Page 1

service manual

r_02_0811

Page 2

SERVICE MANUAL

page 2

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

CONTENTS

1. FIVE BASIC RULES FOR INSTALLATION ............................................................................................................ 4

1.1. SUITABILITY OF THE ENVIRONMENT ........................................................................................................ 4

1.2. AIR INLET ...................................................................................................................................................... 4

1.3. SMOKE UNION .............................................................................................................................................. 4

1.4. FLUE PIPE ..................................................................................................................................................... 4

1.5. CHIMNEY ....................................................................................................................................................... 4

2. COMBUSTION CONTROL ...................................................................................................................................... 5

2.1. The RED recipes ............................................................................................................................................ 5

2.2. Combustion control ........................................................................................................................................ 5

2.3. Modify the recipe after the combustion control. ............................................................................................. 5

3. RED AIR AND MULTIAIR STOVES ........................................................................................................................ 6

3.1. Interpretation of installation ............................................................................................................................ 6

3.2. Recipe selection for AIR and MULTIAIR products ......................................................................................... 8

3.3. Modifying the speed of the smoke blower fan on AIR and MULTIAIR products ............................................ 8

3.4. RED AIR and MULTIAIR stove settings ......................................................................................................... 9

3.4.1. External room thermostat ........................................................................................................................ 9

3.4.2. ECO-STOP mode ................................................................................................................................... 9

3.5. Signals during operation............................................................................................................................... 10

4. RED HYDRO STOVES AND THE COMPACT 24 BOILER .................................................................................. 11

4.1. Adjusting the recipe in HYDRO stoves and in the COMPACT24 ................................................................ 11

4.2. First ignition: what to check .......................................................................................................................... 11

4.2.1. Regular operation of HYDRO stoves and COMPACT24 ...................................................................... 13

4.3. RED HYDRO and COMPACT24 stove settings .......................................................................................... 13

4.3.1. External room thermostat ...................................................................................................................... 13

4.3.2. ECO-STOP mode ................................................................................................................................. 13

4.3.3. Water temperature differential .............................................................................................................. 13

4.4. Information about the operation of the appliance ......................................................................................... 14

4.5. Shut down, recipe adjustment and bypassing the start-up phase ............................................................... 14

5. RED PELLET BOILERS: PRACTIKA 28-33 – VARIOMATIC 33 ......................................................................... 15

5.1. Adjusting the recipe in the boilers ................................................................................................................ 15

5.2. The adjustment of the smoke blower (optional on Practika, standard on Variomatic) ................................. 15

5.3. First ignition: what to check .......................................................................................................................... 16

5.3.1. External room thermostat ...................................................................................................................... 18

5.3.2. ECO-STOP mode ................................................................................................................................. 18

5.3.3. Water temperature differential .............................................................................................................. 19

5.3.4. AUX contact .......................................................................................................................................... 19

5.3.5. Testing individual components .............................................................................................................. 20

5.3.6. Regular operation.................................................................................................................................. 20

5.4. Information about the operation of the appliance ......................................................................................... 20

5.5. Special settings on boilers – TECHNICAL MENU ....................................................................................... 21

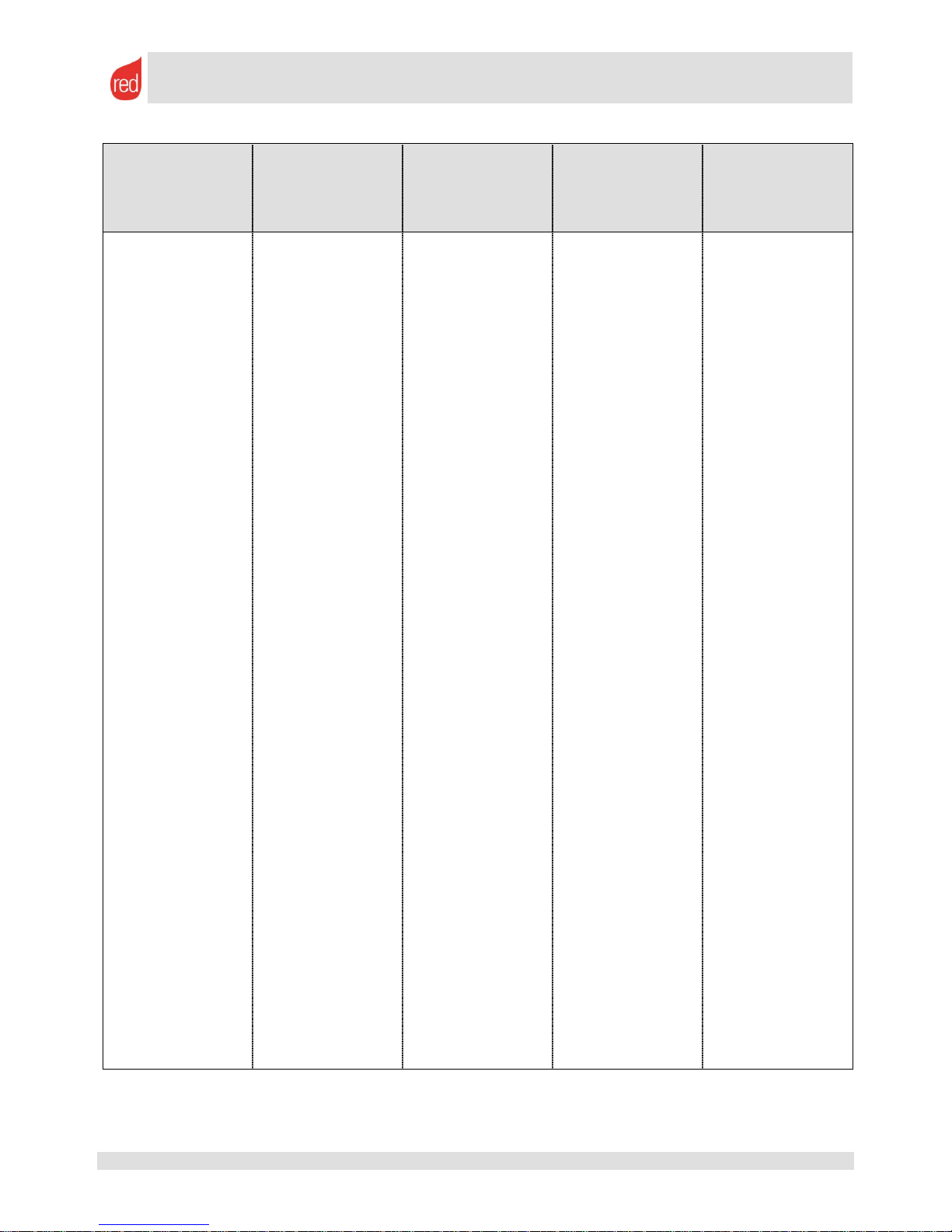

6. TECHNICAL PARAMETERS. ................................................................................................................................ 22

6.1. How to access technical parameters ........................................................................................................... 22

6.2. Stove parameters ......................................................................................................................................... 23

6.3. Boiler parameters ......................................................................................................................................... 27

7. FAULT SIGNALLING ............................................................................................................................................. 30

7.1. Alarm signal and exiting alarm conditions. ................................................................................................... 30

7.2. Control panels and list of alarms .................................................................................................................. 30

7.2.1. RED AIR and MULTIAIR stove alarms ................................................................................................. 30

7.2.2. RED COMPACT 24 boiler alarms ......................................................................................................... 31

7.2.3. RED PRACTIKA 25-33 and VARIOMATIC 33 boiler alarms ................................................................ 32

8. FAULT SOLUTIONS .............................................................................................................................................. 33

Page 3

SERVICE MANUAL

page 3

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

8.1. LED -2 / NO ACC / A01= Start-up failed ...................................................................................................... 33

8.2. LED -1 / ALAR NO FIRE / A02 = Abnormal fire extinguishing ..................................................................... 35

8.3. LED 0 / ALAR SIC FAIL / A03= Pellet tank safety thermostat ..................................................................... 37

8.4. LED 0 / DEP FAIL / A05 ............................................................................................................................... 38

8.5. LED +1 / ALAR FAN FAIL / A08= Smoke blower fan .................................................................................. 39

8.6. LED +2 / ALAR HOT TEMP / ALAR SOND FUMI / A04 .............................................................................. 41

8.7. A10 ............................................................................................................................................................... 41

8.8. A11 ............................................................................................................................................................... 41

8.9. A13 ............................................................................................................................................................... 41

9. SCHEDULED MAINTENANCE. ............................................................................................................................. 43

9.1. RED AIR and MULTIAIR pellet stoves ......................................................................................................... 43

9.2. RED HYDRO pellet stoves ........................................................................................................................... 43

9.3. COMPACT 24 boiler ..................................................................................................................................... 44

9.4. PRACTIKA 28-33 boiler ............................................................................................................................... 44

9.5. VARIOMATIC 33 boiler ................................................................................................................................ 45

9.6. Why perform scheduled maintenance? ........................................................................................................ 45

10. ELECTRICAL CONNECTIONS ........................................................................................................................... 46

10.1. RED AIR and MULTIAIR pellet stoves ..................................................................................................... 46

10.2. RED HYDRO pellet stoves ....................................................................................................................... 47

10.2.1. RED HYDRO stoves without a DHW kit ............................................................................................ 47

10.2.2. RED HYDRO stoves without a DHW kit for high efficiency pumps (if included) ............................... 48

10.3. RED PRACTIKA 28-33 boiler ................................................................................................................... 49

10.4. RED VARIOMATIC 33 boiler .................................................................................................................... 51

11. RED PRODUCTS AND THEIR ELECTRONIC AND MECHANICAL COMPONENTS....................................... 52

Page 4

SERVICE MANUAL

page 4

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

1. FIVE BASIC RULES FOR INSTALLATION

1.1.

SUITABILITY OF

THE

ENVIRONMENT

1.2.

AIR INLET

1.3.

SMOKE UNION

1.4.

FLUE PIPE

1.5.

CHIMNEY

An open fireplace

consumes ~45m3 of

air per kg of fuel.

The installation

environment must

ensure as much air

as the appliance can

consume.

Refer to the

manufacturer's

technical data

concerning fuel

consumption to

determine the

minimum size of the

installation

environment.

Adhere to the safety

distances specified

by the manufacturer

for walls and/ or

flammable surfaces.

Maintain the safety

distances from

furniture and other

furnishing items that

may be damaged by

the heat.

Insulate smoke

ducts positioned

close to flammable

materials.

Installation is not

permitted in rooms

already containing

a type-A or

ventilation hood

appliance.

This is obligatory

to ensure a correct

flow of air to

reintegrate the

oxygen consumed

by the appliance in

the installation

environment.

It is important to

create an air inlet

leading directly to

the external

environment.

Size the air inlet

correctly, according

to the dimensions

specified by the

manufacturer.

The air inlet

performs two

functions:

It provides sufficient

air intake to allow

the product to

operate correctly.

It provides air in the

environment to

compensate the air

consumed by

combustion.

The smoke

connection is the

piece of pipework

that connects the

flue pipe to the

appliance. This

connection must

adhere to

fundamental safety

and heat resistance

requirements.

The use of flexible

pipes is not

permitted.

Therefore the

connection can be

constructed using

only rigid pipes

made from:

stainless steel or

aluminised steel.

Forced outlet

products must be

connected using

airtight pipes fitted

with suitable sealing.

When connecting

closed fireplaces

only use changes of

direction with a

maximum inclination

of 45°.

Use a maximum of

three 90° bends for

pellet stoves.

The connection

must NEVER be

smaller in size at

the smoke outlet of

the appliance.

The flue pipe is a

vital element for the

discharge of smoke

and should

therefore:

Be waterproof and

thermally

insulated.

Be made of suitable

heat-proof materials

that are resistant to

the effects of

combustion

products and any

possible

condensation.

Have a vertical

arrangement with

deviations from the

axis of no more than

45° and without

kinks.

Must discharge the

smoke at the

highest point of

the home.

Comply with the

requisites specified

in the technical

table, such as the

internal crosssection of the

chimney and the

height.

Have an internal

section which is

preferably circular.

Be cleaned if preexisting and has

previously operated.

Wall outlets are

forbidden for pellet

stoves.

The chimney is the

end part of the flue

pipe. Correct

draught for the flue

pipe depends on the

chimney.

The chimney must:

Have an inner

section equal to that

of the flue pipe.

Have a outlet

section of at least

double that of the

inner section of the

flue pipe.

