Page 1

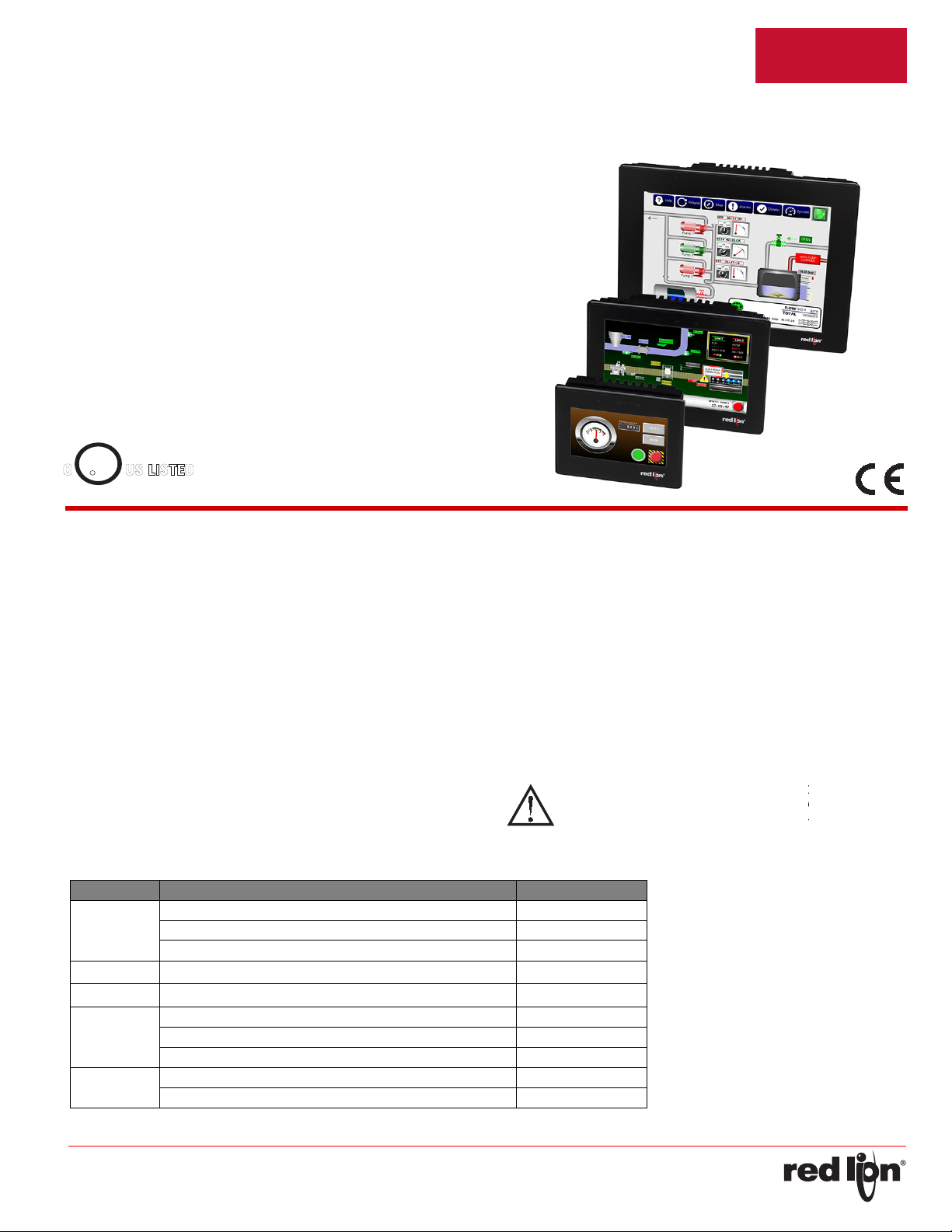

ModelCR1000‐IndustrialOperat orInterfaceWithTFTDisplay

WARNING - EXPLOSION HAZARD - DO NOT D

EQUIPMENT UNLESS POWER HAS BEEN SW

OR AREA IS KNOWN TO BE NON-HAZARDOU

CAUTION: Risk of Danger.

Read complete instructions prior to installation

and operation of the unit.

C

US LISTED

U

L

R

IND. CONT

. EQ.

