Page 1

LP0631

CRIMSON 2

SER MANUAL

U

ODULAR CONTROLLER

M

Page 2

Copyright © 2003-2006 Red Lion Controls.

All Rights Reserved Worldwide.

The information contained herein is provided in good faith, but is subject to change without

notice. It is supplied with no warranty whatsoever, and does not represent a commitment on

the part of Red Lion Controls. Companies, names and data used as examples herein are

fictitious unless otherwise stated. No part of this document may be reproduced or transmitted

in any form or by any means, electronic or mechanical, without the express written

permission of Red Lion Controls.

All trademarks are acknowledged as the property of their respective owners.

Written by Mike Granby and Jesse Benefiel.

Page 3

GETTING STARTED TABLE OF CONTENTS

TABLE OF CONTENTS

GETTING STARTED ........................................................................................... 1

SYSTEM REQUIREMENTS ..................................................................................... 1

INSTALLING THE SOFTWARE................................................................................. 1

CHECKING FOR UPDATES..................................................................................... 1

INSTALLING THE USB DRIVERS ............................................................................ 2

QUICK START .................................................................................................. 3

OVERVIEW ...................................................................................................... 3

MODULES........................................................................................................ 3

COMMUNICATIONS ............................................................................................ 4

MAPPING DATA ................................................................................................ 4

DOWNLOADING ................................................................................................ 7

CONNECT THE TWO ........................................................................................... 8

CRIMSON BASICS............................................................................................. 9

MAIN SCREEN ICONS ......................................................................................... 9

MODULES .......................................................................................................................................9

COMMUNICATIONS ............................................................................................................................9

DATA TAGS................................................................................................................................... 10

USER INTERFACE............................................................................................................................10

PROGRAMMING ..............................................................................................................................10

DATA LOGGER ...............................................................................................................................10

WEB SERVER.................................................................................................................................10

SECURITY MANAGER ....................................................................................................................... 11

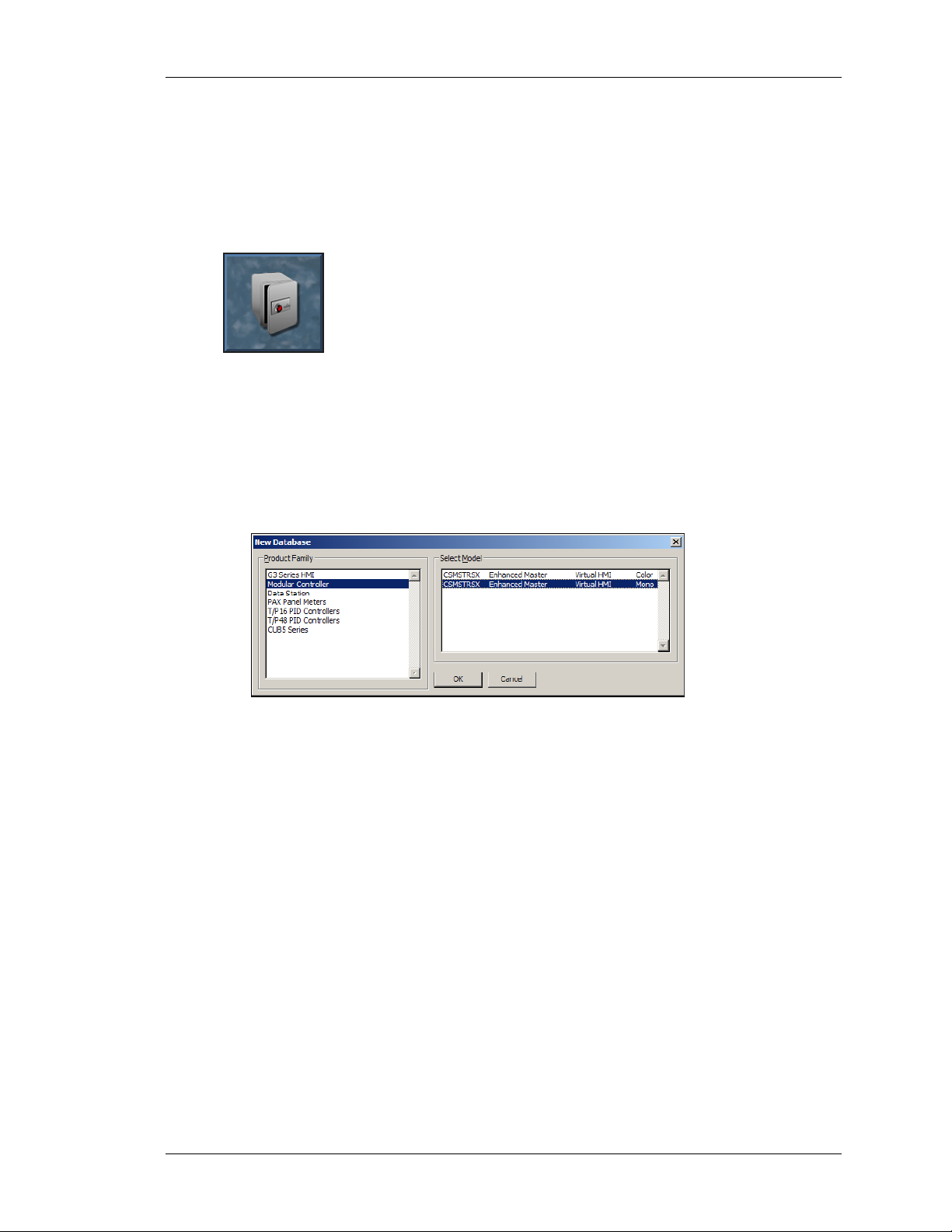

SELECTING THE MODULAR CONTROLLER ............................................................... 11

USING BALLOON HELP...................................................................................... 12

WORKING WITH DATABASES .............................................................................. 12

DOWNLOADING TO THE MASTER......................................................................... 12

CONFIGURING THE LINK ...................................................................................................................12

VERIFYING THE USB LINK ................................................................................................................13

SETTING THE IP ADDRESS................................................................................................................ 13

SENDING THE DATABASE ..................................................................................................................13

EXTRACTING DATABASES.................................................................................................................. 14

MOUNTING THE COMPACTFLASH ........................................................................................................14

FORMATTING THE COMPACTFLASH ......................................................................................................15

SENDING THE TIME AND DATE........................................................................................................... 16

UPDATING VIA COMPACTFLASH........................................................................... 16

MODULE CONFIGURATION ............................................................................... 17

WORKING WITH MODULES ................................................................................ 17

INSERTING MODULES ......................................................................................................................17

MOVING MODULES ......................................................................................................................... 17

EDITING MODULES .........................................................................................................................17

CSPID – PID MODULE PROGRAMMING................................................................ 18

THE GENERAL TAB.......................................................................................................................... 18

THE CONTROL TAB .........................................................................................................................20

REVISION 6 PAGE I

Page 4

TABLE OF CONTENTS CRIMSON USER MANUAL - MODULAR CONTROLLER

THE POWER TAB ............................................................................................................................ 22

THE ALARMS TAB ...........................................................................................................................23

THE OUTPUTS TAB .........................................................................................................................26

AUTO-TUNING...............................................................................................................................27

AVAILABLE DATA ............................................................................................................................ 30

CSSG – STRAIN GAGE INPUT PID MODULE PROGRAMMING....................................... 34

THE GENERAL TAB.......................................................................................................................... 34

THE CONTROL TAB .........................................................................................................................36

THE POWER TAB ............................................................................................................................ 38

THE ALARMS TAB ...........................................................................................................................40

THE OUTPUTS TAB .........................................................................................................................42

AUTO-TUNING...............................................................................................................................43

AVAILABLE DATA ............................................................................................................................ 46

CSTC/CSRTD – TEMPERATURE INPUT MODULE PROGRAMMING................................. 51

THE CONFIGURATION TAB ................................................................................................................51

AVAILABLE DATA ............................................................................................................................ 52

CSINI/CSINV – ANALOG INPUT MODULE PROGRAMMING......................................... 53

THE CONFIGURATION TAB ................................................................................................................53

THE LINEARIZATION TAB.................................................................................................................. 54

AVAILABLE DATA ............................................................................................................................ 55

CSOUT – ANALOG OUTPUT MODULE PROGRAMMING............................................... 56

THE CONFIGURATION TAB ................................................................................................................56

THE INITIAL OUTPUT TAB ................................................................................................................57

AVAILABLE DATA ............................................................................................................................ 58

CSDIO – DIGITAL I/O MODULE PROGRAMMING..................................................... 60

THE CONFIGURATION TAB ................................................................................................................60

THE LOGIC EDITOR TAB................................................................................................................... 60

AVAILABLE DATA ............................................................................................................................ 62