Be built in such a

way as to prevent

rain, snow and any

foreign bodies from

penetrating the flue

pipe.

Be positioned so as

to ensure adequate

dispersion of smoke

and, in all cases,

outside the reflux

area in which backpressures are likely

to form.

Page 5

SERVICE MANUAL

page 5

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

2. Combustion control

2.1. The RED recipes

RECIPES are preset programmes stored on the appliance mother board. These recipes contain a series of

parameters concerning the operation of the stove in all its modes.

Recipes contain, first and foremost, the values relating to the start-up and shutdown times of the geared motor and

the number of revolutions at which the smoke blower fan needs to operate at the various heat outputs.

The concept used to create recipes involves varying the intake of fuel that falls into the brazier, depending on the

quality of the flame.

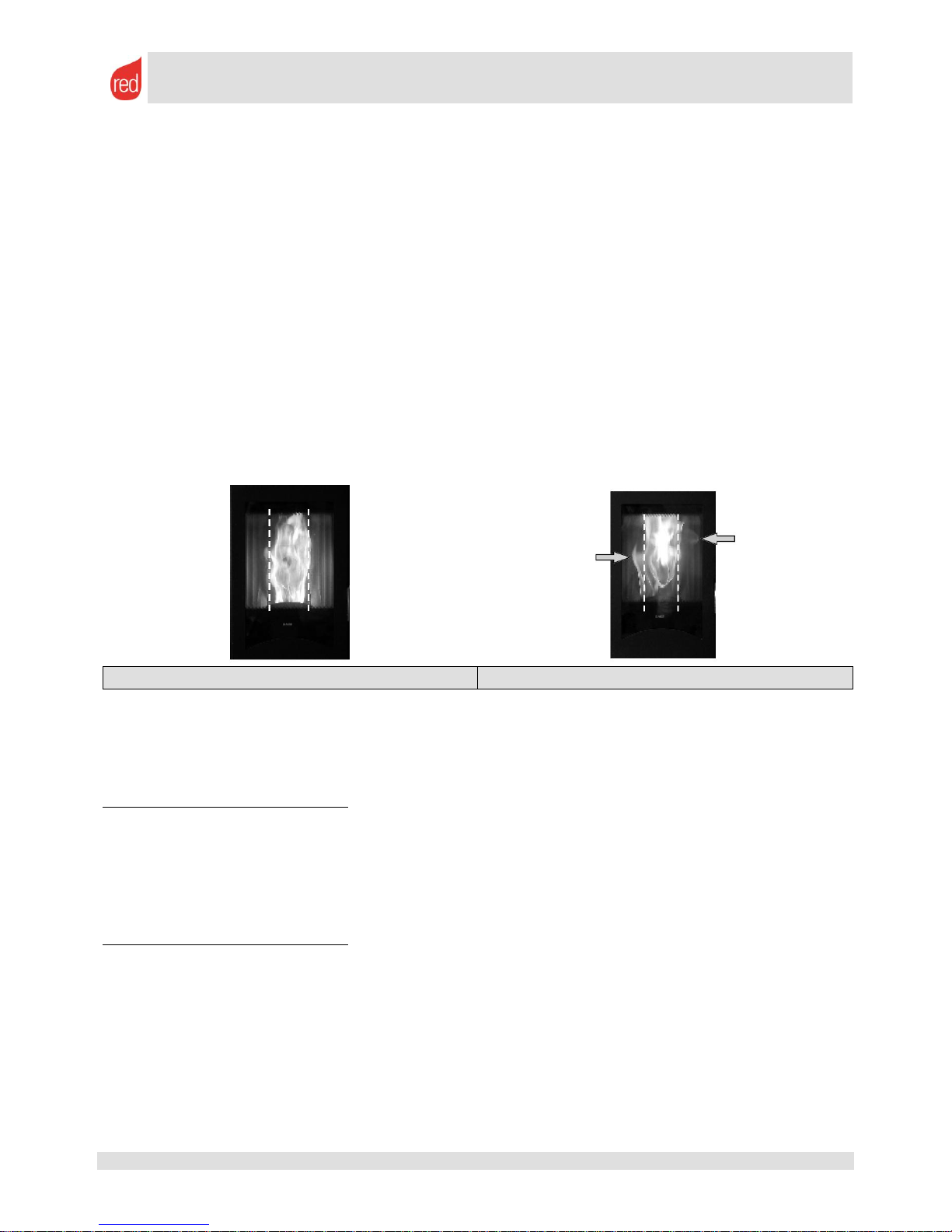

2.2. Combustion control

To be certain that the correct recipe has been created, switch on the appliance and check the combustion when

the flame is stable and regular.

The flame must be yellow on the sides and white in the centre. It should not be excessively slow nor too

oxygenated. The top of the flame must be aspirated towards the top part of the combustion chamber and must

always remain within the outline of the brazier and not overflow to the sides.

The bottom must almost always be visible, given that the whole of the pellets that fall during a cycle of the geared

motor burn fully before the final load cycle.

The flame must also "pulse" (move up and down) as pellets are burnt immediately when loaded.

CORRECT FLAME

IRREGULAR FLAME

2.3. Modify the recipe after the combustion control.

A flame that is too oxygenated is low, very white and "nervous" and the embers of the pellet tend to overflow the

brazier. The most obvious fault is a flame that is always low and a tendency of the fire to go out, particularly at low

outputs.

The variations to make are as follows:

Increase the quantity of pellets falling into the brazier (by percentage)

A flame that is not very oxygenated is orange, weak and tends to produce puffs of smoke. The glass and the

ALUTEC® (white interior refractory material) get dirty and blacken quickly.

The most obvious fault is an accumulation of pellets inside the brazier. The faster the accumulation time, the

greater the variations that must be made to the recipe.

The variations to make are as follows:

Decrease the quantity of pellets falling into the brazier (by percentage)

POSSIBLE OTHER SOLUTIONS TO THE CALIBRATION PROBLEM:

If the problem persists carefully check that the seals on the door and ash drawer are working correctly, that all of

the cleaning caps on the combustion chamber are closed and that there are no obstructions in the flue pipe.

Remember that the quality of the pellets is fundamental for correct combustion and is a basic rule for the

combustion described above.

Page 6

SERVICE MANUAL

page 6

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

3. RED AIR and MULTIAIR stoves

3.1. Interpretation of installation

One of the first actions to carry out to select the correct combustion parameters for our stove is to identify and

understand whether the installation that you are carrying out (or find yourself dealing with) presents any difficulties

with regard to evacuating exhaust smoke. Therefore, we have divided the installation types into three large macro

categories:

ACTIVE, meaning that the smoke connection is very short, free or almost free of bends and allows almost

direct connection in an "active" flue pipe; in other words, a flue pipe with a minimum natural draught of 0.10

mbar when warm.

These types of installation do not usually require additional adjustments as the basic recipe that

the stove leaves the manufacturer with has been designed for installation using a flue pipe with a

minimum natural draught of 0.10 mbar, as indicated in the use and installation manual of the

product.

PASSIVE, meaning that the smoke connection is more winding as it has bends and/ or a few metres of

pipework. If you are carrying out (or find yourself dealing with) an installation of this type, remember that

there are maximum parameters to adhere to. The stove is not guaranteed to operate if these parameters

are exceeded. For this type of installation:

o Never include more that three 90° bends.

o Never include more that three metres of Ø 80 mm horizontal pipework. This pipework must have a

minimum gradient of 3-5%.

o Never use counter-sloping pipes (pointing downwards).

o Never create a connection with more that six metres of Ø 80 mm pipework.

o Always install an inspection "T" at the outlet of the appliance (avoid 90° and 45° bends).

“WALL” installations (forbidden in Italy, Germany, Austria and Switzerland according to current laws but

permitted in some European countries) carry a high degree of risk. If you decide to use this type of

installation we recommend that you adhere to the following:

o Protect the outlet of the pipework from the wind as effectively as possible.

o ALWAYS use a windproof chimney (preferably one of high quality, not restricting the installation

to a simple windproof cap for boilers).

o Do not use 90° or "T" bends instead of windproof chimneys. Usually these stratagems cause a

deterioration in operation.

o Always construct the shortest possible connection.

o Avoid using sections of non-insulated, external pipework

o Avoid vertical rises in pipework close to walls as the walls can become dirty.

o Smoke discharge below balconies, terraces and eaves should be strictly avoided. You may think

that installing the discharge in these areas better protects the outlet from the wind but, in fact, the

opposite is true. Wind nestles in these areas of the home and makes it difficult for smoke to exit.

There is also a high risk of the building become very dirty.

N.B. The manufacturer bears no responsibility for malfunctions or damage to property and persons. An

installation carried out in this manner may also invalidate the guarantee.

These types of installation normally require additional adjustments to modify either the fuel intake

or the combustion air intake. To carry out these modifications follow the general concepts of

observing the flame explained in the previous paragraph and the instructions given in the next

chapter regarding the modification of pellet dosing and the speed of the smoke blower fan.

To further help you to identify the different types of installation, some examples are given below:

Page 7

SERVICE MANUAL

page 7

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

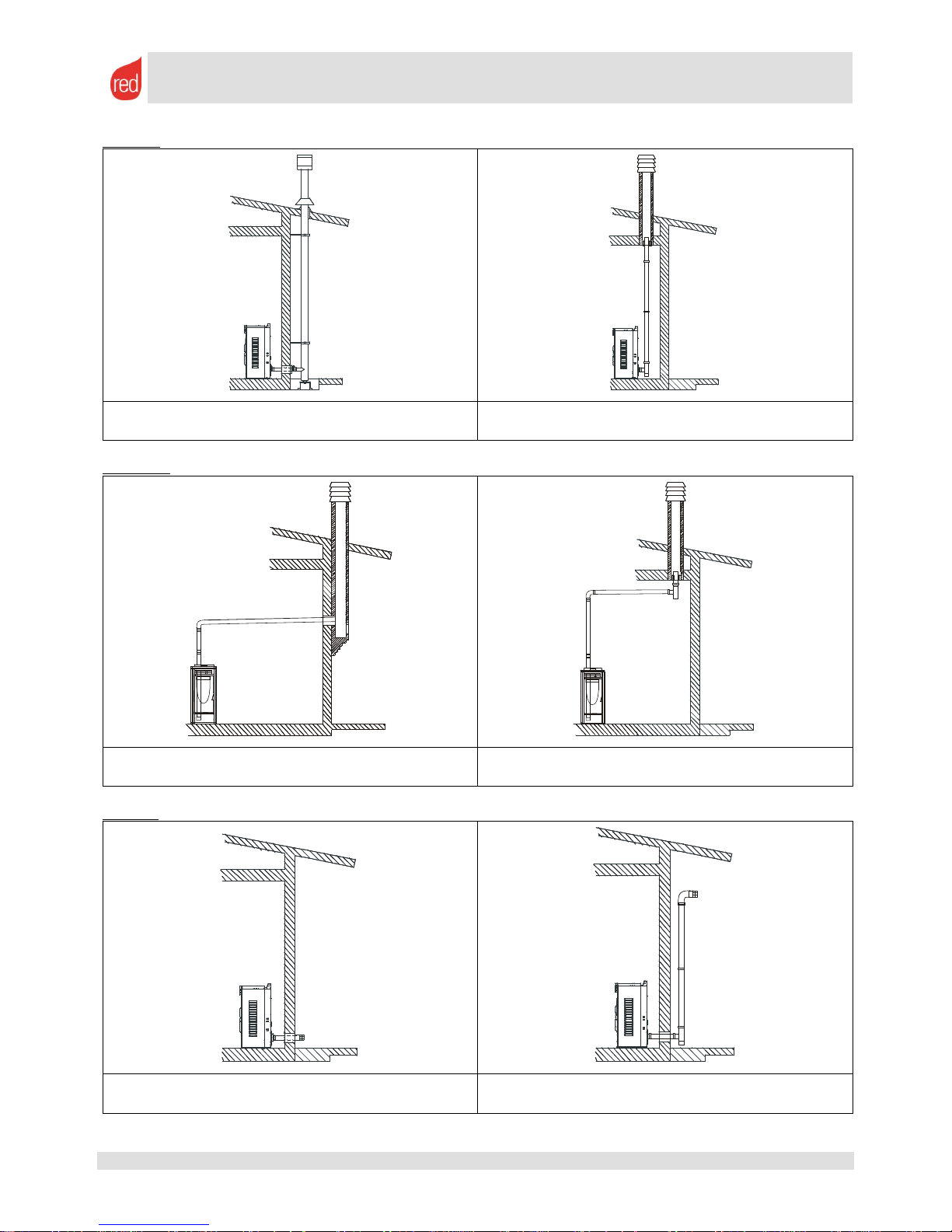

ACTIVE

50-70 cm connection to the insulated flue pipe without

bends.