Bulletin No. CR1000-B

Drawing No. LP1019

Released 2018-01-12

• CONFIGURED USING CRIMSON

®

3.1 SOFTWARE

• TWO SERIAL COMMUNICATION PORTS,

(1 RS-232 and 1 RS-232/422/485)

• 10 BASE T/100 BASE-TX ETHERNET PORT COMMUNICATES

WITH UP TO FOUR PROTOCOLS SIMULTANEOUSLY

• UNIT’S CONFIGURATION IS STORED IN NON-VOLATILE FLASH

MEMORY

• SD CARD SOCKET FOR LOADING DATABASE IN FIELD

• INDUSTRIAL TFT LCD COLOR DISPLAY

• NEMA 4X/IP66 FRONT PANEL

• THREE FRONT PANEL LED INDICATORS

• POWER UNIT FROM 24 ±20% VDC

• RESISTIVE ANALOG TOUCHSCREEN

E302106

GENERALDESCRIPTION

The CR1000 is the perfect solution for applications that require the

operator to monitor and control more than just a single device. With two

serial ports and an Ethernet port, these HMI displays can connect to

multiple serial and Ethernet devices simultaneously, including PLCs,

motor drives, bar code scanners, etc.

The CR1000 performs the functions of a multiple protocol converter,

using two high-speed serial communications ports and a 10/100 BaseTX Ethernet port. The Ethernet port supports up to four protocols

simultaneously, allowing dissimilar Ethernet based products to

communicate with one another. The SD card slot can be used to load the

unit's configuration file, allowing configuration changes to be made and

saved to the card for later transfer.

The CR1000 range of HMIs is programmed with Red Lion's free

Crimson 3.1 software. Crimson offers easy to use drag and drop

communications configuration, while the embedded image library allows

the programmer to create intuitive screens and prompts for the operator.

CONTENTSOFPACKAGE

- CR1000 Operator Interface

- Hardware packet and plate for mounting unit into panel

- Terminal block for connecting power

- Panel gasket

SAFETYSUMMARY

All safety related regulations, local codes and instructions that appear

in the manual or on equipment must be observed to ensure personal

safety and to prevent damage to either the instrument or equipment

connected to it. If equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

Do not use the unit to directly command motors, valves, or other

actuators not equipped with safeguards. To do so can be potentially

harmful to persons or equipment in the event of a fault to the unit.

ORDERINGINFORMATION

MODEL NO. DESCRIPTION PART NUMBER

4.3" HMI with 2 Serial Ports, 1 Ethernet Port, and USB Device Port CR1000 04000 00210

CR1000

SD

CBL

FILM

CRA000

1

Contact your Red Lion distributor or visit our website for selection of SD

7.0" HMI with 2 Serial Ports, 1 Ethernet Port, and USB Device Port CR1000 07000 00210

10.4" HMI with 2 Serial Ports, 1 Ethernet Port, and USB Device Port CR1000 10000 00210

1

SD Card

Communications Cables and Adapter

Protective Film for CR1000 04xxx xxxxx G3FILM4K

Protective Film for CR1000 07xxx xxxxx G3FILM07

Protective Film for CR1000 10xxx xxxxx G3FILM10

Adapter Plate from Kadet 7 to CRX000 07 CRA000 AD070 70000

Replacement Battery CRA000 BT3V0 00000

1

cards, adapters and cables.

-1-

SDxxxxxx

CBLxxxxx

Page 2

Bulletin No. CR1000-B Released 2018-01-12

4 inch

4.12

(104.69)

5.14 (130.65)

4.62

(117.48)

5.65 (143.51)

3.62

(92.08)

1.50

(38.1)

CR100004

7 inch

5.43

(138.02)

7.63 (193.98)

5.80

(147.32)

8.00 (203.2)

4.80

(121.92)

2.00

(50.8)

THIS VIEW SHOWN WITH MOUNTING PLATE AND BRACKETS

CR100007

Drawing No. LP1019

SPECIFICATIONS

1. POWER REQUIREMENTS:

Must use a Class 2 circuit according to National Electrical Code (NEC),

NFPA-70 or Canadian Electrical Code (CEC), Part I, C22.1 or a

Limited Power Supply (LPS) according to IEC 60950-1 or Limitedenergy circuit according to IEC 61010-1.

Power connection via removable three position terminal block.