CONFIGURING COMMUNICATIONS..................................................................... 65

SERIAL PORT USAGE ........................................................................................ 65

SELECTING A PROTOCOL ................................................................................... 65

PROTOCOL OPTIONS ........................................................................................ 66

WORKING WITH DEVICES .................................................................................. 66

ETHERNET CONFIGURATION ............................................................................... 67

IP PARAMETERS............................................................................................................................. 67

IP ROUTING .................................................................................................................................67

PHYSICAL LAYER ............................................................................................................................67

REMOTE UPDATE............................................................................................................................ 68

PROTOCOL SELECTION..................................................................................................................... 68

MAPPING DATA............................................................................................... 69

MAPPING ITEMS TO A BLOCK............................................................................................................. 70

ACCESSING INDIVIDUAL BITS ............................................................................................................70

READ/WRITE VARIABLES.................................................................................................................. 71

PROTOCOL CONVERSION ................................................................................... 71

MASTER AND SLAVE ........................................................................................................................71

MASTER AND MASTER......................................................................................................................72

WHICH WAY AROUND?....................................................................................................................72

DATA TRANSFORMATION ................................................................................... 72

PAGE II http://www.redlion.net/controller

Page 5

GETTING STARTED TABLE OF CONTENTS

ADVANCED COMMUNICATIONS ......................................................................... 75

USING EXPANSION CARDS ................................................................................. 75

SHARING SERIAL PORTS ................................................................................... 76

ENABLING TCP/IP..........................................................................................................................76

SHARING THE REQUIRED PORT.......................................................................................................... 76

CONNECTING VIA ANOTHER PORT ...................................................................................................... 77

CONNECTING VIA ETHERNET .............................................................................................................77

PURE VIRTUAL PORTS ..................................................................................................................... 78

LIMITATIONS.................................................................................................................................79

USING ELECTRONIC MAIL.................................................................................. 79

CONFIGURING SMTP ......................................................................................................................79

CONFIGURING SMS ........................................................................................................................81

THE ADDRESS BOOK .......................................................................................................................82

WORKING WITH MODEMS ................................................................................. 83

SOME TYPICAL APPLICATIONS ........................................................................................................... 83

ADDING A DIAL-IN CONNECTION........................................................................................................ 84

ADDING A DIAL-OUT CONNECTION .....................................................................................................86

ADDING AN SMS CONNECTION..........................................................................................................87

SMS MESSAGE PROCESSING .............................................................................................................88

USING MULTIPLE INTERFACES ...........................................................................................................88

CHECKING THE MODEM STATUS ......................................................................................................... 89

MODEM INITIALIZATION SEQUENCE ....................................................................................................90

TROUBLESHOOTING MODEM COMMUNICATION ...................................................................................... 91

OPC COMMUNICATION ..................................................................................... 93

OPC SERVER SETTINGS ...................................................................................................................93

OPC AND SCADA .......................................................................................................................... 94

OPC LINK (RED LION PRODUCTS DATA EXCHANGE) ............................................................................... 94

USING TIME MANAGEMENT................................................................................ 95

CONFIGURING THE TIME MANAGER ..................................................................................................... 96

SELECTING AN SNTP SERVER............................................................................................................97

TIME-ZONE CONFIGURATION ............................................................................................................ 98

CONFIGURING THE SYNCHRONIZATION MANAGER (FTP CLIENT) ................................. 98

SYNCHRONIZATION MANAGER SETTINGS .............................................................................................. 98

AUTOMATIC LOG SYNCHRONIZATION ...................................................................................................99

ADVANCED FTP EXCHANGE FUNCTIONS ............................................................................................. 100

CONFIGURING THE FTP SERVER ........................................................................100

FTP SERVER SETTINGS.................................................................................................................. 101

FTP SECURITY ............................................................................................................................ 101

ACCESSING THE SERVER................................................................................................................. 102

CONFIGURING DATA TAGS ............................................................................. 102

ALL ABOUT TAGS ...........................................................................................102

TYPES OF TAGS............................................................................................................................ 102

WHY USE TAGS?.......................................................................................................................... 104

CREATING TAGS ............................................................................................105

EDITING TAGS ..............................................................................................106

EDITING PROPERTIES......................................................................................106

EXPRESSION PROPERTIES ............................................................................................................... 106

TRANSLATABLE STRINGS ................................................................................................................ 107

REVISION 6 PAGE III

Page 6

TABLE OF CONTENTS CRIMSON USER MANUAL - MODULAR CONTROLLER

COLOR PROPERTIES ...................................................................................................................... 108

EDITING FLAG TAGS ...................................................................................... 108

THE DATA TAB (VARIABLES) ........................................................................................................... 109

THE DATA TAB (FORMULAE) ........................................................................................................... 110

THE DATA TAB (ARRAYS)............................................................................................................... 110

THE FORMAT TAB.........................................................................................................................112

THE COLORS TAB ......................................................................................................................... 112

THE ALARMS TAB .........................................................................................................................113

THE TRIGGERS TAB ...................................................................................................................... 114

EDITING INTEGER TAGS .................................................................................. 114

THE DATA TAB (VARIABLES) ........................................................................................................... 115

THE DATA TAB (FORMULAE) ........................................................................................................... 116

THE DATA TAB (ARRAYS)............................................................................................................... 117

THE FORMAT TAB.........................................................................................................................117

THE COLORS TAB ......................................................................................................................... 119

THE ALARM TABS .........................................................................................................................119

THE TRIGGERS TAB ...................................................................................................................... 120

EDITING MULTI TAGS..................................................................................... 121

THE DATA TAB (VARIABLES) ........................................................................................................... 121

THE DATA TAB (FORMULAE) ........................................................................................................... 122

THE DATA TAB (ARRAYS)............................................................................................................... 122

THE FORMAT TAB.........................................................................................................................123

THE COLORS TAB ......................................................................................................................... 124

THE ALARM TABS .........................................................................................................................125

THE TRIGGERS TAB ...................................................................................................................... 125

EDITING REAL TAGS ...................................................................................... 126

EDITING STRING TAGS ................................................................................... 126

THE DATA TAB (VARIABLES) ........................................................................................................... 126

THE DATA TAB (FORMULAE) ........................................................................................................... 127

THE DATA TAB (ARRAYS)............................................................................................................... 127

THE FORMAT TAB.........................................................................................................................128

THE COLORS TAB ......................................................................................................................... 129

MORE THAN TWO ALARMS ............................................................................... 129

VALIDATING TAGS ......................................................................................... 130

EXPORTING TAG MAPPINGS.............................................................................. 130

LOGGING EVENT MESSAGES ............................................................................. 130

NOTES FOR EDICT USERS ................................................................................ 130

CONFIGURING THE MONOCHROME VIRTUAL HMI.............................................. 133

CONTROLLING THE VIEW................................................................................. 133

OTHER VIEW OPTIONS ..................................................................................................................133

USING THE PAGE LIST .................................................................................... 134

DISPLAY EDITOR TOOLBOXES ........................................................................... 134

THE DRAWING TOOLBOX................................................................................................................ 134

THE FILL FORMAT TOOLBOX ........................................................................................................... 134

THE LINE FORMAT TOOLBOX ........................................................................................................... 134

THE TEXT FORMAT TOOLBOX .......................................................................................................... 135

THE FOREGROUND TOOLBOX ........................................................................................................... 135

THE BACKGROUND TOOLBOX........................................................................................................... 135

PAGE IV http://www.redlion.net/controller

Page 7

GETTING STARTED TABLE OF CONTENTS

ADDING DISPLAY PRIMITIVES............................................................................135

SMART ALIGNMENT ....................................................................................................................... 135

KEYBOARD OPTIONS .....................................................................................................................136

LOCK INSERT MODE ...................................................................................................................... 136

SELECTING PRIMITIVES ...................................................................................136

MOVING AND RESIZING ...................................................................................137

REORDERING PRIMITIVES.................................................................................137

EDITING PRIMITIVES.......................................................................................138

PRIMITIVE DESCRIPTIONS ................................................................................138

THE LINE PRIMITIVE ..................................................................................................................... 138

THE SIMPLE GEOMETRIC PRIMITIVES ................................................................................................ 138

THE TANK PRIMITIVES................................................................................................................... 139

THE SIMPLE BAR-GRAPH PRIMITIVES................................................................................................. 139

THE FIXED TEXT PRIMITIVE ............................................................................................................140

THE AUTO TAG PRIMITIVE.............................................................................................................. 141

THE TAG TEXT PRIMITIVES ............................................................................................................. 142

EDITING THE UNDERLYING TAG ....................................................................................................... 144

THE TIME AND DATE PRIMITIVE....................................................................................................... 145

THE RICH BAR-GRAPH PRIMITIVES ................................................................................................... 146

THE SYSTEM PRIMITIVES................................................................................................................ 148