Connection to an existing flue pipe with a minimum

draught of 10 Pascal (Pa) when warm.

PASSIVE

Very long connections to the flue pipe

Connections with various bends and a few metres of

pipework.

"WALL"

Direct outlets to walls (not recommended and not

permitted)

Wall outlets with bends and a few metres of pipework

+ chimney (not recommended and not permitted)

Page 8

SERVICE MANUAL

page 8

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

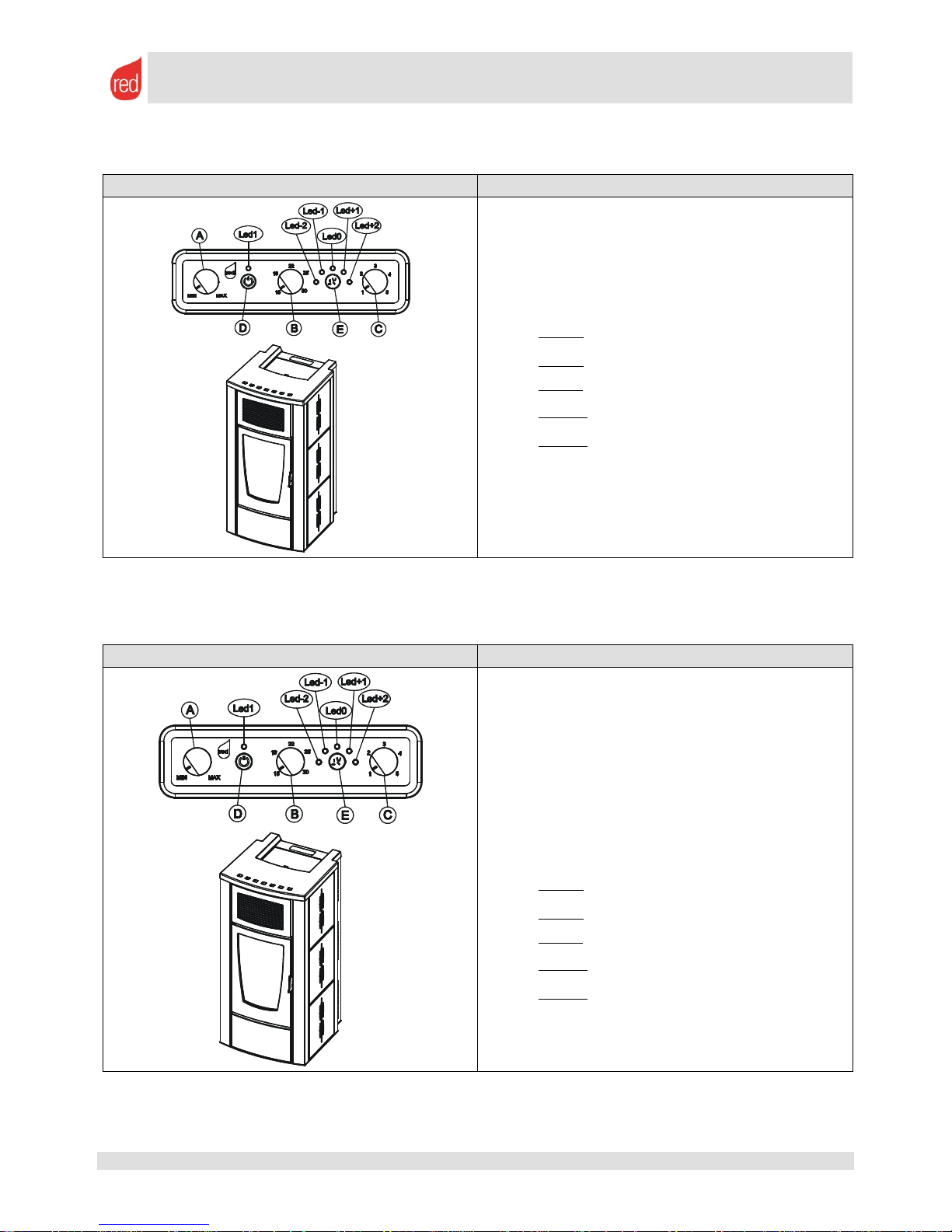

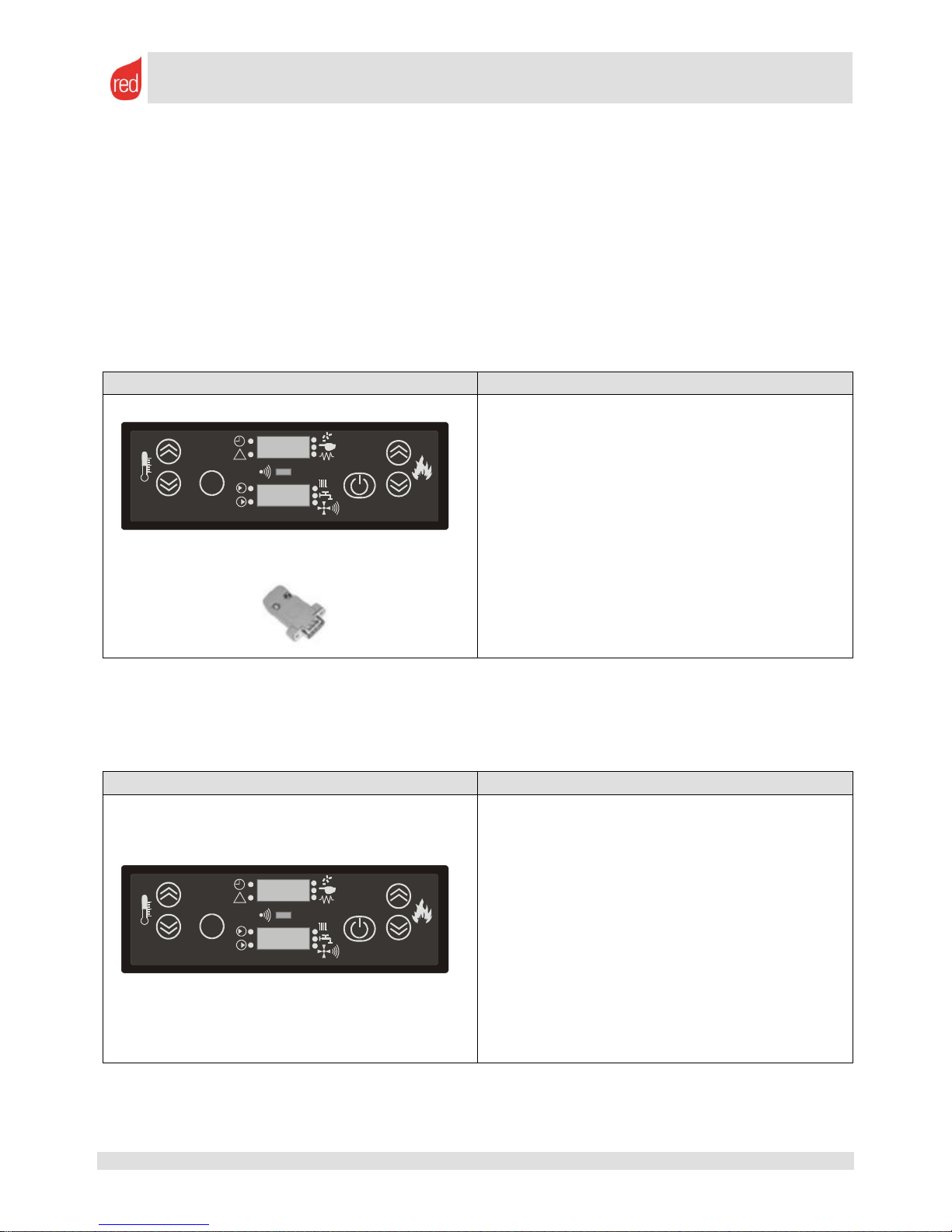

3.2. Recipe selection for AIR and MULTIAIR products

The recipe, and therefore the intake of fuel into the brazier, is modified as follows:

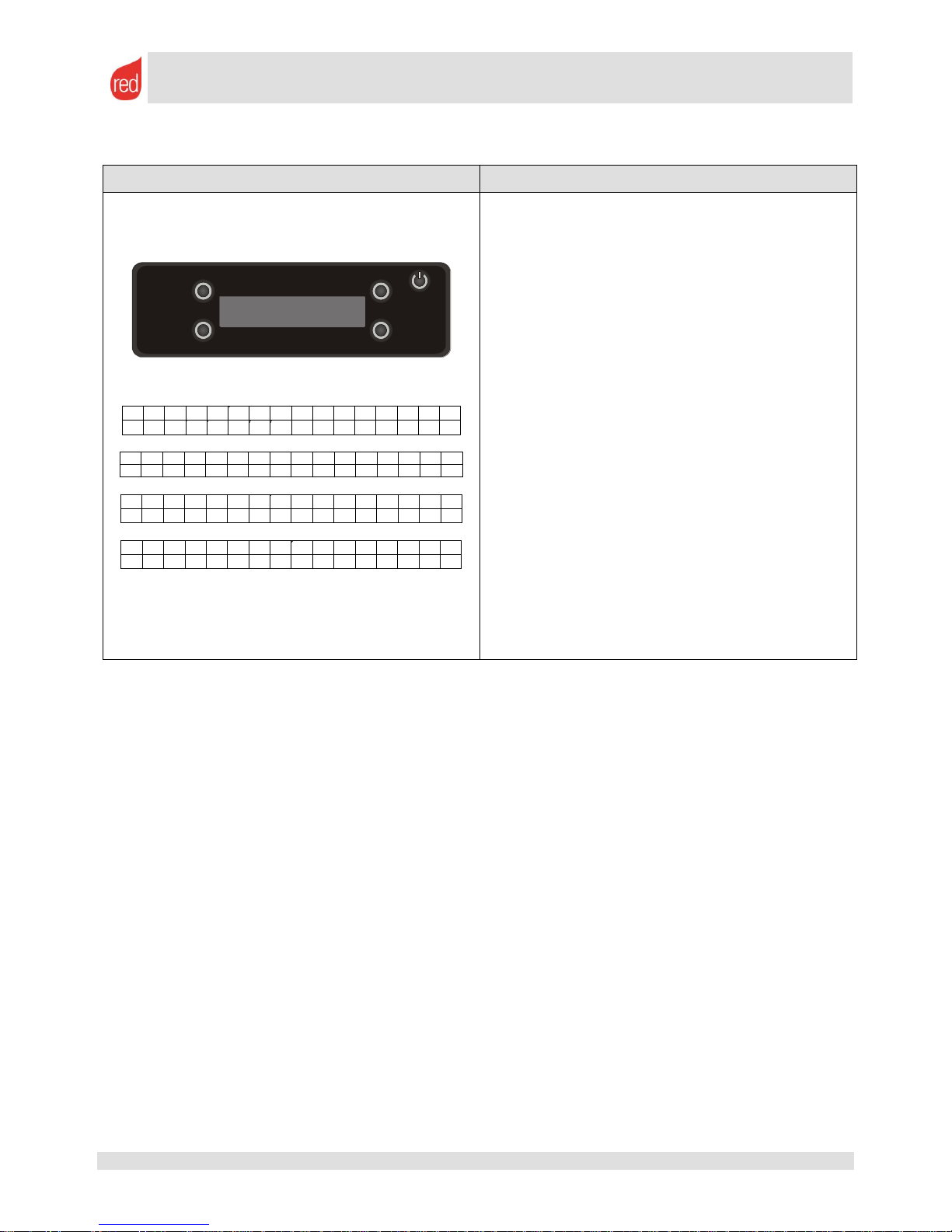

TYPE OF PANEL

INSTRUCTIONS

1. Press button E repeatedly until the led

corresponding to the variation that you wish to

make lights up. Take into account that:

LED -2 = -20% pellet

LED -1 = -10% pellet

LED 0 = no variation from the standard.

LED +1 = +10% pellet

LED +2 = +20% pellet

2. No confirmation is required as the led

corresponding to the selection made will always

remain lit during operation.