Supply Voltage: 24 VDC ±20%, Class 2

@ 24 VDC 4-INCH 7-INCH 10-INCH

Typical Power: 3.9 W 5.3 W 8.3 W

Max Power: 5.0 W 6.2 W 9.0 W

2. BATTERY: Lithium coin cell. Typical lifetime of 5 years, nominal.

To maintain UL rating, replacement battery must be: Red Lion CRA000

BT3V0 00000, Rayovac BR1225X-BA or Panasonic BR1225A/BN.

3. LCD DISPLAY:

4-INCH 7-INCH 10-INCH

TYPE TFT TFT TFT

COLORS 16M 16M 16M

PIXELS 480 x 272 800 X 480 800 X 600

BRIGHTNESS

BACKLIGHT TYPE LED LED LED

BACKLIGHT LIFE 30K HR TYP. 50K HR TYP. 50K HR TYP.

4. TOUCHSCREEN: Four-wire resistive analog

5. MEMORY:

On Board User Memory: 512 Mbyte of non-volatile Flash memory.

Memory Card: SD slot accepts standard capacity cards up to 16 GB.

6. COMMUNICATION CAPABILITIES:

USB Device Port: Isolated and adheres to USB specification 2.0 full

speed only using Type B connection.

SYSTEM SET-UP AND DIAGNOSTICS AND IS NOT INTENDED FOR

PERMANENT CONNECTION.

Serial Ports (2): Ports are individually isolated. Format and Baud

Rates for each port are individually software programmable up to

115,200 baud.

Port to Port Isolation: 3000 Vrms for 1 minute.

Signal Isolation: 500 V.

500 cd/m

2

2

430 cd/m

400 cd/m

USB DEVICE PORT IS FOR

2

Ethernet Port: 10 BASE-T / 100 BASE-TX

RJ45 jack is wired as a NIC (Network Interface Card).

Isolation from Ethernet network to operator interface: 1500 Vrms

7. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range: -10 to 50 °C

Storage Temperature Range: -20 to 70 °C

Vibration to IEC 68-2-6: Operational 5-500 Hz, 2 g

Shock to IEC 68-2-27: Operational 30 g

Operating and Storage Humidity: 0 to 85% max. RH non-condensing

Altitude: Up to 2000 meters

Installation Category II, Pollution Degree 2 as defined in IEC/EN 60664-1.

8. CERTIFICATIONS AND COMPLIANCES:

CE Approved

Immunity: IEC/EN 61000-6-2 for Industrial Locations

Emissions: IEC/EN 61000-6-4 for Industrial Locations; CISPR 11 Class A

IEC/EN 61010-1

RoHS Compliant

UL Listed: File #E302106

Type 4X Indoor / IP66 Enclosure rating (Face only)

9. CONNECTIONS: High compression cage-clamp terminal block

Wire Strip Length: 0.3" (7.5 mm)

Wire Gage Capacity: 12 to 24 AWG (3.31 to 0.20 mm

Torque: 4.4-5.3 inch-lbs (0.5-0.6 N-m)

10. CONSTRUCTION: Polycarbonate enclosure with Type 4X/IP66 rating

when correctly fitted per the mounting instructions provided.

Protection against mechanical impact up to 5 Joule, IK08 per IEC 62262.

11. MOUNTING REQUIREMENTS: Maximum panel thickness is 0.25"

(6.35 mm) with included stiffener plate, or 0.375" (9.53 mm) without

plate. For

thickness of

Mounting screw torque: 4.0 lbf-in (0.45 Nm). CAUTION: DO NOT

12. WEIGHT: Unit weight with stiffener plate and clips

CR1000 04: 15 oz (425 g)

CR1000 07: 1.91 lb (868 g)

CR1000 10: 3.08 lb (1.395 Kg)

NEMA 4X / IP66 sealing, a panel with a minimum

0.06" (1.52 mm) is recommended.