DEFINING PAGE PROPERTIES ............................................................................149

DEFINING SYSTEM ACTIONS .............................................................................150

DEFINING KEY BEHAVIOR.................................................................................150

ENABLING ACTIONS ........................................................................................151

ACTION DESCRIPTIONS....................................................................................151

THE GOTO PAGE ACTION ............................................................................................................... 151

THE PUSH BUTTON ACTION ............................................................................................................152

THE CHANGE INTEGER VALUE ACTION ............................................................................................... 152

THE RAMP INTEGER VALUE ACTION ..................................................................................................153

THE PLAY TUNE ACTION ................................................................................................................ 153

THE USER DEFINED ACTION ........................................................................................................... 154

BLOCK DEFAULT ACTION ................................................................................................................ 154

CHANGING THE LANGUAGE ...............................................................................155

ADVANCED TOPICS .........................................................................................155

ACTION PROCESSING.....................................................................................................................155

DATA AVAILABILITY ...................................................................................................................... 156

CONFIGURING THE COLOR VIRTUAL HMI ........................................................ 157

CONTROLLING THE VIEW .................................................................................157

ZOOM FUNCTION.......................................................................................................................... 157

OTHER VIEW OPTIONS ..................................................................................................................158

USING THE PAGE LIST .....................................................................................158

WORKING WITH THE GRID ...............................................................................159

THE DRAWING TOOLBOX .................................................................................159

ADDING DISPLAY PRIMITIVES............................................................................160

SMART ALIGNMENT ....................................................................................................................... 160

KEYBOARD OPTIONS .....................................................................................................................161

REVISION 6 PAGE V

Page 8

TABLE OF CONTENTS CRIMSON USER MANUAL - MODULAR CONTROLLER

LOCK INSERT MODE ...................................................................................................................... 161

USING THE IMAGE LIBRARY.............................................................................. 161

SELECTING PRIMITIVES................................................................................... 162

MOVING AND RESIZING................................................................................... 162

ALIGNING PRIMITIVES .................................................................................... 163

SPACING PRIMITIVES...................................................................................... 163

REORDERING PRIMITIVES ................................................................................ 163

GROUPING PRIMITIVES ................................................................................... 164

EDITING PRIMITIVES ...................................................................................... 164

DEFINING COLORS......................................................................................... 164

DEFINING FILL PATTERNS................................................................................ 165

DEFINING ACTIONS........................................................................................ 166

ENABLING ACTIONS ....................................................................................... 166

ACTION DESCRIPTIONS................................................................................... 166

THE GOTO PAGE ACTION ............................................................................................................... 167

THE PUSH BUTTON ACTION ............................................................................................................168

THE CHANGE INTEGER VALUE ACTION ............................................................................................... 169

THE RAMP INTEGER VALUE ACTION ..................................................................................................169

THE PLAY TUNE ACTION ................................................................................................................ 170

THE USER DEFINED ACTION ........................................................................................................... 170

USING DEFAULT SETTINGS .............................................................................. 171

PRIMITIVE DESCRIPTIONS................................................................................ 171

THE LINE PRIMITIVE ..................................................................................................................... 171

THE SIMPLE GEOMETRIC PRIMITIVES ................................................................................................ 171

THE TANK PRIMITIVES................................................................................................................... 172

THE SIMPLE BAR PRIMITIVES .......................................................................................................... 172

THE BAR-GRAPH PRIMITIVES .......................................................................................................... 173

THE SCATTER GRAPH PRIMITIVE ......................................................................................................174

THE SCALE PRIMITIVES.................................................................................................................. 177

THE FIXED TEXT PRIMITIVE ............................................................................................................178

THE AUTO TAG PRIMITIVE.............................................................................................................. 180

THE TAG TEXT PRIMITIVES ............................................................................................................. 180

EDITING THE UNDERLYING TAG ....................................................................................................... 183

THE MULTI-LINE TEXT PRIMITIVES...................................................................................................184

THE TIME AND DATE PRIMITIVE....................................................................................................... 184

THE RICH BAR PRIMITIVES ............................................................................................................. 186

THE RICH SLIDER PRIMITIVES .........................................................................................................188

THE ALARM VIEWER PRIMITIVE ....................................................................................................... 190

THE ALARM TICKER PRIMITIVE ........................................................................................................ 195

THE EVENT VIEWER PRIMITIVE ........................................................................................................ 197

THE FILE VIEWER PRIMITIVE........................................................................................................... 197

THE REMOTE DISPLAY PRIMITIVE ..................................................................................................... 198

THE CAMERA PRIMITIVE................................................................................................................. 199

THE TRENDING PRIMITIVES ............................................................................................................ 200

THE GENERAL BUTTON PRIMITIVE ....................................................................................................203

THE RICH BUTTON PRIMITIVE ......................................................................................................... 205

THE SELECTOR PRIMITIVES............................................................................................................. 207

PAGE VI http://www.redlion.net/controller

Page 9

GETTING STARTED TABLE OF CONTENTS

THE PICTURE PRIMITIVE ................................................................................................................ 209

THE CF IMAGE PRIMITIVE ..............................................................................................................213

THE DIAL GAUGE PRIMITIVES.......................................................................................................... 214

SYSTEM PRIMITIVES .......................................................................................216

THE TOUCH TEST PRIMITIVE ........................................................................................................... 217

THE TOUCH CALIBRATION PRIMITIVE ................................................................................................ 217

DEFINING PAGE PROPERTIES ............................................................................218

DEFINING SYSTEM ACTIONS .............................................................................219

ADDITIONAL SYSTEM PROPERTIES ......................................................................219

SELECTING LANGUAGES ...................................................................................221

CHANGING THE LANGUAGE ...............................................................................222

SIMULATING LANGUAGES IN CRIMSON .................................................................222

DEFINING KEY BEHAVIOR.................................................................................223

BLOCKING DEFAULT ACTIONS............................................................................223

DATA AVAILABILITY ........................................................................................224

NOTES FOR EDICT USERS.................................................................................224

CONFIGURING PROGRAMS ............................................................................. 225

USING THE PROGRAM LIST ...............................................................................225

EDITING PROGRAMS .......................................................................................225

PROGRAM PROPERTIES ....................................................................................225

ADDING COMMENTS........................................................................................227

RETURNING VALUES........................................................................................228

HERE BE DRAGONS! ...................................................................................................................... 228

PASSING ARGUMENTS......................................................................................228

PROGRAMMING TIPS .......................................................................................229

MULTIPLE ACTIONS....................................................................................................................... 229

IF STATEMENTS ........................................................................................................................... 230

SWITCH STATEMENTS.................................................................................................................... 231

LOCAL VARIABLES......................................................................................................................... 232

LOOP CONSTRUCTS....................................................................................................................... 232

NOTES FOR EDICT USERS.................................................................................234

CONFIGURING DATA LOGGING ....................................................................... 237

BATCH LOGGING............................................................................................237

CONTROLLING A BATCH ................................................................................................................. 238

CREATING DATA LOGS.....................................................................................238

USING THE LOG LIST ......................................................................................238

DATA LOG PROPERTIES ...................................................................................239

LOG FILE STORAGE.........................................................................................240

THE LOGGING PROCESS...................................................................................241

ACCESSING LOG FILES.....................................................................................241

USING WEBSYNC ...........................................................................................242

WEBSYNC SYNTAX........................................................................................................................ 242

OPTIONAL SWITCHES .................................................................................................................... 242

EXAMPLE USAGE........................................................................................................................... 243

REVISION 6 PAGE VII

Page 10

TABLE OF CONTENTS CRIMSON USER MANUAL - MODULAR CONTROLLER

NOTES FOR EDICT USERS ................................................................................ 243

CONFIGURING THE WEB SERVER .................................................................... 245

WEB SERVER PROPERTIES ............................................................................... 245

ADDING WEB PAGES ...................................................................................... 247

USING A CUSTOM WEB SITE ............................................................................ 247

CREATING THE SITE ...................................................................................................................... 248

EMBEDDING DATA ........................................................................................................................ 248

DEPLOYING THE SITE ....................................................................................................................248

COMPACTFLASH ACCESS.................................................................................. 248

ACCESSING THE WEB SERVER........................................................................... 248

USING ETHERNET ......................................................................................................................... 249

USING MODEMS ........................................................................................................................... 249

WEB SERVER SAMPLES ................................................................................... 250

USING THE SECURITY SYSTEM........................................................................ 255

SECURITY BASICS.......................................................................................... 255

OBJECT-BASED SECURITY............................................................................................................... 255

NAMED USERS ............................................................................................................................. 255

USER RIGHTS .............................................................................................................................. 255

ACCESS CONTROL......................................................................................................................... 256

WRITE LOGGING ..........................................................................................................................256

DEFAULT ACCESS ......................................................................................................................... 256

ON-DEMAND LOGON ..................................................................................................................... 257

MAINTENANCE ACCESS .................................................................................................................. 257