3.3. Modifying the speed of the smoke blower fan on AIR and MULTIAIR products

In addition to medicating the recipe, you can increase or reduce the power of the smoke blower in percentages (in

the same way as for pellet loading) to modify or improve combustion. This modification is carried out as follows:

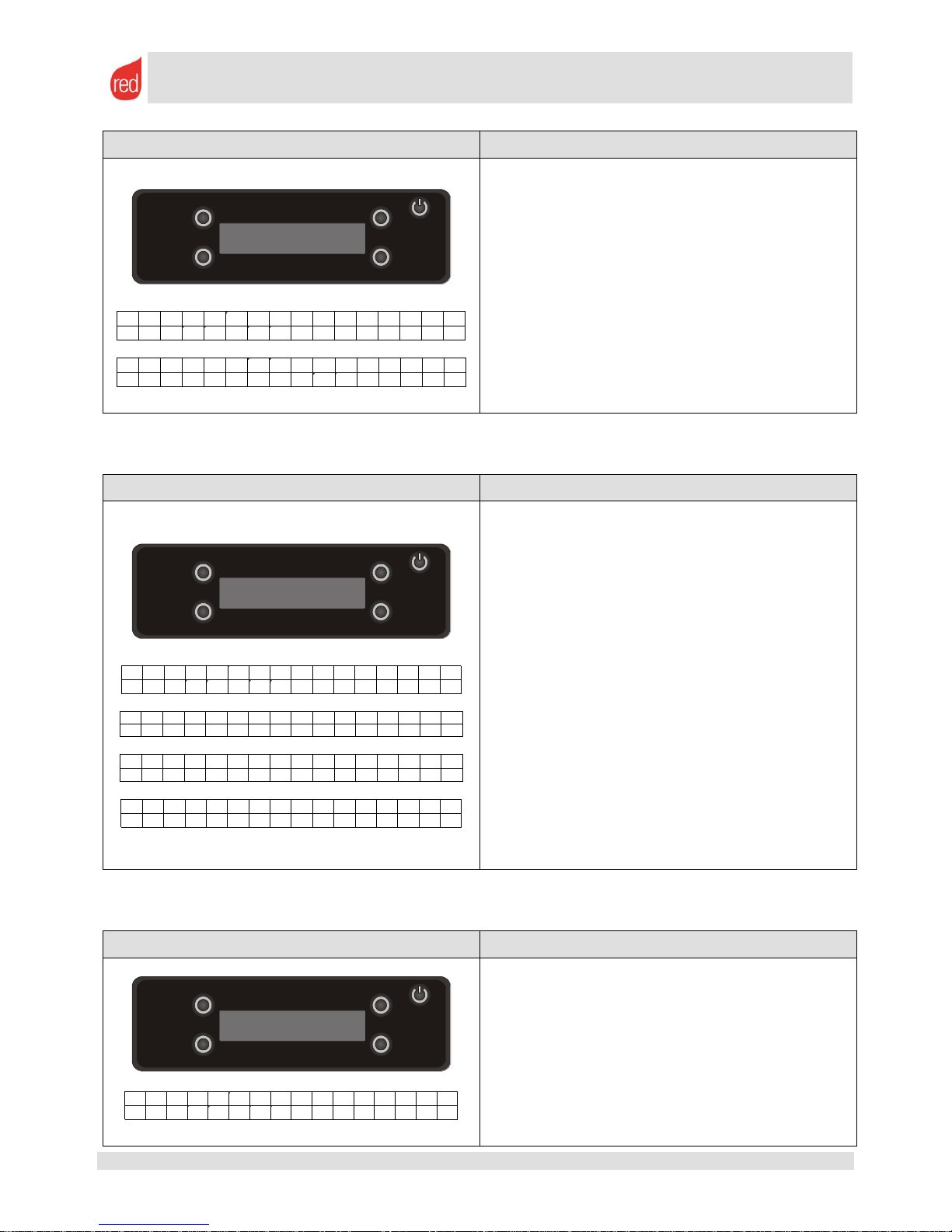

TYPE OF PANEL

INSTRUCTIONS

1. Press buttons E and D at the same time.

2. LED 0 will begin to flash. This means that the

speed of the smoke blower fan (rather than the

pellet dosage) can now be modified. If the pellets

are modified the led remains lit with a fixed light (not

flashing).

3. Press button E until the led corresponding to the

variation that you wish to make lights up. Take into

account that:

LED -2 = -20% rpm

LED -1 = -10% rpm

LED 0 = no variation from the standard.

LED +1 = +10% rpm

LED +2 = +20% rpm

4. No confirmation is required as the led corresponds

to the selection made. Simply wait 5 seconds for the

display to return to the initial status.

Page 9

SERVICE MANUAL

page 9

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

3.4. RED AIR and MULTIAIR stove settings

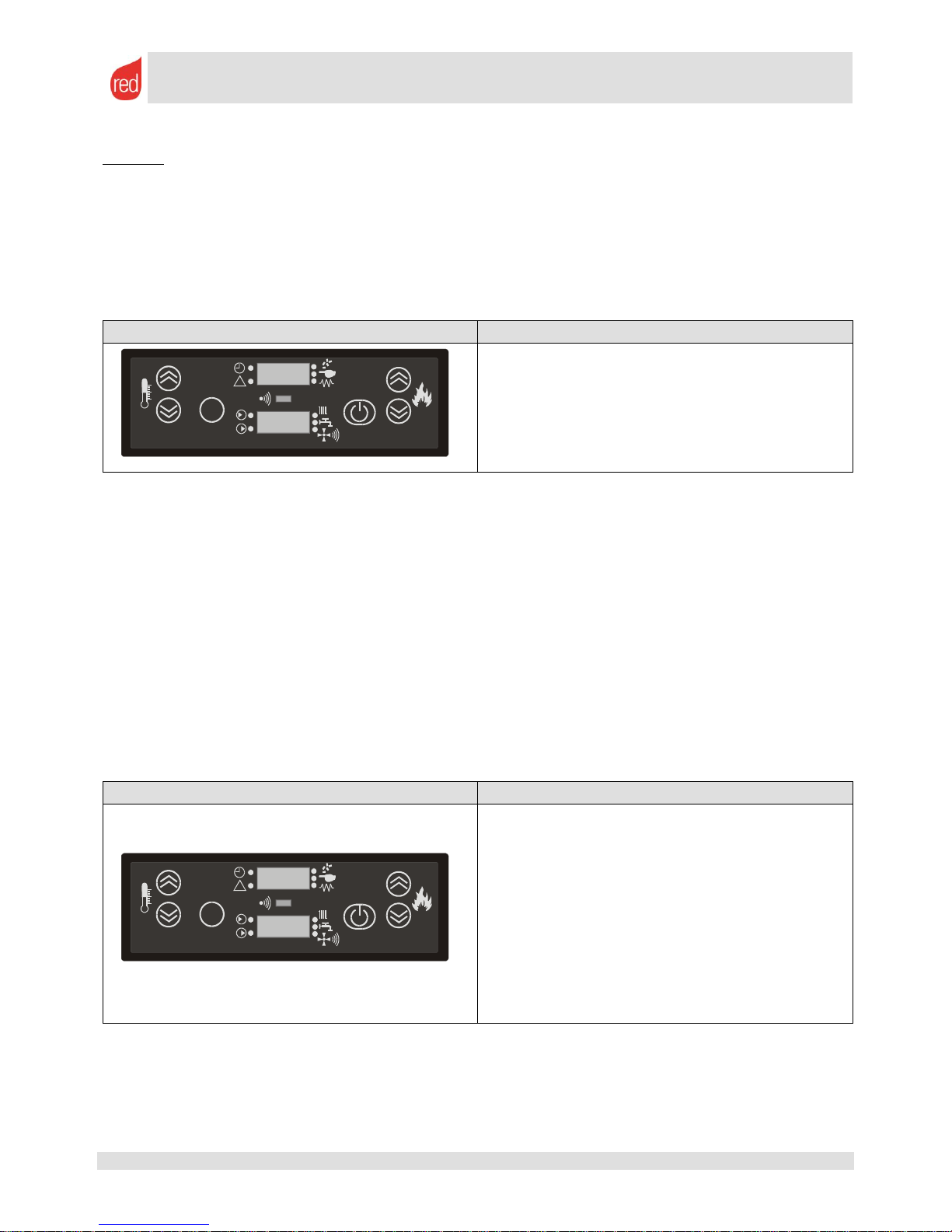

3.4.1. External room thermostat

An external room thermostat can be connected to all appliances. To do this, the two cables from the external

thermostat must be connected directly to the motherboard.

As the internal thermostat, (controlled by potentiometer B) cannot be deactivated, it must be set to the minimum,

that is; turned fully to the left (as shown in the figure). In this way, the external thermostat will take control of the

stove as the internal thermostat is adjusted to a very low temperature and therefore always satisfied (internal

electronic contact always closed).

All types of ON-OFF timed or room thermostat are compatible with RED appliances.

Remember that using a simple ON-OFF thermostat will allow you to reduce the operating power of the stove to a

minimum when the desired room temperature has been reached.

If, on the other hand, you wish the appliance to switch off when the temperature is reached you MUST activate

the ECO-STOP function, as described in the instructions given in the next paragraph.

CONTROL PANEL

INSTRUCTIONS

1. Connect the two cables to the board as shown in

the figure

2. Rotate potentiometer B of the internal thermostat

fully to the left, in other words to the minimum

possible temperature.

3. Adjust the desired temperature on the external

thermostat.

If you wish the stove to switch off when it reaches the

temperature activate the ECO-STOP function

3.4.2. ECO-STOP mode

This function can be considered an "advanced automatic" mode that prompts the appliance to switch off when

the temperature is reached rather than simply reducing the minimum power (ECO). We recommend that you

DO NOT use the ECO-STOP function in rooms with minimal insulation or if cooling in the installation room is

very sudden. If used in these conditions the appliance will be forced to switch on and off frequently, consequently

degrading the igniter and/ or causing failed ignition as the ignition is carried out in a dirty combustion chamber and/

or brazier with obstructed holes.

TYPE OF PANEL

INSTRUCTIONS

ECO-STOP activation

1. Press ON/OFF button D five times in a row

within a 6 second time period

2. The board responds by sounding a long signal to

confirm (3 seconds).

To deactive ECO-STOP: as with activation, press the

ON/OFF button briefly five times in a row within a 6

second time period. The board responds by sounding a

long signal to confirm (4 seconds).

Page 10

SERVICE MANUAL

page 10

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

Other instructions for a full understanding of the ECO-STOP function and how the panel signals the various

behaviours:

When the temperature is satisfied (temperature sensor on the edge of the stove satisfied or external

thermostat, if present, satisfied (open contact)) the stove enters the Eco-Stop counting phase. This phase

prompts the gradual passage from power 5 to power 1. The decrease in temperature lasts for one minute

for each power to prevent the flame from descending too suddenly.

When the first power level has been reached the appliance begins a countdown of 20 minutes. At the end

of the countdown, if the temperature is still satisfied the appliance will begin to shut down. On the other

hand, if during these 20 minutes the temperature once again becomes unsatisfactory for more than 10

seconds (to exclude a momentary indication), the count immediately zeros. If the temperature in the room

has decreased the stove will return to maximum power. If the temperature has not decreased the stove

will remain on minimum power and will restart the countdown to attempt a new shut down in ECO-STOP

20 minutes later.

When shutting down via ECO-STOP, LED1 will flash every 2 seconds with an alternating orange and

green led

When ECO-STOP puts the stove into stand-by mode LED1 will flash every 2 seconds with an alternating

orange and green led

ECO-STOP switches the stove back on when both of the following conditions are present:

At least 5 minutes have elapsed since the switch off process began;

The room temperature is at least 2 °C lower than the set temperature

(e.g.: if set to 20 °C, the stove restarts when the temperature drops below 18 °C)

If operating with an external thermostat the contact of this thermostat will control the restart.

N.B.: to exclude a momentary indication, the aforementioned conditions must remain present for 10

consecutive seconds.