OVERTIGHTEN THE CLAMPS

2

) copper wire

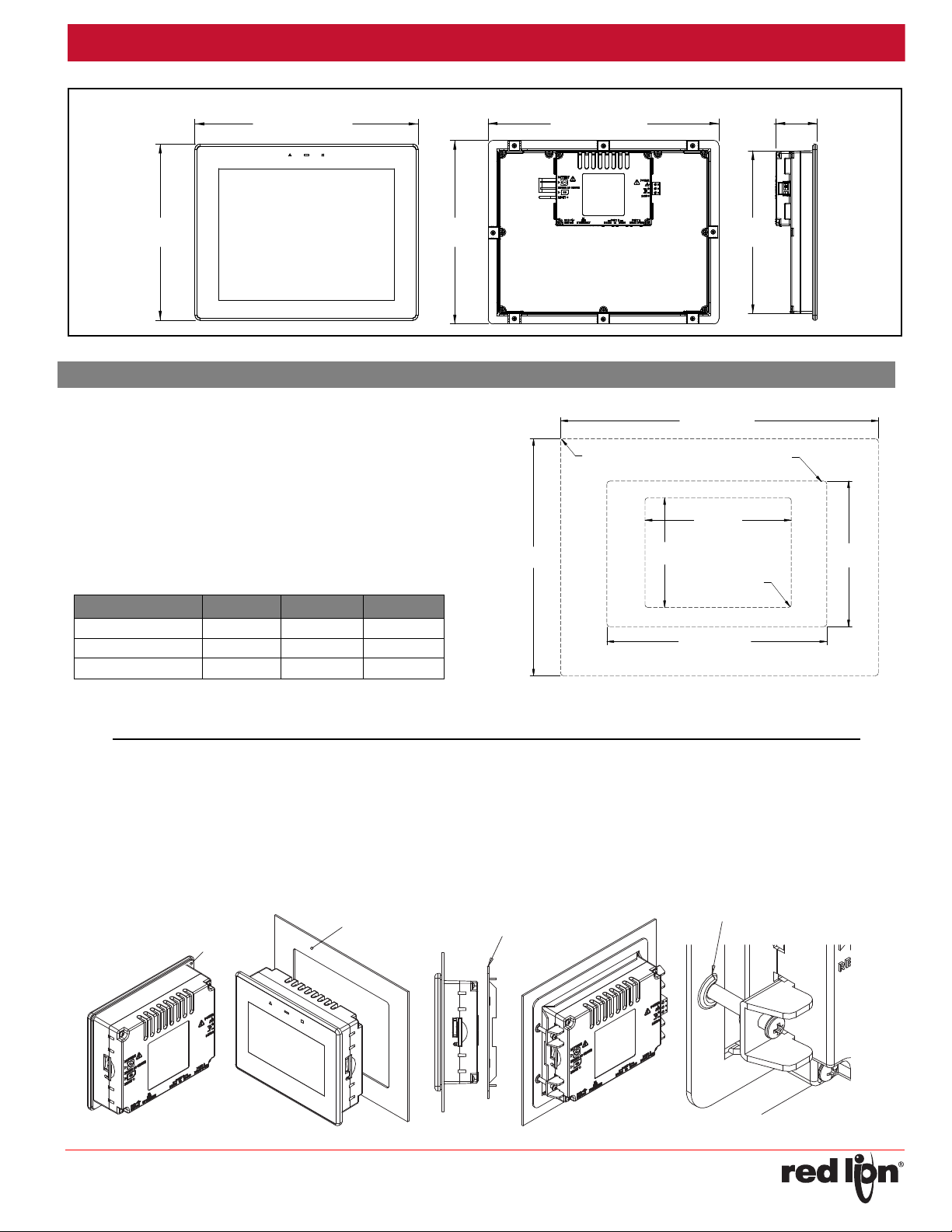

DIMENSIONSINinches(mm)

THIS VIEW SHOWN WITH MOUNTING PLATE AND BRACKETS

-2-

Page 3

Released 2018-01-12 Bulletin No. CR1000-B

10.4 inch

THIS VIEW SHOWN

WITH MOUNTING PLATE

AND BRACKETS

10.78 (273.73)

11.14 (282.96)

8.87

(225.29)

8.50

(215.99)

7.87

(199.9)

2.00

(50.8)

CR100010

10.4 INCH PANEL CUT-OUT

4 INCH PANEL CUT-OUT

7 INCH PANEL CUT-OUT

Must meet hole tolerance specification for

full NEMA4X and IP66 ingress protection.

