARDWARE INSTALLATION

SEPARATE BASE

FROM MODULE

1

2

MODULE

BASE

WIRING

WIRING CONNECTIONS

All conductors should meet voltage and

current ratings for each terminal. Also,

cabling should conform to appropriate

standards of good installation, local codes

and regulations. When wiring the module,

use the numbers on the label to identify the

position number with the proper function.

Strip the wire, leaving approximately 1/4"

(6 mm) of bare wire exposed. Insert the

wire into the terminal, and tighten.

ATTACH THE MODULE BASE

TO THE DIN RAIL

3

4

Terminals 13 to 18

13

7

1

Terminals 7 to 12

Terminals 1 to 6

ATTACH MODULE TO BASE

5

MODULE BASE

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT

WHILE CIRCUIT IS ALIVE UNLESS AREA IS KNOW TO BE

NON-HAZARDOUS.

INPUT AND OUTPUT (I/O) WIRING MUST BE IN

ACCORDANCE WITH CLASS I, DIV. 2 WIRING METHODS

AND IN ACCORDANCE WITH THE AUTHORITY HAVING

JURISDICTION.

INPUT CONNECTIONS

CSTC

8

7

-TC

+TC

-TC

+TC

N/C

5

-TC

+TC

2

-TC

+TC

3 45

N/C

18

6

-TC

+TC

12

3

-TC

+TC

6

1413 1615 17

4

-TC

+TC

87109 11

1

-TC

+TC

2

1

CSRTD

6

5

COMM.

+SIG

+EXC

COMM.

13 14 15 16 17 18

COMM.

7 8910 11 12

COMM.

1 23

+SIG

4

3

+SIG

+EXC

COMM.

+SIG

21

+SIG

+EXC

COMM.

+SIG

4 5 6

+EXC

+EXC

+EXC

7 8

COMM.

0-20mA

COMM.

0-20mA

N/C

15

13 14 18

16 17

6

5

4

COMM.

0-20mA

COMM.

0-20mA

0-20mA

COMM.

0-20mA

COMM.

3

COMM.

78 1291011

12

COMM.

1 2

N/C

0-20mA

0-20mA

6345

CSINVCSINI

7

COMM.

+/-10V

13

14 15

4 5

COMM.

+/-10V

789

12

COMM.

+/-10V

12 3

8

COMM.

16

COMM.

10

COMM.

4

+/-10V

+/-10V

+/-10V

N/C

17 18

COMM.

11 12

COMM.

5 6

N/C

6

+/-10V

3

+/-10V

VDC+

SENSE

+

SENSE

mA DC-

mA DC+

VDC-

EXC/JUMPER

5

Page 6

LEDS

STS – STATUS LED

The Status LED is a dual color LED that provides information regarding the

state of the module. This includes indication of the various stages of the start-up

routine (power-up), as well as any errors that may occur.

Startup Routine

Rapidly Flashing Red

Steady Red Module switching to configuration.

Green Module performing normally.

FIRMWARE UPGRADE

The module's firmware is stored in flash memory so that software/hardware

conflicts are avoided, and so that software features may be added in the future.

During a download, Crimson compares its own library of firmware files with

those stored in the Master module. If they do not match, Crimson will download

the necessary files. The Master then checks to make sure that the I/O modules

contain the same firmware. If they contain a different revision, the Master will

automatically copy those files into the module's flash memory. During this

process, the module LEDs will flash rapidly, starting with the top row, and

progressing through the remaining rows until the process is complete.

Module is currently running the boot loader and/

or being flash upgraded by Crimson. This occurs

for four seconds during a power up.

Error States

Module not controlling, and not communicating.Solid Red

Green/Pulsing Red

Module is controlling properly, but has lost

communication with the Master.

ALM – ALARM LED

The Alarm LED indicates the presence of an input fault condition. When one

or more Input Fault Alarm bits is high, the LED turns on. The alarms may be

disabled for unused inputs.

CONFIGURATION

Programming is done via Crimson® software, a Windows® compatible

configuration interface. Please see the Crimson manual for more information.

ORDERING INFORMATION

DESCRIPTIONMODEL NO.TYPE PART NUMBER

Modular Controller Master, Multi Comms ports and Ethernet

Modular Controller Master with multiple protocol converter, data

CSMSTRMaster Module

CSTC

CSINI

Input Modules

CSINV

CSRTD

Communications

Cables

(10 feet)

Software

Accessories

Note: Certain modules are not suitable for use in Hazardous locations. Check each module’s specifications prior to installation.

1

Visit www.redlion.net for a complete list of PID modules, data acquisition modules, communications drivers and cables.

2

Free at www.redlion.net

CBL

logger, web server with Virtual HMI up to QVGA (320 x 240) size

and expansion slot.

Modular Controller Master with multiple protocol converter, data

logger, web server with Virtual HMI up to VGA (640 x 480) size

and expansion slot with increased SDRAM

1

8 Channel Thermocouple Module

8 Channel 0(4)-20 mA Input Module

8 Channel 0(4)-20 mA Input Module, 100-Point Linearizer

8 Channel ±10 V Input Module

8 Channel ±10 V Input Module, 100-Point Linearizer

6 Channel RTD Module

Programming Cable for CS, G3, & Paradigm Series

Communications Cables

Crimson® Programming Software

Crimson® Programming Software, Manual, and Download Cable

Rail Stops (Qty 2)

Replacement Base

Replacement Termination Plug

1

2

CSMSTRV2

CSMSTRSX

CSMSTRGT

CSTC8000

CSINI800

CSINI8L0

CSINV800

CSINV8L0

CSRTD600

CBLPROG0

CBLxxxxx

SFCRM

SFCRK

RSRSTP00

CSBASE00

CSTERM00

6

Page 7

This page intentionally left blank

7

Page 8

The Company warrants the products it manufactures against defects in materials and workmanship

LIMITED WARRANTY

for a period limited to two years from the date of shipment, provided the products have been stored,

handled, installed, and used under proper conditions. The Company’s liability under this limited

warranty shall extend only to the repair or replacement of a defective product, at The Company’s

option. The Company disclaims all liability for any affirmation, promise or representation with

respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against

damages, claims, and expenses arising out of subsequent sales of RLC products or products

containing components manufactured by RLC and based upon personal injuries, deaths, property

damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be

to any extent liable, including without limitation penalties imposed by the Consumer Product Safety

Act (P.L. 92-573) and liability imposed upon any person pursuant to the Magnuson-Moss Warranty

Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except

those expressly contained herein. The Customer acknowledges the disclaimers and limitations

contained herein and relies on no other warranties or affirmations.

Red Lion Controls

Headquarters

20 Willow Springs Circle

York PA 17406

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

Red Lion Controls

Europe

Printerweg 10

NL - 3821 AD Amersfoort

Tel +31 (0) 334 723 225

Fax +31 (0) 334 893 793

Red Lion Controls

India

54, Vishvas Tenement

GST Road, New Ranip,

Ahmedabad-382480 Gujarat, India

Tel +91 987 954 0503

Fax +91 79 275 31 350

Red Lion Controls

China

Unit 101, XinAn Plaza

Building 13, No.99 Tianzhou Road

ShangHai, P.R. China 200223

Tel +86 21 6113-3688

Fax +86 21 6113-3683

Loading...

Loading...