When ECO-STOP switches the stove back on LED1 will flash green (as with normal ignition)

If the stove is switched off manually using the ON/OFF button with the ECO-STOP function active, ECO-

STOP will still be active the next time the stove is started up

If there is a black-out while the stove is switched on or in stand-by mode with ECO-STOP active, when the

stove restarts ECO-STOP will switch it off and then on again (if the temperature is not satisfactory, with a

delay of 120 seconds)

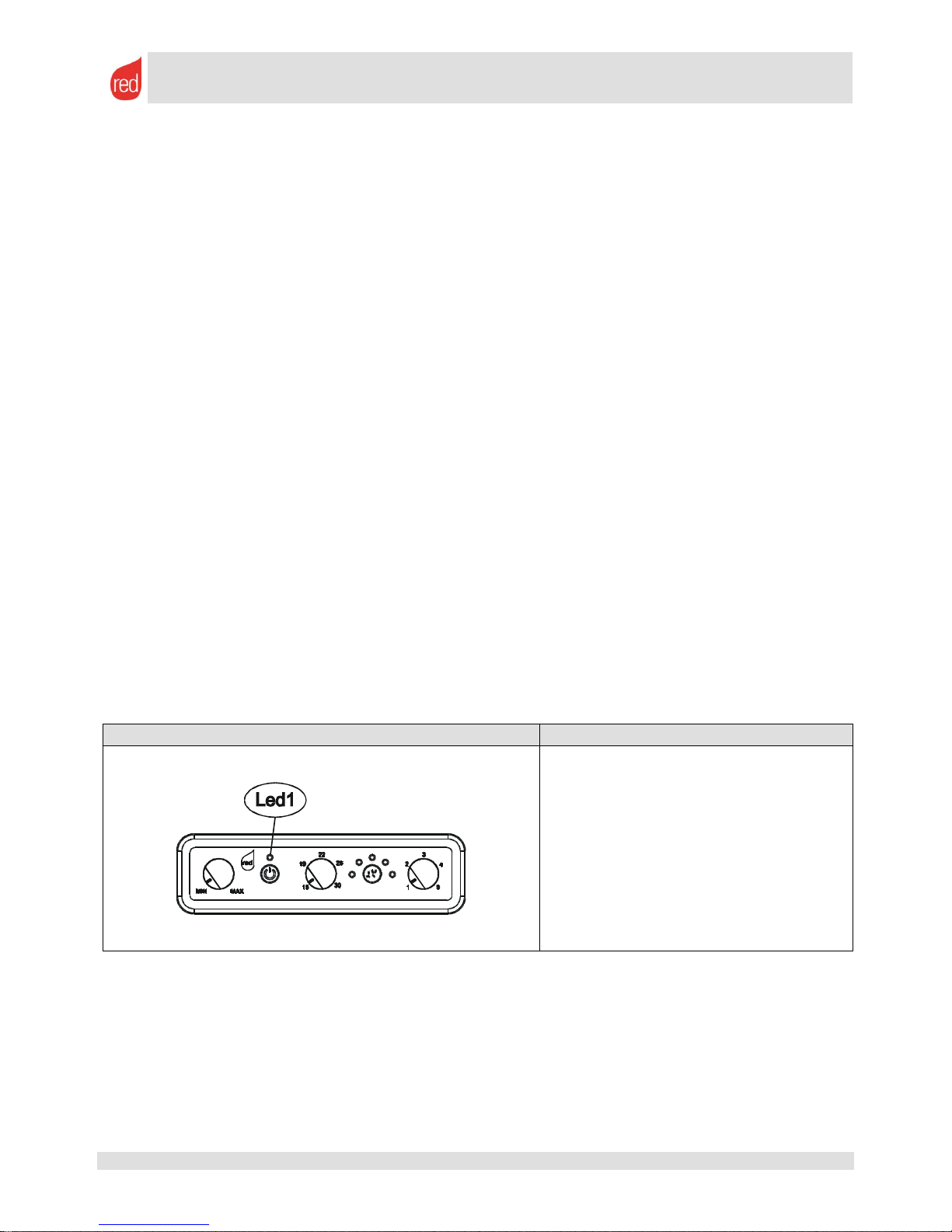

3.5. Signals during operation.

TYPE OF PANEL

LED 1

Off: The stove is waiting to start up

Flashing green: Start up

Fixed green: Stove on at full power

Flashing orange: Shut down

Flashing red: Alarm in progress

Fixed red: Stove switched off after alarm

If the stove switches off after a mains power failure led 1 continues to flash orange even after cooling.

Page 11

SERVICE MANUAL

page 11

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

4. RED HYDRO stoves and the COMPACT 24 boiler

Unlike pellet stoves designed to heat only air, Hydro pellet stoves and boilers have all the complexities of

combining the appliance to an existing hydraulic system.

Therefore, it is essential that these appliances are correctly installed by a specialised heating engineer who

can also calculate the heat requirement of the system.

These appliances are fitted with all the necessary operating and safety devices to apply it to a CLOSED VESSEL

system and, therefore, can only operate when the pressure of the system is between 0.5 and 2.5 bar. The

recommended operating pressure is 1.0 bar when cold and/ or 1.5 bar when warm.

4.1. Adjusting the recipe in HYDRO stoves and in the COMPACT24

Unlike other air stoves, the HYDRO stove and boilers do not present any significant difficulties with regard to

selecting the recipe as the power of the smoke blower fan and the high fuel load make adjusting the combustion

much less delicate.

To set the recipe just follow the simple instructions below. However, you should do this only if there are fuel

accumulation faults or the flame is too low and weak, as explained in chapter 2.

With regard to the COMPACT 24 boiler, the flame in the combustion chamber cannot be fully seen. There is only a

small viewing window on the fire door to allow you to check whether there is a flame. Boilers, even more than

stoves, require very little adjustment. Therefore, adjustments must only be made if the fuel is not compliant or the

boiler output is low due to low/ excessive fuel intake.

Take great care not to overload the brazier. This would undoubtedly produce a better output but would

also cause continuous overheating of the structure and therefore shorten the life of the product.

With the stove is switched off, press buttons

and at the same time

Select the recipe using buttons or

Confirm the selection using button , keeping it

held down until the word OFF appears on the

display

The fuel load is adjusted by percentage. In other words, you can modify the pellet chute by percentage compared

to the basic standard adjustment.

The possible adjustments are:

-3 = -30% pellet

-2 = -20% pellet

-1 = -10% pellet

0 = standard adjustment by the manufacturer

+1 = + 5%

+2 = +10%

+3 = +15%

4.2. First ignition: what to check

Always carry out a preventative check of the number of radiators and the system's potential absorption. Also

check the flow and return pipes, both in terms of the diameter and the insulation.

The stove MUST be connected to the hydraulic system using flexible pipes and inserting cut-off cocks to

isolate the appliance should it require maintenance.

Load the system with cold water using the associated filler cock located on the rear of the system or via

another filler cock on the system. Bring the pressure to 1.5 bar.

The pressure of the system must be checked using an external pressure gauge that must be installed near to

the stove (recommended), using the gauge supplied (Compact 24) or a gauge already fitted on the system, for

example the gauge already fitted on the gas boiler (if present)

SET

TURBO

1

2

6 4

3

5

!

Page 12

SERVICE MANUAL

page 12

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

Check that there are no leaks from the hydraulic connections of the stove and the system. Tighten the

connections if necessary. The internal pipes are tightened dry and tested with compressed air at 4 bar.

However, an additional check is essential when the system is filled with water and pressurised.

Vent the air from the system of radiators via the associated valves.

Vent the stove via the relief valve underneath the ceramic/ steel top. If necessary, reintegrate the system to

bring the pressure to the recommended levels (1.5 bar).

Check that the room sensor (located on the rear of the system) is not touching any hot parts and is in a

suspended position to detect the temperature of the room.

Adjust the correct recipe according to procedure.

Check the calibration of the room temperature by pressing the SET button .

Use buttons and to bring the temperature to the desired level. This must be a higher temperature than

that in the room to power the appliance.

Check the calibration of the water temperature by pressing the SET button . Use buttons and to bring

the temperature to the desired level. This temperature must NEVER BE LOWER THAN 55 °C. Below this

temperature significant production and condensation problems can occur. The recommended temperature is

65 °C.

Start up the stove and wait for the water in the boiler to reach 50 °C. At this temperature the circulation pump

(water pump) begins to operate and the hot water begins to circulate in the system. When cold water returns to

the boiler the water inside the boiler itself will rapidly drop in temperature and the circulation pump will stop.

This is perfectly normal and can last 20 to 40 minutes, depending on the size of the system. When all the

water inside the system reaches a temperature above 52 °C, the circulation pump will remain permanently

active.

You can adjust the temperature at which the pump intervenes by entering the technical parameters (see

chap. 6. ) and, more precisely, by modifying parameter PR 28.

Use buttons and to modify the start up/ shut down temperature of the circulation pump. We recommend

that you do not excessively lower the temperature (MIN 40 °C) or excessively exceed the threshold (MAX

55 °C).

SET

TURBO

1

2

6 4

3

5

!

21°C

52°C

SET

TURBO

1

2

6 4

3

5

!

H2O

65°C

SET

TURBO

1

2

6 4

3

5

!

AMB

25°C

Page 13

SERVICE MANUAL

page 13

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

4.2.1. Regular operation of HYDRO stoves and COMPACT24

Once the appliance reaches regular operation it autonomously selects the operating power according to the

difference between the required and desired room and water temperatures.

THE APPLIANCE OPERATES ONLY IN AUTOMATIC MODE (MANUAL mode does not exist)

The flame begins to decrease its operating power 5 °C before reaching the temperature of the water in the boiler.

This prevents the stove from exceeding the desired water temperature due to the thermal flywheel. The stove goes

into ECO mode (minimum power) when one or both of the temperatures requested (water and air) have been

satisfied.

4.3. RED HYDRO and COMPACT24 stove settings

4.3.1. External room thermostat

An external room thermostat can be connected to all appliances. To do this, connect the thermostat to the serial

port using the associated connector supplied (photo to the side). The method for operating this option is shown

below.

CONTROL PANEL

INSTRUCTIONS

1. Press buttons and at the same time to

access UT01

2. Press button several times until you reach

UT16

3. Press and hold the button

4. While pressing this key, press button several

times at the same time until you reach UT20

5. Set the internal thermostat to OFF using button

or

6. Confirm the selection using button

4.3.2. ECO-STOP mode

This function can be considered an "advanced automatic" mode that prompts the appliance to switch off when

the temperature is reached rather than simply reducing the minimum power (ECO). We recommend that you

DO NOT use the ECO-STOP function in rooms with minimal insulation or if cooling in the installation room is

very sudden. If used in these conditions the appliance will be forced to switch on and off frequently.

CONTROL PANEL

INSTRUCTIONS

1. Press buttons and at the same time to

access UT01

2. Press button several times until you reach

UT16

3. Press and hold the button

4. While pressing this key, press button at the

same time until you reach UT19

5. Set the internal ECO-STOP to ON using keys

or and select the number of minutes after which

you want the ECOSTOP to intervene.

6. Confirm the selection using button

4.3.3. Water temperature differential

You can increase or decrease the temperature differential to prevent the temperature of the water in the boiler from

exceeding a value determined and set by the user. This differential is set in UT18 in sets of 10 °C. To access

SET

TURBO

1

2

6 4

3

5

!

SET

TURBO

1

2

6 4

3

5

!

Page 14

SERVICE MANUAL

page 14

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

UT18, follow the same procedure used to access UT19.This interval forces the stove to decrease the operating

power if the water reaches the set temperature plus 10 °C.

Example: SET WATER TEMPERATURE = 65 °C

TEMPERATURE DIFFERENTIAL = 10 °C

At a temperature of 75 °C the stove is forced to go to minimum power to prevent the water from

overheating and boiling.

4.4. Information about the operation of the appliance

You can retrieve information about the operation of the appliance while is it switched on or during some specific

operating phases.

This information is often fundamental to solving problems or correctly diagnosing operation and faults.

CONTROL PANEL

INSTRUCTIONS

Pressing and holding down button will provide two

pieces of information:

The number of revolutions of the smoke blower

detected by the encoder (E.g.: 1840)

The instant temperature of the smoke sensor (E.g.:

103°)

4.5. Shut down, recipe adjustment and bypassing the start-up phase

Should it be necessary to alter the recipe after observing the quality of the flame, remember that the appliance

must be switched off. This is because the adjustment procedure can only be performed when the product is set to

OFF, as illustrated previously, (chap. 4.1. ).

Once the recipe has been modified, you must restart the stove and wait until the full start-up process has been

completed and the product is operating (15 to 18 minutes) before checking whether the modifications to the recipe

have had the desired effect.

To avoid having to wait for the entire start-up process to finish you can skip the entire procedure, allowing you to

check the new settings immediately. However, to carry out this operation you must ensure that:

The flame is full before switching off the product. This ensures that you have the necessary time to carry

out adjustments before the flame extinguishes normally due to lack of fuel.