4.69

(119.13)

3.66

(92.96)

4.87

(123.7)

7.93

(201.42)

10.20 (259.08)

7.06 (179.32)

R

0.10

(2.54)

R

0.08

(2.03)

R

0.10

(2.54)

ALL TOLERANCES +/-0.03" (+/-0.762 mm)

1

2

3

4

5

GASKET

MOUNTING

SURFACE

STIFFENER

PLATE

SCREW ANTI-WALK

FEATURE

Drawing No. LP1019

INSTALLINGANDPOWERINGTHECR1000

MOUNTINGINSTRUCTIONS

This operator interface is designed for through-panel mounting. The

mounting surface should have a minimum thickness of 0.06" (1.53 mm)

and maximum thickness of 0.375" (9.53 mm). There should be a minimum

of 4" clearance behind the panel for unit installation. Allow a minimum of

2.5" below the bottom connectors for communication cables. Cut the

mounting hole per the dimensions shown in the diagram. Care should be

taken to remove any loose material from the mounting cut-out to prevent

that material from falling into the operator interface during installation.

If installing the unit in an enclosure, follow the table below for minimum

enclosure size to allow for proper ventilation and cabling to meet UL

requirements. Consider heat produced by other devices in the enclosure.

Follow these steps to install the unit.

1. Make sure the bezel gasket is properly in place.

2. Place the unit into the front of the panel cutout.

3. Install stiffener plate over unit on the inside of the panel. This ensures

4. Insert clamps into the slots provided on the sides (CR100004) or top

5. Make sure the clamp’s screw sits in the “U” shaped feature located on

PART NUMBER WIDTH HEIGHT DEPTH

CR1000 04000 00210 10.5 inch 12.5 inch 6.25 inch

CR1000 07000 00210 10.5 inch 12.5 inch 6.25 inch

CR1000 10000 00210 12.55 inch 14.55 inch 8.31 inch

the mounting surface is stiff enough for a proper seal. The plate is

required to meet NEMA 4X and IP66.

and bottom (CR100007 and CR100010) of the unit.

the stiffener plate. This will prevent the screw from “walking”. Tighten

the clamping screws in an even pattern until the unit is secured in the

panel. To seal to Type 4X/IP66 specifications, all supplied mounting

clamps must be used and be torqued to 4.0 lbf-in (0.45 Nm). CAUTION:

DO NOT OVERTIGHTEN THE CLAMPS. The panel must not flex more

than 0.010" for proper sealing. The safety of any system incorporating

the equipment is the responsibility of the assembler of the system.

-3-

Page 4

Bulletin No. CR1000-B Released 2018-01-12

Drawing No. LP1019

CONNECTING POWER

The CR1000 requires a 24 VDC

±20% power supply. A pluggable power

block is provided to connect the 24

VDC. There are three screw terminals.

Strip and connect the wire according to

the terminal block specifications on

Page 2. Connect the positive lead to the

plus (+) screw and the negative lead to

the minus (-) screw.

Please take care to observe the following points:

– Mount the power supply close to the unit, with usually not more than

6 feet (1.8 m) of cable between the supply and the operator

interface. Ideally, the shortest length possible should be used.

– The wire used to connect the operator interface’s power supply

should be at least 22-gage wire suitably rated for the temperatures

of the environment to which it is being installed. If a longer cable run

is used, a heavier gage wire should be used. The routing of the

cable should be kept away from large contactors, inverters, and

other devices which may generate significant electrical noise.

– A power supply with an NEC Class 2 or Limited Power Source (LPS)

and SELV rating is to be used. This type of power supply provides

isolation to accessible circuits from hazardous voltage levels generated

by a mains power supply due to single faults. SELV is an acronym for

“safety extra-low voltage.” Safety extra-low voltage circuits shall exhibit

voltages safe to touch both under normal operating conditions and after

a single fault, such as a breakdown of a layer of basic insulation or after

the failure of a single component has occurred. A suitable disconnect

device shall be provided by the end user.

CONNECTING TO EARTH GROUND

Each operator panel has a chassis ground terminal on the back of the

unit. Your unit should be connected to earth ground. Steps should be

taken beyond connecting to earth ground to eliminate the buildup of

electrostatic charges.

The chassis ground is not connected to signal common of the unit.

Maintaining isolation between earth ground and signal common is not

required to operate your unit. But, other equipment connected to this unit

may require isolation between signal common and earth ground. To

maintain isolation between signal common and earth ground care must

be taken when connections are made to the unit. For example, a power

supply with isolation between its signal common and earth ground must

be used. Also, plugging in a USB cable may connect signal common and

earth ground.