SECURITY SETTINGS ...................................................................................... 257

CREATING USERS .......................................................................................... 258

SPECIFYING TAG SECURITY.............................................................................. 259

SPECIFYING PAGE SECURITY ............................................................................ 259

THE SECURITY MANAGER PRIMITIVE .................................................................. 259

SECURITY RELATED FUNCTIONS ........................................................................ 259

WRITING EXPRESSIONS................................................................................ 260

DATA VALUES............................................................................................... 260

CONSTANTS ................................................................................................................................260

TAG VALUES................................................................................................................................ 261

COMMUNICATIONS REFERENCES ....................................................................................................... 262

SIMPLE MATH............................................................................................... 262

OPERATOR PRIORITY...................................................................................... 262

TYPE CONVERSION ........................................................................................ 262

COMPARING VALUES ...................................................................................... 263

TESTING BITS .............................................................................................. 263

MULTIPLE CONDITIONS................................................................................... 264

CHOOSING VALUES ........................................................................................ 264

MANIPULATING BITS ...................................................................................... 265

AND, OR AND XOR ...................................................................................................................... 265

SHIFT OPERATORS........................................................................................................................ 265

BITWISE NOT ............................................................................................................................. 265

PAGE VIII http://www.redlion.net/controller

Page 11

GETTING STARTED TABLE OF CONTENTS

INDEXING ARRAYS..........................................................................................266

INDEXING STRINGS ........................................................................................266

ADDING STRINGS...........................................................................................266

CALLING PROGRAMS .......................................................................................266

USING FUNCTIONS .........................................................................................266

PRIORITY SUMMARY .......................................................................................266

NOTES FOR EDICT USERS.................................................................................267

WRITING ACTIONS....................................................................................... 269

CHANGING PAGE............................................................................................269

CHANGING NUMERIC VALUES ............................................................................269

SIMPLE ASSIGNMENT ..................................................................................................................... 269

COMPOUND ASSIGNMENT ............................................................................................................... 269

INCREMENT AND DECREMENT ..........................................................................................................269

CHANGING BIT VALUES....................................................................................269

RUNNING PROGRAMS ......................................................................................270

USING FUNCTIONS .........................................................................................270

OPERATOR PRIORITY ......................................................................................270

NOTES FOR EDICT USERS.................................................................................270

USING RAW PORTS ...................................................................................... 271

CONFIGURING A SERIAL PORT ...........................................................................271

CONFIGURING A TCP/IP SOCKET.......................................................................271

READING CHARACTERS ....................................................................................272

READING ENTIRE FRAMES ................................................................................272

SENDING DATA..............................................................................................273

NOTES FOR EDICT USERS.................................................................................273

SYSTEM VARIABLE REFERENCE ....................................................................... 275

HOW ARE SYSTEM VARIABLES USED....................................................................275

ACTIVEALARMS..............................................................................................276

COMMSERROR...............................................................................................277

DISPBRIGHTNESS...........................................................................................278

DISPCONTRAST .............................................................................................279

DISPCOUNT..................................................................................................280

DISPUPDATES ...............................................................................................281

ISSIRENON ..................................................................................................282

PI..............................................................................................................283

TIMEZONE ...................................................................................................284

TIMEZONEMINS.............................................................................................285

USEDST......................................................................................................286

PROGRAMMING REFERENCE ........................................................................... 287

EXPRESSION OPERATORS .................................................................................287

ACTION OPERATORS .......................................................................................288

PROGRAMMING STATEMENTS.............................................................................289

REVISION 6 PAGE IX

Page 12

TABLE OF CONTENTS CRIMSON USER MANUAL - MODULAR CONTROLLER

FUNCTION REFERENCE .................................................................................. 291

NOTES FOR EDICT USERS ................................................................................ 291

ABS(

VALUE

)................................................................................................. 292

ACOS(

VALUE

) ............................................................................................... 293

ALARMACCEPTALL()....................................................................................... 294

ASIN(

VALUE

) ................................................................................................ 295

ATAN(

VALUE

) ............................................................................................... 296

ATAN2(

BEEP(

A, B

) ................................................................................................ 297

FREQ, PERIOD

) ..................................................................................... 298

CLEAREVENTS()............................................................................................ 299

CLOSEFILE(

FILE

)........................................................................................... 300

COMMITANDRESET() ..................................................................................... 301

COMPACTFLASHEJECT() .................................................................................. 302

COMPACTFLASHSTATUS()................................................................................ 303

CONTROLDEVICE(

COPY(

DEST, SRC, COUNT

COS(

THETA

CREATEDIRECTORY(

CREATEFILE(

DATATOTEXT(

DATE(

Y, M, D

DECTOTEXT(

DEG2RAD(

DELETEDIRECTORY(

DELETEFILE(

DEVCTRL(

DEVICE, FUNCTION, DATA

DISABLEDEVICE(

DEVICE, ENABLE

).................................................................... 304

) ............................................................................... 305

)................................................................................................. 306

NAME

) .............................................................................. 307

NAME

) ....................................................................................... 308

DATA, LIMIT

)............................................................................. 309

) ............................................................................................. 310

DATA, SIGNED, BEFORE, AFTER, LEADING, GROUP

THETA

) ......................................................................................... 312

NAME

) .............................................................................. 313

FILE

) ......................................................................................... 314

) ............................... 311

) ................................................................. 315

DEVICE

)................................................................................. 316

DISPOFF() .................................................................................................. 317

DISPON() ................................................................................................... 318

DRVCTRL(

EMPTYWRITEQUEUE (

ENABLEDEVICE(

PORT, FUNCTION, DATA OR VALUE

DEV

).............................................................................. 320

DEVICE

).................................................................................. 321

???

) .................................................. 319

ENDBATCH()................................................................................................ 322

EXP(

VALUE

) ................................................................................................. 323

EXP10(

VALUE

) .............................................................................................. 324

FILL(

ELEMENT, DATA, COUNT

FIND(

STRING,CHAR,SKIP

FINDFILEFIRST(

DIR

) ...................................................................................... 327

).......................................................................... 325

)................................................................................ 326

FINDFILENEXT() ........................................................................................... 328

FINDTAGINDEX(

LABEL

)................................................................................... 329

FORMATCOMPACTFLASH() ............................................................................... 330

PAGE X http://www.redlion.net/controller

Page 13

GETTING STARTED TABLE OF CONTENTS

FTPGETFILE(

FTPPUTFILE(

GETALARMTAG(

SERVER, LOC, REM, DELETE

SERVER, LOC, REM, DELETE

INDEX

)....................................................................................333

) ............................................................331

) ............................................................332

GETBATCH().................................................................................................334

GETCAMERADATA(

GETDATE (

TIME

GETDISKFREEBYTES(

GETDISKFREEPERCENT(

GETDISKSIZEBYTES(

GETFORMATTEDTAG(

GETINTERFACESTATUS(

GETINTTAG(

GETMONTHDAYS(

GETNETGATE(

GETNETID(

GETNETIP(

PORT

GETNETMASK(

PORT, CAMERA, PARAM

)...........................................................335

) AND FAMILY ...........................................................................336

DRIVE

).............................................................................337

DRIVE

) .........................................................................338

DRIVE

) .............................................................................339

INDEX

).............................................................................340

PORT

)...........................................................................341

INDEX

)........................................................................................342

Y, M

) ...................................................................................343

PORT

) ......................................................................................344

PORT

) ..........................................................................................345

)...........................................................................................346

PORT

) ......................................................................................347

GETNOW()...................................................................................................348

GETNOWDATE()............................................................................................349

GETNOWTIME() ............................................................................................350

GETPORTCONFIG(

GETREALTAG(

GETSTRINGTAG(

GETTAGLABEL(

GETUPDOWNDATA(

GETUPDOWNSTEP(

GOTOPAGE(

PORT, PARAM

INDEX

)......................................................................................352

INDEX

)...................................................................................353

INDEX

) ....................................................................................354

DATA, LIMIT

DATA, LIMIT

NAME

) .........................................................................................357

) .......................................................................351

).......................................................................355

) .......................................................................356

GOTOPREVIOUS() ..........................................................................................358

HASACCESS (

RIGHTS

) .....................................................................................359

HIDEPOPUP() ...............................................................................................360

INTTOTEXT(

ISDEVICEONLINE(

ISWRITEQUEUEEMPTY(

LEFT(

LEN(

STRING

LOADCAMERASETUP(

LOG(

VALUE

LOG10(

DATA, RADIX, COUNT

DEVICE

STRING, COUNT

) ...............................................................................362

DEV

) ....................................................................................364

).....................................................................361

).............................................................................363

) ................................................................................................365

PORT, CAMERA, INDEX, FILE

) .................................................366

) .................................................................................................367

VALUE

)..............................................................................................368

LOGSAVE()...................................................................................................369

MAKEFLOAT(

MAKEINT(

VALUE

) .......................................................................................370