The temperature sensor reads more than 60 °C

When restarted, the pellet in the chute feeds the flame or the embers that are still alive in the combustion

chamber.

If these conditions are adhered to you can restart the product and skip the entire start-up phase, arriving

immediately at the regular operation and flame checking phase.

CONTROL PANEL

INSTRUCTIONS

Shut down:

Press button for 3 seconds

Start-up:

Press button for 3 seconds

Start-up bypass:

Press button for 3 seconds when the following

instruction appear: LOAD WOOD or FIRE ON. If

the procedure has been carried out correctly these

instructions will disappear and the instructions

shown during normal operation will appear.

SET

TURBO

1

2

6 4

3

5

!

SET

TURBO

1

2

6 4

3

5

!

Page 15

SERVICE MANUAL

page 15

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

5. RED pellet boilers: Practika 28-33 – Variomatic 33

Unlike Hydro stoves or the COMPACT24, these appliances are NOT fitted with all operating and safety devices

(circulating pump, expansion vessel, safety valve, relief valve, etc.). These must be installed and sized by a

specialised heating engineer who can also calculate the heat requirement of the system.

The creation and set up of the heating system is therefore subordinate to installation in compliance with

the standards and laws of the installation country. These laws normally anticipate the issue of a statement

of conformity and installation of the highest standard. Any installation not carried out in accordance with these

criteria may potentially cause malfunctions or damage to the product and the system as well as invalidating all

guarantees.

We recommend installing these products on a CLOSED VESSEL system given that the recommended operating

pressure is 1.0 bar when cold and/ or 1.5 bar when warm. If installed with an OPEN VESSEL the minimum

pressure required is 0.3 bar (3 metres of water column)

5.1. Adjusting the recipe in the boilers

The boilers do not present any difficulties in terms of adjusting combustion as the power and high fuel load make

adjusting the combustion much less delicate.

Boilers, even more than stoves, require very little adjustment. Therefore, adjustments must only be made if the fuel

is not compliant or the boiler output is low due to low fuel intake.

Take great care not to overload the brazier. This would undoubtedly produce a better output but would

also cause continuous overheating of the structure and therefore shorten the life of the product.

CONTROL PANEL

INSTRUCTIONS

M o d e : M A N U M e n u

F i r e : 1 F a n : 2

e s c S e t

< S e t t i n g >

e s c 0 S e t

- P e l l e t R e c i p e +

e s c - 2 O K

- P e l l e t R e c i p e +

1. Press the button at the TOP RIGHT of the display

to access the MENU.

2. Using the two keys at the bottom, scroll through the

various menus until you reach the SETTINGS

3. Press the button corresponding to the word SET.

4. Using the two keys at the bottom, scroll through the

various menus until you reach the PELLET

RECIPE menu.

5. Confirm by pressing the the button corresponding

to the SET key.

6. Modify the value using the bottom keys

corresponding to symbols + and -

7. Confirm by pressing the the button corresponding

to the OK key.

THE AVAILABLE VALUES ARE

- 5 = 25% decrease in pellets in all power levels.

- 4 = 20% decrease in pellets in all power levels.

- 3 = 15% decrease in pellets in all power levels.

- 2 = 10% decrease in pellets in all power levels.

- 1 = 5% decrease in pellets in all power levels.

0 = Standard adjustment by the manufacturer

1 = 5% increase in pellets in all power levels.

2 = 10% increase in pellets in all power levels.

3 = 15% increase in pellets in all power levels.

4 = 20% increase in pellets in all power levels.

5 = 25% increase in pellets in all power levels.

5.2. The adjustment of the smoke blower (optional on Practika, standard on Variomatic)

To improve smoke discharge in difficult installations or where the flue pipe does not have the required

characteristics (minimum draught 20 Pa) an additional smoke blower fan can be installed. This fan can be easily

Page 16

SERVICE MANUAL

page 16

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

managed by the control panel by modifying the intake power of the fan (in percentage) until the required draught

values are reached in the flue pipe or the correct operation.

CONTROL PANEL

INSTRUCTIONS

F i r e : 5 M e n u

T . H 2 0 : 2 5 °

e s c S e t

< S e t t i n g >

e s c 0 S e t

- S m o k e B l o w e r O +

e s c - 2 O k

- S m o k e B l o w e r O +

1. Press the button at the TOP RIGHT of the display

to access the MENU

2. Using the two keys at the bottom, scroll through the

various menus until you reach the SETTINGS

menu.

3. Press the button corresponding to the word SET.

4. Using the two keys at the bottom, scroll through the

various menus until you reach the SMOKE BLOWER

OFFSET menu.

5. Confirm by pressing the the button corresponding

to the SET key.

6. Modify the value using the bottom keys

corresponding to symbols + and -

7. Confirm by pressing the the button corresponding

to the OK key.

THE AVAILABLE VALUES ARE

From -10 to +10

Each point corresponds to a 5% positive or negative

variation.

5.3. First ignition: what to check

Wash the system prior to installation and put the system into operation

Always carry out a preventative check of the number of radiators and the system's potential absorption.

Check the flow and return pipes, both in terms of the diameter and the insulation.

Check that all the cut-off cocks of the system are open or that the thermostats that control the solenoids in the

area permit opening (heat requirement from the thermostat)

The boiler must be connected to the hydraulic system, preferably using flexible pipes and inserting cut-off

cocks to isolate the appliance should it require maintenance.

Load the system with cold water using a filler cock.

Bring the pressure to 1.5 bar.

The pressure of the system can be checked using the pressure gauge supplied or the gauge already fitted on

the system, for example the gauge already fitted on the gas boiler

Check that there are no leaks from the hydraulic connections.

Check that the safety valve of the system is connected to a sewer drain.

Vent the air from the circuit using the associated valves that should be located along the system.

If there is an external thermostat ensure that it is correctly connected to the boiler.

Check the calibration of the water temperature in the boiler as indicated below:

Page 17

SERVICE MANUAL

page 17

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

CONTROL PANEL

INSTRUCTIONS

F i r e : 5 M e n u

T . H 2 0 : 2 5 °

e s c 6 5 ° C O k

- T e m p . H 2 0 +

1. Press the button at the BOTTOM LEFT of the

display to adjust the desired temperature of the

water in the boiler.

2. Modify the value using the bottom keys

corresponding to symbols + and -

3. Confirm by pressing the the button corresponding

to the OK key.

Use buttons + and - to bring the temperature to the

desired level. This temperature must NEVER BE

LOWER THAN 55 °C AND HIGHER THAN 80° C.

Below 55 °C there is a risk of generating condensation

while above 80 °C there is a risk of boiling.

The recommended temperature is 65 °C.

Activate the auger to transport pellets quickly along the duct until the pellets cannot be seen or heard falling

into the brazier. Operate as follows to carry out this operation:

CONTROL PANEL

INSTRUCTIONS

F i r e : 5 M e n u

T . H 2 0 : 2 5 °

e s c S e t

< S e t t i n g >

e s c O f f S e t

< L o a d p e l l e t >

e s c O n O k

< L o a d p e l l e t >

1. Press the button at the TOP RIGHT of the display

to access the MENU.

2. Using the two keys at the bottom, scroll through the

various menus until you reach the SETTINGS

menu.

3. Press the button corresponding to the word SET.

4. Using the two keys at the bottom, scroll through the

various menus until you reach the LOAD PELLET

5. Confirm by pressing the the button corresponding

to the SET key.

6. Select ON using the bottom keys corresponding to

symbols < and >

7. Confirm by pressing the the button corresponding

to the OK key.

8. As soon as the pellets can be seen/ heard select

OFF using the bottom keys corresponding to

symbols < and > to switch of the geared motor.

N.B. This menu is only visible when the boiler is set

to OFF.

Test the correct connection and operation of the water pump via the associated option on the control panel.

Operate as follows to carry out this operation:

CONTROL PANEL

INSTRUCTIONS

F i r e : 5 M e n u

T . H 2 0 : 2 5 °

1. Press the button at the TOP RIGHT of the display

to access the MENU.

2. Using the two keys at the bottom, scroll through the

various menus until you reach the SETTINGS

menu.

3. Press the button corresponding to the word SET.

4. Using the two keys at the bottom, scroll through the

various menus until you reach the START PUMP

5. Confirm by pressing the button corresponding to

Page 18

SERVICE MANUAL

page 18

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

e s c S e t

< S e t t i n g >

e s c O f f S e t

< S t a r t p u m p >

e s c O n O k

< S t a r t p u m p >

the SET key.

6. Select ON using the bottom keys corresponding to

symbols < and >

7. Confirm by pressing the button corresponding to

the OK key.

8. As soon as the correct water circulation and the

operation of the pump can be seen/ heard, select

OFF using the bottom keys corresponding to

symbols < and > to return to normal status.

Switch on the boiler and wait for the water in the boiler to arrive at the temperature set for activation of the

pump (standard 50 °C, can be modified in the associated menu). At this temperature the circulation pump

(water pump) begins to operate and the hot water begins to circulate in the system. When cold water from the

system returns to the boiler the temperature inside the boiler itself will rapidly drop and the circulation pump

will stop. This is perfectly normal and can last several minutes, depending on the size of the system. When all

the water inside the system reaches a temperature above the set value, the circulation pump will remain

permanently active. In the time interval before the pump activation temperature is reached, the pump will

switch on for 10 seconds every minute to mix the water inside the system.

As mentioned above, you can modify the temperature at which the pump intervenes by entering the setting

menu:

CONTROL PANEL

INSTRUCTIONS

F i r e : 5 M e n u

T . H 2 0 : 2 5 °

e s c S e t

< S e t t i n g >

e s c 5 0 ° C S e t

< T e m p . O N p u m p >

e s c 5 0 ° C O k

- T e m p . O N p u m p +

1. Press the button at the TOP RIGHT of the display

to access the menu.

2. Using the two keys at the bottom, scroll through the

various menus until you reach the SETTINGS

menu.

3. Press the button corresponding to the word SET.

4. Using the two keys at the bottom, scroll through the

various menus until you reach the TEMP.ON

PUMP

5. Confirm by pressing the button corresponding to

the SET key.

6. Modify the value using the bottom keys

corresponding to symbols + and -

7. Confirm by pressing the button corresponding to

the OK key.

5.3.1. External room thermostat

An external room thermostat can be connected to all appliances.

To do this, connect the thermostat to the serial port using the associated connector.

When an external thermostat is connected to the boiler the display shows T ON. Otherwise the display shows

T OFF.

No temperature measurement is shown on the display as there if no local room sensor. The boiler only waits for

the external thermostat to close or open the contact to switch on, switch off or alter its power. If there is no external

room thermostat the power will be fully dosed on the temperature of the water in the boiler.

In the same way, it is possible to connect an external water sensor (to insert in a puffer or accumulation tank, for

example) or a domotic control unit.

5.3.2. ECO-STOP mode

This function can be considered an "advanced automatic" mode that prompts the appliance to switch off when

the temperature is reached rather than simply reducing the minimum power (ECO).

We recommend that you DO NOT use the ECO-STOP function in rooms with minimal insulation or if cooling

in the installation room is very sudden. If used in these conditions the appliance will be forced to switch on and off

frequently.

Page 19

SERVICE MANUAL

page 19

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

CONTROL PANEL

INSTRUCTIONS

F i r e : 5 M e n u

T . H 2 0 : 2 5 °

e s c S e t

< S e t t i n g >

e s c O f f S e t

< E C O >

e s c O f f O k

< E C O >

1. Press the button at the TOP RIGHT of the display

to access the MENU.

2. Using the two keys at the bottom, scroll through the

various menus until you reach the SETTINGS

menu.

3. Press the button corresponding to the word SET.

4. Using the two keys at the bottom, scroll through the

various menus until you reach the ECO

5. Confirm by pressing the button corresponding to

the SET key.

6. Modify the value using the bottom keys

corresponding to symbols + and -

7. Confirm by pressing the button corresponding to

the OK key.

5.3.3. Water temperature differential

You can increase or decrease the temperature differential in the boilers to prevent the temperature of the water in

the boiler from exceeding a value determined and set by the user. This differential is set to 5 Cas standard.

Example: SET WATER TEMPERATURE = 65 °C

TEMPERATURE DIFFERENTIAL = 5 °C

At a temperature of 70 °C the stove stops in ECO-STOP mode to prevent the water in the boiler

from boiling.

To modify this parameter you must access the advanced settings in the TECHNICAL MENU – HYDRO MENU

(using the C93 password). For clearer instructions refer to chapter 5.5.