1

USB’s shield may be connected to earth ground at the host. USB’s

shield in turn may also be connected to signal common.

1

b. Connect the shield to earth ground at both ends of the cable, usually

when the noise source frequency is over 1 MHz.

3. Never run Signal or Control cables in the same conduit or raceway with

AC power lines, conductors, feeding motors, solenoids, SCR controls,

and heaters, etc. The cables should be run through metal conduit that

is properly grounded. This is especially useful in applications where

cable runs are long and portable two-way radios are used in close

proximity or if the installation is near a commercial radio transmitter.

Also, Signal or Control cables within an enclosure should be routed as

far away as possible from contactors, control relays, transformers, and

other noisy components.

4. Long cable runs are more susceptible to EMI pickup than short cable runs.

5. In extremely high EMI environments, the use of external EMI

suppression devices such as Ferrite Suppression Cores for signal and

control cables is effective. The following EMI suppression devices (or

equivalent) are recommended:

Fair-Rite part number 0443167251 (Red Lion Controls #FCOR0000)

Line Filters for input power cables:

Schaffner # FN2010-1/07 (Red Lion Controls #LFIL0000)

6. To protect relay contacts that control inductive loads and to minimize

radiated and conducted noise (EMI), some type of contact protection

network is normally installed across the load, the contacts or both. The

most effective location is across the load.

a. Using a snubber, which is a resistor-capacitor (RC) network or metal

oxide varistor (MOV) across an AC inductive load is very effective at

reducing EMI and increasing relay contact life.

b. If a DC inductive load (such as a DC relay coil) is controlled by a

transistor switch, care must be taken not to exceed the breakdown

voltage of the transistor when the load is switched. One of the most

effective ways is to place a diode across the inductive load. Most

Red Lion products with solid state outputs have internal zener diode

protection. However external diode protection at the load is always a

good design practice to limit EMI. Although the use of a snubber or

varistor could be used.

Red Lion part numbers: Snubber: SNUB0000

Varistor: ILS11500 or ILS23000

7. Care should be taken when connecting input and output devices to the

instrument. When a separate input and output common is provided,

they should not be mixed. Therefore a sensor common should NOT be

connected to an output common. This would cause EMI on the

sensitive input common, which could affect the instrument’s operation.

EMCINSTALLATIONGUIDELINES

Although Red Lion Controls products are designed with a high degree

of immunity to Electromagnetic Interference (EMI), proper installation and

wiring methods must be followed to ensure compatibility in each

application. The type of the electrical noise, source or coupling method

into a unit may be different for various installations. Cable length, routing,

and shield termination are very important and can mean the difference

between a successful or troublesome installation. Listed are some EMI

guidelines for a successful installation in an industrial environment.

1. A unit should be mounted in a metal enclosure, which is properly

connected to protective earth.

2. Use shielded cables for all Signal and Control inputs. The shield

connection should be made as short as possible. The connection point

for the shield depends somewhat upon the application. Listed below

are the recommended methods of connecting the shield, in order of

their effectiveness.

a. Connect the shield to earth ground (protective earth) at one end

where the unit is mounted.

-4-

Page 5

Released 2018-01-12 Bulletin No. CR1000-B

PORT B

RS232 RS485/422

PORT B

RS232 (PGM)

PORT AETHERNETUSB DEVICE

TYPE B

PORT B

RS232 RS485/422

PORT B

RS232 (PGM)

PORT A

COMM

COMM

COMM

COMM

COMM

TxA (PIN 8)

TxB (PIN 1)

RTS (PIN 6)

CTS (PIN 1)

CTS (PIN 1)

RTS (PIN 6)

RxA

RxB

TxB

TxENTxTxA

Rx

Tx

Rx

ETHERNET

(NIC)

USB

TYPE B

Only one Port B connector

may be used at a time.

CR1000 PORT PIN OUTS

Drawing No. LP1019

COMMUNICATINGWITHTHECR1000

CONFIGURINGACR1000

The CR1000 is configured using Crimson® 3.1 software. Crimson is

available as a no charge download from Red Lion’s website. Crimson

updates for new features and drivers are posted on the website as they

become available. By configuring the CR1000 using the latest Crimson

version, you are assured that your unit has the most up to date feature

set. Crimson software can configure the CR1000 through the RS232

PGM port, USB port, or SD card.