VALUE

)...........................................................................................371

REVISION 6 PAGE XI

Page 14

TABLE OF CONTENTS CRIMSON USER MANUAL - MODULAR CONTROLLER

MAX(A, B)................................................................................................... 372

MEAN(

ELEMENT, COUNT

MID(

STRING, POS, COUNT

) ................................................................................ 373

).............................................................................. 374

MIN(A, B) ................................................................................................... 375

MULDIV(

A, B, C

) .......................................................................................... 376

MUTESIREN()............................................................................................... 377

NEWBATCH(

NAME

) ........................................................................................ 378

NOP() ........................................................................................................ 379

OPENFILE(

NAME, MODE

)................................................................................. 380

PI()........................................................................................................... 381

PLAYRTTTL(

POPDEV(

PORTCLOSE(

PORTGETCTS(

PORTINPUT(

PORTPRINT(

PORTREAD(

PORTSETRTS(

PORTWRITE(

POSTKEY(

POWER(

RAD2DEG(

RANDOM(

READDATA(

READFILE(

READFILELINE(

RENAMEFILE(

RIGHT(

SAVECAMERASETUP(

SCALE(

SENDFILE(

SENDMAIL(

SET(

TAG, VALUE

SETINTTAG(

SETLANGUAGE(

SETNETCONFIG(

SETNOW(

SETPORTCONFIG(

SETREALTAG(

SGN(

VALUE

SHOWMENU(

TUNE

) ....................................................................................... 382

ELEMENT, COUNT

PORT

) ........................................................................................ 384

PORT

PORT, START, END, TIMEOUT, LENGTH

PORT, STRING

PORT, PERIOD

PORT, STATE

PORT, DATA

CODE, TRANSITION

VALUE, POWER

THETA

) ......................................................................................... 393

RANGE

) .......................................................................................... 394

DATA, COUNT

FILE, CHARS

FILE

HANDLE, NAME

STRING, COUNT

DATA, R

1

,

R

RCPT, FILE

RCPT, SUBJECT, BODY

) ............................................................................. 383

) ..................................................................................... 385

) .............................................. 386

) ............................................................................. 387

).............................................................................. 388

)............................................................................ 389

)............................................................................... 390

).......................................................................... 391

).................................................................................. 392

)............................................................................... 395

).................................................................................. 396

) ...................................................................................... 397

)........................................................................... 398

).................................................................................. 399

PORT, CAMERA, INDEX, FILE

2

,

E

1

,

E

2

).......................................................................... 401

) ................................................. 400

).................................................................................... 402

) .................................................................... 403

) .......................................................................................... 404

INDEX, VALUE

CODE

PORT, ADDR, MASK, GATE

TIME

) ............................................................................................ 408

PORT, PARAM, VALUE

INDEX, VALUE

) ............................................................................. 405

)..................................................................................... 406

) ......................................................... 407

) ............................................................. 409

)............................................................................ 411

) ................................................................................................ 412

NAME

) ....................................................................................... 413

PAGE XII http://www.redlion.net/controller

Page 15

GETTING STARTED TABLE OF CONTENTS

SHOWPOPUP(

SIN(

THETA

NAME

) .......................................................................................414

) ..................................................................................................415

SIRENON() ..................................................................................................416

SLEEP(

PERIOD

) .............................................................................................417

SQRT(

VALUE

)................................................................................................418

STDDEV(

ELEMENT, COUNT

) ..............................................................................419

STOPSYSTEM()..............................................................................................420

STRIP(

TEXT, TARGET

SUM(

ELEMENT, COUNT

TAN(

THETA

) .................................................................................................423

TESTACCESS(

TEXTTOADDR(

TEXTTOFLOAT(

TEXTTOINT(

TIME(

H, M, S

STRING, RADIX

) ..............................................................................................428

USECAMERASETUP(

) .....................................................................................421

)...................................................................................422

RIGHTS, PROMPT

ADDR

)......................................................................................425

STRING

)...................................................................................426

).........................................................................424

) ............................................................................427

PORT, CAMERA, INDEX

) ..........................................................429

USERLOGOFF() .............................................................................................430

USERLOGON() ..............................................................................................431

WAITDATA(

WRITEFILE(

WRITEFILELINE(

DATA, COUNT, TIME

FILE, TEXT

)...................................................................................433

FILE, TEXT

).............................................................................434

).......................................................................432

TROUBLESHOOTING ...................................................................................... 435

GENERAL .....................................................................................................435

CRIMSON MESSAGES.......................................................................................438

SERIAL COMMUNICATION .................................................................................439

ETHERNET COMMUNICATION.............................................................................440

PROGRAMS ...................................................................................................441

WEB SERVER ................................................................................................442

REVISION 6 PAGE XIII

Page 16

Page 17

CRIMSON 2

SER MANUAL

U

MODULAR CONTROLLER

Page 18

Page 19

GETTING STARTED SYSTEM REQUIREMENTS

GETTING STARTED

Welcome to Crimson 2—the latest configuration package from Red Lion Controls. Crimson

is designed to provide quick and easy access to the features of the Modular Controller and

Data Station series, while still allowing the advanced user to take advantage of high-end

features, such as Crimson’s unique programming support.

SYSTEM REQUIREMENTS

Crimson 2 is designed to run on PCs with the following specifications…

• A Pentium class processor as required by the chosen operating system.

• RAM and free disk space as required by the chosen operating system.

• An additional 50MB of disk space for software installation.

• A display of at least 800 by 600 pixels, with 256 or more colors.

• An RS-232 or USB port for downloading.

Crimson 2 is designed to operate with all versions of Microsoft Windows from Windows 95

upwards. If you want to take advantage of the USB port provided by the Master module, you

will need to use, as a minimum, Windows 98. If you intend to use the USB port to remotely

access the Master’s CompactFlash card, we recommend that you use Windows 2000 or

Windows XP. While Windows 98 is capable of accessing the card, the later versions of the

operating system provide more robust operation, and are much better about when they choose

to lock the card, thereby preventing the C2 runtime from writing data.

INSTALLING THE SOFTWARE

If you downloaded the Crimson software from Red Lion’s website, simply execute the

download file, and follow the instructions. If you received a copy of Crimson on CD, place

the CD in your system’s CDROM drive, and follow the instructions that will appear. If no

instructions appear, you may have auto-run disabled. In that case, select the Run option from

the Start menu, and enter

follow the resulting instructions, and the software will be installed.

x:\setup, where x is the drive letter of your CDROM drive. Again,

CHECKING FOR UPDATES

If you have an Internet connection, you can use the Check for Update command in the Help

menu to scan Red Lion’s web site for a new version of Crimson. If a later version than the

one you are using is found, Crimson will ask if it should download the upgrade and update

your software automatically. You may also manually download the upgrade from Red Lion’s

website by visiting the Downloads page within the Support section. Either way, when the

upgrade package executes, be sure to select the Repair option to update your installation.

REVISION 6 PAGE 1

Page 20

INSTALLING THE USB DRIVERS CRIMSON USER MANUAL - MODULAR CONTROLLER

INSTALLING THE USB DRIVERS

When you first connect a Master module to your PC using a USB cable, Windows will

prompt you for the location of the drivers for the device. The default location for these drivers

is C:\Program Files\Red Lion Controls\Crimson 2.0\Device. When the Hardware Setup

Wizard appears, choose the Browse option, and either point the Wizard at that location or

whatever other location you specified during installation of the software. It is important that

you perform this step correctly, or you may have to manually remove the drivers using the

Device Manager, and repeat the installation once more. Windows XP users should note that

Crimson’s USB drivers have not been digitally signed by Microsoft, and you will therefore a

dialog offering you the chance to stop the installation. You should be sure to select the

Continue option to indicate that you do indeed wish to install the drivers.

PAGE 2 http://www.redlion.net/controller

Page 21

QUICK START OVERVIEW

QUICK START

The Modular Controller is a versatile platform, truly requiring a 300+ page manual. However,

you’ll no doubt want to jump right into programming before reading it in its entirety. The

following section provides you with enough information to develop a working system.