5.3.4. AUX contact

To allow functions combined with other heating devices there is an auxiliary contact on the motherboard (AUX1 or

AUX2). This contact can be used to set the temperature of the water in the boiler. Above this temperature a second

heat generator (if used) can be deactivated or an auxiliary contact can be opened.

CONTROL PANEL

INSTRUCTIONS

F i r e : 5 M e n u

T . H 2 0 : 2 5 °

e s c S e t

< S e t t i n g >

e s c 6 0 ° C S e t

< O f f A U X >

e s c 6 0 ° C O k

- O f f A U X +

1. Press the button at the TOP RIGHT of the display

to access the MENU.

2. Using the two keys at the bottom, scroll through the

various menus until you reach the SETTINGS

menu.

3. Press the button corresponding to the word SET.

4. Using the two keys at the bottom, scroll through the

various menus until you reach the OFF AUX

5. Confirm by pressing the button corresponding to

the SET key.

6. Modify the temperature value using the bottom

keys corresponding to symbols + and -

7. Confirm by pressing the button corresponding to

the OK key.

Page 20

SERVICE MANUAL

page 20

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

5.3.5. Testing individual components

Individual components can be activated to check their function via the TECHNICAL MENU

CONTROL PANEL

INSTRUCTIONS

F i r e : 5 M e n u

T . H 2 0 : 2 5 °

e s c S e t

< T e c h n i c a l m e n u >

e s c S e t

< M e n u t e s t >

1. Press the button at the TOP RIGHT of the display (2)

to access the MENU.

2. Using the two keys at the bottom, scroll through the

various menus until you reach the TECHNICAL

MENU

3. Press the button corresponding to the word SET.

4. Insert password C93

5. Press the button corresponding to the word SET.

6. Using the two keys at the bottom, scroll through the

various menus until you reach the MENU TEST

7. Press the button corresponding to the word SET.

8. Choose which of the following components to activate:

o Auger

o Smoke Blower

o Pump

o Pellet igniter

9. Press the button corresponding to the word OK.

10. Perform the same operation in reverse to switch off the

component

5.3.6. Regular operation

Once the boiler reaches regular operation is autonomously chooses to decrease the operating power depending

on whether the thermostats request heat.

THE BOILER OPERATES ONLY IN AUTOMATIC MODE (MANUAL mode does not exist)

The boiler goes into ECO mode (minimum power) when one or both of the temperatures requested (water and air)

have been satisfied.

5.4. Information about the operation of the appliance

You can retrieve information about the operation of the appliance while is it switched on or during some specific

operating phases. This information is often fundamental to solving problems or correctly diagnosing faults.

CONTROL PANEL

INSTRUCTIONS

F i r e : 5 M e n u

T . H 2 0 : 2 5 °

e s c S e t

< I n f o >

1. Press the button at the TOP RIGHT of the display

(2) to access the MENU.

2. Using the two keys at the bottom, scroll through the

various menus until you reach the INFO menu.

3. Press the button corresponding to the word SET.

4. Using the two keys at the bottom, scroll through the

various menus to view the information. Specifically,

this information may concern:

o The motherboard code

o The motherboard safety code

o The display code

o The boiler operating times

o The service time counter

o The no. of revolutions (RPM) of the smoke

blower

o The auger start-up time

o The photo resistance level.

Page 21

SERVICE MANUAL

page 21

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

5.5. Special settings on boilers – TECHNICAL MENU

The technical menu of the boiler allows you to modify various settings that we recommend you alter only if strictly

necessary. ACCESS PASSWORD FOR THE TECHNICAL MENU: C 93

MAIN MENU

SUBMENU

INFORMATION NOTES

GENERAL SETTINGS

BOILER TYPE

Boiler model (Practika 28-33 or Variomatic)

ZEROING THE SERVICE TIMES

Zeroing the counter for unscheduled maintenance at 2000

hours

ECO MENU

WAITING ON

Standard 20 min. Waiting prior to start-up in ECO mode

WAITING OFF

Standard 20 min. Waiting prior to shut down in ECO mode

AUGER MENU

AUGER BRAKING

Standard ON. Electrical signal to instantly stop the geared

motor

OFFSET IN START-UP

Standard +5. Increase or decrease in pellet load in start-up

T.ON P.MIN

Standard 2.0 sec. Start-up time in seconds of the auger at

minimum power

T.ON P.MAX

Standard 6.5 sec. Start-up time in seconds of the auger at

maximum power

BLOWER MENU

OFFSET IN START-UP

Standard +10. Increase or decrease in pellet load in start-

up

MIN P. RPM

Standard 1700 rpm. Start-up time in seconds of the smoke

blower fan at minimum power

MAX P. RPM

Standard 2750 rpm. Start-up time in seconds of the smoke

blower fan at maximum power.

SECOND BLOWER MENU

START-UP

Start-up temperature

SHUT DOWN

Shut down temperature

LEVEL 1

Speed at minimum power

LEVEL 5

Speed at maximum power

HYDRO MENU

HYDRO SHUT DOWN

Activation of ECO-STOP controlled by the temperatures of

the water in the boiler when the boiler exceeds hysteresis

WATER TEMPERATURE

HYSTERESIS

Standard 5 °C. Delta temperature HYDRO SHUT DOWN

intervention

SHAKER MENU

Only for VARIOMATIC model

SHAKER

Standard ON. Activation of the brazier cleaning shaker

(Variomatic model)

INTERVAL BETWEEN CYCLES

Standard 0.5 h

NO. OF CYCLES

Standard 2

CYCLE DURATION

Standard 60 sec.

START-UP MENU

PRE-IGNITION DURATION

Standard 20 sec

START-UP DURATION

Standard 600 sec.

FIRE-ON DURATION

Standard 120 sec

PHOTORESISTANCE ON

3346. Value to consider the boiler as switched on

PHOTORESISTANCE OFF

7665. Value to consider the boiler as switched off

BRAZIER CLEANING MENU

POWER THRESHOLD

Standard 3. Threshold to distinguish the cleaning operation

intensive or reduced

P. WAITING NORMAL

Standard 1800 sec. Interval between two cleaning events

P. DURATION NORMAL

Standard 60 sec. Cleaning duration normal

P. WAITING REDUCED

Standard 1800 sec. Interval between two cleaning events

P. DURATION REDUCED

Standard 20 sec. Reduced cleaning duration

TEST MENU

AUGER

Supply of the geared motor/ auger to test its operation

SMOKE BLOWER

Supply of the smoke blower fan to test its operation

PUMP

Supply of the water pump to test its operation

PELLET IGNITER

Supply of the pellet igniter to test its operation

Page 22

SERVICE MANUAL

page 22

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

6. Technical parameters.

The technical parameters constitute all of the information and timeframes that the appliance must adhere to to

operate correctly. You can make modifications to improve various aspects of operation such as consumption,

frequency of regular cleaning, smoke discharge, etc. but we recommend that you perform these variations only if

you are certain of the consequences.

Below is an explanation of how to access these parameters, which are protected with a password, and how to

modify them if necessary.