The CR1000 has two serial ports, a USB device port, and an Ethernet

port as shown below. Note that the Port B serial port has two RJ

connectors, one for RS232 and one for RS485/422.

The two serial ports are available via RJ connectors. The Port A is only

an RS232 port and can be used as a Programming Port or you can

assign a protocol to it.

Note: If you assign a protocol to the Programming Port, you will no

longer be able to download to that port. You should create a means

to call the StopSystem() function from the HMI touchscreen, such

that the Programming Port activity can be halted on command.

Alternatively, the HMI's memory can be cleared to restore download

functionality.

The Port B is a combination port that provides either a RS232 or

RS485/422 connection. Only one connection (RS232 or RS485/422) can

be used at a time.

The Ethernet port can be programmed to communicate via four

protocols simultaneously. For more information on protocol support,

please refer to the Crimson 3 programming software.

The USB port is a standard device port with a Type B connector, and is

used as the programming port. The driver needed to use the USB port

will be installed with

The SD card can be used to program a CR1000 by placing a

configuration file and firmware on the SD card. The card is then inserted

into the target CR1000 and powered. Refer to the Crimson literature for

more information on the proper names and locations of the files.

Crimson.

INSERTION/REMOVALOFTHESDCARD

Insert the SD card into the slot provided with the card oriented as shown.

The card is inserted properly when the end of the card is flush with the

CR1000 case. To remove the SD card, push in slightly on the card.

CABLESANDDRIVERS

Red Lion has a wide range of cables and drivers for use with many

different communication types. A list of these drivers and cables along

with pin outs is available from Red Lion’s website. New cables and

drivers are added on a regular basis. If making your own cable, refer to

the “Port Pin Outs” that corresponds to your specific model for wiring

information.

ETHERNETCOMMUNICATIONS

Ethernet communications can be established at either 10 BASE-T or

100 BASE-TX. The unit’s RJ45 jack is wired as a NIC (Network Interface

Card). For example, when wiring to a hub or switch use a straight-through

cable, but when connecting to another NIC use a crossover cable.

The Ethernet connector contains two LEDs. A yellow LED in the upper

right, and a green LED in the upper left. The LEDs represent the following

statuses:

LED COLOR DESCRIPTION

YELLOW solid Link established.

YELLOW flashing Data being transferred.

GREEN (OFF) 10 BASE-T Communications

GREEN (ON) 100 BASE-TX Communications

On the rear of each unit is a unique 12-digit MAC address. Refer to the

Crimson manual and Red Lion’s website for additional information on

Ethernet communications.

USB,DA TATRANSFERSFROMTHESDCARD

In order to transfer data from the SD card via the USB port, a driver

must be installed on your computer. This driver is installed with Crimson

and is located in the folder C:\Program Files\Red Lion Controls\Crimson

3.1\Device\ after Crimson is installed. This may have already been

accomplished if your CR1000 was configured using the USB port.

Once the driver is installed, connect the CR1000 to your PC with a

USB cable, and follow “Mounting the SD” instructions in the Crimson 3.1

user manual.

RS232PORTS

The CR1000 has two serial

ports. There is the Port A

RS232 PGM port and the Port

B RS232/RS422/485 COMMS

port. Although only one of

these ports can be used for

programming, both ports can

be used for communications

with a PLC. The serial ports

can be used for either master

or slave protocols with any

CR1000 configuration. Each

serial port has a pair of LEDs

to indicate transmit and receive

activity. The pinouts of Port A

and B are shown here.

-5-

CR1000 RS232 TO A PC

HMI: RJ12 Name PC: DB9 Name

4 COMM 1 DCD

5Tx2Rx

2Rx3Tx

N/C 4 DTR

3 COMM 5 GND

N/C 6 DSR

1 CTS 7 RTS

6RTS8CTS

N/C 9 RI

Page 6

Bulletin No. CR1000-B Released 2018-01-12

TX

5V

8

1

7

2

TxB

TxA

130K

130K

5

TxEN (OC)

RX

130K

5V

130K

RxB

4

RxA

3

COMM

6

RS422/485 4-WIRE

CONNECTIONS

RS485 2-WIRE

CONNECTIONS

TX/RX

130K

5

TxA

2

8

130K

5V

7

1

TxB

6 COMM

CR1000 to Modular Controller

HMI Name

Modular

Controller

Name

1,4 TxB 1,4 TxB

4,1 RxB 4,1 RxB

2,3 TxA 2,3 TxA

3,2 RxA 3,2 RxA

5TxEN 5 TxEN

6COMM 6 COMM

7TxB 7 TxB

8TxA 8 TxA

Drawing No. LP1019

RS232/RS422/485COMMSPORT

The Port B of the CR1000 can be used as a RS232 or RS422/485 port.