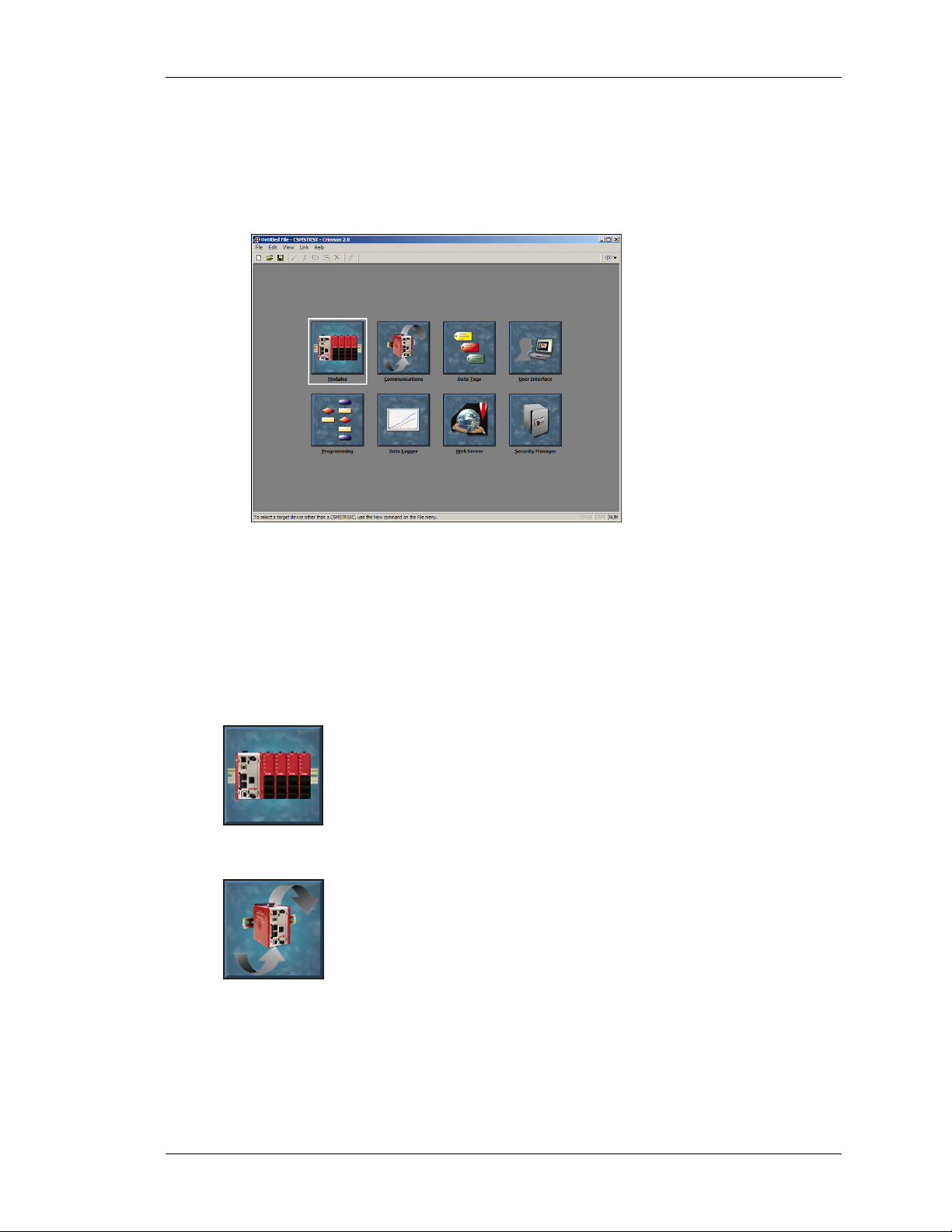

OVERVIEW

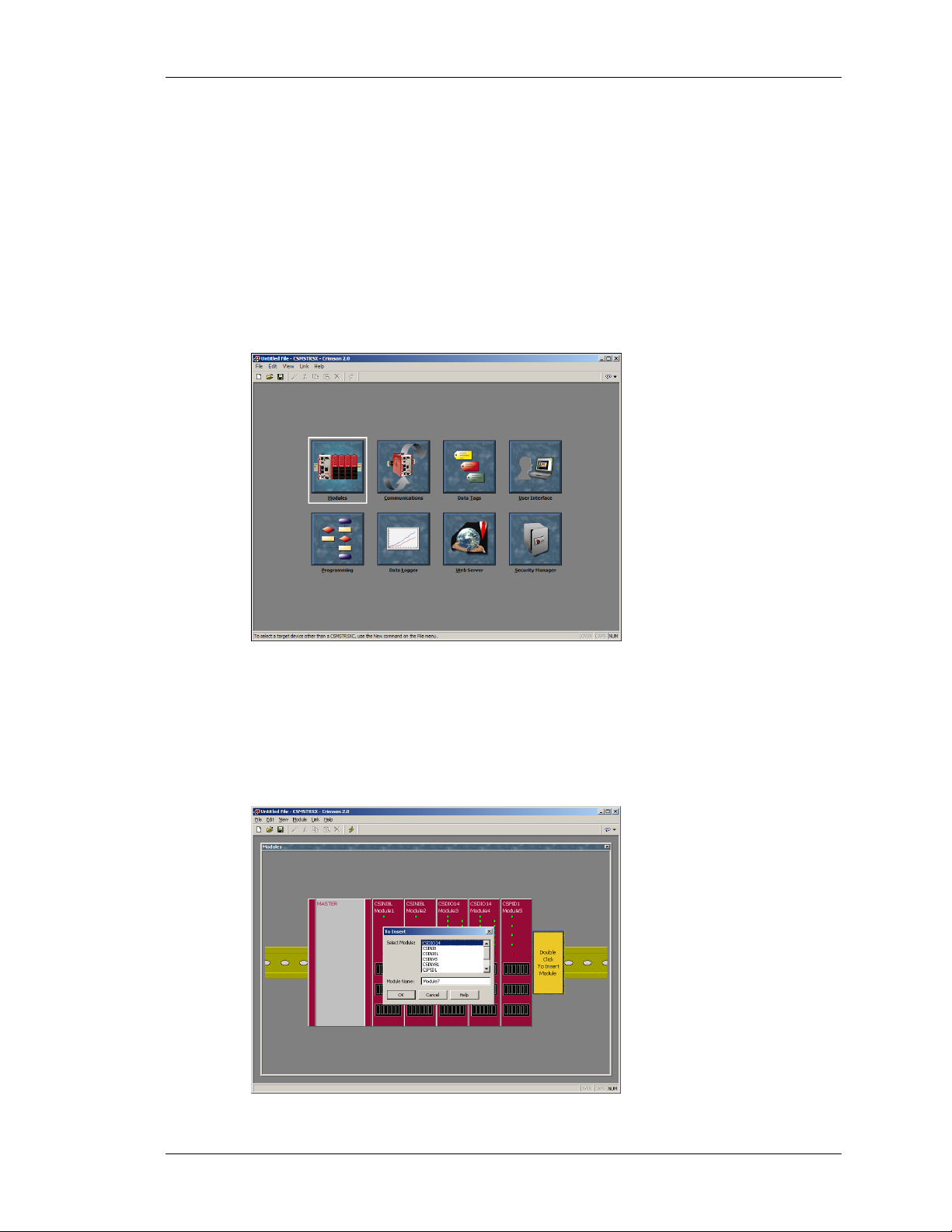

For the simplest of applications, only the first two icons eg. Modules and Communications,

are necessary. The former configures the system, allowing you to add, delete and edit

modules, while the latter allows module data to be mapped to an external device(s).

MODULES

The first step in the configuration of a database is to create and configure the various modules

used in the application. This is done under the Modules window of Crimson.

To insert a module into the system, double click on the blank base. You will be prompted to

choose the type of module to insert. You may also provide a descriptive name for the module.

REVISION 6 PAGE 3

Page 22

COMMUNICATIONS CRIMSON USER MANUAL - MODULAR CONTROLLER

Edit the individual module’s properties by double-clicking it. Each module and its properties

are explained in detail in later sections.