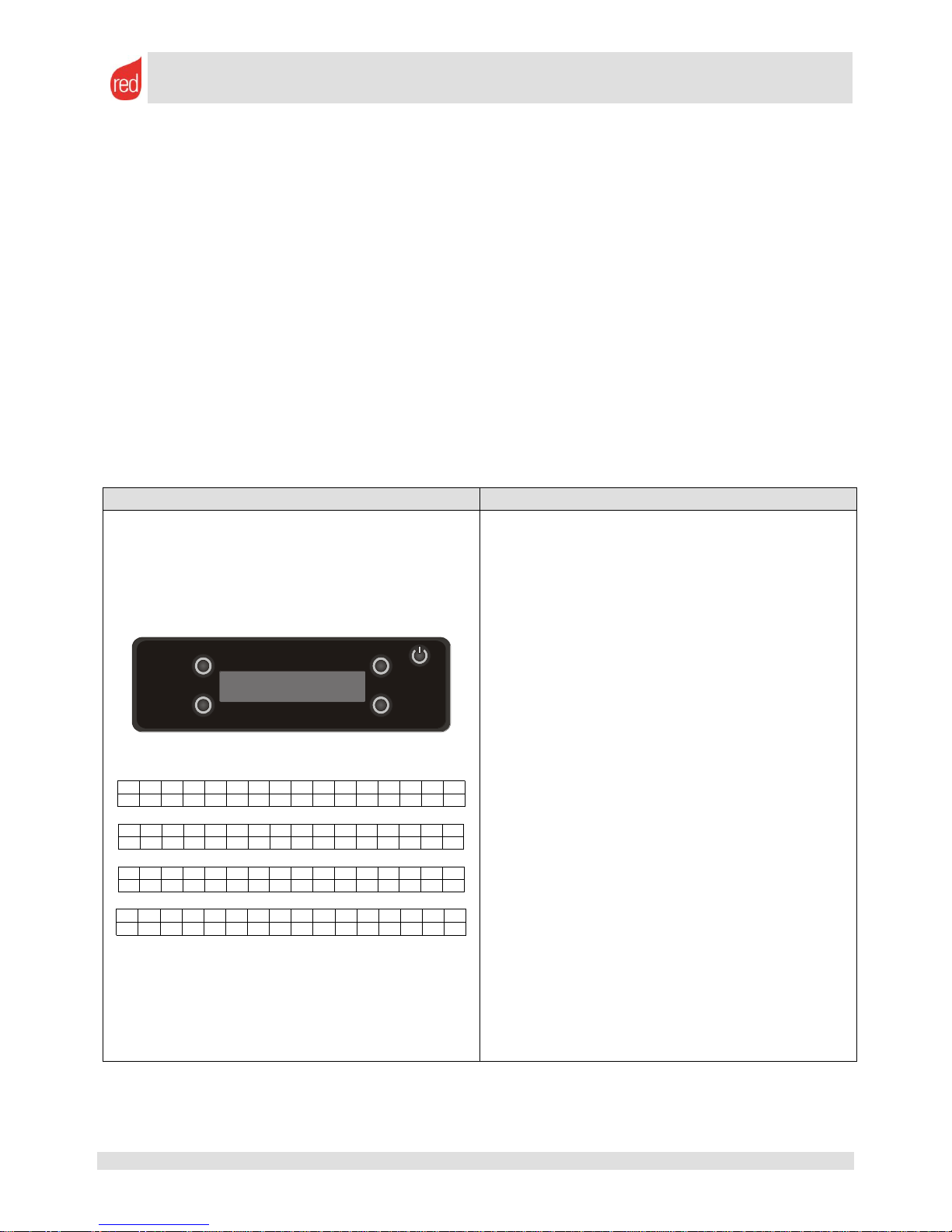

6.1. How to access technical parameters

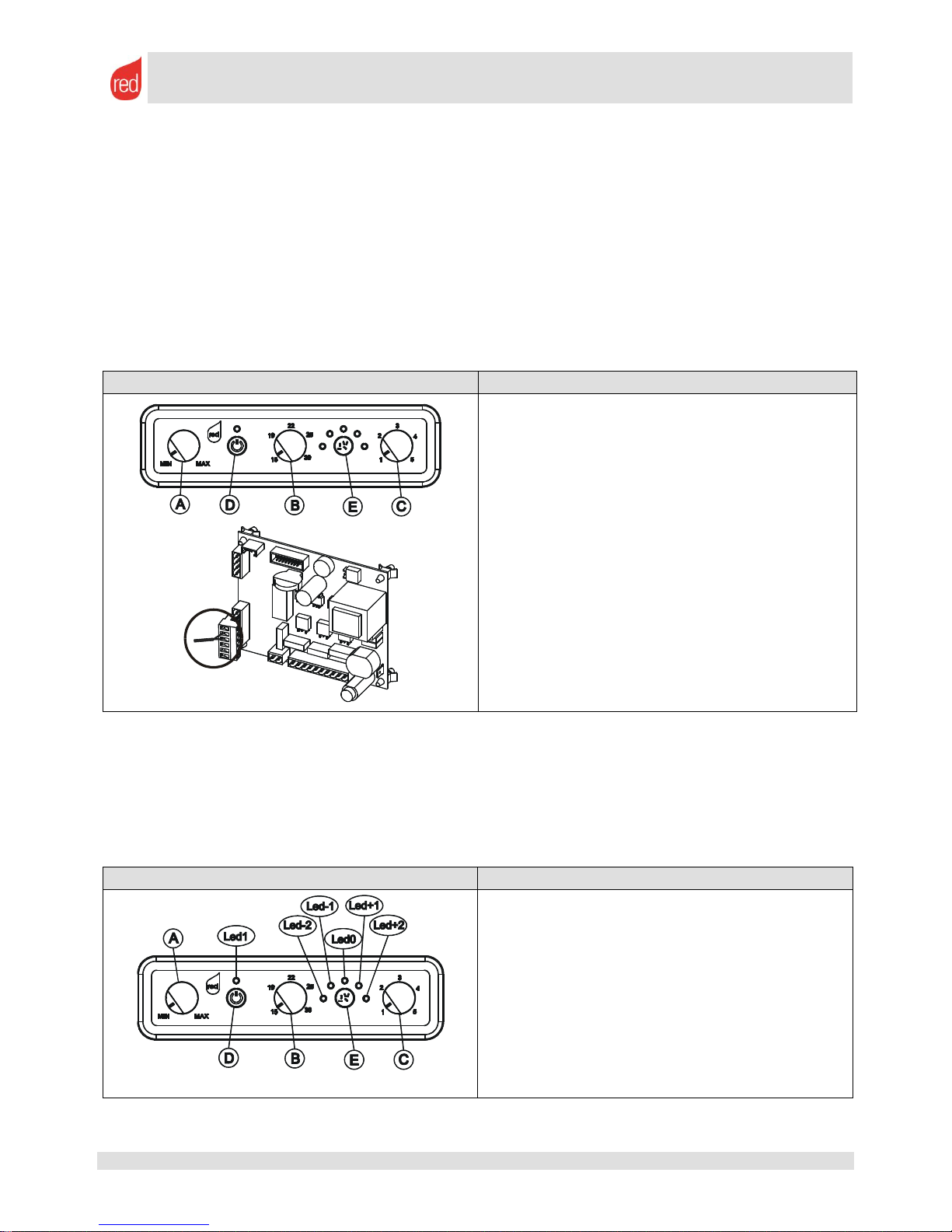

CONTROL PANEL

INSTRUCTIONS

The control panel for RED AIR and MULTIAIR stoves

does not allow you to access the technical

parameters as there is no display.

However, this difficulty can be overcome by temporarily

replacing the control panel with a panel that includes an

LCD display such as that used for MCZ MERCURY (code

4160388) model stoves. Once this panel has been fitted,

follow the instructions below:

Press the menu key and press the buttons until you

reach MENU 9

Press the MENU button to gain access

Enter the password (A9) using buttons or

Confirm the password by pressing the MENU button.

Use button to scroll between the various parameters

Use buttons or to modify the parameters

We recommend that you refit the standard panel after

performing the necessary variations.

1. Press buttons and at the same time to access

UT01

2. Press button three times to access parameter UT04

3. Enter the password (A9) using buttons or

4. Confirm the password by pressing .

5. Use button to scroll through the various parameters

6. Use buttons or to modify the parameters

1. Press the button at the TOP RIGHT to access the

MENU.

2. Using the two keys at the bottom, scroll through the

various menus until you reach the SETTINGS menu.

3. Press the button corresponding to the word SET.

4. Using the two keys at the bottom, scroll through the

various menus until you reach the TECHNICAL

MENU

5. Press the button corresponding to the word SET and

enter the password C 93 using the keys at the bottom.

Confirm the letter and number using OK.

6. Confirm by pressing the the button corresponding to

the SET key.

7. Navigate within the various menus illustrated in the

previous chapter5.5. Special settings on boilers –

TECHNICAL MENU

SET

TURBO

1

2

6 4

3

5

!

Page 23

SERVICE MANUAL

page 23

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

6.2. Stove parameters

Parameters for RED AIR 6 kW – DALIA stoves

Parameters/ Databases

LED -2

LED -1

LED 0

LED +1

LED +2

01: max start-up time (min)

15

02: Fire On (min)

2

03: Interval between brazier cleanings (min)

20*

04: Load wood auger ON (sec)

-30% pellet

-15% pellet

3

+5% pellet

+10% pellet

05: Fire On auger ON (sec)

-30% pellet

-15% pellet

3

+5% pellet

+10% pellet

06: Auger on at Power 1 (sec) **

-30% pellet

-15% pellet

1.5

+5% pellet

+10% pellet

07: Auger on at Power 2 (sec) **

-30% pellet

-15% pellet

1.9

+5% pellet

+10% pellet

08: Auger on at Power 3 (sec)

-30% pellet

-15% pellet

2.3

+5% pellet

+10% pellet

09: Auger on at Power 4 (sec)

-30% pellet

-15% pellet

2.7

+5% pellet

+10% pellet

10: Auger on at Power 5 (sec)

-30% pellet

-15% pellet

3

+5% pellet

+10% pellet

11: Shut down revolutions after alarm (g/1 minute)

1100

12:duration of brazier cleaning (sec)

30

13. minimum temperature for the start-up phase (C°)

50

14: max smoke temperature threshold for modulation (C°)

240

15: temperature for starting up and shutting down the

exchanger (C°)

60

16: speed of smoke suction in Load wood (g/1 min)

1403

1556

1700

1845

1998

17: speed of smoke suction in Fire On (g/1 min)

1155

1281

1400

1519

1645

18: speed of smoke suction at Power 1 g/1 min)

825

915

1000

1085

1175

19: speed of smoke suction at Power 2 g/1 min)

908

1007

1100

1194

1293

20: speed of smoke suction at Power 3 (g/1 min)

990

1098

1200

1302

1410

21: speed of smoke suction at Power 4 g/1 min)

1073

1190

1300

1411

1528

22: speed of smoke suction at Power 5 g/1 min)

1155

1281

1400

1519

1645

23: speed of exchanger 1

30

24: speed of exchanger 2

32

25: speed of exchanger 3

34

26: speed of exchanger 4

36

27: speed of exchanger 5

68

28: speed of smoke suction in brazier cleaning

2500

29: delay of eco-stop restarting (N.P.=Not Present)

5

30: Delta °C

5

Parameters for RED AIR 8 kW – MARGHERITA / GARDENIA stoves

Parameters/ Databases

LED -2

LED -1

LED 0

LED +1

LED +2

01: max start-up time (min)

15

02: Fire On (min)

2

03: Interval between brazier cleaning (min)

20*

04: Load wood auger ON (sec)

-30% pellet

-15% pellet

3.4

+5% pellet

+10% pellet

05: Fire On auger ON (sec)

-30% pellet

-15% pellet

3.4

+5% pellet

+10% pellet

06: Auger on at Power 1 (sec) **

-30% pellet

-15% pellet

2.3

+5% pellet

+10% pellet

07: Auger on at Power 2 (sec) **

-30% pellet

-15% pellet

3.2

+5% pellet

+10% pellet

08: Auger on at Power 3 (sec)

-30% pellet

-15% pellet

4.1

+5% pellet

+10% pellet

09: Auger on at Power 4 (sec)

-30% pellet

-15% pellet

4.9

+5% pellet

+10% pellet

10: Auger on at Power 5 (sec)

-30% pellet

-15% pellet

5.8

+5% pellet

+10% pellet

11: Shut down revolutions after alarm (g/1 minute)

1100

12:duration of brazier cleaning (sec)

30**

13. minimum temperature for the start-up phase (C°)

50

14: max smoke temperature threshold for modulation (C°)

190

15: temperature for starting up and shutting down the

exchanger (C°)

60

16: speed of smoke suction in Load wood (g/1 min)

1568

1739

1900

2062

2233

17: speed of smoke suction in Fire On (g/1 min)

1238

1373

1500

1628

1763

18: speed of smoke suction at Power 1 g/1 min)

1155

1281

1400

1519

1645

19: speed of smoke suction at Power 2 g/1 min)

1279

1418

1550

1682

1821

20: speed of smoke suction at Power 3 (g/1 min)

1403

1556

1700

1845

1998

21: speed of smoke suction at Power 4 g/1 min)

1526

1693

1850

2007

2174

22: speed of smoke suction at Power 5 g/1 min)

1650

1830

2000

2170

2350

23: speed of exchanger 1

30

24: speed of exchanger 2

32

25: speed of exchanger 3

34

26: speed of exchanger 4

36

27: speed of exchanger 5

68

28: speed of smoke suction in brazier cleaning

2500

29: delay of eco-stop restarting (N.P.=Not Present)

5

30: Delta °C

5

Page 24

SERVICE MANUAL

page 24

Rev. 02

08/11 – M.C.

Service Manual – 8901118900 – EN

All rights reserved

Parameters for RED AIR 9.5 kW – PRIMULA / ORCHIDEA stoves

Parameters/ Databases

LED -2

LED -1

LED 0

LED +1

LED +2

01: max start-up time (min)

15

02: Fire On (min)

2

03: Interval between brazier cleaning (min)

20*

04: Load wood auger ON (sec)

-30% pellet

-15% pellet

3.4

+5% pellet

+10% pellet

05: Fire On auger ON (sec)

-30% pellet

-15% pellet

3.4

+5% pellet

+10% pellet

06: Auger on at Power 1 (sec) **

-30% pellet

-15% pellet

2.3

+5% pellet

+10% pellet

07: Auger on at Power 2 (sec) **

-30% pellet

-15% pellet

3.3

+5% pellet

+10% pellet

08: Auger on at Power 3 (sec)

-30% pellet

-15% pellet

4.3

+5% pellet

+10% pellet

09: Auger on at Power 4 (sec)

-30% pellet

-15% pellet

5.2

+5% pellet

+10% pellet

10: Auger on at Power 5 (sec)

-30% pellet

-15% pellet

6.2

+5% pellet

+10% pellet

11: Shut down revolutions after alarm (g/1 minute)

1100

12:duration of brazier cleaning (sec)

30*

13. minimum temperature for the start-up phase (C°)

50

14: max smoke temperature threshold for modulation (C°)

200

15: temperature for starting up and shutting down the

exchanger (C°)

60

16: speed of smoke suction in Load wood (g/1 min)

1568

1739

1900

2062

2233

17: speed of smoke suction in Fire On (g/1 min)

1238

1373

1500

1628

1763

18: speed of smoke suction at Power 1 g/1 min)

1155

1281

1400

1519

1645

19: speed of smoke suction at Power 2 g/1 min)

1361

1510

1650

1790

1939

20: speed of smoke suction at Power 3 (g/1 min)

1485

1647

1800

1953

2115

21: speed of smoke suction at Power 4 g/1 min)

1609

1784

1950

2116

2291

22: speed of smoke suction at Power 5 g/1 min)

1733

1922

2100

2279

2468

23: speed of exchanger 1

30

24: speed of exchanger 2

32

25: speed of exchanger 3

36

26: speed of exchanger 4

40

27: speed of exchanger 5

68

28: speed of smoke suction in brazier cleaning

2500

29: delay of eco-stop restarting (N.P.=Not Present)

5

30: Delta °C 5

Parameters for RED MULTIAIR 11 kW – PRIMULA / ORCHIDEA stoves

Parameters/ Databases

LED -2

LED -1

LED 0

LED +1

LED +2

01: max start-up time (min)

15

02: Fire On (min)

2

03: Interval between brazier cleaning (min)

20*

04: Load wood auger ON (sec)

-30% pellet

-15% pellet

3.4

+5% pellet

+10% pellet

05: Fire On auger ON (sec)

-30% pellet

-15% pellet

3.4

+5% pellet

+10% pellet

06: Auger on at Power 1 (sec) **

-30% pellet

-15% pellet

2.4

+5% pellet

+10% pellet

07: Auger on at Power 2 (sec) **

-30% pellet

-15% pellet

3.5

+5% pellet

+10% pellet

08: Auger on at Power 3 (sec)

-30% pellet

-15% pellet

4.6

+5% pellet

+10% pellet

09: Auger on at Power 4 (sec)

-30% pellet

-15% pellet

5.6

+5% pellet

+10% pellet

10: Auger on at Power 5 (sec)

-30% pellet

-15% pellet

6.7

+5% pellet

+10% pellet

11: Shut down revolutions after alarm (g/1 minute)

1100

12:duration of brazier cleaning (sec)

45*

13. minimum temperature for the start-up phase (C°)

50

14: max smoke temperature threshold for modulation (C°)

210

15: temperature for starting up and shutting down the

exchanger (C°)

60

16: speed of smoke suction in Load wood (g/1 min)

1568

1739

1900

2062

2233

17: speed of smoke suction in Fire On (g/1 min)

1238

1373

1500

1628

1763