There is a separate RJ connector for each option. In addition, the RS485/

422 option can be configured to act as either RS485 or RS422. Each

serial port has a pair of LEDs to indicate transmit and receive activity.

TxEN (OC)

Note: All Red Lion devices connect A to A and B to B. Refer to

for additional information.

ExamplesofRS4852‐WireConnections

CR1000 to Red Lion RJ11

HMI:RJ45 Name RLC:RJ11 Name

5TxEN 2 TxEN

6COMM 3 COMM

1TxB 5 B-

2TxA 4 A+

DH485COMMUNICATIONS

The CR1000’s RS422/485 COMMS port can also be used for Allen

Bradley DH485 communications.

WARNING: DO NOT use a standard DH485 cable to connect this port to

Allen Bradley equipment.

SOFTWARE/UNITOPERATION

CRIMSON®SOFTWARE

Crimson software is available as a no charge download from Red Lion’s

website. The latest version of the software is always available from the

website, and updating your copy is free.

DISPLAY

This operator interface uses a liquid crystal display (LCD) for displaying

text and graphics. The display utilizes an LED backlight for lighting the

display. The backlight can be dimmed for low light conditions.

The LED backlight has a limited lifetime. Backlight lifetime is based

upon the amount of time the display is turned on at full intensity. Turning

the backlight off when the display is not in use can extend the lifetime of

your backlight. This can be accomplished through the Crimson software

when configuring your unit.

FRONTPAN ELLEDS

There are three front panel LEDs that can be configured using Crimson.

Shown below is the default status of the LEDs.

LED INDICATION

GREEN (▲)

STEADY Unit is powered.

BLUE (▬)

FLASHING

OFF No SD card is present.

STEADY Valid SD card present.

Unit is in the boot loader

LED INDICATION

FLASHING RAPIDLY SD card being checked.

FLICKERING SD card accessed.

FLASHING SLOWLY Incorrectly formatted SD card present.

RED (■)

FLASHING Data tag is in an alarm active state.

STEADY Data tag is in an alarm accepted state.

FACTORYRESETBUTTON

The factory reset button located in the lower right area of the rear panel

can be used to access the system menu.

-6-

Page 7

Released 2018-01-12 Bulletin No. CR1000-B

To maintain UL rating, battery must

be replaced with one listed in the

Specifications.

Drawing No. LP1019

TOUCHSCREEN

This operator interface utilizes a resistive analog touchscreen for user

input. The unit will only produce an audible tone (beep) when a touch on

an active touchscreen cell is sensed. The touchscreen is fully functional

as soon as the operator interface is initialized, and can be operated with

gloved hands.

TROUBLESHOOTINGYOURCR1000

If for any reason you have trouble operating, connecting, or simply

have questions concerning your new CR1000 unit, contact Red Lion’s

technical support.

BATTERY&TIMEKEEPING

A battery is used to keep time when the unit is without power. The

battery of a CR1000 unit does not affect the unit’s memory, all

configurations and data is stored in non-volatile memory.

ChangingtheBattery

To change the battery of a CR1000, first remove power to the unit.

Remove the SD card if one is installed. Insert a small screwdriver into the

slot provided on the battery holder and pry the battery holder with battery

out of the unit. Remove the old battery from the plastic holder and replace

it with a new battery. Make sure the orientation of the battery is correct

and as shown in the diagram.

Re-install the battery holder with battery into the CR1000 unit. Using

Crimson or the unit’s keypad, enter the correct time and date.

CAUTION: Lithium battery. Danger of explosion if battery is

incorrectly replaced. Replace only with the same or equivalent

type recommended by the manufacturer.

Please note that the old battery must be disposed of in a

manner that complies with your local waste regulations. The

battery must not be disposed of in fire, or in a manner whereby

it may be damaged and its contents could come into contact

with human skin.

-7-

Loading...

Loading...