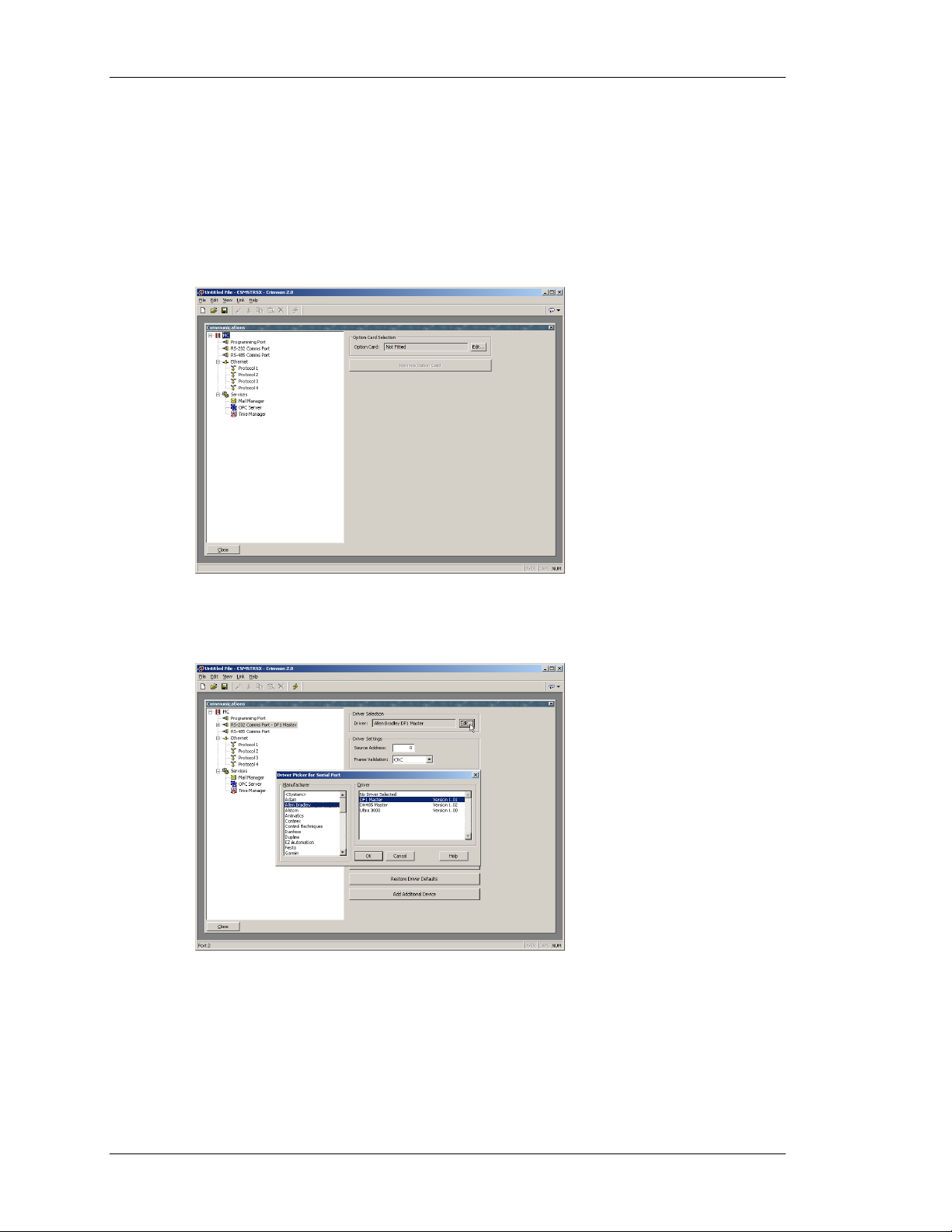

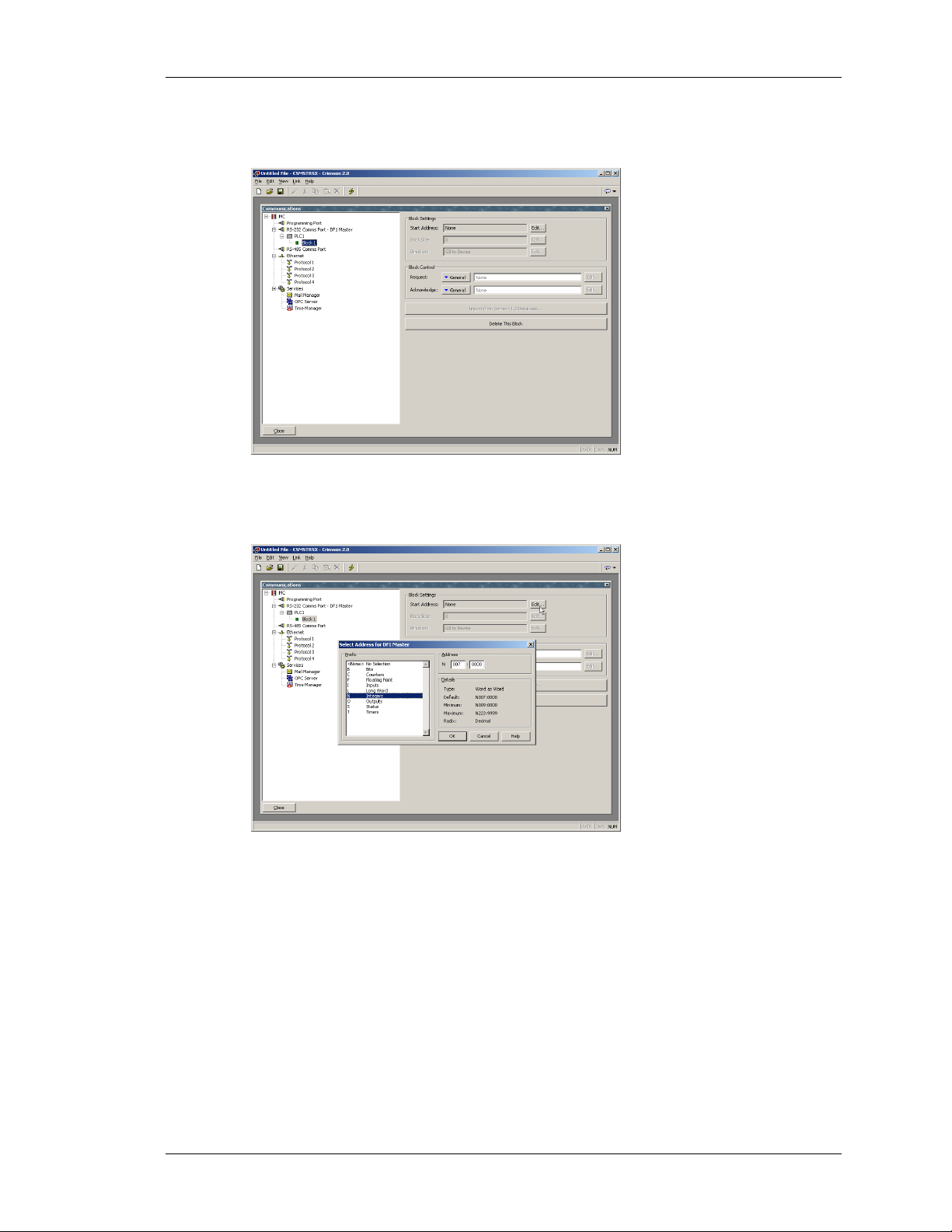

COMMUNICATIONS

Next, you’ll want to configure a port to communicate data to your PLC, PC, etc. The ports are

configured under the Communications window of the software. Click the Edit button in the

driver selection area to choose a protocol.

In the example below, Allen Bradley DF1 Master has been selected as the protocol. By doing

so, a device called PLC1 has been created. You should verify that the driver properties eg.

parity, baud rate, address, etc. make sense for your application.

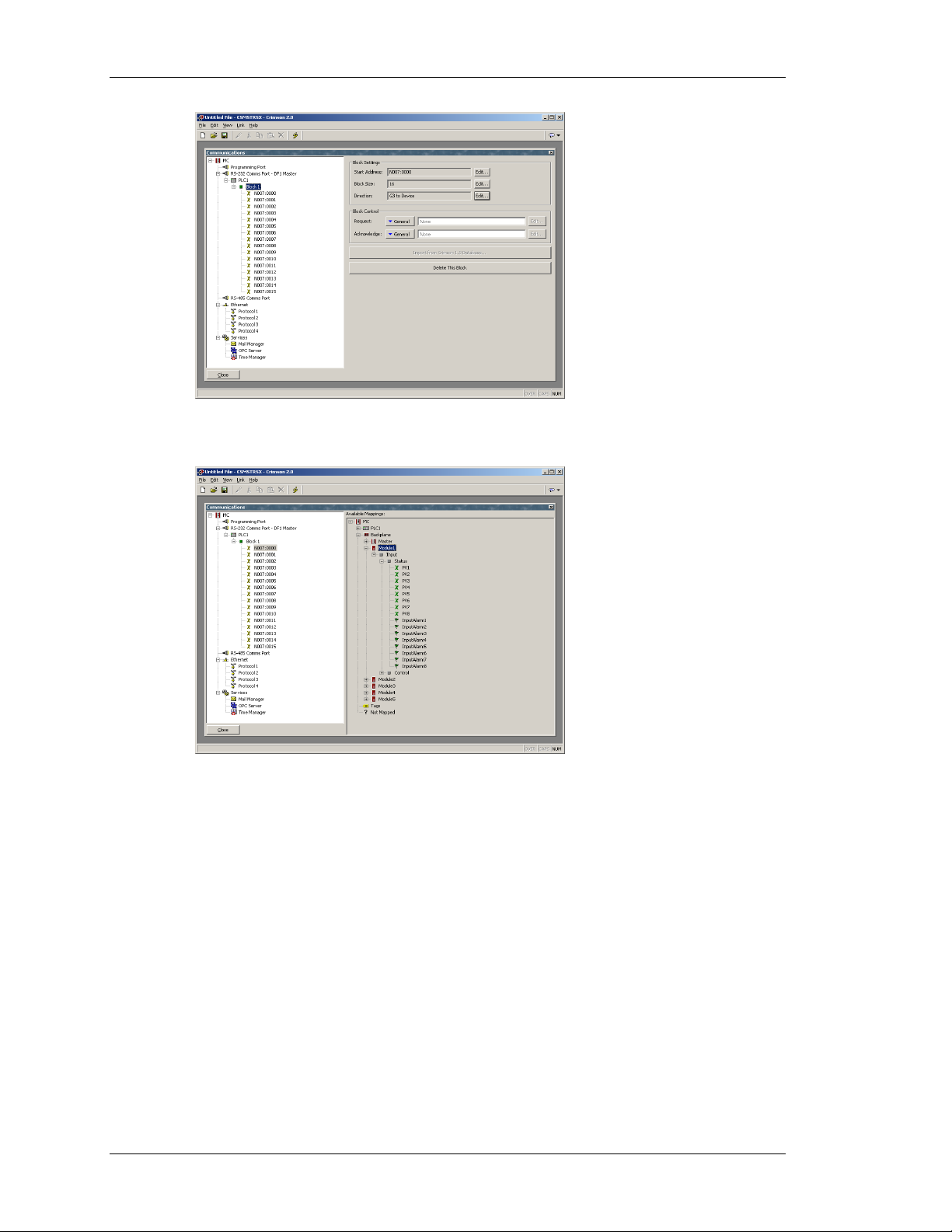

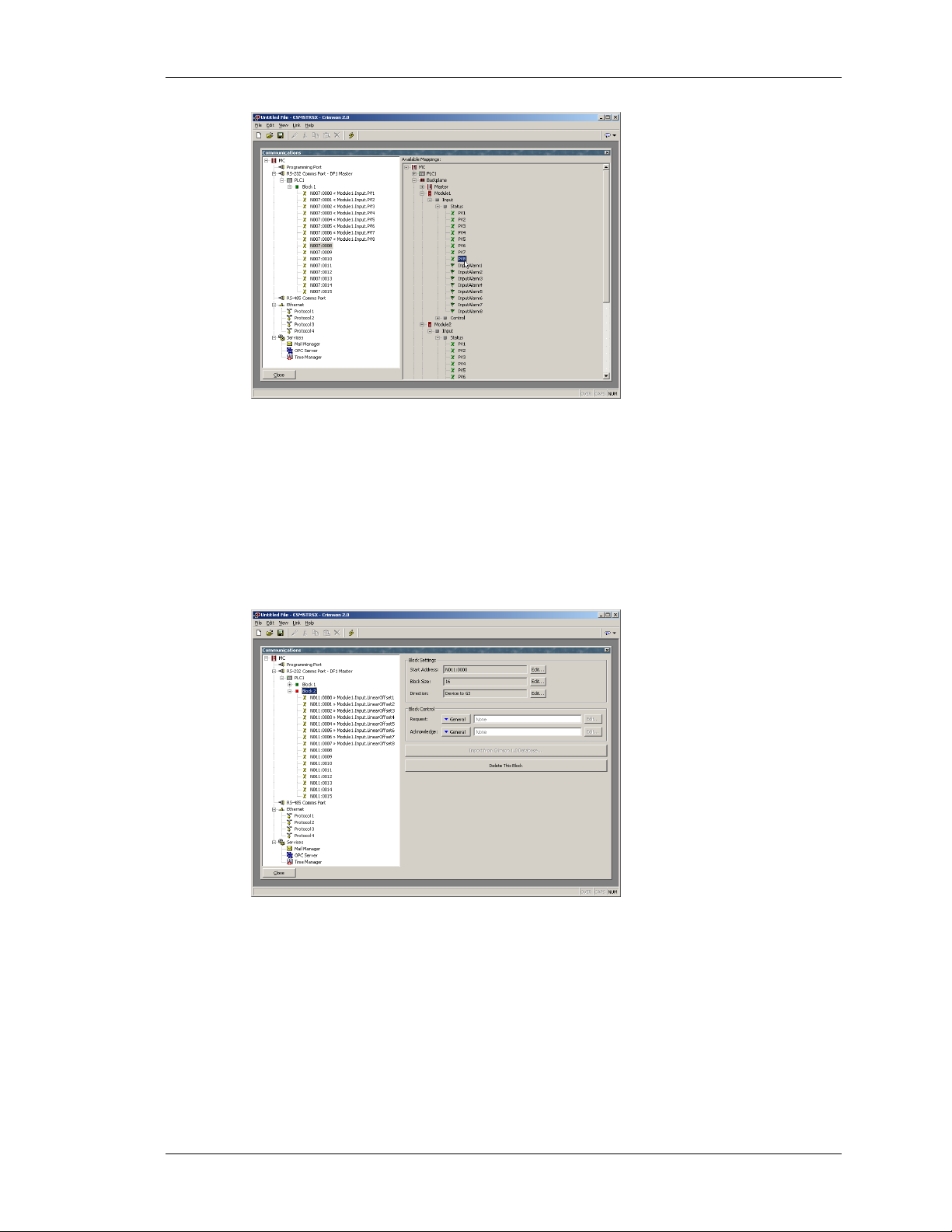

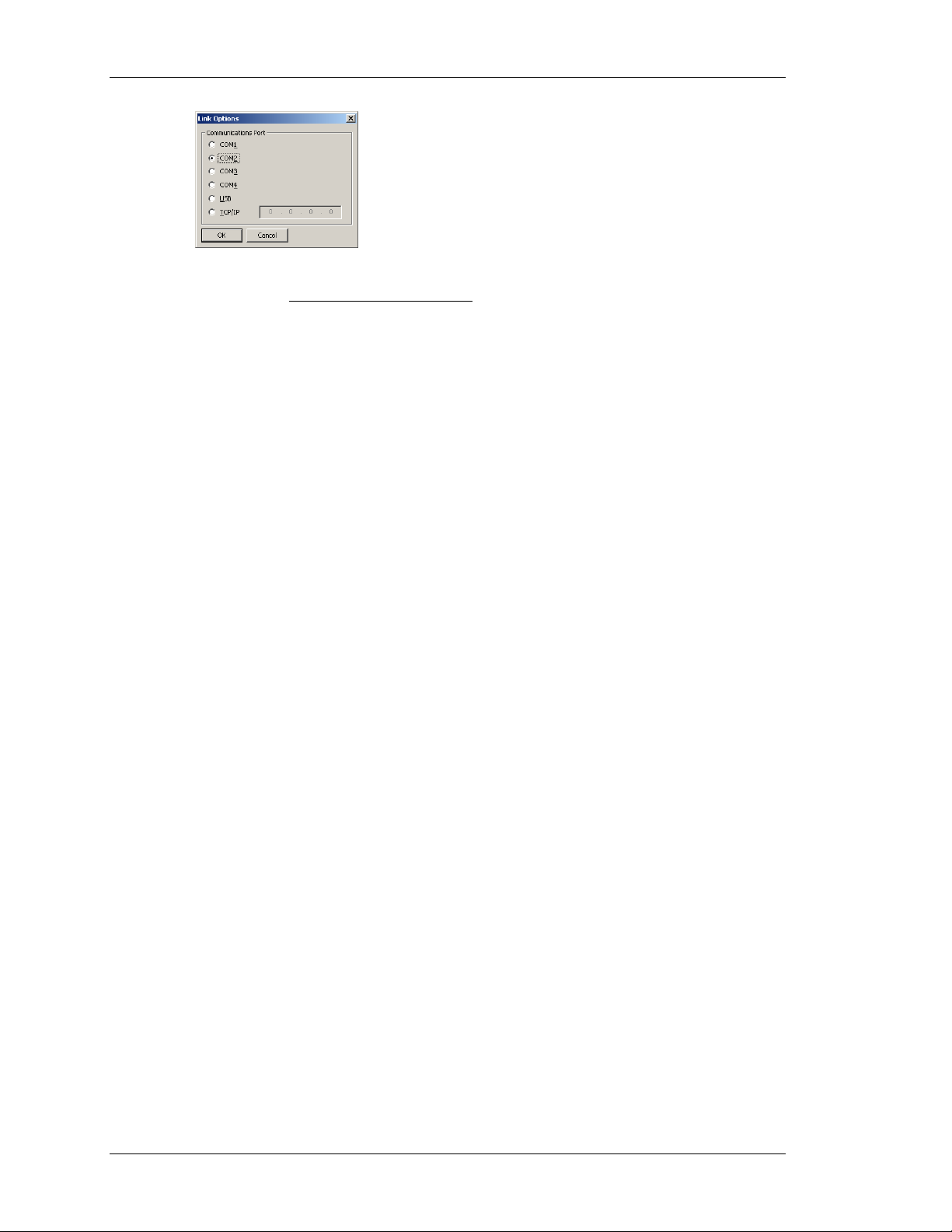

MAPPING DATA

To map data between the Modular Controller and an external device, you’ll need to create

two so-called Gateway Blocks; one for moving module data into your device, and one for

getting module data from your device.